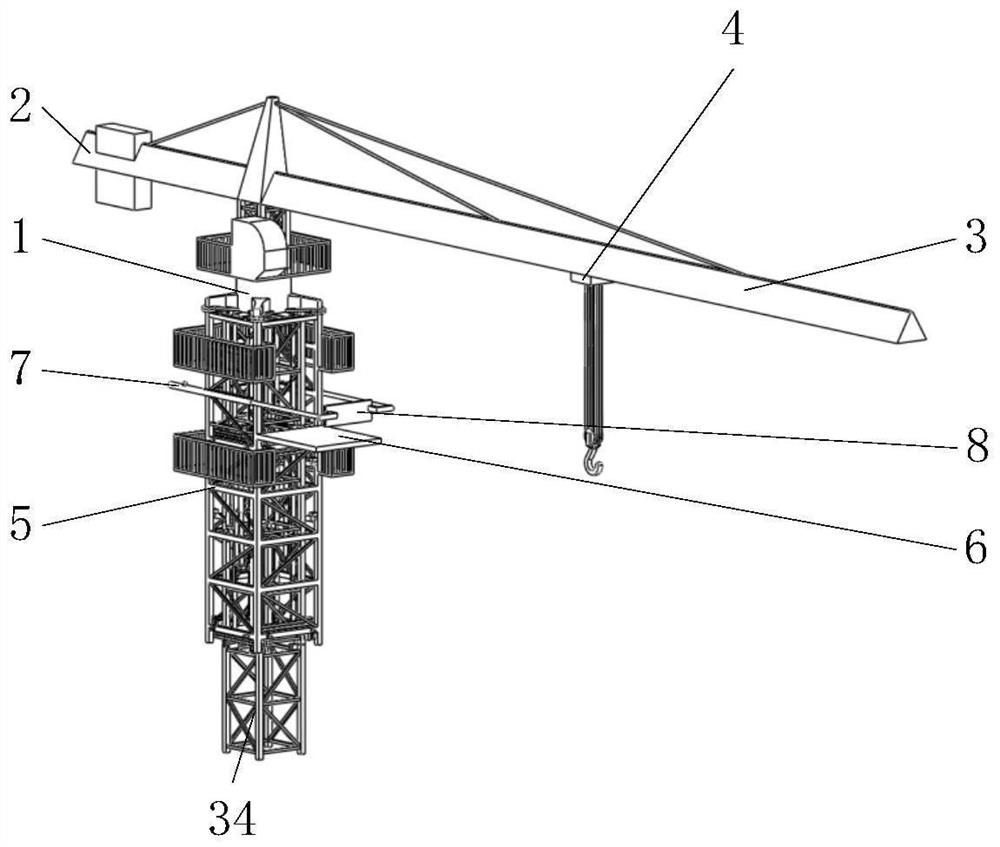

Automatic jacking tower crane structure

A tower crane and automatic technology, applied in the direction of cranes, etc., can solve the problems of increasing the lifting resistance of the hydraulic cylinder, shaking, and the adjustment balance is not in place, so as to improve the lifting efficiency, improve the use effect, and reduce the effect of the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

