Jacking jig frame for main beam assembly

A beam assembly and jacking technology, used in auxiliary devices, auxiliary welding equipment, welding/welding/cutting items, etc., can solve the problems of wide area, inflexible adjustment, single setting, etc. Low effort and high lifting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

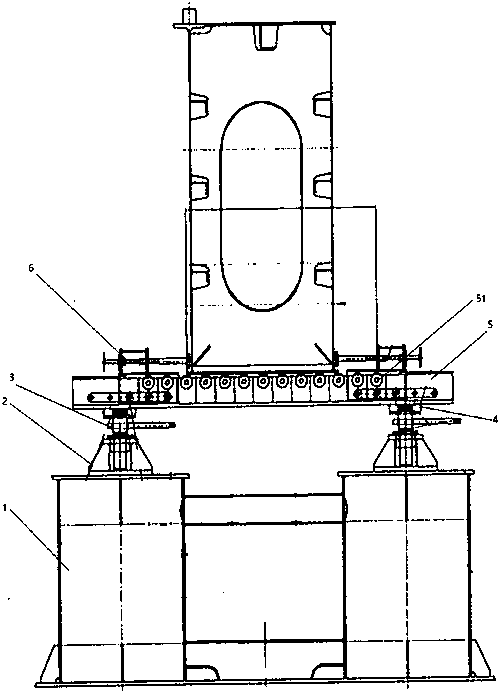

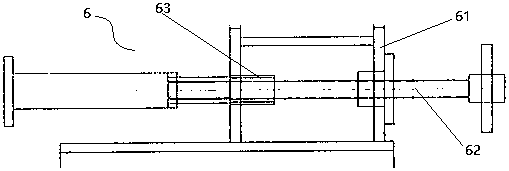

[0021] Such as Figure 1 to Figure 3 The main beam assembly jacking tire frame shown includes a support frame 1 , a longitudinal jacking seat 2 , a jacking adjustment module 3 , a jacking plate 4 , a jacking beam 5 and a lateral jacking module 6 .

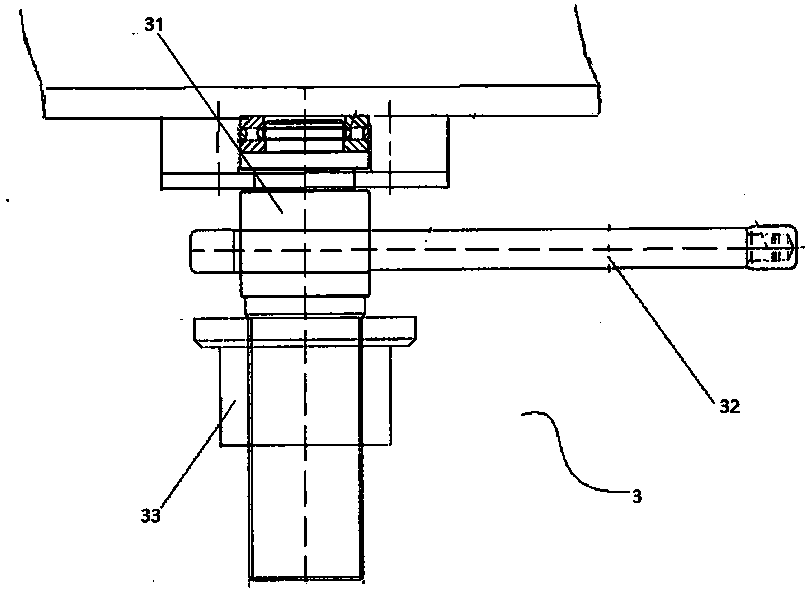

[0022] The bottom end of the longitudinal jacking seat 2 is fixedly connected to the support frame 1, and the longitudinal jacking seat 2 is in a cylindrical structure, and the center of the longitudinal jacking seat 2 is opened along the axis direction to cooperate with the jacking adjustment module 3. through hole.

[0023] The jacking adjustment module 3 includes an adjustment shaft 31, an adjustment handle 32 and an adjustment nut 33; the bottom end of the adjustment nut 33 is fixedly connected to the top of the longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com