Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Improve outflow efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

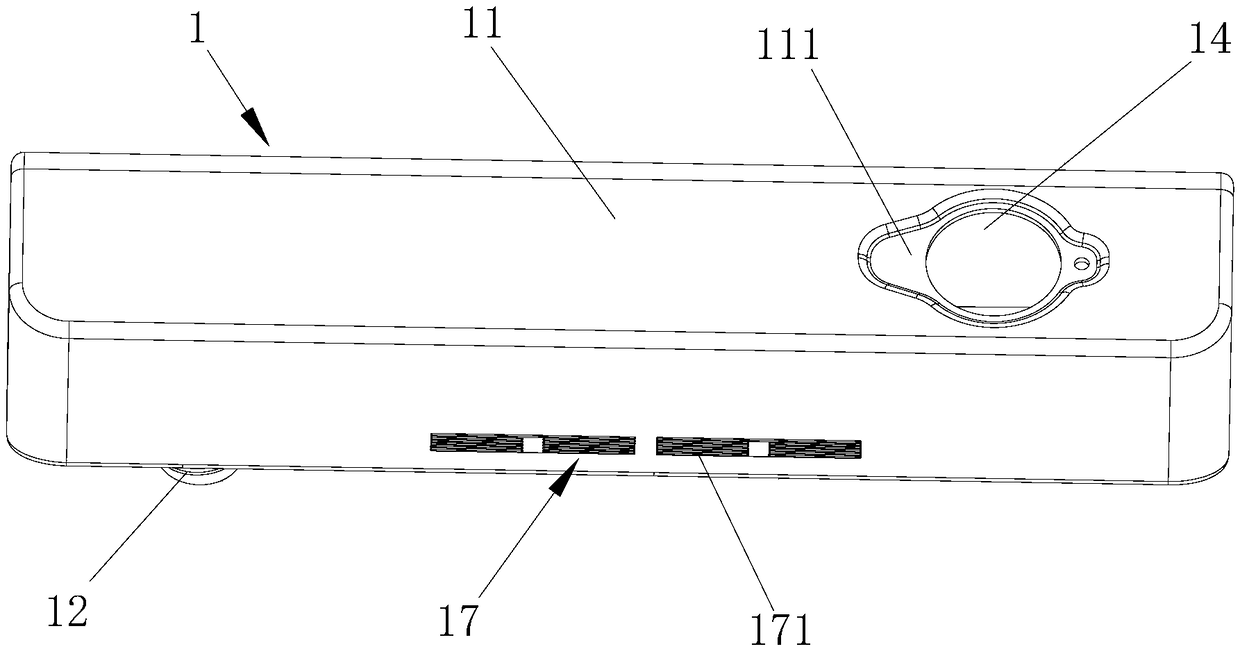

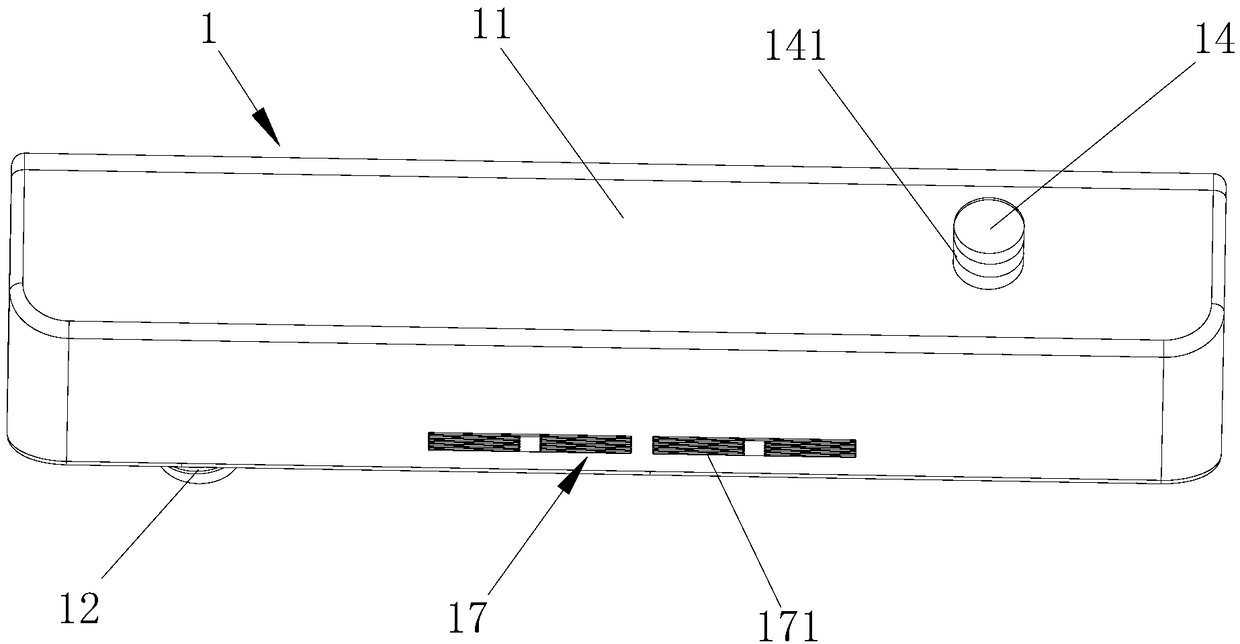

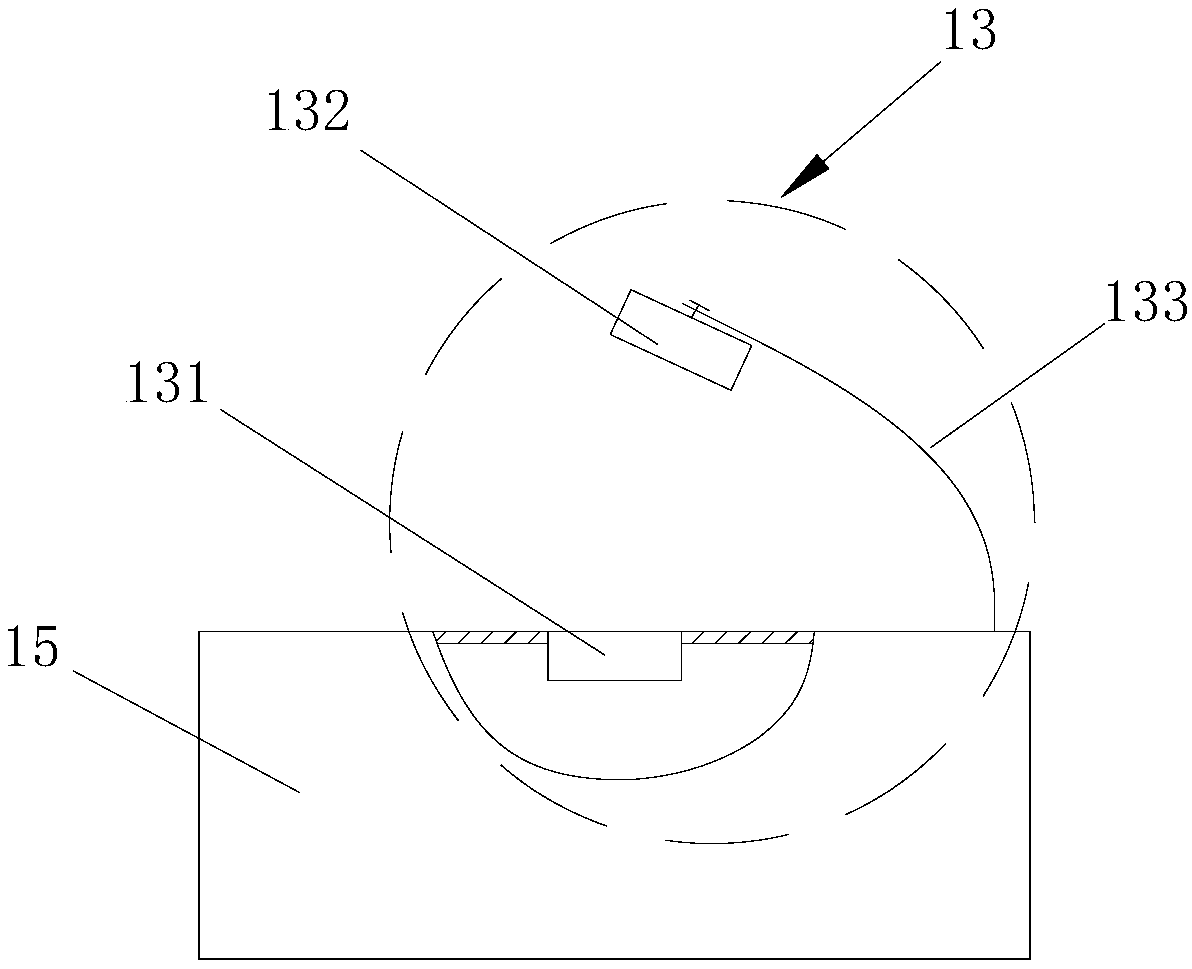

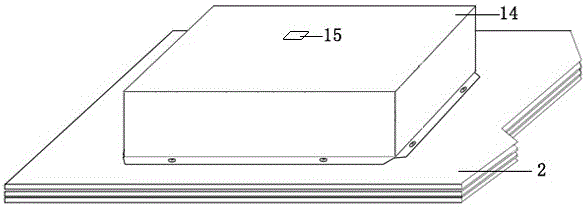

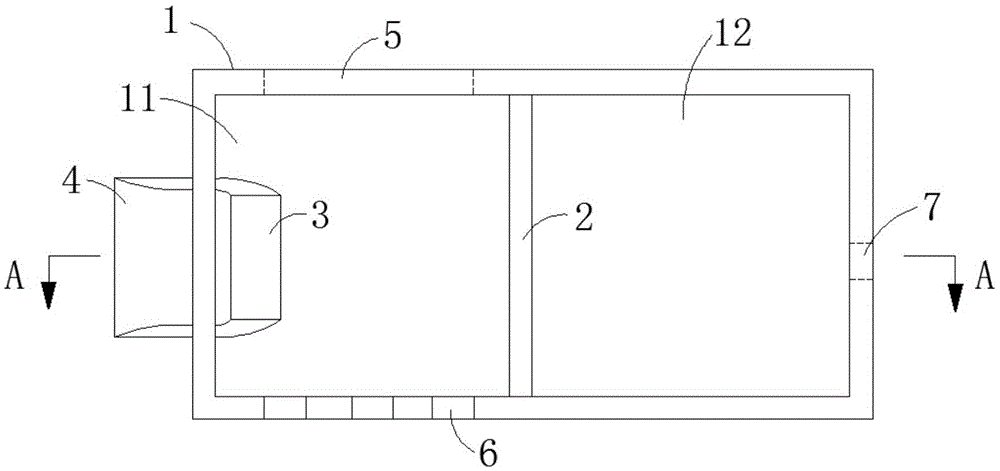

External liquid storage box and household appliance

PendingCN108978132AEasy to storeGood dustproof performanceTableware washing/rinsing machine detailsOther washing machinesExternal LiquidEngineering

The invention discloses an external liquid storage box and a household appliance. The external liquid storage box comprises an internally hollow box body for accommodating liquid and also comprises abreathable unit which balances the air pressure inside the hollow box body with that of the outside. The breathable unit comprises an opening and a sealing cover mounted on the opening, one side surface of the sealing cover facing the opening is provided with a ventilation structure, and the ventilation structure communicates with the inside and the outside of the box body through the opening. Thepresent invention also provides the household appliance which is provided with a communication unit that is quickly connected to an external accessory, and the communication unit is mated with and connected to the external liquid storage box. According to the household appliance of the invention, an external detachable liquid storage box assembly manner is employed, so the maintenance of the liquid storage box is simple and convenient, a phenomenon that a clogging problem and the like cannot be solved is effectively avoided, the structure is simple, the disassembly is convenient, and replacement and cleaning are facilitated.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

