Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc. It can solve the problems of not necessarily sufficient durability, not necessarily significant durability effects, and increased ground pressure, etc. problem, achieve high performance on ice and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

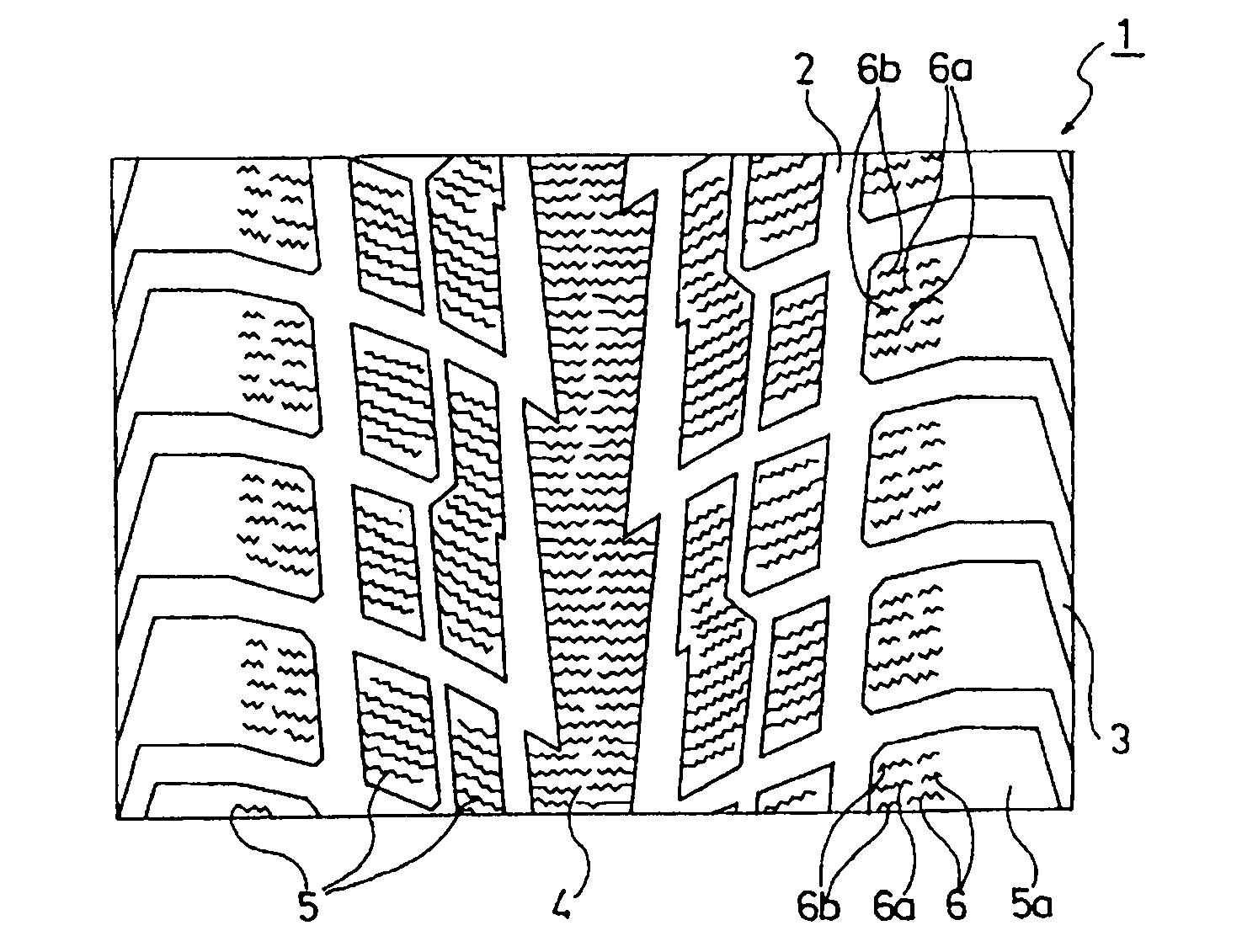

[0046] The specifications of the manufactured tires are 225 / 65R17 101Q, all of which have figure 1 The tread patterns shown are conventional examples 1 and 2 and tires of examples 1 to 3 having different forms as shown in Table 1.

