Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Improve jacking efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

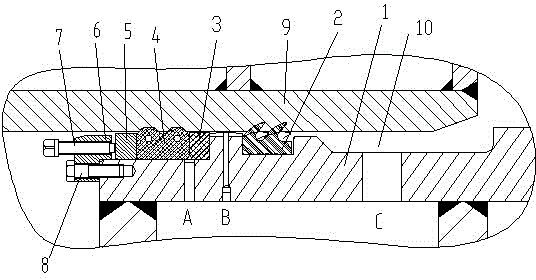

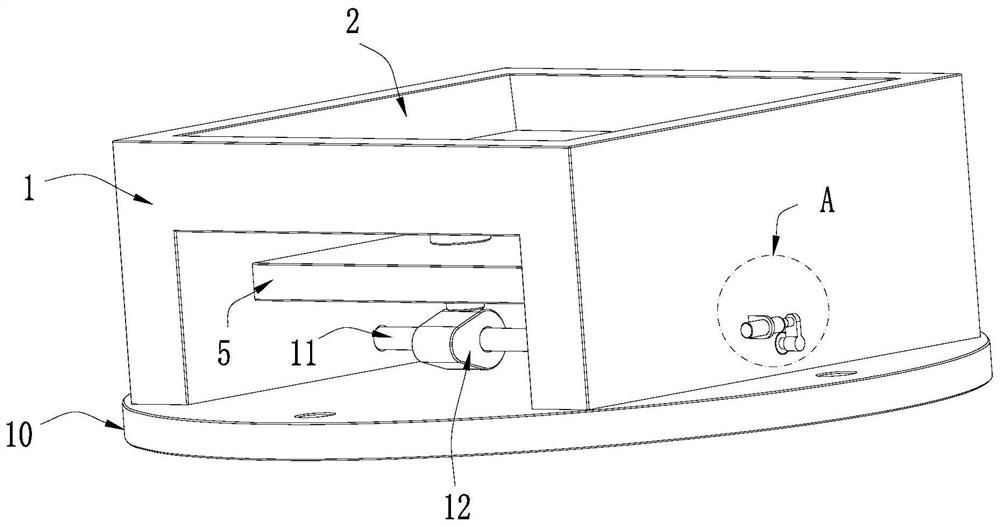

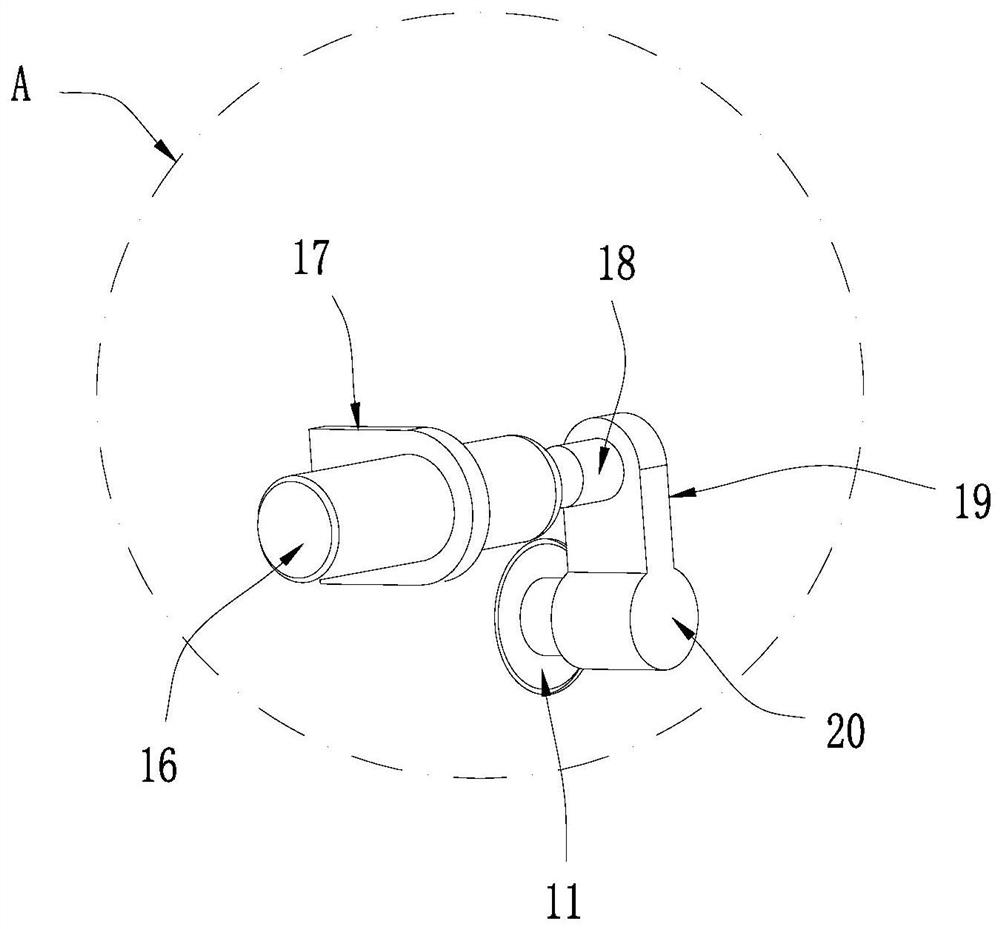

Adjustable hinging sealing device of rectangular shielding tube push bench

InactiveCN104089023AExtended service lifeDone successfullyEngine sealsMechanical engineeringEngineering

The invention discloses an adjustable hinging sealing device of a rectangular shielding tube push bench. The adjustable hinging sealing device comprises a hinging sealing ring, wherein the hinging sealing ring is sequentially provided with a lip-shaped seal, a nylon baffle strip, a steamed bun shaped seal, a pressing ring and an adjusting device from front to back; the hinging sealing ring is arranged on a tail shield; the lip-shaped seal is positioned inside the lip hole in the front of the hinging sealing ring; the steamed bun shaped seal is positioned at the rear part of the hinging sealing ring; the nylon baffle strip and the pressing ring are respectively arranged on two sides of the steamed bun shaped seal; the adjusting device is fixed at the tail part of the hinging sealing ring. The adjustable hinging sealing device disclosed by the invention is more reliable in sealing performance when compared with two sets of static seals used in a conventional tube push bench, the service life of the hinging sealing is prolonged, and thus successful accomplishment of each push distance is facilitated, the overhaul times are reduced, the maintenance cost is lowered, and the push efficiency is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Multilevel speed regulation jack

InactiveUS7040091B2Improve jacking efficiencyImprove efficiencyFluid couplingsTelemotorsEngineeringCylinder block

Owner:FAN QUN

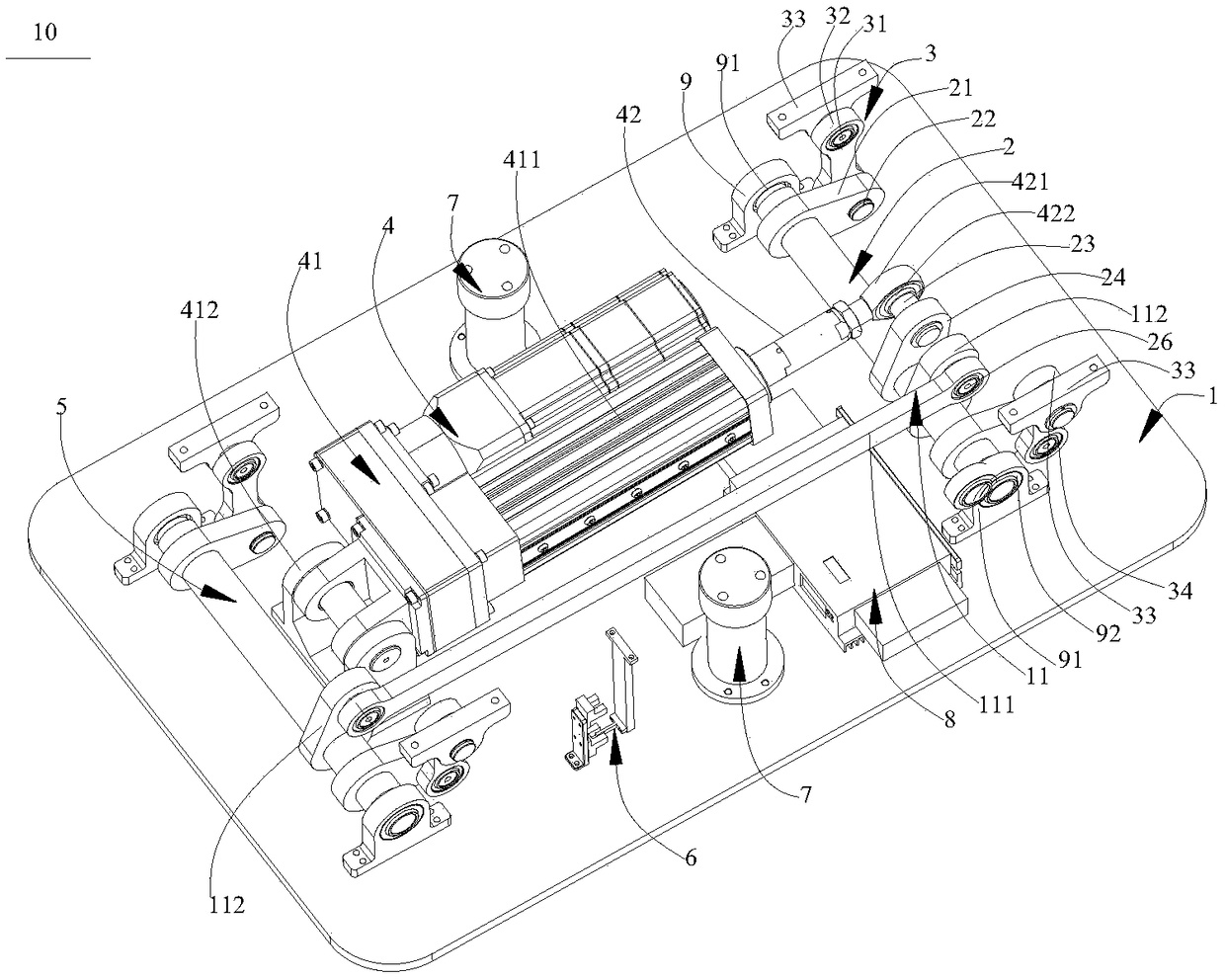

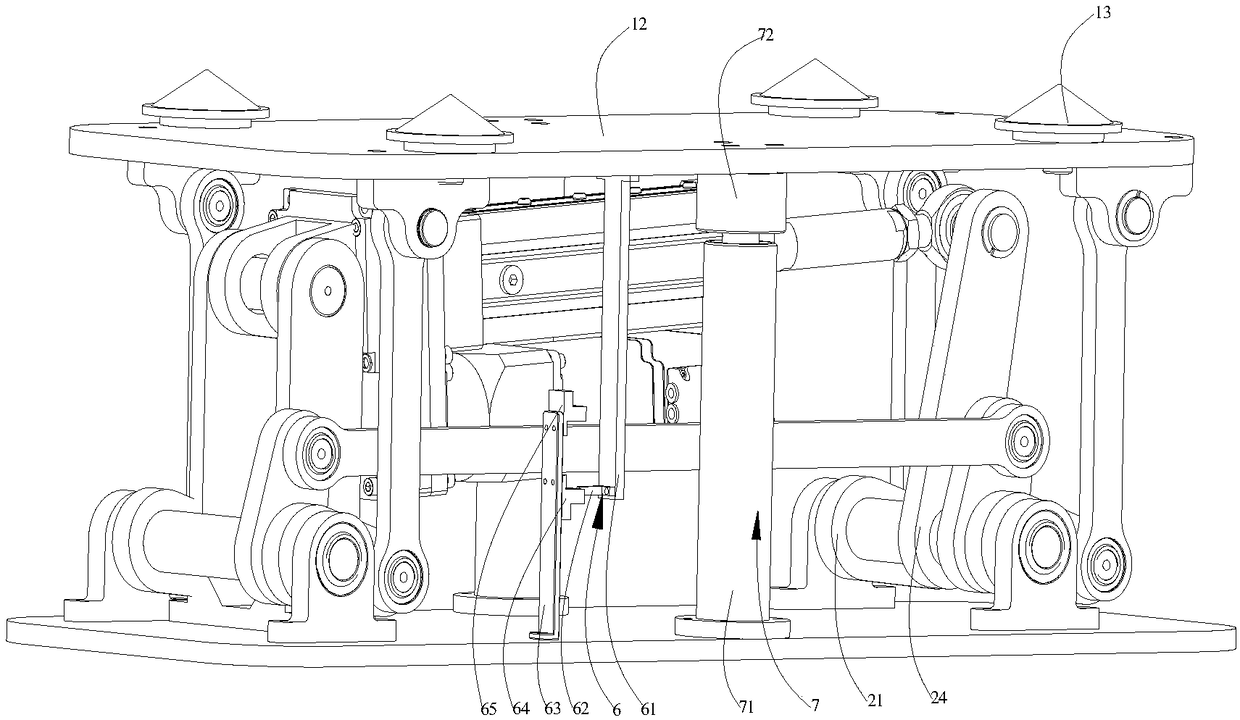

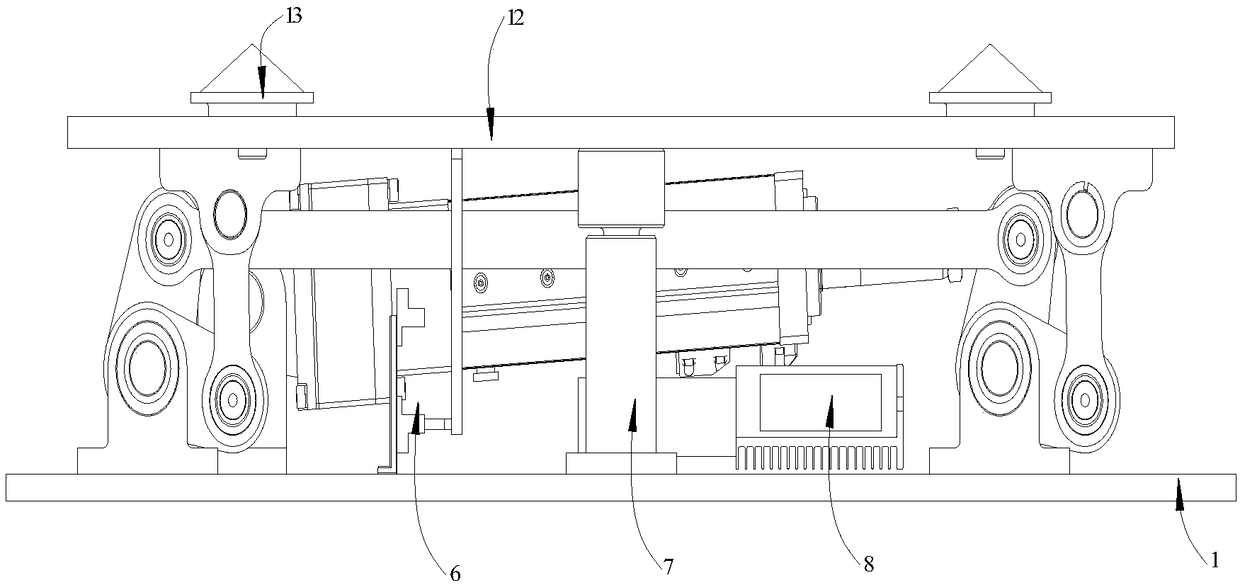

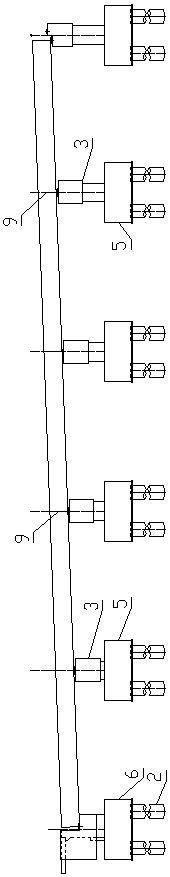

Automatic guiding transportation vehicle and jacking device thereof

Owner:KUKA ROBOTICS GUANGDONG CO LTD

Uneven jacking system and uneven jacking construction method for existing bridge superstructure

PendingCN111236089ATake advantage ofReduce wasteBridge erection/assemblySynchronous controlControl system

The invention discloses an existing bridge superstructure uneven jacking system which comprises a hydraulic synchronous control system, each bearing platform is provided with an enlarged foundation inthe circumferential direction, and the enlarged foundation of each bridge pier is upwards connected with a plurality of pairs of heightening jack mechanisms and heightening temporary bridge pier mechanisms. The invention further discloses a corresponding construction method. The method comprises the steps that 1, the enlarged foundation is built; 2, the variable-height jack mechanisms and the variable-height temporary pier mechanisms are installed on the bearing platform and / or the expanded foundation in pairs; 3, pier cutting and jacking are conducted; 4, piers are connected; 5, a connectingpier and a bent cap are newly built; 6, beam falling is carried out. In updating of existing infrastructure of a city, the existing bridge structure can be fully utilized, waste is reduced, the construction efficiency is improved, jacking equipment is convenient to install, jacks participating in jacking cannot be damaged, and the jacking amplitude of jacking mechanisms at piers can be accuratelycontrolled.