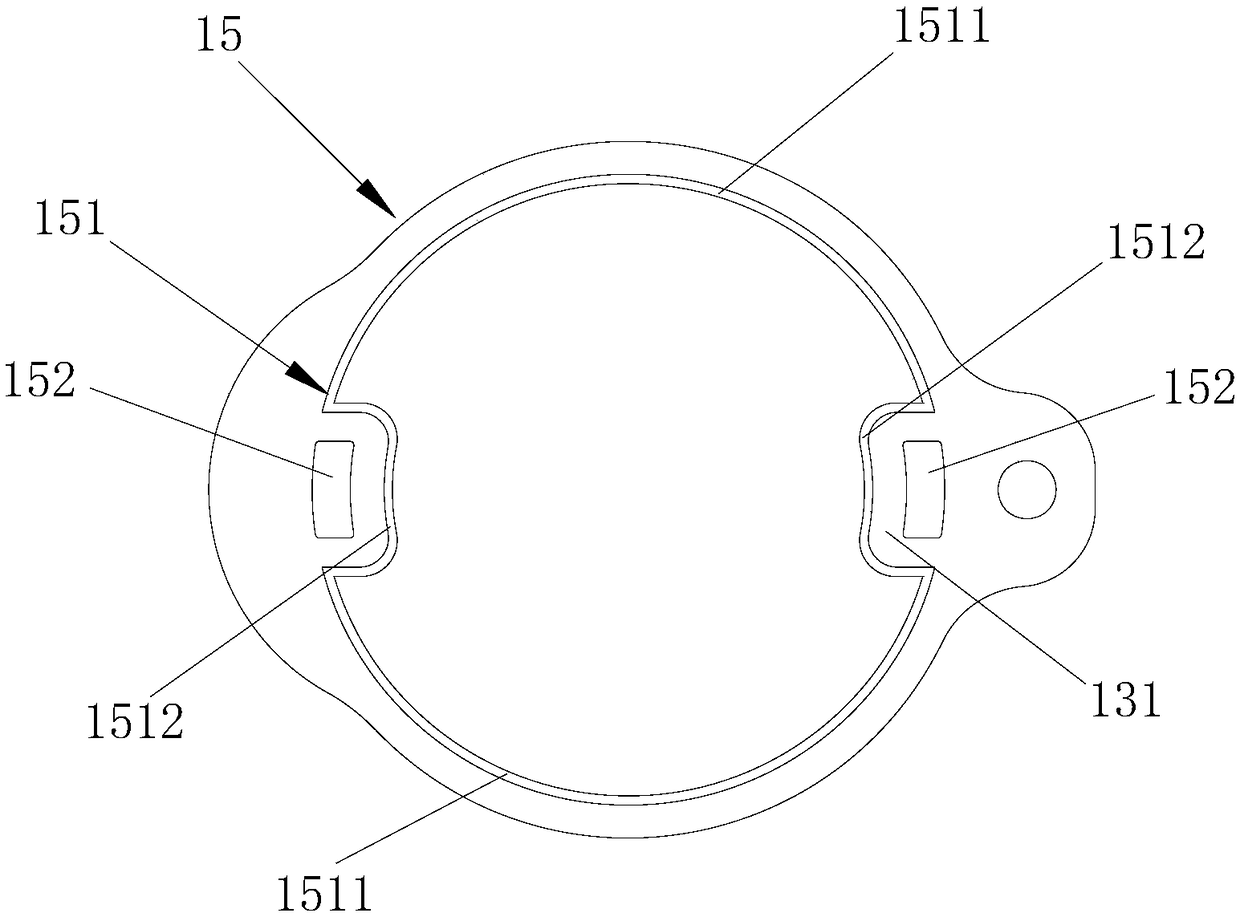

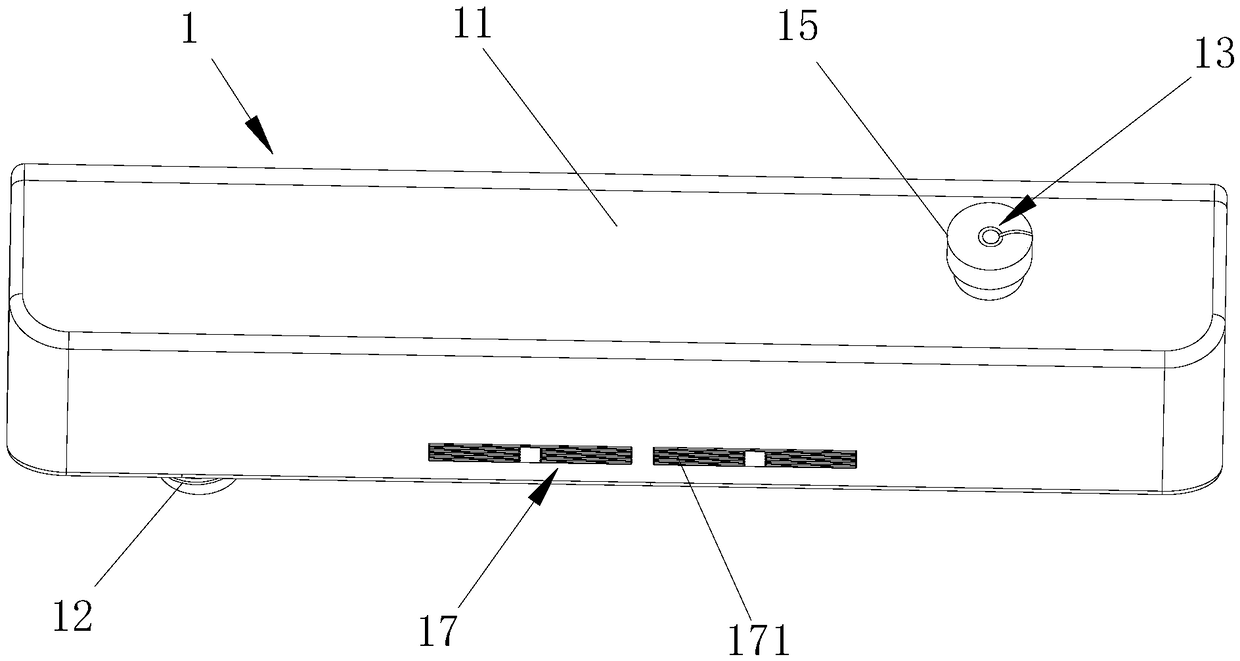

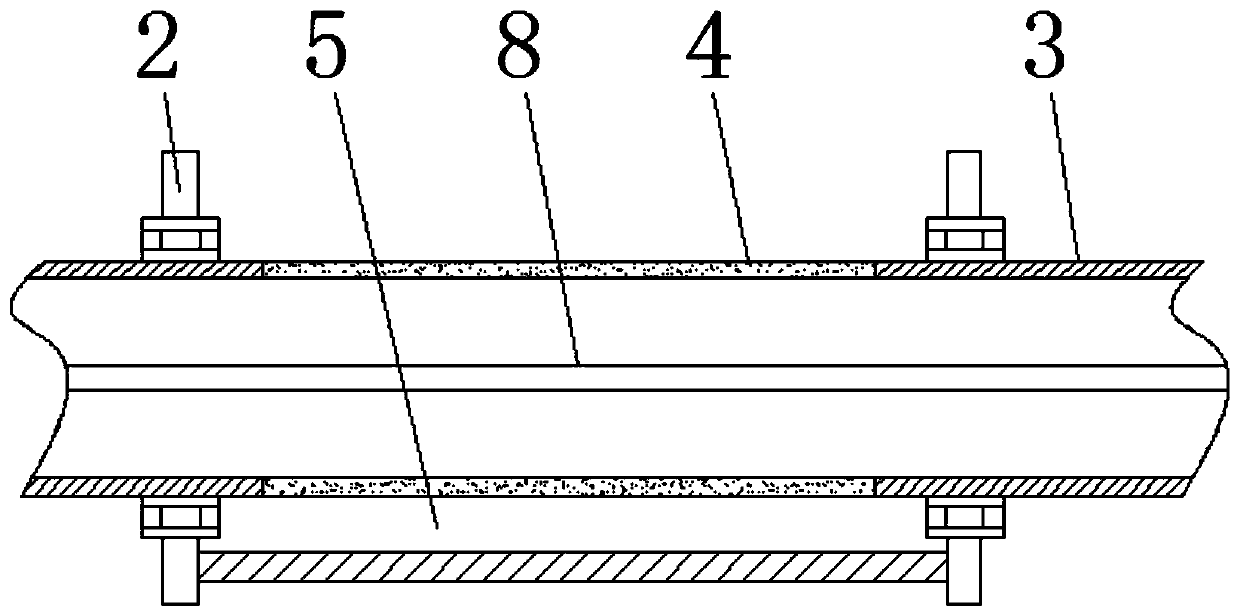

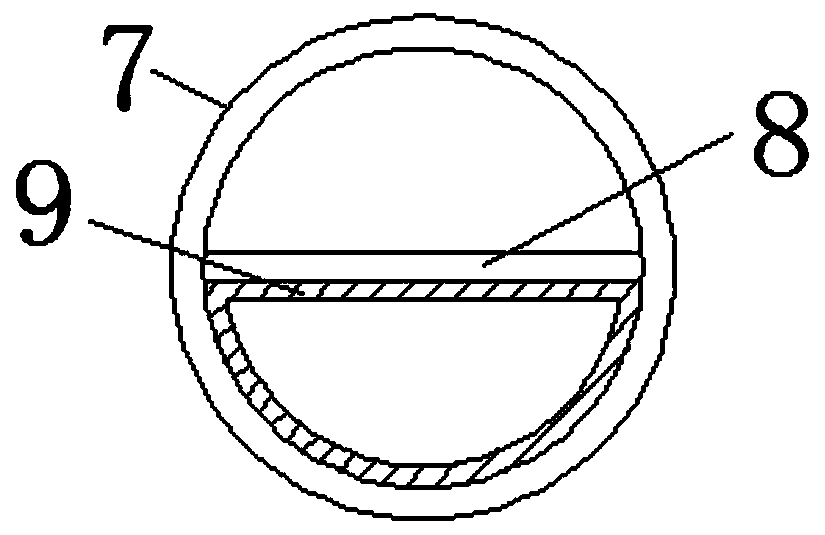

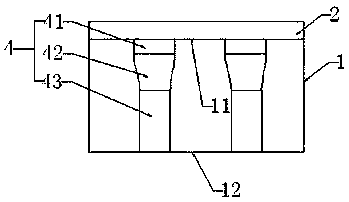

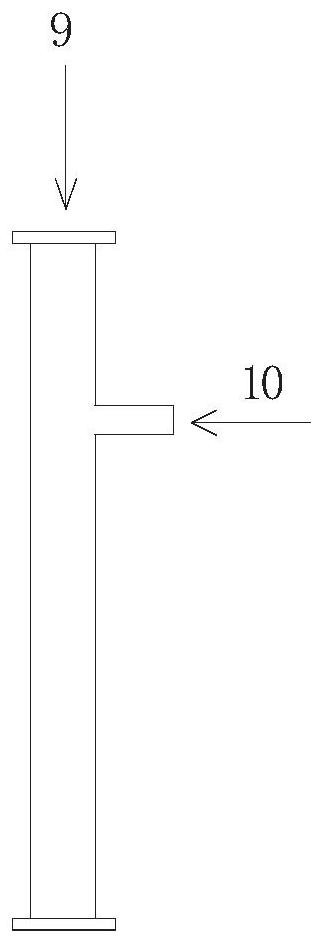

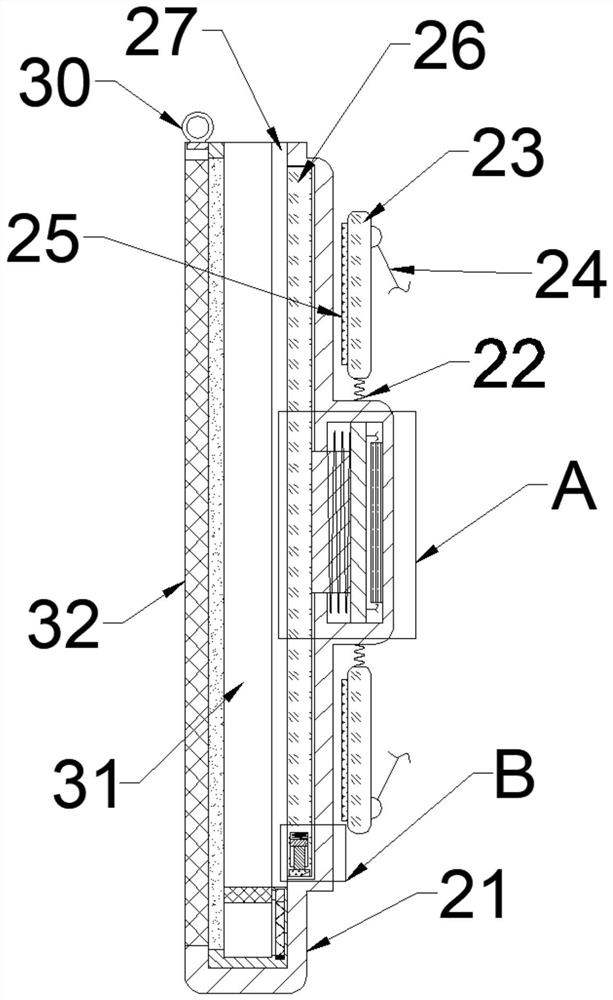

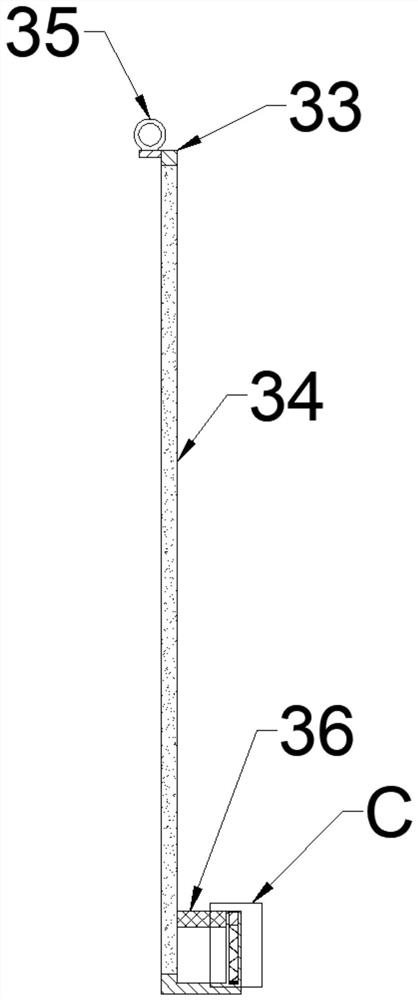

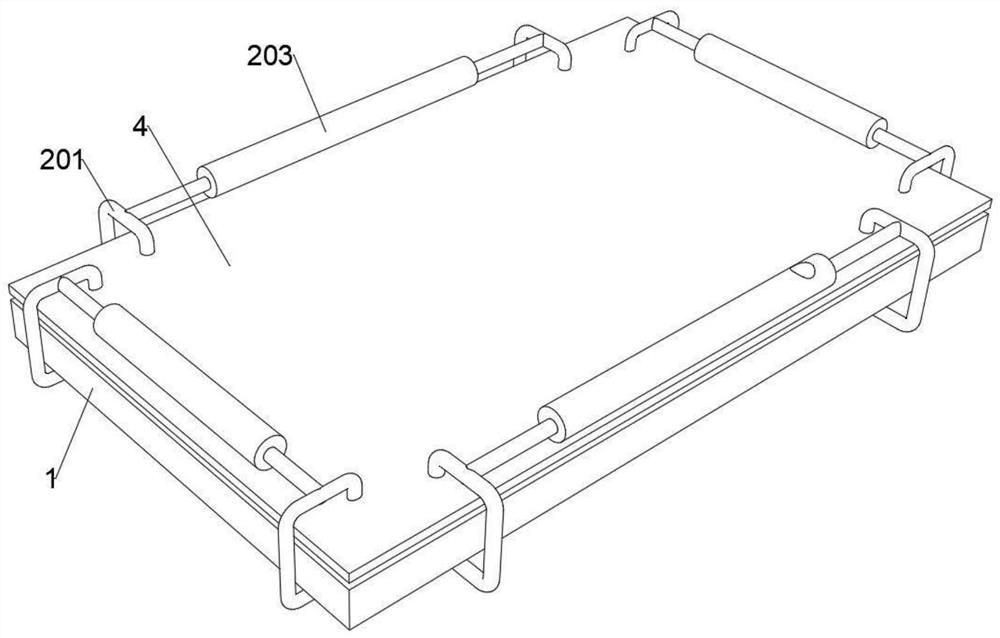

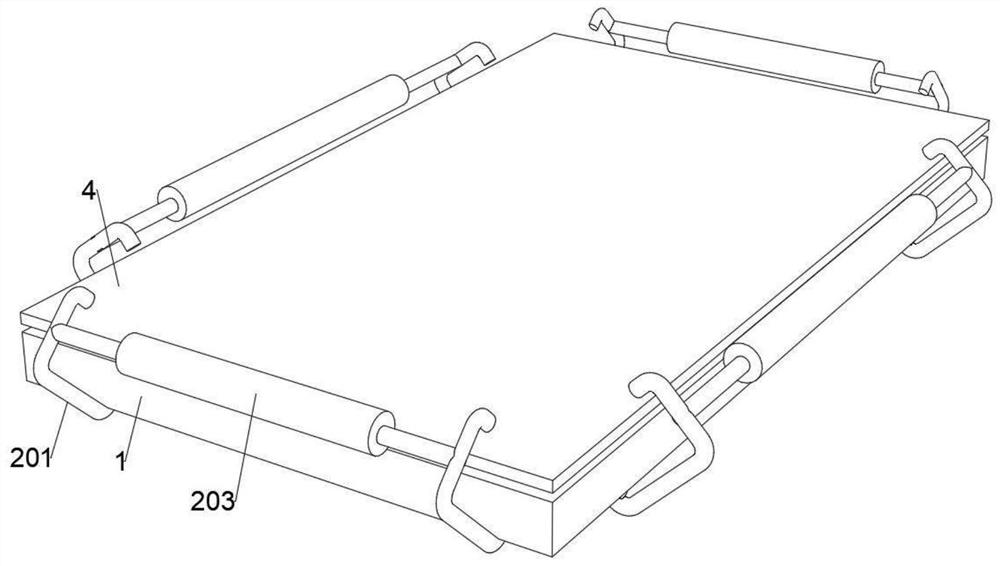

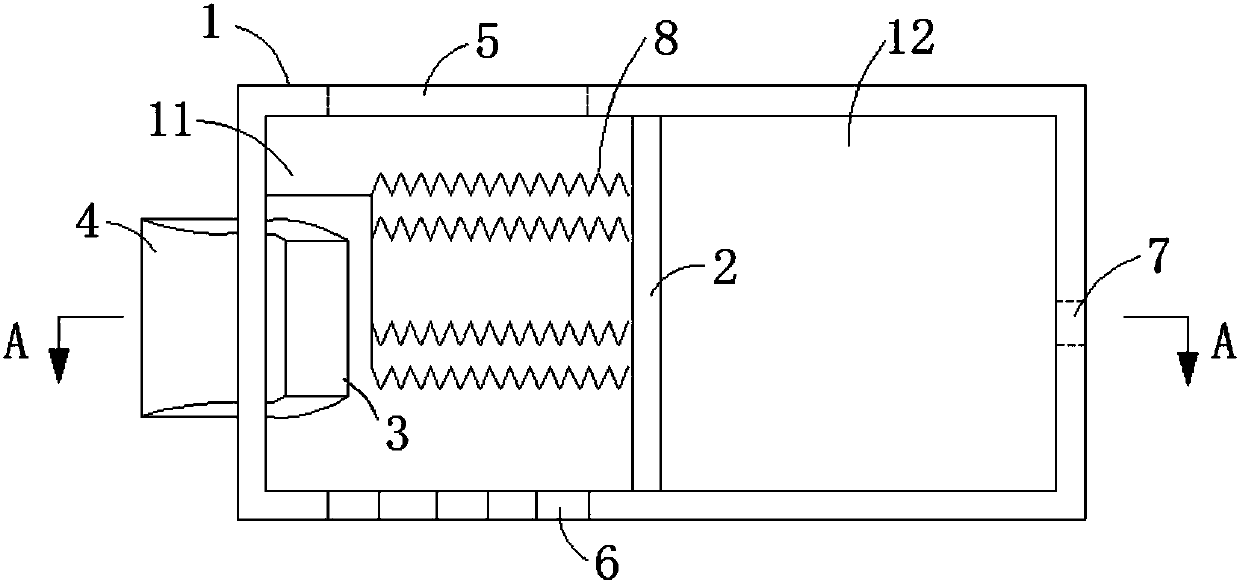

Liquid storage box, switching device and washing machine

PendingCN109137404AEasy to storeGood dustproof performanceOther washing machinesTextiles and paperEngineeringLiquid storage

The invention discloses a liquid storage box, a switching device and a washing machine. The liquid storage box comprises a box body whose internal portion is hollow and can accommodate a liquid, a liquid outlet used for discharging the liquid, and a ventilation structure which makes the inner and outer air pressure of the box body be balance. The ventilation structure comprises a ventilation portand a seal cap used for opening and closing the ventilation port. The seal cap is sealed and connected with the ventilation port. The liquid storage box is provided with an opening. The opening is provided with a seal cover. The ventilation structure is arranged on the seal cover. The switching device is detachably installed on the liquid outlet of the liquid storage box. The washing machine provided in the invention comprises a washing machine body. The washing machine body is provided with an external fitting connection structure. The external fitting connection structure is matched with andconnected with the liquid storage box through the switching device. The liquid storage box is the external and replaceable fitting of the washing machine. In the invention, the liquid storage box isconveniently stored and transported, and the liquid storage box can be directly installed on the washing machine after purchase, dustproof performance is good, liquid outflow efficiency is high and usage is convenient and fast.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

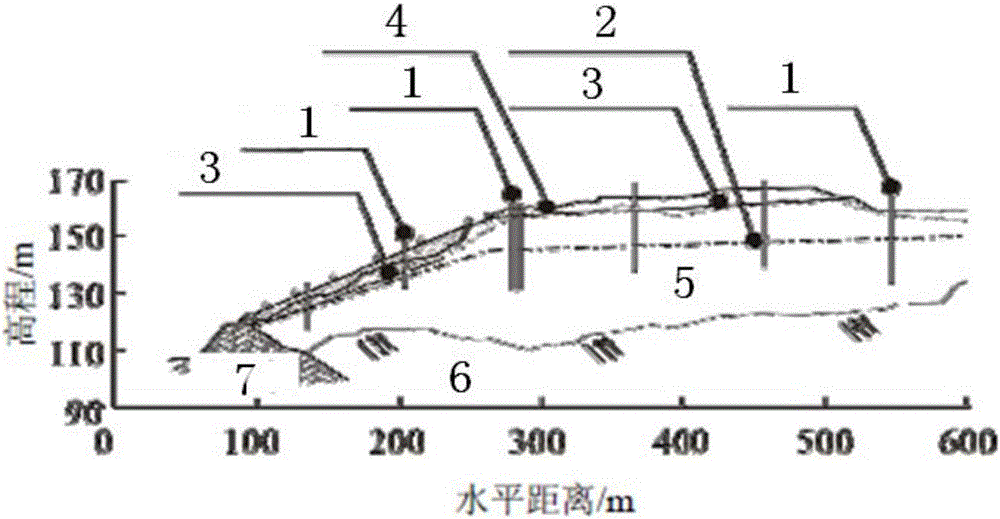

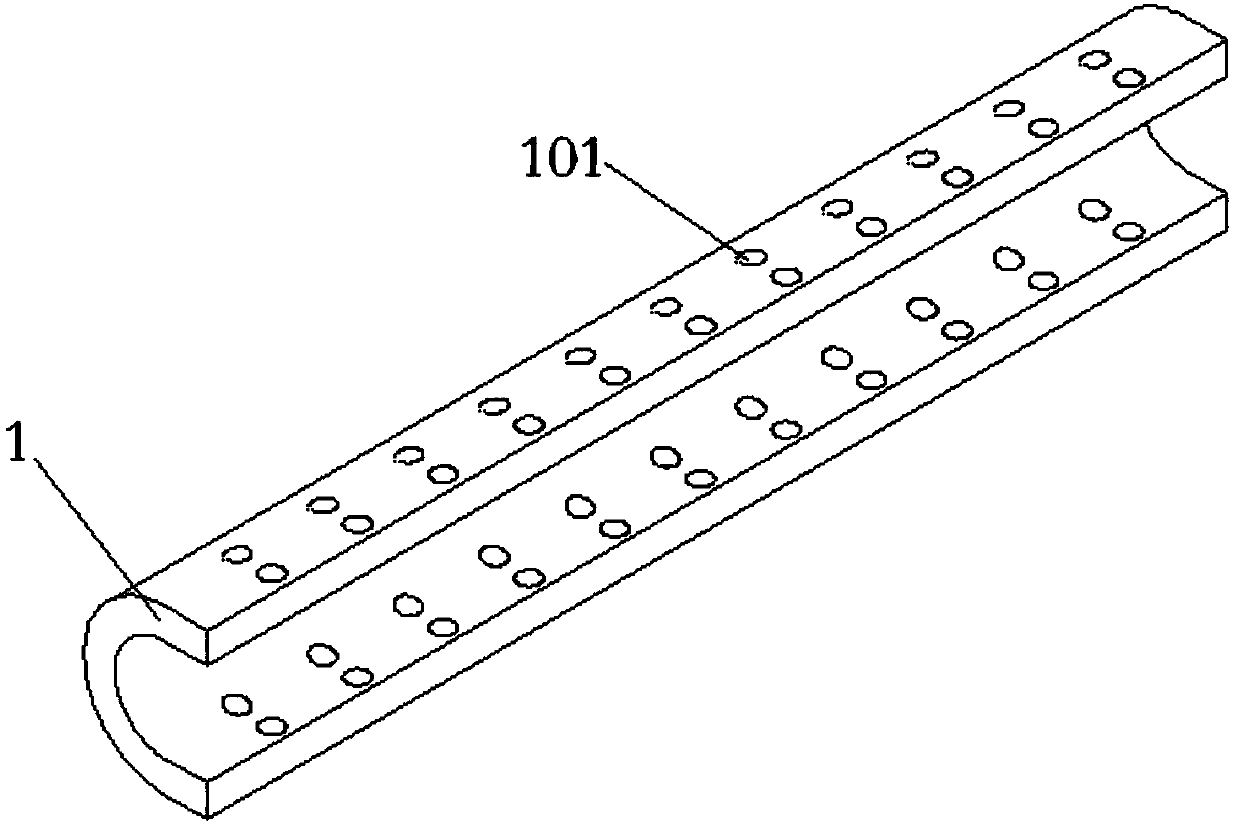

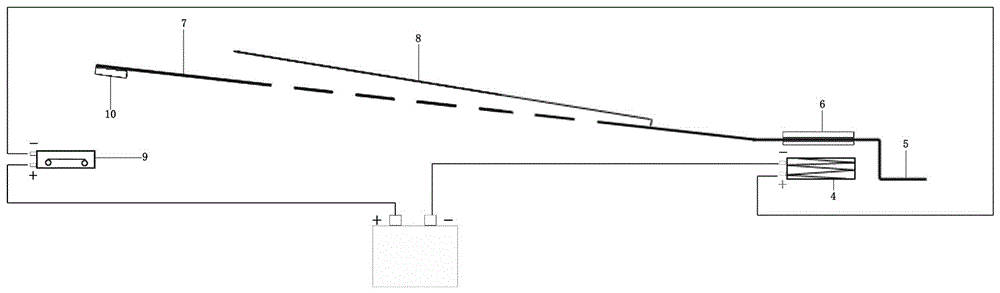

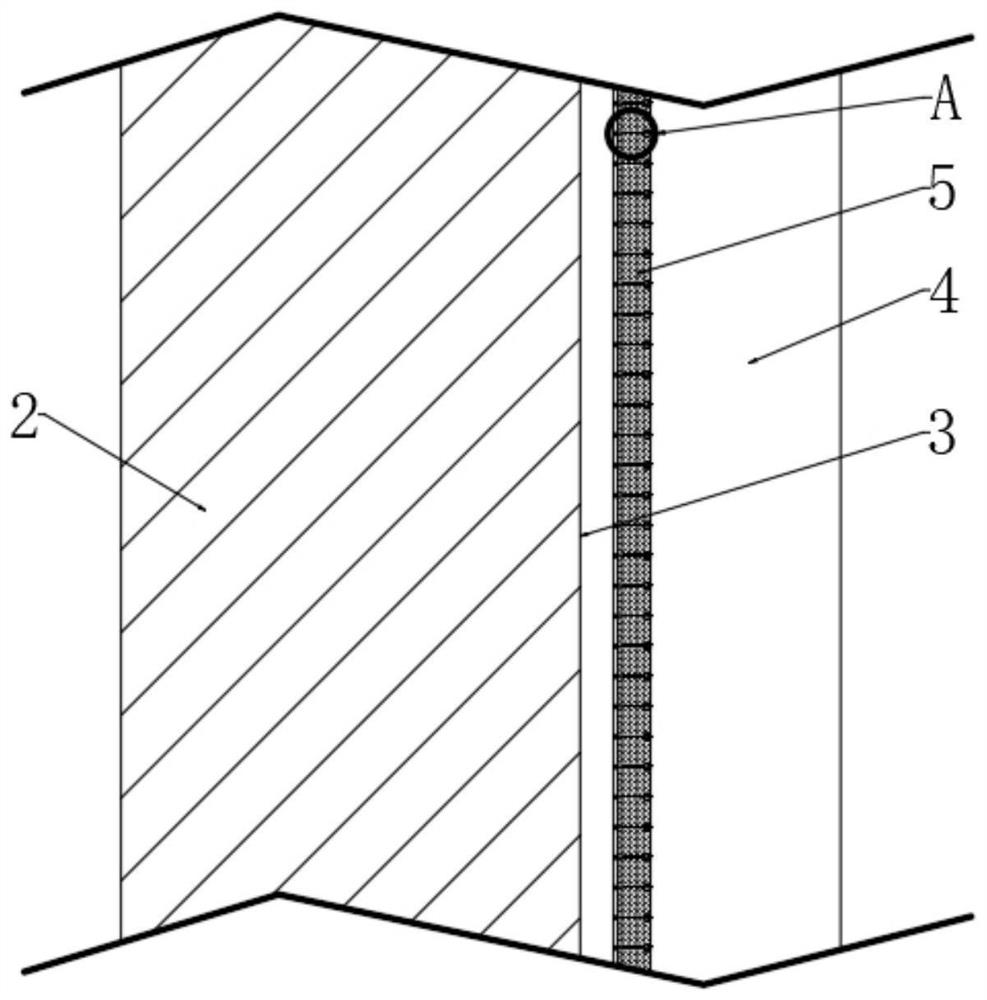

Method for applying horizontal directional drilling to refuse landfill leachate drainage

InactiveCN106436776AGood for drainage and consolidationLower Wetting LineProtective foundationEnvironmental engineeringLeachate

The invention discloses a method for applying horizontal directional drilling to refuse landfill leachate drainage. The method comprises the steps that a drill hole of K meters is drilled in the part, in a preset low-point position of a side slope of a refuse dam, of a refuse dump body by a horizontal directional drilling rig, a leachate guiding pipe is carried by a drill bit of the horizontal directional drilling rig to enter the drill hole and enter the refuse dump body along with the drill bit, and finally a leachate drainage channel is formed; and the pipe body, located within the range from the front end to the position away from the front end of the leachate guiding pipe by S meters, of the leachate guiding pipe is of a floral pipe structure wrapped with geotextile, grooves are formed in the two sides and the top of the floral pipe structure at intervals, wherein S is smaller than K. According to the method for applying horizontal directional drilling to refuse landfill leachate drainage, the horizontal directional drilling technology is introduced into the field of refuse landfill leachate drainage and combined with the refuse landfill leachate drainage technical characteristics, so that an artesian leachate drainage facility is formed, the phreatic line is effectively lowered, and drainage consolidation of stockpiling refuse is facilitated; and the method has the advantage of being easy and convenient to construct, low in manufacturing cost and the like.

