Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., to achieve the effect of improving performance on snow and ice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

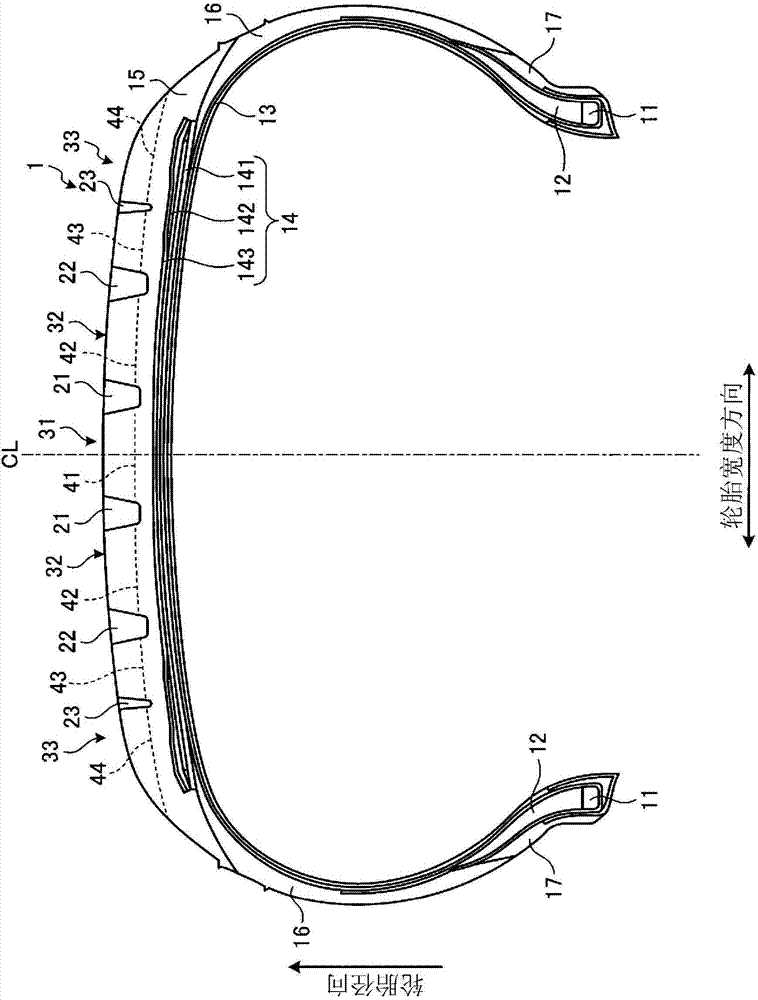

[0093] The pneumatic tire 1 of Example 1 has Figure 1 ~ Figure 4 the documented structure. The pneumatic tires 1 of Examples 2 to 13 are modified examples of the pneumatic tire 1 of Example 1. In addition, the distance L from the tire equatorial plane CL to the ground contact edge T is L=80 mm. In addition, the maximum groove depth H of the outermost circumferential main groove 22 is H=13.5 mm.

[0094] The pneumatic tire of the conventional example has Figure 8 structure shown. The pneumatic tire of the comparative example has Figure 9 structure shown.

[0095] As shown in the test results, it can be seen that in the pneumatic tires 1 of Examples 1 to 13, the uneven wear resistance performance, performance on ice and performance on snow of the tire were improved.

[0096] Symbol Description

[0097] 1: Pneumatic tire

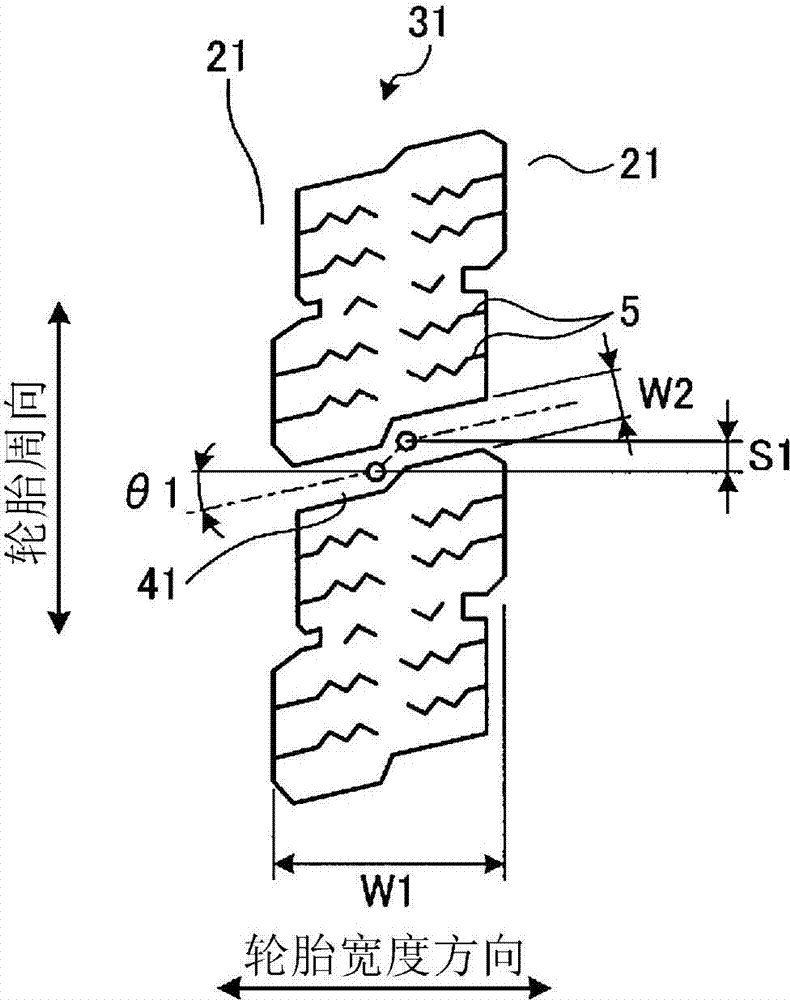

[0098] 5: Three-dimensional groove

[0099] 11: Bead core

[0100] 12: Bead core

[0101] 13: Ply

[0102] 14: belt layer

[0103] 15: Tread ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com