Owner:ZHENGZHOU MUNICIPAL ENG CORP

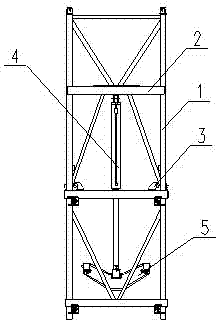

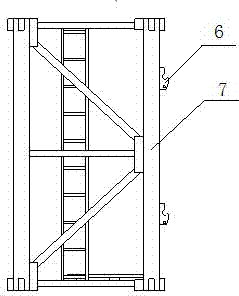

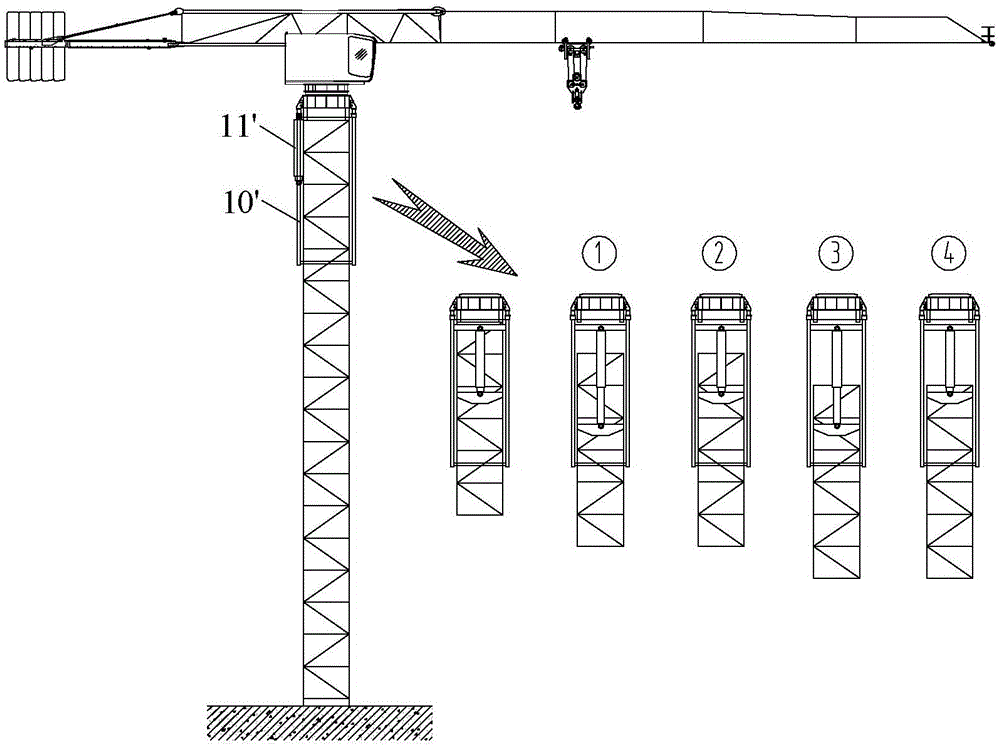

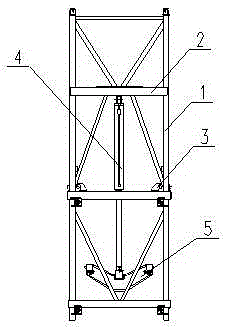

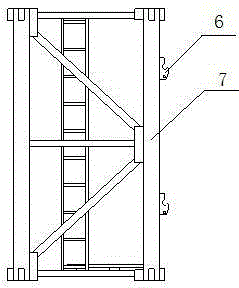

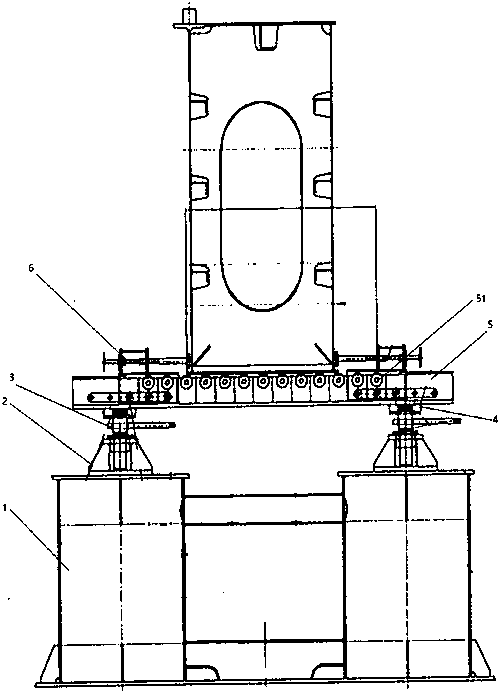

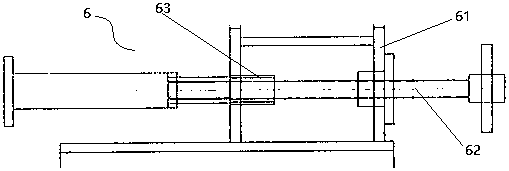

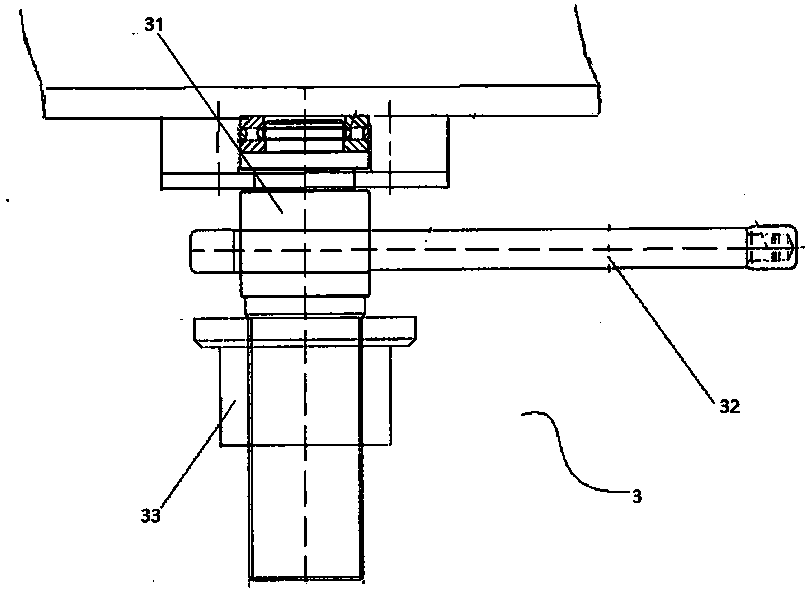

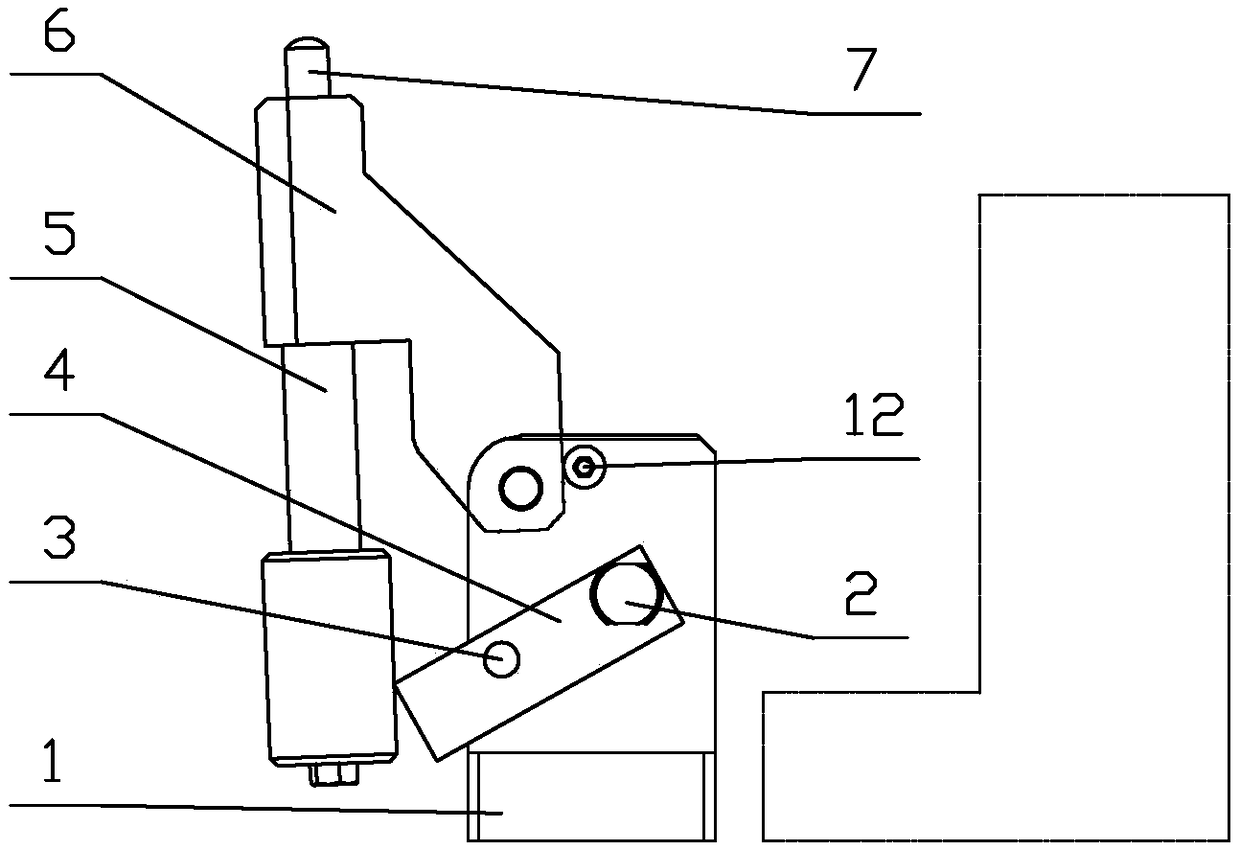

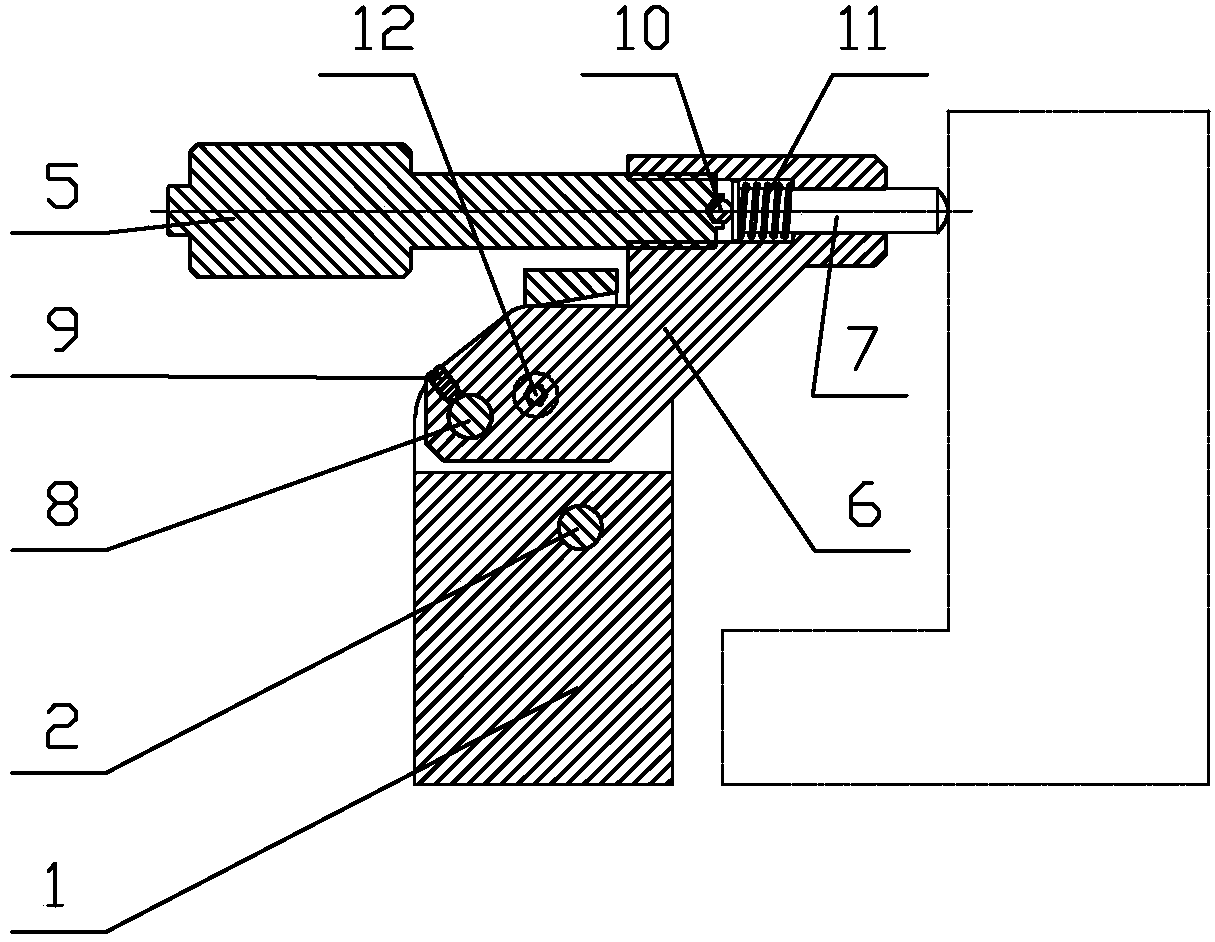

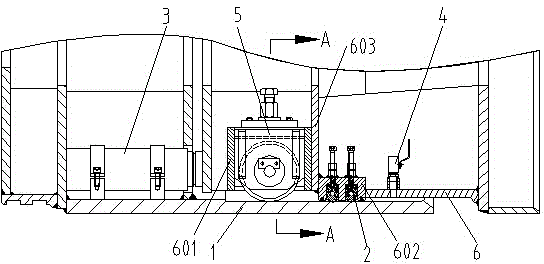

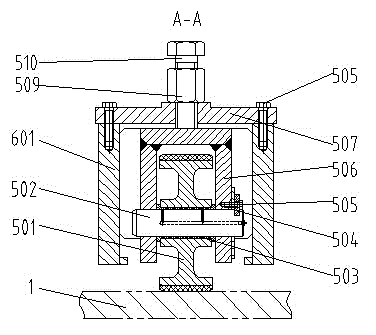

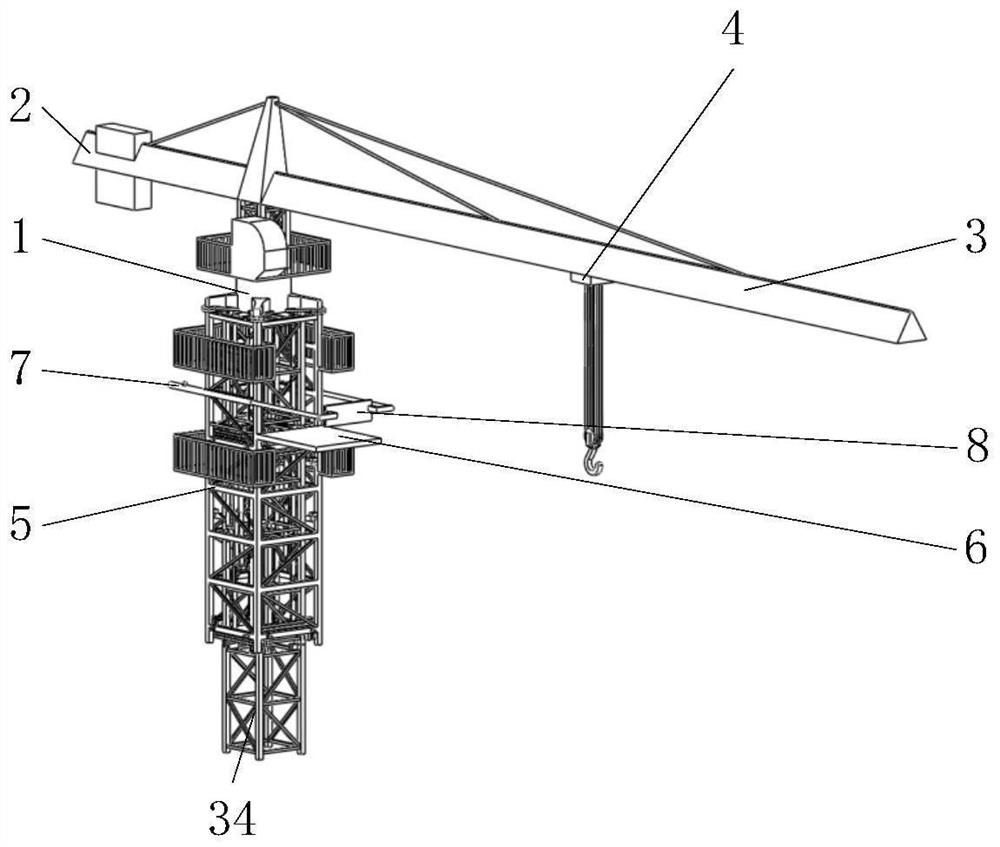

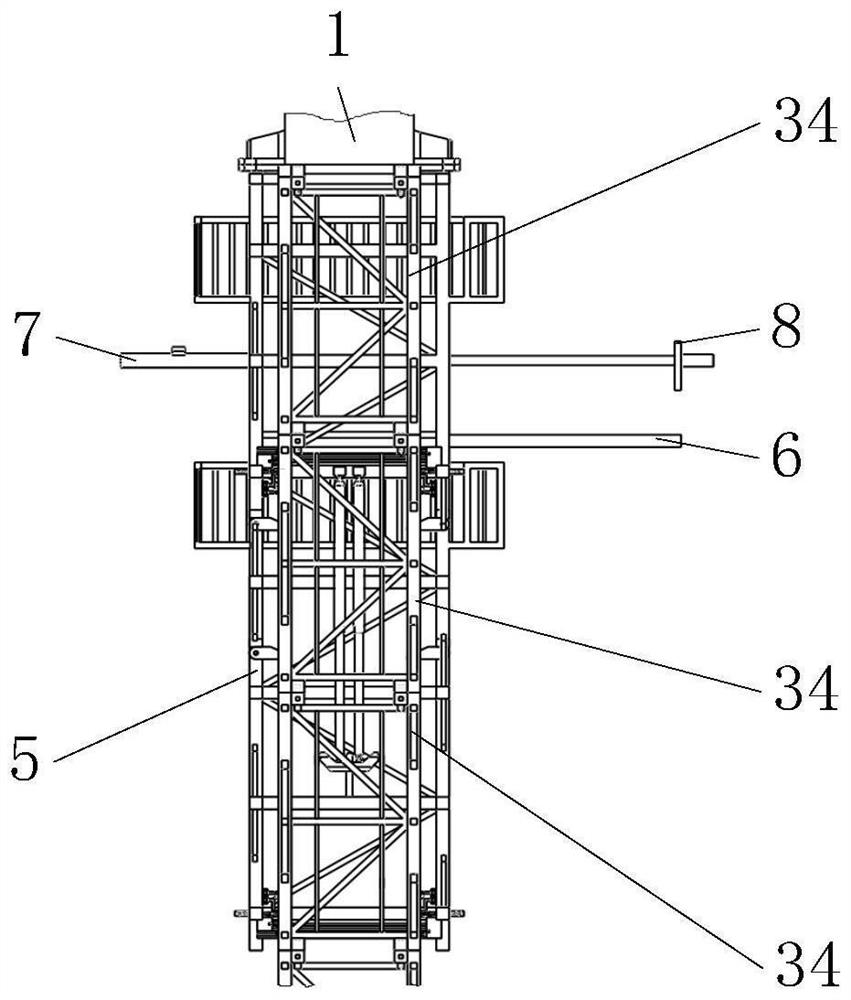

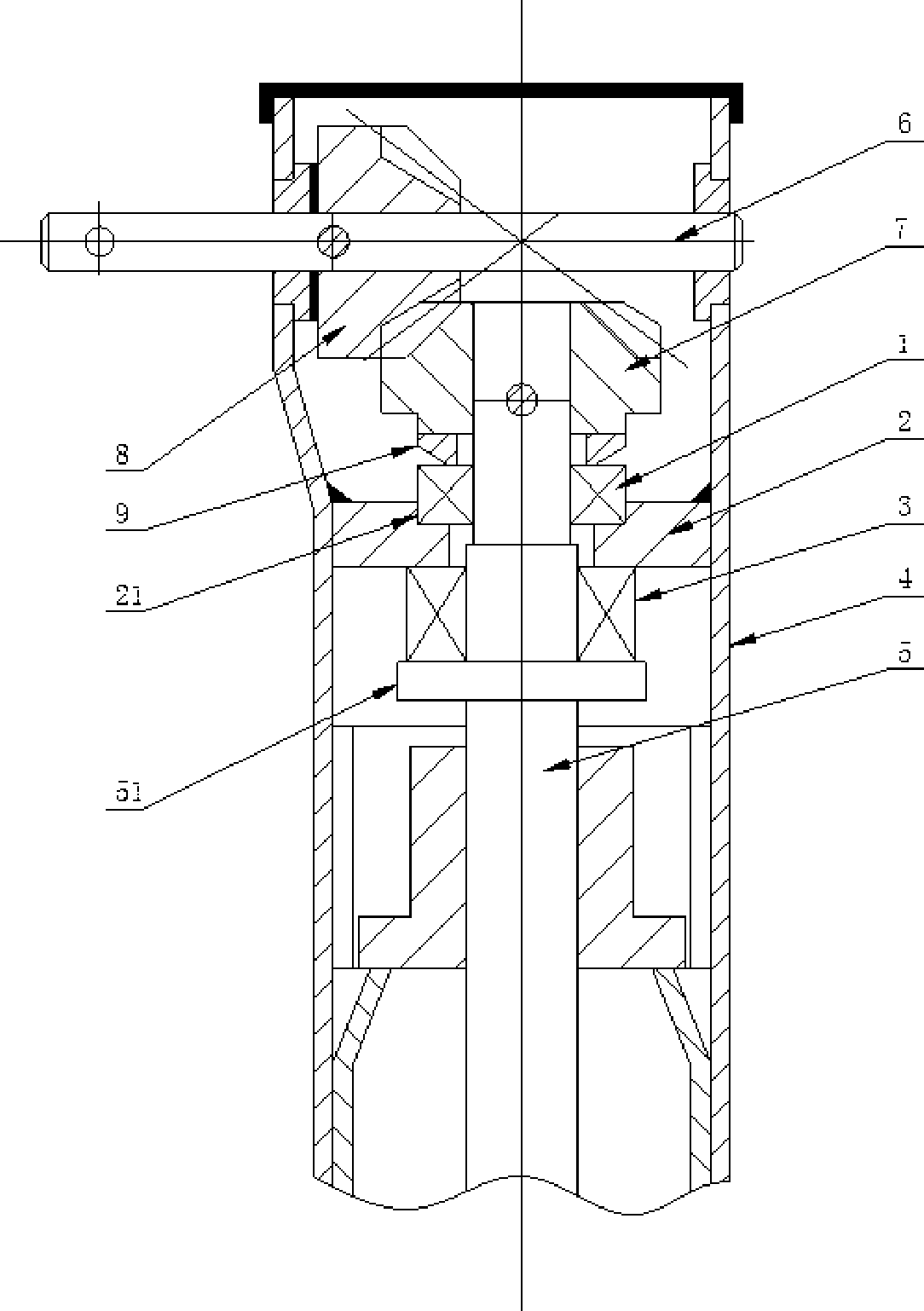

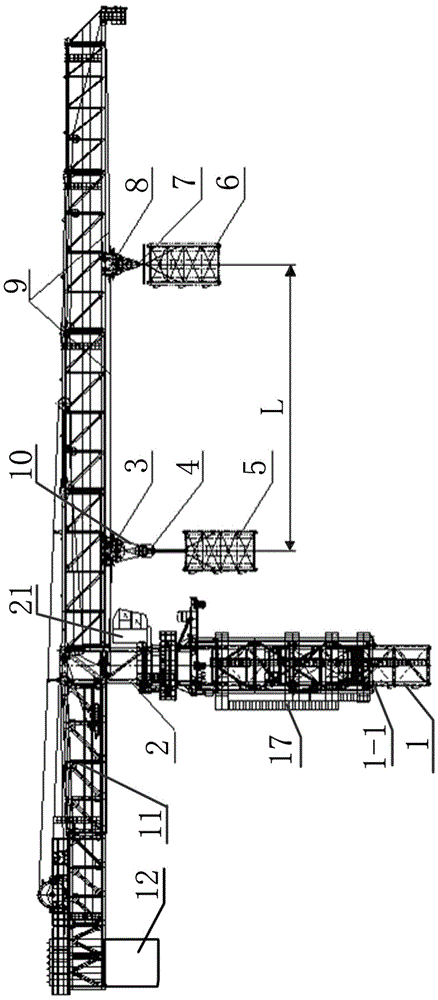

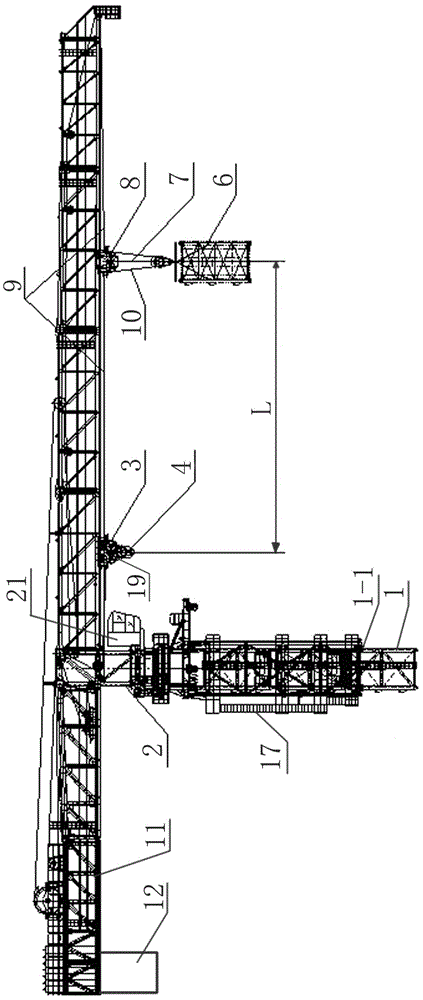

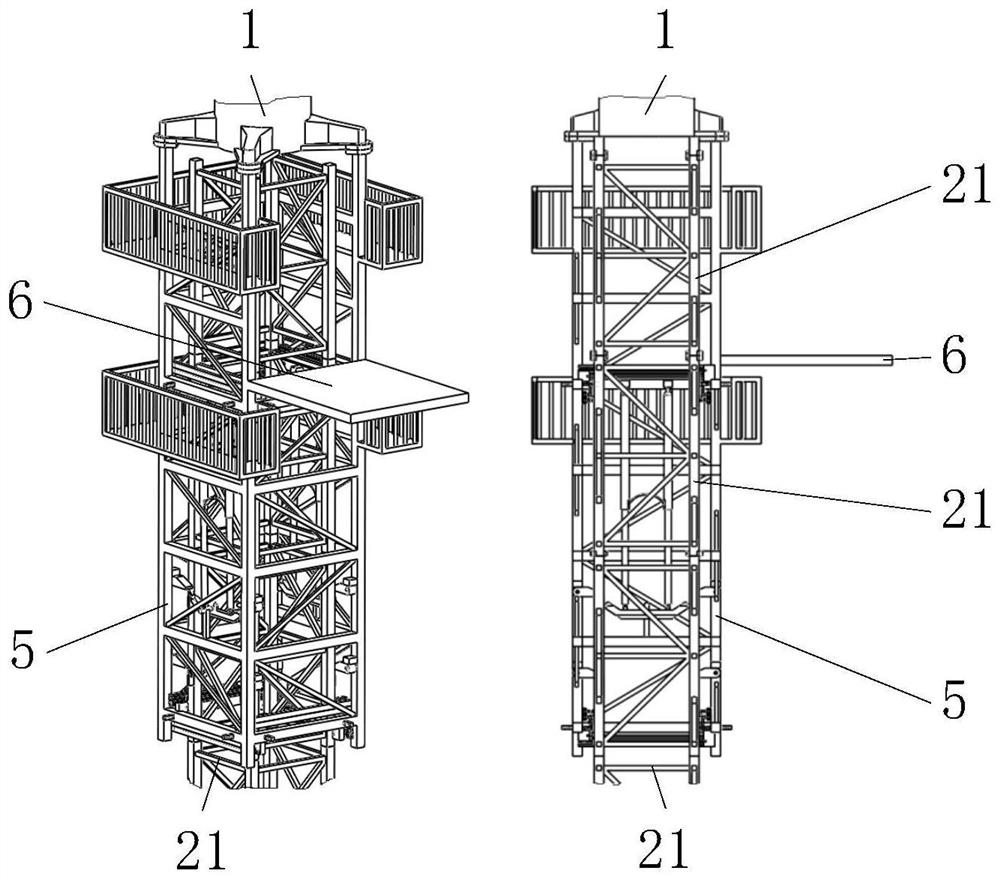

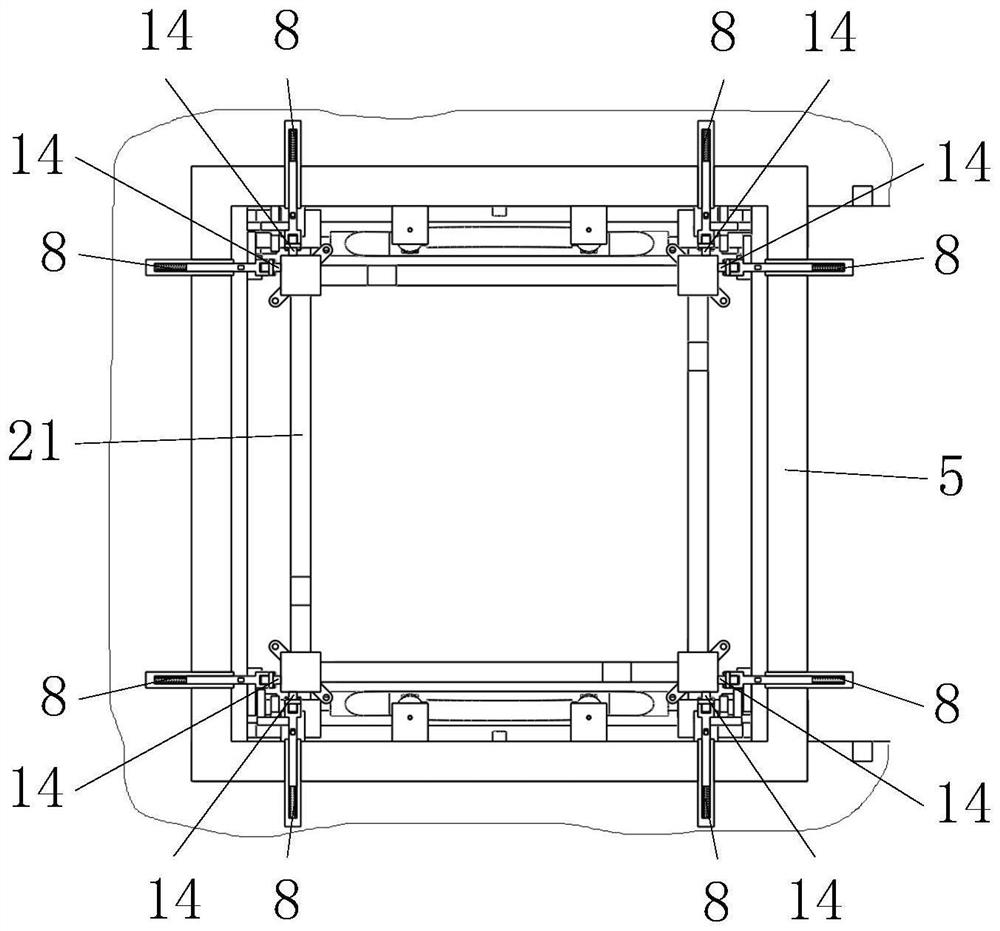

Anti-fall control device for tower crane lifting

ActiveCN103787211AImprove jacking efficiencySmall operating forceCranesTower cranePetroleum engineering

The invention discloses an anti-fall control device for tower crane lifting, belonging to the technical field of tower cranes. The anti-fall control device comprises a climbing frame (1) and steps (6), wherein the climbing frame comprises an oil cylinder beam, a lifting oil cylinder and a lifting beam, and climbing claws (3) are arranged on the oil cylinder beam; the steps are arranged on the outer side of a standard joint, the climbing pawls are suspension pawls which are articulated onto lug plates (2-1) welded on the oil cylinder beam through a pawl shaft (3-1), and the distance between the center of the pawl shaft and a main chord member of the standard joint is smaller than the length of each suspension pawl; fixing holes (6-1) for supporting lifting beam supporting shafts (5-2) are formed in the middles of the steps, and positioning grooves (6-2) are formed in the upper end and the lower end; telescopic mechanisms are arranged at two ends of the lifting beam. Manual operation is not required when the climbing frame passes through the standard joint steps, the lifting beam penetrates into the central hole of the standard joint step through a telescopic supporting shaft, the telescopic supporting shaft is positioned by using a safety pin so that telescopic misoperation of the oil cylinder is prevented, and the safety and reliability are high.

