Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Implement the crawling function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Under-actuated manipulator claw for picking fruits and vegetables

InactiveCN102441892AVersatileStrong flexibilityProgramme-controlled manipulatorGripping headsTorsion springManipulator

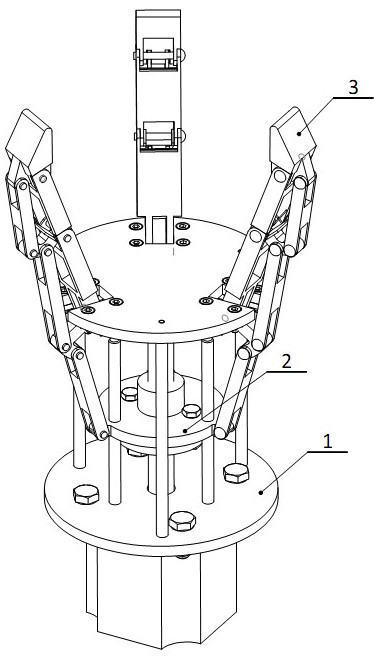

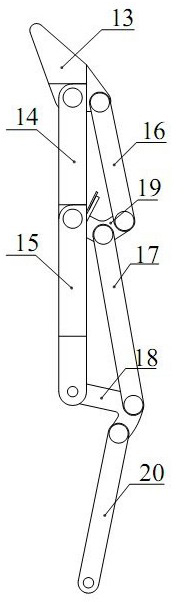

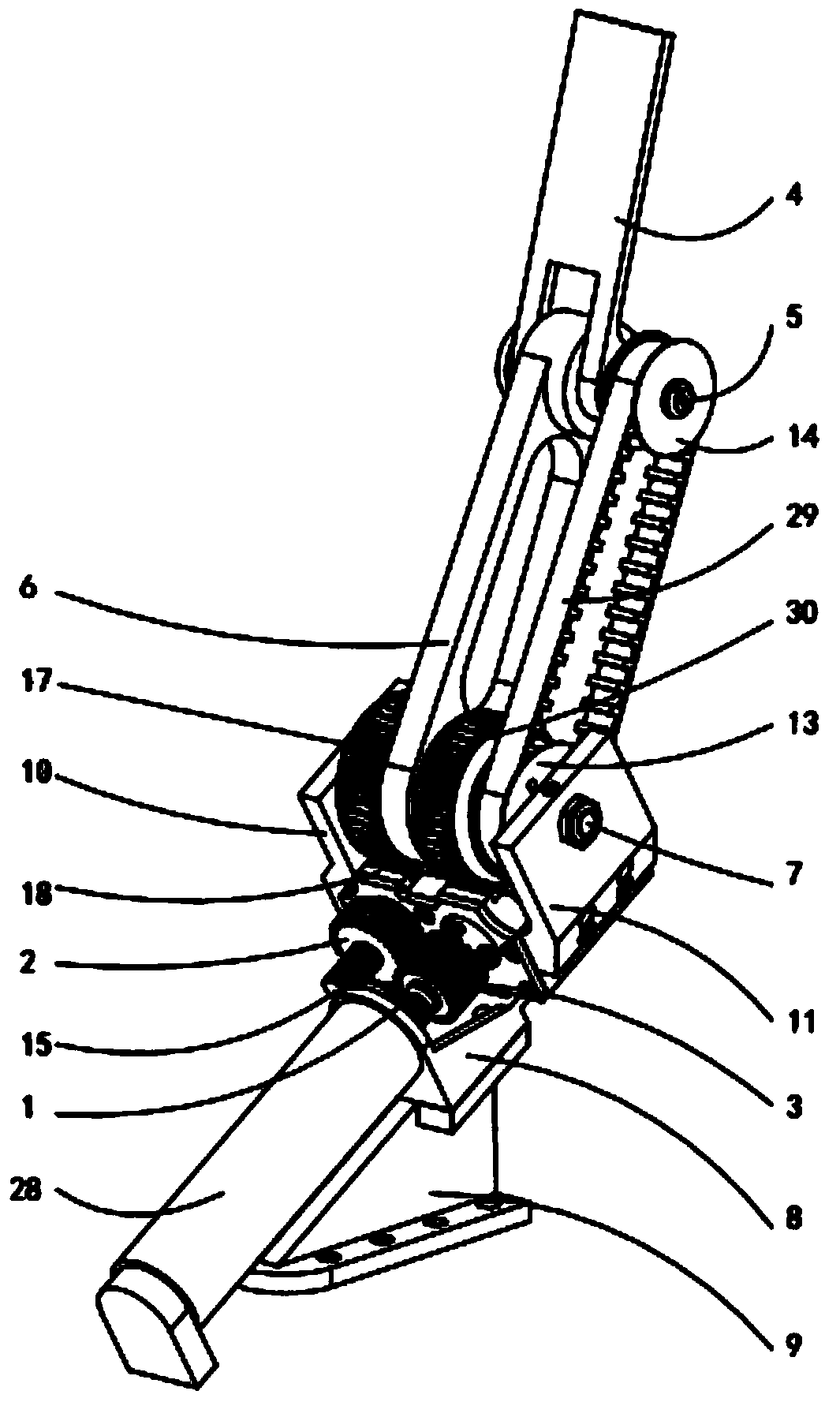

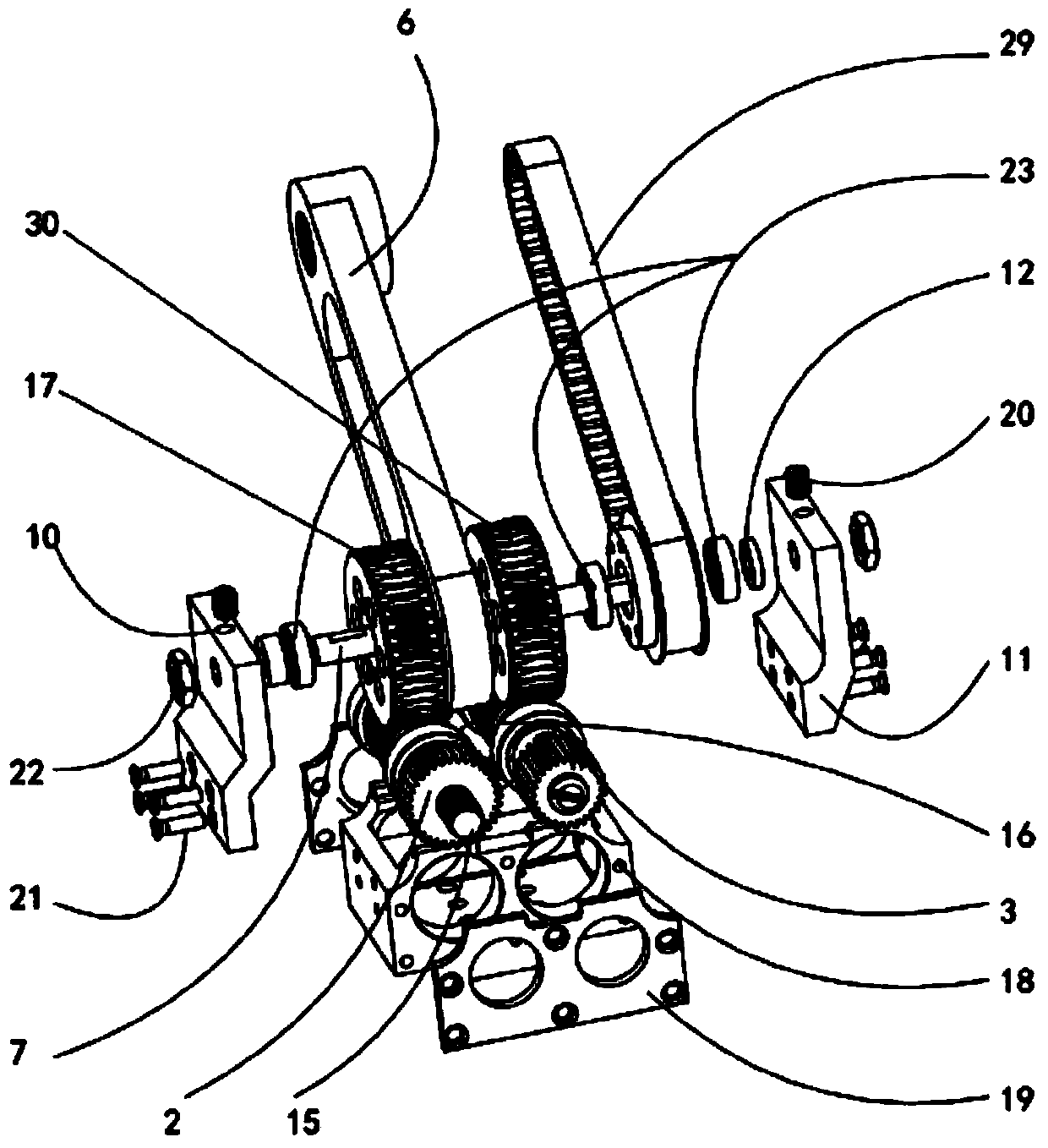

The invention discloses an under-actuated manipulator claw for picking fruits and vegetables. At present, fruits and vegetables are manually picked basically. The under-actuated manipulator claw for picking the fruits and the vegetables comprises a machine frame, a driving transmission mechanism and a finger mechanism, and particularly comprises an upper base, a finger fixing component, a supporting post, a lower base, a step motor, a screw rod, a nut, a lifting platform, a guiding post, a far finger, a middle finger, a near finger, a first connecting rod, a second connecting rod, a third connecting rod, a fourth connecting rod, a driving rod, a first torsion spring and a second torsion spring. A plurality of fingers are driven by one step motor at the same time, an under-actuated finger mechanism is adopted, and the torsion springs are used as a limiting mechanism, so that the under-actuated manipulator claw for picking the fruits and the vegetables has enwrapping and clawing functions; and a contact force sensor is arranged on a clawing surface, so that the clawing force can be fed back and controlled through detection of the contact force; the under-actuated manipulator claw for picking the fruits and the vegetables is simple in structure and easy to control; and the self adapting capability of the under-actuated manipulator claw to the shape of an object is improved; and the clawing stability is improved. Therefore, the fruits and the vegetables can be picked in a damage-free way.

Owner:ZHEJIANG UNIV

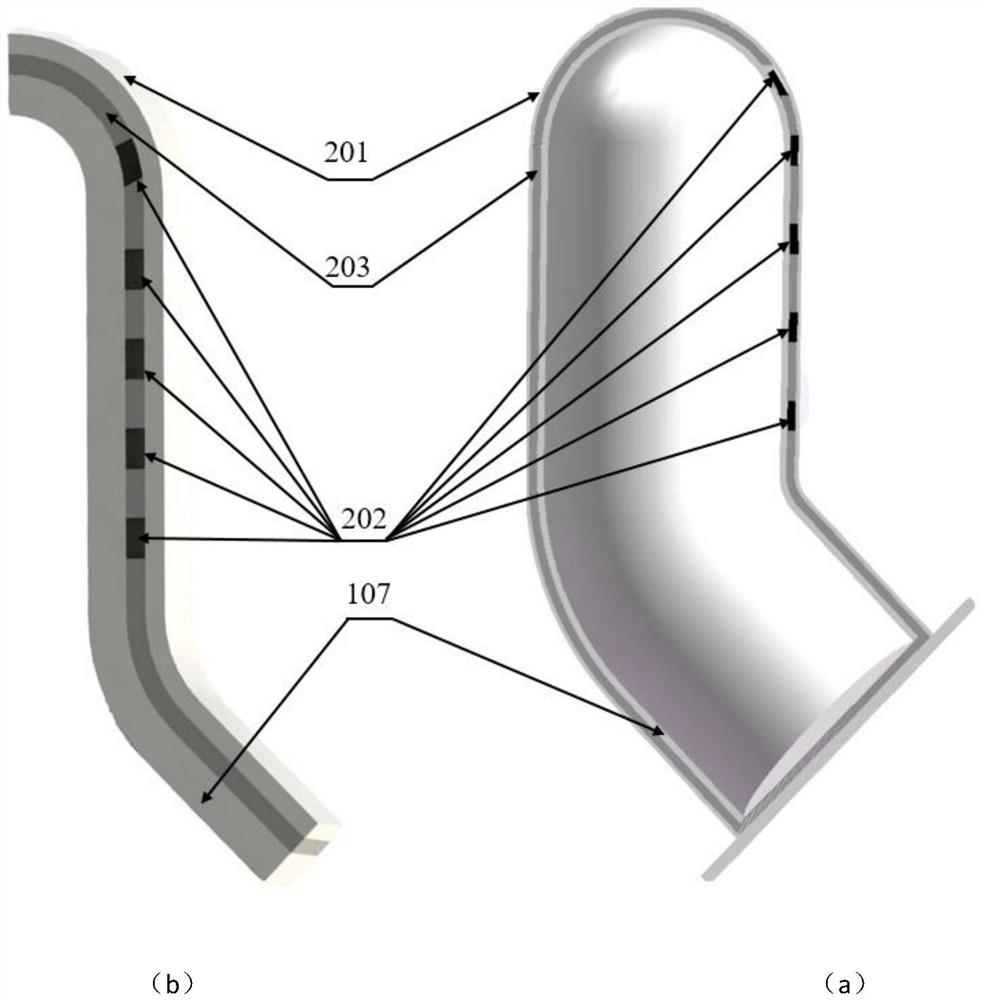

Humanoid finger inflatable soft three-finger gripper

The invention discloses a humanoid finger inflatable soft three-finger gripper, and relates to a three-finger gripper. The problem that existing soft grippers are low in load capacity is solved. Eachsoft finger module is installed on one end face of a bottom plate through a module base, a soft finger module body is internally provided with a first air cavity and a second air cavity in sequence, the first air cavity communicates with one end of a first interphalangeal joint air pipe, and the second air cavity communicates with one end of a second interphalangeal joint air pipe. The finger backof each soft finger module body is provided with at least two phalangeal joint clearance grooves through machining in the length direction of the finger back, the positions, except the finger prominence side, of the soft finger module body is wrapped with an elastic bandage, the finger prominence of the soft finger module body is provided with an elastic body, and a limiting layer is arranged between the finger prominence and the elastic body of the soft finger module body and made of a material which is easy to bend and cannot be stretched. The humanoid finger inflatable soft three-finger gripper is applied to manufacturing of a soft gripper, a robot hand, an artificial limb, a rehabilitation hand and the like.

Owner:HARBIN INST OF TECH

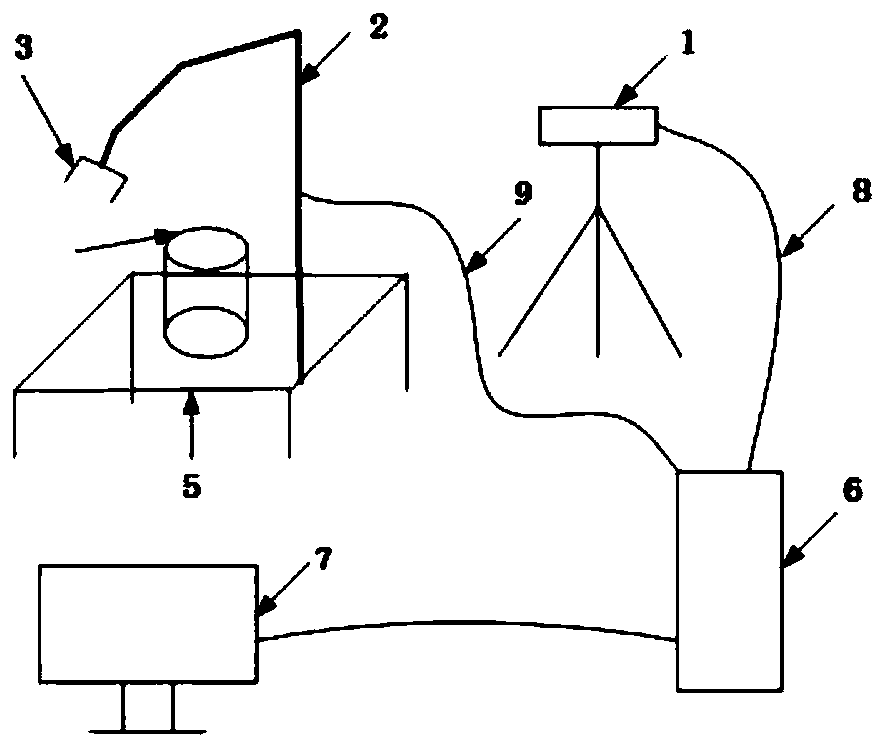

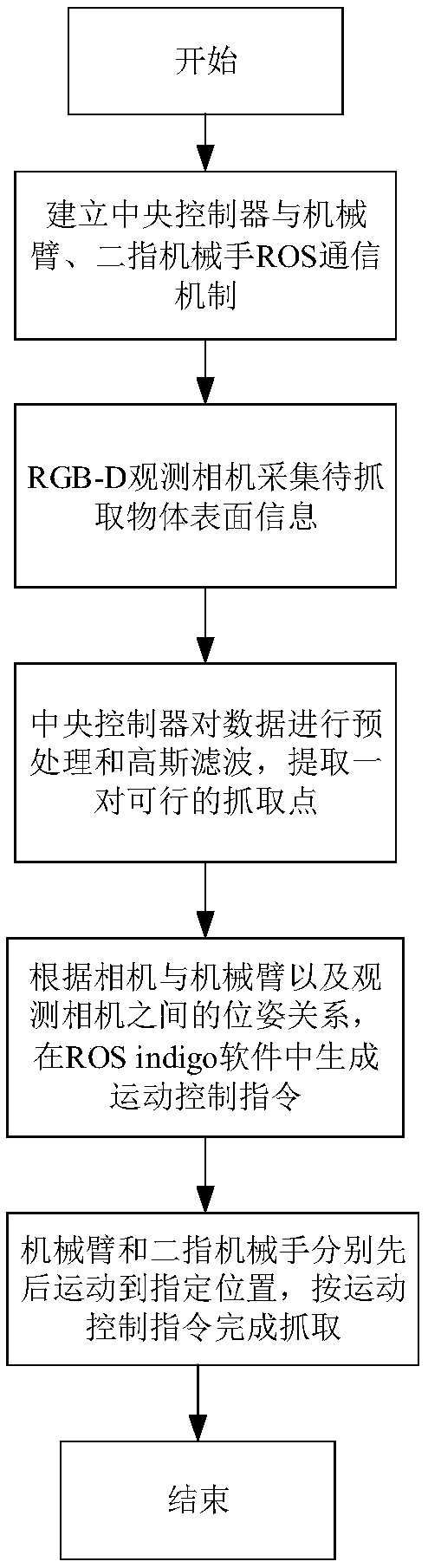

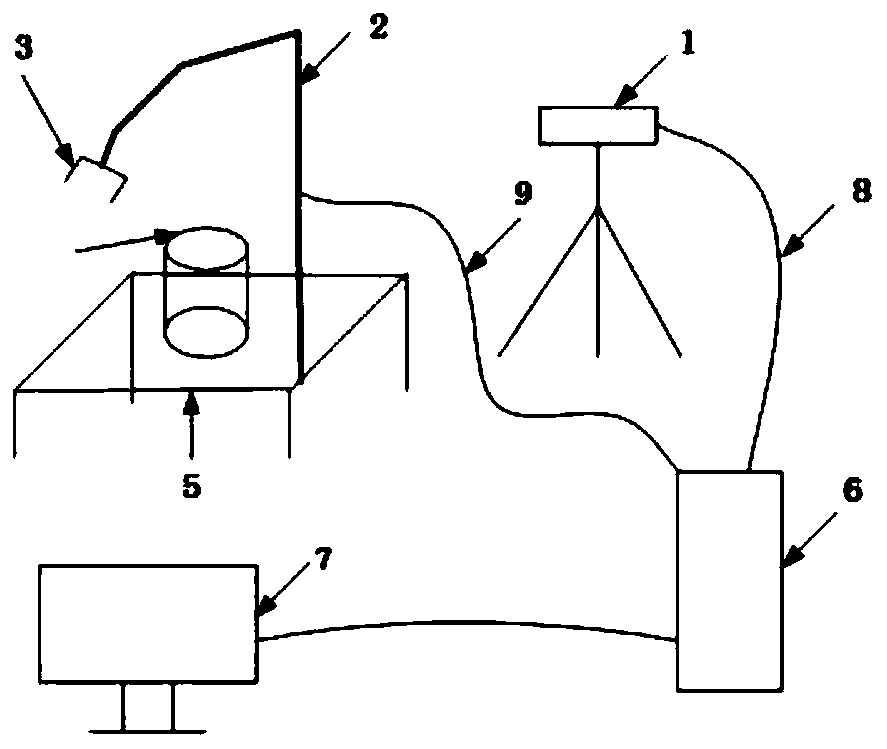

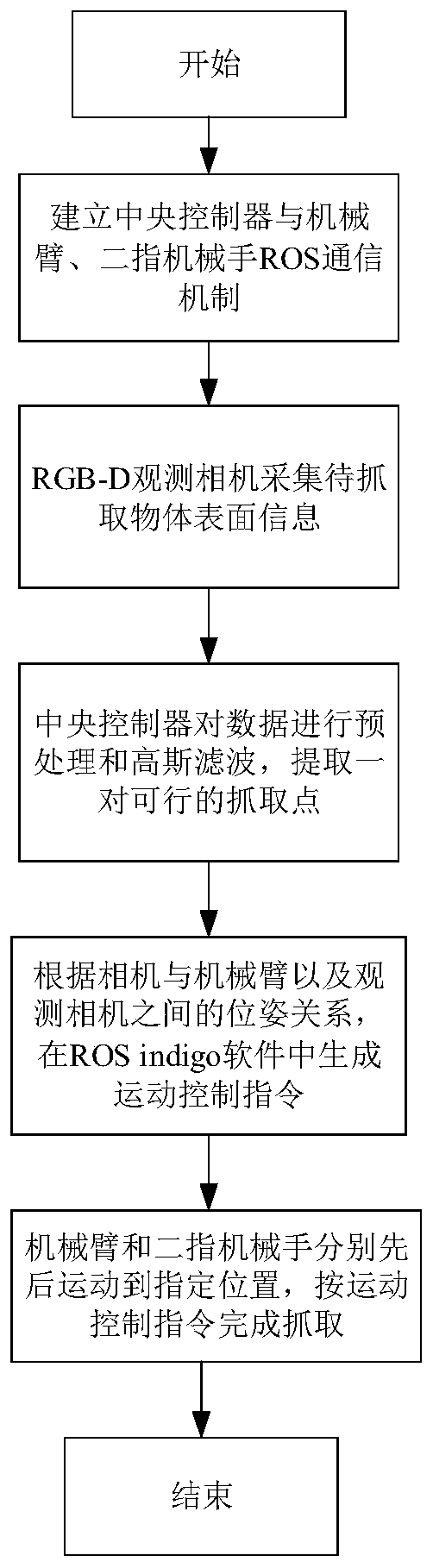

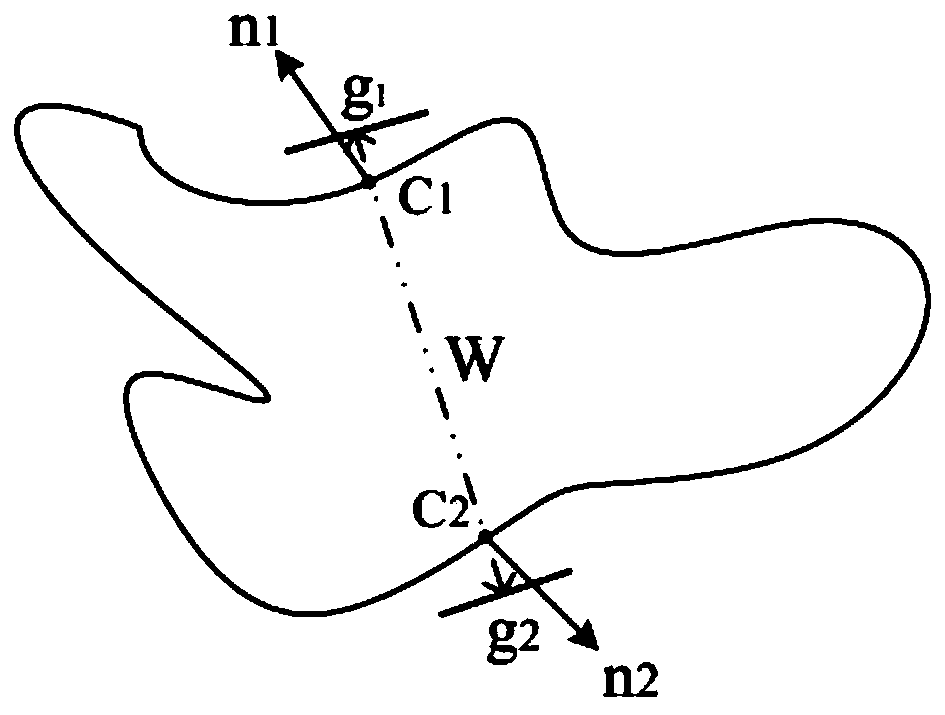

Mechanical arm grabbing method and system

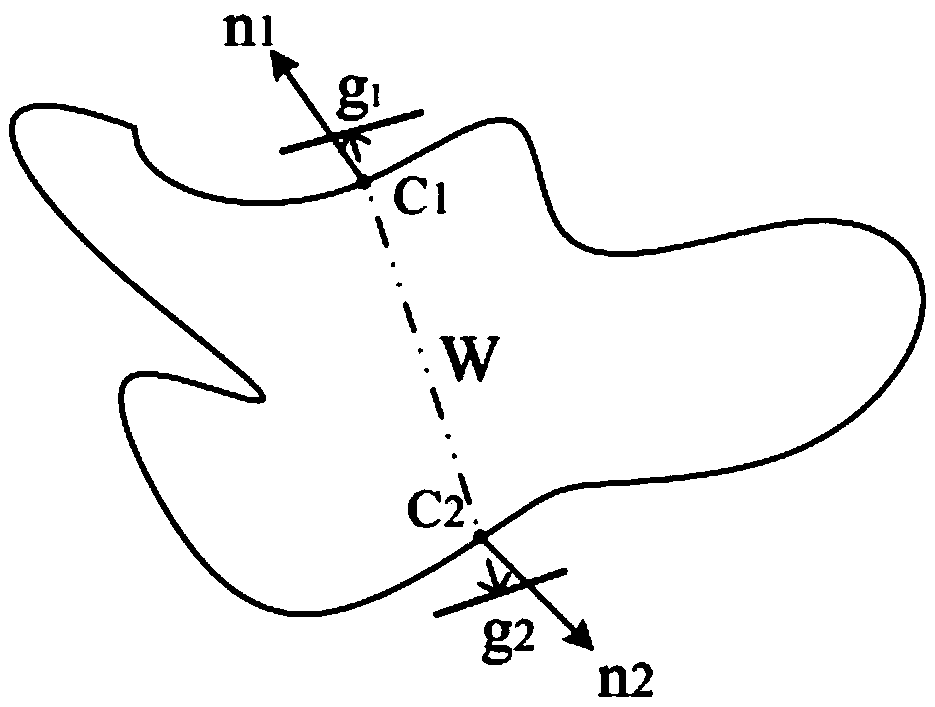

ActiveCN108858193AAchieve robustnessImplement the crawling functionProgramme-controlled manipulatorPoint cloudVision sensor

The invention provides a mechanical arm grabbing method and a system for achieving the method. The method comprises the following steps that S1, point cloud information of the surface (the surface capable of being seen in the view field of a camera) of an object to be grabbed is collected; S2, data of the point cloud information is further processed, and feasible grabbing points meeting constraintconditions are extracted through a grabbing programming algorithm; S3, the grabbing points are adopted as inverse kinematics input of a mechanical arm, and a motion control instruction is sent to themechanical arm and a two-finger parallel gripper; and S4, the mechanical arm executes the motion control instruction, and moves to the specified position, and according to the motion timing relationship in the motion control instruction, the two-finger parallel gripper is opened and clamped to complete the grabbing task. The mechanical arm grabbing method and the system for achieving the method have the beneficial effects that under the condition that the shape of the object is uncertain, a single visual sensor can be used for achieving the mechanical arm grabbing function with robustness.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