Owner:上海胜义环境科技有限公司

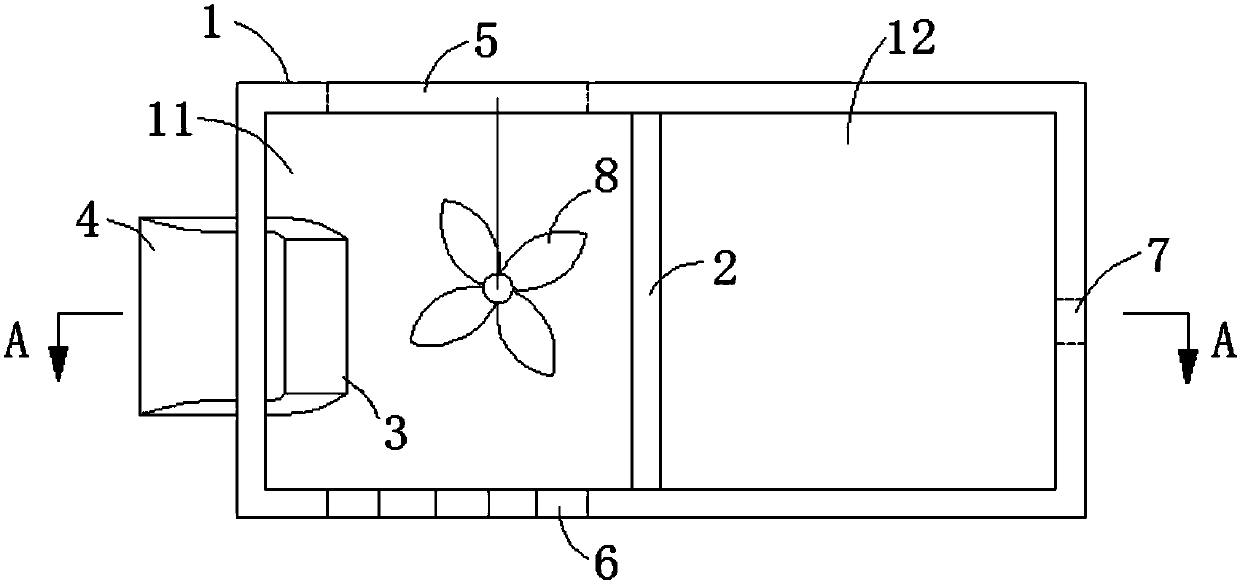

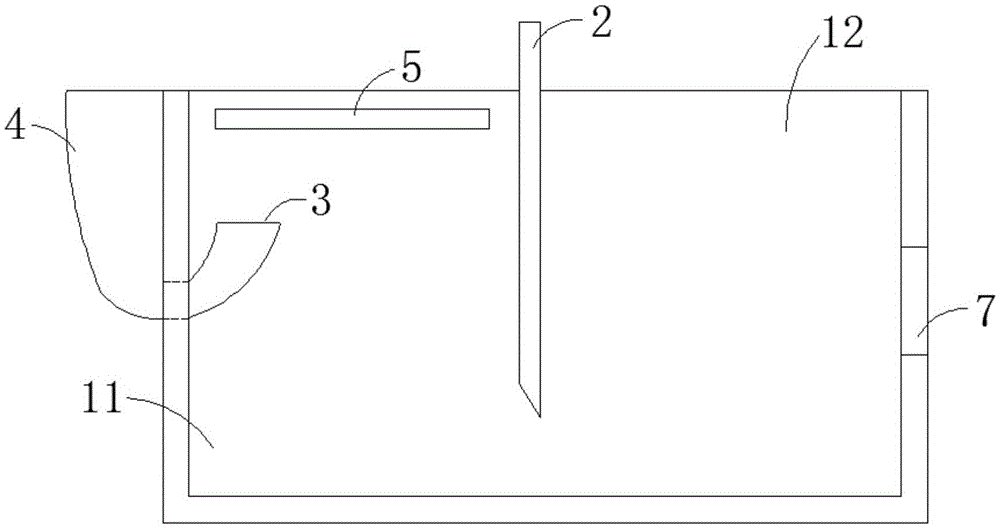

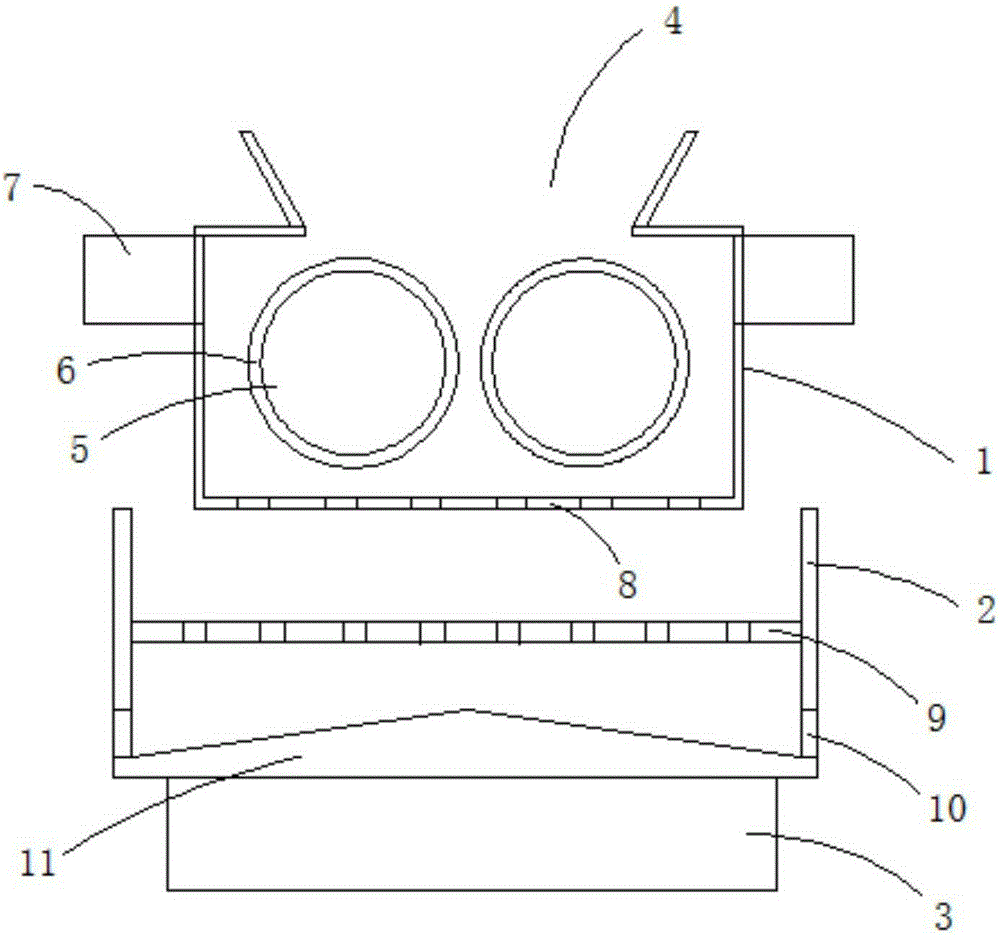

Automatic smelting, water-containing and residue-filtering slot

InactiveCN106338207ASpeed up the outflowImprove outflow efficiencyCharge manipulationWater dischargeEngineering

The invention relates to an automatic smelting, water-containing and residue-filtering slot which comprises a slot body; the slot body is made of a refractory material; the slot body comprises a first sub slot and a second sub slot; a partition plate capable of moving in the vertical direction is arranged between the first sub slot and the second sub slot; a water inlet is formed in the inner side surface of the first sub slot; the opening of the water inlet faces upwards; a water containing hole is formed in the outer side surface, which corresponds to the side wall, of the water inlet; the water containing hole communicates with the water inlet; a residue discharge hole is formed in one side wall, which is adjacent to the side wall where the water containing hole is located; at least one fan is arranged at the upper end of the other side wall, which is adjacent to the side wall where the water containing hole is located; a water discharge hole is formed in the side wall of the second sub slot; the upper end of the partitioning plate is equipped with an air cylinder; the output shaft of the air cylinder is fixedly connected with the partition plate; and the output shaft of the air cylinder drives the partition plate to vertically move in a telescopic manner. Compared with the prior art, floating residues float quickly, residue removal efficiency is high, continuous operation can be realized, and degree of automation is high.