Owner:XUZHOU CONSTR MACHINERY

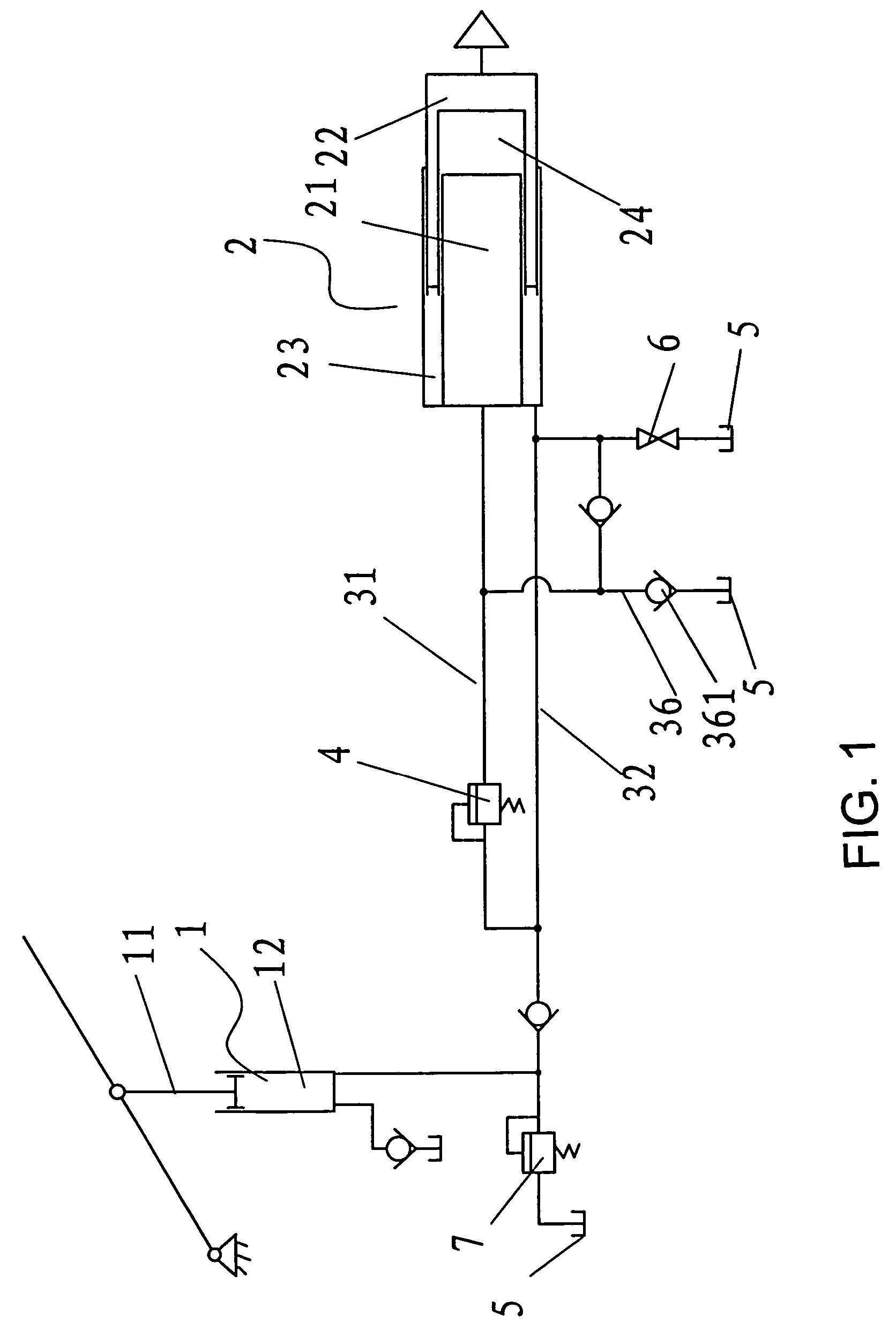

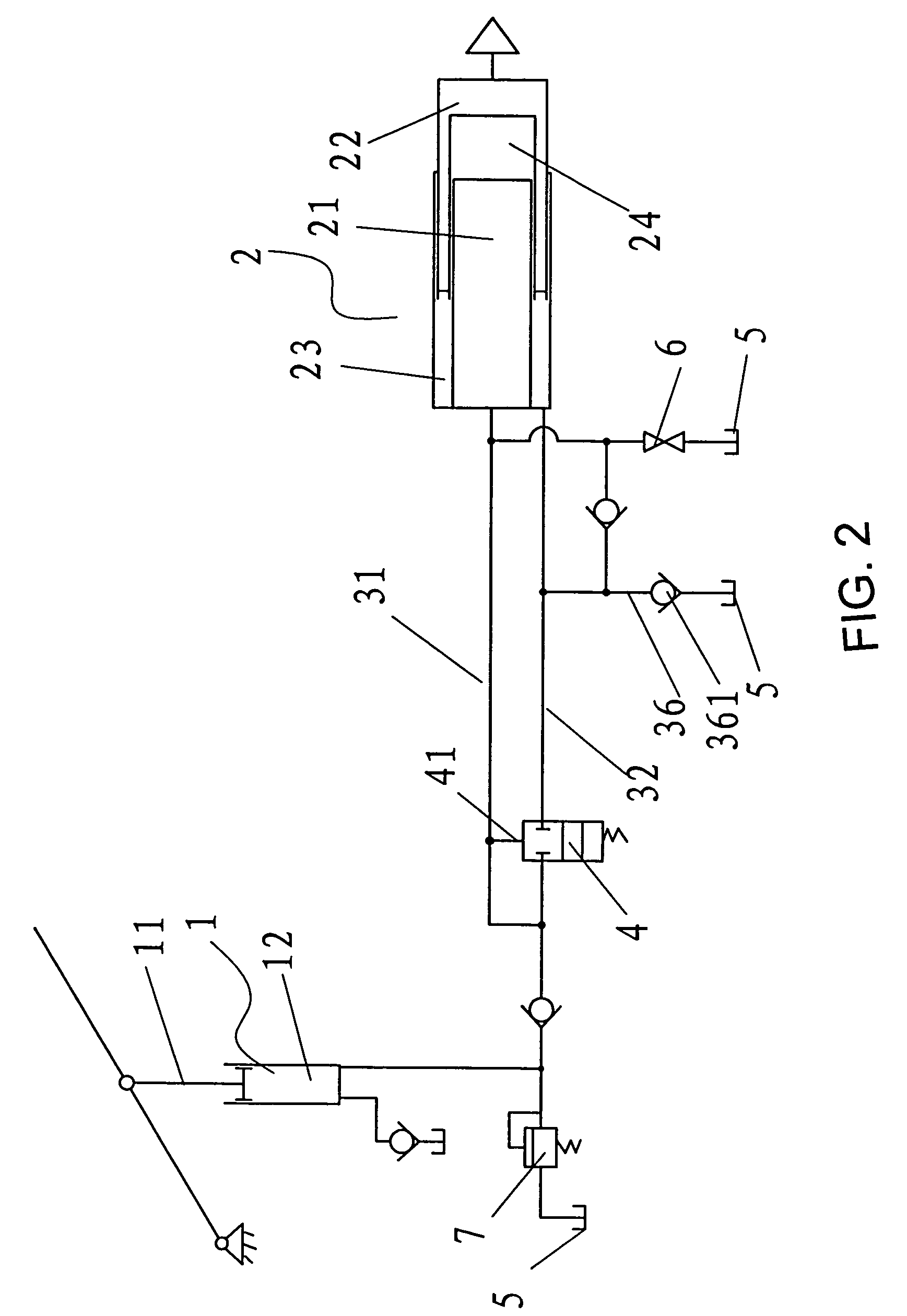

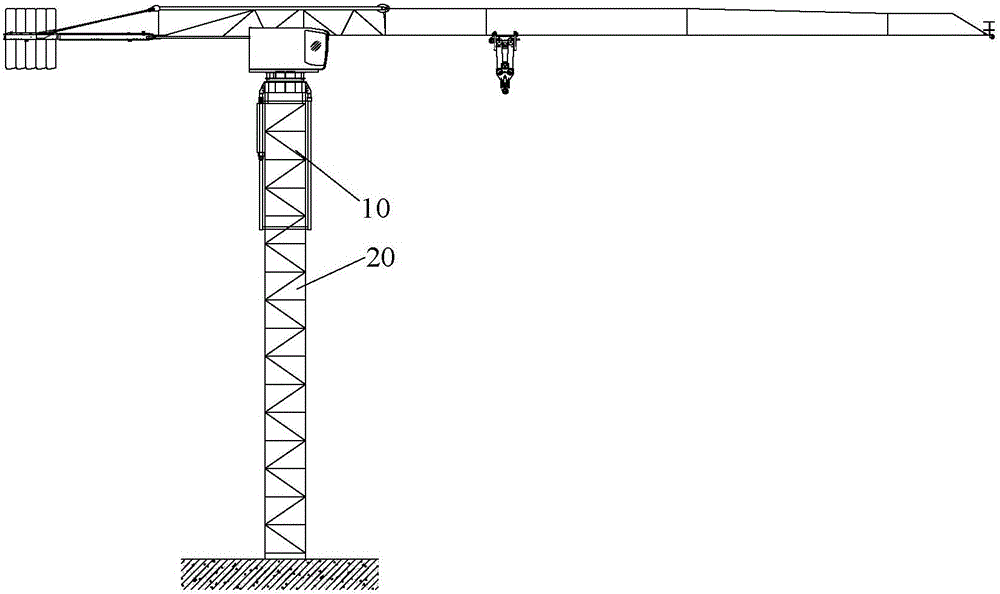

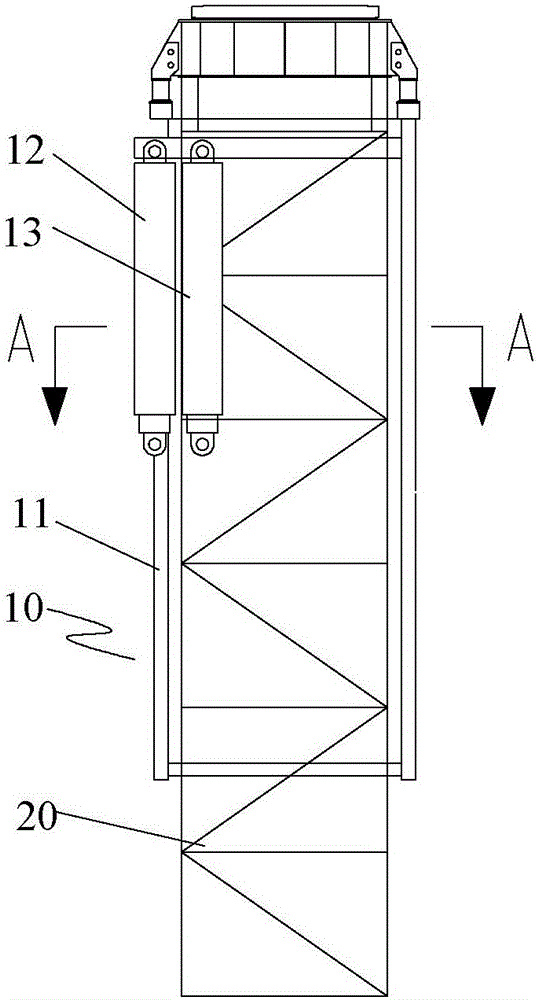

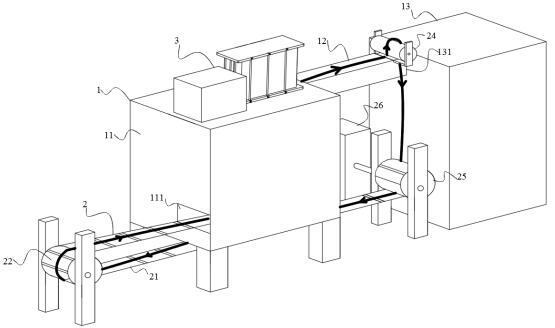

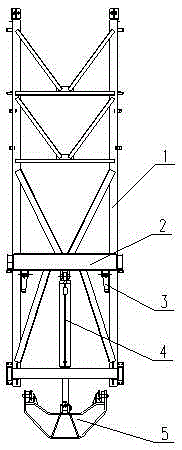

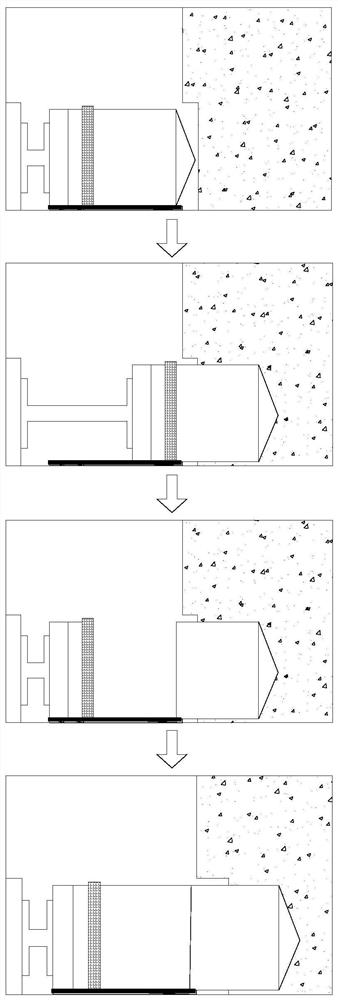

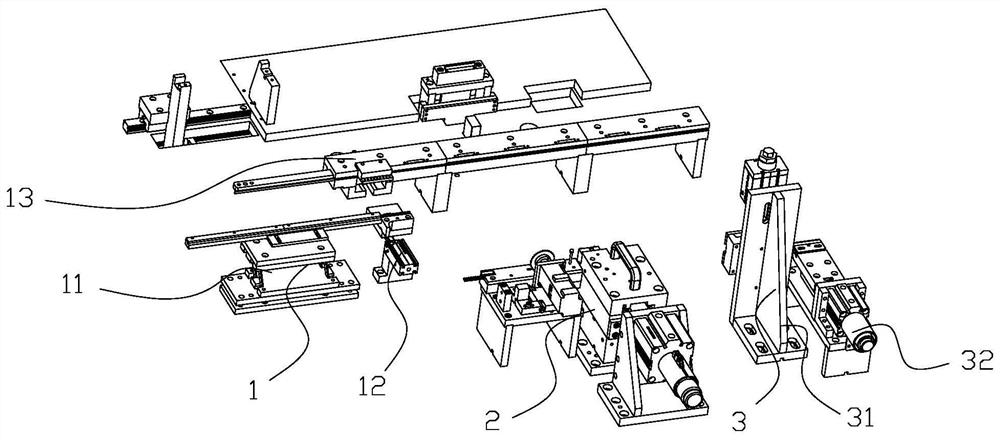

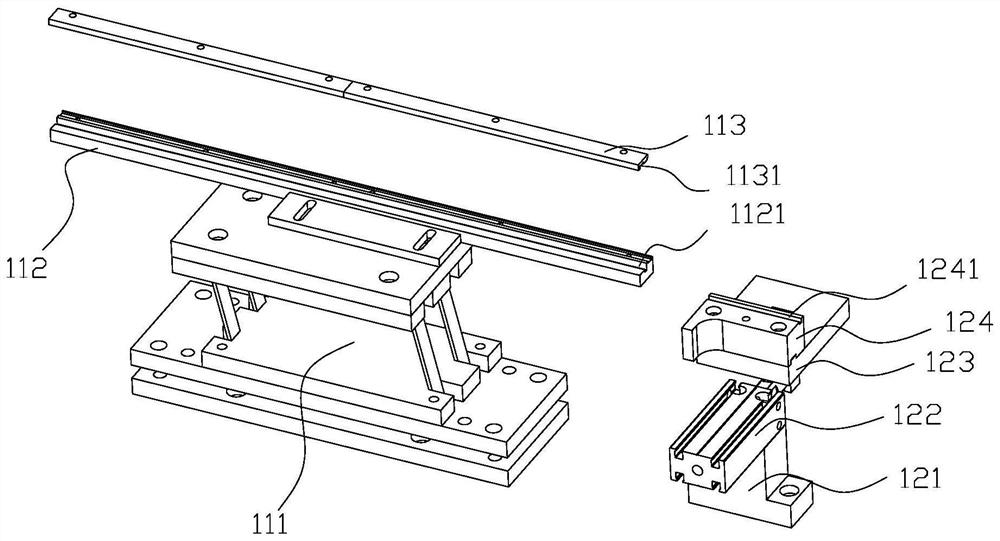

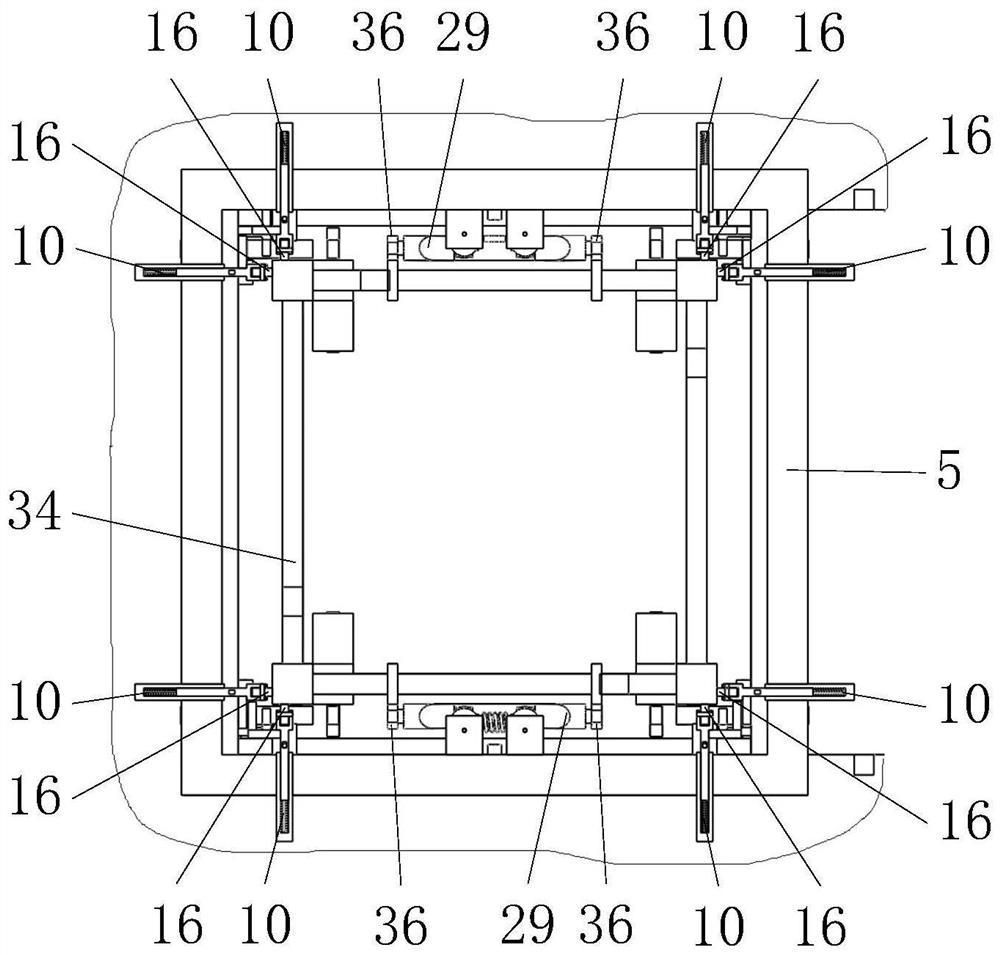

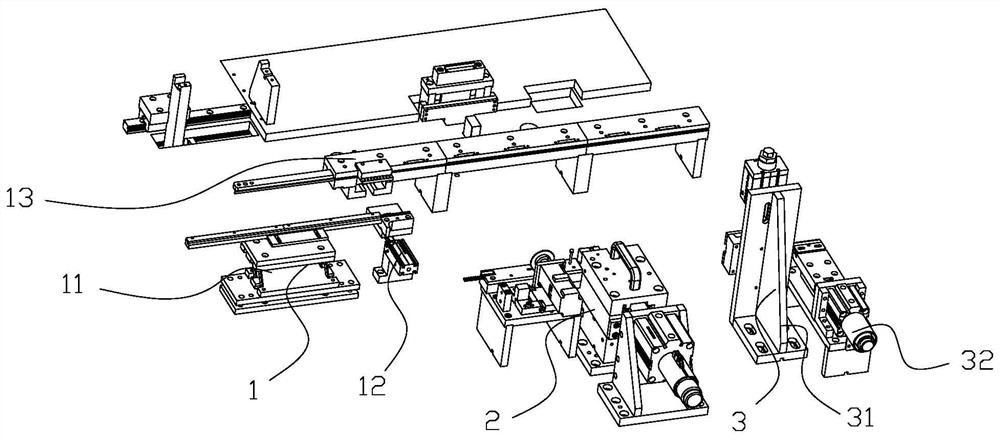

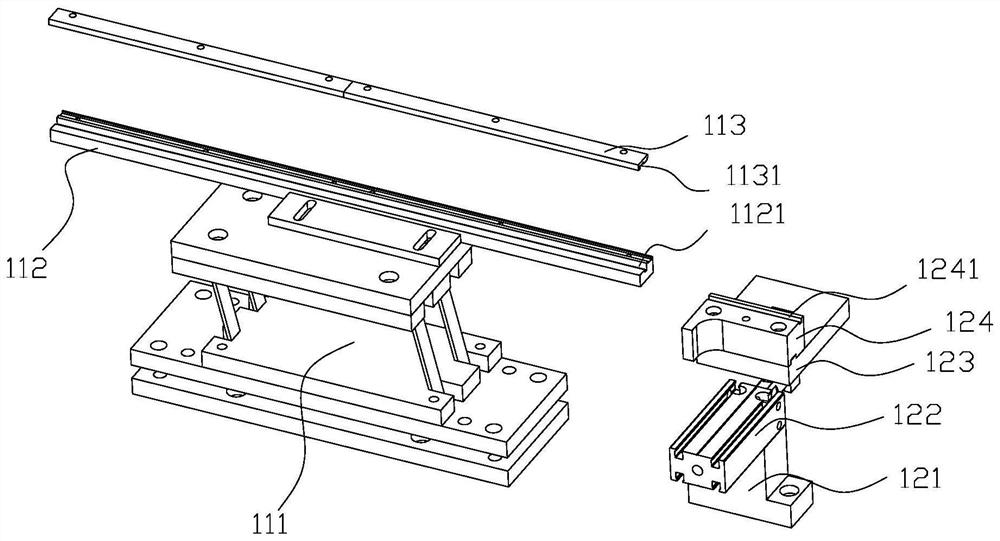

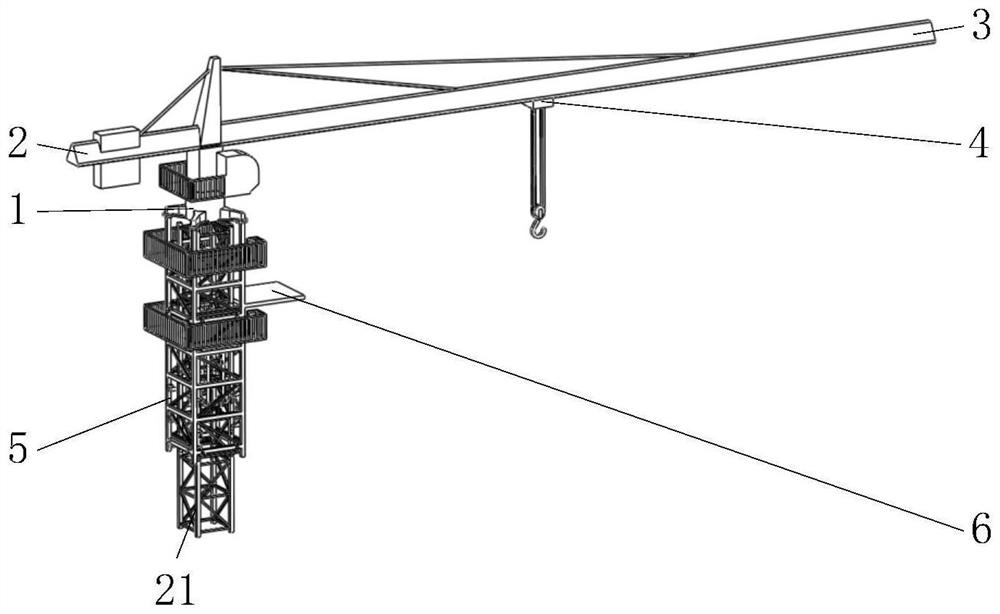

Jacking mechanism, jacking method and tower crane with jacking mechanism

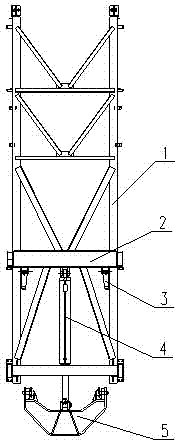

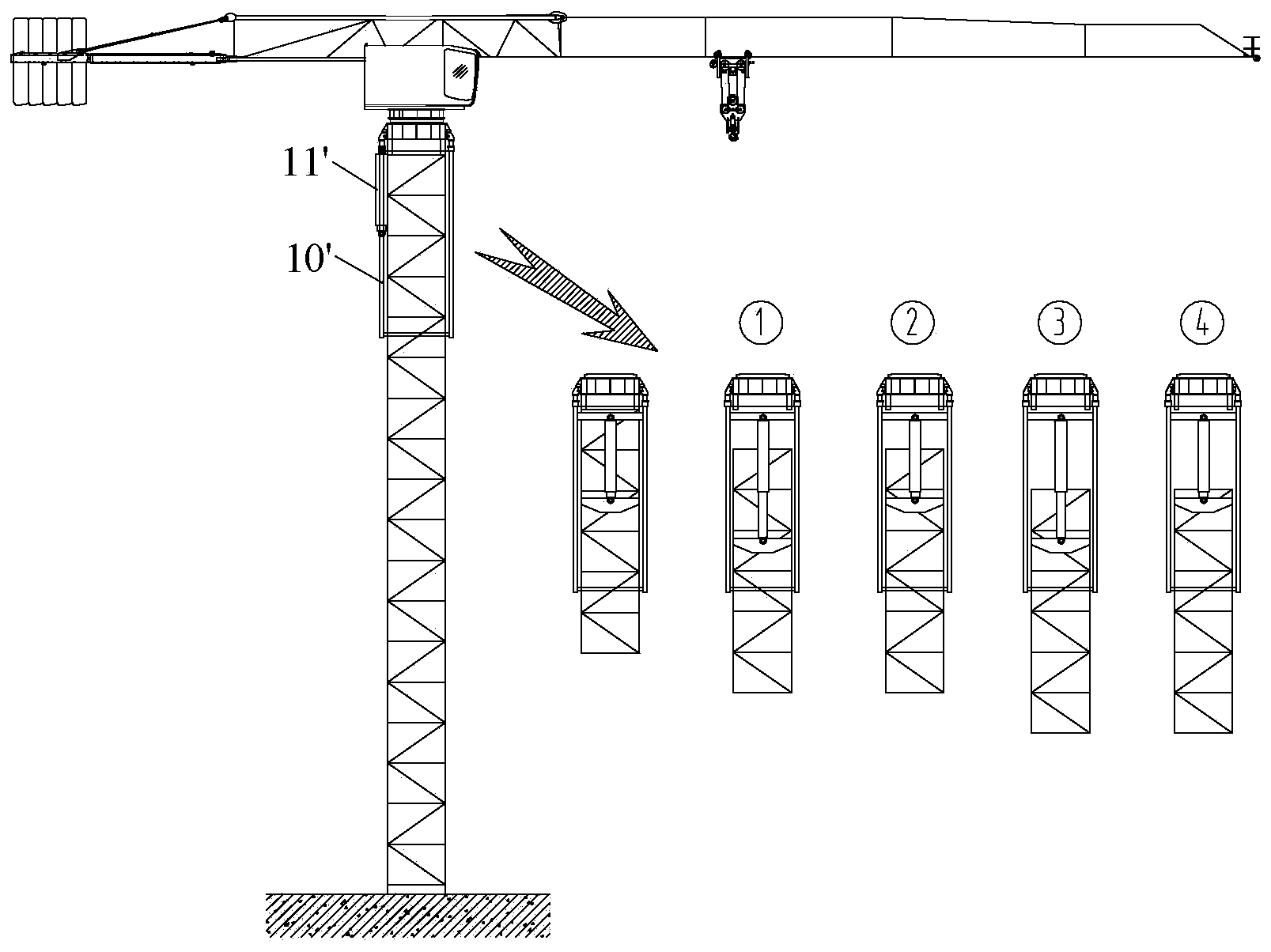

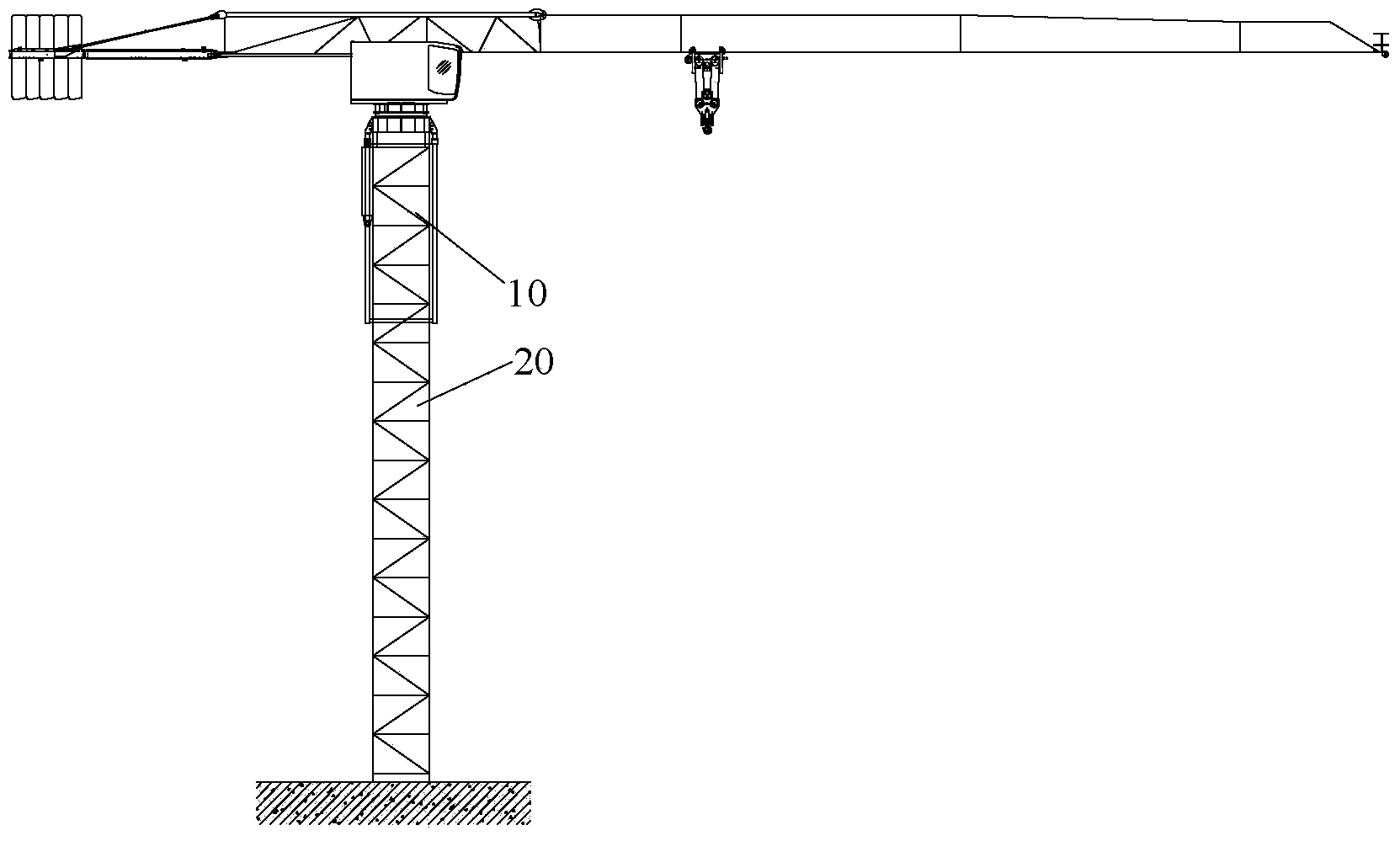

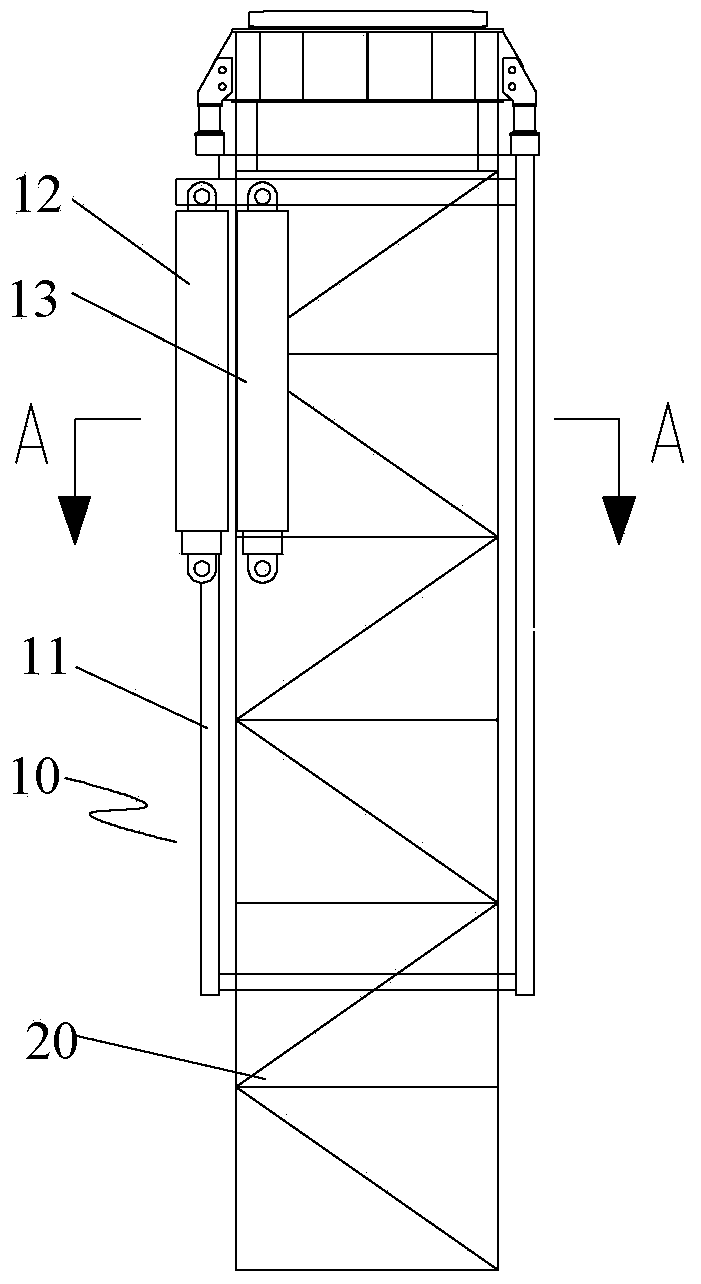

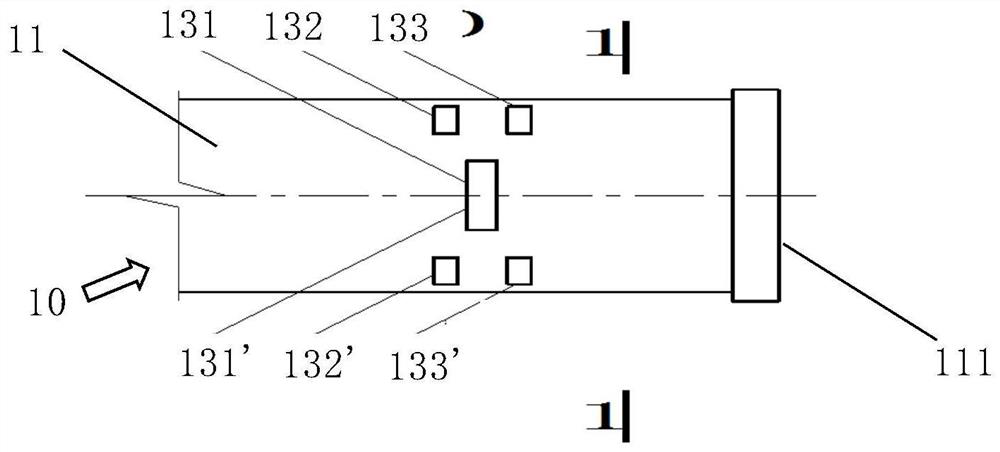

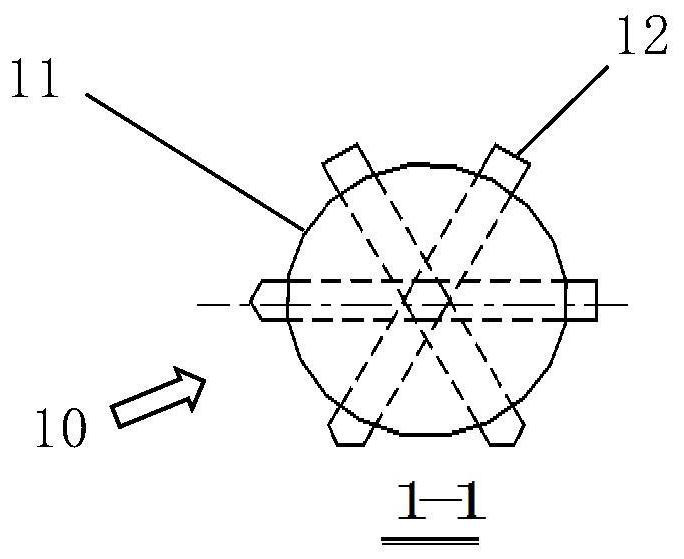

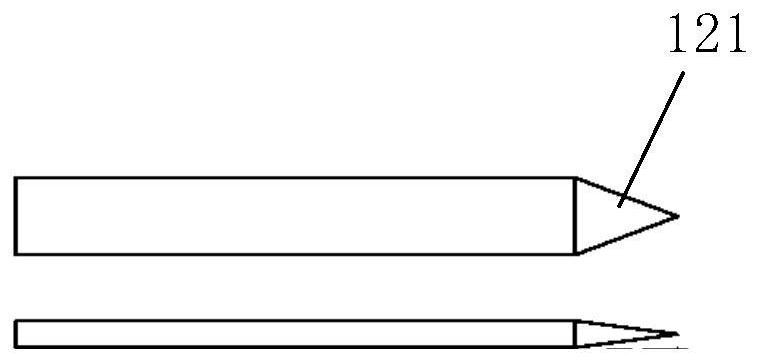

The invention provides a jacking mechanism, a jacking method and a tower crane with the jacking mechanism. The jacking mechanism comprises a climbing frame (11), a first jacking device (12) and a second jacking device (13), wherein the first jacking device (12) is fixedly connected to the climbing frame (11); and the second jacking device (13) is fixedly connected to the climbing frame (11) and enters a jacking readiness state when the first jacking device (12) jacks the climbing frame (11). The first jacking device (12) enters a jacking readiness state when the second jacking device (13) jacks the climbing frame (11), and the first jacking device (12) and the second jacking device (13) alternately jack the climbing frame (11). Jacking efficiency of the jacking mechanism can be effectively improved.

Owner:ZOOMLION HEAVY IND CO LTD

Jacking mechanism, jacking method, and tower crane with the same

The invention provides a jacking mechanism, a jacking method and a tower crane with the jacking mechanism. The jacking mechanism comprises a climbing frame (11), a first jacking device (12) and a second jacking device (13), wherein the first jacking device (12) is fixedly connected to the climbing frame (11); and the second jacking