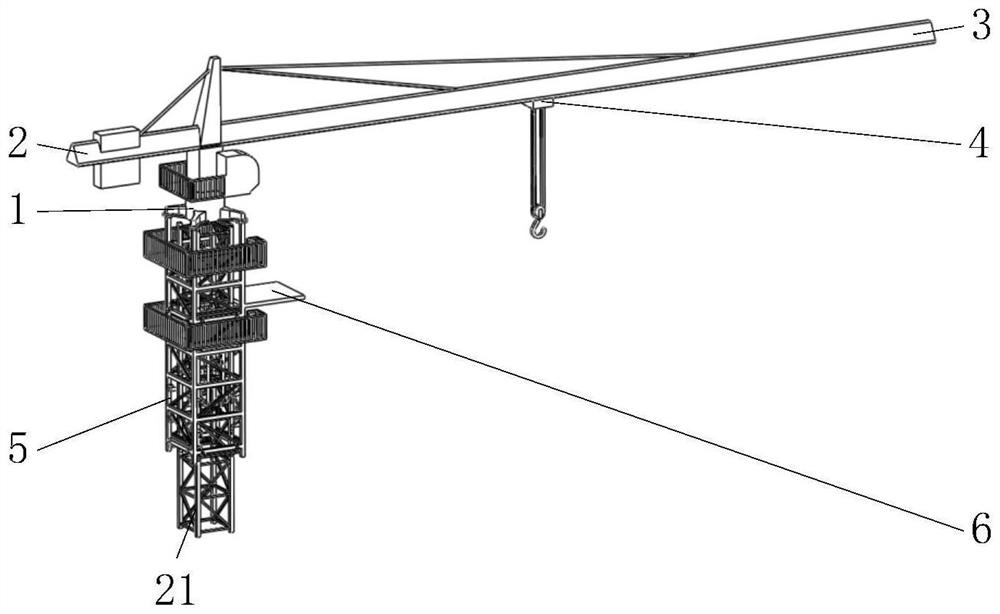

Intelligent unmanned tower crane jacking device

A technology of jacking device and tower crane, which is applied to cranes and other directions, can solve the problems of cumbersome adjustment and balance operation, imprecise shape, shaking of tower body, etc., and achieve the effect of saving process, simple structure and reducing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