Owner:桂林百坚汽车附件有限公司

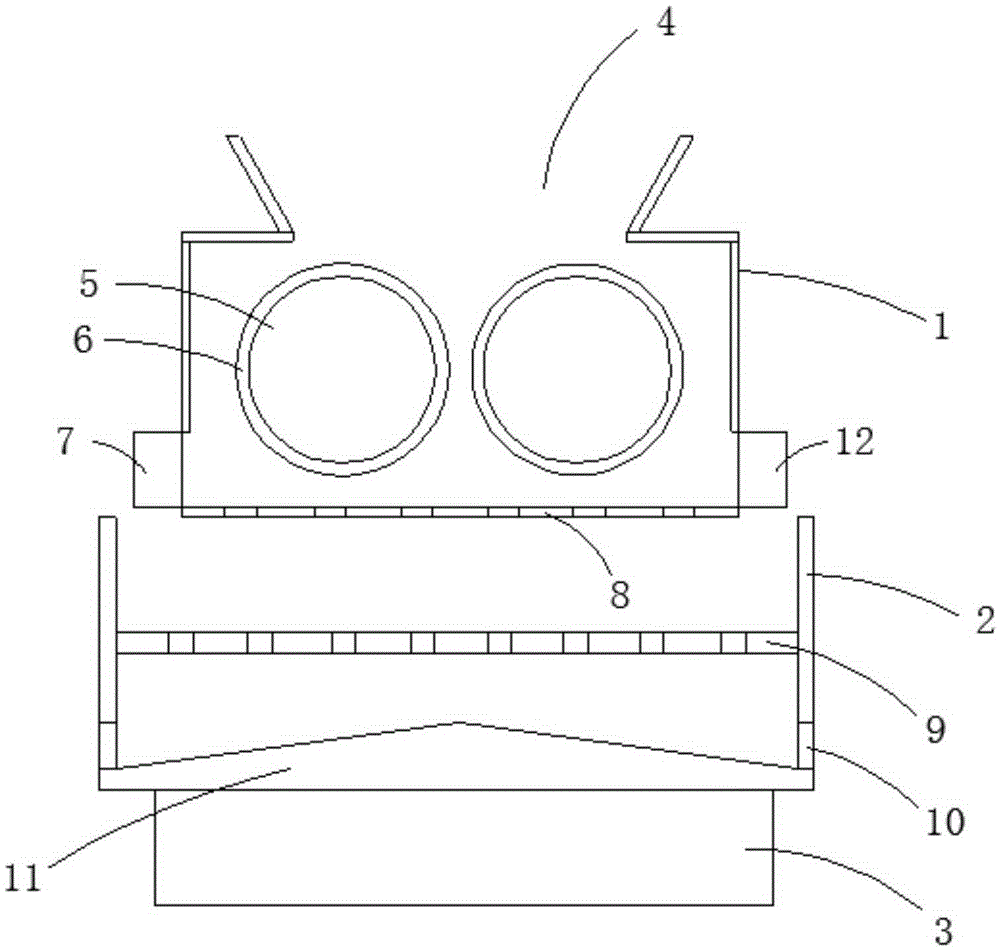

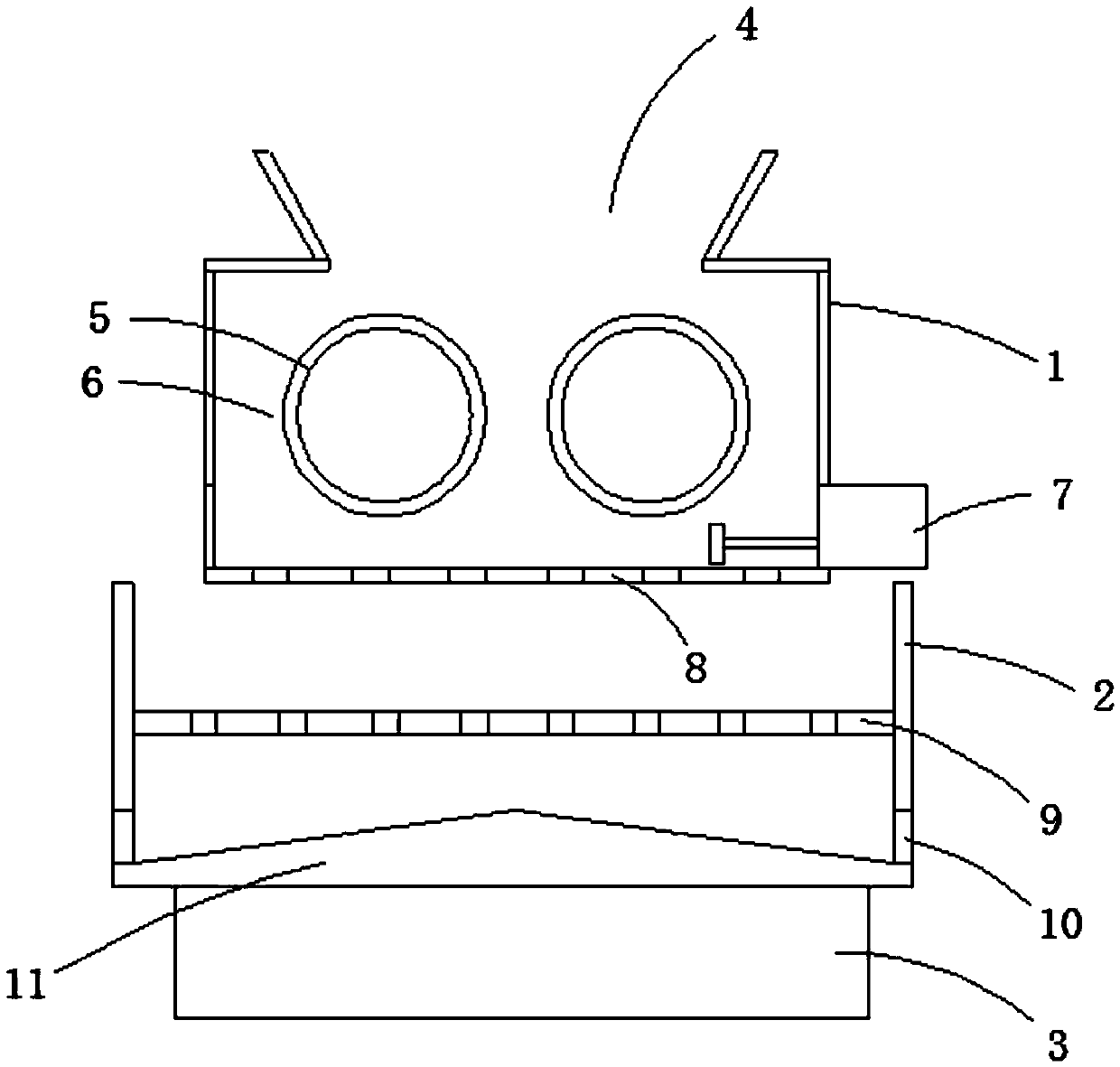

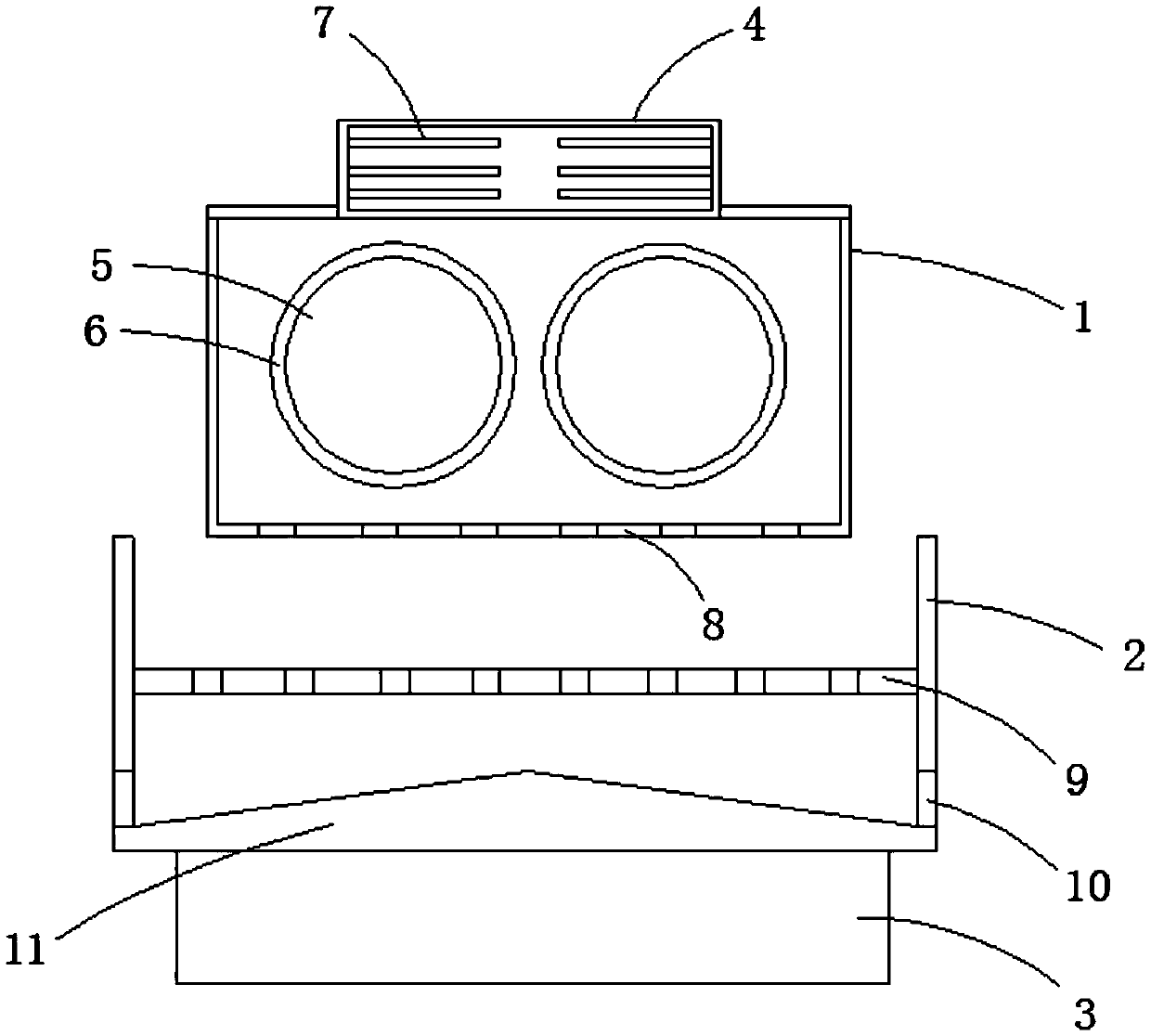

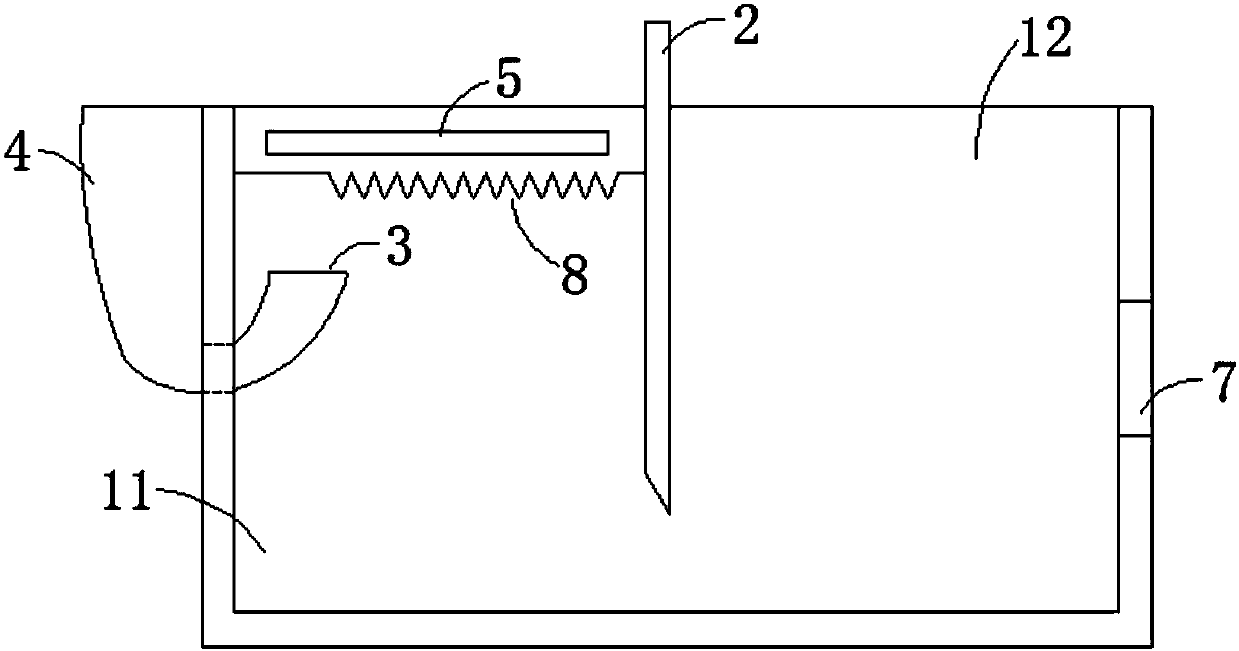

Dry grain thresher

The present invention relates to a dry grain thresher. The thresher comprises a threshing cylinder, a grain collector and a vibrator. The threshing cylinder is disposed above the grain collector; the vibrator is disposed at the lower end of the grain collector; the upper end of the threshing cylinder is fixedly provided with a grain placing port; two rollers are arranged in the threshing cylinder and are located below the grain placing port in parallel; spiral blades for threshing are arranged on the two rollers; the bottom of the threshing cylinder is a screen; and a blower capable of blowing out hot air is arranged on one side of the threshing cylinder and an induced draft pump is arranged on the other side of the threshing cylinder. Compared with the prior art, the dry grain thresher disclosed by the present invention has the features that the threshing speed is high; grains can be dried by hot air; grain waste is avoided; and the grains are clean.

Owner:GUILIN UNIV OF AEROSPACE TECH

Grain threshing machine with stable running

The invention relates to a grain threshing machine with stable running, and the machine comprises a threshing cylinder, a grain collecting device and a vibrator, wherein the threshing cylinder is placed over the grain collecting device; the vibrator is placed on the lower end of the grain collecting device; a grain placement entrance is firmly disposed in the upper end of the threshing cylinder; two rollers are disposed inside the threshing cylinder; the two rollers are located in parallel under the grain placement entrance; spiral blades used for threshing are disposed on both the rollers; the bottom part of the threshing cylinder is a screen; a pushing device is disposed on one side of the lower part of the threshing cylinder; an impurity discharge hole is formed in the other side of the lower part of the threshing cylinder; a push plate is firmly connected on an output shaft of the pushing device; and the push plate can be driven by the output shaft of the pushing device to push impurities on the bottom of the threshing cylinder outwards from the impurity discharge hole. In comparison with the prior art, according to the invention, the threshing becomes quick; the impurities can be pushed out; and the impurities can be disposed timely, so that influences brought by the impurities on threshing efficiency can be avoided and grains become clean.

Owner:GUILIN UNIV OF AEROSPACE TECH

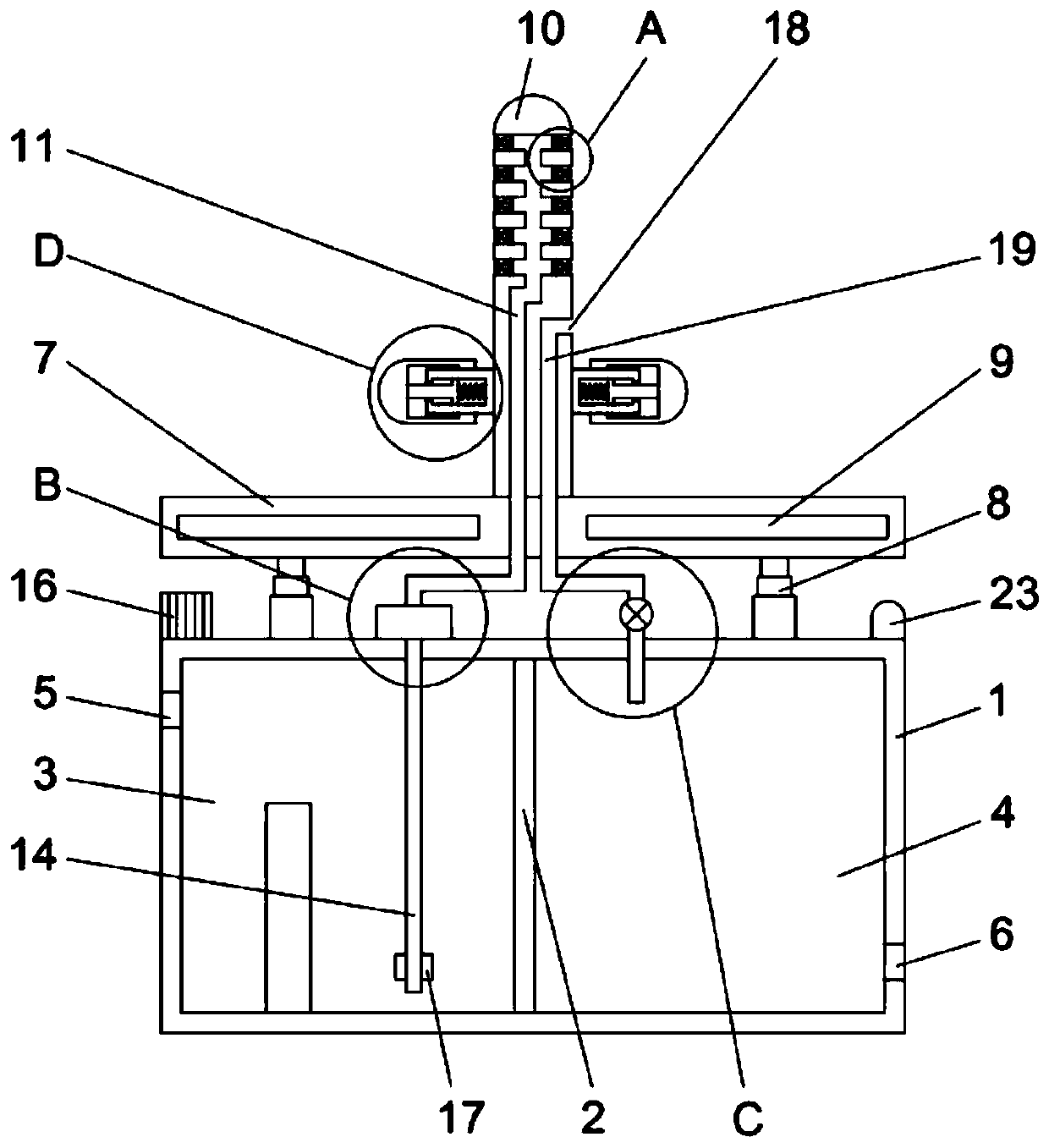

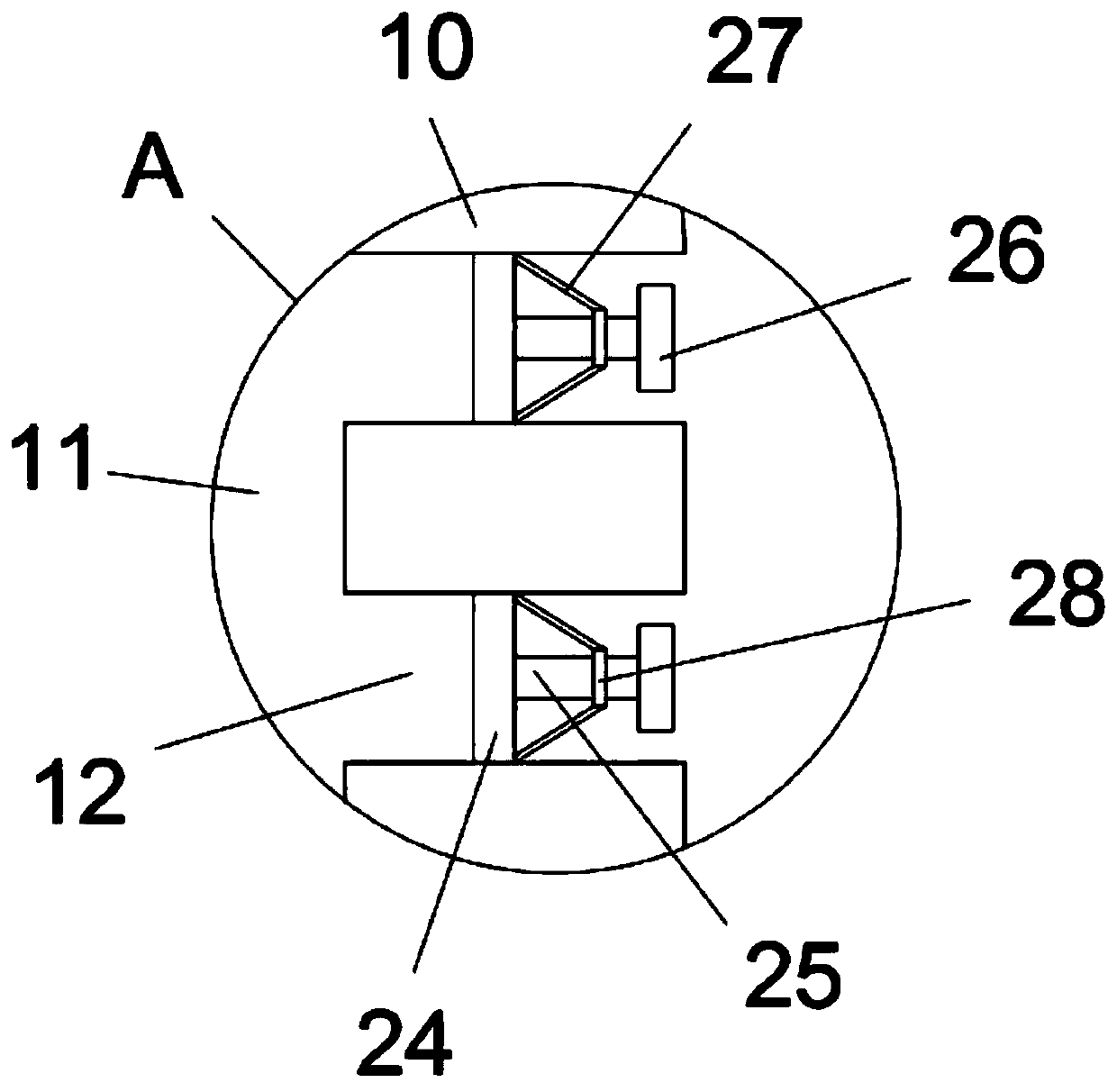

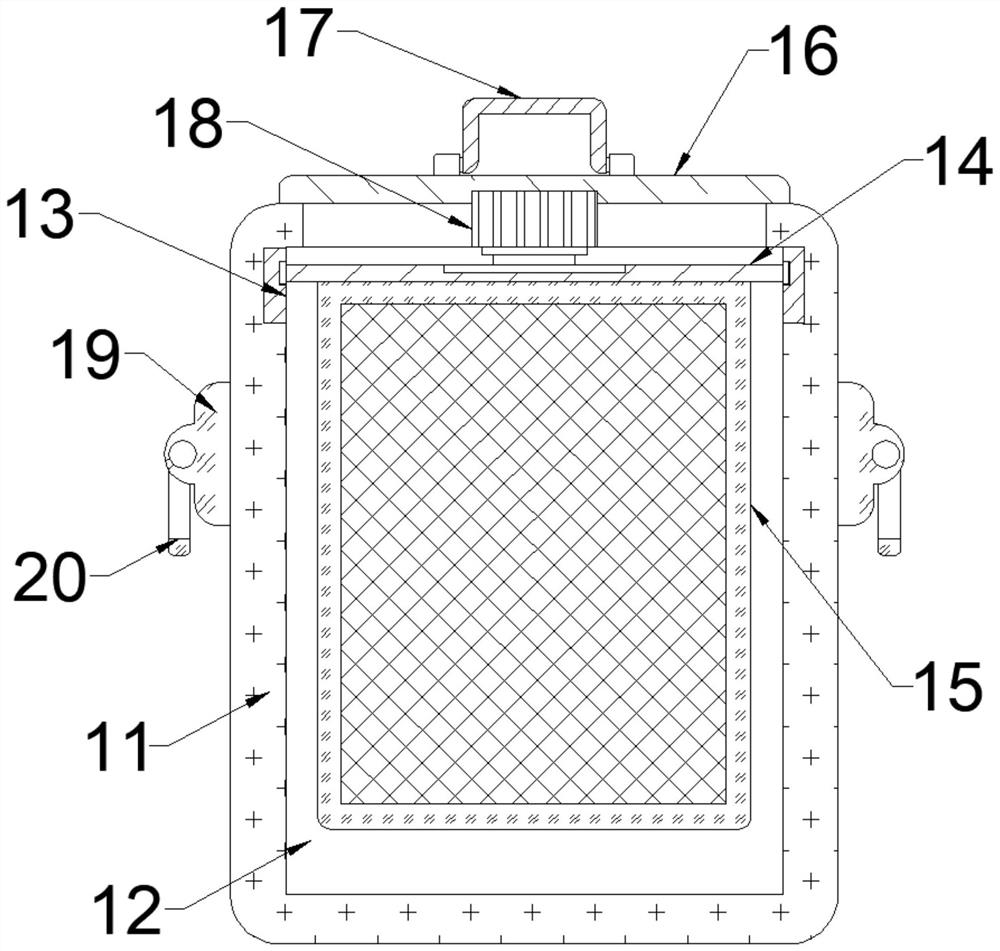

Cleaning device for urological and anorectal surgical nursing

ActiveCN111420153AFreely change the areaImprove comfortCannulasEnemata/irrigatorsNursing careEngineering

The invention discloses a cleaning device for urological and anorectal surgical nursing. The device comprises a box body, a blocking mechanism and an anti-backflow mechanism; a partition plate is vertically and fixedly connected into the box body; and the box body is divided into a cleaning liquid chamber and a waste liquid chamber by the partition plate. The device is provided with the blocking mechanism, so that when the anorectum of a user is blocked, the anorectum of the user can freely stretch and retract, damage to the anorectum of the user by a hard blockage mode is avoided, and comfortfor the user is improved. Meanwhile, anorectum with different diameters can be blocked by a freely telescopic elastic rubber frame, so that applicability is improved. The device is further provided with the anti-backflow mechanism, so that waste liquid generated after anorectal cleaning is prevented from flowing back into a liquid distribution pipe to pollute the liquid distribution pipe and a cleaning catheter, a cleaning device is convenient to clean and disinfect after being used, meanwhile, outflow efficiency of cleaning liquid is improved, and the outflow time of the cleaning liquid is shortened. An electric telescopic rod is further arranged, and the height of a cushion is adjusted through the electric telescopic rod, so that a user can sit more comfortably.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Internal drainage expanding device for viscoelastic tubule

InactiveCN107616872AAvoid damageFor quick outflowEye surgeryPostoperative complicationFiltering bleb

The invention discloses an internal drainage expanding device fro a viscoelastic tubule. The internal drainage expanding device comprises an aqueous fluid internal drainage tube and a viscoelastic tubule expanding tube; the outer wall of the viscoelastic tubule is wrapped by a thin film layer, the section of the viscoelastic tubule is in an open circular ring shape, the thin film layer is made from biodegradable materials, the viscoelastic tubule expanding tube has tension ans can be expanded to keep the section in a C type after the thin film layer is degraded, and fluid permeation holes areformed in the tube wall of the viscoelastic tubule expanding tube; one end of the aqueous fluid internal drainage tube can be arranged in the viscoelastic tubule expanding tube. By the adoption of internal drainage, the internal drainage expanding device avoids postoperative complications, filtering bleb scarring and other problems caused by an external drainage operation; the internal drainage mode has small injury to the normal physiological structure of eyeballs, can keep stable during eyeball tension fluctuations after an operation, and reserves the maximum space for other operations for patients in the future.