device (13) is fixedly connected to the climbing frame (11) and enters a jacking readiness state when the first jacking device (12) jacks the climbing frame (11). The first jacking device (12) enters a jacking readiness state when the second jacking device (13) jacks the climbing frame (11), and the first jacking device (12) and the second jacking device (13) alternately jack the climbing frame (11). Jacking efficiency of the jacking mechanism can be effectively improved.

Owner:ZOOMLION HEAVY IND CO LTD

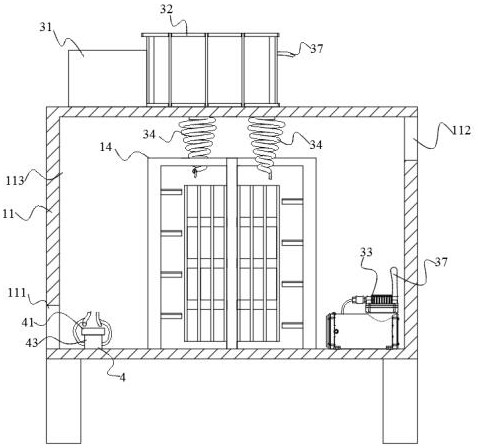

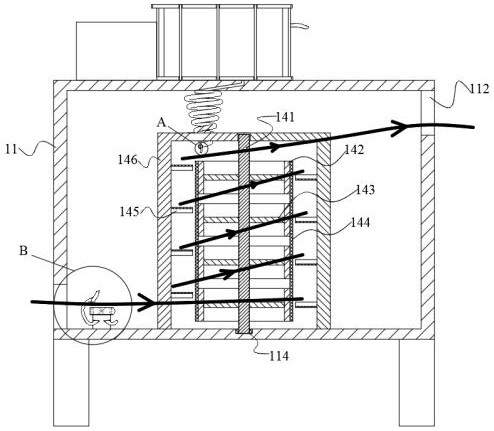

Gradient freezing storage device with double-helix quick-freezing diversion function

ActiveCN113959142APrevent leakageInstantaneous speed increaseLighting and heating apparatusDomestic refrigeratorsFrozen storageEngineering

The invention discloses a gradient freezing storage device with a double-helix quick-freezing diversion function. The gradient freezing storage device comprises a fixing device, a transmission device, a quick-freezing device and a pre-cooling device, the transmission device is movably connected with the fixing device, the fixing device comprises a freezing chamber, a connecting pipe and a storage tank, and the freezing chamber is connected with the storage tank through the connecting pipe. The quick-freezing device is connected with the freezing chamber, the freezing chamber is provided with a freezing cavity, the pre-cooling device is connected with the freezing chamber in a fastened mode, one side of the freezing cavity is provided with a conveying outlet, the freezing cavity communicates with the conveying outlet, the storage tank is provided with a feeding port, the two ends of the connecting pipe communicate with the conveying outlet and the feeding port respectively, the storage tank is provided with a storage cavity, the feeding port communicates with the storage cavity, and the conveying outlet is located at the upper end of one side of the freezing cavity. The side, away from the conveying outlet, of the freezing cavity is provided with a conveying inlet, and the conveying inlet is located at the lower end of one side of the freezing cavity.

