Winter tire

A winter tire and tread technology, applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as the inability to exhibit tire grip performance, lateral grooves cannot catch snow, etc. The effect of suppressing snow accumulation and suppressing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

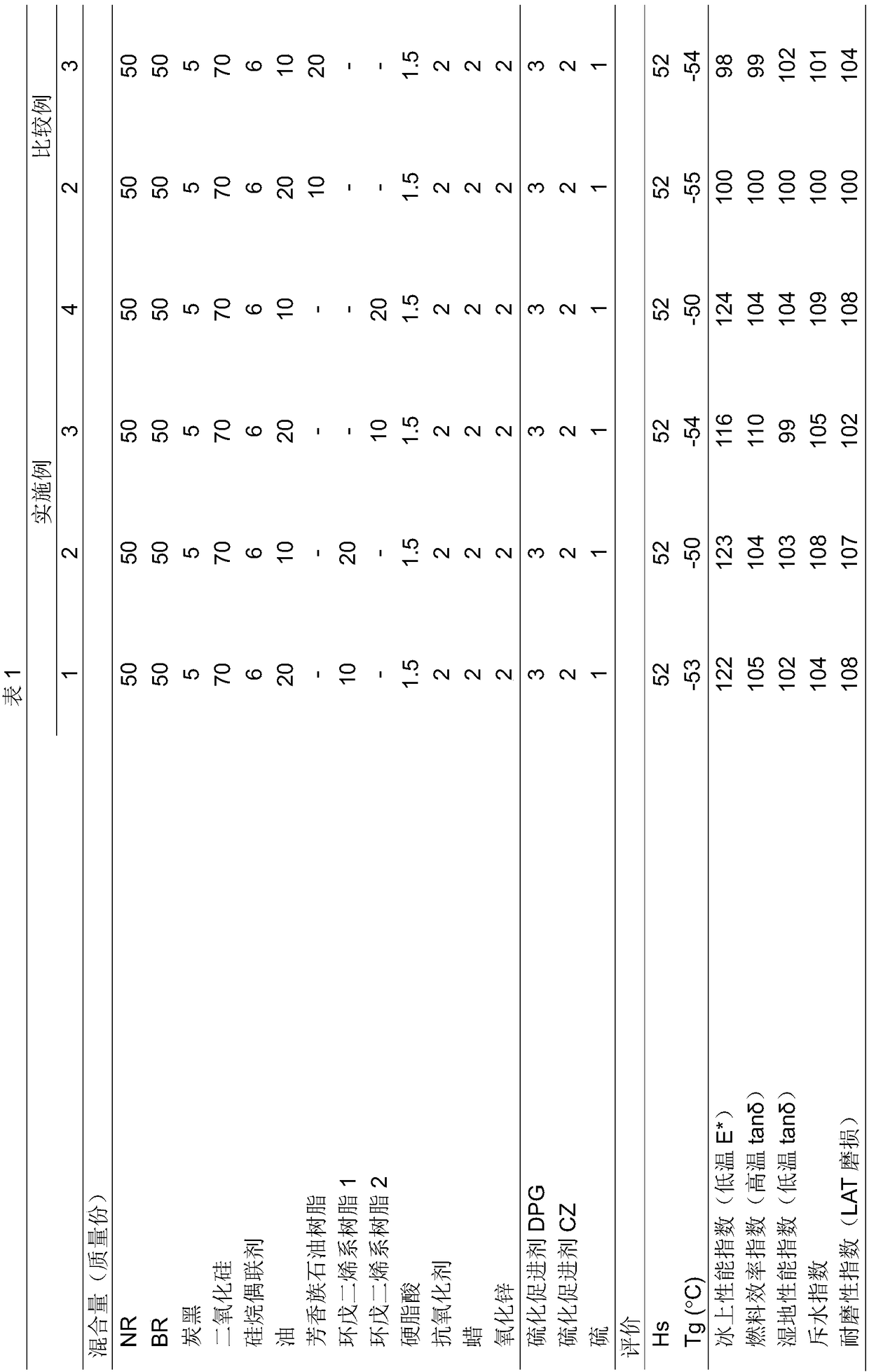

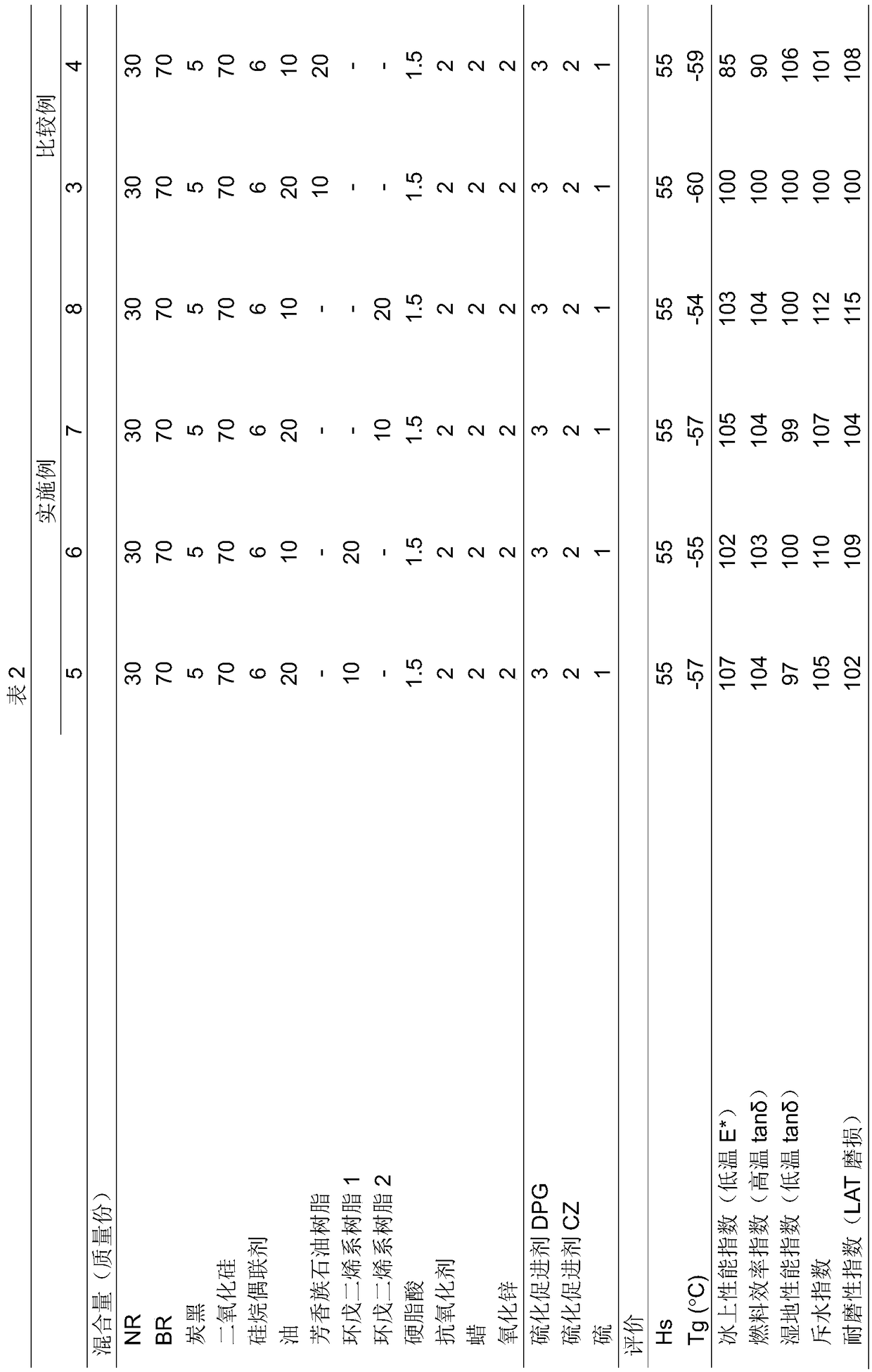

[0055] The invention is then illustrated by way of examples, but the invention is not limited to these examples.

[0056] Various chemicals used in Examples and Comparative Examples will be described below.

[0057] NR:TSR20

[0058] BR: BR1220 manufactured by Zeon Corporation (unmodified BR, cis content: 96% by mass)

[0059] Carbon black: DIABLACK I manufactured by Mitsubishi Chemical Corporation (ASTM No. N220, N 2 SA: 114m 2 / g, DBP: 114ml / 100g)

[0060] Silica: ULTRASIL VN3 (N 2 SA: 175m 2 / g, average primary particle size: 15nm)

[0061] Silane coupling agent: Si75 (bis(3-triethoxysilylpropyl) disulfide) manufactured by Evonik Degussa

[0062] Oil: Process X-140 (aromatic oil) manufactured by Jikun Nippon Oil & Energy Co., Ltd.

[0063] Aromatic petroleum resin: Sylvatraxx 4401 manufactured by Arizona Chemical Co., Ltd. (main component: α-methylstyrene, softening point: 85° C.)

[0064] Cyclopentadiene-based resin 1: Oppera PR-140 (hydrogenated dicyclopentadiene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com