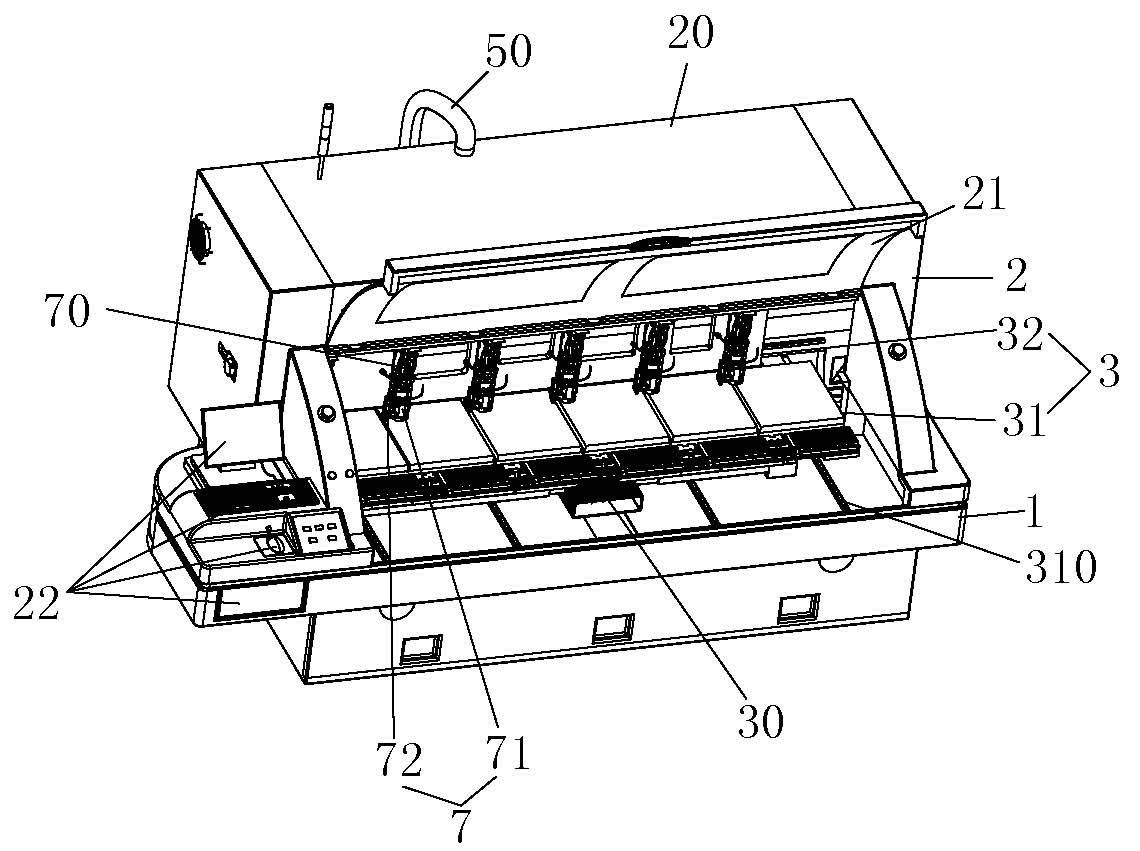

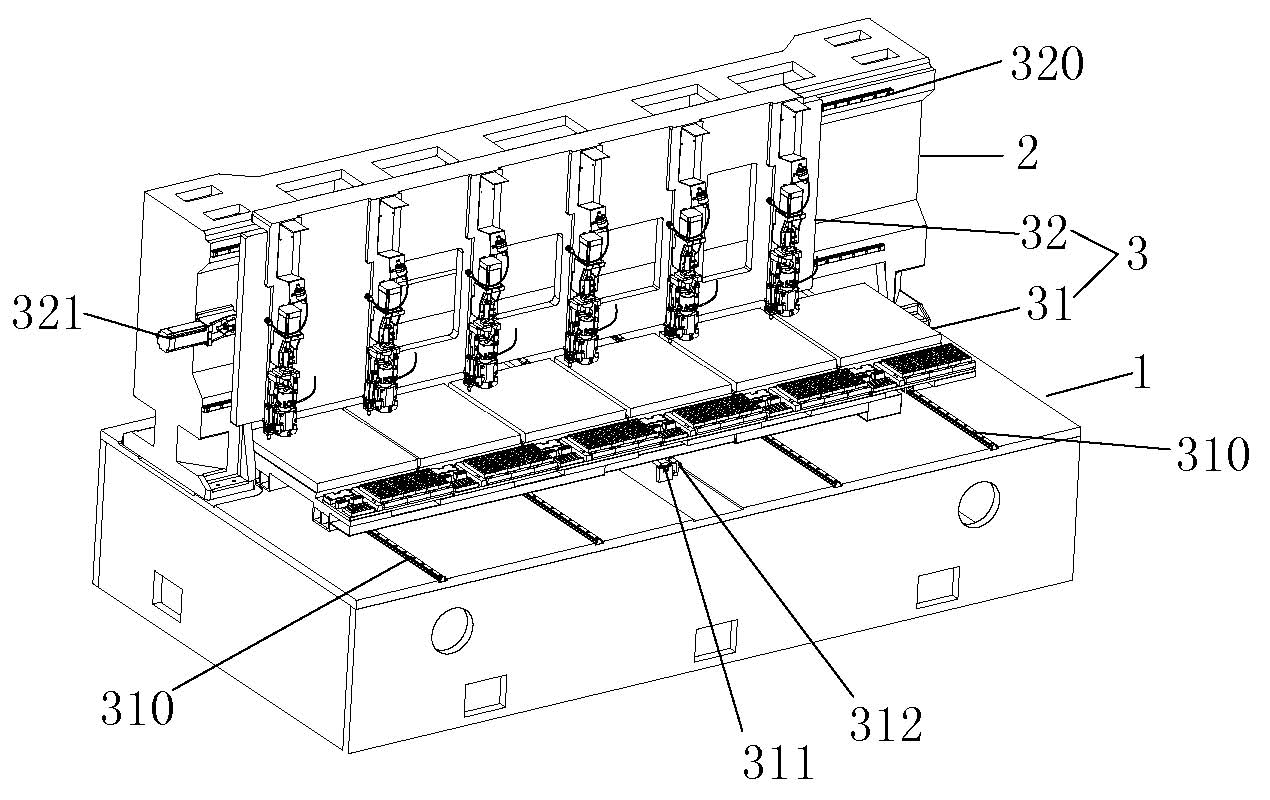

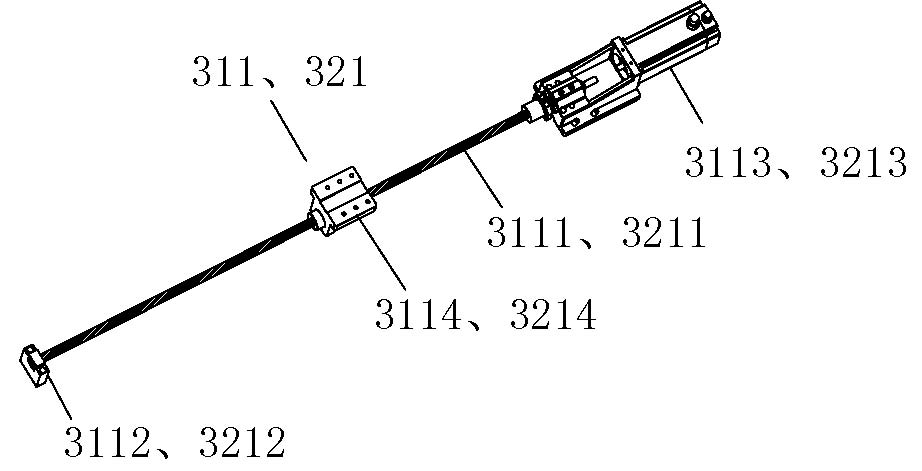

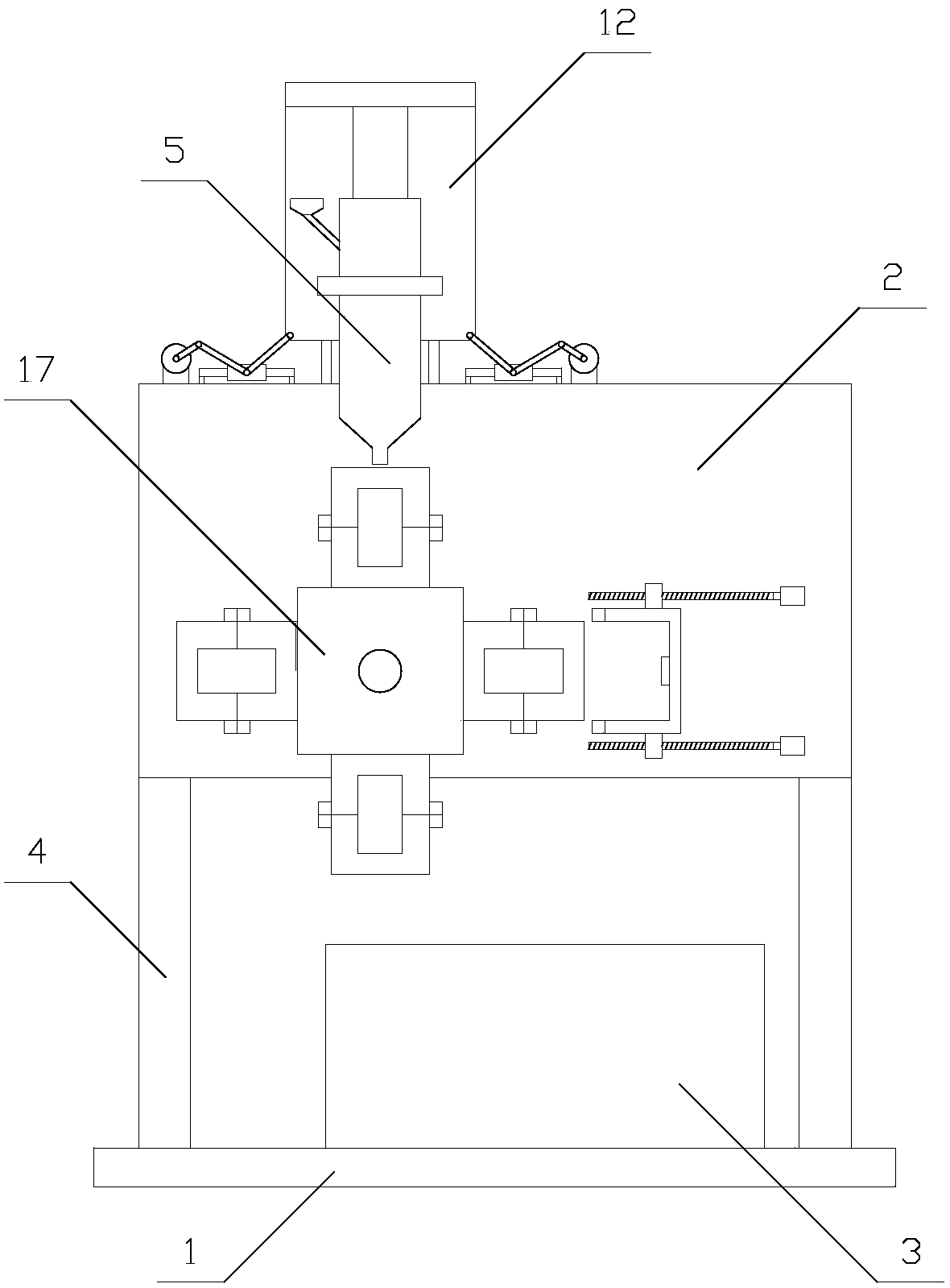

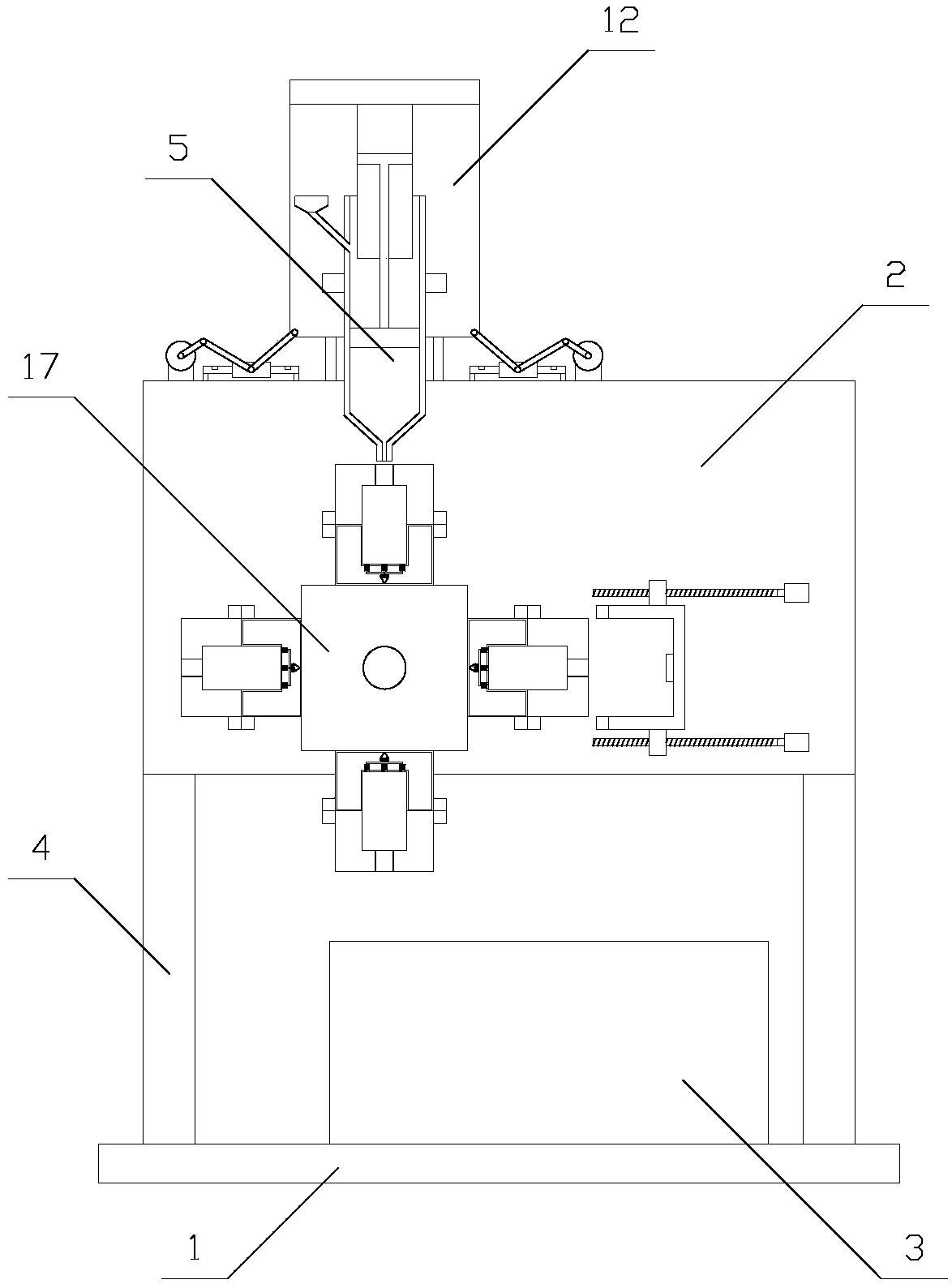

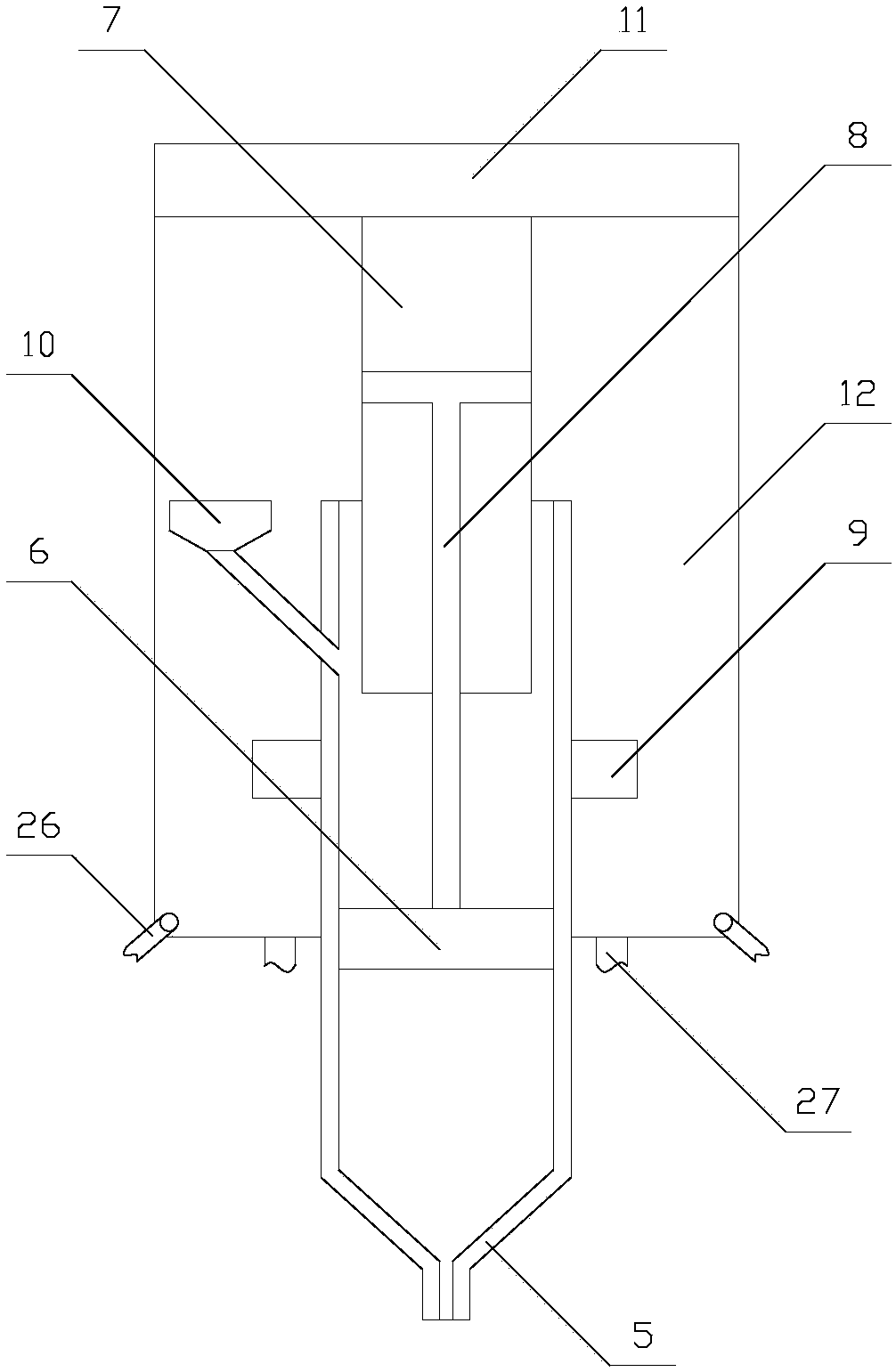

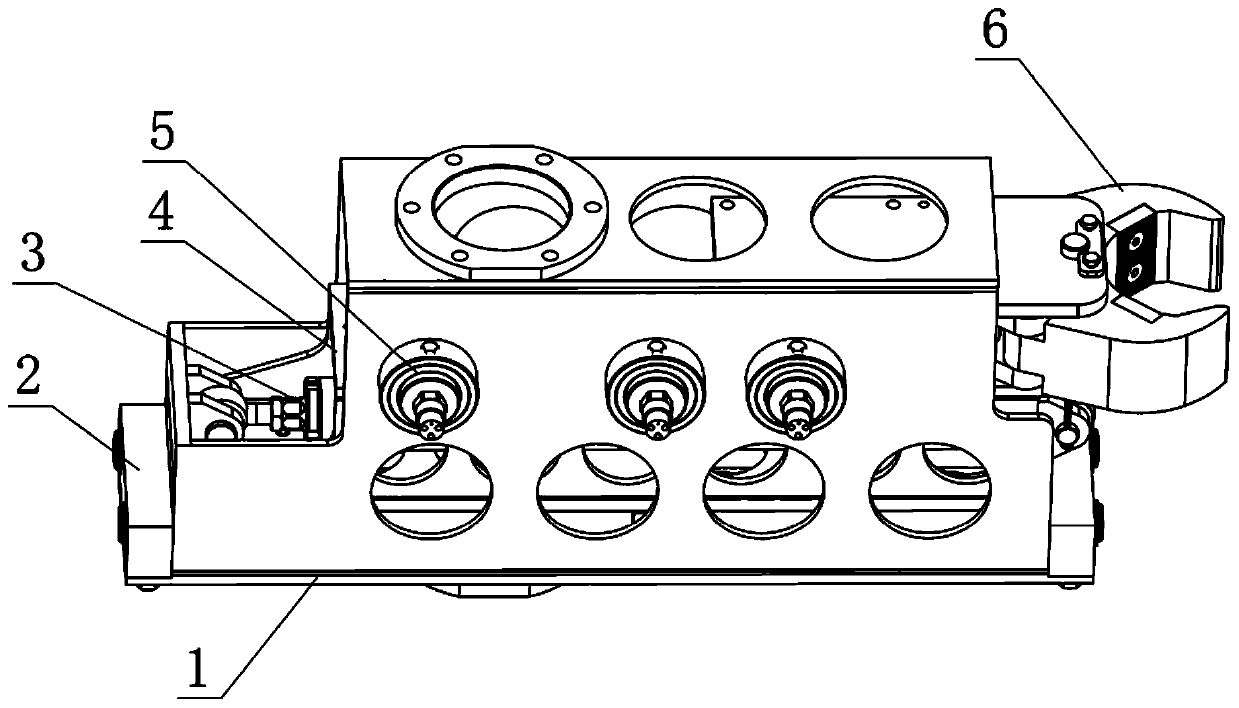

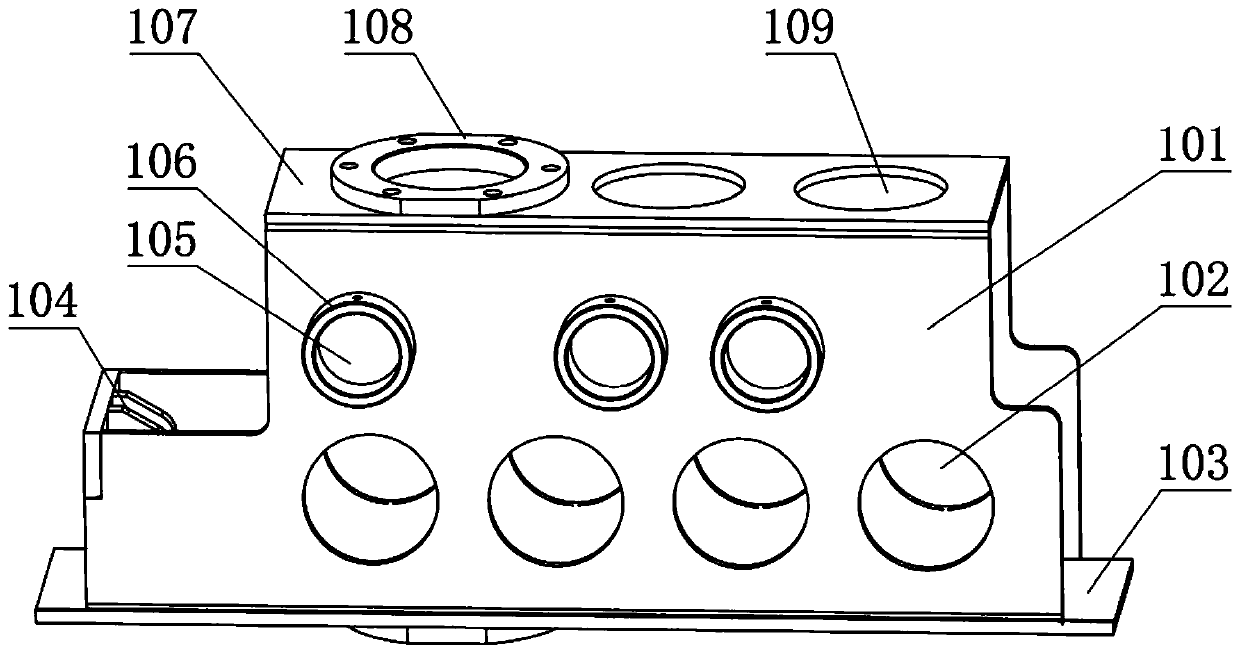

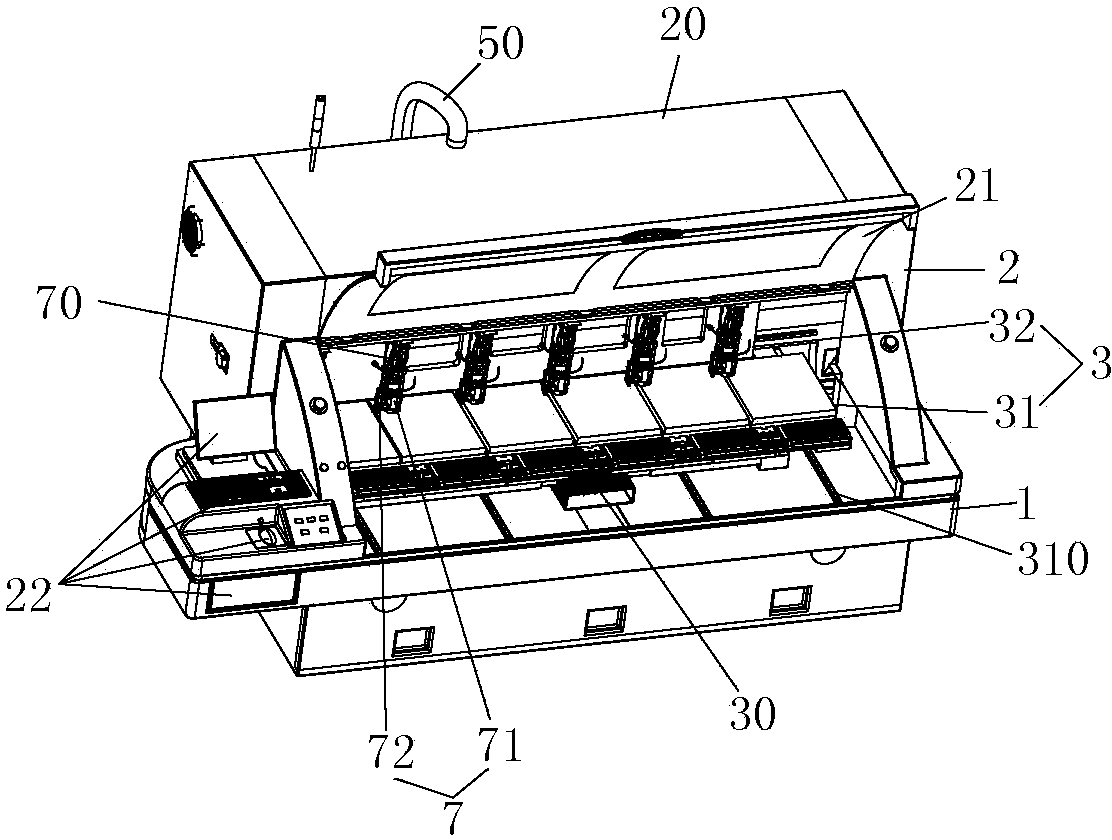

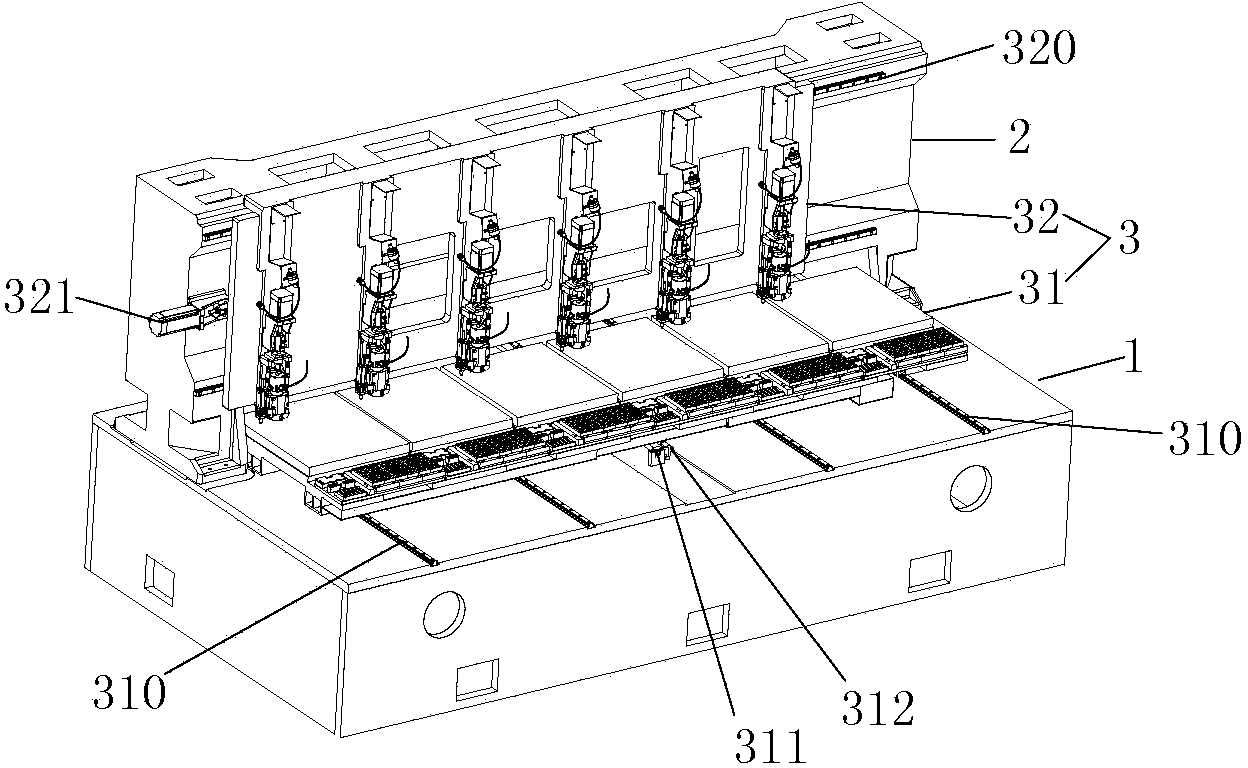

Drilling machine

InactiveCN102514043AReduce pollutionImprove manufacturing efficiencyMetal working apparatusEngineeringMaterial resources

The invention discloses a drilling machine, which comprises a machine platform, a frame, a movable platform, a cutting detection mechanism, a powder absorption device and an oil cooling device. The machine platform serves as a bearing device of the whole drilling machine, the frame is arranged on the machine platform, the movable platform comprises an X axis platform installed on the machine platform and a Y axis platform installed on the frame, the cutting detection mechanism is fixedly installed on the frame through a casing of the cutting detection mechanism, and the powder absorption device is arranged on the side of the frame and is communicated with the casing of the cutting detection mechanism through a connection pipe. At least six mechanical arm devices are arranged on the frame, and each mechanical arm device comprises a main holder device and an auxiliary holder device installed on the side of the main holder device. The drilling machine is compact in structure and high in manufacture accuracy and production efficiency, can save material resources and greatly lower production and manufacture cost.