Owner:陈慧慧

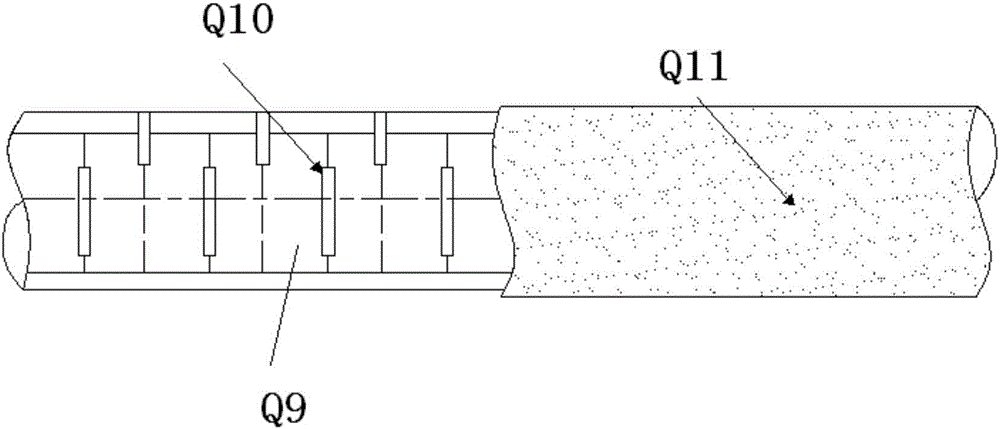

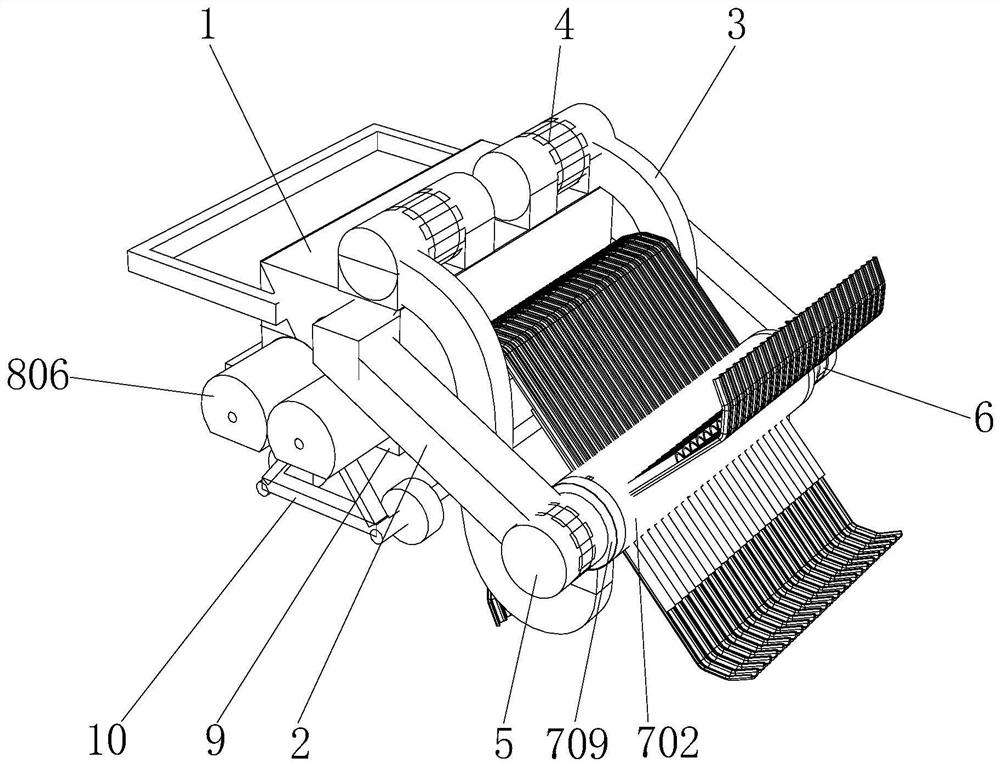

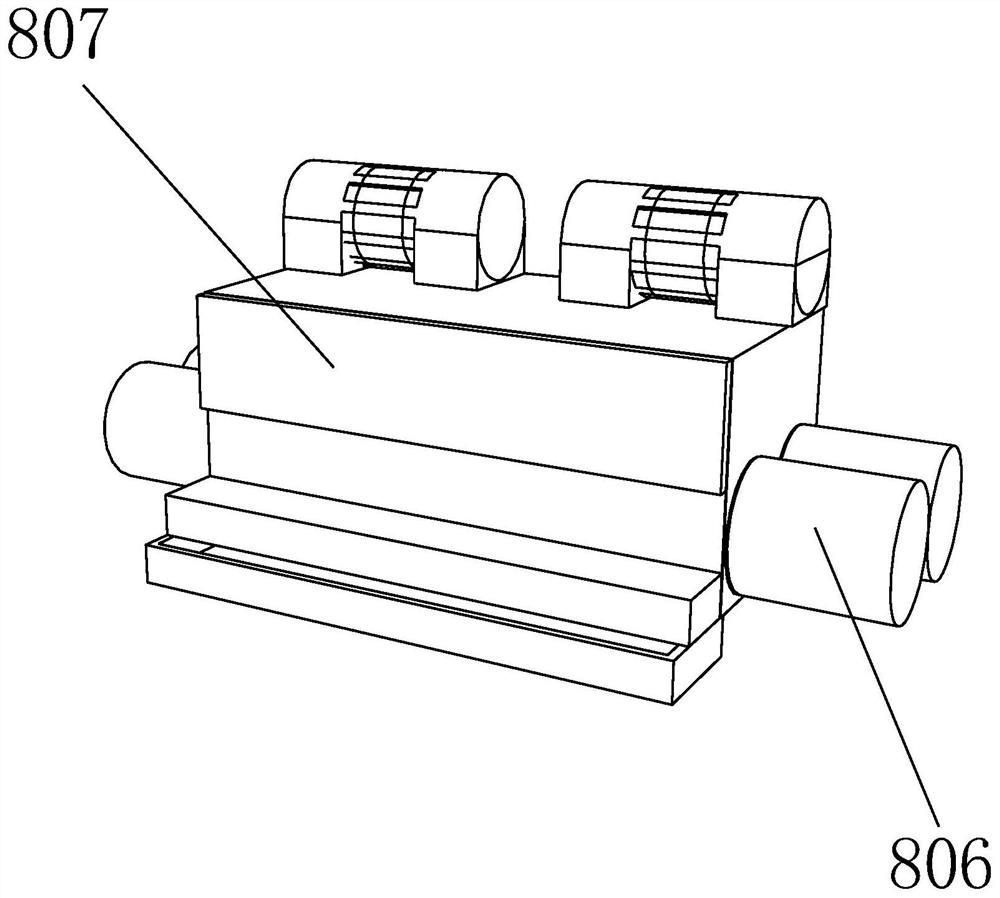

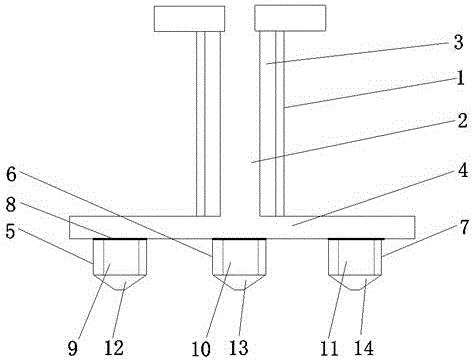

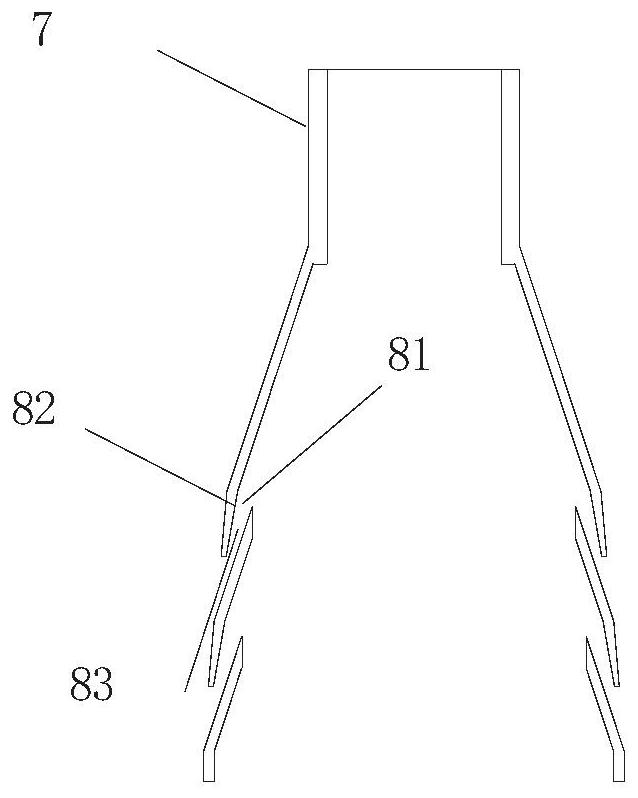

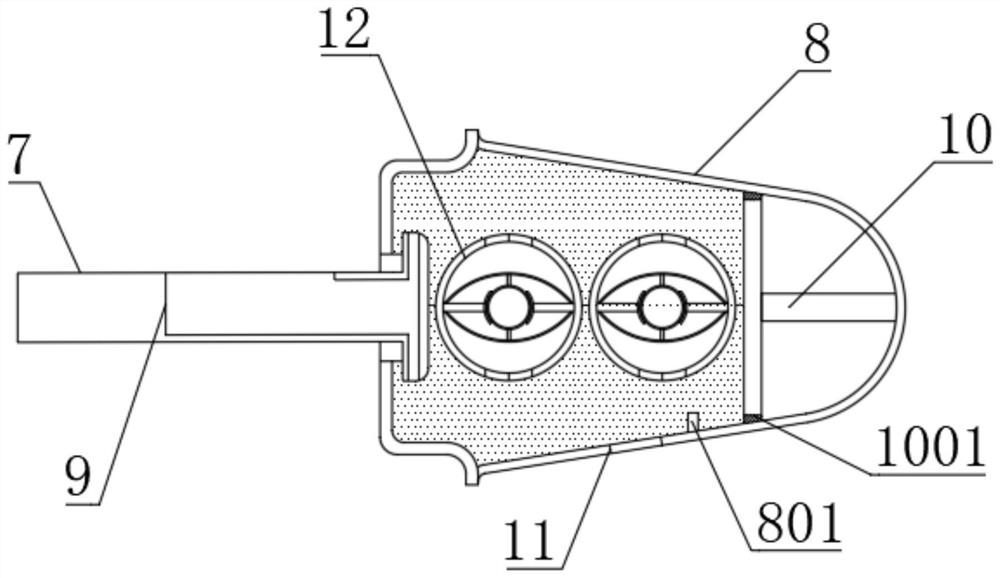

Down filling pipe assembly of down filling machine for down product production

ActiveCN110775935AImprove outflow efficiencyImprove down filling efficiencyUpholstery manufactureDispersed particle filtrationManufacturing engineeringMechanical engineering

The invention relates to the field of down product production and processing equipment, and discloses a down filling pipe assembly of a down filling machine for down product production. The down filling pipe assembly comprises a pipe base; one side of the top of the pipe base is fixedly connected with two limiting plates between which a rotatable down filling pipe is movably mounted in a sleeved manner; and the down filling pipe is provided with a full circle of filtering net located between the two limiting plates. According to the down filling pipe assembly of the down filling machine for down product production, the limiting plates, the down filling pipe, the filtering net, a packing sleeve, a linkage pipe, a control seat and a packing plate are arranged; in the down filling stage, downis injected from the lower space of the down filling pipe, air in a down product is discharged from the filtering net on one side of an upper half inner cavity of the down filling pipe, the filteringnet filters out the down mixed in the air, and the down is blown to the rightmost position of an upper half inner cavity of the linkage pipe under the effect of outflow of the air in the inner cavityof the down filling pipe, so that the down does not block the filtering net, the outflow efficiency of the air is improved, and the down filling efficiency is correspondingly improved.

Owner:济宁晨阳制衣股份有限公司

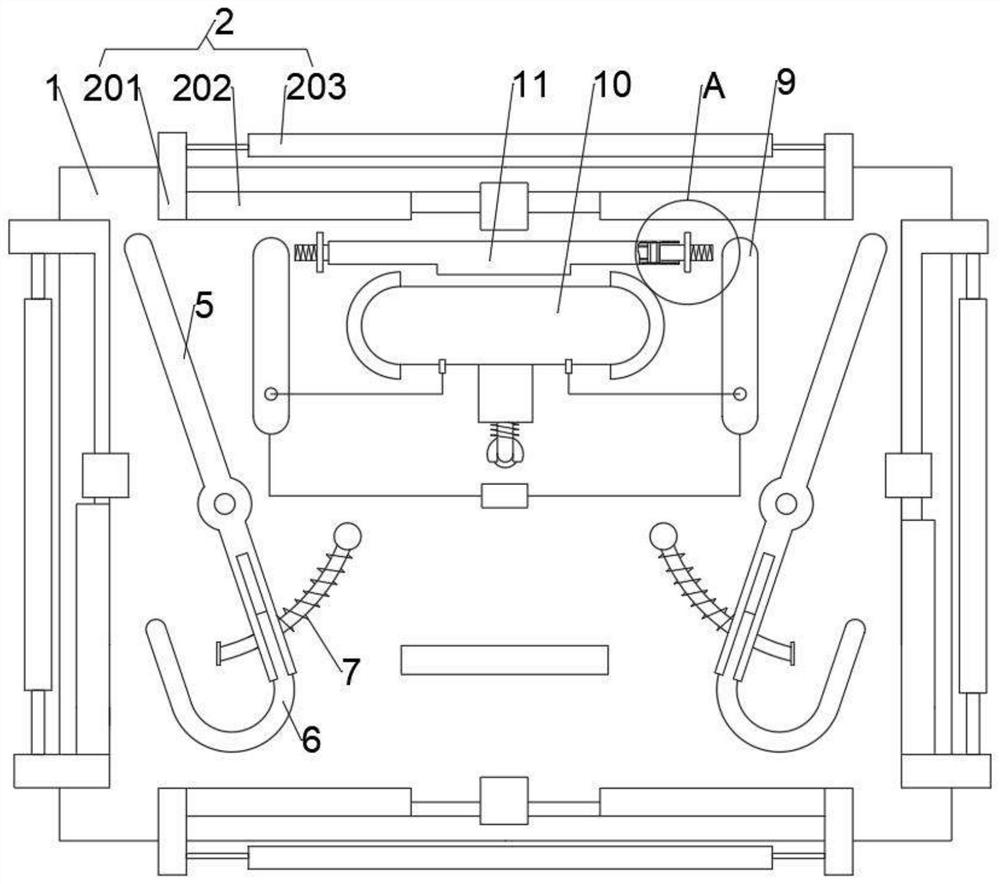

Cipangopaludina chinensis catching device

InactiveCN112136776AImprove capture efficiencyAchieve captureSievingScreeningElectric machineryAnimal science

The invention provides a cipangopaludina chinensis catching device, and relates to the technical field of cipangopaludina chinensis processing. The cipangopaludina chinensis catching device comprisesa machine shell, a connecting frame, a hose, a sucking pump, a first driving motor, a second driving motor, a catching mechanism, a separating mechanism, a collecting box and a support. The connectingframe is fixedly connected to the position, close to the top end, of the right side of the machine shell, the first driving motor is fixedly connected to the left end of the other end of the connecting frame, and the second driving motor is fixedly connected to the right end of the connecting frame. The catching mechanism is arranged in the end, away from the machine shell, of the connecting frame, the right end of the catching mechanism is movably connected with the first driving motor, the right side of the top end of the machine shell is fixedly connected with the sucking pump, the right side of the sucking pump is fixedly connected with the hose, and the other end of the hose is fixedly connected with the catching mechanism. The separating mechanism is arranged in the machine shell, the left side of the bottom end of the machine shell is in sliding connection with the collecting box, and the middle of the bottom end of the machine shell is fixedly connected with the support. The problems that cipangopaludina chinensis cannot be automatically caught and the catching efficiency is low are solved.

Owner:黎石英

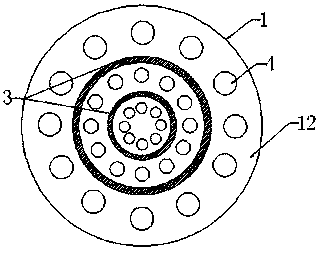

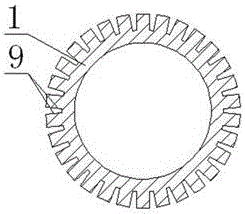

Efficient cooling forming fiber spinneret plate

The invention discloses a high-efficiency cooling molding fiber spinneret, which includes a spinneret body, a filter screen and a cooling system; wherein, the spinneret body is a cylinder, and the filter screen is embedded and fixed on the spinneret The feeding surface of the body; the spinneret body has spinneret holes distributed in an orderly interval, the spinneret holes are distributed in a ring around the center of the spinneret body, and the cooling system is installed on the on the spinneret body, and embedded between the spinneret holes distributed between adjacent rings. On the one hand, the mechanism design of the spinneret hole of the present invention improves the shaping effect of the fiber filament and increases its tensile strength; on the other hand, it effectively improves the outflow efficiency of the fiber mucus, avoids mucus retention, and improves the outflow rate; The design improves the cooling uniformity and cooling timeliness of the fiber filaments, and the resulting fiber filament structure and performance are excellent.

Owner:SUZHOU DONGSHENG CHEM FIBER TEXTILE

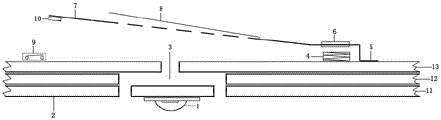

Plastic mold used for automotive interior

The invention discloses a plastic mold used for an automotive interior. The plastic mold comprises a mold body. The center of the mold body is provided with a main runner and cooling water channels. The cooling water channels are arranged on the two sides of the main runner. An auxiliary runner is arranged at the lower end of the main runner and perpendicular to the main runner. A first hot nozzle, a second hot nozzle and a third hot nozzle are arranged on the auxiliary runner and connected with spouts of the auxiliary runner through sealing rings correspondingly. According to the plastic mold used for the automotive interior, the structure and the principle are simple; the adopted main runner and the adopted auxiliary runner are both hot runners, and thus the material cost can be reduced; and the auxiliary runner is provided with the multiple nozzles, and hence the production efficiency can be improved.

Owner:上海文业扬实业有限公司

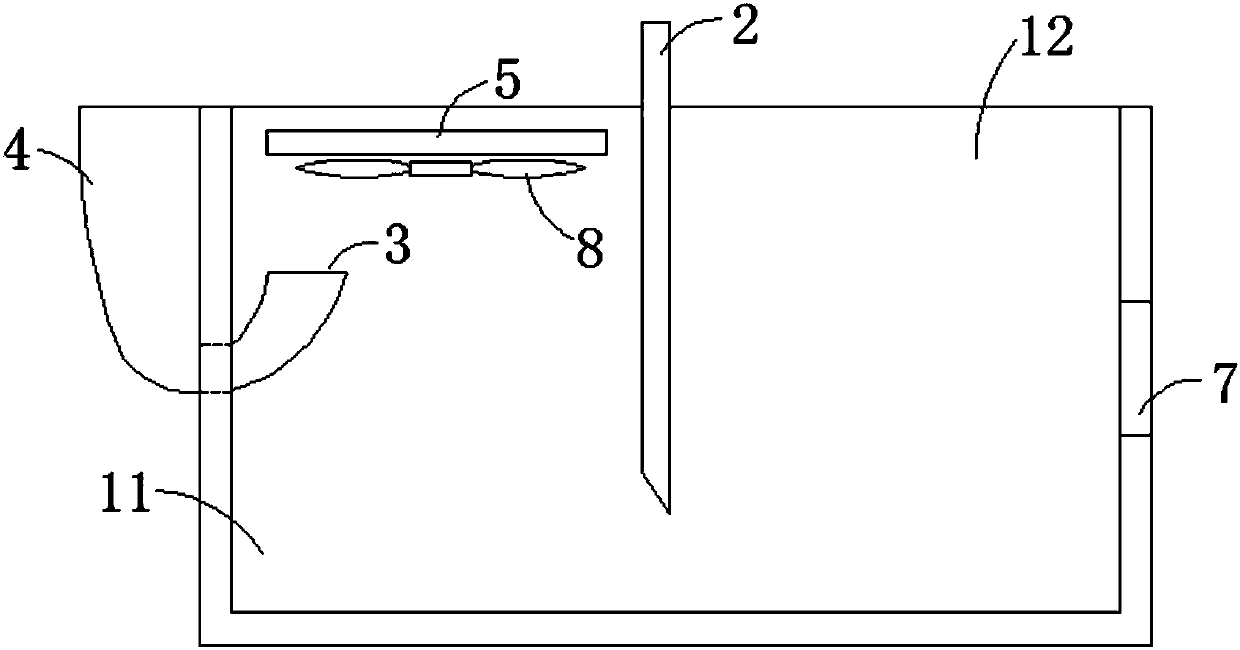

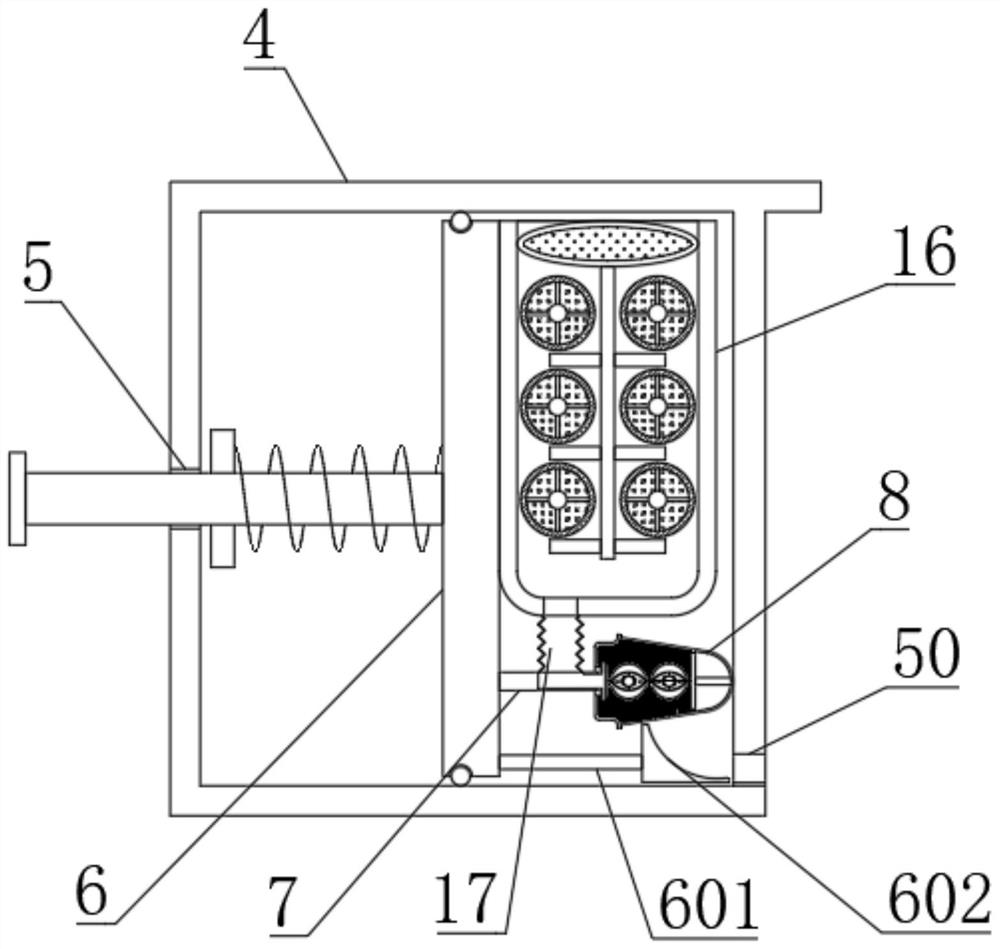

LED lamp

ActiveCN105822919AReduce heat buildupImprove conversion efficiencyElectric circuit arrangementsLighting heating/cooling arrangementsFlapping wingControl switch

The invention discloses an LED lamp. The LED lamp comprises an LED lamp bead, a lampshade, a heat conduction apparatus for fixing the LED lamp bead and a radiator, wherein the heat conduction apparatus is provided with an air flue; the radiator comprises an electromagnet, a spring leaf, an armature, a fan blade with a flapping wing structure, a one-way flow auxiliary ring and a magnetic-control switch, wherein the electromagnet, the magnetic-control switch and a power supply form a circuit; one end of the armature is connected with the spring leaf, and the other end of the armature is connected with the fan blade with the flapping wing structure; the fan blade with the flapping wing structure is provided with a plurality of pores; and one end, close to the armature, of the one-way flow auxiliary ring is fixed to the fan blade with the flapping wing structure. After the power supply is switched on, the electromagnet attracts the armature to drive the fan blade with the flapping wing structure to move downwards, so that a seam capable of allowing air to pass through is formed between the fan blade with the flapping wing structure and the one-way flow auxiliary ring; a permanent magnet magnetic sheet on the fan blade with the flapping wing structure is in contact with the magnetic control switch, so that the circuit is switched off; under the action of the spring leaf, the armature drives the fan blade with the flapping wing structure to return, so that the circuit is switched on; and the processes are repeated. The LED lamp actively realizes one-way flow of air, so that the heat dissipation effect is achieved.