Owner:杰欧(江苏)冷链装备有限公司

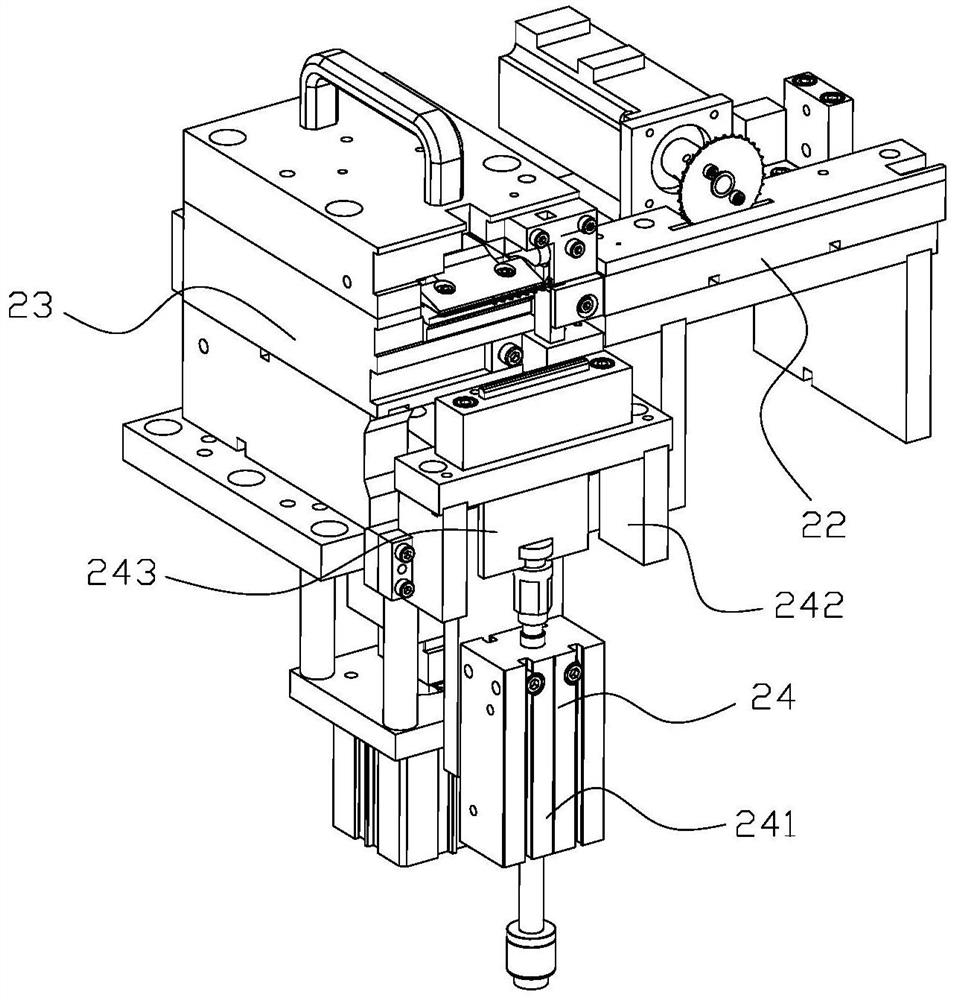

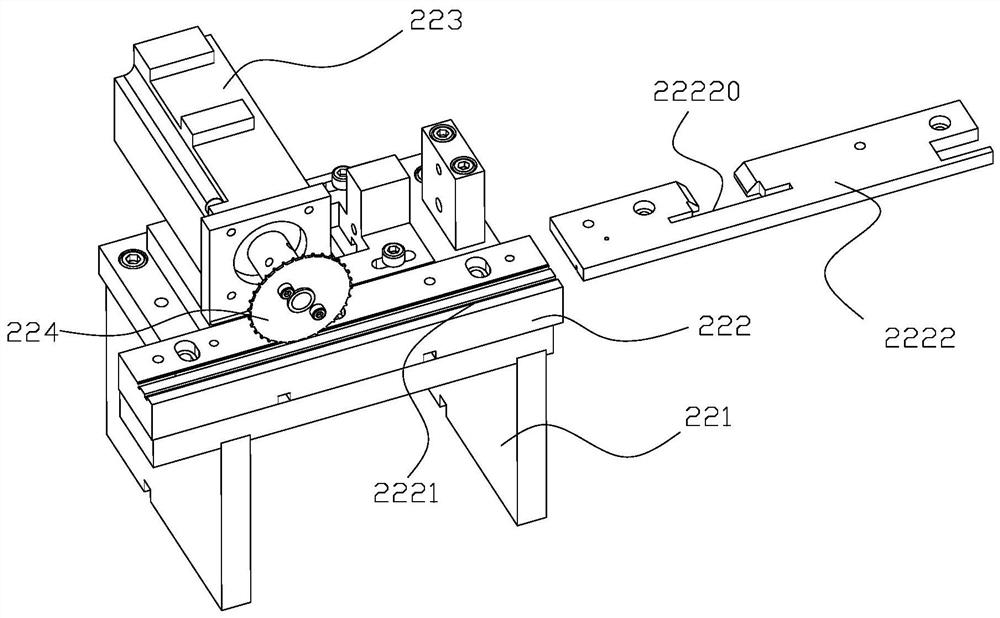

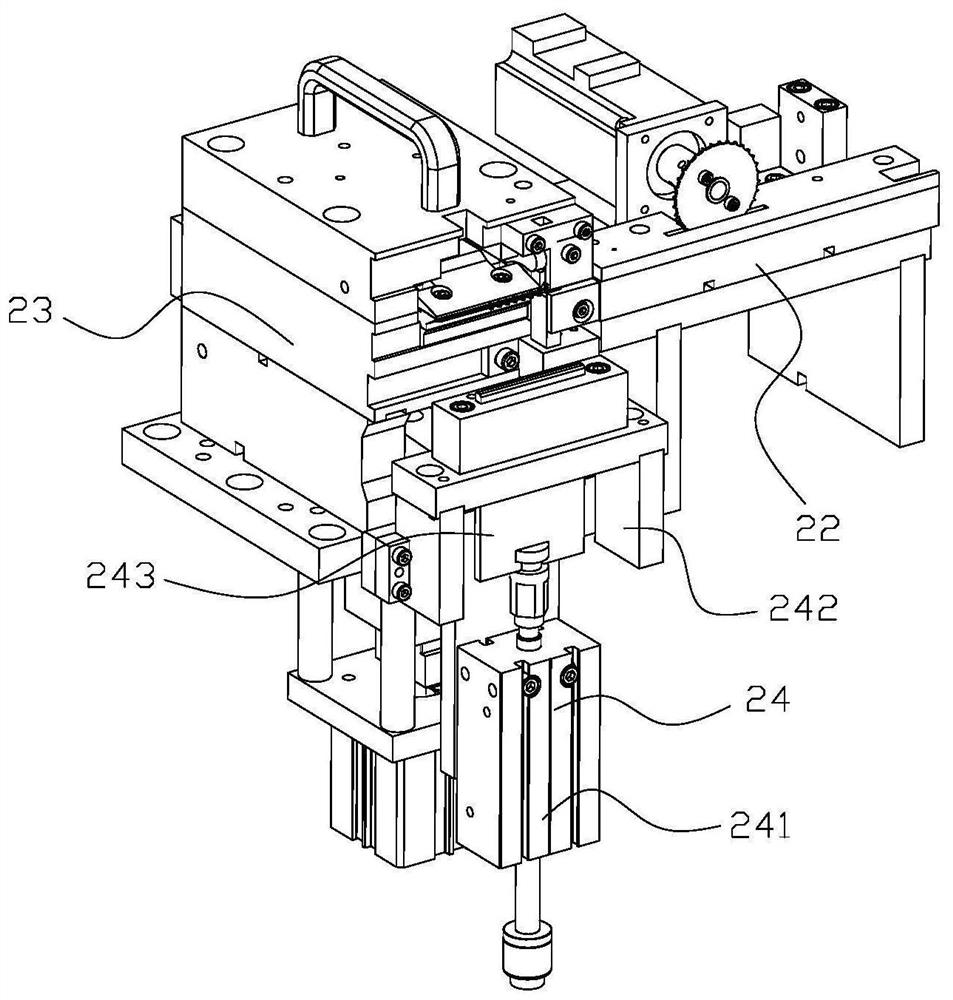

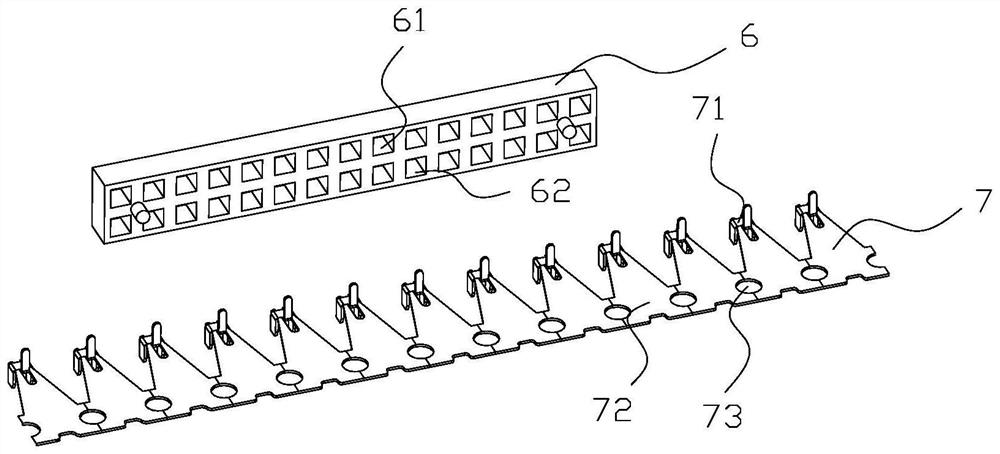

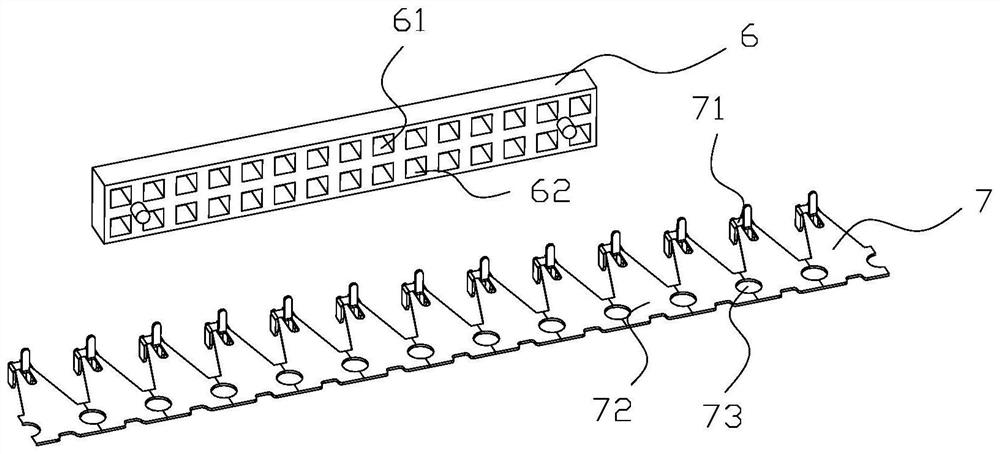

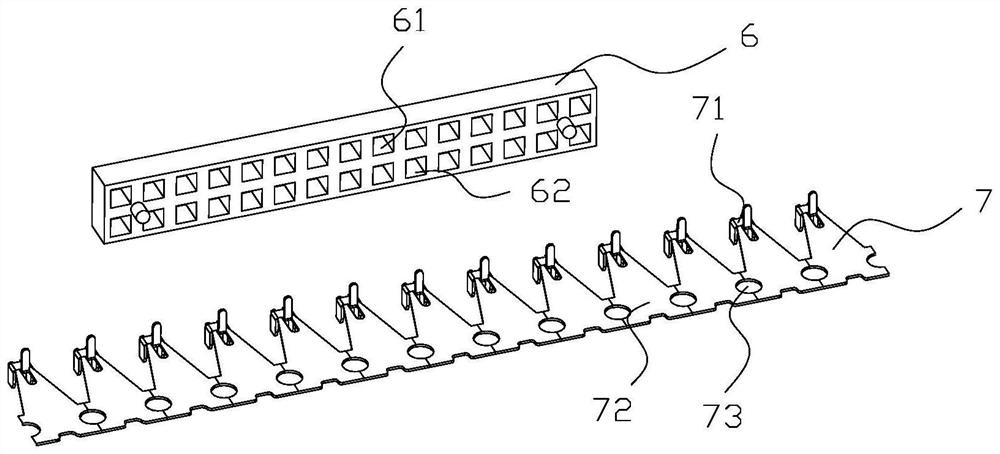

Pin header clamping and inserting mechanism and method for pin header connecting terminal production

InactiveCN111769422AImprove insertion qualityEasy to cutContact member assembly/disassemblyComputer hardwareEngineering

The invention belongs to the technical field of the automatic production of electronic connectors. A pin header clamping and inserting mechanism for pin header connecting terminal production comprisesa pin header cutting and inserting support, a pin header lifting module and a pin header clamping and inserting module. The pin header cutting and inserting support is arranged on a rack; a pin header clamping and inserting groove is formed in the top of the pin header cutting and inserting support; the pin header lifting module is located below the pin header cutting and inserting support, the pin header clamping and inserting module is located in the pin header clamping and inserting groove, and the pin header clamping and inserting module is used for clamping and inserting a set of cut-offpin header material strips into female headers. The pin header clamping and inserting mechanism has the advantages that the clamping firmness of pin headers is improved; the accuracy of pin header insertion positioning is improved; and the assembly quality of the pin headers and the female headers is improved.

Owner:陈如会

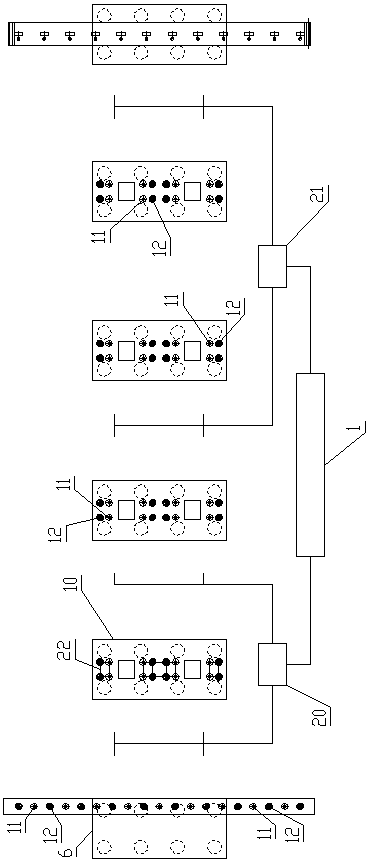

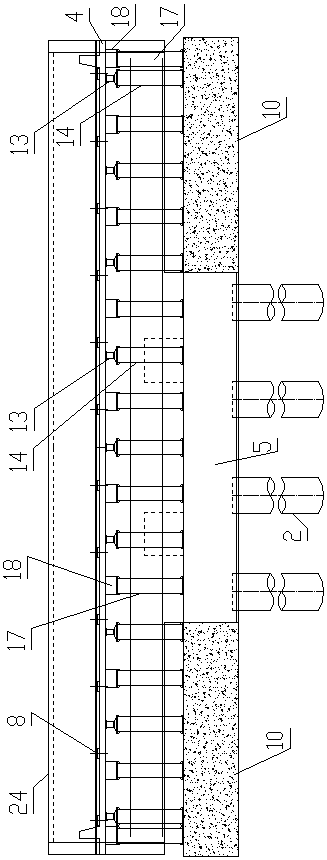

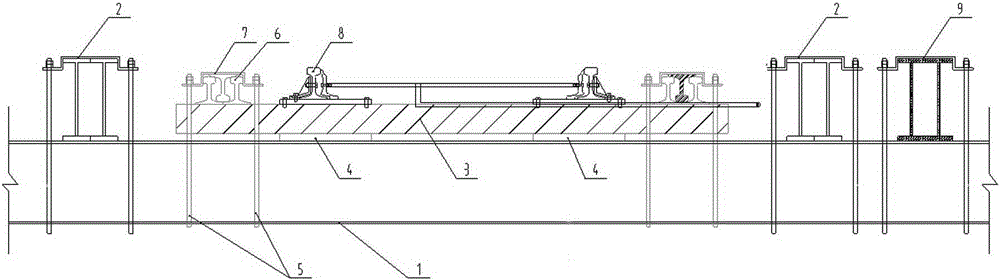

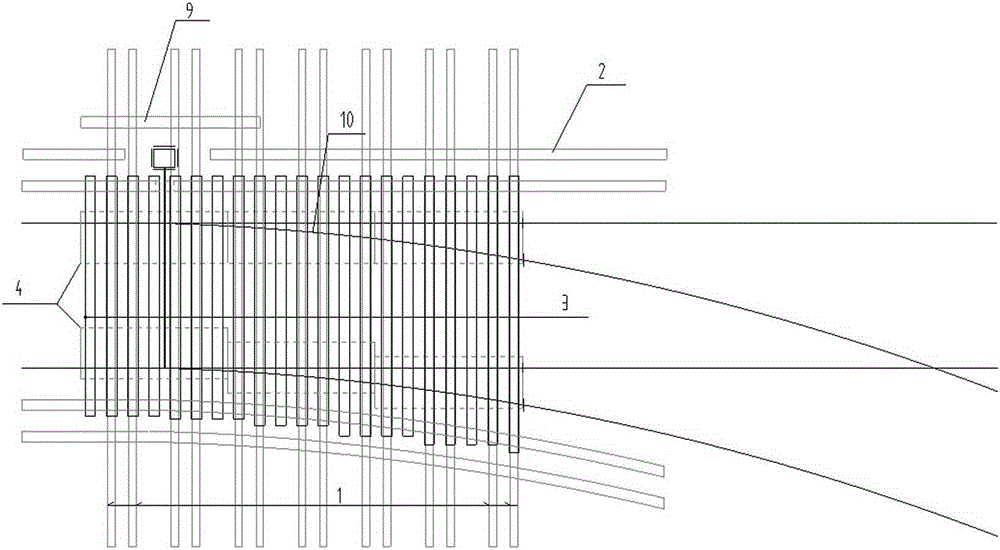

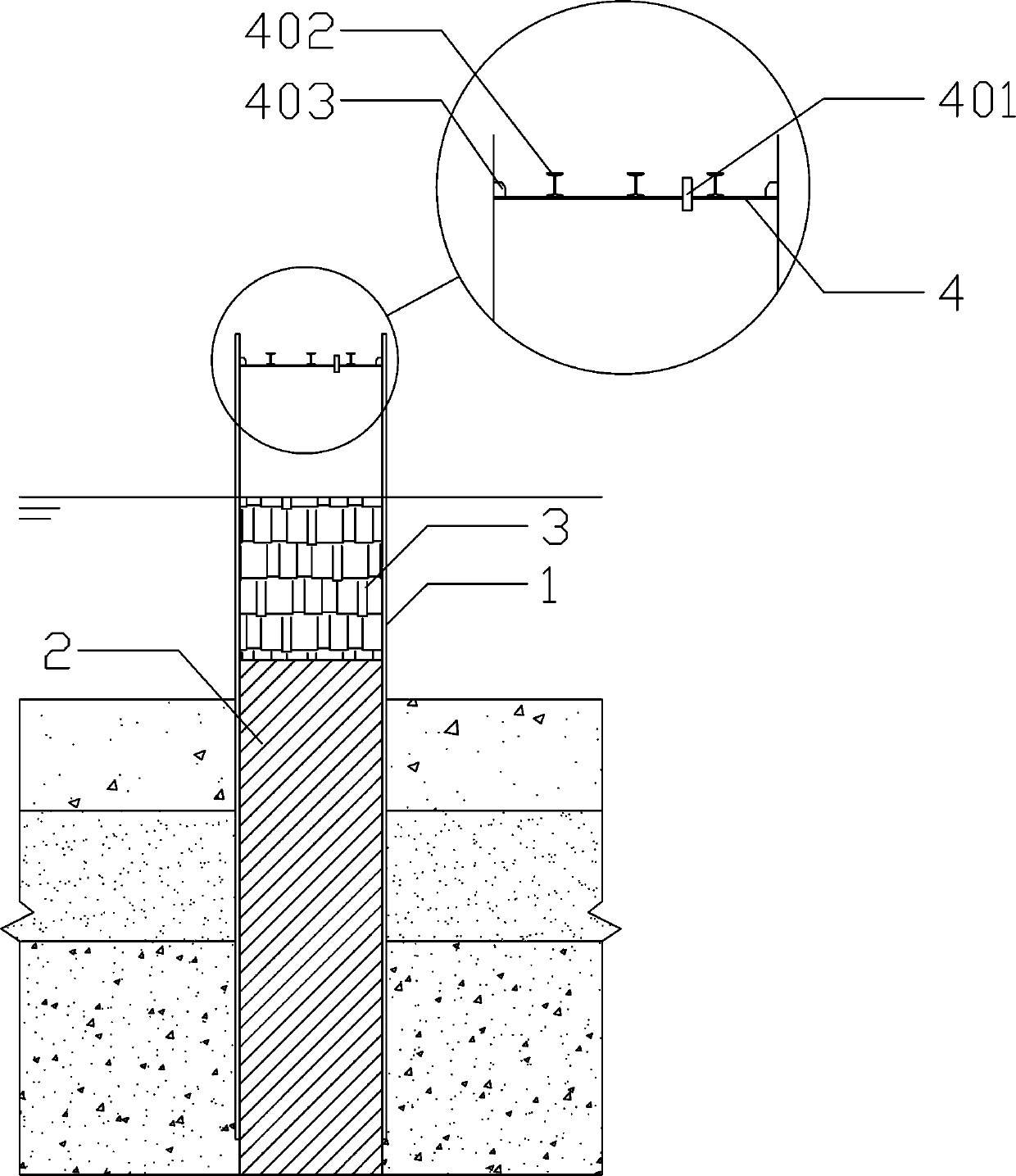

Line reinforcement device for frame bridge jacking into railway branch area

InactiveCN103437254BReduce geometric distortionSolve the problem of weak reinforcementRailway track constructionSteel platesBuilding construction

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

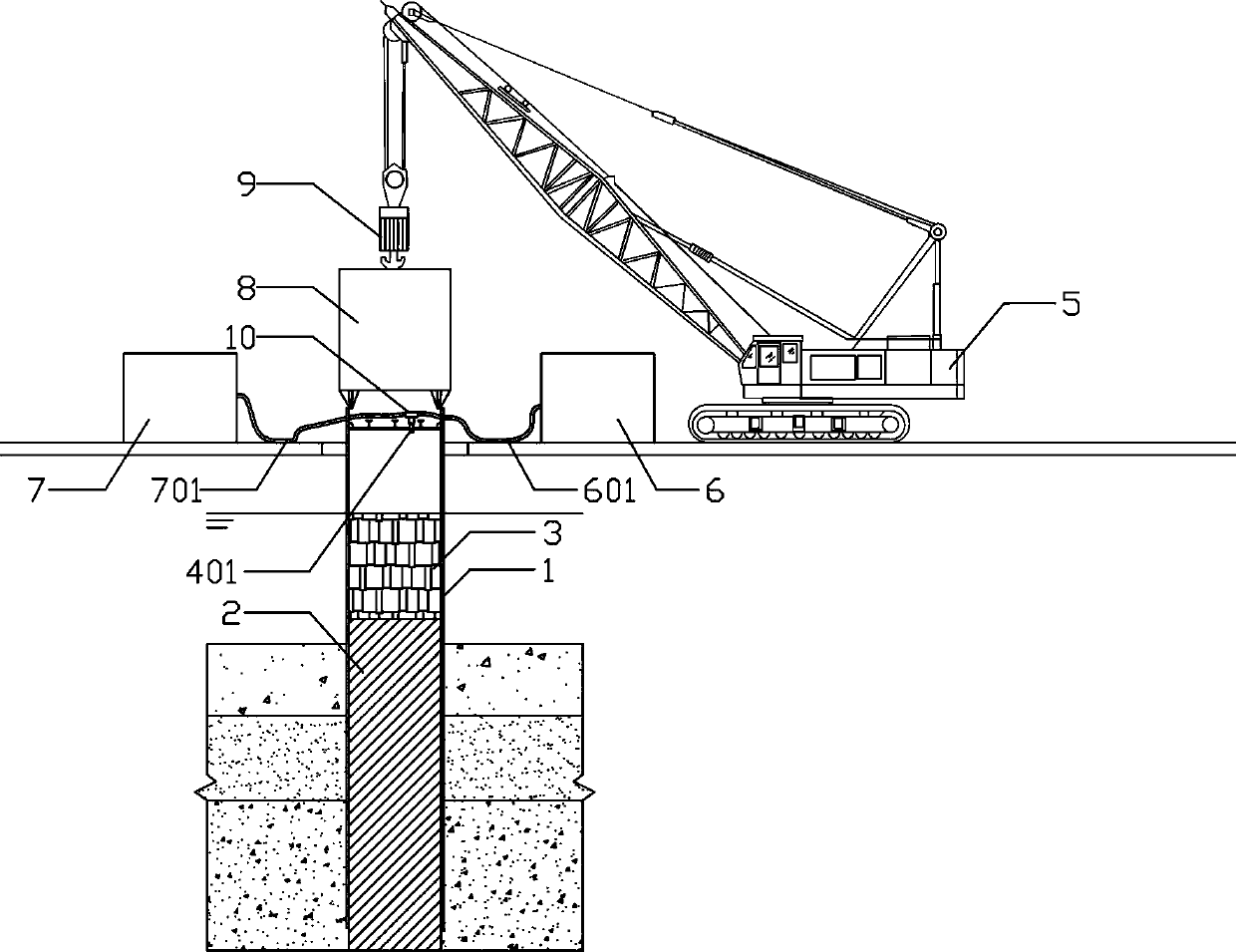

Steel casing pulling-removal method

The invention relates to a steel casing pulling-removal method which comprises the following steps of (1) adopting impermeable soil for backfilling, and preparing a mud slurry for plugging a formation; (2) full-length welding a capping steel plate at the upper end of a steel casing, and reserving a gas-liquid inlet pipe; (3) installing and moving equipment in: moving lifting equipment in, and installing a rotary motor and a vibration hammer, wherein the vibration hammer is connected with the steel casing; (4) liquifying a soil mass: starting the vibration hammer to liquify the soil mass aroundthe steel casing; (5) pressurizing through a hydraulic system: applying water pressure in the steel casing, slowly lifting the lifting equipment, and starting the rotary motor at the same time; (6) pressurizing through an air pressure system: applying air pressure into the steel casing, and continuously lifting the steel casing; and (7) pressurizing through a hydraulic system: when the steel casing is 3 to 5m away from a pile block, stopping air feeding, releasing pressure, starting the hydraulic system to apply water pressure into the steel casing, and then pulling out of a pile body. By adopting the method, through a gas-liquid pressurization combination method, the difficulty in pulling and removing the steel casing under a special condition in the prior art is saved, and the safety and the stability in the steel casing pulling-removal process are effectively ensured.