Owner:TEXIN MICROELECTRONICS DONGGUAN

Inchworm imitated soft robot

InactiveCN109176501AAvoid radial expansionAchieving bending redundant driveProgramme-controlled manipulatorVehiclesSEMI-CIRCLEShape-memory alloy

The invention relates to the technical field of bionics, in particular to an inchworm imitated soft robot. The inchworm imitated soft robot can be driven through combination of a pneumatic manner anda shape memory alloy and comprises a head component, a trunk component and a tail component. The head component and the tail component are arranged at the two ends of the trunk component. The trunk component comprises a trunk body, a head installation module and a tail installation module, and the head installation module and the tail installation module are arranged at the two ends of the trunk body. The trunk body is in a regular long strip shape, the cross section of the trunk body is in a semi-circular shape, and the periphery of the semi-circle of the trunk body is provided with a spiralgroove. The head installation module is connected with the head component, the tail installation module is connected with the tail component, and the rectangular bottom of the trunk body is provided with an installation groove used for installing memory metal.

Owner:JIANGSU UNIV OF SCI & TECH

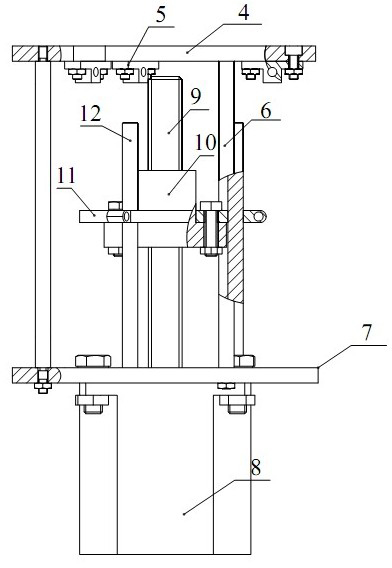

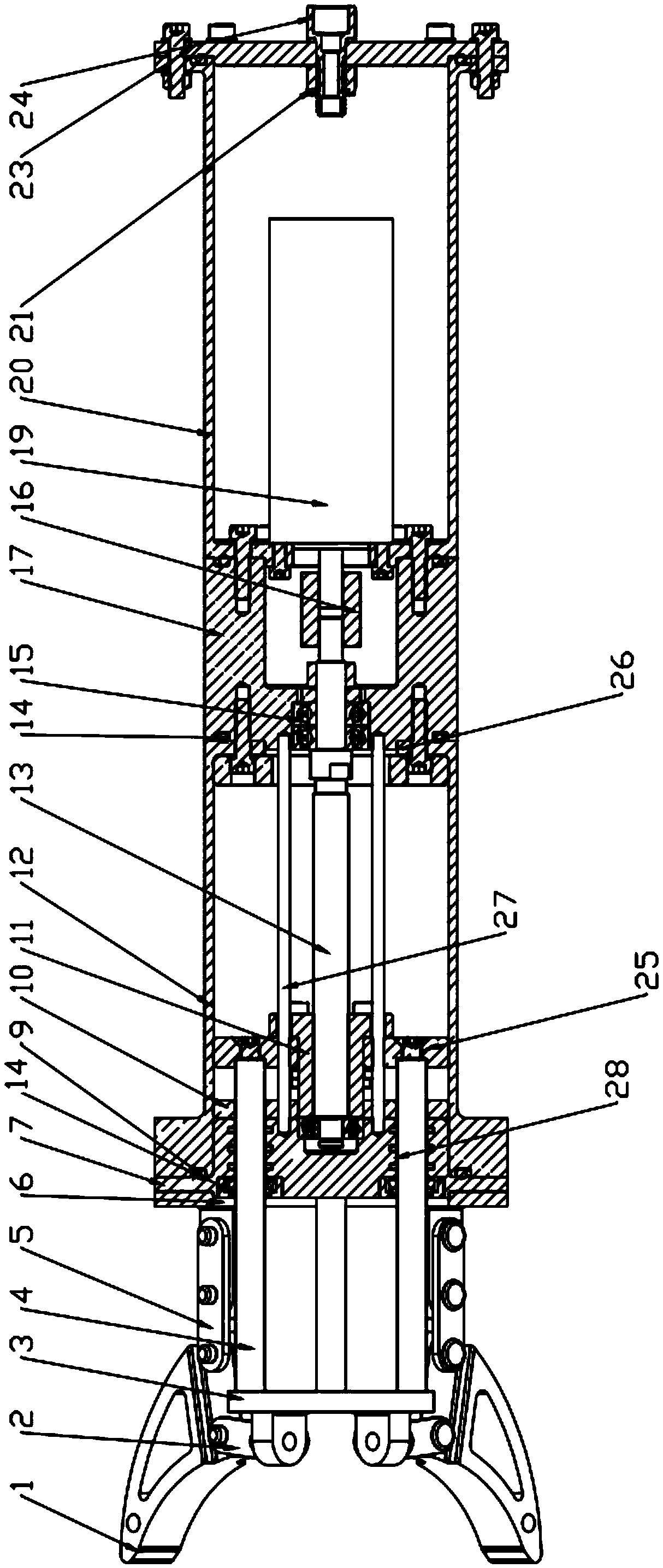

Underwater mechanical arm

PendingCN109291041AImplement the crawling functionPerfect water seal structureProgramme-controlled manipulatorGripping headsArm functionMarine engineering

The invention discloses an underwater mechanical arm. The underwater mechanical arm comprises a cabin, a telescopic drive piece, clamping claws and guide rods. The telescopic drive piece is arranged in the cabin arranged in a sealed manner. The guide rods are in sealed sliding connection with the cabin. One ends of the guide rods are connected with the telescopic executing end of the telescopic drive piece, the other ends of the guide rods are hinged to one ends of the clamping claws, and the other ends of the clamping claws are hinged to the cabin. The multiple clamping claws conduct clampingor loosening along with the process that the telescopic drive piece drives the guide rods to stretch and contract. A motor and lead screw transmission manner is adopted for driving, the four-claw linkage manner is used for achieving the underwater object grabbing function, the mechanical arm function is achieved through a simple structure, and the cost and operation difficulty are reduced. Meanwhile, a complete watertight structure is achieved, stability of underwater automatic operation is improved, the difficulty of underwater fishing work is effectively lowered, the application field of anunderwater robot is widened, and wide popularization value is achieved in the fields of water surface management, underwater fishing and the like.

Owner:CENT SOUTH UNIV

Flexible gripper with surface micro structure

The invention relates to a flexible gripper with a surface micro structure. The flexible gripper includes a motor, a bending grabbing mechanism is connected to the end part of an output shaft of the motor through a connecting body; an air guiding channel is formed in the connecting body, one end of the air guiding channel communicates with an inflating connector on the surface of one side of the connecting body, and the other end of the air guiding channel communicates with the bending grabbing mechanism; the structure of the bending grabbing mechanism includes a flexible finger plate, the topend of the flexible finger is connected with the bottom surface of the connecting body, the bottom end of the flexible finger plate is the free end, an elastomer is connected to one side of the flexible finger plate and is formed to a whole by connecting a plurality of mutual communicating air bags in the length direction sequentially, an inflating cavity is formed in each air bag, the inflatingcavities of the every two adjacent air bags are in communication through an air channel, and the inflating cavity of the air bag located at the top most communicates with the air guiding channel; andunder the uninflated state, the sizes of the inflatable cavities of the air bags decrease in sequence in the direction away from the connecting body. According to the flexible gripper with the surfacemicro structure, effective grasping of objects with the complex shapes and regular structures can be met.

Owner:JIANGNAN UNIV +1

Plastic product production equipment with high production efficiency based on Internet of things

The invention relates to plastic product production equipment with high production efficiency based on Internet of things. The equipment comprises a base, a worktable, a storage box and four brackets,wherein the worktable is fixed to the base through the brackets which are uniformly distributed at four corners of the worktable; the storage box is arranged on the base and is located below the worktable; an injection mechanism is arranged above the worktable; a rotating mechanism and a grabbing mechanism are arranged on the worktable; the injection mechanism comprises an injection assembly andtwo lifting assembles; the injection assembly comprises an injection pipe, a push plate, an air cylinder, a piston, a fixed ring, a feeding hole, a connecting plate and a lifting plate. The plastic product production equipment with the high production efficiency based on Internet of things provided by the invention accelerates the processing speed of products through the injection mechanism and the rotating mechanism, so that the production efficiency is improved. Furthermore, the finished product is conveyed to the storage box through the grabbing mechanism, so that an intelligent unloading function is achieved.

Owner:晋江万智进出口贸易有限公司

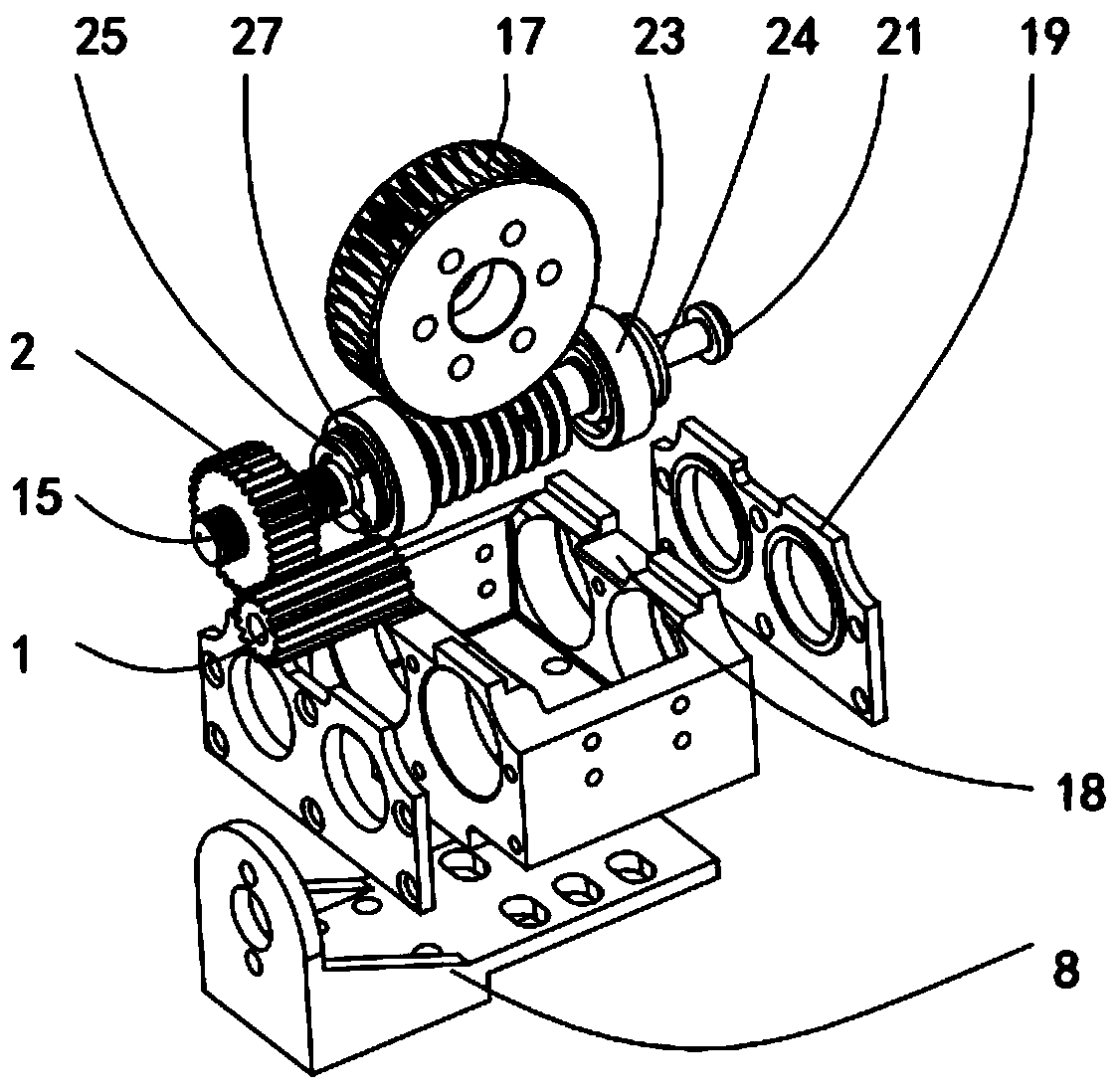

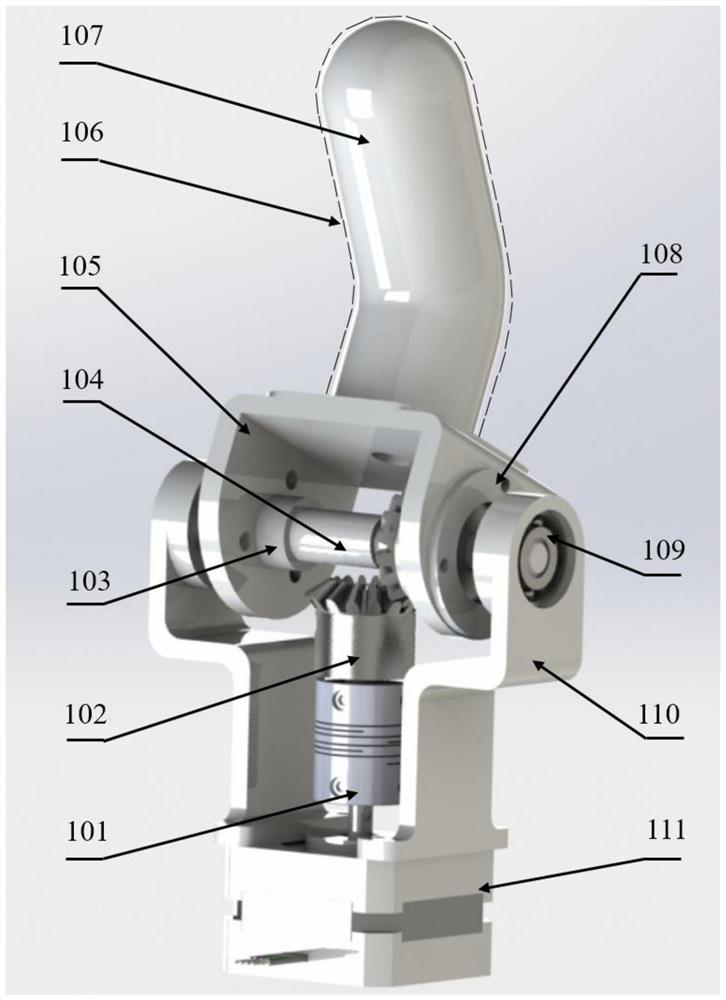

Variable torque converter for under-actuated dexterous hand

InactiveCN104175319AImplement the crawling functionSimplify the drive structureGripping headsTorque transmissionDrive motor

The invention discloses a variable torque converter for an under-actuated dexterous hand. The variable torque converter comprises a first worm gear, an inner worm shaft, a second worm gear, an outer worm shaft and a first gear, wherein the inner worm shaft is meshed with the first worm gear which is connected with an inner knuckle of the dexterous hand, the outer worm shaft is meshed with the second worm gear which drives an outer knuckle of the dexterous hand, and the first gear is connected with an output shaft of a driving motor. A third gear is fixed onto the outer worm shaft and meshed with the first gear, a second gear capable of axially moving along the inner worm shaft is in threaded connection with the inner worm shaft and meshed with the first gear, a Belleville spring which enables the second gear to be fixed or rotate relative to the inner worm shaft is arranged on the inner worm shaft, and a retainer ring is arranged between the Belleville spring and the second gear. The variable torque converter is simple and convenient to mount, reliable in connection, capable of effectively realizing control of torque transmission and especially applicable to logic control of knuckle rotation of the under-actuated dexterous hand.

Owner:SOUTHEAST UNIV

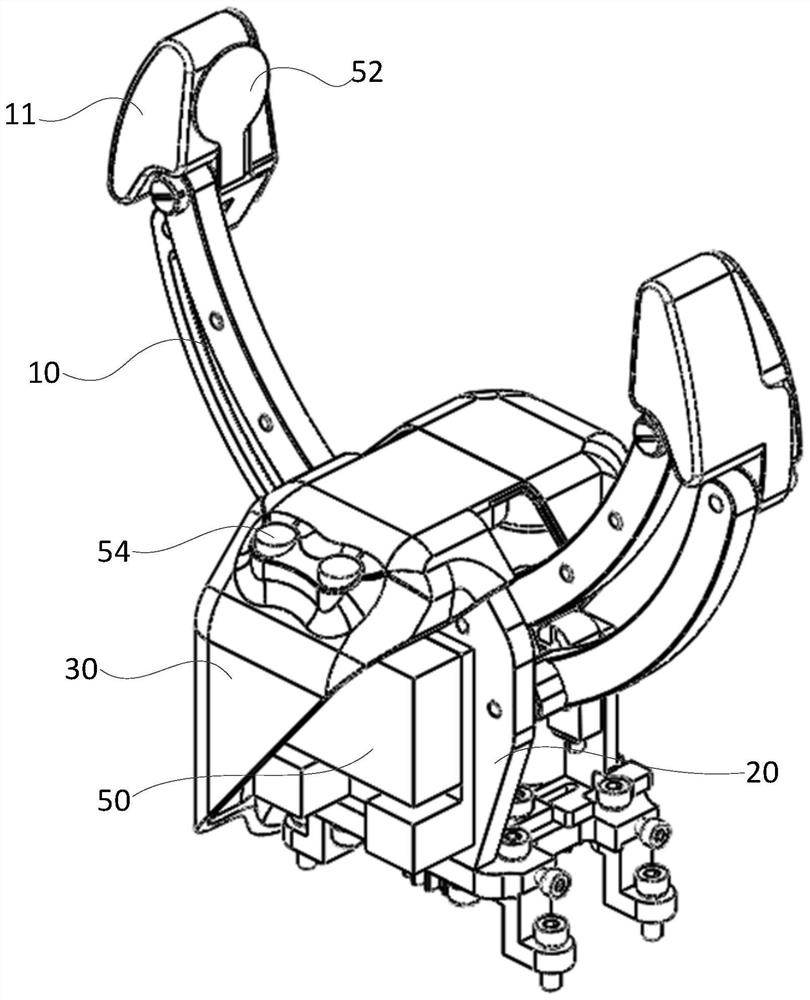

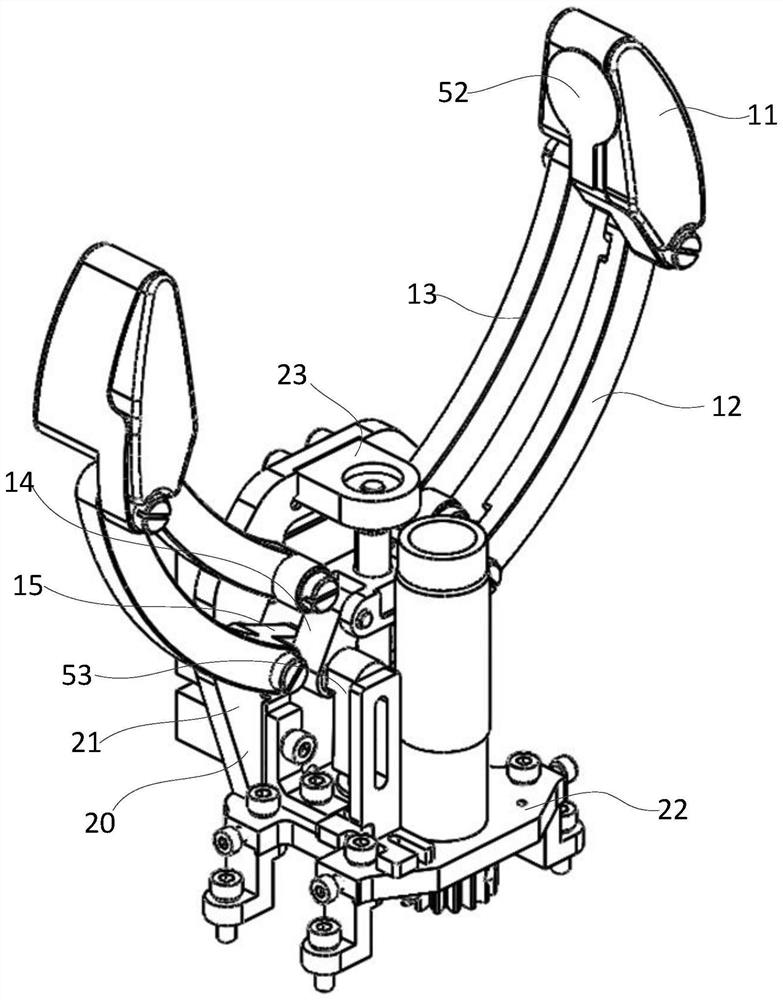

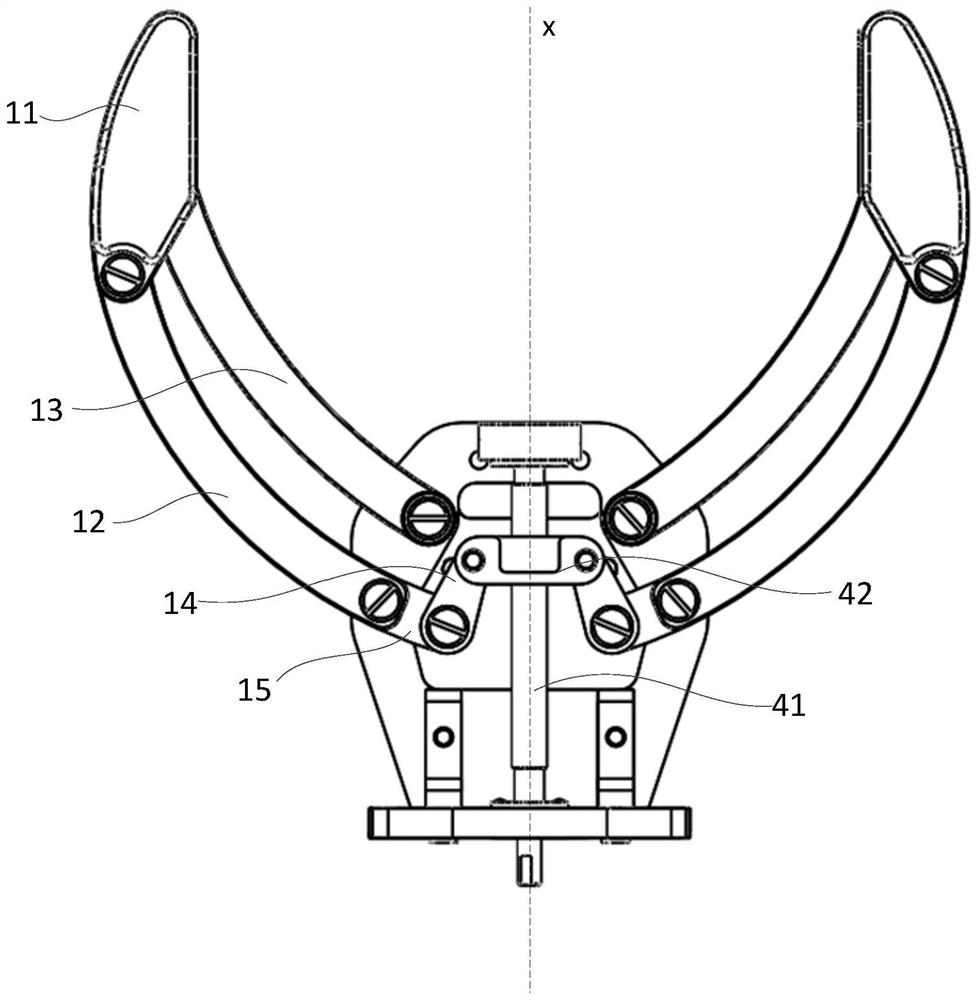

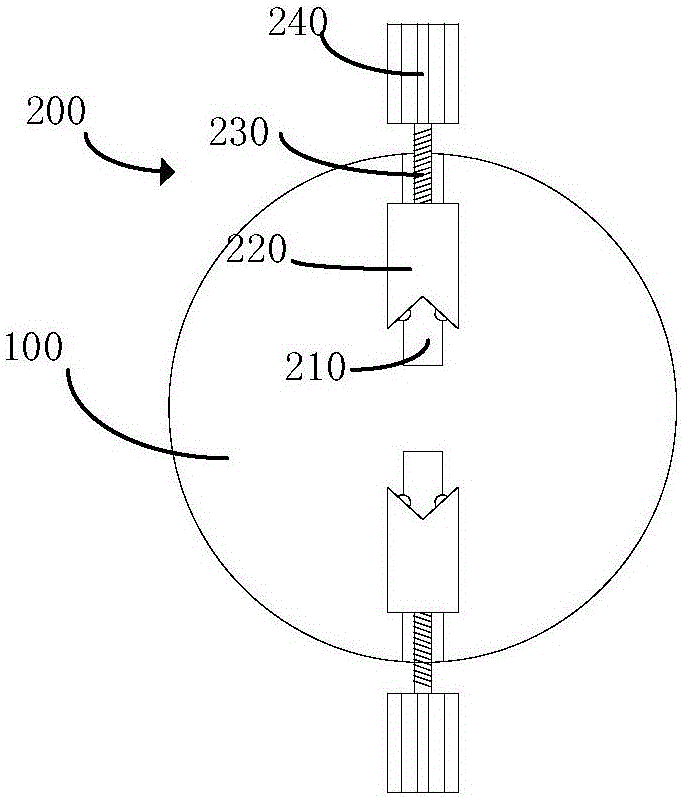

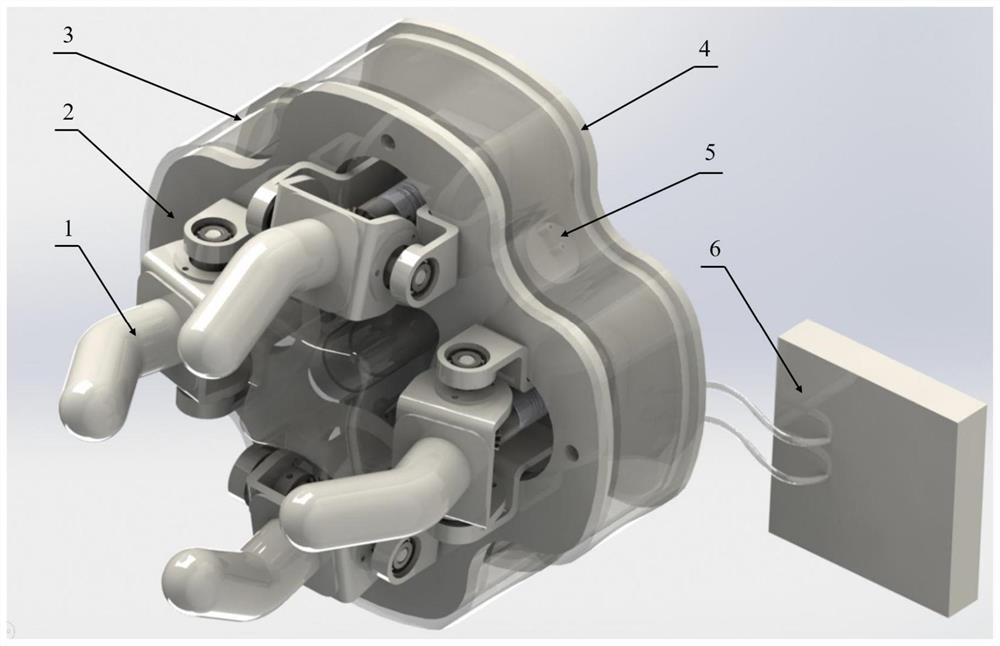

Robot gripper and control method thereof

The invention provides a robot gripper and a control method thereof. The gripper comprises a support and a plurality of gripper mechanisms arranged on the support, each gripper mechanism comprises a fingertip part, a first connecting rod and a second connecting rod, each fingertip part swings around the support under the support of the first connecting rod and the second connecting rod and swings towards the center shaft side of the support to be folded, in the folded state, the first connecting rod is located on the outer side of a center shaft of the support, the second connecting rod is located on the inner side of the center shaft of the support, a lead screw for driving is arranged along the center shaft of the support, the lead screw is sleeved with a lead screw nut, a push rod is arranged for each gripper mechanism, one end of each push rod is rotationally connected with the lead screw nut, and the other ends of the push rods are rotatably connected with swing arms extending from the other end of the first connecting rod or the second connecting rod to the opposite side of the body part of the first connecting rod or the second connecting rod. The robot gripper is small in size and compact in structure. Real-time communication with the robot gripper is realized through the Ethercat.

