Method for integrally jacking airplane

An integral jacking and aircraft technology, applied in aircraft maintenance, lifting devices, etc., can solve the problems of heavy jack, low work efficiency, difficult movement, etc., to reduce the influence of human factors, reduce work intensity, and fast and accurate alignment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

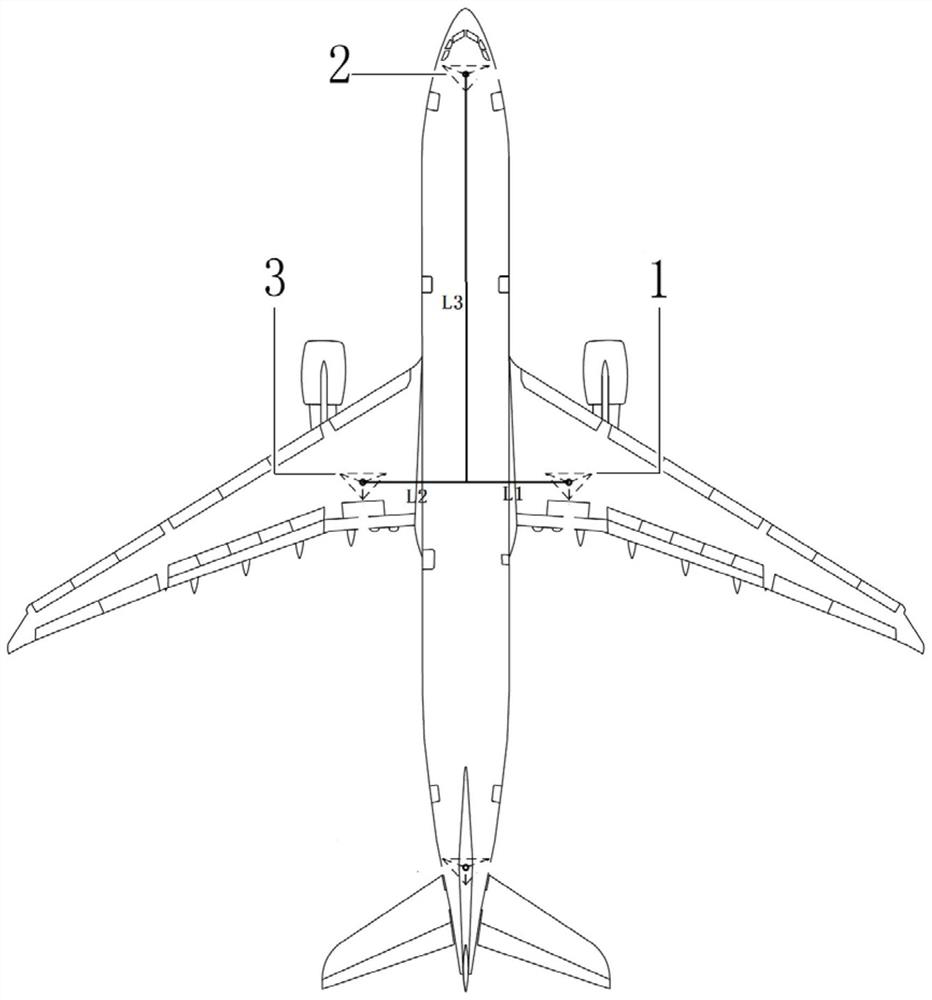

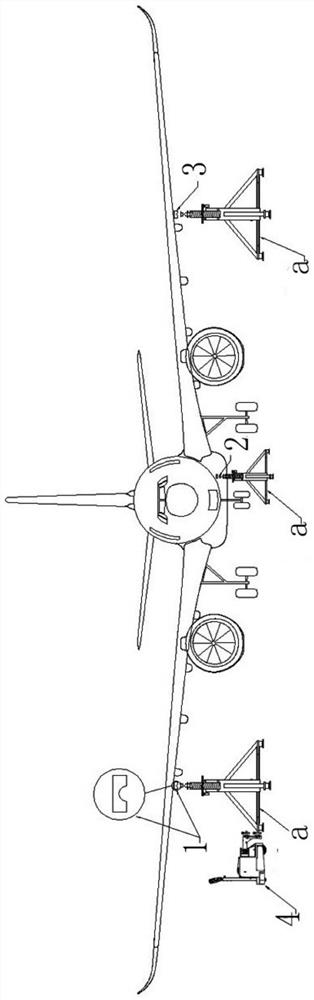

[0048] Such as Figure 3 to Figure 6 As shown, the present embodiment takes the jacking of the Airbus A330 aircraft as an example to illustrate the specific technical content of the present invention.