Owner:CCCC SECOND HARBOR ENG

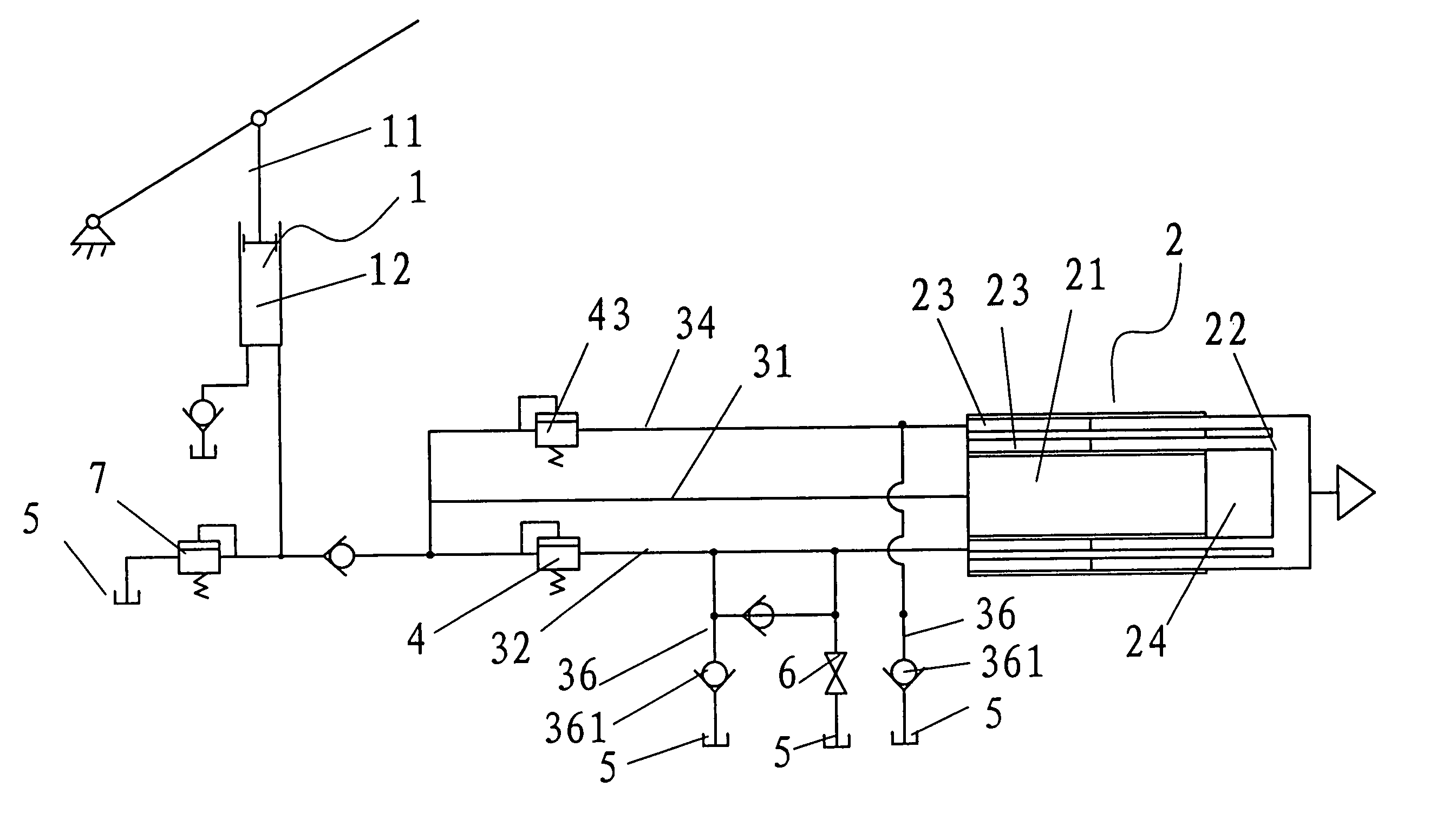

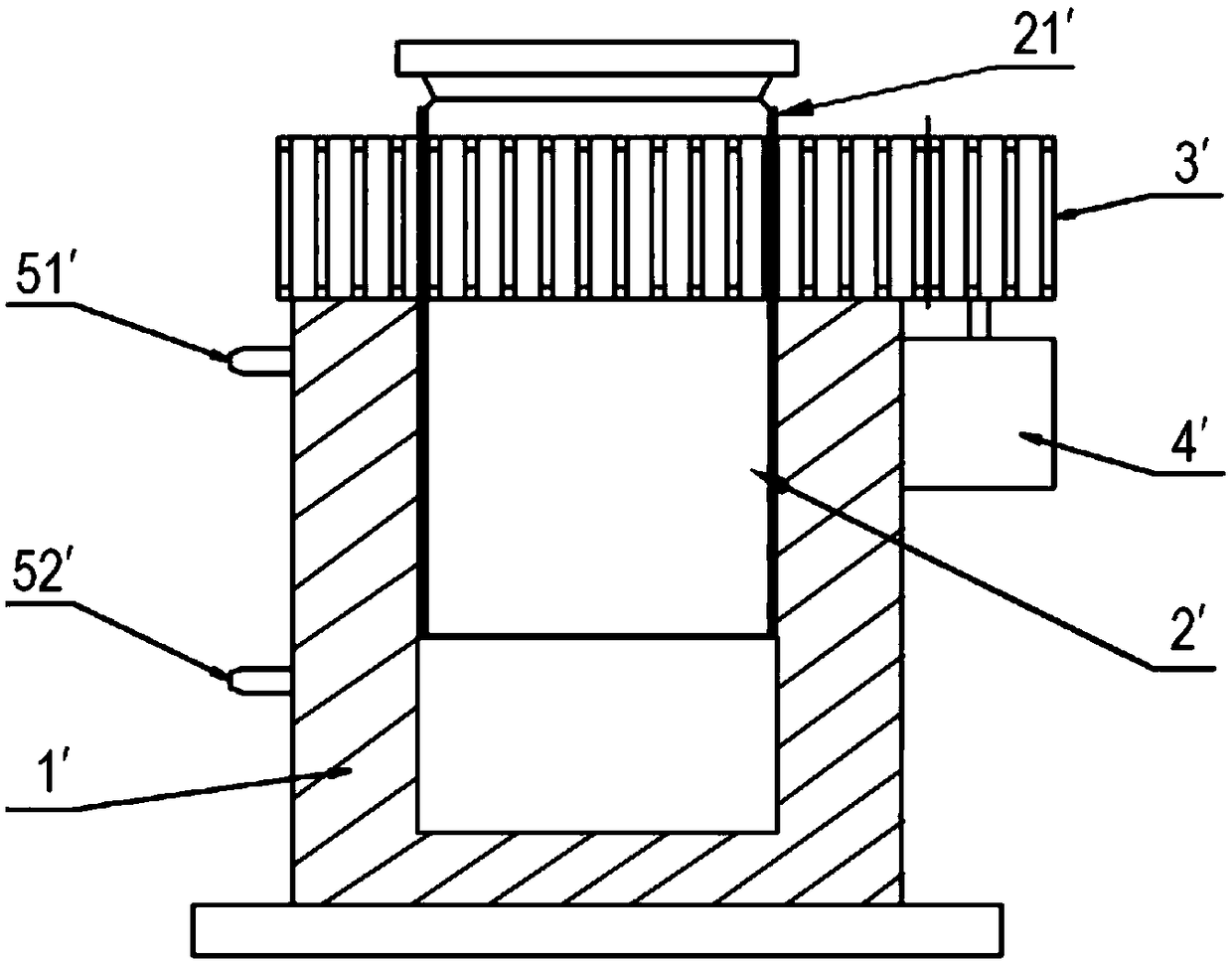

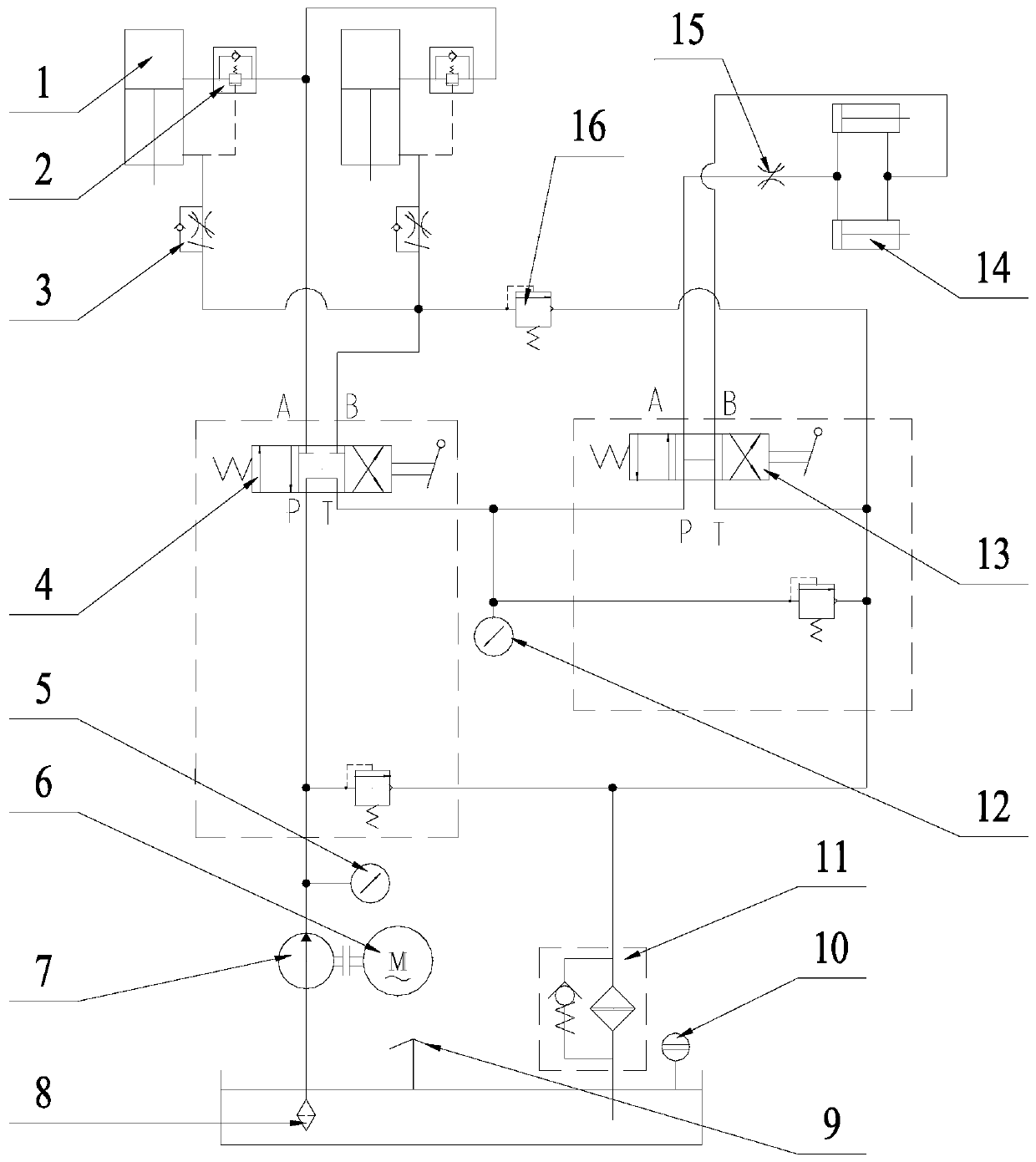

Continuous building jacking system and jacking method thereof

PendingCN109264613AImprove jacking efficiencyReduce construction difficultyLifting devicesEngineeringHydraulic pump

Provided are a continuous building jacking system and a jacking method thereof. The jacking system comprises a hydraulic pump station controlled by a control console, at least one group of mechanicalself-perpetuating jacks controlled by the hydraulic pump station and used for alternative jacking by turns and supporting cushion blocks for supporting the mechanical self-perpetuating jacks, whereineach mechanical self-perpetuating jack comprises an oil cylinder and a piston rod and also comprises a lifting ring, a linkage mechanism, an oil motor and a connecting pipeline. The lifting ring sleeves the oil cylinder or the piston rod and performs synchronous lifting with the piston rod under the driving of the oil motor, the linkage mechanism is connected with the lifting ring and the piston rod or the oil cylinder or the piston rod, the lifting ring is kept relevant to the immediate height position of the piston rod through the linkage mechanism, and when the hydraulic pump station or theoil cylinder suddenly loses pressure, the oil motor instantly stops rotating and lock the immediate position of the lifting ring, and meanwhile the lifting ring enables the piston rod to also keep anoriginal immediate position through the linkage mechanism and prevents the piston rod from suddenly falling after rise. The continuous building jacking system is high in efficiency and low in construction difficulty and construction cost and thus has competitive advantage.

Owner:SHANGHAI TONGGANG ARCHITECTURAL ENG

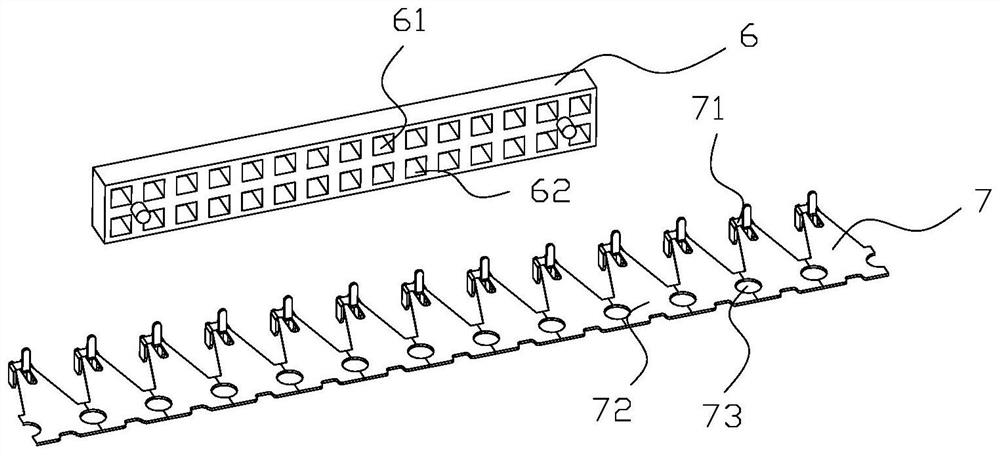

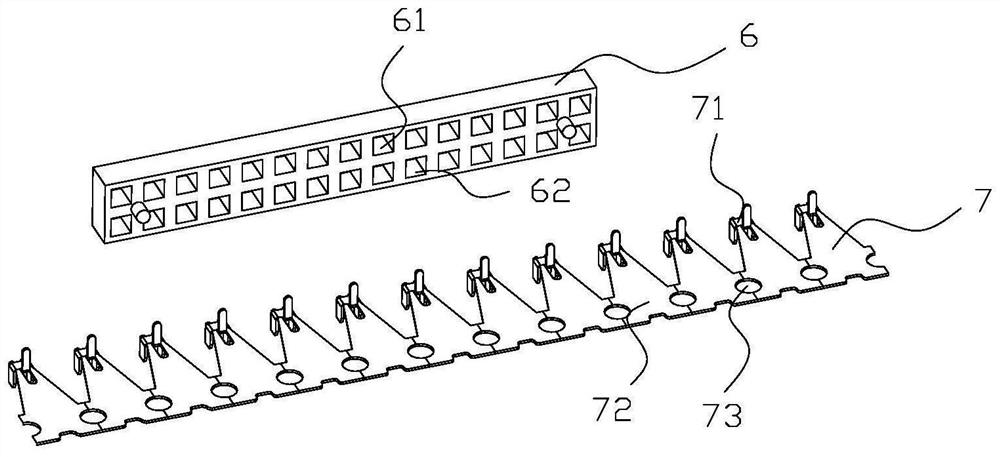

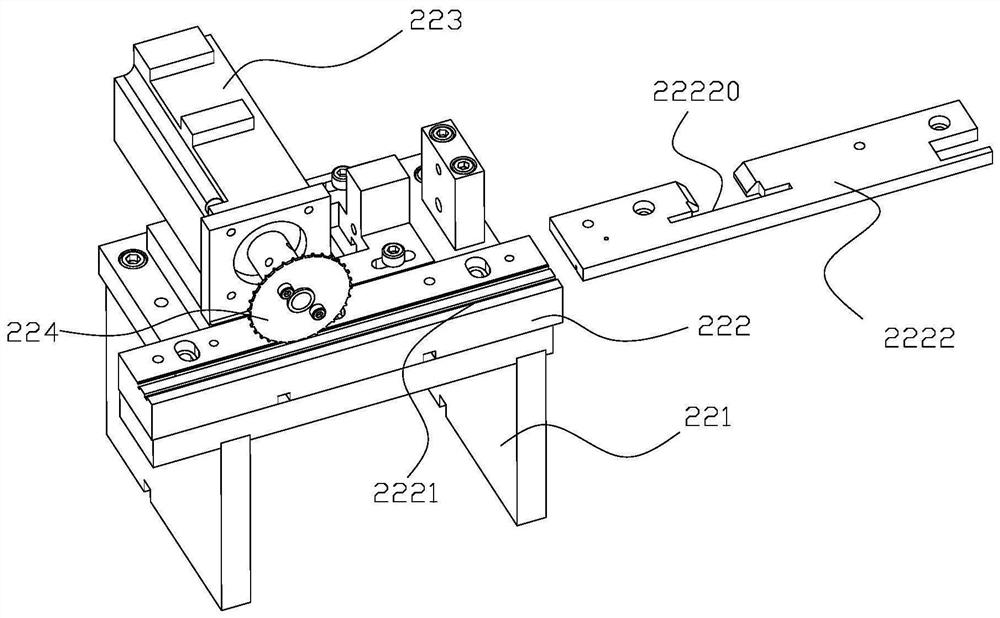

Female header cutting mechanism and method for pin header connecting terminal production

InactiveCN111804850AEasy to limitEasy to cut off at one timeCoupling contact membersTwo-part coupling devicesEngineeringElectrical connector

The invention belongs to the technical field of automatic production of electronic connectors. The invention discloses a female header cutting mechanism for pin header connecting terminal production.The mechanism comprises a pin header cutting inserting support, a pin header lifting module and a pin header cutting module; the pin header cutting inserting support is arranged on a rack; a pin header conveying connection block is arranged on the rear side of the pin header cutting inserting support, a pin header conveying connection groove is formed in the pin header conveying connection block,and multiple pin header conveying positioning holes are formed in the middle of the pin header conveying connection block; and a pin header conveying connection limiting block is arranged on the pin header cutting inserting support. The mechanism and method have the advantages that the pin header conveying efficiency and conveying positioning accuracy are improved, the pin header cutting efficiency and cutting quality are improved, and the pin header inserting quality is improved.

Owner:陈如会

A tower crane jacking anti-falling control device

ActiveCN103787211BImprove jacking efficiencySmall operating forceCranesTower cranePetroleum engineering

The invention discloses a tower crane jacking anti-falling control device, which belongs to the technical field of tower cranes and comprises a climbing frame (1) and a step (6). The climbing frame includes an oil cylinder beam, a jacking oil cylinder, a jacking beam, and an oil cylinder beam Climbing claws (3) are installed on the top; the steps are installed on the outside of the standard section, and the climbing claws are suspension pawls, which are hingedly connected to the ear plate (2-1) welded on the cylinder beam through the pawl shaft (3-1). ), the distance between the center of the pawl shaft and the main chord of the standard section is less than the length of the suspension pawl; there is a fixing hole (6-1) in the middle of the step for supporting the support shaft (5-2) of the jacking beam, and the upper and lower Positioning slots (6-2) are provided at both ends; telescopic mechanisms are provided at both ends of the jacking beam. The climbing frame of the present invention does not need manual operation when stepping through the standard section. The jacking beam passes through the telescopic support shaft into the center hole of the standard section step, and uses the safety pin to position the telescopic support shaft, effectively preventing the oil cylinder from telescopic misoperation, safe and reliable high sex.

Owner:XUZHOU CONSTR MACHINERY

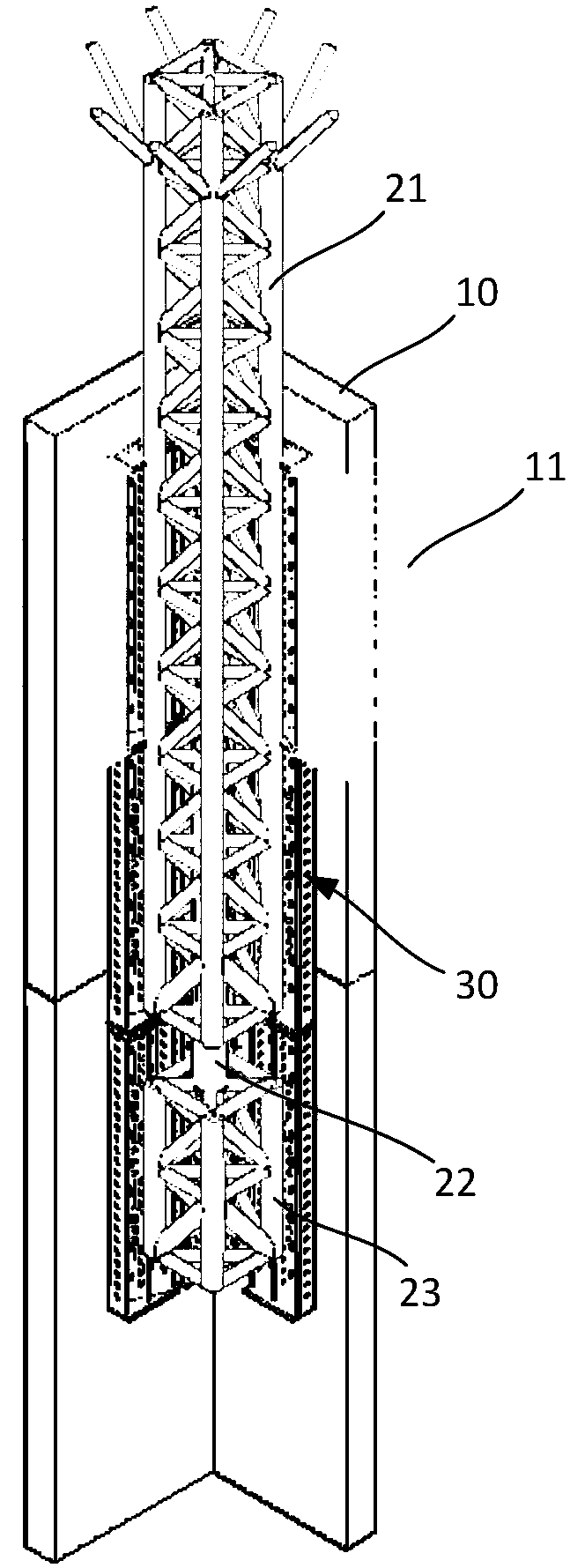

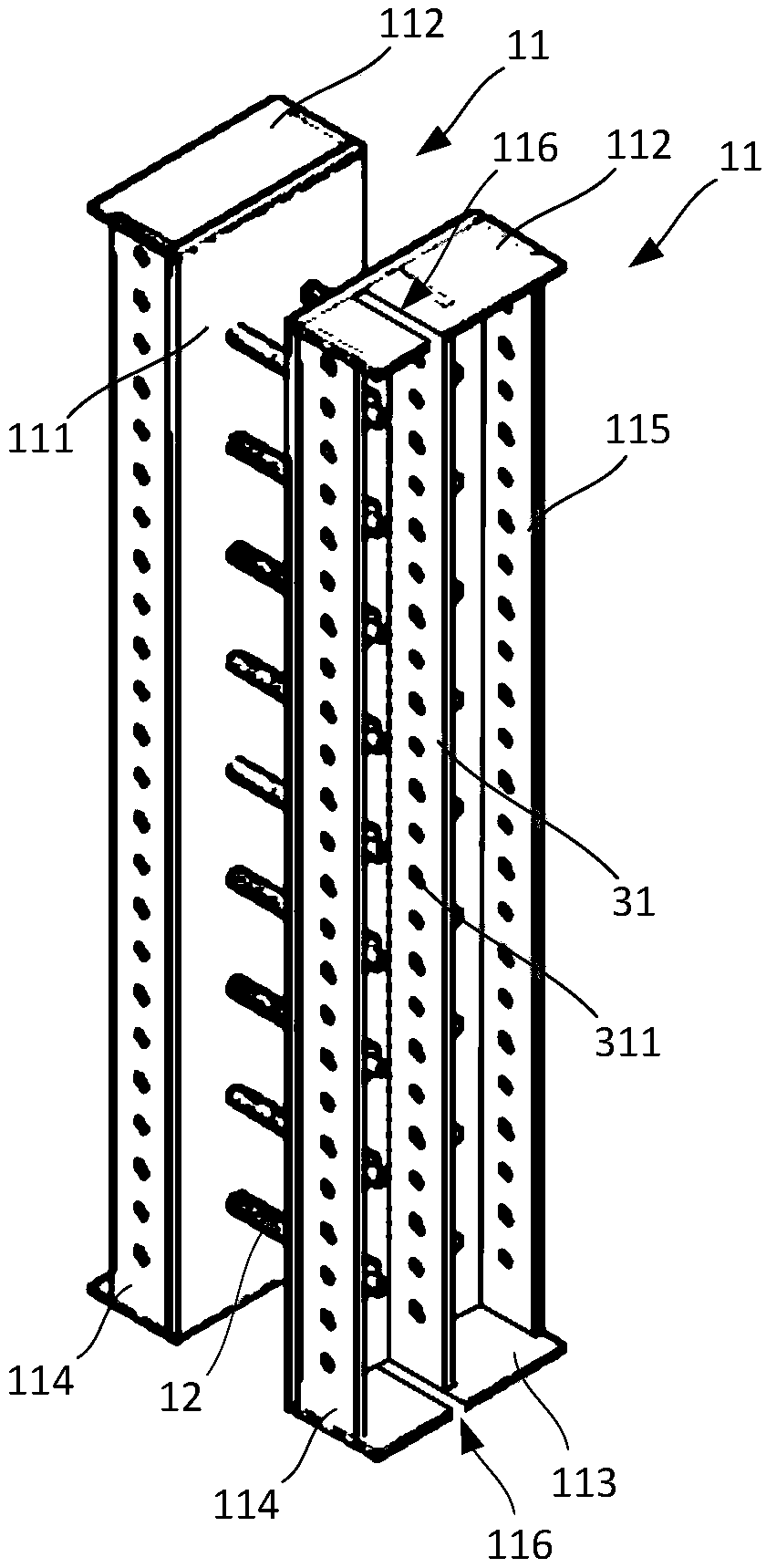

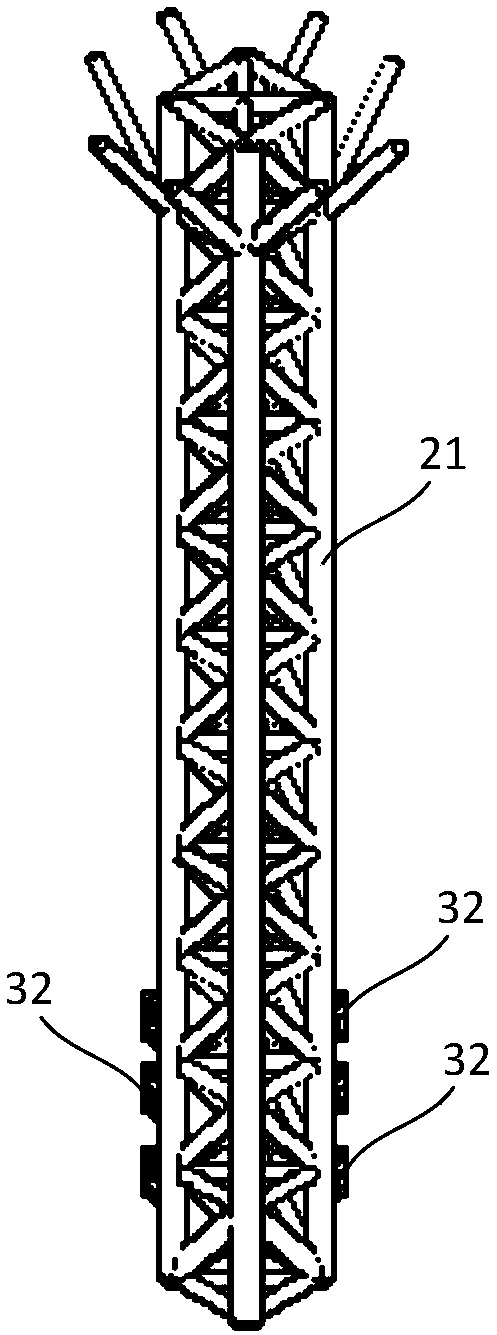

Integrated template type connection device for jacking platform and jacking method of lattice column