Owner:TSINGHUA UNIV +1

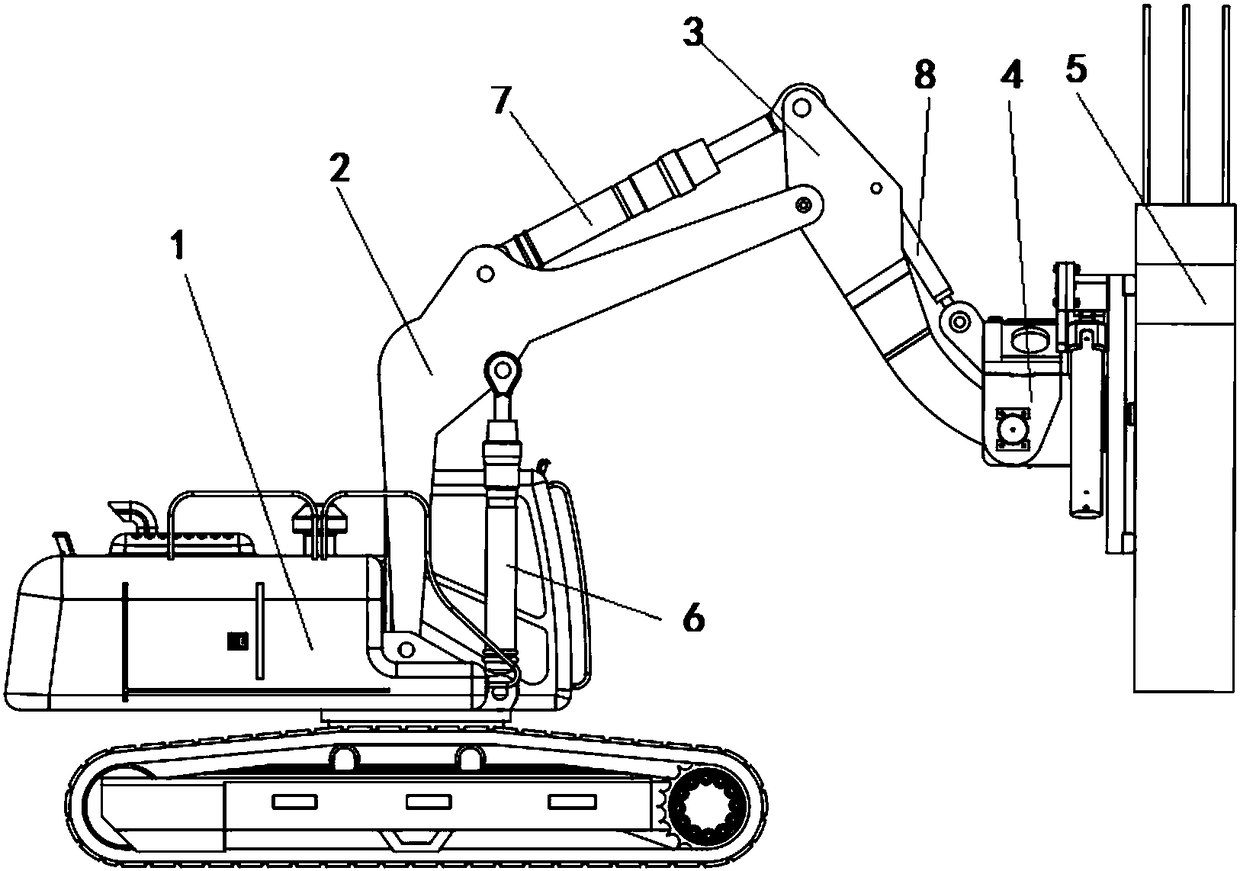

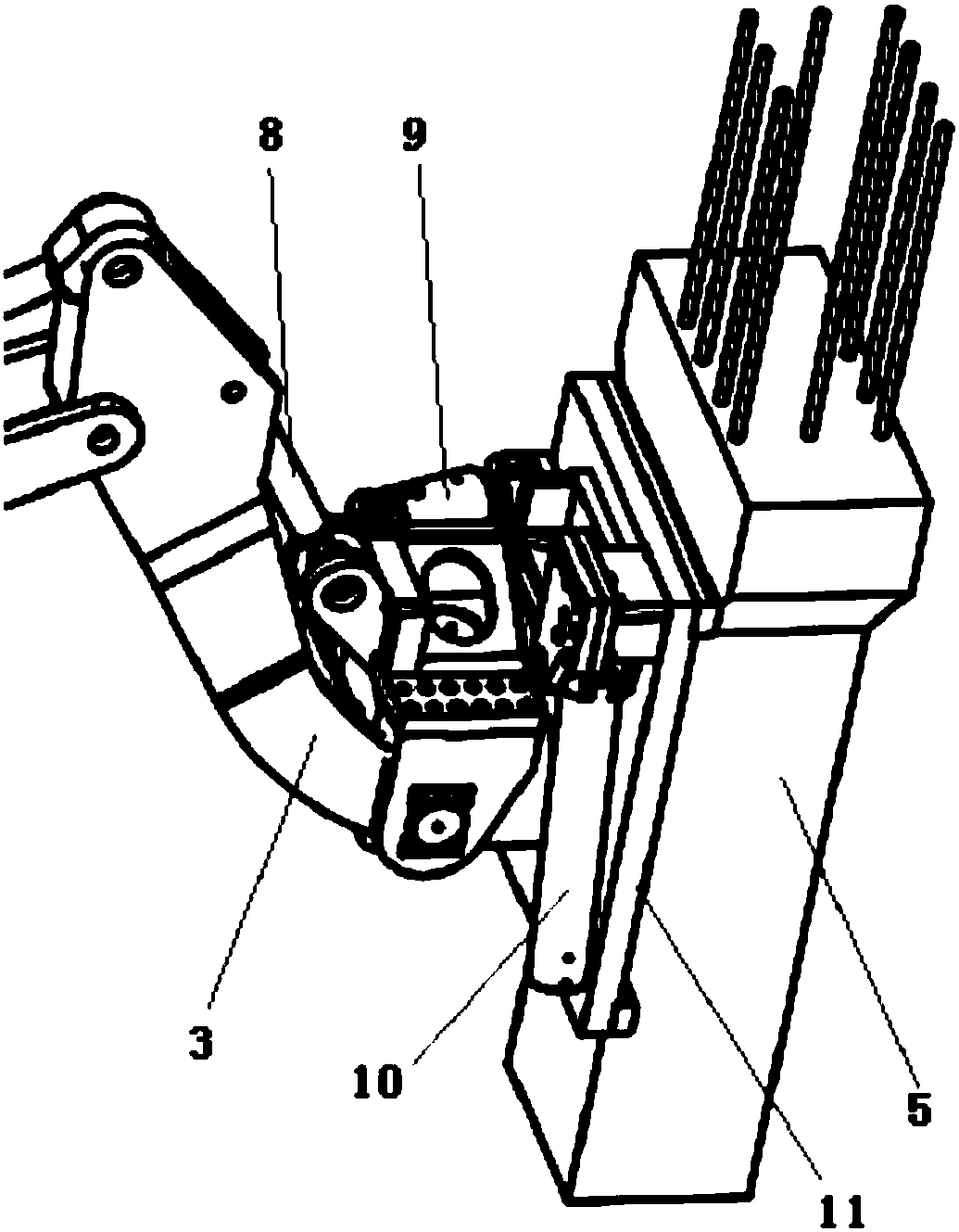

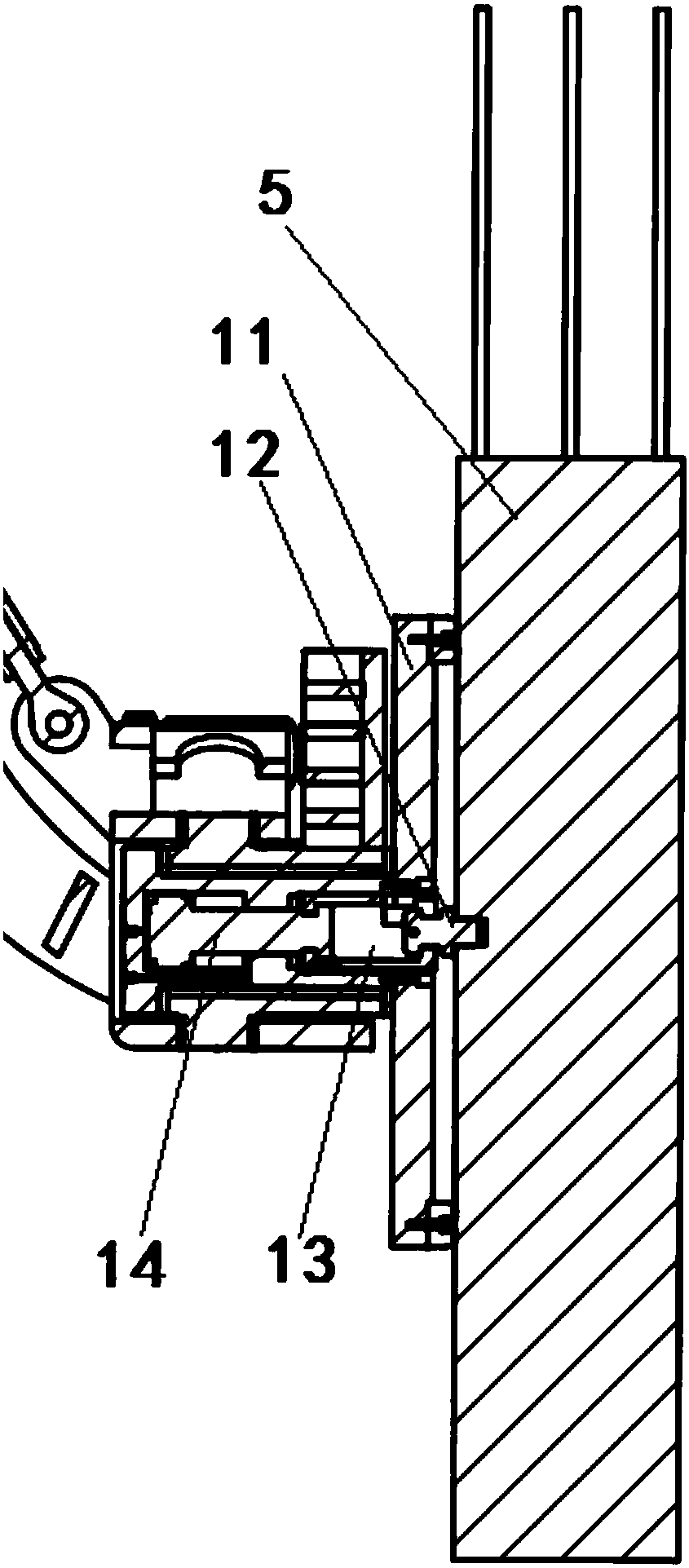

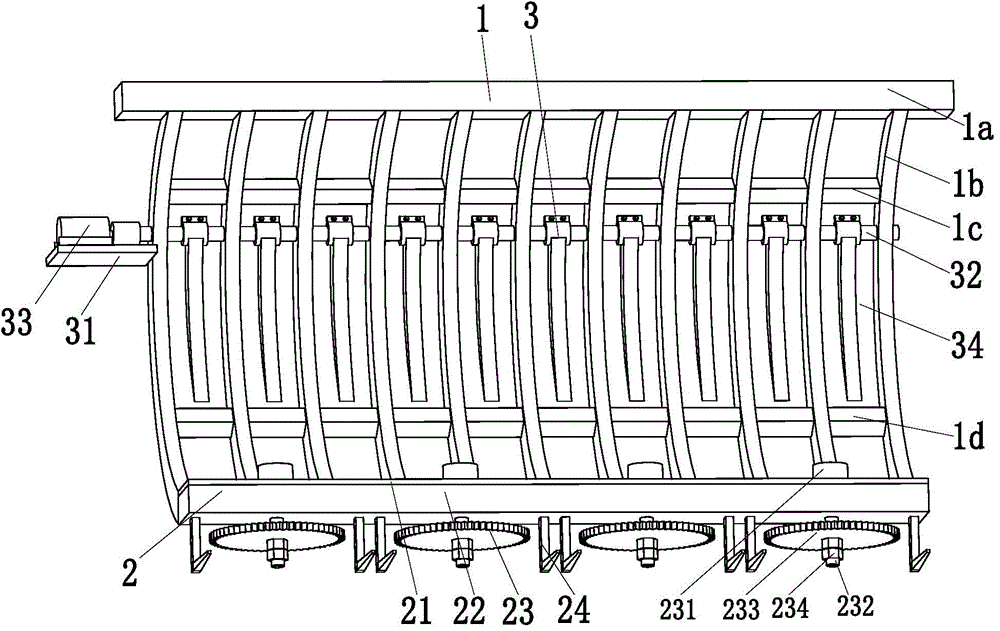

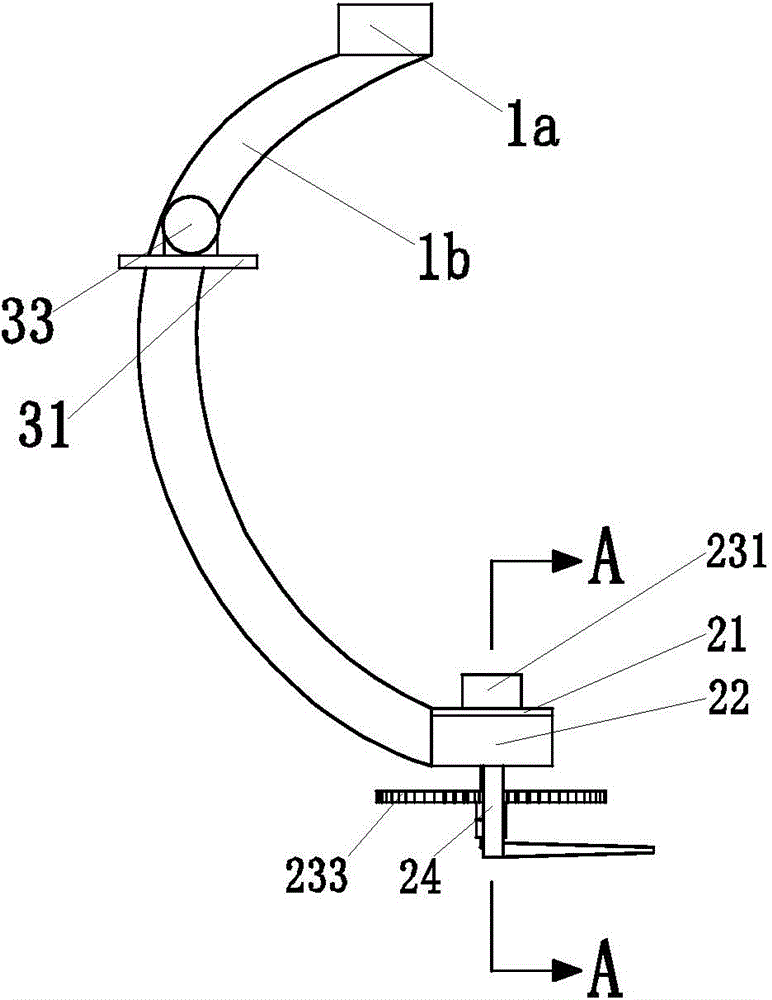

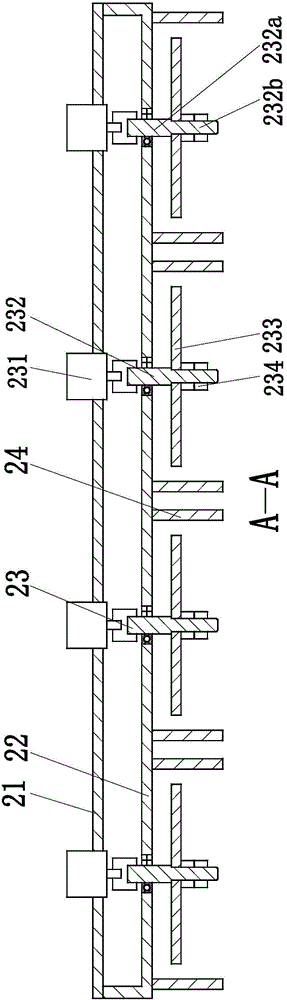

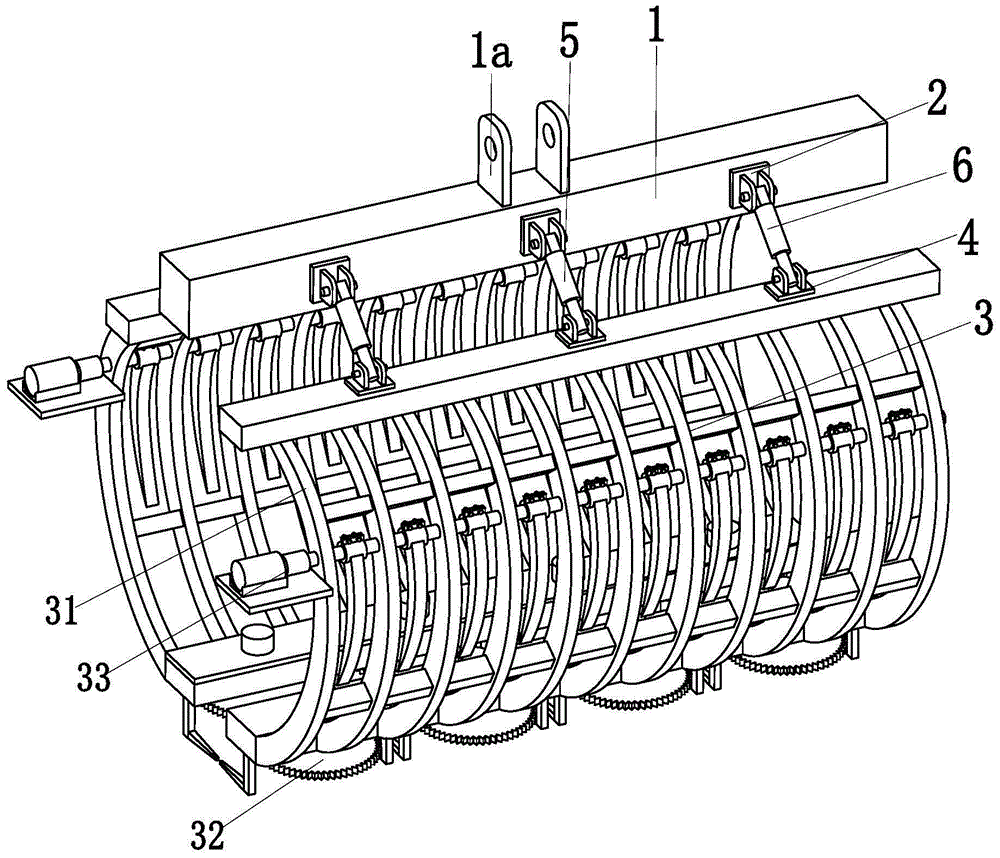

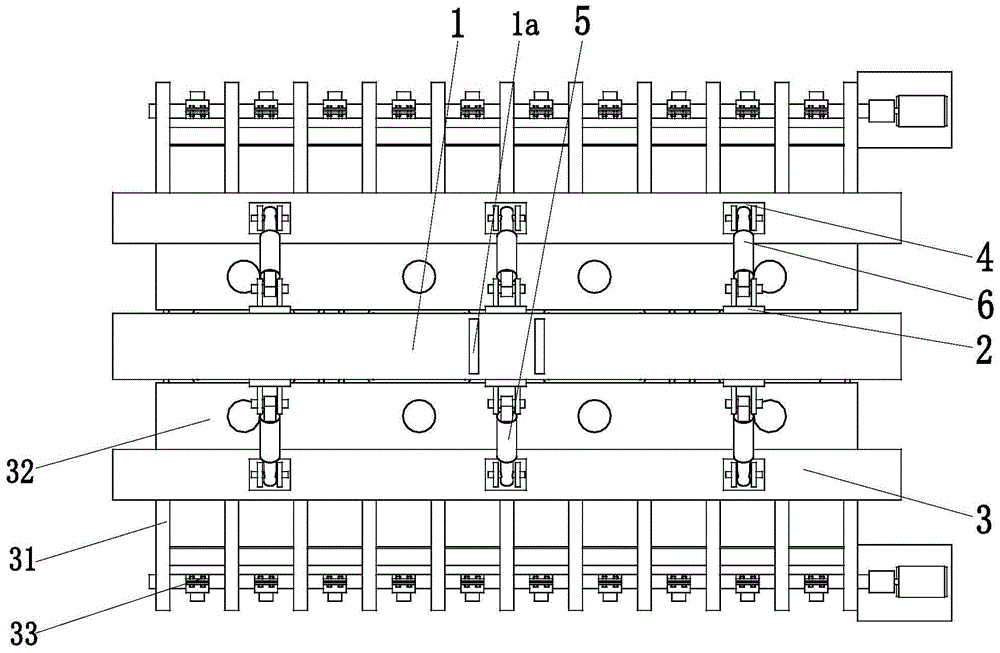

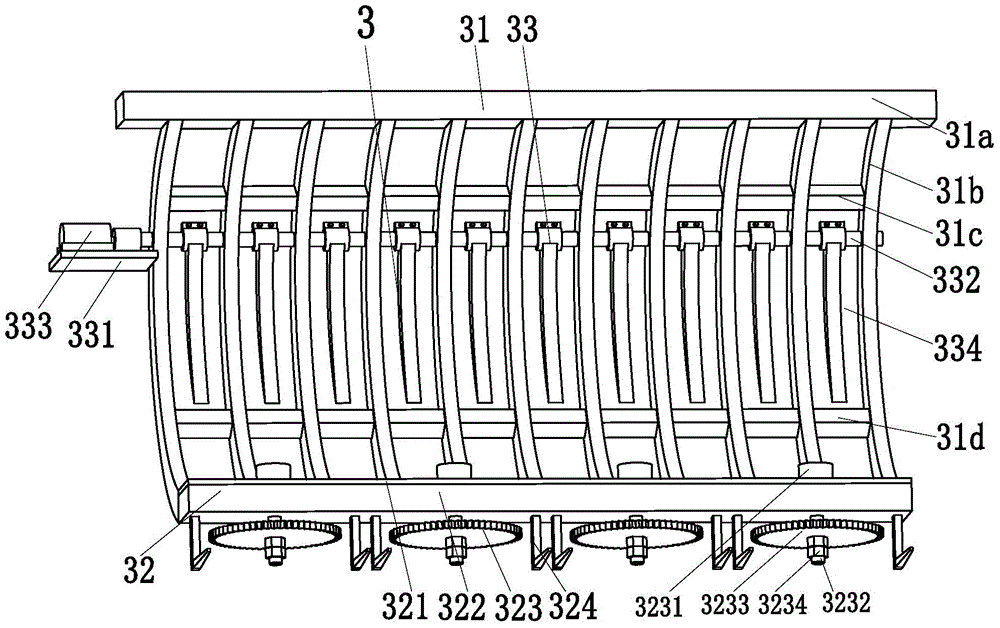

Prefabricated stand column erector for double-layer tunnel internal structure construction

InactiveCN108167001AImplement the crawling functionAdjust assembly angleUnderground chambersTunnel liningEngineeringManipulator

The invention provides a prefabricated stand column erector for double-layer tunnel internal structure construction. The prefabricated stand column erector comprises a moving chassis, a mechanical rotating arm and a mechanical hand; the mechanical hand is rotatably arranged on the moving chassis through the mechanical rotating arm; the mechanical hand is provided with a mechanical hand body internally provided with a telescopic device and a load lifting device telescopic cylinder connected with a telescopic end of the telescopic device; the mechanical hand is provided with a stand column fixing plate used for sticking the prefabricated stand column to be assembled; the stand column fixing plate is rotatably connected with the mechanical hand body through rotating an oil cylinder group in multiple directions; the stand column fixing plate is provided with a through hole; and the load lifting device telescopic cylinder is arranged in the through hole in a penetrating mode and is connected with a stand column load lifting device. The prefabricated stand column erector for the double-layer tunnel internal structure construction can solve the problem of overcoming the limited internal structure space inside the tunnel to assemble a pre-supported stand column.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

