Method for applying horizontal directional drilling to refuse landfill leachate drainage

A technology of landfill and horizontal directional drilling, which is used in protection devices, buildings, infrastructure projects, etc., can solve the problem of the large amount of horizontal seepage and drainage shaft projects and the large amount of horizontal seepage blind trench excavation projects. , destroying the stability of the heap and the surrounding environment, etc., to achieve the effect of being conducive to drainage consolidation, good splicing strength, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

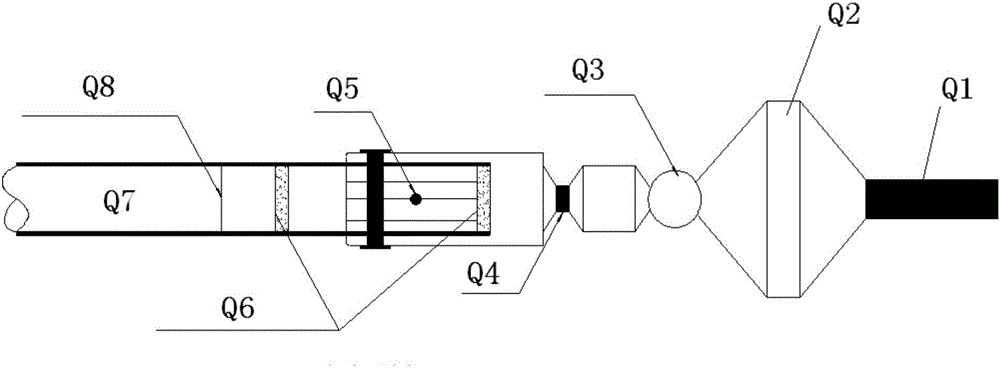

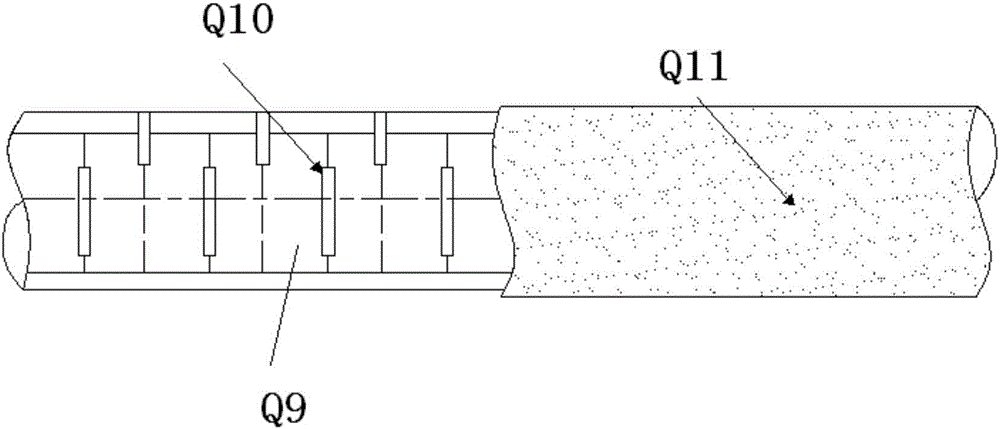

[0020] The horizontal directional drilling rig mechanism utilized in the method for the horizontal directional drilling of the present invention to be applied to the leachate drainage in the landfill (hereinafter referred to as "the method") can be found in figure 2 As shown, the horizontal directional drilling machine has a drill pipe Q1, the drill pipe Q1 is connected to the reamer Q2, the reamer Q2 is equipped with a rotary joint Q3, and the rotary joint Q3 is connected to the drawing head through the soft joint Q4, and the drawing head installation guide Seepage pipe Q7, the pipe head is installed with flexible waterproof material plugging Q6 through the set screw Q5, the figure shows the connection position Q8 between the seepage pipe Q7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com