Sole in-mold pressing process

A shoe sole mold and internal pressure technology, applied in shoe soles, footwear, applications, etc., can solve problems such as long time, poor work efficiency, irregular bonding products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

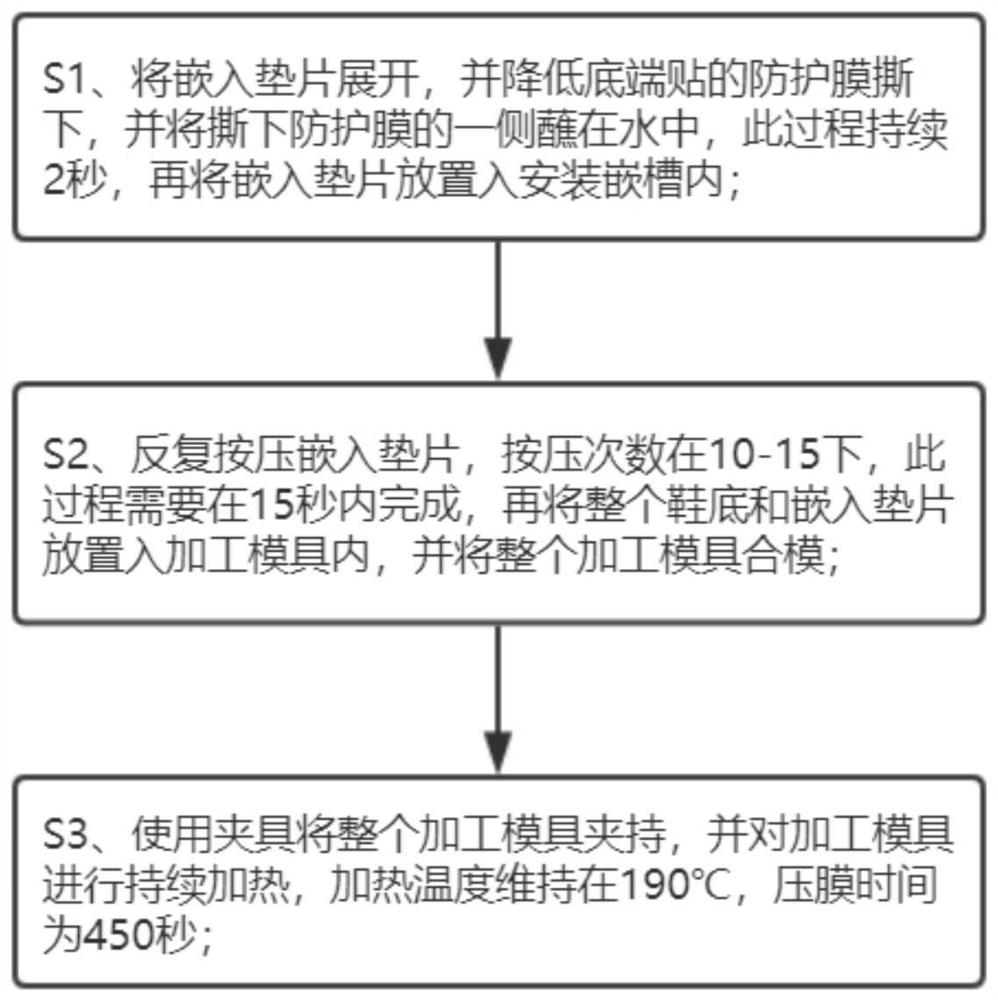

[0043] see figure 1 , a sole in-mold pressing process, comprising the following steps:

[0044] S1. Unfold the embedded gasket 4, and tear off the protective film attached at the lower end, and dip the side of the torn protective film in water. This process lasts for 2 seconds, and then place the embedded gasket 4 into the installation groove within 3;

[0045] S2. Repeatedly press the embedded gasket 4, the number of times of pressing is 10-15 times, this process needs to be completed within 15 seconds, and then the entire shoe sole 2 and the embedded gasket 4 are placed in the processing mold 1, and the entire processing mold 1 is combined mold;

[0046] S3. Clamp the entire processing mold 1 with a clamp, and continuously heat the processing mold 1. The heating temperature is maintained at 190° C., and the film pressing time is 450 seconds.