Owner:江苏创导光电科技有限公司

Smelting dross filter tank with fan blades

The invention relates to a smelting dross filter tank with fan blades. The smelting dross filter tank comprises a tank body which is made of refractory materials. The tank body comprises a first branch tank and a second branch tank, a separation plate capable of being moved in the vertical direction is arranged between the first branch tank and the second branch tank, a water inlet is arranged onthe inner side face of a lateral part of the first branch tank, an opening of the water inlet faces upwards, a water receiving nozzle is arranged on the outer side face of the lateral part corresponding to the water inlet, and the water receiving nozzle communicates with the water inlet. A dross discharge outlet is arranged on a lateral part adjacent to the lateral part where the water receiving nozzle is located. At least one draught fan is arranged at the upper end of another lateral part adjacent to the lateral part where the water receiving nozzle is located. A water discharge outlet is arranged on a lateral part of the second branch tank. The fan blades are arranged inside the first branch tank and correspondingly located at the liquid level position inside the first branch tank. Thefan blades are connected with one side wall of the tank body through a connecting rod and are rotatably connected with the connecting rod. Compared with the prior art, the smelting dross filter tank has the advantages that dross rises quickly, the dross removal efficiency is high, and continuous operation can be realized.

Owner:路望培

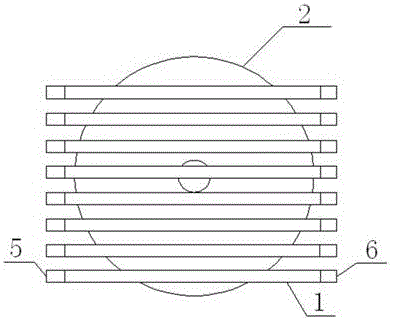

Vertical efficient water-cooling condenser

PendingCN106152627AIncrease contact areaImprove heat exchange efficiencyEvaporators/condensersEngineeringWater tanks

The invention discloses a vertical efficient water-cooling condenser. The vertical efficient water-cooling condenser comprises a bucket body and a plurality of cooling water tanks sequentially arranged in the bucket body from top to bottom. Each cooling water tank is a tank body with the middle portion being higher than the periphery. Through holes are formed in the cooling water tanks correspondingly. The two ends of each cooling water tank communicate with a cooling water inlet pipe and a cooling water outlet pipe correspondingly. The top of the bucket body communicates with a hot air inlet pipe. The bottom of the bucket body communicates with a condensate water outlet pipe. A temperature monitor is arranged on the side wall of the bucket body and comprises a temperature displayer arranged on the outer wall of the bucket body and a temperature sensor arranged on the inner wall of the bucket body. A plurality of evenly-distributed first through holes are formed in the middle portions of the tank bodies, and a plurality of evenly-distributed second through holes are formed in the peripheries of the tank bodies. The diameter of the first through holes is smaller than the diameter of the second through holes. The bottom of the bucket body is an arc-surface sheet with the middle portion being lower than the periphery. The diameter of the hot air inlet pipe is larger than the diameter of the condensate water outlet pipe. Compared with the prior art, the vertical efficient water-cooling condenser has the advantage of being high in heat exchange efficiency.

Owner:成都馨迪璐莎科技有限公司

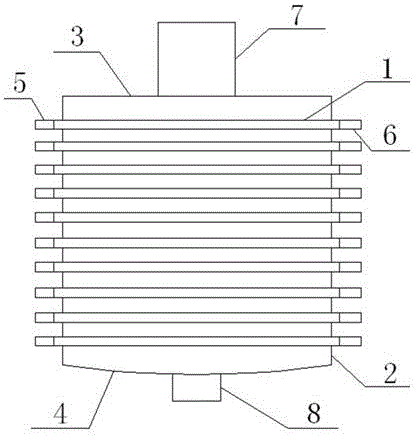

Multi-cold pipe vertical efficient condenser

PendingCN106197056AIncrease contact areaImprove heat exchange efficiencyEvaporators/condensersSteam/vapor condensersEngineeringHigh heat

The invention discloses a multi-cold pipe vertical efficient condenser. The multi-cold pipe vertical efficient condenser comprises a closed cylindrical barrel body, and multiple cold pipes inserted in the barrel body; the barrel body includes a side wall plate vertically placed, a top plate connected to the top of the side wall plate, and a baseplate connected to the bottom of the side wall plate; the middle parts of the cold pipes are inserted in the side wall plate; two ends of the cold pipes are arranged on the outer side of the side wall plate, and are respectively connected with cooling liquid inlet pipes and cooling liquid outlet pipes; the top of the top plate is communicated with a hot air intake pipe; the bottom of the baseplate is communicated with a condensed water outlet pipe; multiple grooves are formed in the axle directions of the outer walls of the cold pipes; the baseplate is an arc disc with upwards bent periphery; the middle part of the baseplate is communicated with the condensed water outlet pipe; and the cold pipes are uniformly distributed on the horizontal surface and the vertical surface in the barrel body. Compared with the prior art, the multi-cold pipe vertical efficient condenser has the advantage of high heat exchange efficiency.

Owner:成都馨迪璐莎科技有限公司

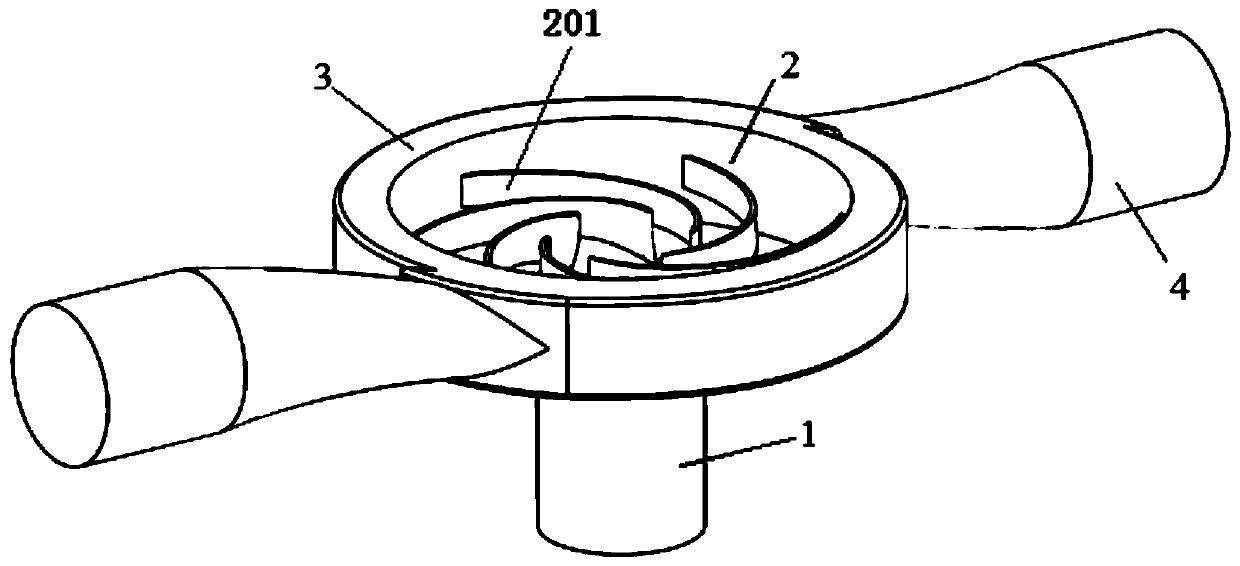

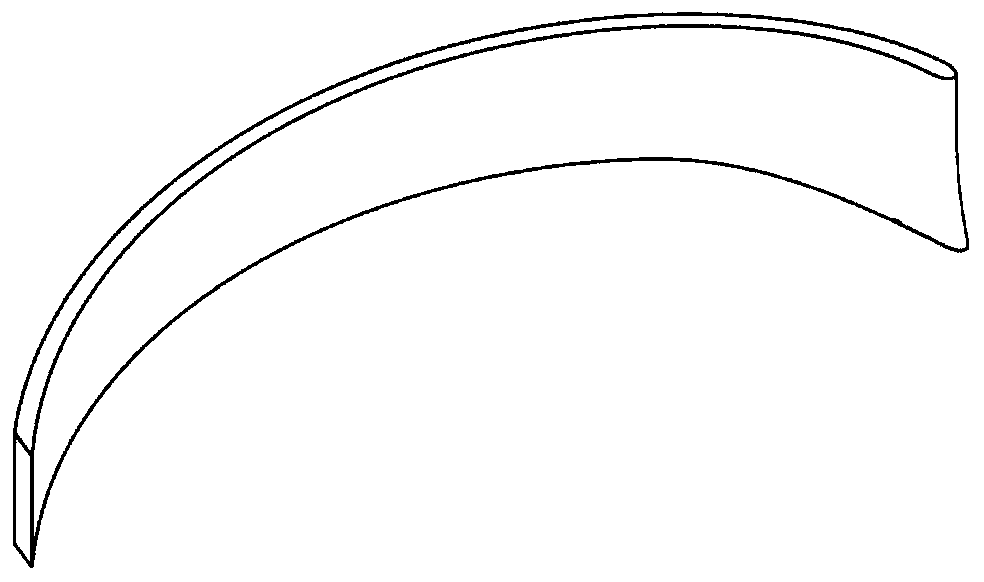

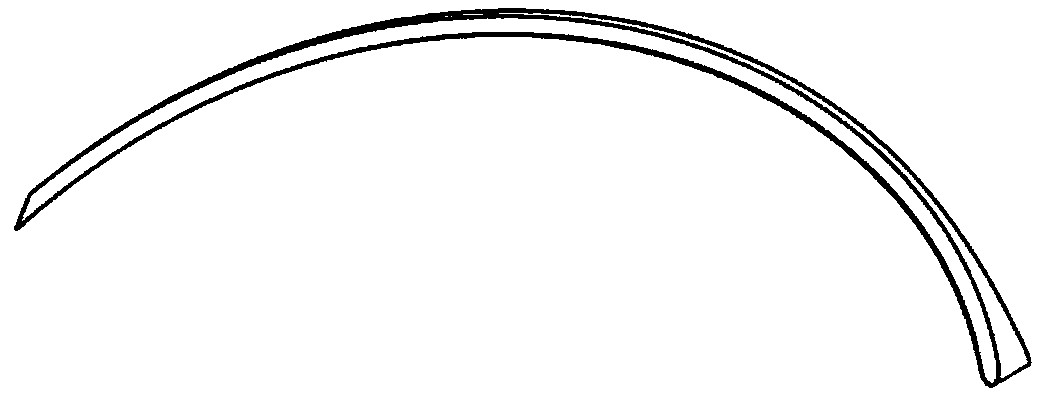

Double outlet type volute centrifugal pump with high specific speed

InactiveCN111536077AImprove outflow efficiencyImprove efficiencyPump componentsRadial flow pumpsWater flowEngineering

The invention discloses a double outlet type volute centrifugal pump with a high specific speed. An impeller is arranged at an annular opening of the inner side of a double outlet type volute, the bottom of the impeller is connected to a water suction pipeline, and two water outlets of the double outlet type volute are connected to water outlet pipelines; blades of the impeller are of cylindrical-like twisting structures, and the front and back surfaces of the blades are in smooth connection from top to bottom by curved surfaces with different curvatures; and the water suction pipeline, the impeller and the center of the double outlet type volute are in the same axis. The double outlet type volute centrifugal pump discharges water bidirectionally through the two water outlets, so that theeffluent efficiency of the centrifugal pump is improved. Meanwhile, the speed component of a water flow in the circumferential direction of the volute is enhanced, the water flow condition at the outlets of the volute are improved, and the hydraulic loss is reduced, so that the centrifugal pump has good hydraulic performance and operating efficiency.

Owner:HOHAI UNIV

A pipeline protection device

The invention discloses a pipeline protection device, comprising a low-temperature fluid pipeline and a high-temperature fluid pipeline, the low-temperature fluid pipeline intersects with the high-temperature fluid pipeline and communicates with each other; the fluid output port of the high-temperature fluid pipeline is arranged in the low-temperature fluid pipeline, And the direction in which the high-temperature fluid is output from the fluid output port of the high-temperature fluid pipeline into the low-temperature fluid pipeline is parallel to the flow direction of the low-temperature fluid in the low-temperature fluid pipeline. The pipeline protection device provided by the invention reduces the vibration amplitude of the pipeline, avoids the damage caused by material cavitation and high pressure and high flow rate to the pipeline wall, reduces costs, and ensures safe and stable production operation.