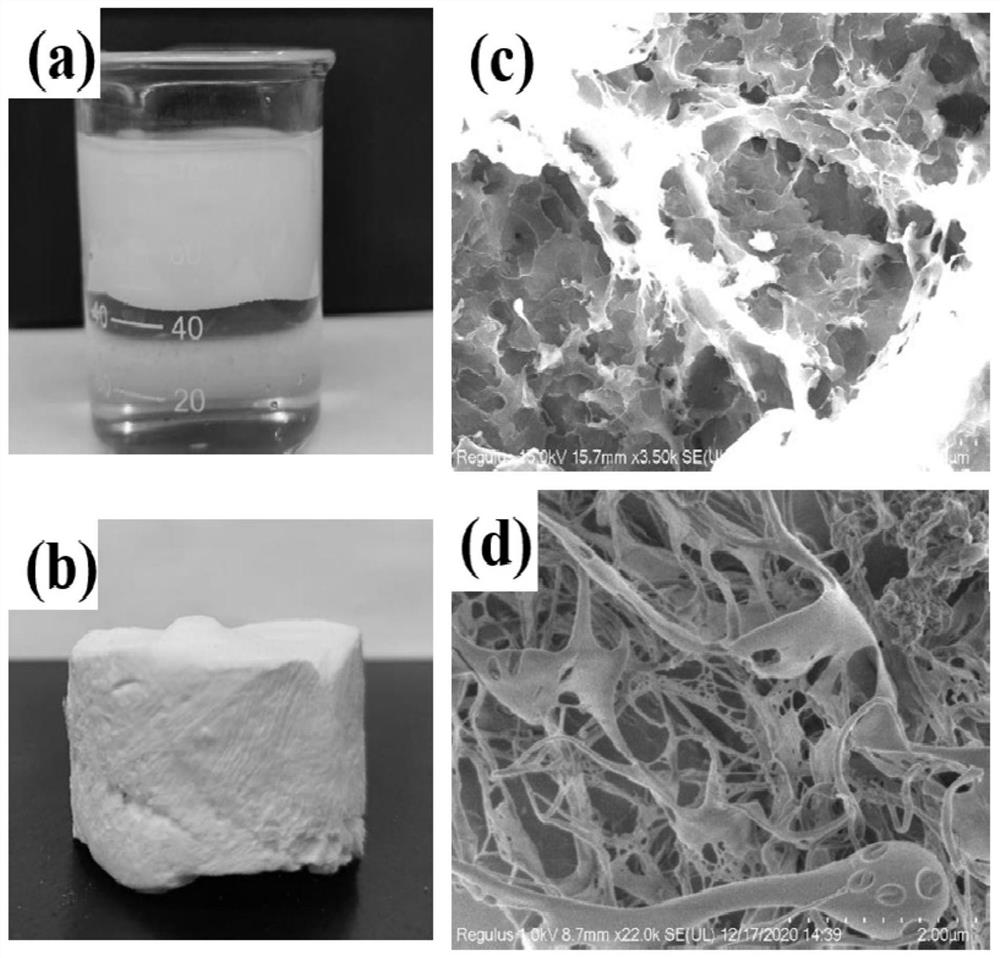

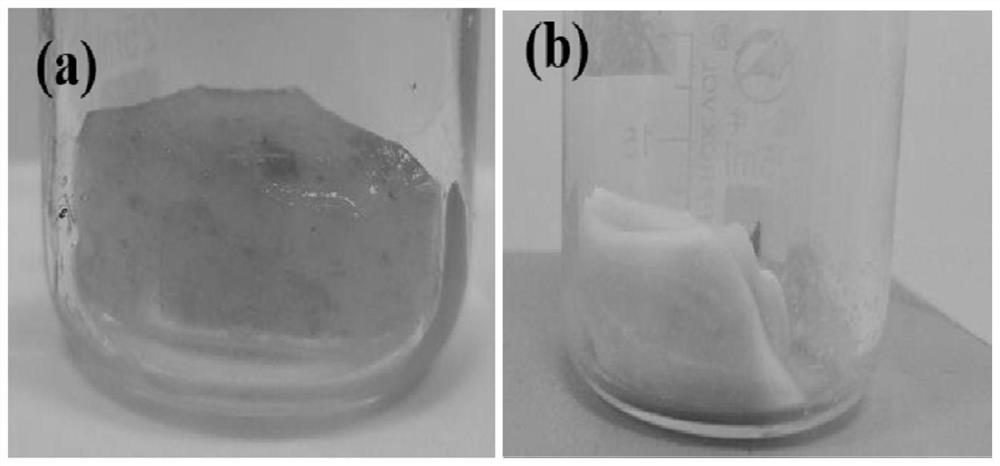

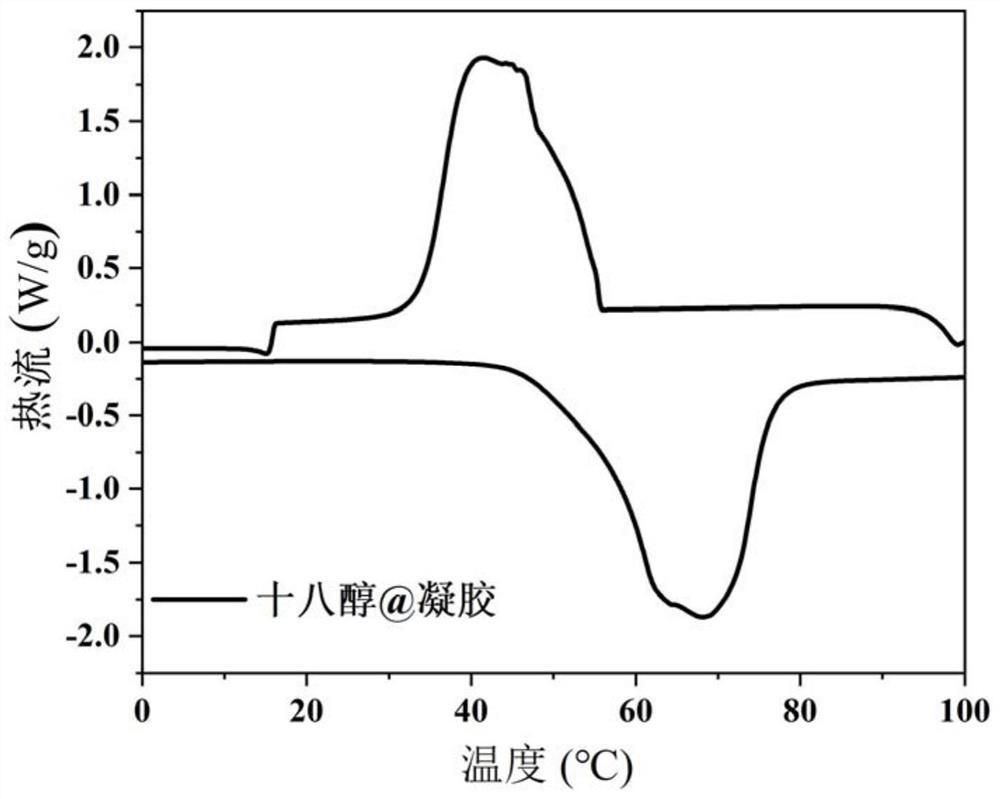

Preparation method of phase change gel material with variable mechanical state

ActiveCN113527573APrevent leakageReduce thermal resistanceHeat-exchange elementsPolymer scienceIsopropyl

The invention discloses a preparation method of a phase change gel material with a variable mechanical state. The method comprises the following steps: (1) preparing poly (N-isopropylacrylamide) hydrogel with a three-dimensional cross-linked network structure by taking an initiator / tetramethylethylenediamine oxidation-reduction system as an initiation system, and then soaking the hydrogel in lower alcohol for alcoholization to obtain alcogel; and (2) heating and melting a phase change material, and carrying out solvent replacement on the phase change material and the alcogel to obtain a phase change gel material. The phase change gel material prepared according to the preparation method disclosed by the invention is high in phase-change latent heat and excellent in stability, has good elasticity and softness, is an energy storage material with more excellent mechanical properties, can change the shape and rigidity as required, and can be applied to multi-scale adhesion and attachment of various three-dimensional surfaces.

Owner:苏州双碳新材料有限公司

Rotary-cutting pressing type grab bucket device

ActiveCN104925659AImplement the crawling functionImprove efficiencyHarvestersLoad-engaging elementsSludgeEngineering

The invention relates to a rotary-cutting pressing type grab bucket device. The rotary-cutting pressing type grab bucket device comprises a grab bucket mechanism, a rotary-cutting mechanism and a pressing mechanism. The grab bucket mechanism comprises an installing rod, fixed pieces, upper connecting rods and lower connecting rods. The row of fixed pieces are evenly welded to the lower end of the installing rod, the corresponding upper connecting rod is welded between every two adjacent fixed pieces at the upper end, and the corresponding lower connecting rod is welded between every two adjacent fixed pieces at the lower end. The rotary-cutting mechanism comprises a fixed plate, a fixed box, rotary-cutting branched chains and L-type limiting insertion rods. The fixed plate and the fixed box are welded, the rear side wall of the fixed box is welded to the fixed pieces, the row of rotary-cutting branched chains are installed between the fixed box and the fixed plate, and the part, between every two rotary-cutting branched chains, of the fixed box is provided with the two corresponding L-type limiting insertion rods. The rotary-cutting branched chains comprise rotary-cutting motors, rotating shafts, rotary-cutting cutter heads and double nuts. The function of treating pond sludge and water plants in a mechanized mode is achieved, and the rotary-cutting pressing type grab bucket device has the advantages of being low in labor intensity, easy and convenient to operate, high in working efficiency and the like.

Owner:菏泽智慧新材料科技有限公司

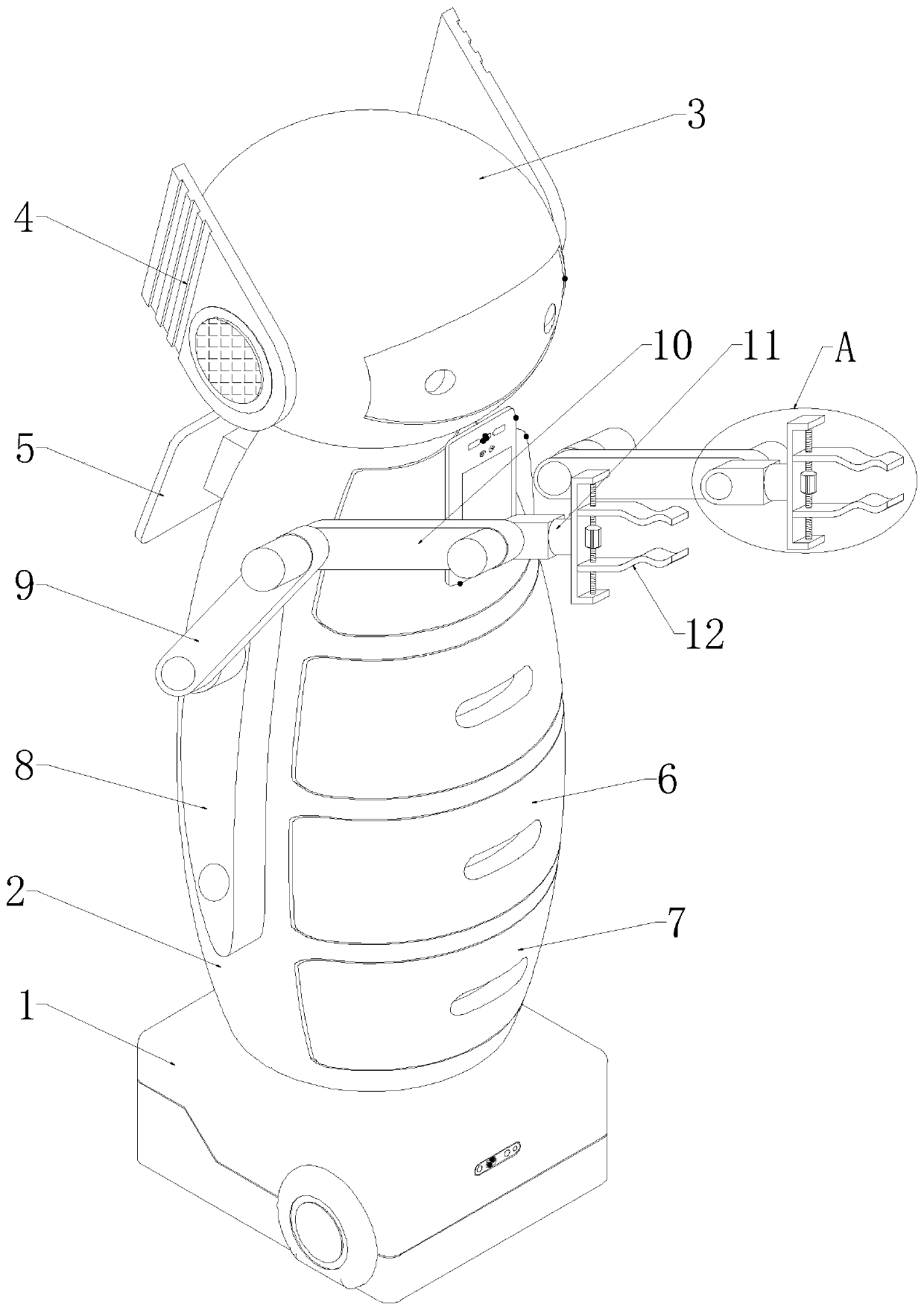

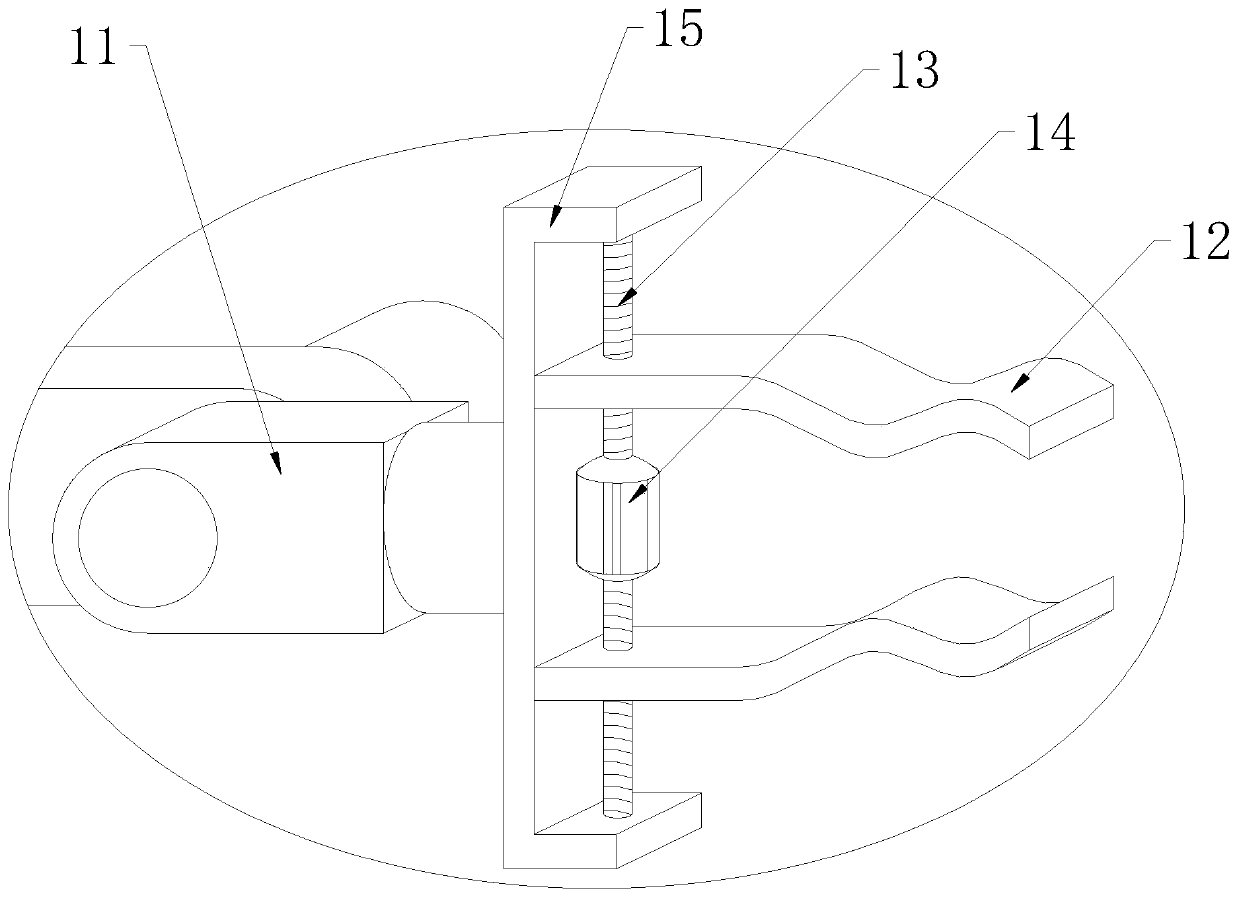

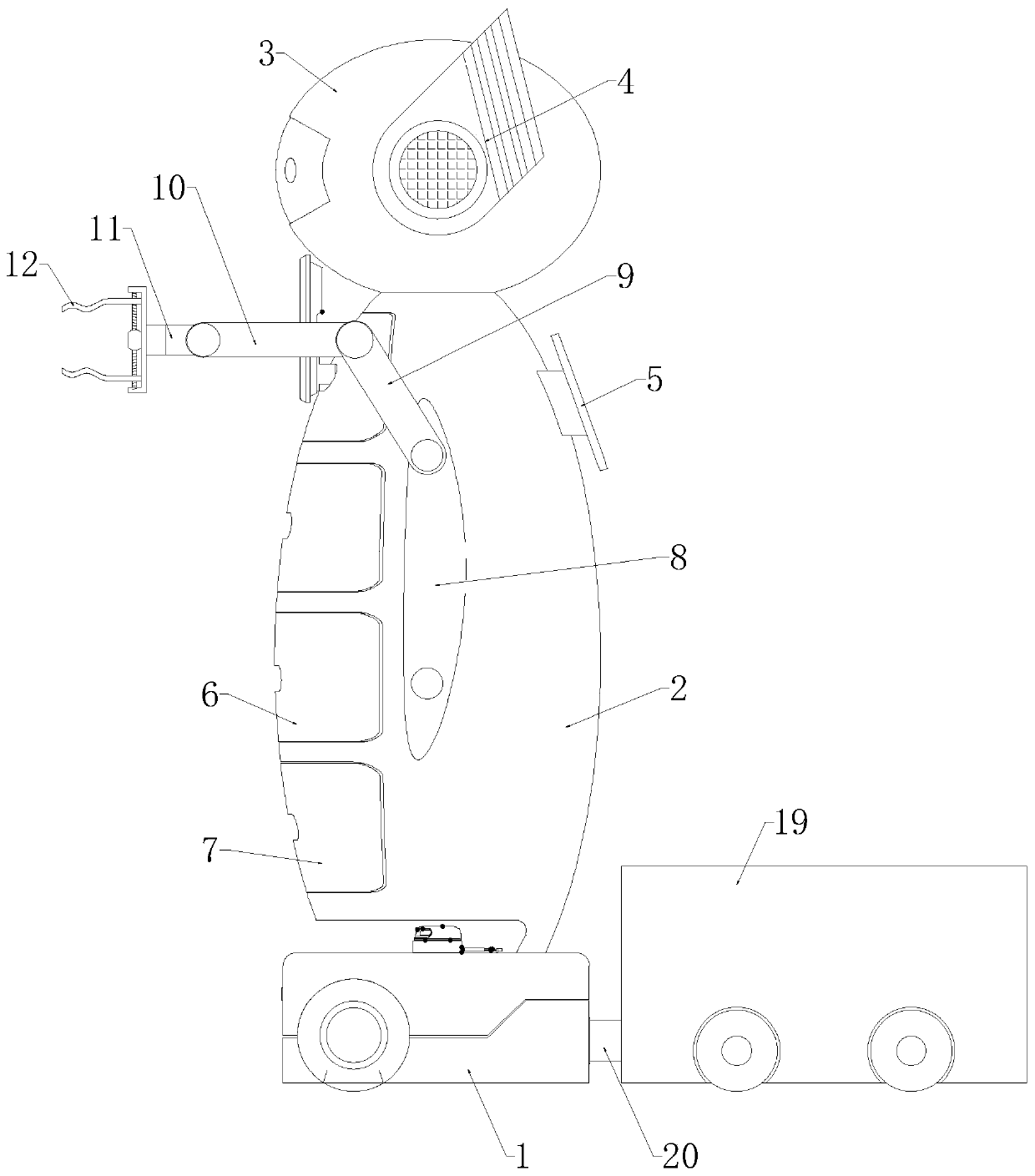

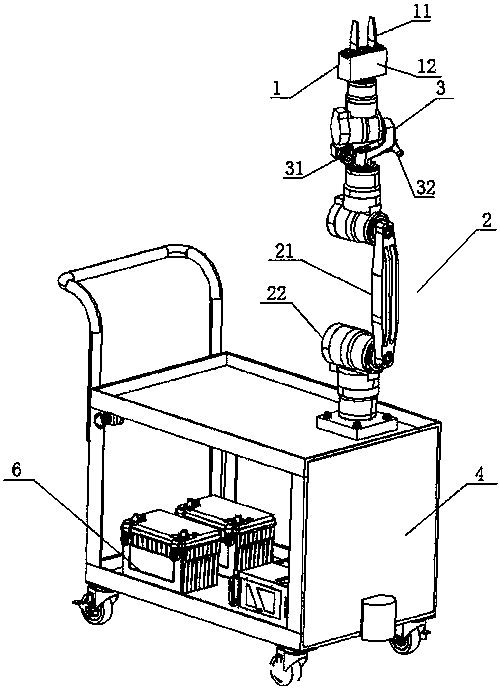

Unmanned human face recognition intelligent mechanical arm robot

InactiveCN111251317ASecurityGuaranteed medicinal propertiesManipulatorHuman body temperatureInfrared thermometry

The invention discloses an unmanned human face recognition intelligent mechanical arm robot. The robot comprises an automatic walking system, a six-axis mechanical arm system, an automatic charging system, a human body temperature measuring system, a human face recognition system and an alarming system, wherein the automatic walking system, the six-axis mechanical arm system, the automatic charging system, the human body temperature measuring system, the human face recognition system and the alarming system are connected with a control system of the robot. The human body temperature measuringsystem comprises an infrared temperature detection module and a human body temperature analyzing module. The infrared temperature detection module comprises multiple infrared thermometers inlaid in the head of the robot. The infrared temperature detection module and the human body temperature analyzing module are connected with the control system. The head is located at the end, away from a walking base, of a body. By means of the robot, the human body temperatures of multiple persons can be measured at the same time anytime and anywhere; and storage drawers are arranged so that storing and conveying of medicines or other objects can be facilitated, meanwhile, an unlocking module is combined with electromagnetic locks on the storage drawers, an antitheft effect can be achieved, and in addition, due to the human face recognition system, objects and medicines can be effectively prevented from being taken wrongly.

Owner:安徽玄离智能科技股份有限公司

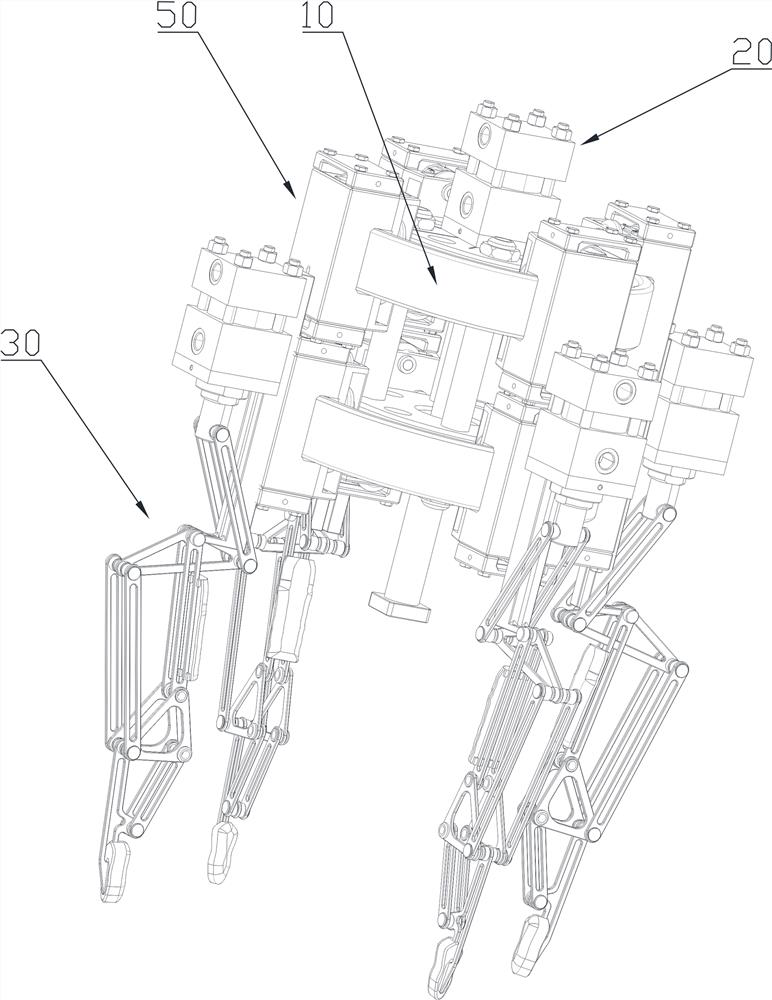

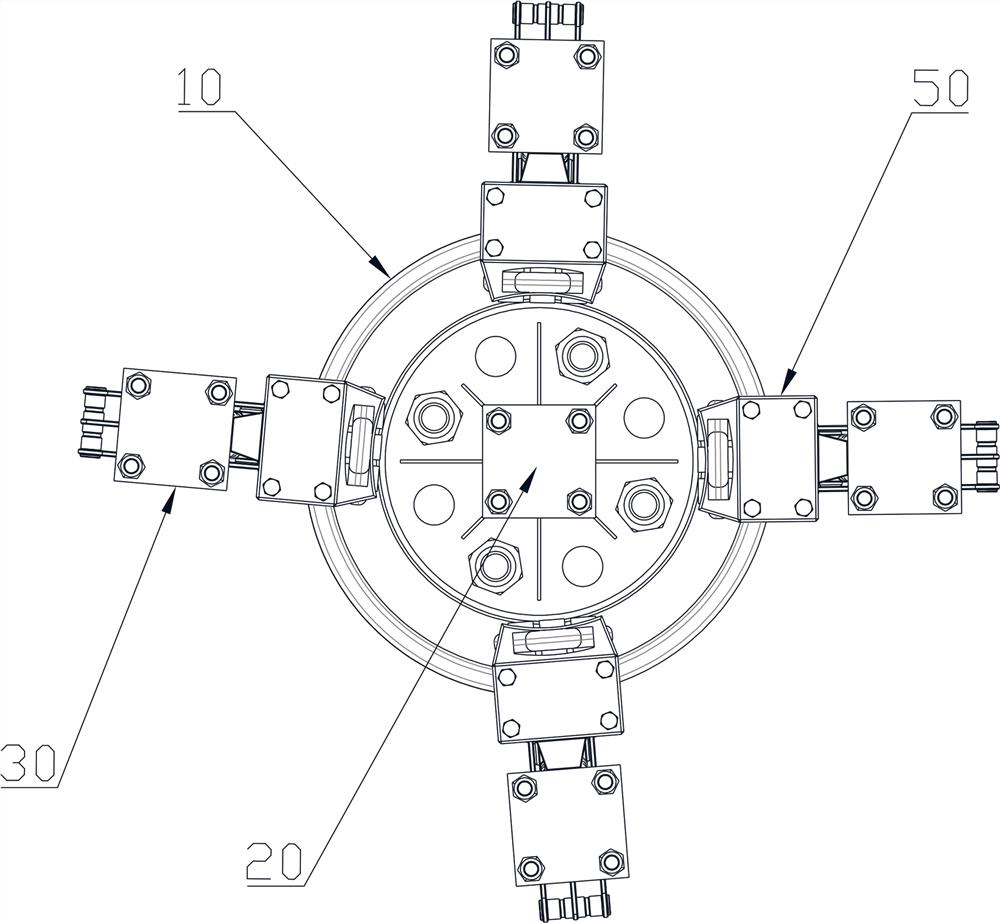

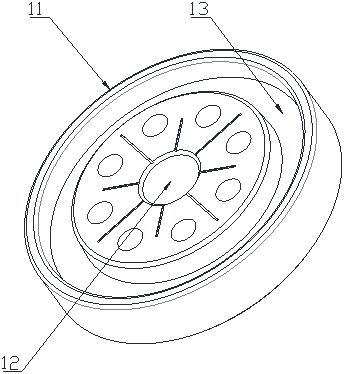

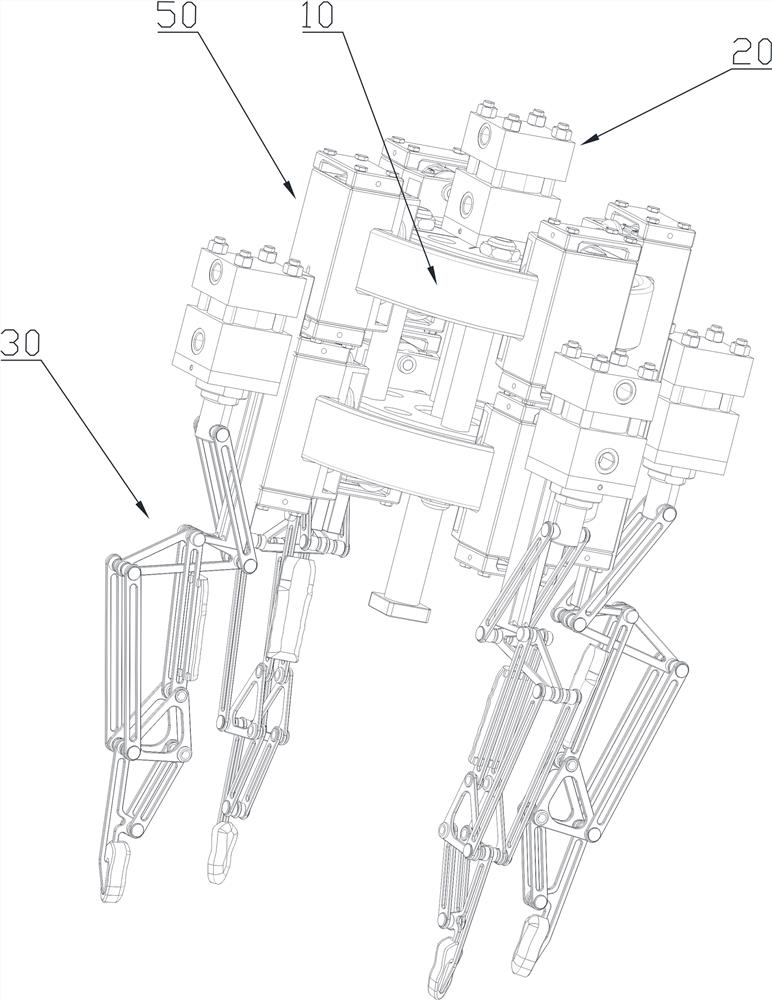

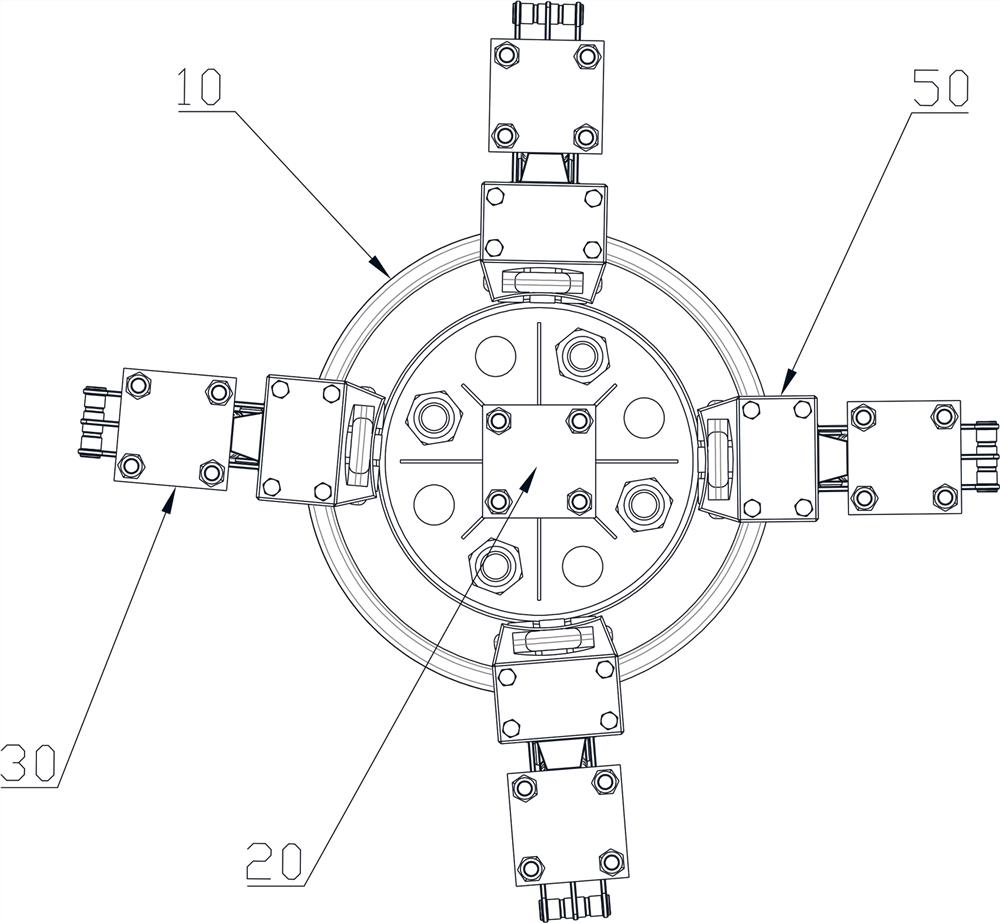

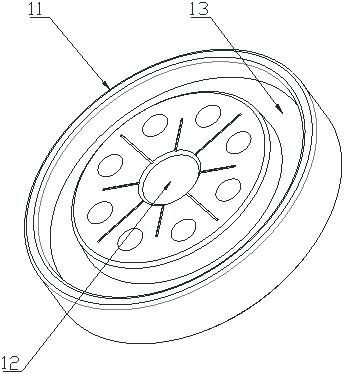

Variable-posture joint type dexterous hand

ActiveCN113561215AImplement the crawling functionEasy to grabGripping headsStructural engineeringMechanical engineering

The invention discloses a variable-posture joint type dexterous hand, and belongs to the technical field of mechanical hands. The variable-posture joint type dexterous hand comprises a base, a jacking assembly and a clamping assembly, wherein the jacking assembly and the clamping assembly are arranged on the base; the jacking assembly is in sliding fit with the base; and the clamping assembly comprises a plurality of multi-connecting-rod fingers which are connected to the edge of the base and can be changed in form. According to the variable-posture joint type dexterous hand, the jacking assembly and the clamping assembly are arranged on the base, the multi-connecting-rod fingers capable of changing various grabbing forms are arranged on the clamping assembly; and when an object needs to be grabbed, the jacking assembly is used for jacking the top surface of the object, the multi-connecting-rod fingers are used for grabbing the outer side of the object, the object is grabbed through the cooperation of the jacking assembly and the clamping assembly, and therefore the grabbing function under the condition of the complex contour of the object is realized.