ActiveCN108729664AGuarantee the safety of useImprove jacking efficiencyHydro energy generationForms/shuttering/falseworksWall plateShear wall

The invention relates to an integrated template type connection device for a jacking platform and a jacking method. The connection device comprises a connection plate and a first wall-attaching plate,wherein the connection plate is arranged at a corresponding position on a shear wall template; the first wall-attaching plate is fixedly arranged at one side on a lattice column, which is close to the shear wall template; the first wall-attaching plate is attached to the connection plate and is in detachable connection with the connection plate so as to fasten and connect the lattice column and the shear wall template. According to the connection device disclosed by the invention, the lattice column for supporting, which is arranged on the jacking platform, is directly attached to the shear wall template, and the lattice column is connected by a poured shear wall structure and the shear wall template which is not demoulded, so that in one aspect, powerful supporting is provided for the lattice column and use safety of the jacking platform is ensured, and in the other aspect, jacking efficiency of the jacking platform is improved, a user does not need to wait for a shear wall to be demoulded and reach set intensity, construction time can be shortened, and a construction period is saved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

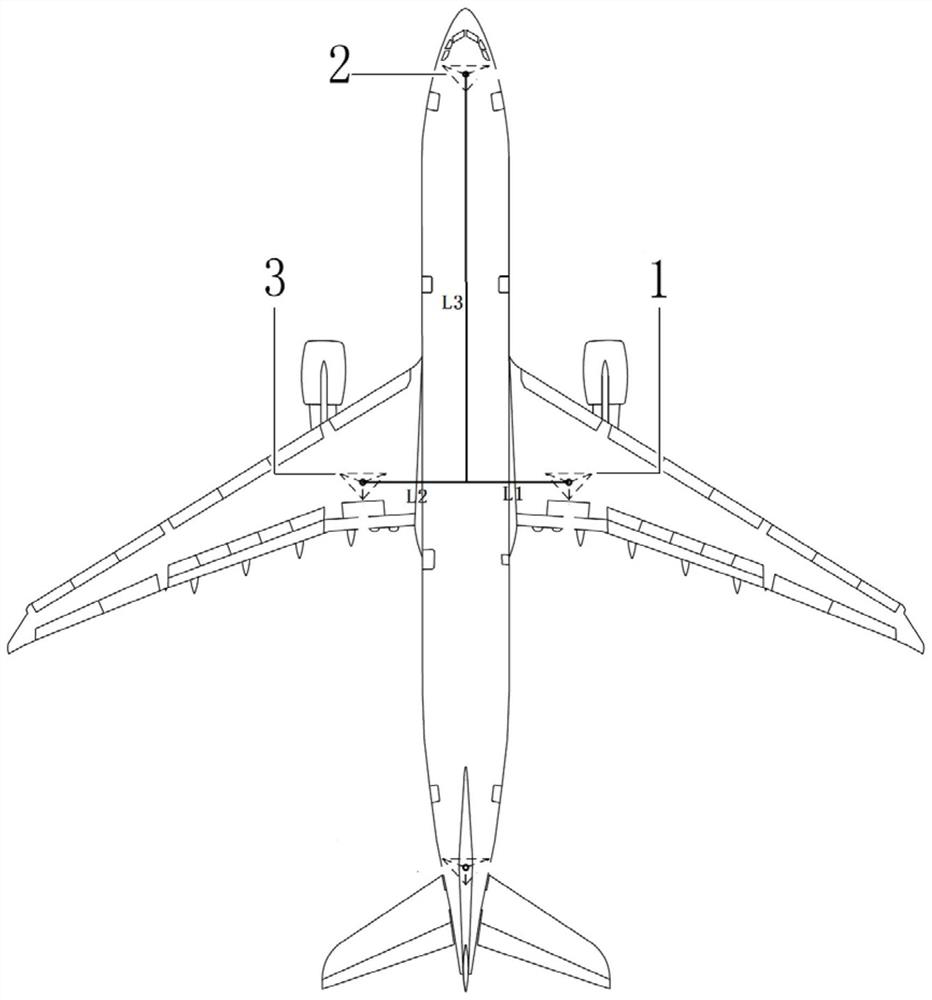

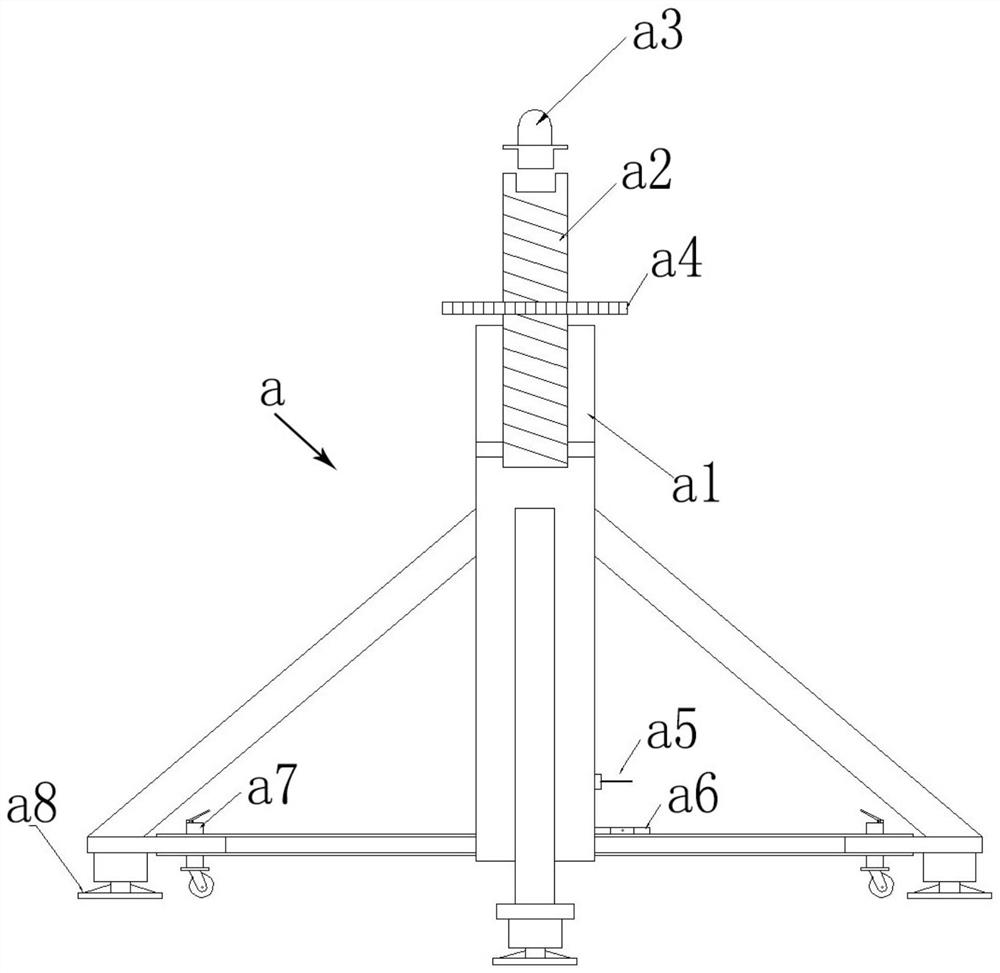

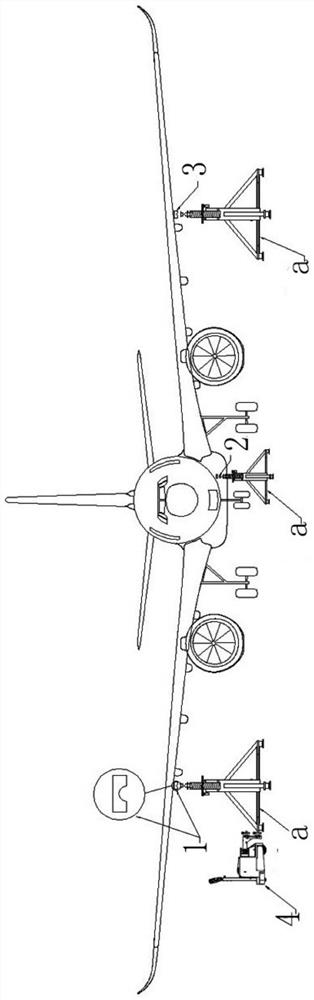

Method for integrally jacking airplane

ActiveCN112194034AReduce work intensityImprove jacking efficiencyLifting devicesAircraft maintainanceAutomatic controlLight beam

The invention discloses a method for integrally jacking an airplane. The method comprises the steps that S1, the airplane is adjusted to be horizontal; S2, a tractor is used for dragging a plurality of jacks to the position, below corresponding top nests, of the airplane, and the centers of the top nests are positioned through a light beam emitter; S3, the jacks are adjusted to be horizontal, andthe positions of the jacks are finely adjusted to enable light beams emitted by the light beam emitter to vertically irradiate the centers of the corresponding top nests; S4, a power switch of each jack is turned on through an automatic control program, so that lifting cylinders of the jacks synchronously ascend, the airplane is lifted to the required target height, safety nuts on the lifting cylinders are driven to rotate through a motor while the lifting cylinders of the jacks ascend, and thus a constant distance is kept between the safety nuts and the outer cylinders of the jacks; and S5, the lifting cylinders of the jacks are synchronously descended until the jacks are separated from the top nests of the airplane after the airplane is maintained and detected, and the airplane is put down. The airplane jacking efficiency can be improved, and the labor intensity can be reduced.

Owner:GUANGZHOU AIRCRAFT MAINTENANCE ENG

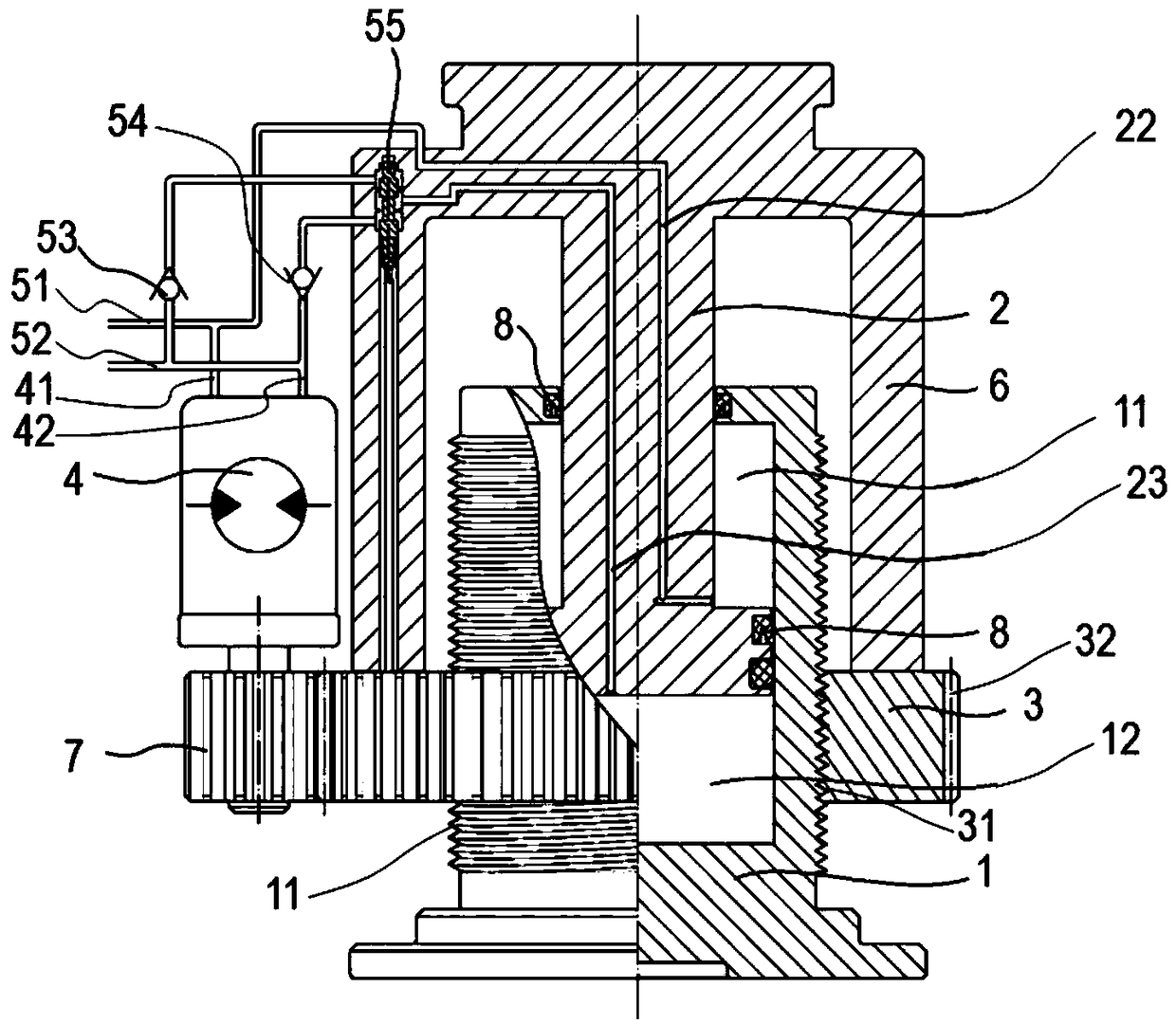

Backflow prevention device

PendingCN111706685AEasy to makeImprove jacking efficiencyCheck valvesSlide valveBackflow prevention deviceStructural engineering

The invention discloses a backflow prevention device. The backflow prevention device includes a stop valve; the stop valve includes a tubular valve body and a plurality of valve gates inserted on thepipe wall of the valve body; the upper and lower ends of the valve body are used to be tightly connected between a pipe column to be poured and a pouring material delivery pipe; when pouring, the valve gates are pulled out from the valve body, so that the pouring material in the pouring material conveying pipe is lifted into the pipe column through the valve body; and after the pouring is completed, and when the pouring material delivery pipe is disassembled, the valve gates are inserted and passed out of the valve body to prevent the pouring material in the pipe column from gushing down fromthe valve body. The backflow prevention device disclosed by the invention is simple to manufacture, can be used repeatedly, can effectively improve the jacking efficiency, and can reduce a large amount of manual rework.

Owner:MCC5 GROUP CORP SHANGHAI

Washing machine shell punch forming mold with demolding assembly

InactiveCN113275438AEasy to take outImprove jacking efficiencyEjection devicesLaundry washing machineStructural engineering

The invention discloses a washing machine shell punch forming mold with a demolding assembly. The washing machine shell punch forming mold comprises a base, a lower mold seat and a mold cavity, an installation space is formed in the bottom of the lower mold seat, jacking rods are vertically arranged on the installation space in a penetrating mode, the multiple jacking rods are driven by a jacking assembly to move upwards, and the top ends of the jacking rods extend into the mold cavity. By arranging the jacking rods, the jacking rods are driven by the jacking assembly to move upwards, so that the washing machine shell in the mold cavity is jacked out by the jacking rods until the washing machine shell is separated from the contact state of the inner bottom wall of the mold cavity, a worker can conveniently take out the washing machine shell subjected to punch forming from the mold cavity, and the working efficiency is improved; and the jacking assembly is arranged, a rotating driving unit drives a rotating shaft to rotate, so that a plurality of cams synchronously drive the multiple jacking rods to move, the jacking rods move upwards, then the multiple jacking rods synchronously abut against the washing machine shell, and the jacking efficiency of the washing machine shell is improved.

Owner:滁州市东华模具制造有限公司

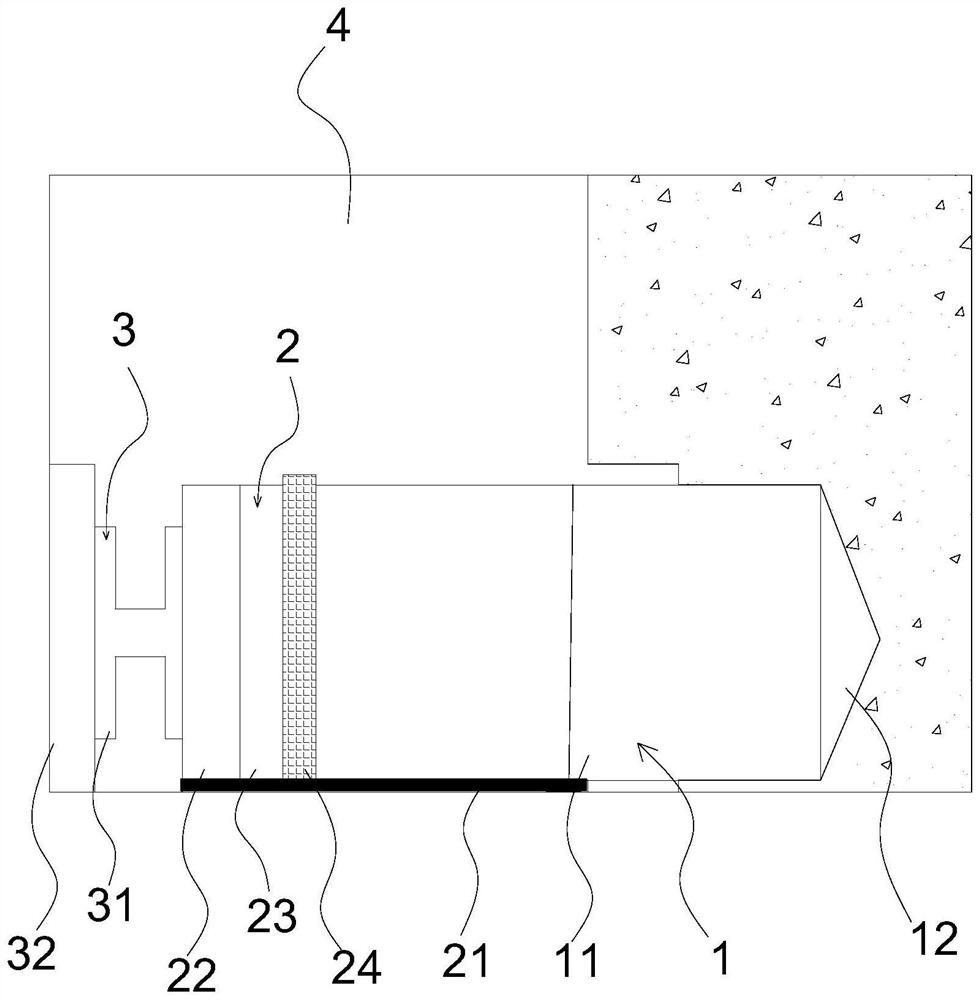

Multi-cylinder synchronous jacking system for tower crane and tower crane

ActiveCN109654076BSolve the technical problem of unsynchronized lifting of oil cylinderImprove securityFluid-pressure actuator testingServomotor componentsMarine engineeringArchitectural engineering

The invention relates to the technical field of hydraulic equipment, and discloses a multi-oil-cylinder synchronous jacking system for a tower crane and the tower crane. The multi-oil-cylinder synchronous jacking system for the tower crane comprises an oil supply main oil path, a first reversing valve, at least two jacking oil cylinders, a first jacking control oil path, a second jacking control oil path and a speed adjusting valve, wherein the speed adjusting valve can control the flow of oil liquid entering the jacking oil cylinders, and accordingly the jacking oil cylinders can synchronously run. The multi-oil-cylinder synchronous jacking system effectively solves the technical problem that oil cylinder jacking of a double- cylinder jacking system is not synchronous, due to great improvement of the synchronous performance, the safety of the jacking system is enhanced, and the service life of guiding wheels is effectively prolonged. The jacking process is smoother, the operation timeis shortened, and efficiency is improved.

Owner:ZOOMLION HEAVY IND CO LTD

A kind of screw top drilling construction method

The invention relates to a construction method for auger jacking, which includes a screw jacking system. The screw jacking system includes a jacking device, a rotating device, a threaded pipe cap and a multi-section spliceable threaded pipe joint. The outer wall of the threaded pipe joint is Threads are provided, and a plurality of threaded pipe joints are spliced head to tail to form a threaded pipe body, the threaded pipe cap is connected to the front end of the threaded pipe body, and the rotating device is arranged at the rear end of the threaded pipe body for In order to drive the threaded pipe body and the threaded pipe cap to rotate, the jacking device is arranged at the rear end of the rotating device to push the rotating device, the threaded pipe body and the threaded pipe cap forward During construction, there is no need to drill pilot holes, ream holes and discharge soil first, which can simplify the construction process, increase jacking efficiency, shorten the construction period, reduce construction safety and quality risks, reduce pipeline damage and overheating of jacking equipment The risk of damage, economic and social benefits are significantly improved.

Owner:GUANGZHOU NO 2 MUNICIPAL ENG CO LTD

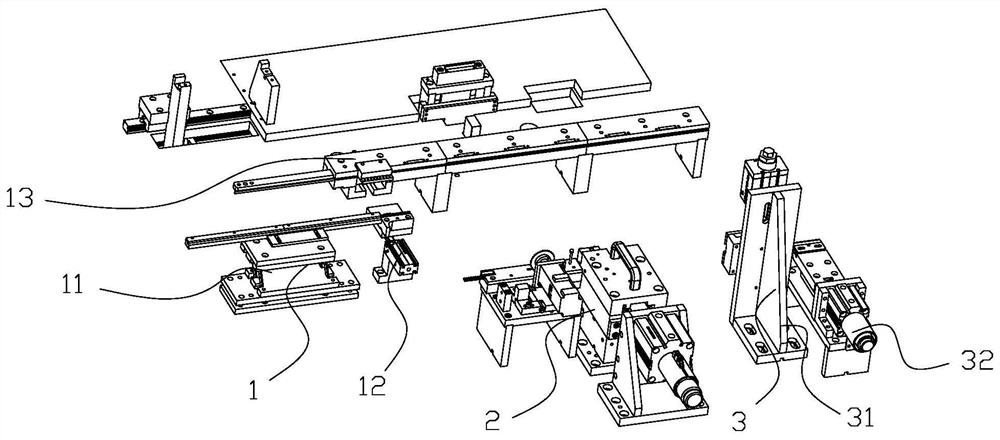

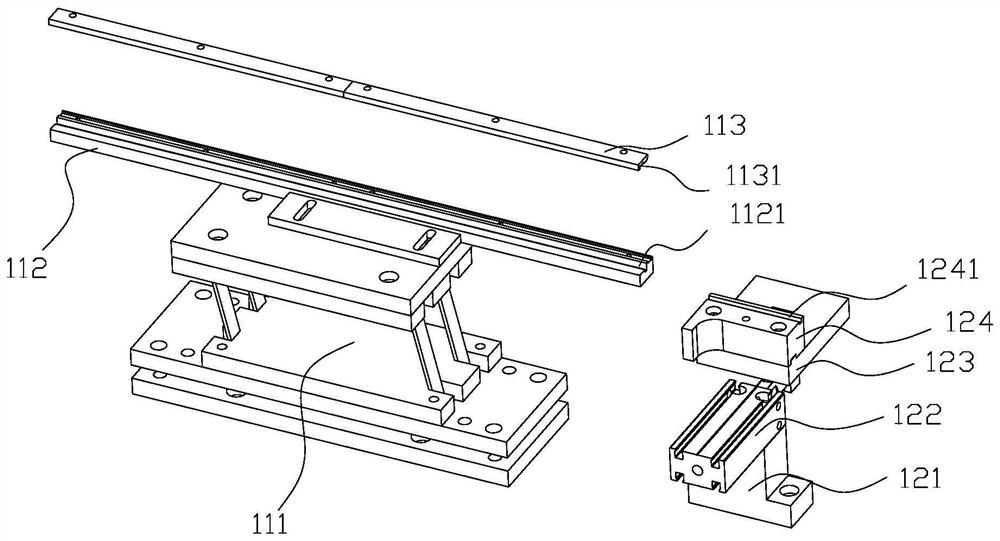

Jacking jig frame for main beam assembly

PendingCN111069828AImprove jacking efficiencySmall footprintWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsEngineering

The invention relates to a jacking jig frame for a main beam assembly. The jacking jig frame for the main beam assembly is characterized in that the jig frame comprises support frames, longitudinal jacking seats, jacking adjusting modules, jacking plates, a jacking cross beam and lateral jacking movement modules, wherein each jacking adjusting module adopts a lead screw transmission type structure, and adjusting handles can move horizontally, so that the longitudinal height adjustment is more convenient; and conveying rollers are arranged on the jacking cross beam, so that the lateral jackingmovement modules are capable of horizontally moving the main beam assembly with less labor and higher efficiency. The jacking jig frame for the main beam assembly is high in jacking efficiency, smallin occupied area, simple to operate and flexible to adjust.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

Female header feeding and conveying device and method for producing pin header connection terminals

InactiveCN111846859APrevent fallingHigh conveying positioning accuracyContact member assembly/disassemblyJigging conveyorsAnimal scienceMedicine

The invention belongs to the technical field of automatic production of electronic connectors. A female header feeding and conveying device for producing pin header connection terminals comprises a female header feeding component, a female header transfer component and a female header horizontal conveying component; the discharge end of the female header feeding component is connected to the female header transfer component, and the female header feeding component is used for transporting the female header to the female header transfer component; the female header transfer component is connected to the front side of the feeding end of the female header horizontal conveying component, and the female header transfer component is used for pushing and transferring the female header to the female header horizontal conveying component; and the female header horizontal conveying component is used for performing ordered horizontal transportation on the female header. The advantages of the female header feeding and conveying device and method for producing the pin header connection terminals are as follows: the conveying efficiency of the female headers is improved, the spaced conveying ofthe female headers one by one is convenient, the conveying positioning accuracy is improved, and the overall assembly quality of the female header and pin header is improved.