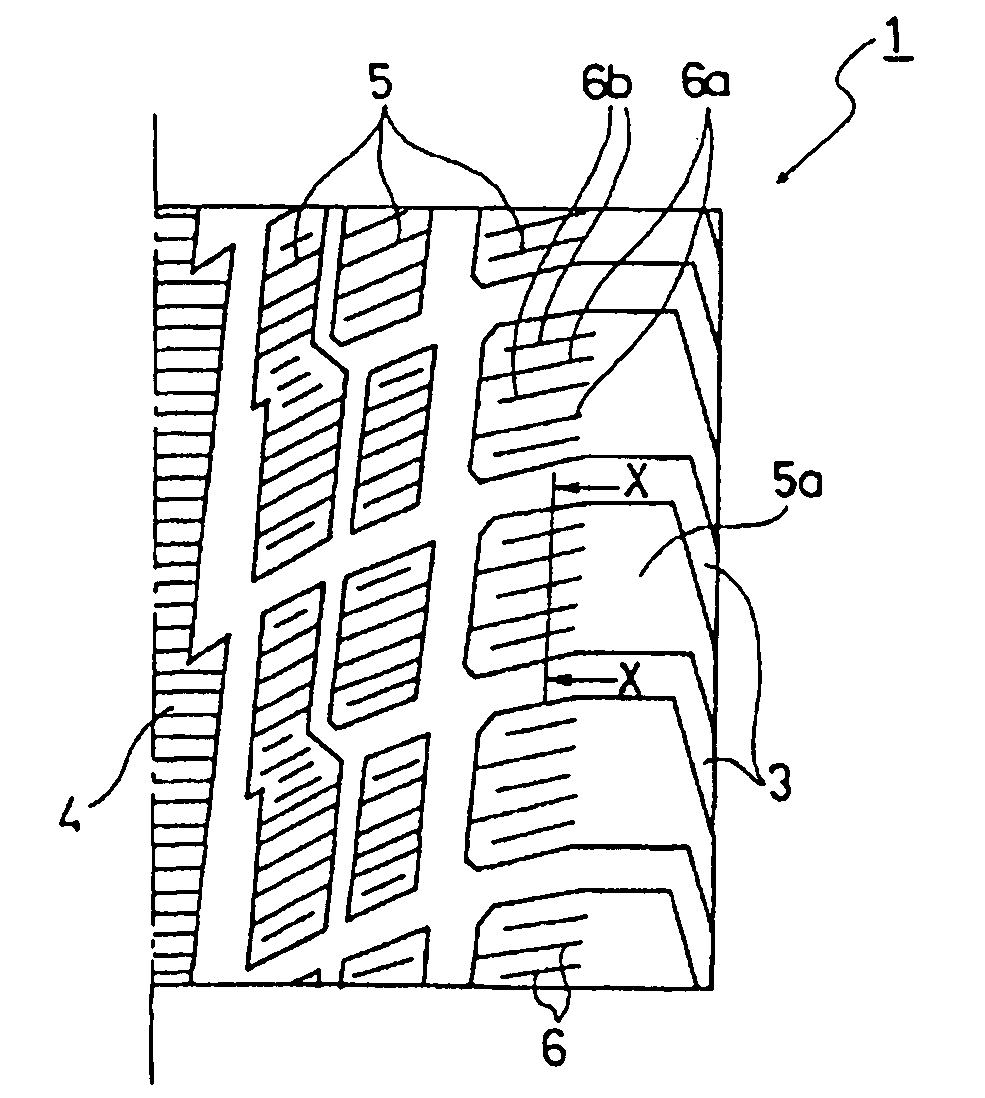

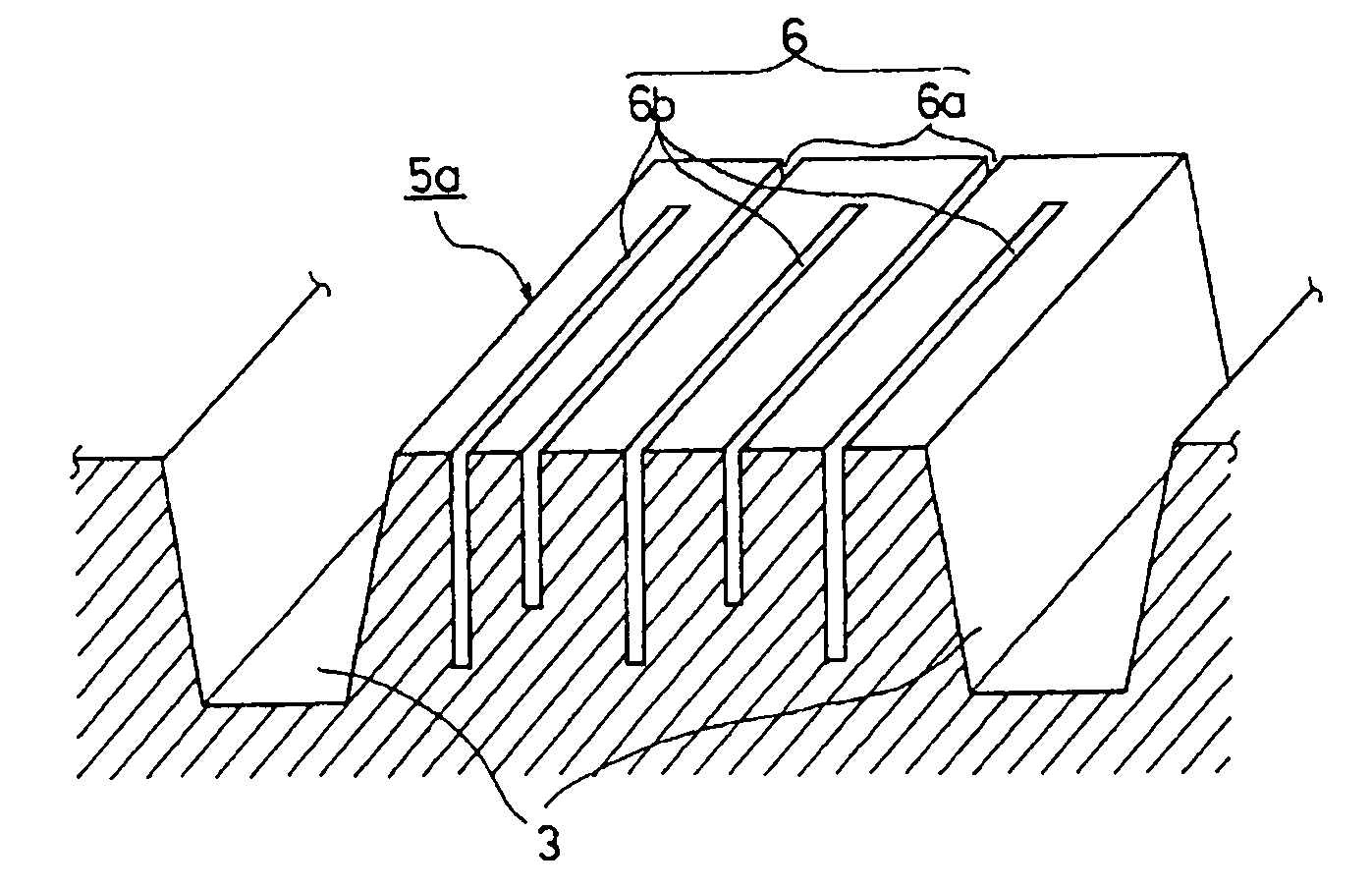

[0047] In Conventional Example 1, the sipes had the same depth and were open sipes, the sipe was not divided and the block consisted of only one layer of rubber composition. In Conventional Example 2, only the sipe depths were shifted, and all were undivided sipes, and the blocks consisted of only one layer of the rubber composition. Example 1 is an example in which open sipes and closed sipes are alternately arranged, and the open sipe is shifted shallower than the closed sipe, and this example corresponds to image 3 . Embodiment 2 is an embodiment in which the sipe is divided on the basis of Embodiment 1, and this embodiment corresponds to Figure 4 . Example 3 is an example with a two-layer structure in which the block is formed into a rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com