Owner:SOUTHWEAT UNIV OF SCI & TECH

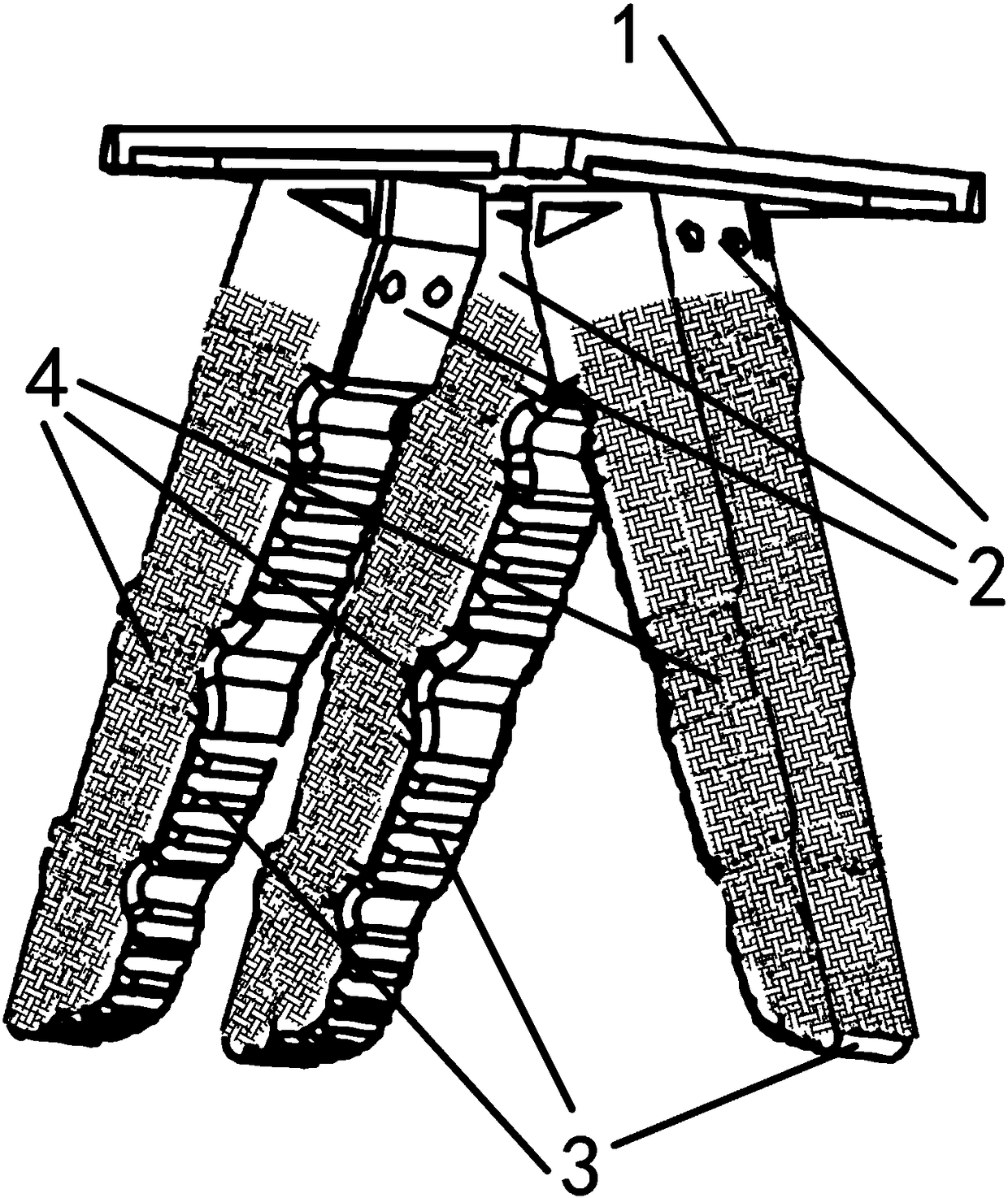

Grab separator and branch-leaf separating system and device

ActiveCN106738156AImplement the crawling functionIncrease productivityTree debarkingEngineeringBiomass

The invention relates to the technical field of forestry, in particular to a grab separator and a branch-leaf separating system and device to alleviate the problems that in the prior art, the working efficiency is low and the hands are prone to be injured since branches and leaves are manually separated in the forest biomass acquisition process. The grab separator comprises a drive plate, and two sliding mechanisms oppositely arranged on the drive plate. Statistical personnel only need to put branches between the two sliding mechanisms, afterthe two sliding mechanisms move face to face to clamp the branches tightly, the drive plate drives the two sliding mechanisms to move in the length direction of the branches, and the sliding mechanisms apply high stripping force to the junctions of the branches and leaves in the moving process so as to separate the branches from the leaves. The grab separator provided by the embodiment is high in production efficiency, injuries tothe hands of an operator are avoided, and the technical problems that in the prior art, the working efficiency is low and the hands of the operator are prone to be injured due to manual separation are thoroughly solved.

Owner:BEIJING FORESTRY UNIVERSITY

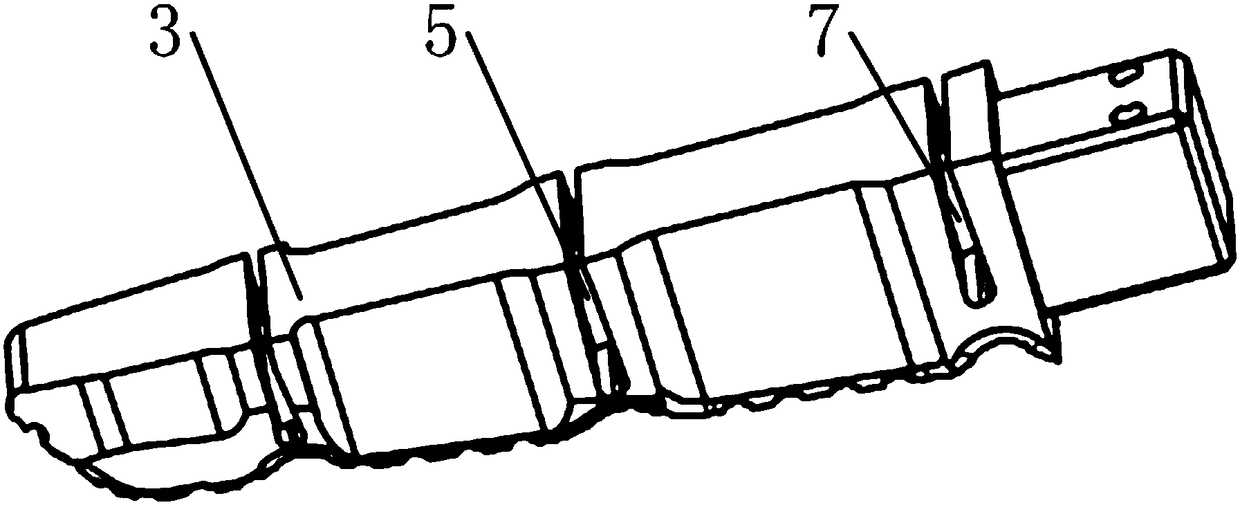

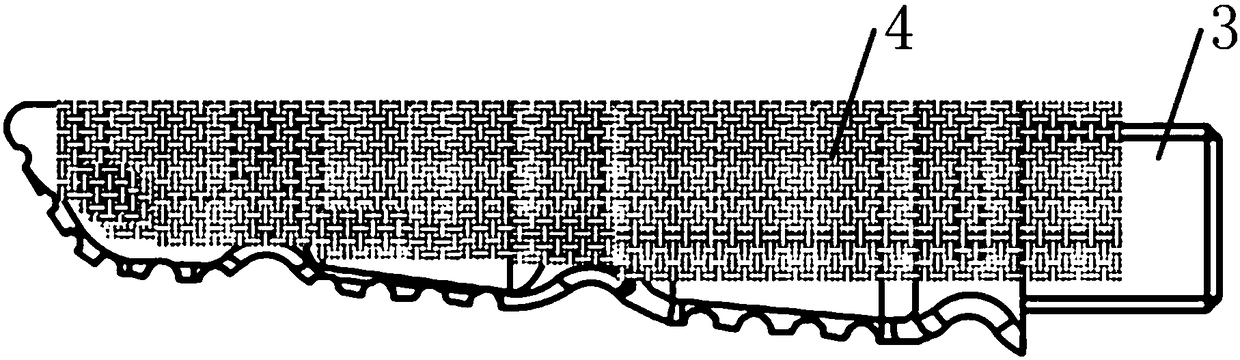

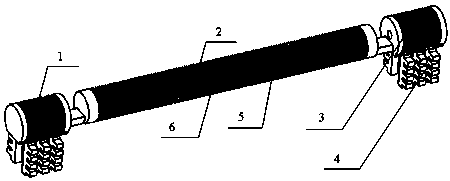

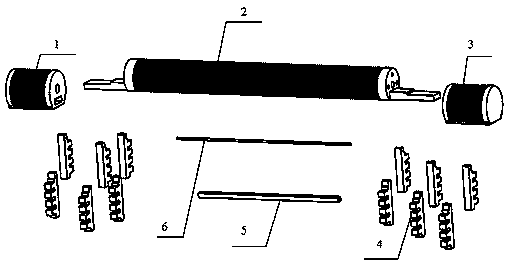

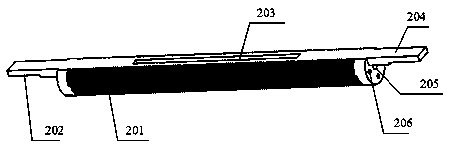

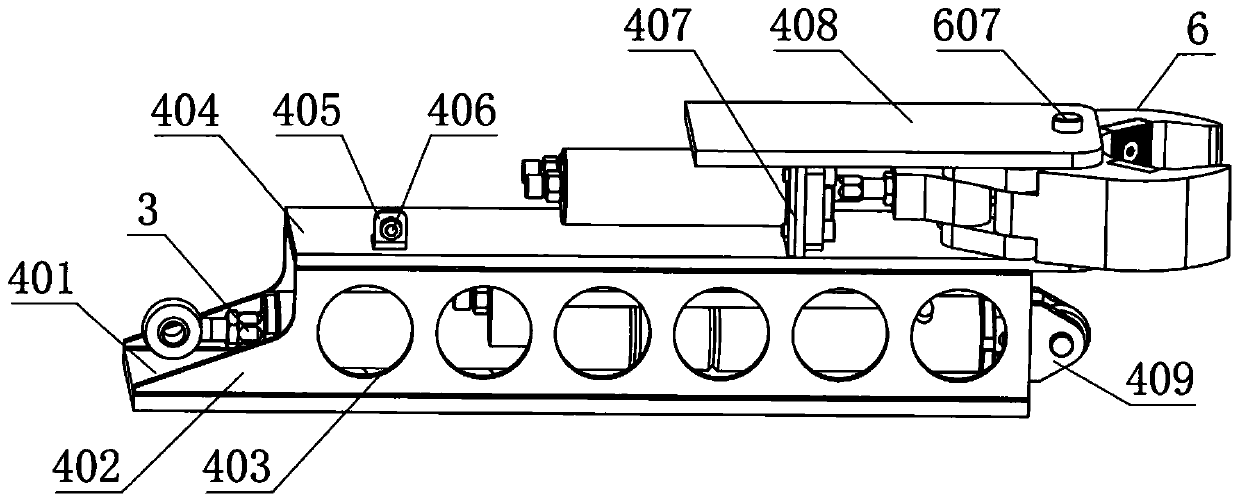

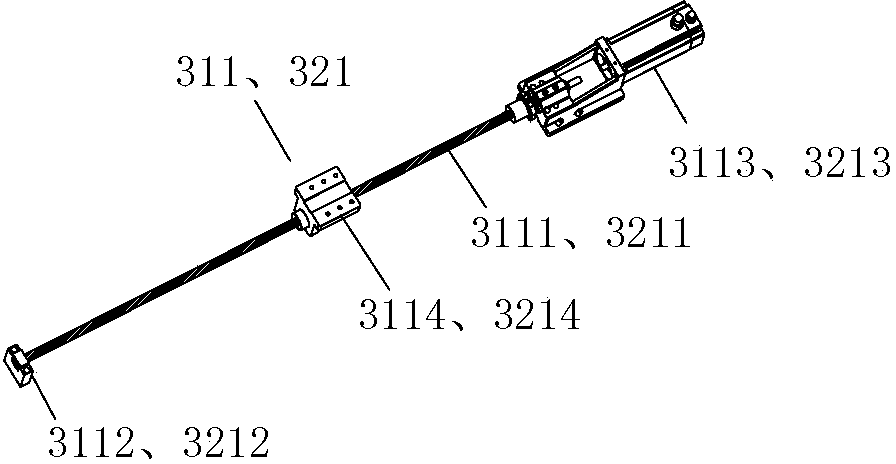

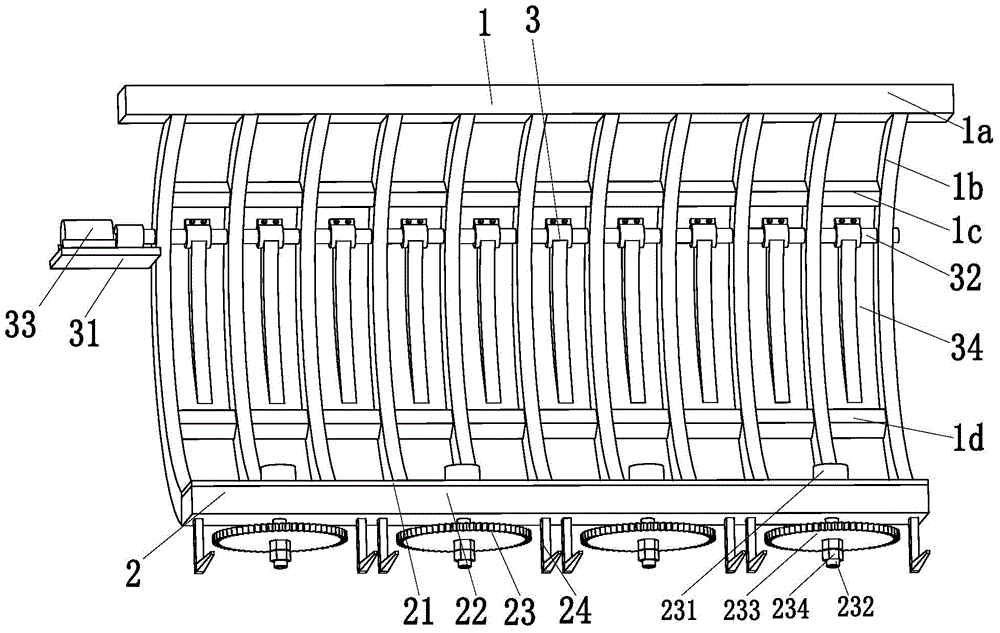

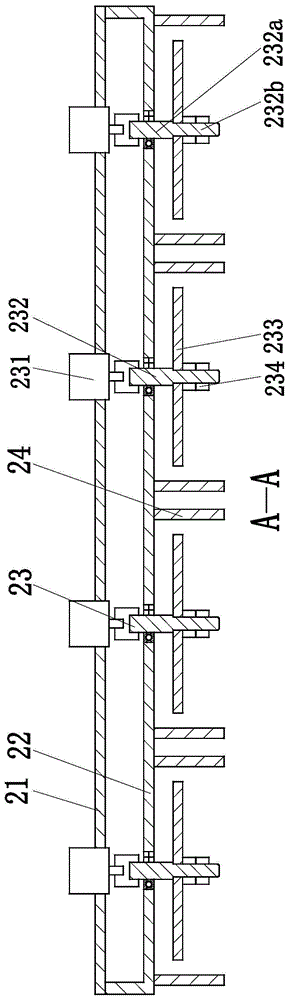

Multiposition and multifunctional pipe moving manipulator for submarine drilling machine

ActiveCN110145263AImplement the crawling functionImprove adaptabilityDrilling rodsDrilling casingsManipulatorSubmarine

The invention discloses a multiposition and multifunctional pipe moving manipulator for a submarine drilling machine. The multiposition and multifunctional pipe moving manipulator comprises an outer frame, a guide rail, a boom oil cylinder, a telescopic arm component, a position sensor and a manipulator component, wherein the boom oil cylinder can drive the telescopic arm component to swing on theguide rail; and a manipulator oil cylinder stretches out and draws back to drive two manipulators to open and close. According to the multiposition and multifunctional pipe moving manipulator, the boom oil cylinder stretches out and draws back to drive the telescopic arm component to reach the positions of drill pipes, drilling tools and core barrels at different floors of a drill pipe warehouse;a spring and disc spring combined structure in the manipulator oil cylinder can grab drill pipes, drilling tools and core barrels with different diameters, also can protect the pipes when the drilling pipes and the drilling tools are connected and dismantled and the core barrels are put down in the sea and taken up and is high in adaptation; and the multiposition and multifunctional pipe moving manipulator further has the advantages of being simple and compact in structure and convenient in control.

