Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., which can solve the problems of no consideration of noise, achieve noise dispersion, improve performance on ice, and improve noise resistance performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, one embodiment of the present invention will be described based on the drawings.

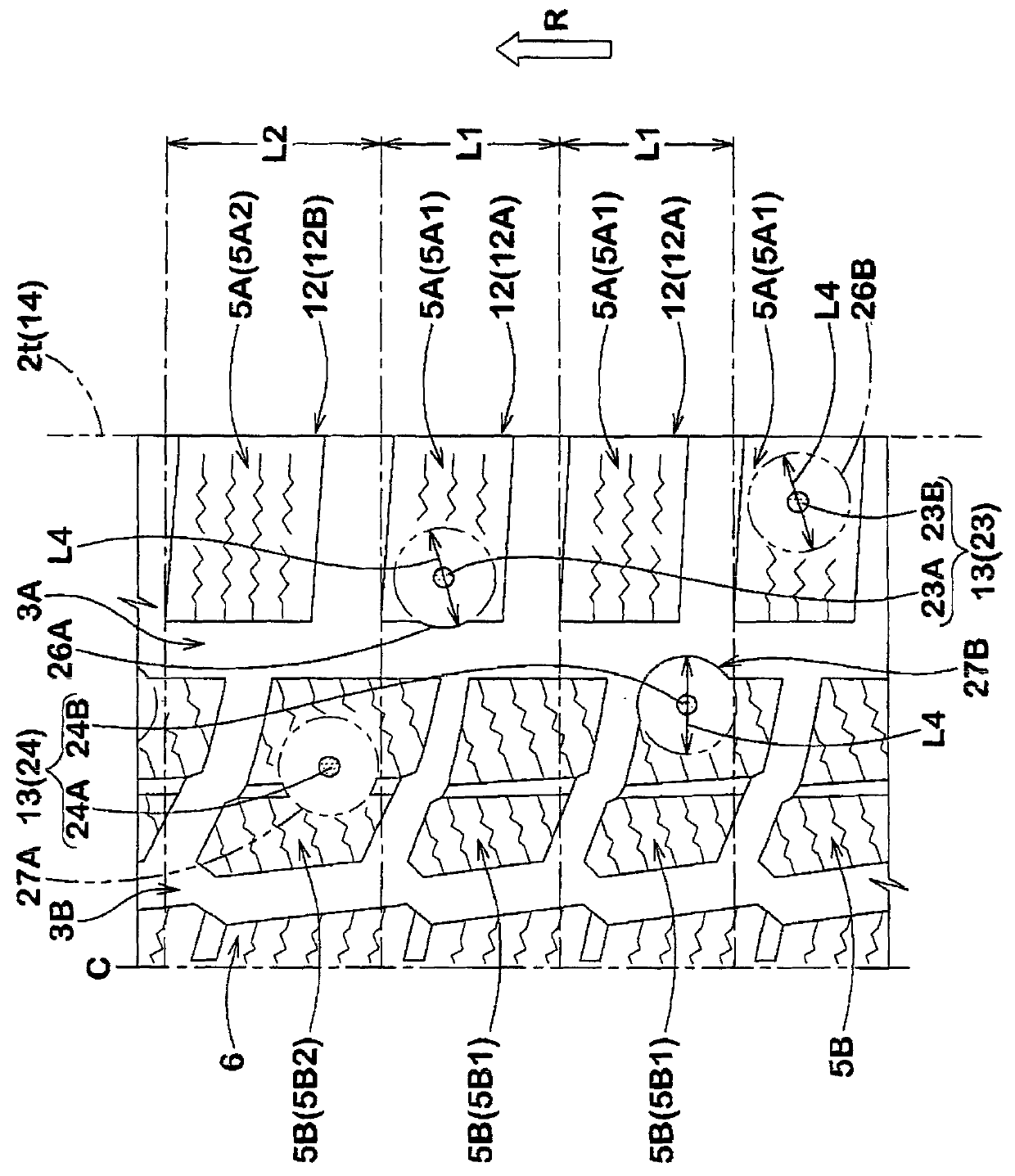

[0030] figure 1 A tire for a car, for example, is shown as a pneumatic tire (hereinafter, sometimes simply referred to as a "tire") 1 according to the present embodiment. A tread portion 2 of the tire 1 is provided with a longitudinal groove 3 extending continuously in the tire circumferential direction, and a plurality of lateral grooves 4 intersecting the longitudinal groove 3 and spaced apart in the tire circumferential direction. Accordingly, on the tread portion 2, a plurality of blocks 5 defined by the longitudinal groove 3 and the lateral groove 4 are spaced apart in the tire circumferential direction.

[0031] In addition, the tread portion 2 of the present embodiment includes a one-side area T1 located on one side of the tire equator C and an other-side area T2 located on the other side of the tire equator C, and has a direction for specifying the tire rotation dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com