Owner:青海亚洲硅业硅材料有限公司

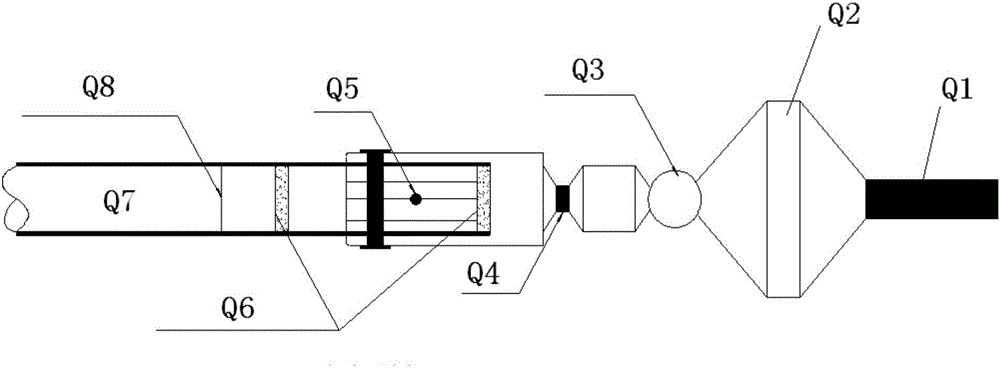

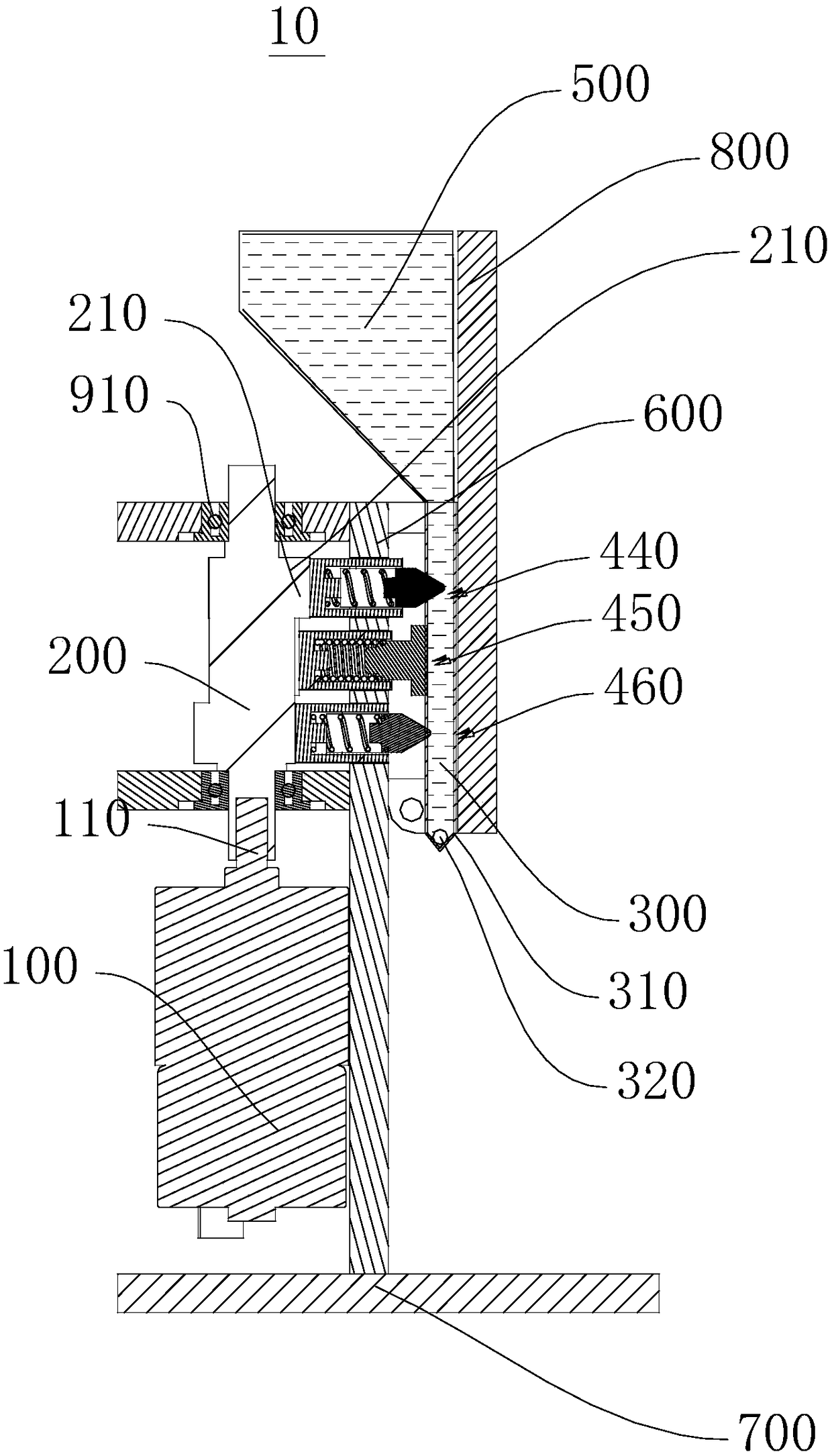

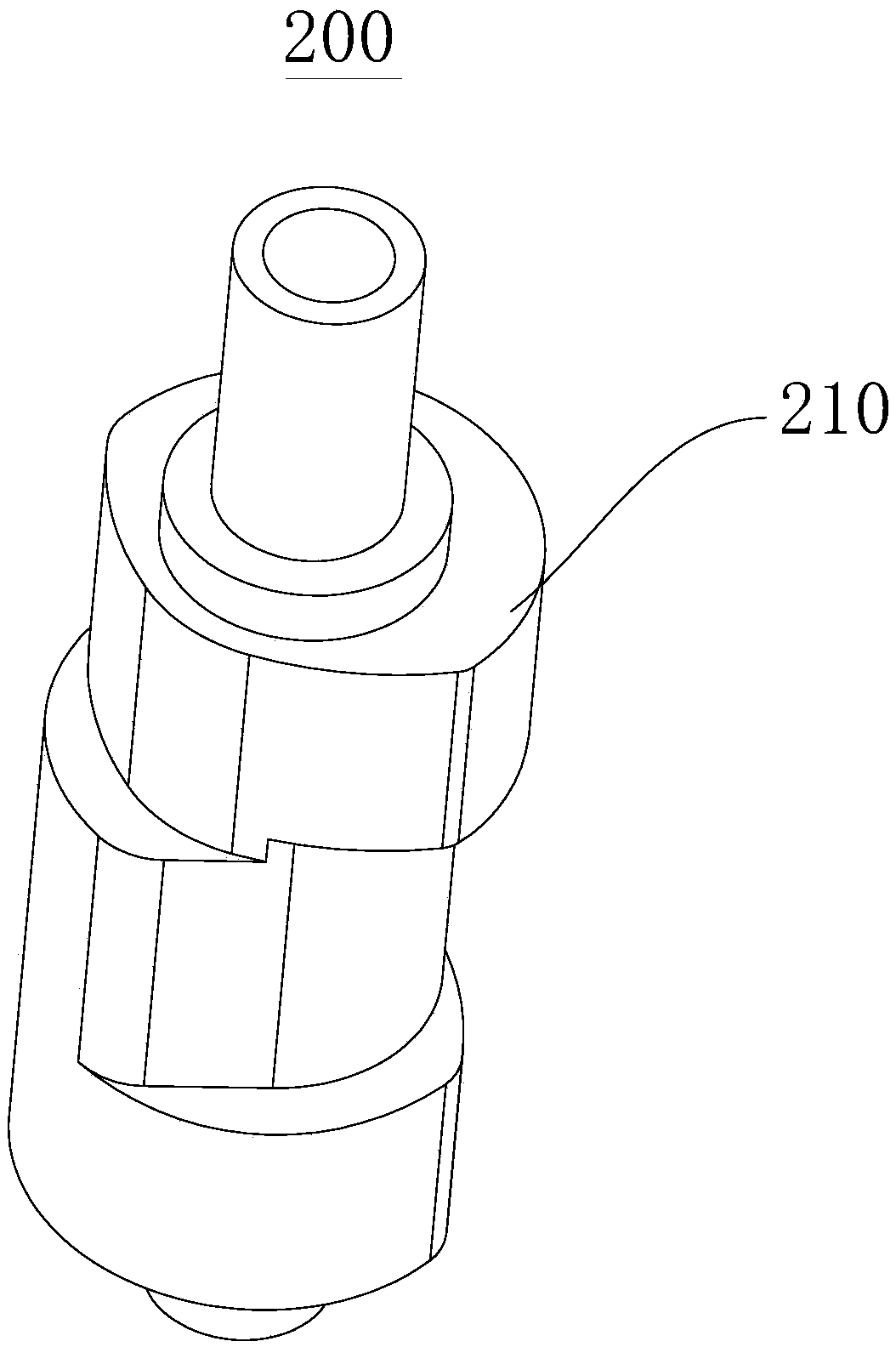

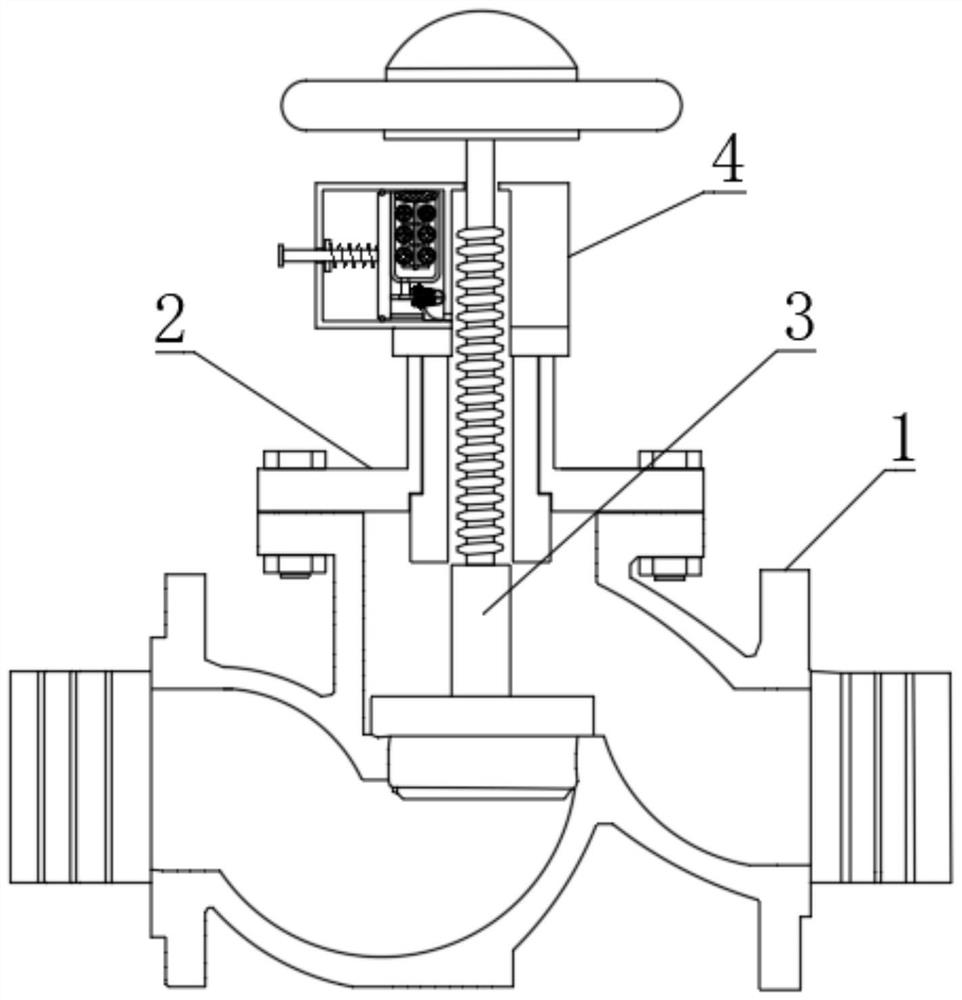

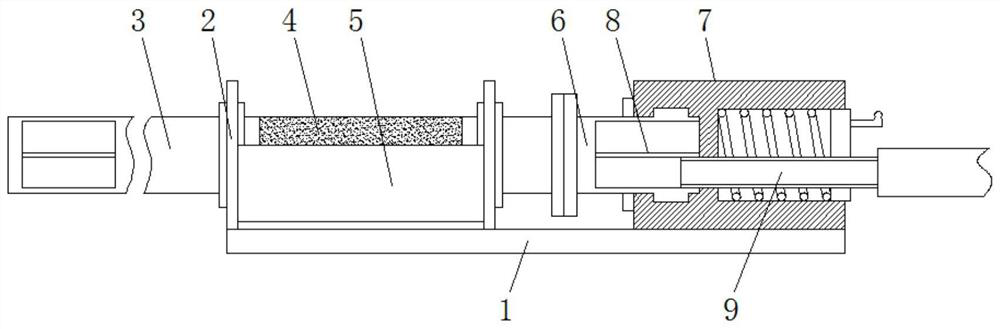

Shut-off valve devices and fluid transfer equipment

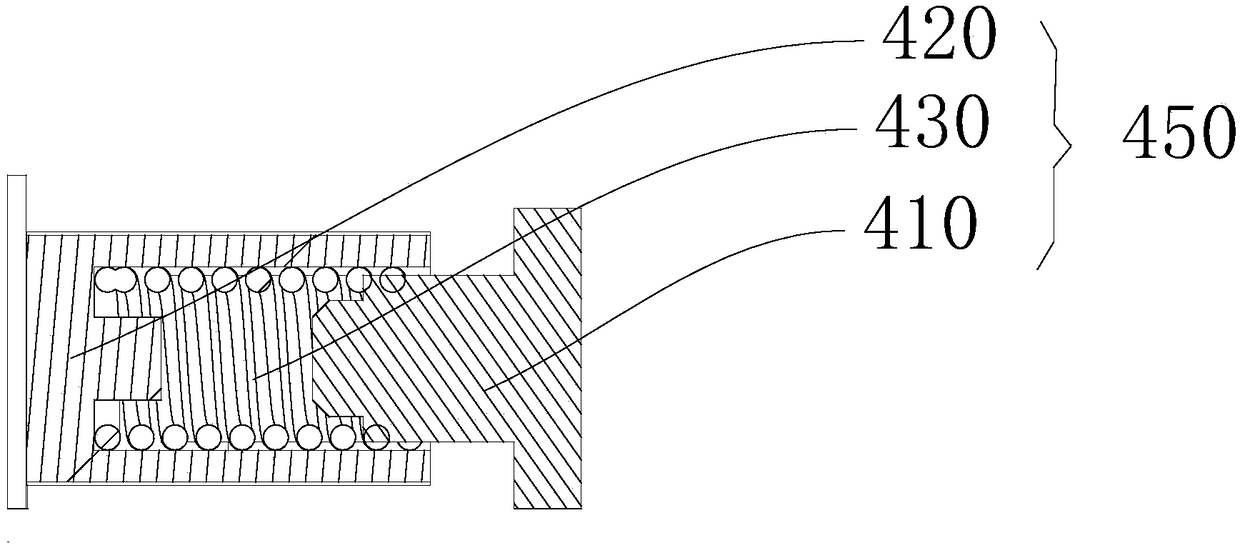

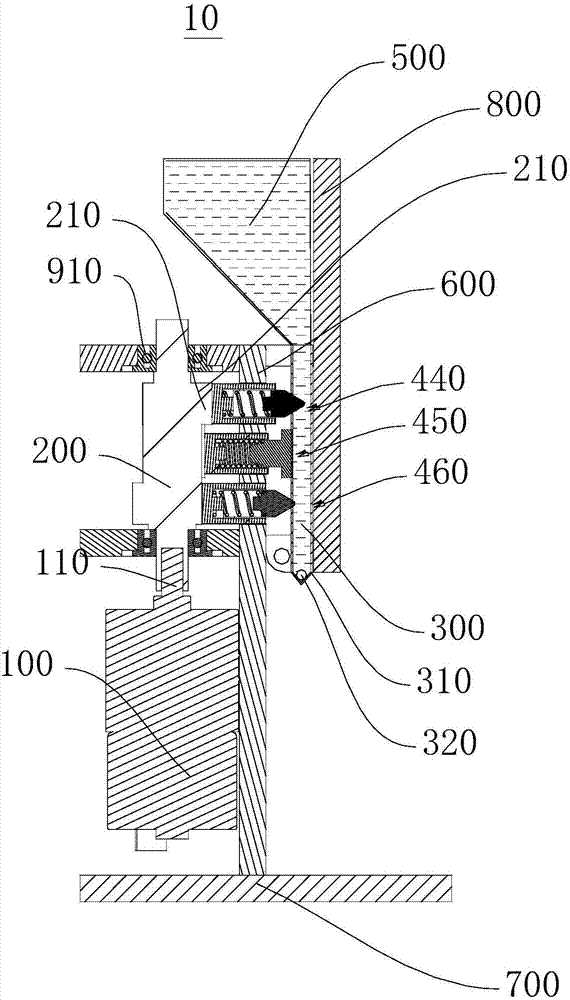

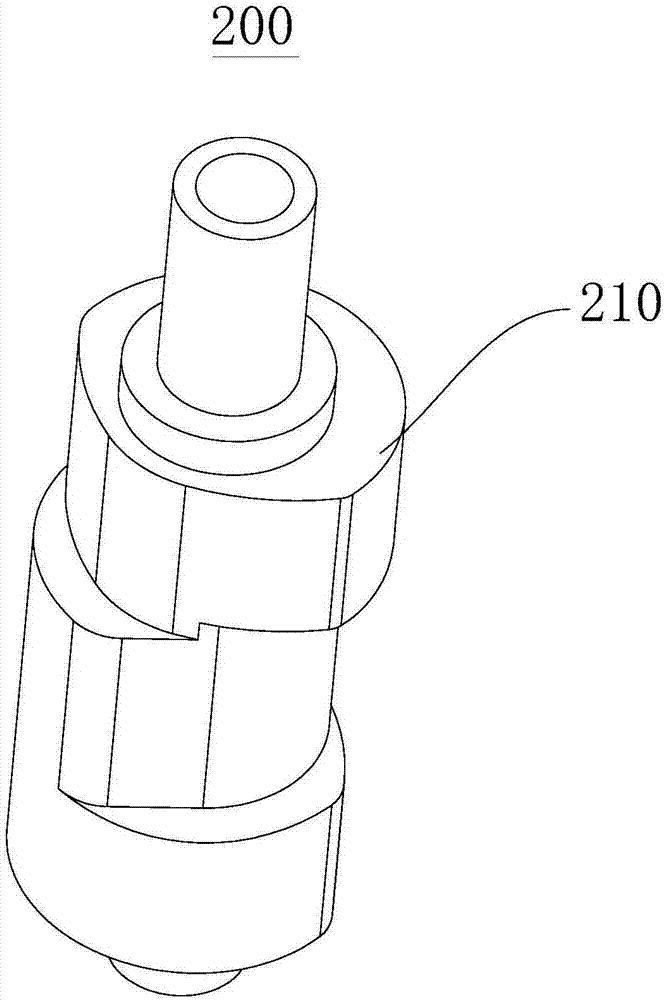

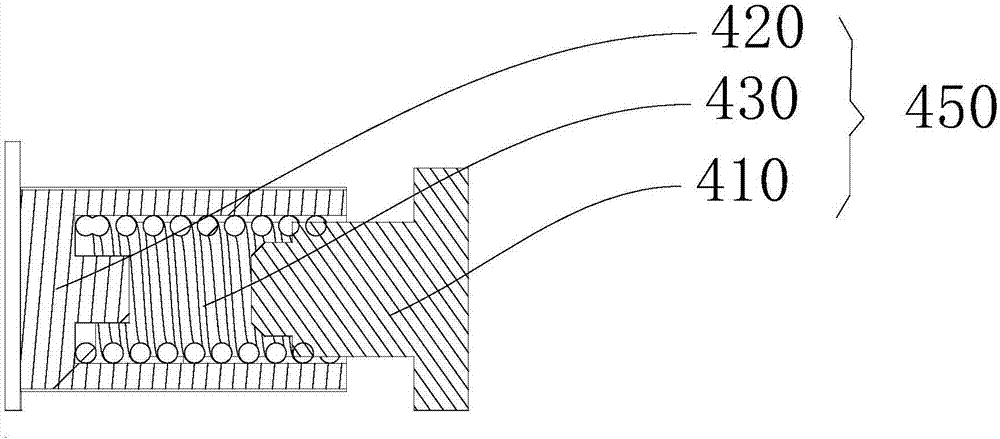

ActiveCN107100813BImprove outflow efficiencyReduce wearPositive displacement pump componentsPumpsDrive shaftEngineering

The invention discloses a stop valve device and a fluid conveying device. The stop valve device comprises a driving shaft and a conveying pipe; eccentric components arranged along the extension direction of the driving shaft are arranged in the circumferential direction of the driving shaft in a staggered mode; an inlet extrusion assembly, one or more middle extrusion assemblies and an outlet extrusion assembly are arranged in sequence in the extension direction of the conveying pipe; the outlet extrusion assembly extrudes and intercepts fluid in the conveying pipe, and the inlet extrusion assembly and the middle extrusion assemblies leave the conveying pipe; the inlet extrusion assembly extrudes and intercepts the fluid in the conveying pipe, the outlet extrusion assembly leaves the conveying pipe, and the middle extrusion assemblies extrude the conveying pipe; then the middle extrusion assemblies and the inlet extrusion assembly leave the conveying pipe; and the process is repeated to enable the fluid in the conveying pipe to quickly flow downstream. According to the stop valve device and the fluid conveying device, due to the fact that the extruding assemblies extrude the conveying device vertically, friction to the conveying device does not exist, and therefore the abrasion to the conveying device can be reduced, and meanwhile, the good extrusion effect can be achieved.

Owner:ZHUHAI YOUTE SMART KITCHEN TECH CO LTD

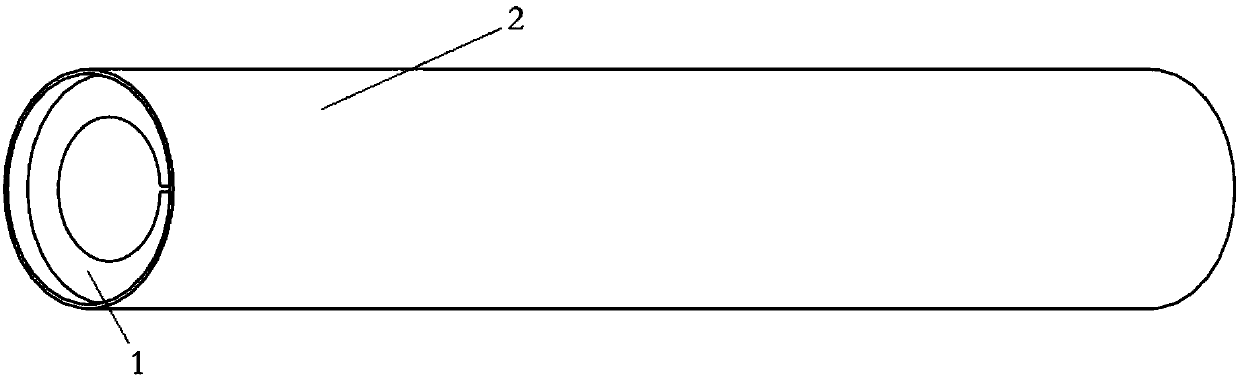

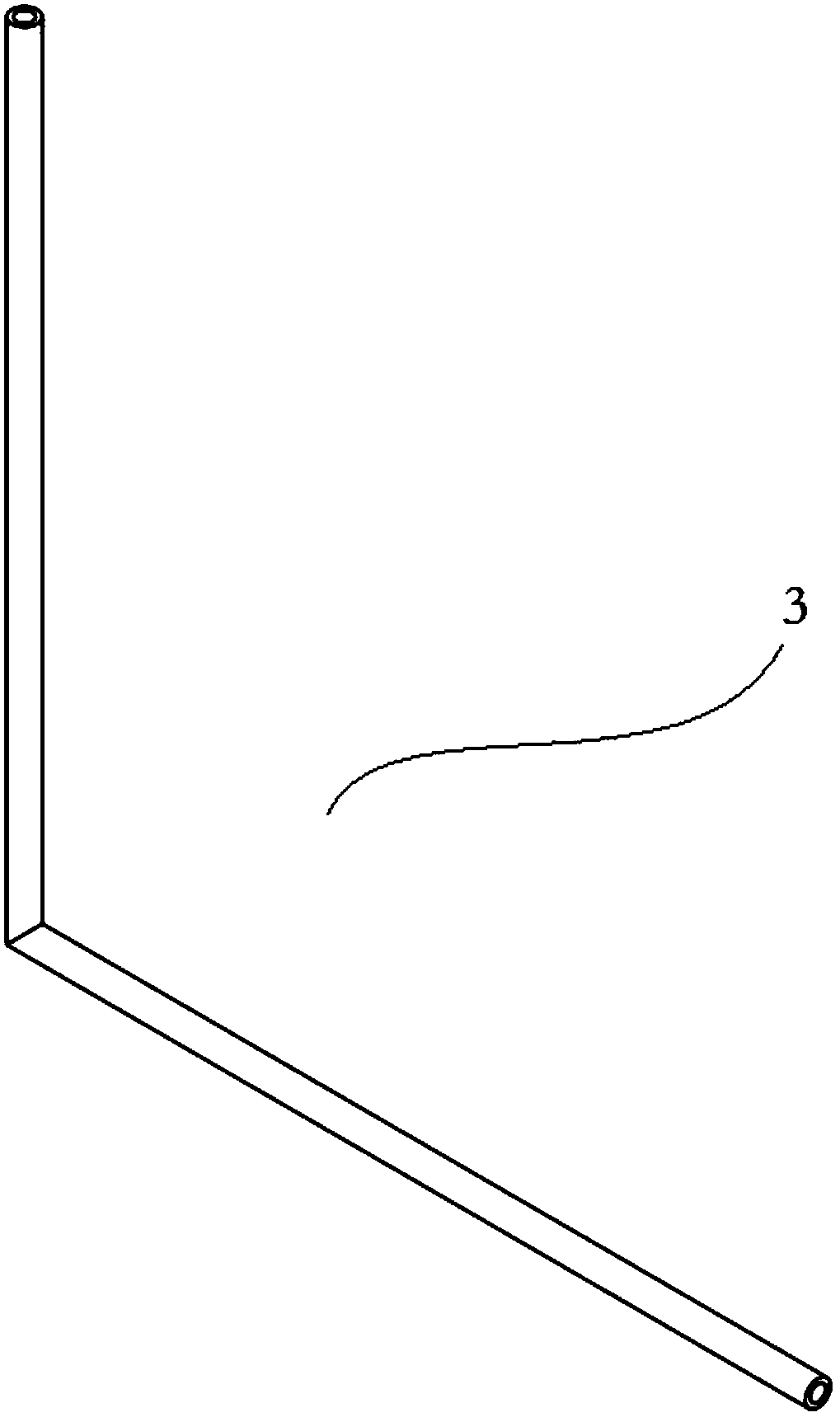

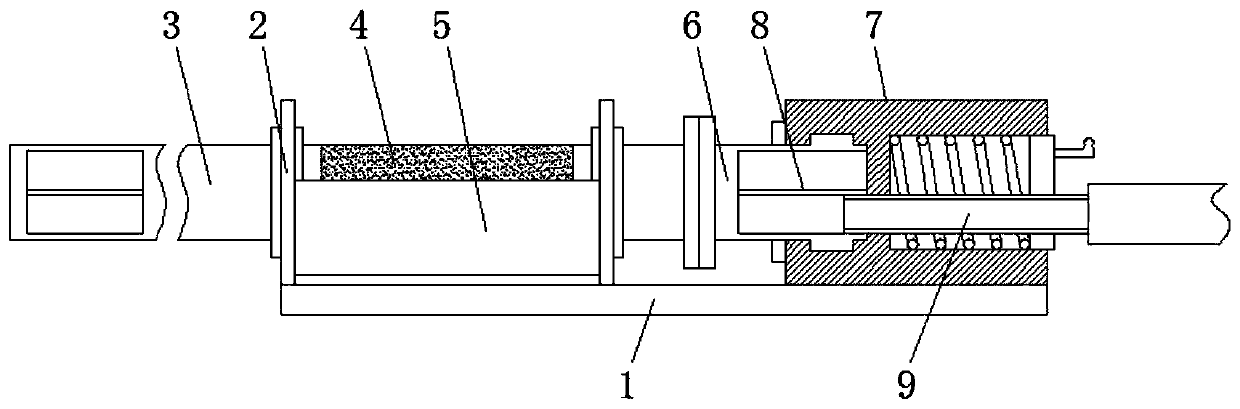

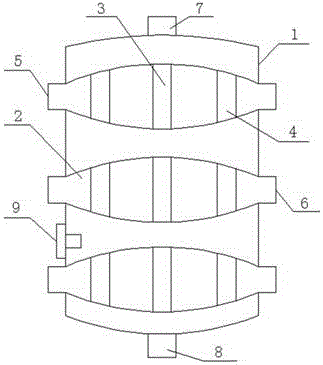

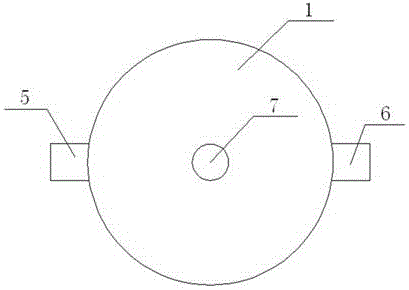

Stop valve device and fluid conveying device

ActiveCN107100813AImprove outflow efficiencyReduce wearPositive displacement pump componentsPumpsDrive shaftEngineering