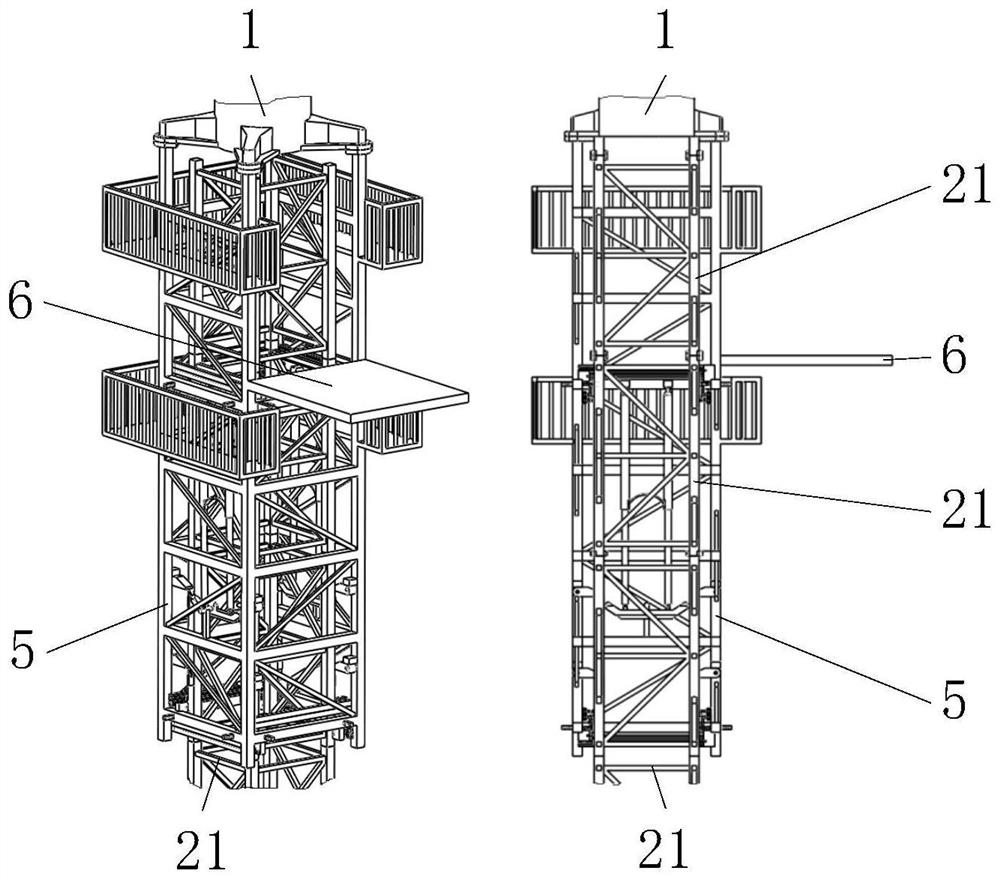

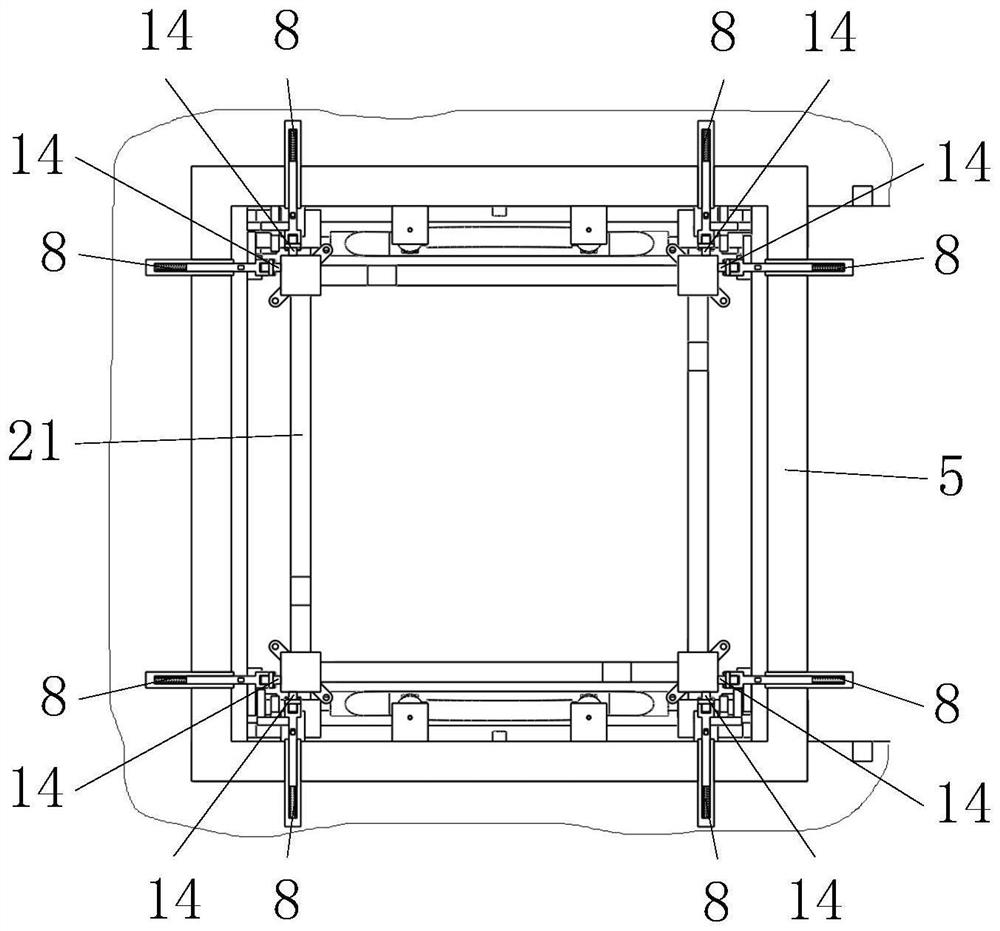

[0031] The accompanying drawings are schematic diagrams of the implementation of the present invention, so as to facilitate the understanding of the operation principle of the structure. The specific product structure and proportions can be determined according to the use environment and conventional techniques.

[0032] like figure 1 , 2 As shown in , 3, it includes a top sleeve 5, an outer sleeve 8, an inner rod 10, a return spring 13, a guide wheel 14, a guide sleeve 15, a limit rod 16, a tower body section frame installed on the lower end of the revolving seat 1 through high-strength bolts 21. Block A22, jacking mechanism 7, electric push rod 28, such as figure 2 , 3 As shown, the top sleeve 5 is nested outside a number of tower body section frames 21 that are stacked and connected together through high-strength bolts in turn, and two layers of outer sleeves 8 are installed on the inside of the top sleeve 5, and each layer has eight symmetrical outer sleeves 8; such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com