Owner:HUNAN UNIV OF SCI & TECH

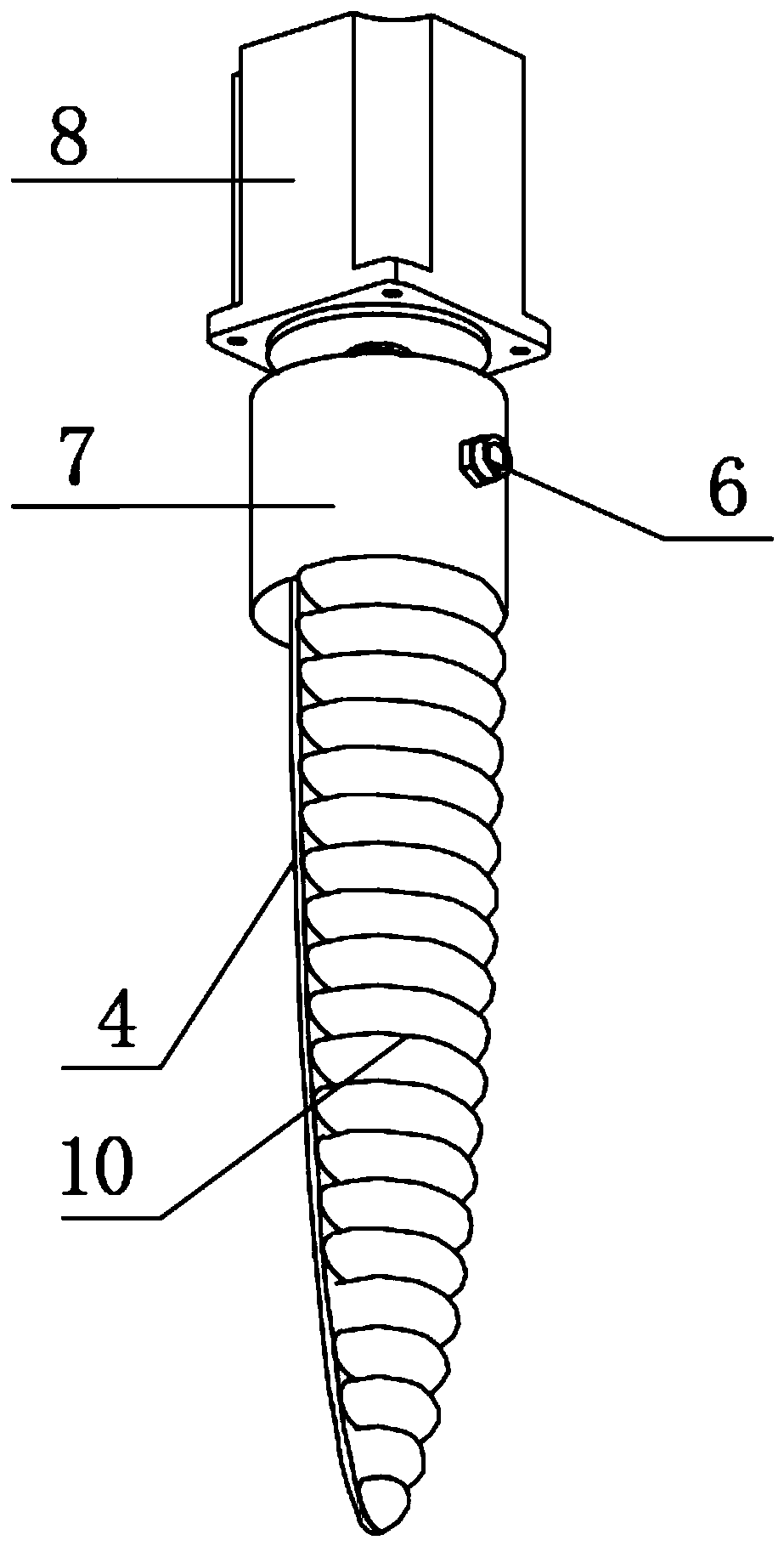

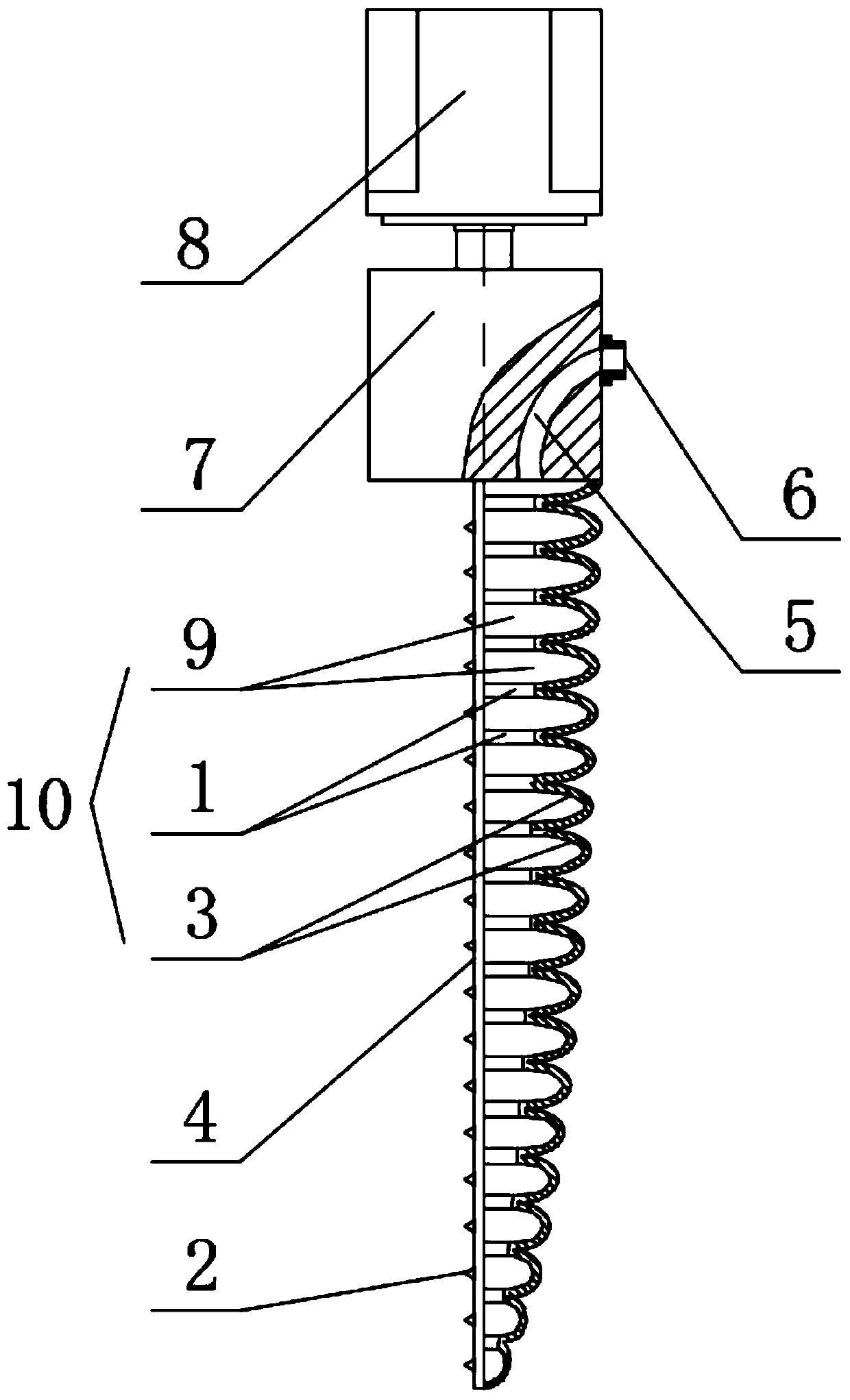

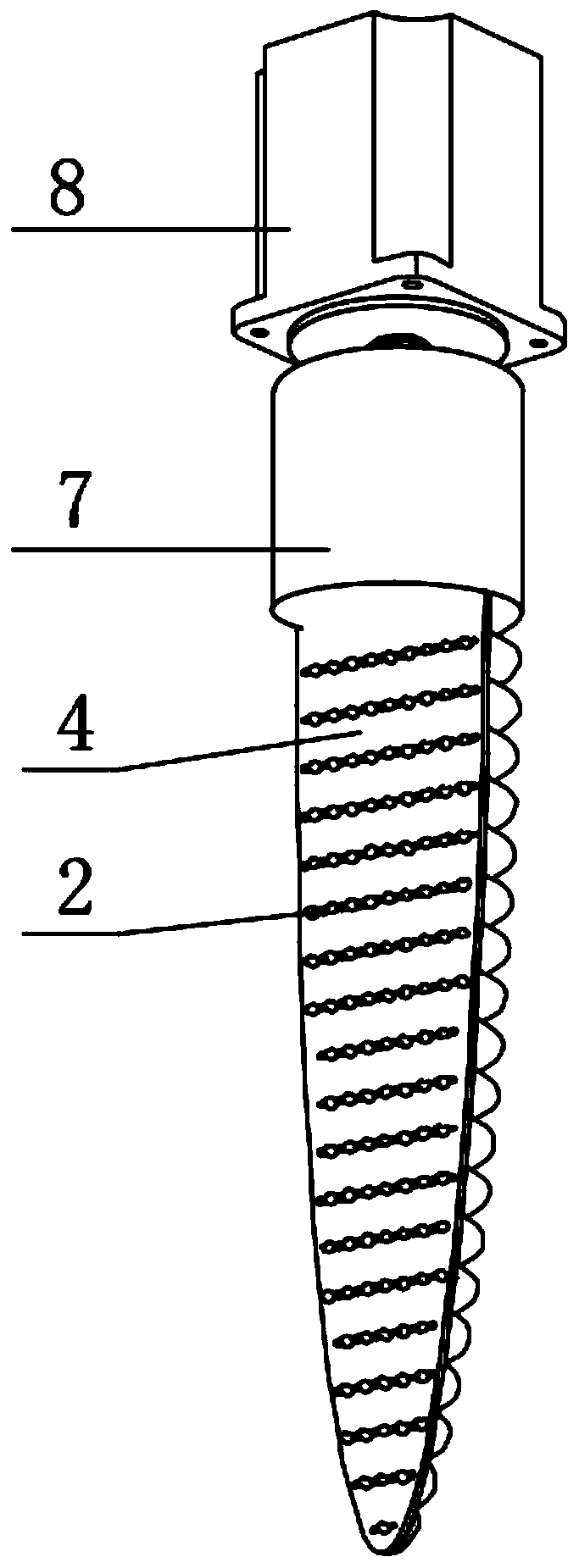

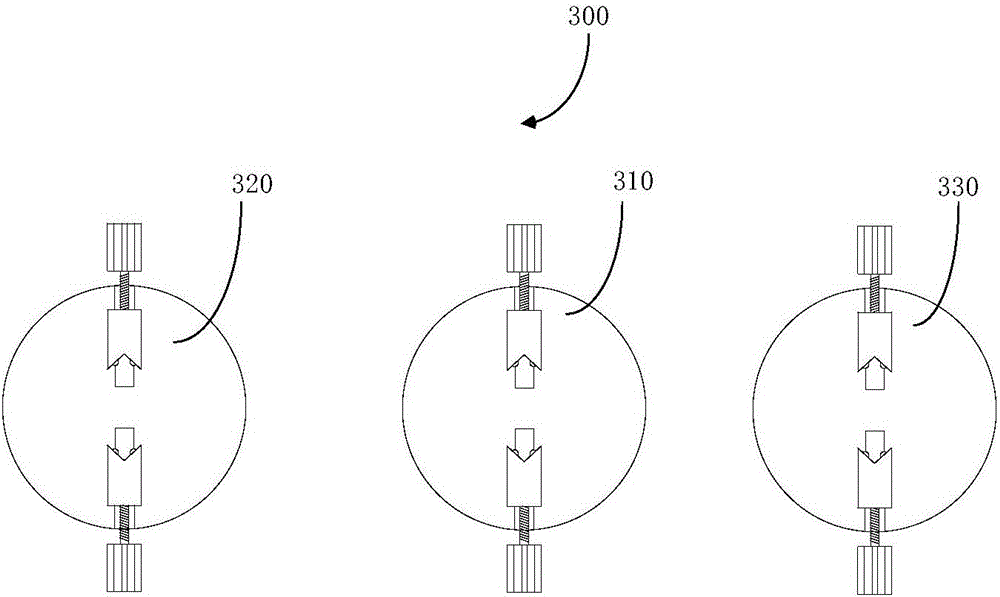

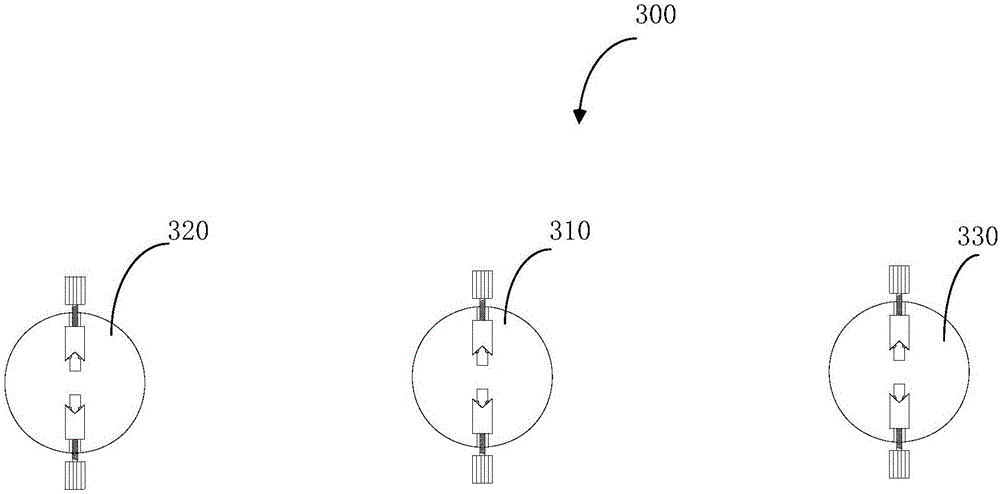

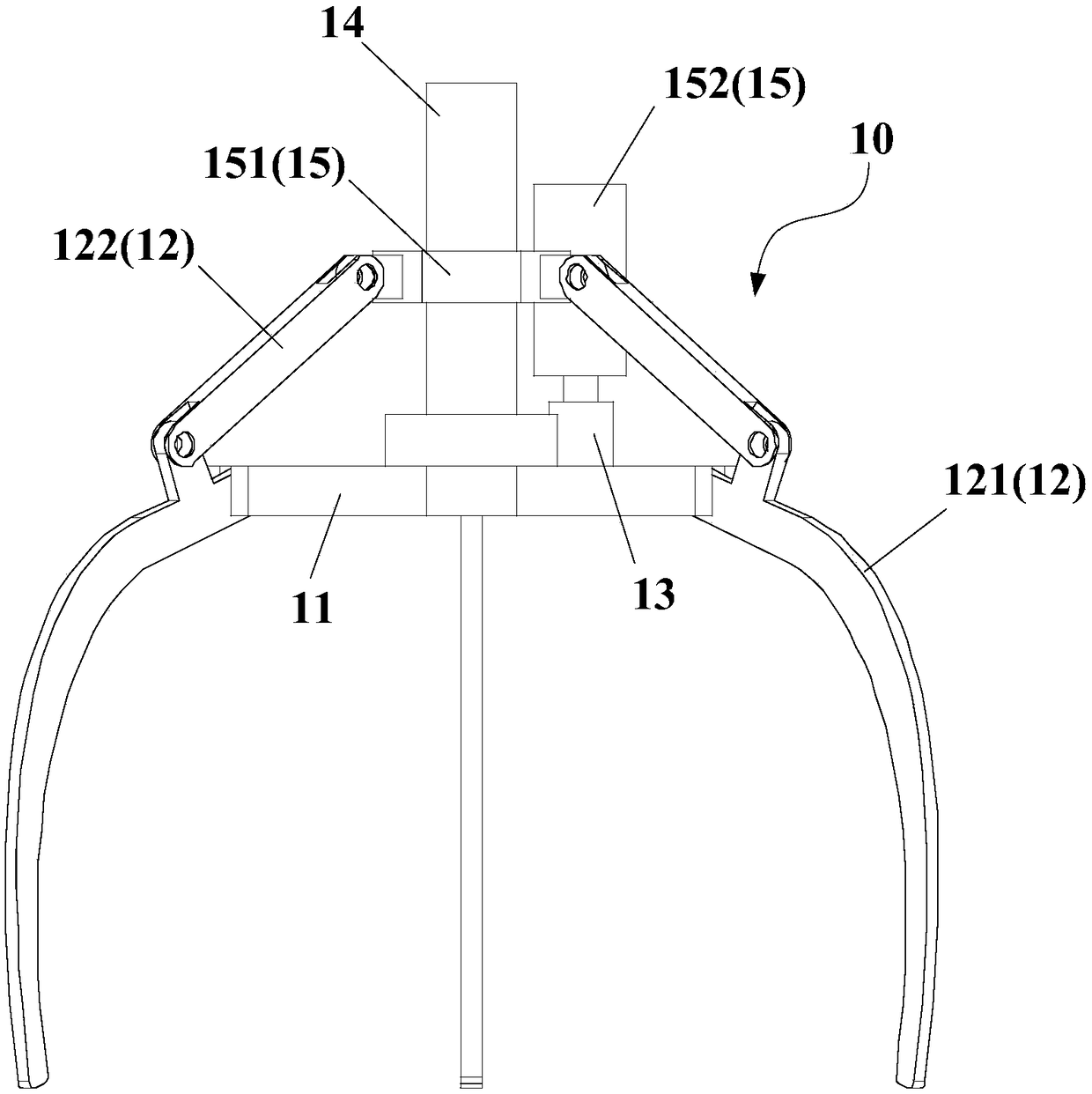

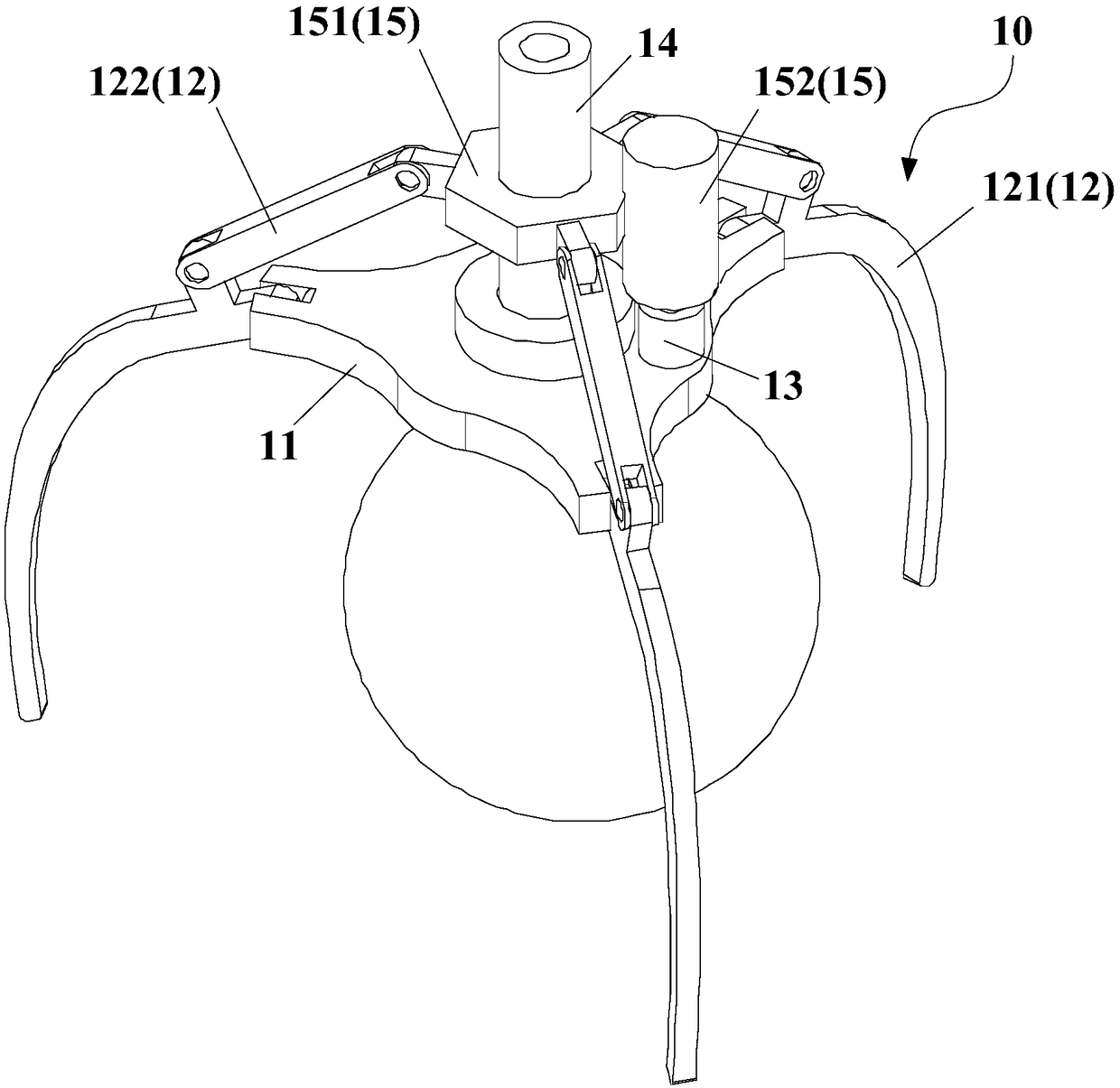

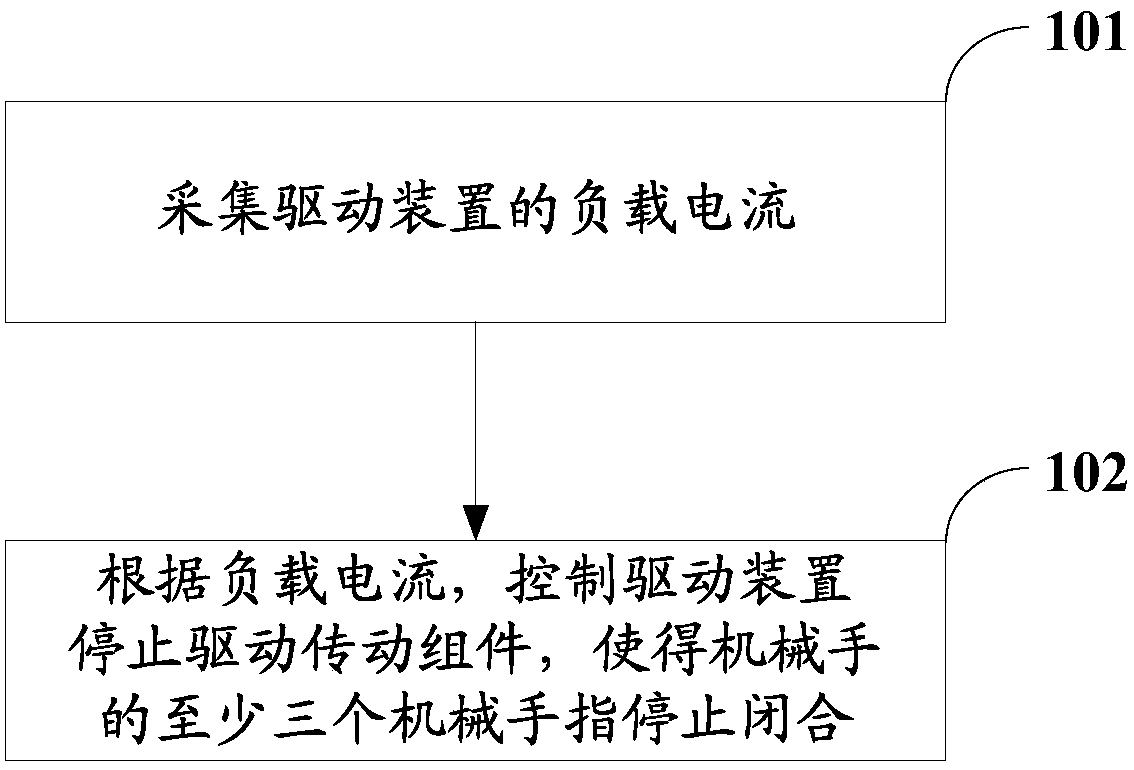

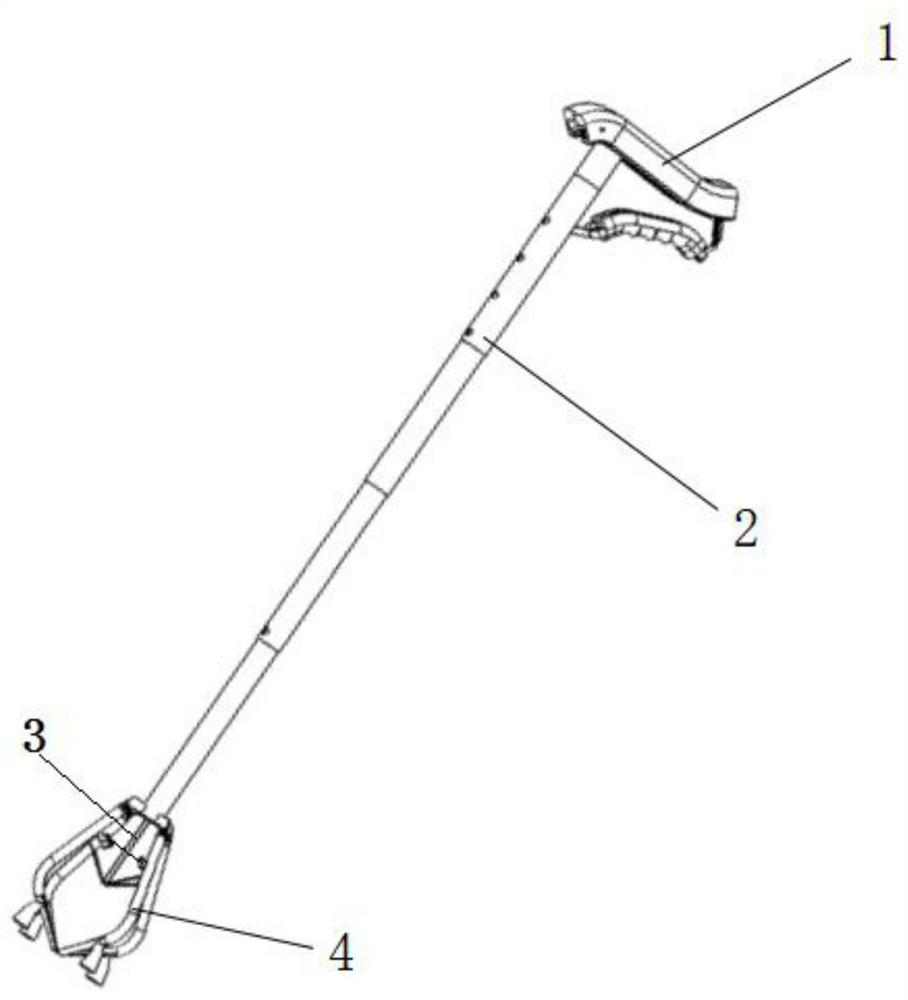

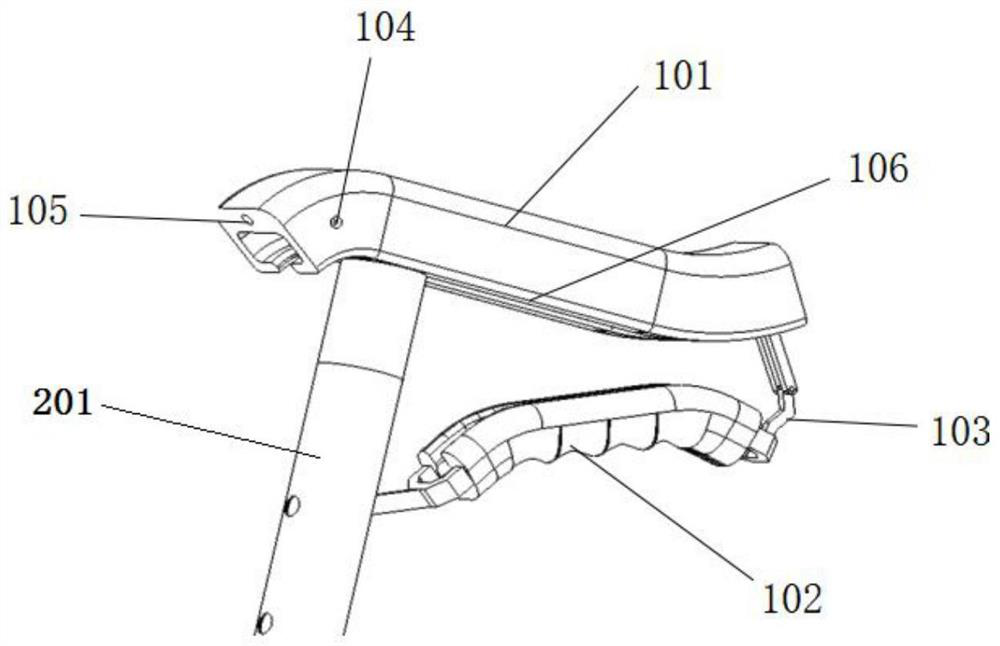

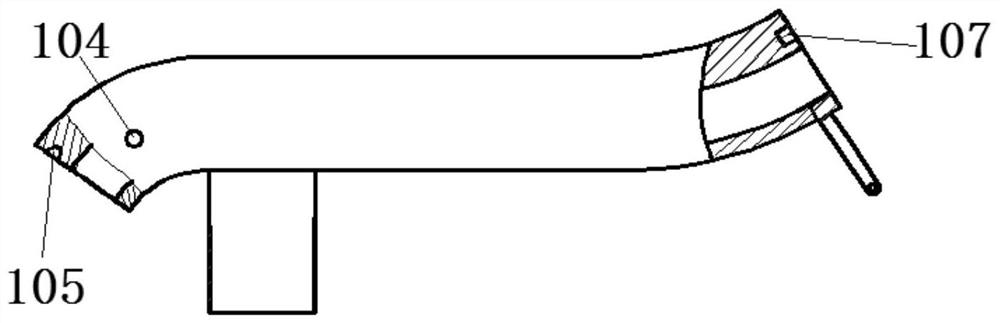

Mechanical claw for unmanned aerial vehicle, control method and device thereof and unmanned aerial vehicle

InactiveCN108994875ASimple structureImprove reliabilityAircraft componentsGripping headsUncrewed vehicleSimulation

The invention relates to the technical field of unmanned aerial vehicles, and discloses a mechanical claw for an unmanned aerial vehicle, a control method and device thereof and the unmanned aerial vehicle. The unmanned aerial vehicle with a grabbing function and the simple structure can be provided, and thus the reliability and stability of the unmanned aerial vehicle are improved. The mechanicalclaw for the unmanned aerial vehicle comprises a pedestal, at least three mechanical fingers arranged on the pedestal, a driving device, a guiding shaft and a drive assembly. The driving device, thedrive assembly and the at least three mechanical fingers are connected in sequence. The drive assembly and the guiding shaft are connected in a sliding mode. The driving device is used for driving thedrive assembly to slide along the guiding shaft so that the at least three mechanical fingers can be opened and closed.

Owner:POWERVISION TECH

A Dexterous Hand with Changing Posture

ActiveCN113561215BImplement the crawling functionEasy to grabGripping headsPhysical medicine and rehabilitationRobot hand

The invention discloses a posture-changing joint type dexterous hand, which belongs to the technical field of manipulators. A posture-changing joint-type dexterous hand, comprising: a base, a clamping component and a clamping component respectively arranged on the base; the clamping component and the base are slidably matched; the clamping component includes: Varying multi-link fingers. In the present invention, a jacking assembly and a clamping assembly are arranged on the base, and multi-link fingers capable of changing various grasping forms are provided on the clamping assembly. The surface is tightened, and the multi-link fingers grasp the outside of the object, and the object is grasped through the cooperation of the clamping component and the clamping component, so as to realize the grasping function in the case of complex contours of the object.

Owner:SOUTHWEAT UNIV OF SCI & TECH

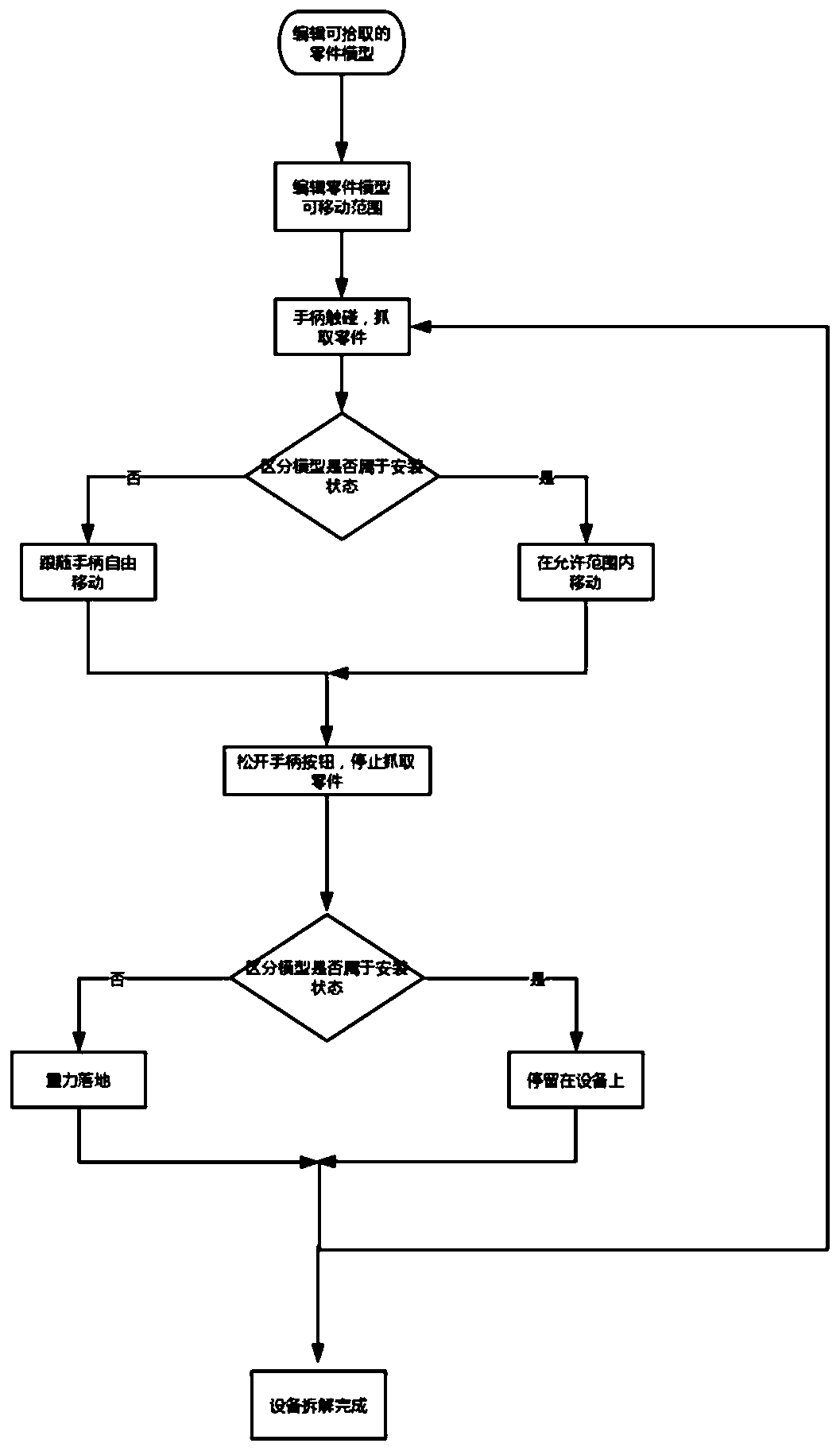

A manual touch simulation equipment disassembling system and method based on Unity 3d and VR equipment

InactiveCN109739477AEasy to useImplement the crawling functionSoftware designElectrical appliancesData transmissionAnalog device

The invention discloses a manual touch simulation equipment disassembling system and a manual touch simulation equipment disassembling method based on Unity 3d and VR equipment. The manual touch simulation equipment disassembling system comprises a data acquisition module used for acquiring real data of each part model of equipment to be simulated; a model building module used for building a partmodel which can be manually touched and disassembled in the equipment and setting a movable range of the part model; a disassembling sequence setting module used for setting the disassembling sequenceof the part models; an action feedback calling module used for obtaining action feedback for calling a VR handle of the VR equipment; and a data transmission module used for transmitting the positioninformation of the part model and the action information of the VR handle between the VR equipment and the client.