The invention discloses a stop valve device and a fluid conveying device. The stop valve device comprises a driving shaft and a conveying pipe; eccentric components arranged along the extension direction of the driving shaft are arranged in the circumferential direction of the driving shaft in a staggered mode; an inlet extrusion assembly, one or more middle extrusion assemblies and an outlet extrusion assembly are arranged in sequence in the extension direction of the conveying pipe; the outlet extrusion assembly extrudes and intercepts fluid in the conveying pipe, and the inlet extrusion assembly and the middle extrusion assemblies leave the conveying pipe; the inlet extrusion assembly extrudes and intercepts the fluid in the conveying pipe, the outlet extrusion assembly leaves the conveying pipe, and the middle extrusion assemblies extrude the conveying pipe; then the middle extrusion assemblies and the inlet extrusion assembly leave the conveying pipe; and the process is repeated to enable the fluid in the conveying pipe to quickly flow downstream. According to the stop valve device and the fluid conveying device, due to the fact that the extruding assemblies extrude the conveying device vertically, friction to the conveying device does not exist, and therefore the abrasion to the conveying device can be reduced, and meanwhile, the good extrusion effect can be achieved.

Owner:珠海优特智厨科技有限公司

A smelting water filter slag tank

ActiveCN104390467BSpeed up the outflowImprove outflow efficiencyCharge manipulationSlagWater filter

The invention relates to a smelting water receiving and residue filtering tank. The smelting water receiving and residue filtering tank comprises a tank body, wherein the tank body is made of a refractory material and comprises a first branch tank and a second branch tank; a partition plate which can move in the vertical direction is arranged between the first branch tank and the second branch tank; a water inlet is formed in an inner side face of a side part of the first branch tank, and an opening of the water inlet faces upwards; a water receiving opening, corresponding to the water inlet, is formed in an outer side face of the side part of the first branch tank; the water receiving opening is communicated with the water inlet; a residue discharging opening is formed in one side part adjacent to the side part of the water receiving opening; at least one fan is arranged at the upper end of the other side part adjacent to the side part of the water receiving opening; a water drainage opening is formed in a side part of the second branch tank. Compared with the prior art, the smelting water receiving and residue filtering tank has the advantages that dross floats quickly, the residue removing efficiency is high and continuous operation can be realized.

Owner:XINGHUA GUANGFU METAL PROD

Grain threshing machine with shearing function

InactiveCN105359732AFast threshing speedGuaranteed threshing efficiencyThreshersSpiral bladeEngineering

The invention relates to a grain threshing machine with a shearing function, which comprises a threshing cylinder, a grain collecting device and a vibrator, wherein the threshing cylinder is placed over the grain collecting device; the vibrator is placed on the lower end of the grain collecting device; a grain shearing device is firmly disposed on the upper end of the threshing cylinder; two rollers are disposed inside the threshing cylinder; the two rollers are located in parallel under the grain shearing device; spiral blades used for threshing are disposed on the two rollers; the bottom part of the threshing cylinder is a screen; and a plurality of shearing knives are disposed inside the grain shearing device and can shear grains which are put into the grain shearing device. In comparison with the prior art, the machine has the advantages that the grains can be sheared; the grains are avoided from being wound on the machine and influencing threshing efficiency; the threshing becomes quick; and the threshing efficiency is guaranteed.

Owner:GUILIN UNIV OF AEROSPACE TECH

Honey extractor capable of preventing honeycomb honey chippings from flowing out and preventing honey from remaining

The invention relates to the related technical field of honey processing, and discloses a honey extractor capable of preventing honeycomb honey chippings from flowing out and preventing honey from remaining. The honey extractor comprises a honey extracting barrel; a honey cavity is formed in the honey extracting barrel; an adapter ring is fixedly installed in the honey cavity; a power rotating rod is rotatably installed in the adapter ring; a pushing and knocking honey extracting device is detachably mounted on the lower side of the power rotating rod; the pushing and knocking honey extracting device comprises a honey extracting plate; a honey extracting cavity is formed in the honey extracting plate; a functional groove is formed in the inner wall of the right side of the honey extracting cavity; and a pushing and squeezing plate is slidably mounted in the functional groove. According to the honey extractor capable of preventing the honeycomb honey chippings from flowing out and preventing the honey from remaining, through the arrangement of the pushing and knocking honey extracting device, the honey in the pushing and knocking honey extracting device containing honeycomb honey flows out into the honey cavity through a leakage net plate under the rotation of a centrifugal motor; and in the centrifugal honey extracting process, through the arrangement of an internal debris treatment device, debris in the honey is intercepted.

Owner:廖文朵

Clamping device for preventing display screen from falling off

The invention discloses a clamping device for preventing a display screen from falling off. The clamping device comprises a clamping mechanism for clamping a display back plate and the display screen, and a magnetic driving mechanism for driving the clamping mechanism to rotate, the magnetic driving mechanism comprises a first driving rod, an electromagnetic sheet, a heat conduction shell, hot melting metal, a partition plate, a limiting ring and memory metal, the heat conduction shell is fixedly connected to the display back plate, the hot melting metal is placed in the heat conduction shell, the partition plate is arranged on one side of the heat conduction shell in an attached and penetrating mode, and the lower end of the partition plate is fixedly connected with the memory metal. In the process that the first driving rod jacks up the clamping mechanism, the clamping mechanism continuously clamps the display back plate and the display screen, separation of the display back plate and the display screen caused by glue solution melting is prevented, and therefore, external gas or dust can be prevented from entering the inside of the display screen from the gaps to damage electrical components.

Owner:深圳市一米云安保运营有限公司

High-voltage straight-flow stop valve

PendingCN114658864AThe effect of effective maintenanceExtended use timeLubricant transferLift valveEngineeringSlide plate

The invention discloses a high-pressure straight-flow type stop valve, and belongs to the field of stop valves. According to the high-pressure straight-flow type stop valve, when the interior of a valve seat needs to be opened and closed, the interior of the valve seat can be opened and closed by rotating a valve rod to ascend or descend, and after the valve rod is rotated, a T-shaped sliding plate can be pressed to extrude a lubricating mechanism; the liquid storage bag makes contact with the fixing frame and deforms through pushing of the T-shaped sliding plate, then lubricating liquid in the liquid storage bag is guided out through the guiding-out opening and flows into the valve rod through the connecting opening to lubricate the valve rod, the lubricating mechanism is supplemented through the lubricating filling mechanism after being consumed, and therefore flowing water guiding is formed. The whole service time is prolonged, the rotating part of the valve rod is comprehensively lubricated when the valve rod rotates, and therefore the effect of effectively maintaining the valve rod is achieved, and meanwhile the valve rod is not prone to being eroded, so that large resistance is generated in rotation.

Owner:CARMEL VALVE CO LTD

Anti-surging smelting filter residue tank

InactiveCN107755680APrevent gushingImprove outflow efficiencyCasting cleaning apparatusRefractoryEngineering

The invention relates to an anti-surge smelting filter slag tank, which comprises a tank body made of refractory material, the tank body includes a first sub-channel and a second sub-channel, and a A partition plate that can move in the vertical direction. A water inlet is provided on the inner side of the side of the first sub-groove. The water port is connected, and a slag discharge port is provided on the side adjacent to the side where the water receiving port is located, and at least one fan is provided at the upper end of the adjacent side of the side where the water receiving port is located, and the side of the second sub-groove A drain port is provided; a spring row is arranged inside the first sub-trough, and the spring row corresponds to the liquid level in the first sub-trough; the spring row is composed of a plurality of springs connected in parallel at intervals. Compared with the prior art, the invention has fast scum floating up, high slag removal efficiency, and can realize continuous operation.

Owner:路望培

A kind of processing method of Chinese medicinal decoction pieces

ActiveCN112957386BGood diuretic effectReduce the burden onDigestive systemUnknown materialsTraditional medicineWheat Brans

Owner:湖北孟氏中药饮片有限公司

Grain threshing machine

The invention relates to a grain threshing machine comprising a threshing barrel, a grain collector and a vibrator; the threshing barrel is arranged above the grain collector; the vibrator is arranged on the bottom of the grain collector; the top of the threshing barrel is fixedly provided with a grain placing port; two rollers are arranged in the threshing barrel, and arranged in parallel below the grain placing port, and respectively provided with a spiral impeller used for threshing; two sides of the upper portion of the threshing barrel are respectively provided with a cleaner used for sucking impurities; the bottom of the threshing barrel is a sieve screen. Compared with the prior art, the grain threshing machine is fast in threshing speed, the grains can be cleanly threshed, and impurities can be timely removed.

Owner:GUILIN UNIV OF AEROSPACE TECH

A down filling tube assembly for a down filling machine used in the production of down products

ActiveCN110775935BLow costWon't blockUpholstery manufactureDispersed particle filtrationMechanical engineeringIndustrial engineering

The invention relates to the field of production and processing equipment for down products, and discloses a down filling tube assembly for a down filling machine used in the production of down products, including a tube base, and two limiting plates are fixedly connected to one side of the top of the tube base A rotatable velvet-filling tube is provided in the movable sleeve, and a full circle of filter screen located between the two limiting plates is arranged on the velvet-filling tube. The down filling tube assembly for the down filling machine used in the production of down products, through the setting of the limit plate, the down filling tube, the filter screen, the sealing sleeve, the linkage tube, the control seat and the sealing plate, in the down filling stage, the down Injected from the lower space of the down-filling tube, the air in the down product is discharged from the filter screen on one side of the upper half of the down-filling tube, and the filter screen filters out the down mixed in the air, and the air flows out of the inner cavity of the down-filling tube Under the action of the action, it is blown to the rightmost part of the upper half of the inner cavity of the linkage tube to ensure that the down will not block the filter screen, thereby improving the outflow efficiency of air and relatively improving the down filling efficiency.

Owner:济宁晨阳制衣股份有限公司

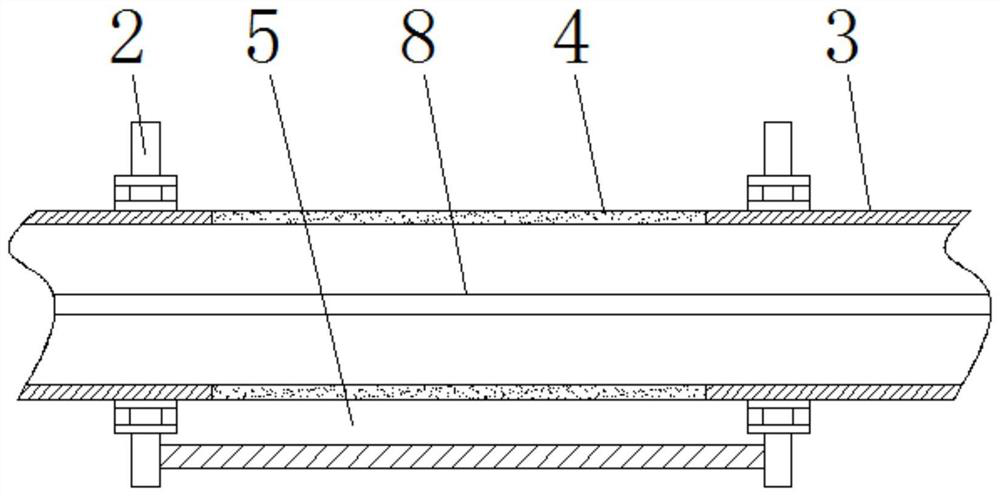

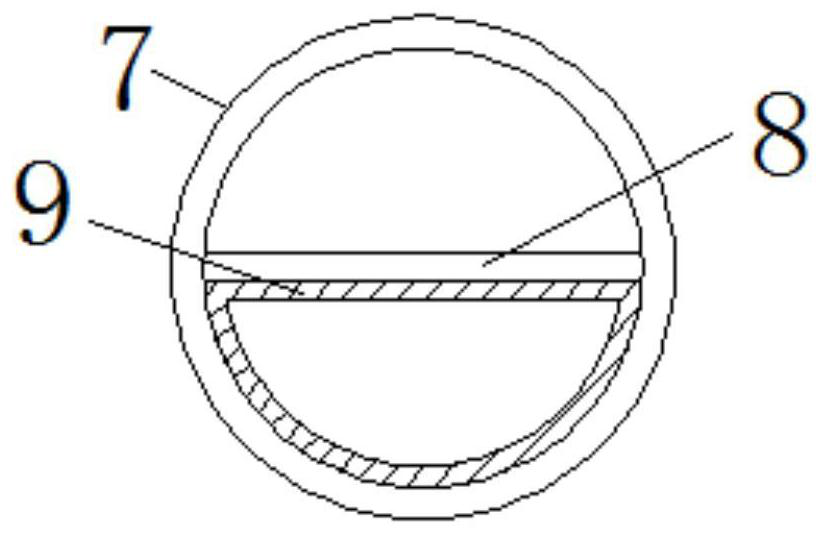

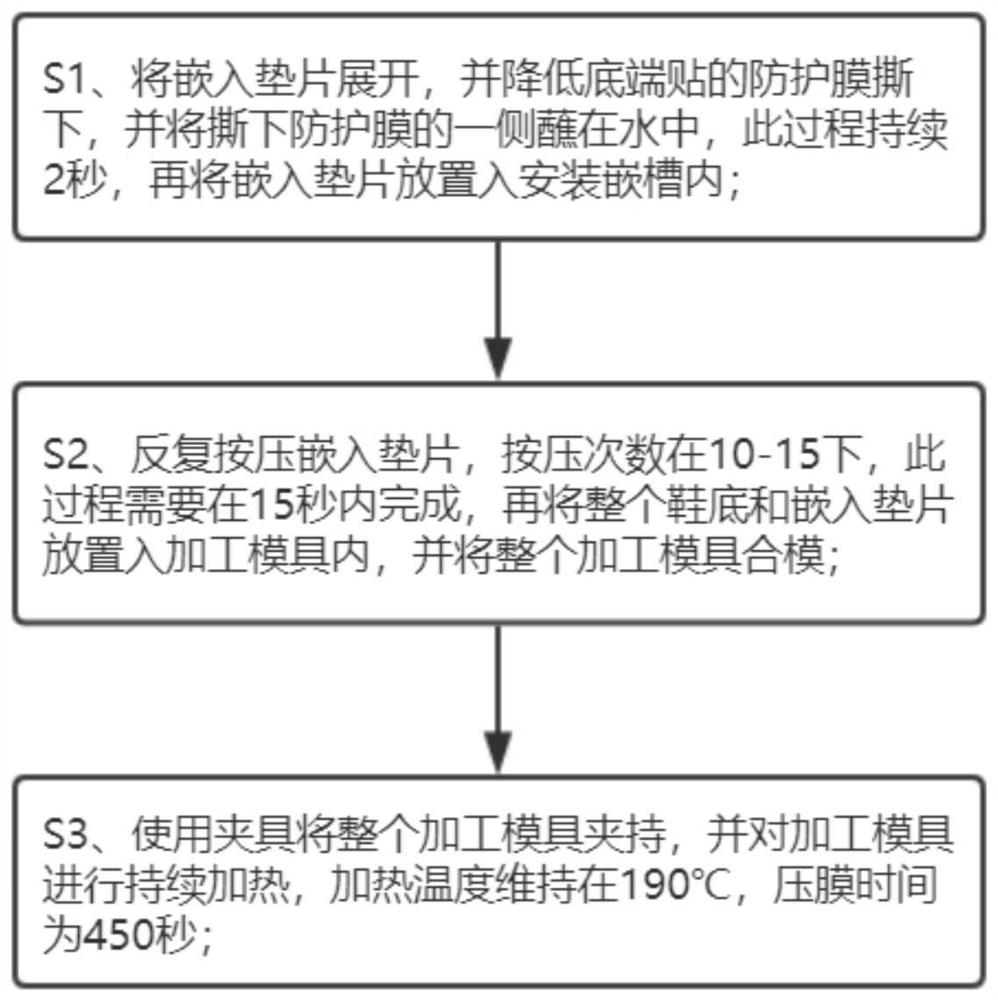

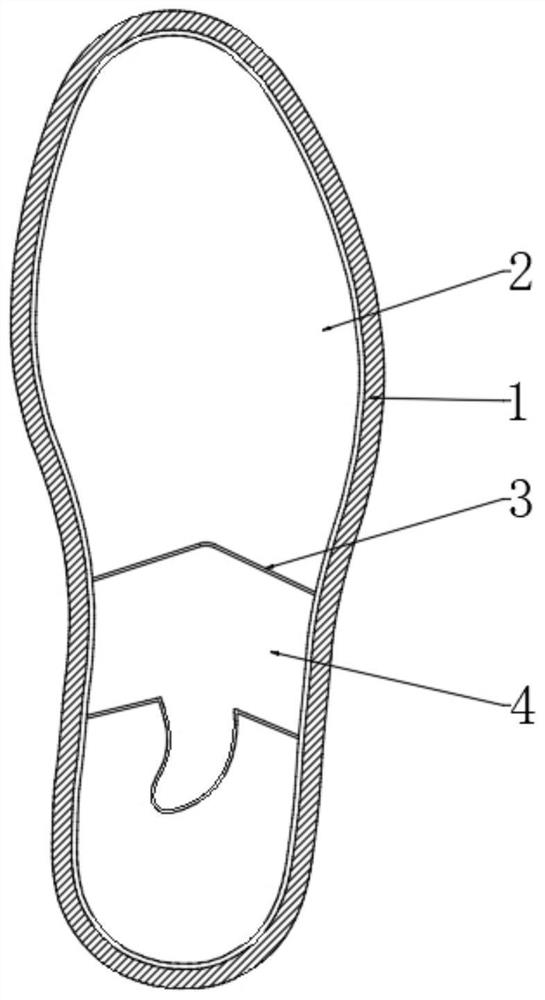

Sole in-mold pressing process

The invention discloses a shoe sole in-mold pressing process and belongs to the technical field of shoe sole processing. The shoe sole in-mold pressing process can realize the contact between a pre-dissolving plug and water to promote the pre-dissolving plug to be gradually dissolved, so a hot melt adhesive solution in an outer protective cladding is released from an exchange hole, and the hot melt adhesive solution in the outer protective cladding is released from the exchange hole and is filled between a mounting groove and an outer protective cladding a large amount of heat can be generated by means of contact and reaction of the reducing iron powder and part of air, on one hand, flowing efficiency of the hot melt adhesive liquid can be improved by means of the heat so that the hot melt adhesive liquid can be released more uniformly, and on the other hand, with the help of ferric oxide produced in the reaction process, under the mutual attraction effect, the whole connecting guide rope and the reducing iron powder are curled up into a ball, outflow efficiency of the hot melt adhesive liquid is further improved, and meanwhile the connecting strength between the embedded gasket and the shoe sole is improved.

Owner:温州东浩塑胶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com