Steel casing pulling-removal method

A steel casing and steel plate technology, which is applied in construction, sheet pile walls, and foundation structure engineering, can solve the problems that cannot be applied in permeable strata, the casing cannot be removed, and the air pressure control is complicated, so as to improve construction efficiency and speed up removal progress, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

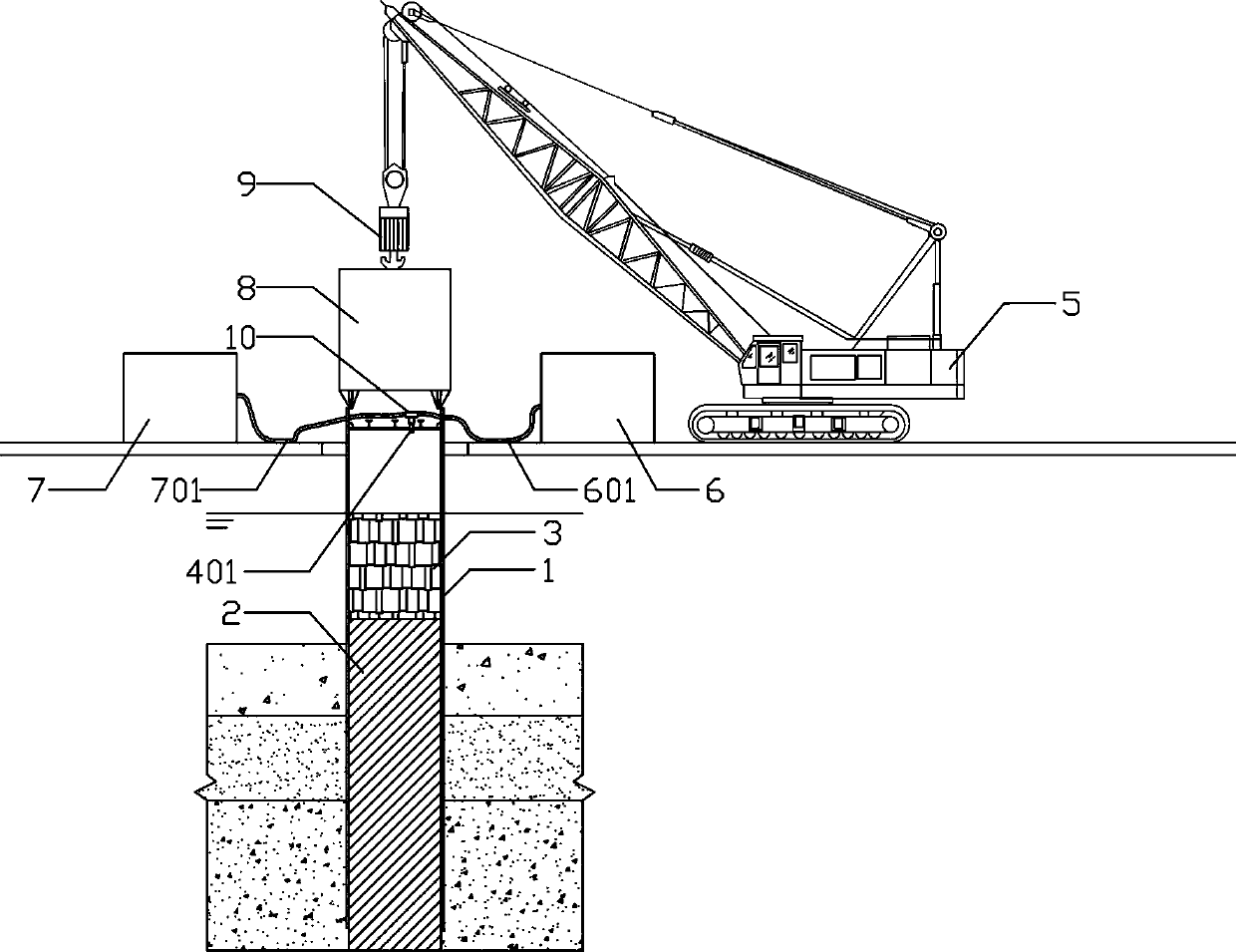

[0050] On the basis of Embodiment 1, the air supply pipe 601 and the liquid supply pipe 701 are connected to the gas-liquid inlet pipe 401 through a three-way 10, and the three-way 10 adopts an L-shaped three-way regulating valve.