Owner:BEIJING INBASIS TECH

Mechanical clamping device

InactiveCN109202854AImplement the crawling functionRealize scanningManipulatorRobotic armEngineering

The invention provides a mechanical clamping device. The mechanical clamping device comprises a mechanical jaw, a mechanical arm, a positioning mechanism and a movable table; the mechanical arm is mounted on the movable table, and the detachable mechanical clamping jaw is fixedly mounted at the end of the mechanical arm; the mechanical arm comprises a power arm and at least two sensors; the positioning mechanism, also a power arm, is mounted on the mechanical arm; a camera mechanism and a laser emission mechanism are mounted on the positioning mechanism. The mechanical clamping device has theadvantages of convenience in use, novel design, scientificity, reasonableness, good using effect, high promotion value and huge market economy prospect.

Owner:常州钟楼高新技术创业服务有限公司

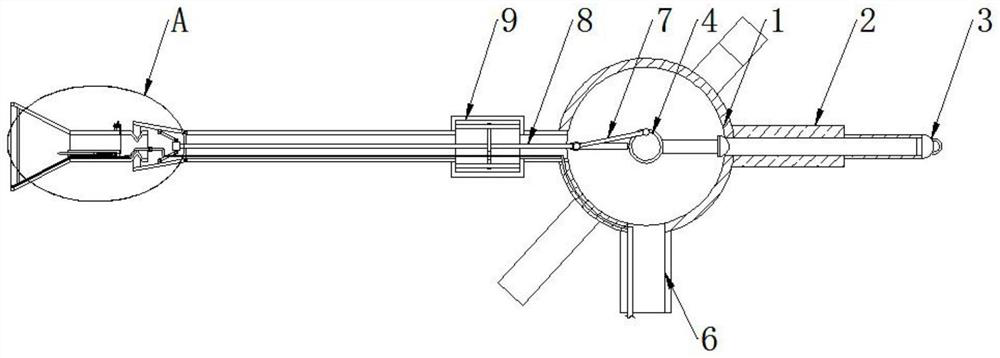

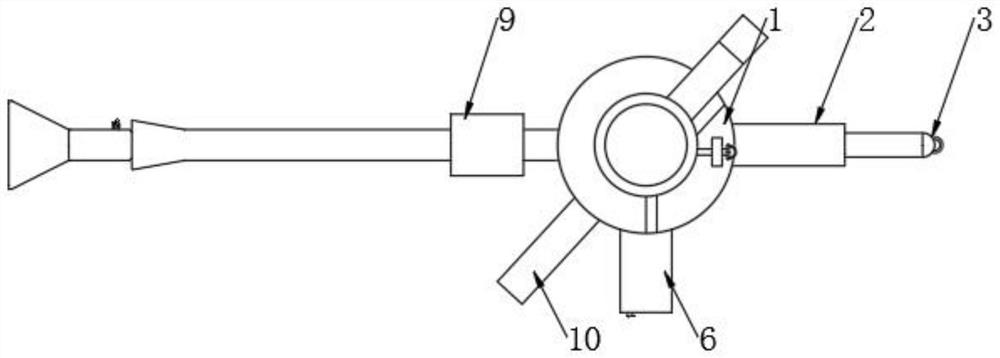

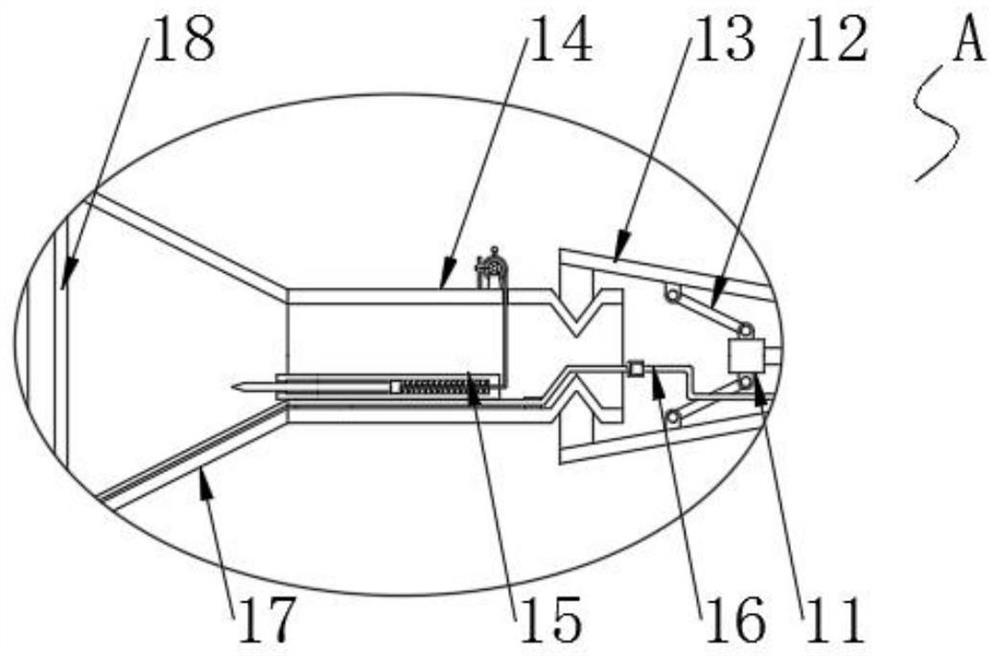

Laparoscope suction device

PendingCN114557736AEasy to storeImplement the crawling functionSurgical needlesSuction devicesLaparoscopesAbdominal cavity

The invention discloses a laparoscope suction device.The laparoscope suction device comprises a shell, the shell is rotationally connected with a rotating column, and according to the laparoscope suction device, firstly, a three-jaw clamp is connected with a suction cup and then enters the abdominal cavity, the suction cup can be well fixed through the three-jaw clamp, and after an external negative pressure suction device is opened, the suction cup is fixed through the rotating column; and the outer side wall of the bag body can be effectively adsorbed and fixed by the sucker. The puncture structure is opened, the puncture structure can explode the bag body, seepage inside the bag body can be sucked by the device in time after the bag body is exploded, the ligation belt can well ligate a puncture part after suction is completed, and residual liquid is prevented from leaking outwards. After ligation, the three-jaw forceps can be separated from the suction cup, and at the moment, the grabbing function of the three-jaw forceps can be achieved. In the operation process, if seepage still exists in the abdominal cavity, the claw forceps structure is changed into a cylinder structure, and meanwhile suction can be conducted; meanwhile, when the suction cup is not used, the bag body can be broken through the three-jaw pliers, and the multifunctional effect of the three-jaw pliers is achieved.

Owner:SHANGHAI PUTUO DISTRICT CENT HOSPITAL

Method and system for grabbing with a robotic arm

ActiveCN108858193BAchieve robustnessImplement the crawling functionProgramme-controlled manipulatorPoint cloudRobot hand

The invention provides a mechanical arm grabbing method and a system for achieving the method. The method comprises the following steps that S1, point cloud information of the surface (the surface capable of being seen in the view field of a camera) of an object to be grabbed is collected; S2, data of the point cloud information is further processed, and feasible grabbing points meeting constraintconditions are extracted through a grabbing programming algorithm; S3, the grabbing points are adopted as inverse kinematics input of a mechanical arm, and a motion control instruction is sent to themechanical arm and a two-finger parallel gripper; and S4, the mechanical arm executes the motion control instruction, and moves to the specified position, and according to the motion timing relationship in the motion control instruction, the two-finger parallel gripper is opened and clamped to complete the grabbing task. The mechanical arm grabbing method and the system for achieving the method have the beneficial effects that under the condition that the shape of the object is uncertain, a single visual sensor can be used for achieving the mechanical arm grabbing function with robustness.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

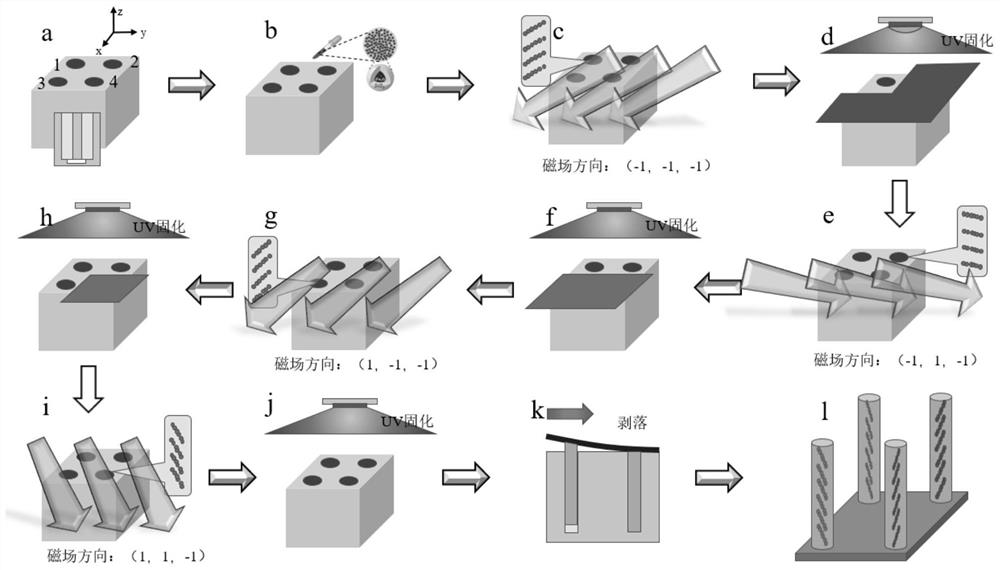

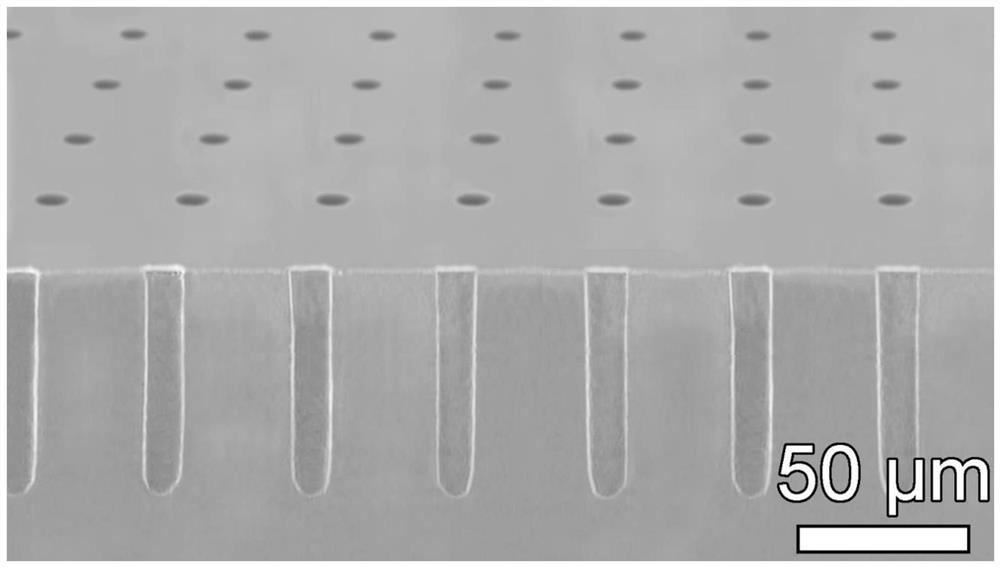

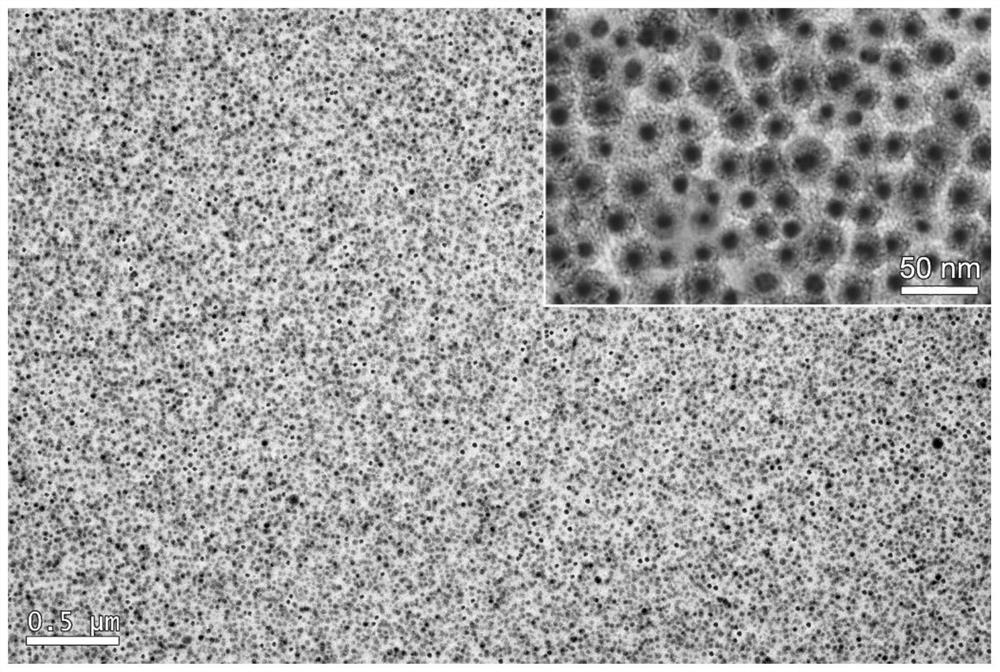

Preparation and use method of a microscopic intelligent robot and a microscopic magnetic gripper

ActiveCN113580196BHigh strengthIncrease stiffnessMicromanipulatorGripping headsMicron scaleEngineering

The invention discloses a preparation and use method of a microscopic intelligent robot and a microscopic magnetic gripper. Drop the particle-filled composite resin onto a template with a micron-scale column cavity to allow the resin to penetrate into the column cavity of the template; apply a magnetic field from the origin of the spatial coordinate to any direction in the seventh quadrant to illuminate the resin outside the photomask Make it solidify; then rotate the magnetic field clockwise around the z-axis by 90°, 180°, and 270°, respectively, after each rotation, illuminate the resin outside the photomask to solidify it; cover the PET substrate on the resin, and the substrate and the After the resin is combined, it is peeled off from the template to obtain a microscopic intelligent robot; the microscopic intelligent robot made by the present invention can achieve different deformations in the four micro-columns by applying different magnetic fields, thereby generating horizontal movement, turning, and grasping the micro-particles. Movements such as take and release.

Owner:WUHAN UNIV

A rotary cutting and compacting integrated grab

ActiveCN104925658BImplement the crawling functionImprove efficiencyLoad-engaging elementsHydraulic cylinderSludge

The invention relates to an integral grab bucket capable of rotary-cutting and compressing. The integral grab bucket capable of rotary-cutting and compressing comprises a beam, six first lug seats, two grabbing devices, six second lug seats, two hydraulic cylinders and four telescopic rods; two hanging lugs are symmetrically arranged on the upper end face of the beam, three first lug seats which are located at the same side of the beam are evenly welded to the outer wall of the beam, the two grabbing devices are symmetrically located at two sides of the beam, three second lug seats which are located at the same side of the beam are evenly welded to the grabbing devices, the bottom ends of the hydraulic cylinders are connected with the first lug seats which are located on the outer wall of the middle portion of the beam through pin shafts, and the top ends of the hydraulic cylinders are connected with the second lug seats which are located in the middle portions of the grabbing devices through pin shafts, the top ends of the telescopic rods are connected with the first lug seats through pin shafts, and the bottom ends of the telescopic rods are connected with the second lug seats which are located at the same sides of the hydraulic cylinders through pin shafts. By means of the grab bucket, the function of mechanized handling of sludge in a pond and aquatic plants is achieved, and the grab bucket has the advantages that the labor strength is small, the operation is simple and convenient, and the work efficiency is high.

Owner:湖州优研知识产权服务有限公司

An intelligent flexible manipulator

ActiveCN109291072BImplement the crawling functionControls are widely applicableGripping headsRobot handPressure.drive

The invention discloses an intelligent flexible operating hand. The flexible tactile fingers are connected to the lower base plate of the base through the upper base plate of the base; the upper base plate of the base and the lower base plate of the base are connected and fixed with the base plate in the base; And fixed on the bottom plate of the base, it can realize the air pressure drive in the flexible touch finger; the air pump and the flexible touch finger are respectively connected to the main control module; the intelligent flexible operator uses four movable flexible touch fingers, which can realize the target object The flexible grasping of the flexible tactile finger is achieved by using conductive silica gel to realize the force perception of the flexible tactile finger, thereby realizing the purpose of adjusting and controlling the grip force of the flexible tactile finger; The intelligent manipulator grasps the attitude control, and the conductive silica gel is connected with the main controller to realize the reading of the force information of the flexible intelligent manipulator. The operator can be widely used in places where flexible gripping is required.

Owner:SHANGHAI UNIV

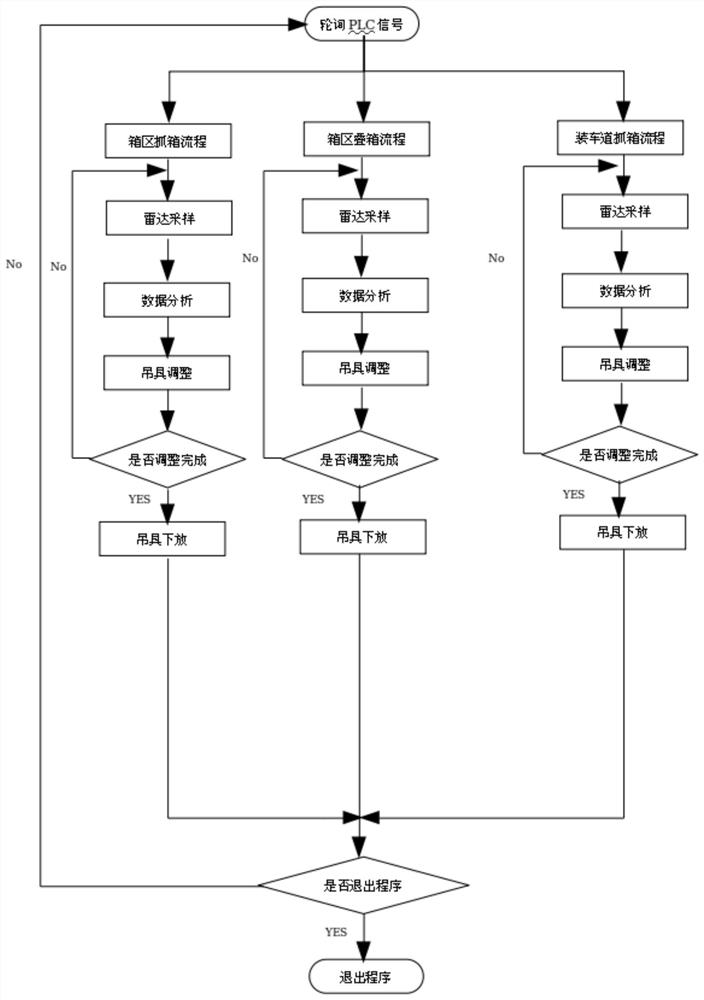

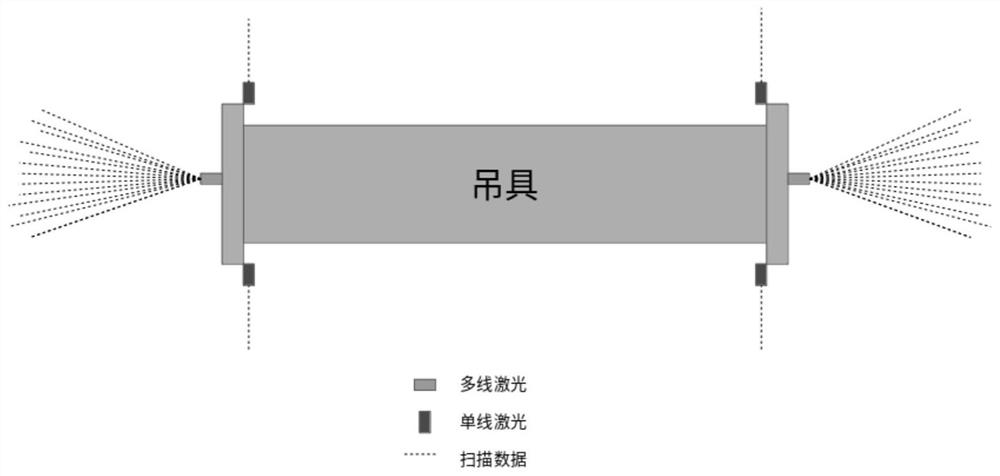

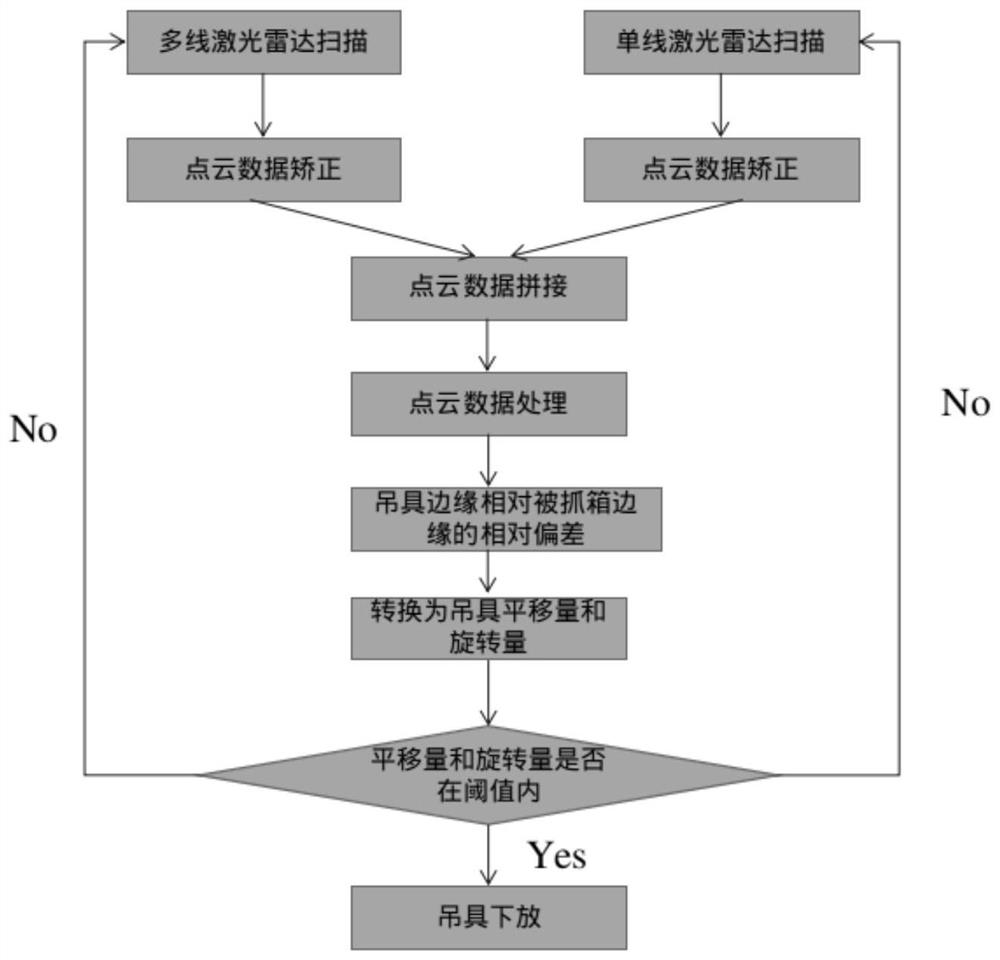

Automatic box grabbing method for spreader of gantry crane

PendingCN113460888AAdjust the current posture in real timeImplement the crawling functionLoad-engaging elementsComputer hardwareComputational science

The invention provides an automatic box grabbing method for a spreader of a gantry crane. The automatic box grabbing method comprises the steps of: arranging first laser radars at two ends of the spreader in the long edge direction separately; arranging second laser radars at the middle positions of the spreader in the short edge direction separately, wherein each laser radar is used for acquiring point cloud data below the spreader; constructing a world coordinate system by using the spreader center of the gantry crane; after the spreader of the gantry crane moves to a certain height above a to-be-grabbed or to-be-stacked container, acquiring point cloud data below the spreader by the first laser radars and the second laser radars,calibrating the point cloud data into the world coordinate system separately, carrying out point cloud splicing on the calibrated point cloud data, eliminating repeated point cloud data, and processing the point cloud data to acquire point cloud data of various edge lines of the spreader, a container loaded on the spreader and various edge lines of a container to be grabbed or stacked on the ground and space coordinates of the point cloud data in the world coordinate system; and calculating the translation amount and rotation amount of the edge lines of the spreader and the edge lines of the to-be-grabbed container.

Owner:武汉港迪智能技术有限公司

A graspable multifunctional crutch

InactiveCN111297004BImplement the crawling functionPrevent fallingWalking sticksPhysical medicine and rehabilitationEngineering

The invention discloses a grabbable multifunctional walking stick. The grabbed multifunctional walking stick can be divided into a handle, an external telescopic rod, an internal telescopic rod, a gripper and an electric control and combination part. The handle is an integral central part, all the function control buttons and a function control mechanical device are arranged on the handle; the oldpeople are directly in contact with the handle when using the stick, and all the control buttons are designed on the handle, so that convenience in use is facilitated, and the purpose of design is achieved. The external telescopic rod and the internal working rod are divided into four sections and can stretch out or draw back simultaneously. The gripper part is a functional core designed by the inventor and is arranged at the bottom of the walking stick and is hinged to the internal telescopic rod to achieve the purpose of normal work. The electric control and combination plate is a combinedelectric control part, so that the walking stick not only has a simple mechanical function, but also has a series of other auxiliary functions, such as GPS positioning, one-key alarming and night lighting.

Owner:CHONGQING UNIV

Drilling machine

InactiveCN102514043BReduce pollutionImprove manufacturing efficiencyMetal working apparatusMaterial resourcesEngineering

The invention discloses a drilling machine, which comprises a machine platform, a frame, a movable platform, a cutting detection mechanism, a powder absorption device and an oil cooling device. The machine platform serves as a bearing device of the whole drilling machine, the frame is arranged on the machine platform, the movable platform comprises an X axis platform installed on the machine platform and a Y axis platform installed on the frame, the cutting detection mechanism is fixedly installed on the frame through a casing of the cutting detection mechanism, and the powder absorption device is arranged on the side of the frame and is communicated with the casing of the cutting detection mechanism through a connection pipe. At least six mechanical arm devices are arranged on the frame, and each mechanical arm device comprises a main holder device and an auxiliary holder device installed on the side of the main holder device. The drilling machine is compact in structure and high in manufacture accuracy and production efficiency, can save material resources and greatly lower production and manufacture cost.

Owner:TEXIN MICROELECTRONICS DONGGUAN

A rotary cutting and pressing grab device

ActiveCN104925659BImplement the crawling functionImprove efficiencyHarvestersCranesStationary caseSludge

The invention relates to a rotary-cutting pressing type grab bucket device. The rotary-cutting pressing type grab bucket device comprises a grab bucket mechanism, a rotary-cutting mechanism and a pressing mechanism. The grab bucket mechanism comprises an installing rod, fixed pieces, upper connecting rods and lower connecting rods. The row of fixed pieces are evenly welded to the lower end of the installing rod, the corresponding upper connecting rod is welded between every two adjacent fixed pieces at the upper end, and the corresponding lower connecting rod is welded between every two adjacent fixed pieces at the lower end. The rotary-cutting mechanism comprises a fixed plate, a fixed box, rotary-cutting branched chains and L-type limiting insertion rods. The fixed plate and the fixed box are welded, the rear side wall of the fixed box is welded to the fixed pieces, the row of rotary-cutting branched chains are installed between the fixed box and the fixed plate, and the part, between every two rotary-cutting branched chains, of the fixed box is provided with the two corresponding L-type limiting insertion rods. The rotary-cutting branched chains comprise rotary-cutting motors, rotating shafts, rotary-cutting cutter heads and double nuts. The function of treating pond sludge and water plants in a mechanized mode is achieved, and the rotary-cutting pressing type grab bucket device has the advantages of being low in labor intensity, easy and convenient to operate, high in working efficiency and the like.

Owner:菏泽智慧新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com