A rolling support type sealing device for the relay room of the rectangular shield pipe jacking machine

A technology of sealing device and rolling support, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of self-weight of pipe joints, extrusion of two seals, damage of tread surface roughness, etc., to improve safety and reliability. , prolong the service life and improve the effect of jacking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

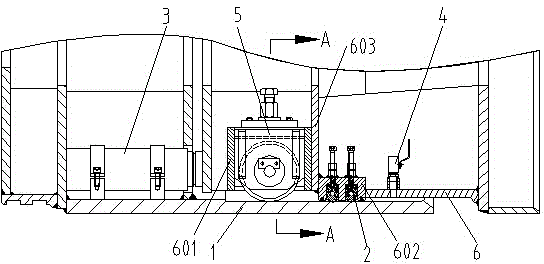

[0020] A rolling support type sealing device between relays of rectangular shield pipe jacking machines, such as figure 1 As shown, it includes a support wheel device 5 and an adjustable sealing device 2 . The supporting wheel device 5 and the adjustable sealing device 2 are all located on the tread at the rear of the front housing 1 , and the supporting wheel device 5 and the adjustable sealing device 2 are respectively fixed on both sides of the baffle plate 603 in the rear housing 6 .

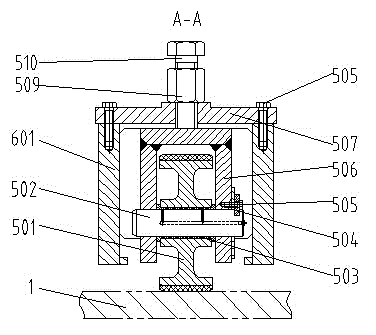

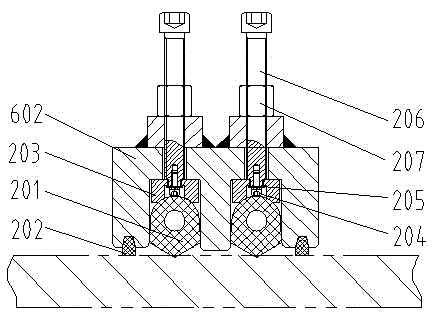

[0021] The support wheel device 5 includes an outer slide rail 601, a shield seal 201, a mandrel 502, an inner sliding beam 506, a stop cover 507 and a jacking bolt 510, such as figure 2 shown. The supporting wheel device 5 is fixed on the baffle plate 603 of the rear housing 6 through the outer slide rail 601 . A shaft sleeve 503 is provided between the wheel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com