Embodiment 3

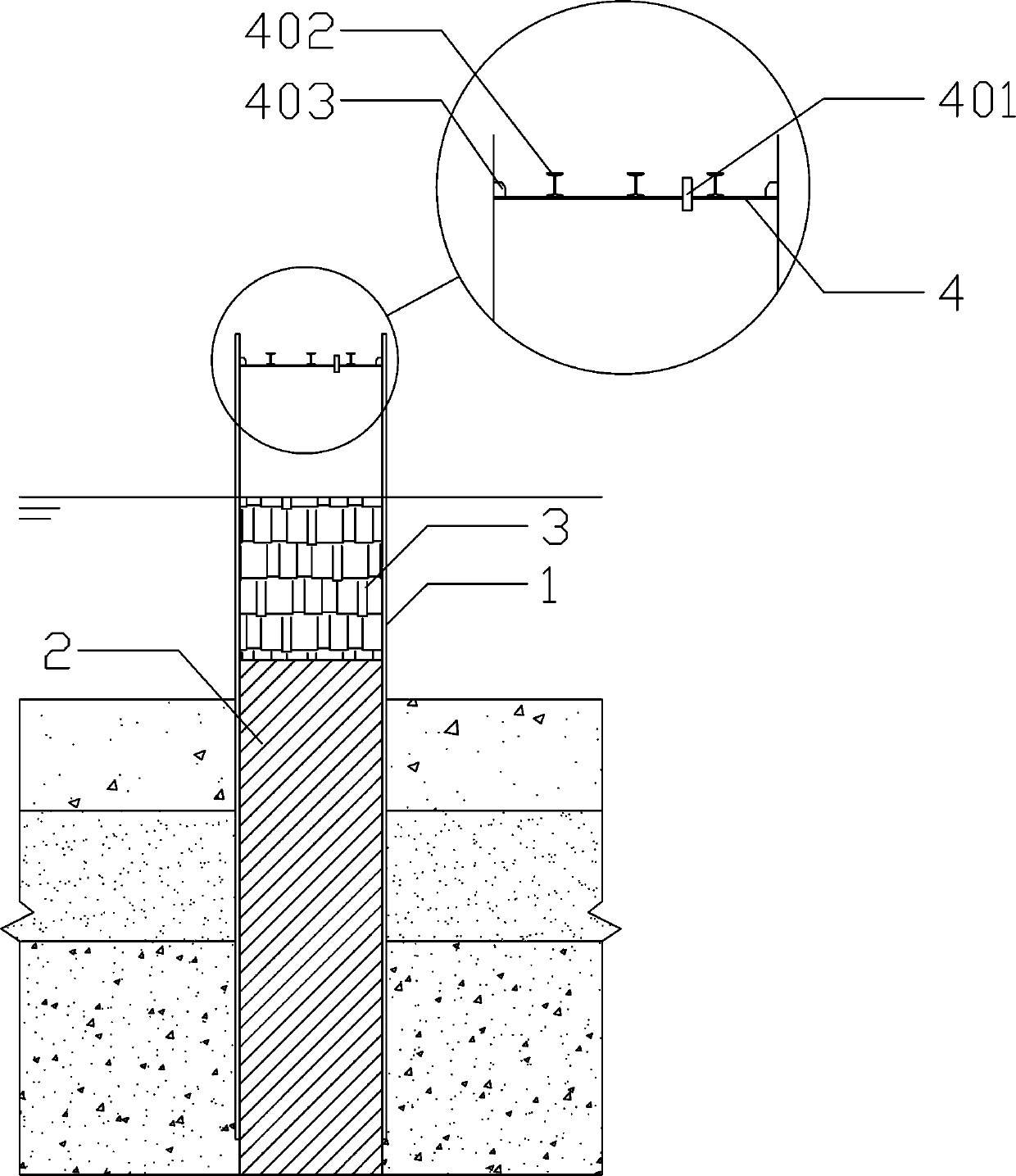

[0052] Such as figure 2 , on the basis of Example 1, in step 2), after the capping steel plate 4 is welded, a plurality of parallel stiffening steels 402 are welded on the top surface of the capping steel plate 4, and at the same time, on the top surface of the capping steel plate 4 and the steel guard A plurality of stiffening plates 403 are welded at equal angles between the inner walls of the barrel 1 .

[0053] The present invention adopts the above-mentioned method of "mud plugging + gas-liquid jacking combination + vibrating hammer weight", which can effectively improve the safety and stability in the construction process of removing the steel casing and ensure the smooth progress of the pulling operation of the steel casing. The extraction of steel casing under stratum conditions provides an effective means.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com