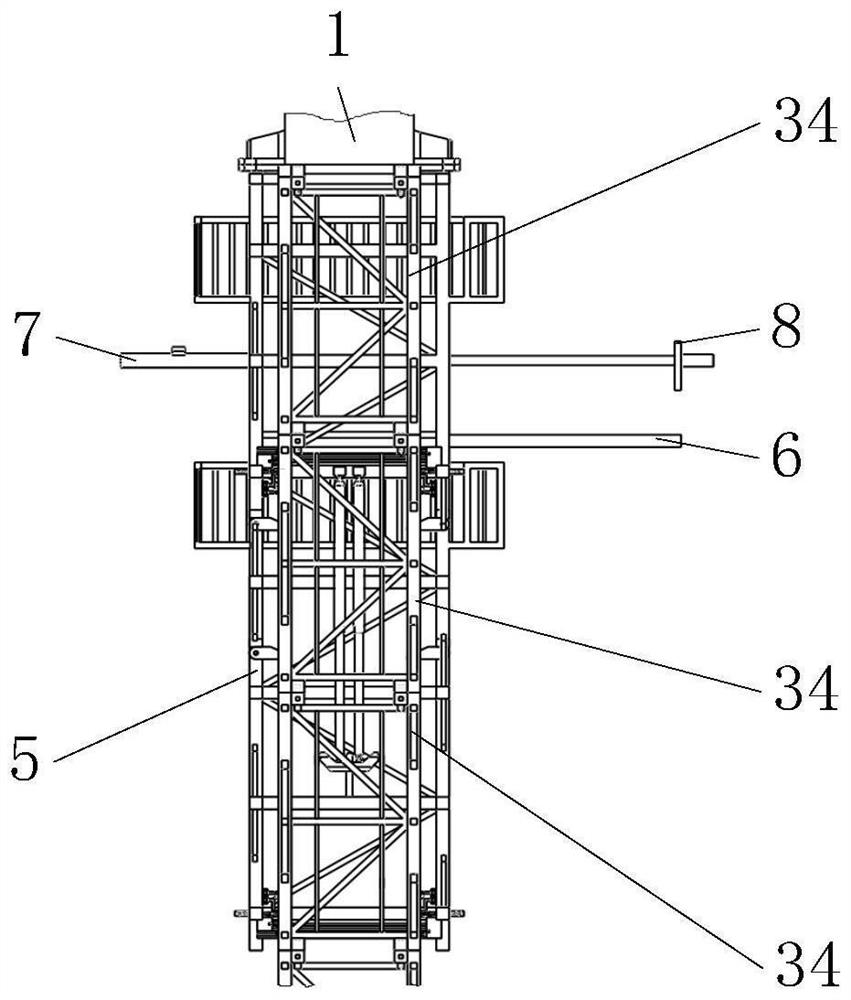

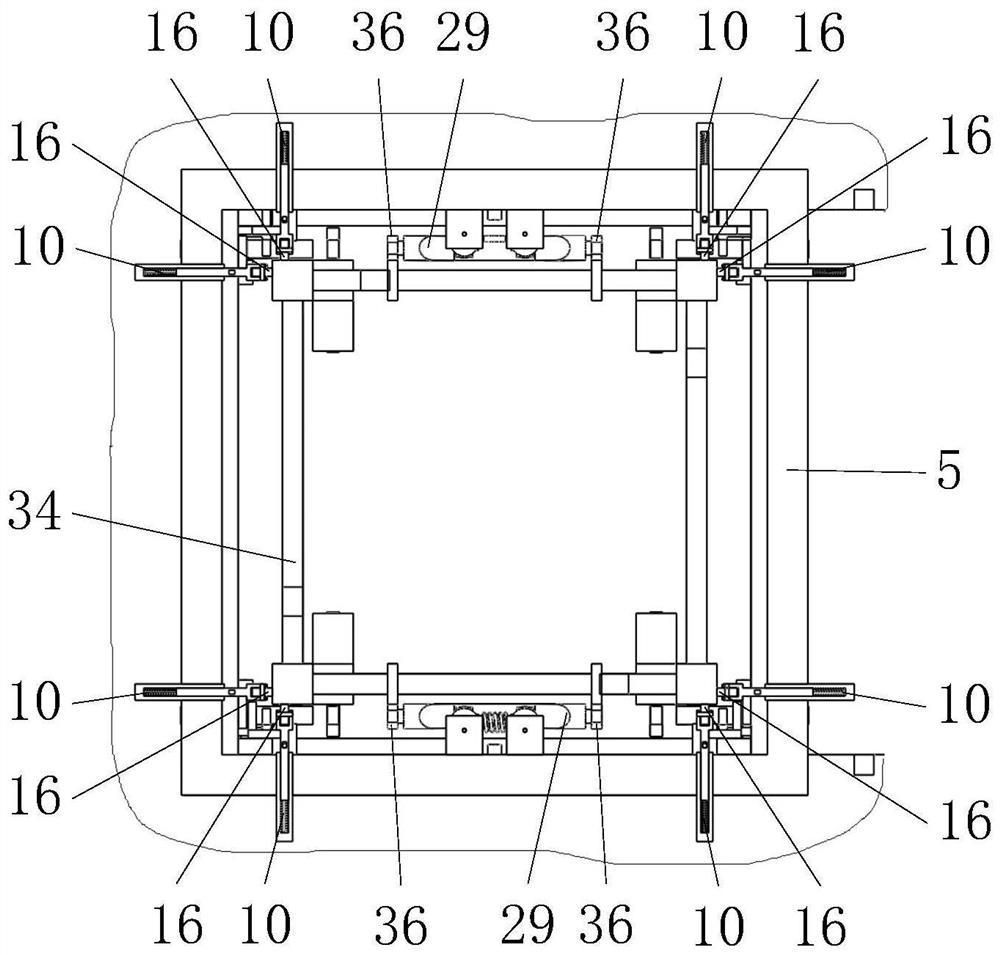

[0038] The accompanying drawings are schematic diagrams of the implementation of the present invention, so as to facilitate the understanding of the operation principle of the structure. The specific product structure and proportions can be determined according to the use environment and conventional techniques.

[0039] like figure 1 , 2 As shown in , 3, it includes a jacking frame 5, a hydraulic cylinder A7, a push plate 8, a jacket 10, an inner rod 12, a spring A15, a guide wheel 16, a guide seat 17, a guide wheel 16, a guide base 17, a guide wheel 16, a Rod A19, electric push rod A33, tower section 34, card plate 36, electric push rod B54, top mechanism 9, such as figure 1 , 6 As shown, two hydraulic cylinders A7 symmetrically distributed on both sides of the platform 6 and horizontally telescopic are installed on the jacking frame 5 nested in the tower section 34. The tower section 34 of the platform 6 is horizontally pulled into the push plate 8 in the jacking frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com