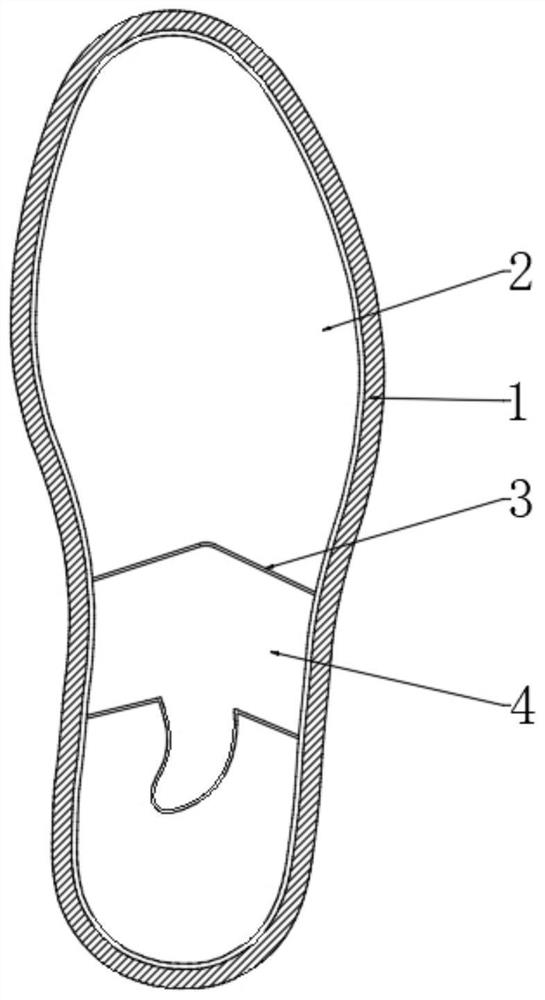

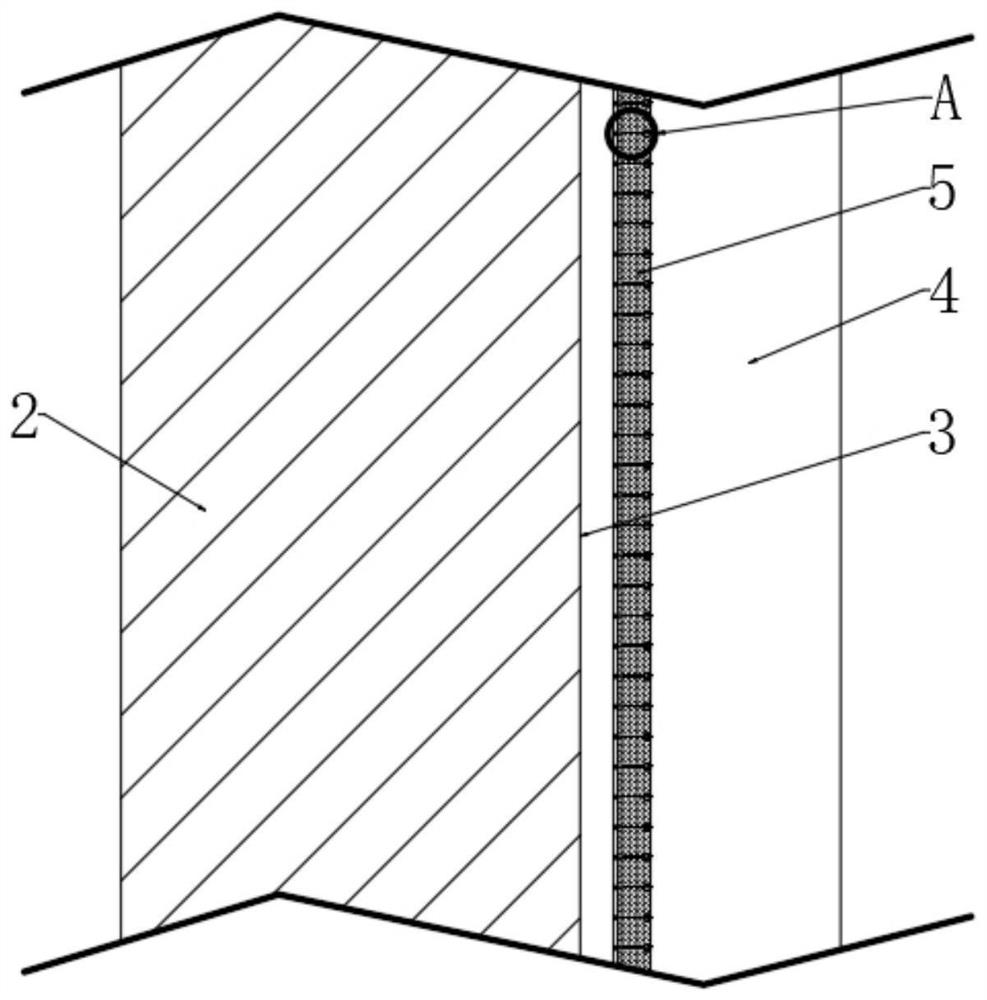

[0047] see Figure 2-5 , the sole 2 is embedded in the processing mold 1, the upper end of the sole 2 is dug with a mounting slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com