High-voltage straight-flow stop valve

A technology of high-voltage direct current and stop valves, which is applied in the direction of lifting valves, valve devices, lubricating parts, etc., can solve the problems of corrosion of rotating parts, high resistance of rotation, and affecting the efficiency of closing or opening, etc., to achieve the purpose of prolonging the use time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

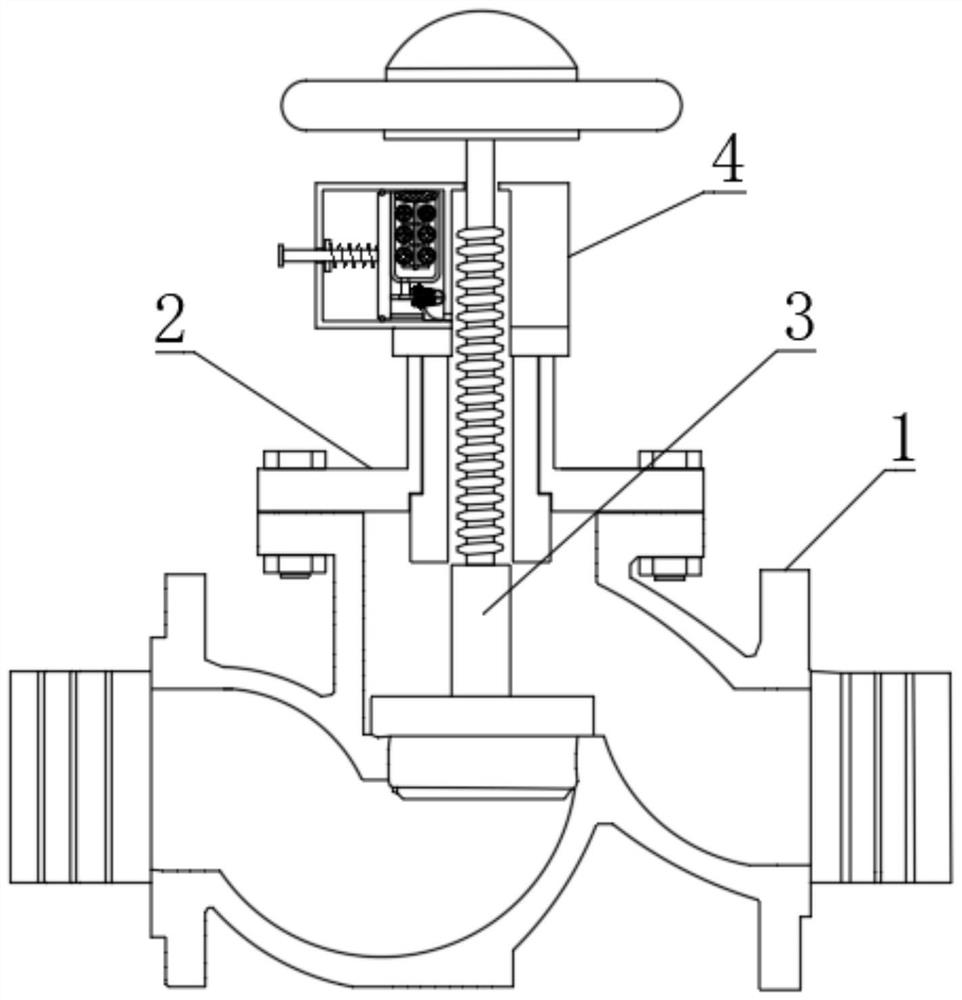

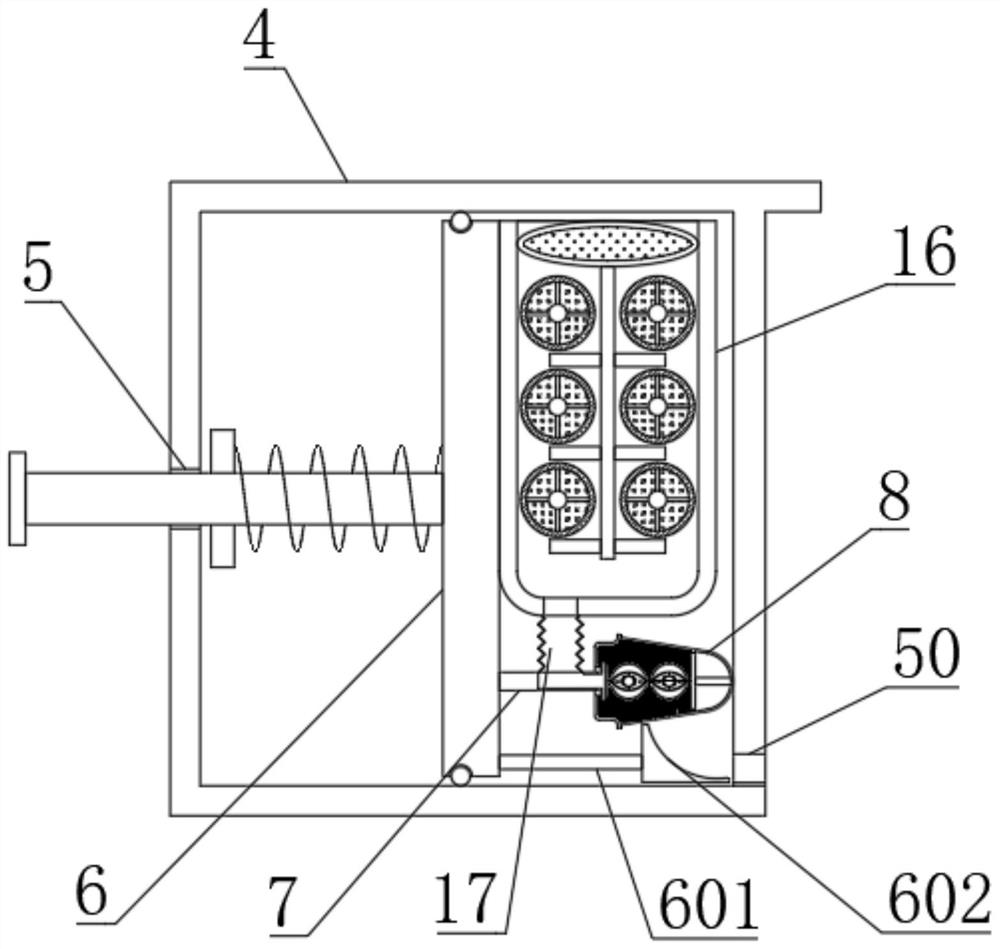

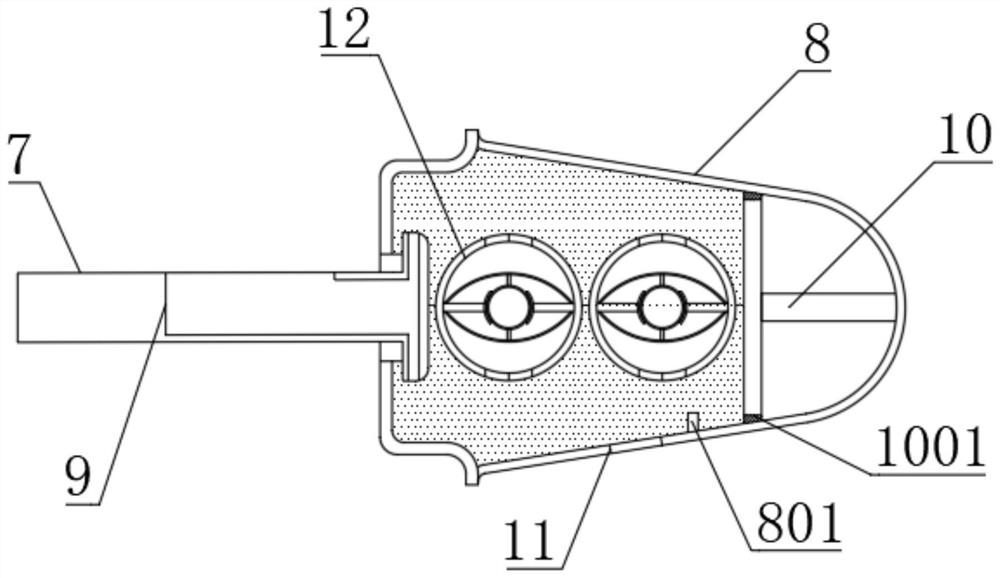

[0040] see Figure 1-6 , a high-voltage DC globe valve, comprising a valve seat 1, a valve body 2 is fixedly connected to the upper end of the valve seat 1, a valve stem 3 is rotatably connected to the upper end of the valve body 2, and the valve stem 3 extends into the valve seat 1 through the valve body 2, The upper end of the valve body 2 is fixedly connected with a fixed frame 4, the fixed frame 4 is sleeved on the outer end of the valve stem 3, the left end of the fixed frame 4 is drilled with a sliding hole 5, and the fixed frame 4 is slidably connected with a T-shaped sliding plate 6, and the T-shaped sliding plate 6 The through sliding hole 5 extends to the outside of the fixed frame 4, the right end of the T-shaped sliding plate 6 is provided with a lubricating mechanism, the right end of the T-shaped sliding plate 6 is provided with a lubricating filling mechanism, the right end of the fixing frame 4 is drilled with a connection port 50, and the connection port 50 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com