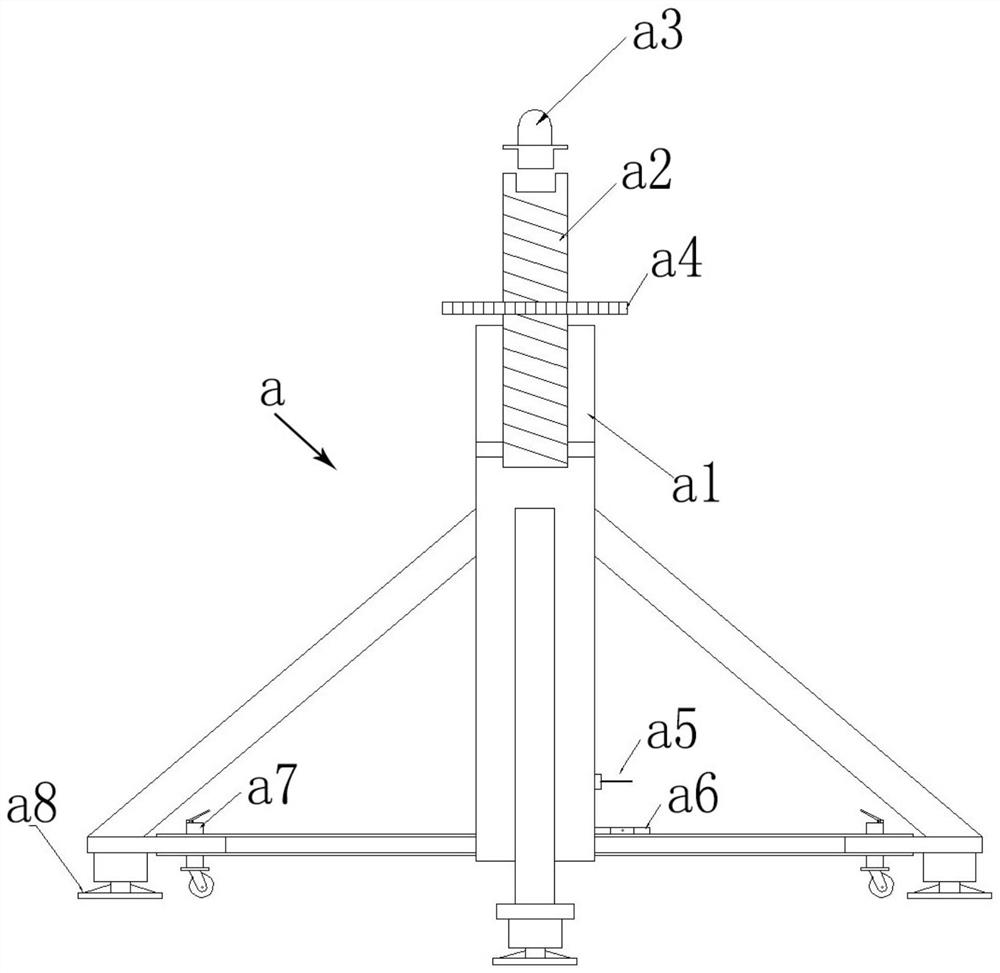

[0049] The present invention has adopted a kind of improved jack, and its working principle is as Figure 4 As shown, a beam emitter a9 is added to the top a3 of the existing jack a, which can emit a positioning beam vertically upwards, and an electronic rangefinder a10 is added to the original lifting cylinder a2 to measure the rise of the lifting cylinder a2 Or the real-time moving distance during the descent process, and send the measurement data to the remote host, and it will be displayed on the display screen, the safety nut a4 is connected to a motor a11, and the safety nut a4 is driven by the motor a11 to rotate, and the speed of the motor a11 can be controlled by the control program According to the synchronous adjustment of the lifting speed of the lifting cylinder a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com