Owner:陈如会

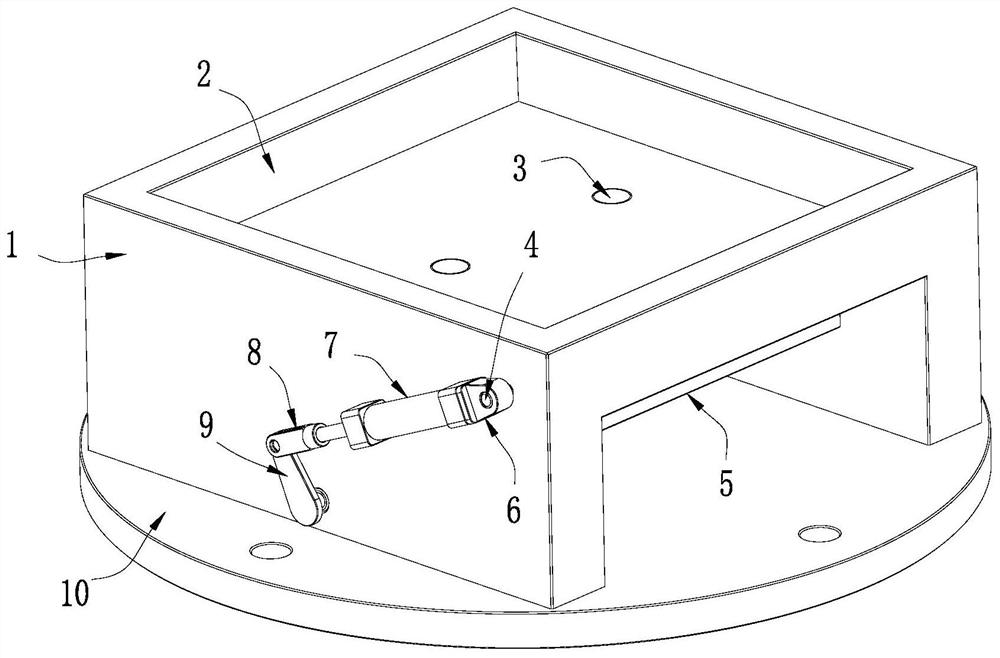

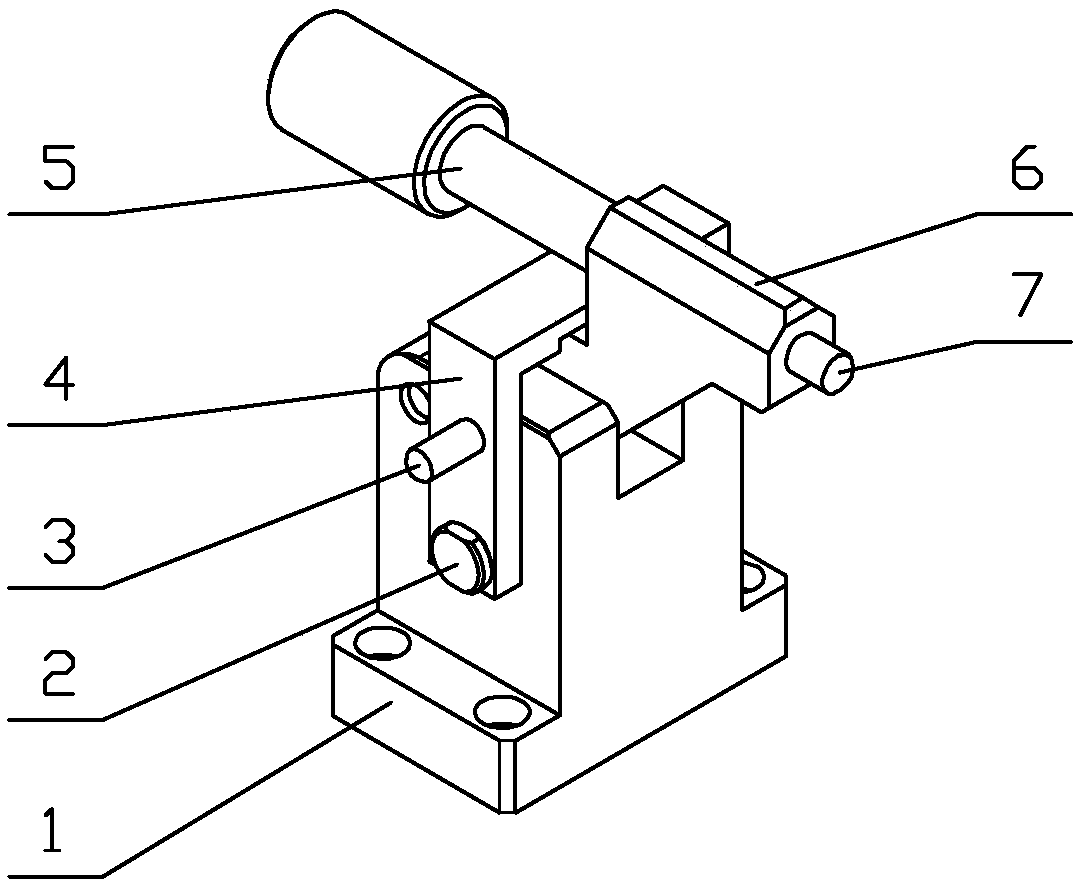

Quick turn top tightening mechanism

ActiveCN106624958BTight and reliableExpand the range of processingMetal working apparatusFree rotationEngineering

The invention relates to a rapid overturning and tightly-abutting mechanism. An installation groove is formed in the top of the installation seat. An overturning block is hinged to the installation seat through small hinge shafts installed on side plates on the two edges of the installation groove. The small hinge shafts are installed on the side plates on the two edges of the installation groove. The overturning block can freely rotate with the small hinge shafts as the rotation center. When the overturning block is overturned to a limiting position, the overturning block abuts against the bottom of the installation groove. The overturning block is provided with a pin hole. A tightly-abutting shaft is assembled in the pin hole and can axially and freely move in the pin hole. A screwing-down handle is connected to threads at the left end of the pin hole in a threaded manner. The right end of the screwing-down handle is connected with the tightly-abutting shaft. The right end of the tightly-abutting shaft is used for tightly abutting against a workpiece and locating the workpiece. An overturning frame is hinged to the installation seat through hinge shafts. The hinge shafts are installed on the installation seat. The overturning frame can freely rotate with the hinge shafts as the rotation center. When overturning to the limiting position upwards, the overturning frame presses the overturning frame without exerting force. The rapid overturning and tightly-abutting mechanism is convenient to operate and capable of reliably and tightly abutting against the workpiece, rapidly leaving a workpiece machining area, expanding the machining range and shortening the operation time.

Owner:WUXI BEST PRECISION MACHINERY

Pin header feeding and assembling device and method for pin header female connector production

InactiveCN111884004AImprove the accuracy of conveying positioningImprove cutting quality and cutting efficiencyContact member assembly/disassemblyEngineeringStructural engineering

The invention belongs to the technical field of automatic production of electronic connectors. The invention discloses a pin header feeding and assembling device for pin header connecting terminal production. The pin header feeding and assembling device comprises a pin header feeding assembly, a pin header conveying assembly, a pin header cutting and inserting assembly and a pin header waste bending assembly. The pin header feeding assembly conveys a pin header material belt to the pin header conveying assembly. The pin header conveying assembly is used for conveying a pin header material beltto the pin header cutting assembly in order, and the pin header cutting and inserting assembly is connected with the discharging end of the pin header conveying assembly. The pin header cutting and inserting assembly is used for cutting a group of pin header strips and then clamping and inserting the pin header strips into the female header; the pin header waste bending assembly is used for bending pin header waste on the pin header material belt. The pin header conveying device has the advantages that the pin header conveying efficiency and conveying positioning accuracy are improved, the pin header cutting efficiency and cutting quality are improved, and the quality is improved through pin header insertion.

Owner:陈如会

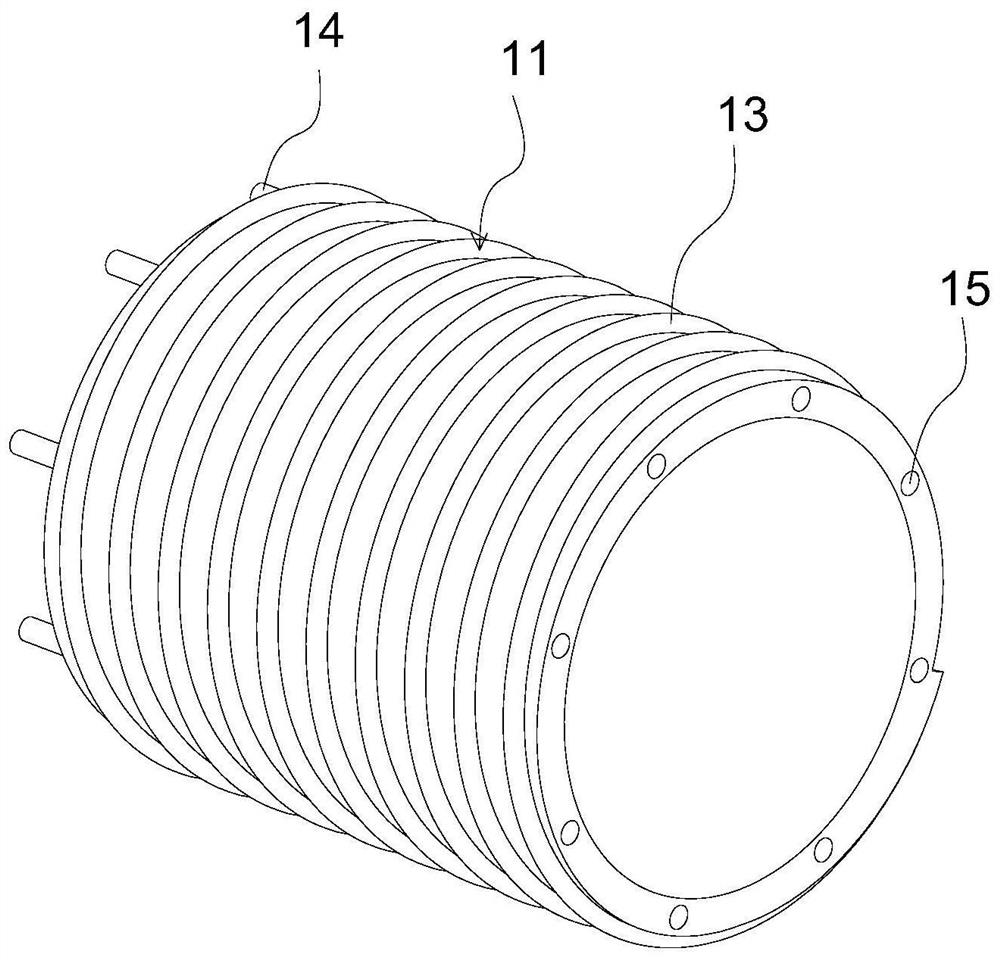

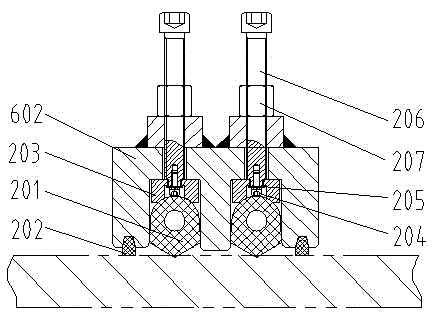

A rolling support type sealing device for the relay room of the rectangular shield pipe jacking machine

ActiveCN104132140BExtended service lifeImprove safety and reliability performanceEngine sealsShaft and bearingsEngineeringMechanical engineering

A rolling supporting type sealing device for an intermediate jacking station of a rectangular shield tube jacking machine comprises a supporting wheel device and an adjustable sealing device. The supporting wheel device and the adjustable sealing device are both arranged on a step face at the tail portion of a front casing, and the supporting wheel device and the adjustable sealing device are respectively fixed to the two ends of a blocking plate in a rear casing. The supporting wheel device comprises an external slide rail, a shield seal, a mandrel, an inner sliding beam, a stopping sealing cover and a puller bolt, wherein a supporting wheel is arranged on the inner sliding beam through the mandrel, the inner sliding beam is surrounded by the external slide rail, the stopping sealing cover is fixed to the external slide rail, and the puller bolt penetrates through an internal thread of the stopping sealing cover and is tightly attached to the top of the inner sliding beam. The supporting wheel device can roll relative to the tail portion of the front casing and can effectively guarantee the gap between the tail portion of the front casing and a foundation ring. Thus, the stability of the compression amount between the shield seal and the tail portion of the front casing is guaranteed, the service life of the shield seal is prolonged, the fitting degree between the jacking direction and the tunnel axis is improved, and the jacking efficiency is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Automatic jacking tower crane structure

The invention belongs to the field of tower cranes, and particularly relates to an automatic jacking tower crane structure which comprises a jacking frame fixedly installed at the lower end of a tower crane rotary table, two hydraulic cylinders A, guide wheels, a tower section, an upward jacking mechanism and the like. The tail ends of the two hydraulic cylinders A are provided with push plates which are used for horizontally pulling the tower section which is hoisted to the platform through the hoisting trolley into the jacking frame; two hydraulic cylinders A can hoist a crane carriage to a tower section on a platform through a push plate to automatically pull the tower section into a jacking frame, and after the tower section is pulled into the jacking frame, an electric push rod B pushes a corresponding locking block to be inserted into a locking groove in a corresponding fixing block A to fasten and lock the tower section; and the reciprocating swing of the hydraulic cylinder B in the jacking process of the rotary table is completed by the electric push rod A, so that unmanned operation to a certain degree is realized, and effective technical support is provided for the subsequent intelligent unmanned operation of the tower crane.

Owner:JIANGXI ZHONGTIAN INTELLIGENT EQUIP CO LTD

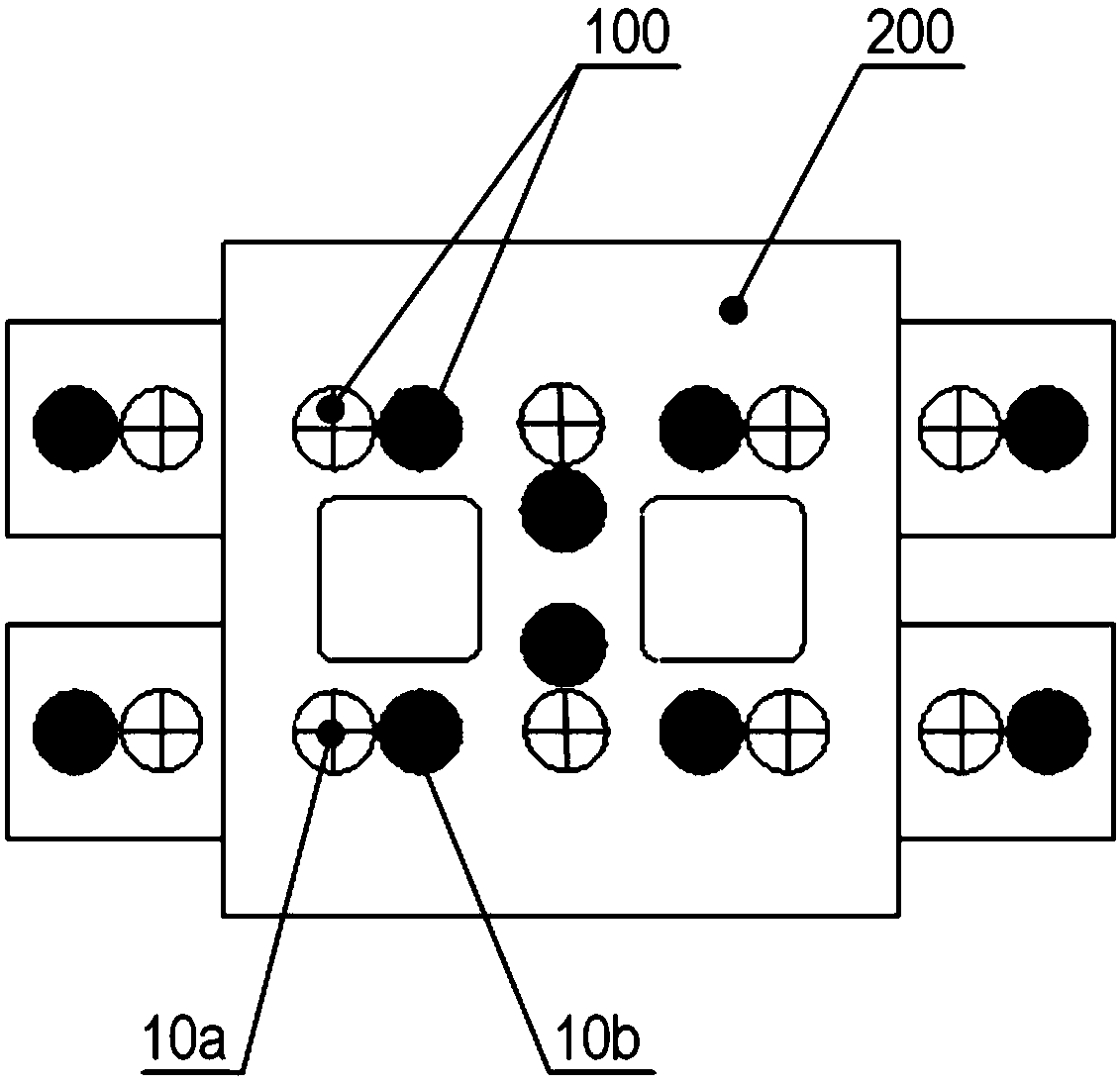

Pin header cutting and press-fitting device and method for pin header connecting terminal production

InactiveCN111834859AEasy to cut off at one timePrevent looseningContact member manufacturingContact member assembly/disassemblyEngineeringElectrical connector

The invention belongs to the technical field of automatic production of electronic connectors, and discloses a pin header cutting and press-fitting device for pin header connecting terminal production. The pin header cutting and press-fitting device comprises a pin header waste cutting assembly and a pin header press-fitting assembly, wherein the pin header waste cutting assembly is used for cutting pin header waste, and the pin header press-fitting assembly is located on the discharging end side of the pin header waste cutting assembly and used for pressing pin headers into pin header groovesof a female header; the pin header waste cutting assembly comprises a pin header waste cutting support, a pin header waste cutting drive module and a pin header waste cutting module; the pin header press-fitting assembly comprises a pin header press-fitting support, a pin header press-fitting driving module and a pin header press-fitting module. The pin header cutting and press-fitting device hasthe advantages that the pin header waste cutting quality is improved, the pressing quality of the pin headers and the female header is improved, and the overall assembling quality of the female header and the pin headers is improved.

Owner:陈如会

Screw rod positioning device of elevator

ActiveCN101462675AEasy to install and adjust the radial clearanceReasonable structureLifting devicesEngineeringMechanical engineering

The invention relates to a screw rod positioning mechanism for a hoisting machine. The accuracy of verticality of a screw rod in a pipe body of the hoisting machine is greatly improved by setting axial and radial positioning at the input end of the screw rod, so as to improve the jacking efficiency of the hoisting machine, prolong the service life and improve the convenience of operation.

Owner:NINGBO TIANYI SHAFT

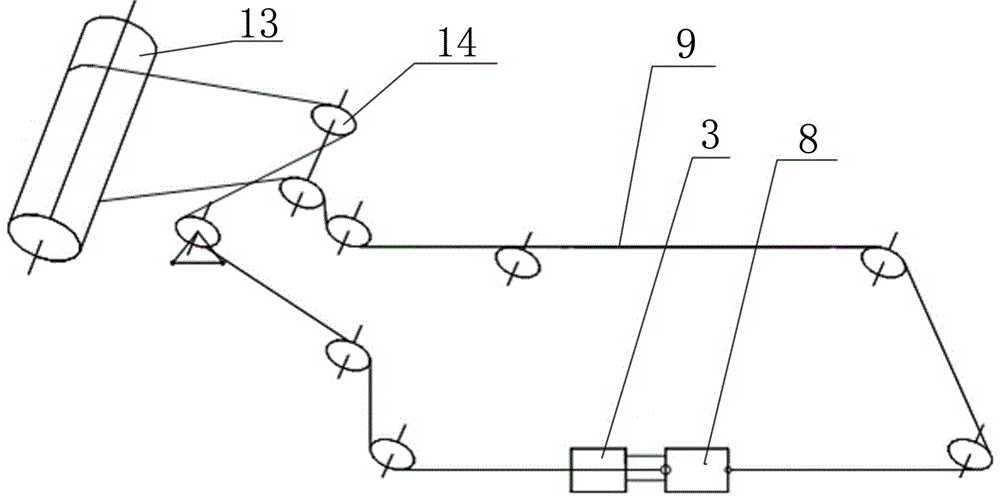

Standard knot lead-in device for self-lifting tower crane

The invention discloses a standard knot lead-in device for a self-lifting tower crane. The standard knot lead-in device comprises a top bearing base located at the upper end of a tower body, a cargo boom installed at the upper end of the top bearing base in a hinged mode, a peripheral sleeving frame installed between the lower end of the top bearing base and the upper end of the tower body in a sleeved mode, a front trolley, a rear trolley, a front pulley set and a rear pulley set, wherein the front trolley and the rear trolley are installed in the positions, at the bottom of the cargo boom, of a guide rail; the front pulley set is installed on the front trolley and composed of a front fixed pulley and a front movable pulley; and the rear pulley set is installed on the rear trolley and composed of a rear fixed pulley and a rear movable pulley. A space which is formed in an inner cavity of the peripheral sleeving frame and located between the two adjacent ends of the top bearing base and the tower body is an installation position of a to-be-led-in standard knot. The front and rear movable pulleys as well as the corresponding front and rear fixed pulleys are all provided with stand-by pin shaft holes. According to the standard knot lead-in device for the self-lifting tower crane, another equipment does not need to be arranged in the heightening process of the tower body, connection parts between the tower body and the top bearing base do not need to be disassembled and assembled repeatedly, continuous jacking operation is achieved, and the jacking efficiency is greatly improved; and meanwhile balance of the cargo boom of the tower crane is considered.

Owner:KERUN ELECTRO MECHANICAL ENG

Intelligent unmanned tower crane jacking device

PendingCN114735603AReduce processImprove jacking efficiencyCranesArchitectural engineeringTower crane

The invention belongs to the field of tower cranes, and particularly relates to an intelligent unmanned tower crane jacking device which comprises a jacking sleeve, an outer sleeve, an inner rod, a reset spring, a guide wheel, a guide sleeve, a limiting rod, a tower body section frame, a clamping block A, a jacking mechanism and an electric push rod. Wherein the top sleeve is nested outside a plurality of tower body section frames which are sequentially stacked and connected together through high-strength bolts, two layers of outer sleeves are mounted on the inner side of the top sleeve, and eight symmetrical outer sleeves are arranged in each layer; the transmission connection cooperation between the telescopic structures where any two opposite guide wheels are located can effectively prevent the rotary base from shaking relative to the tower body section frame in the lifting process due to the fact that the balance arm and the cargo boom are unbalanced. The transmission connection cooperation between the telescopic structures where any two opposite guide wheels are located ensures that the tower body section frame with the inaccurate or deformed appearance cannot be stuck with the guide wheels in the jacking process.

Owner:JIANGXI ZHONGTIAN INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com