Automatic box grabbing method for spreader of gantry crane

A gantry crane and spreader technology, which is applied in the directions of load hanging components, transportation and packaging, can solve the problems of easy deviation of the RTG cart base, the inability to effectively improve the operation efficiency, and the inconvenience of the attitude detection of the spreader. The effect of reduced human intervention, accurate and reliable translation and rotation, and reduced adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

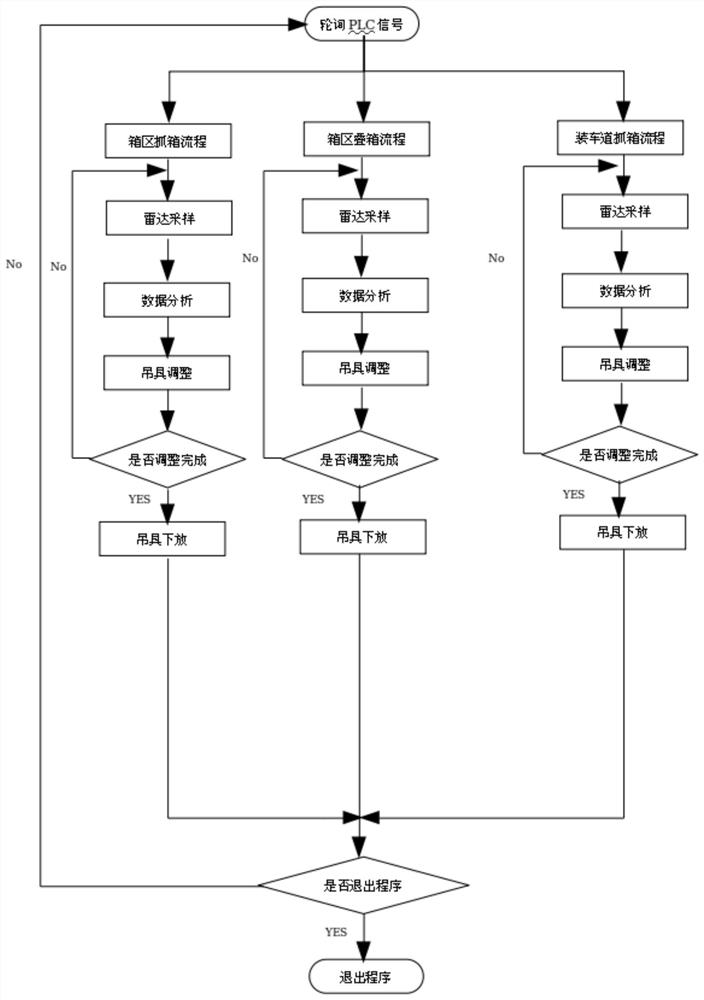

[0054] Example 1: The spreader adjustment process for grabbing boxes in the box area: as figure 1 combine image 3 and Figure 4 As shown, here the vertical and vertical planes are defined as the front, the vertical plane is perpendicular to the vertical plane and the inside is defined as the rear, the spreader moving to the left is defined as the left, and the spreader is defined as the right moving to the right, the same below.

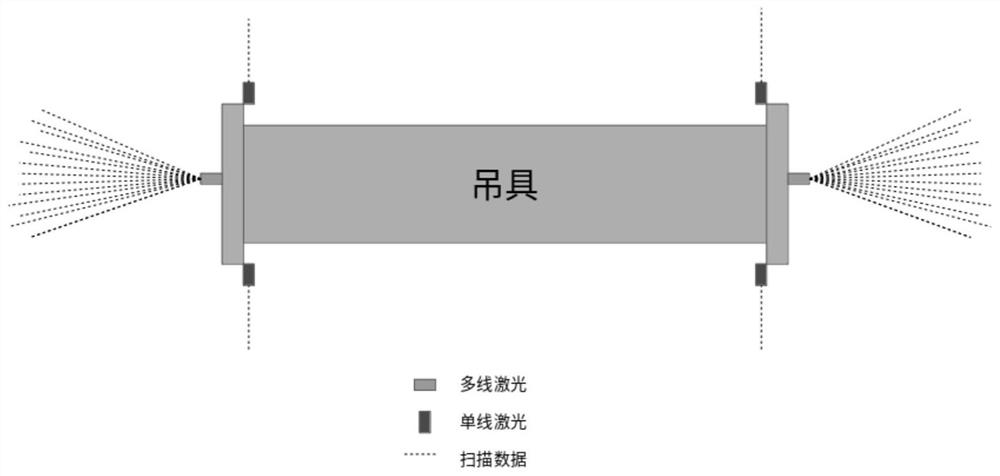

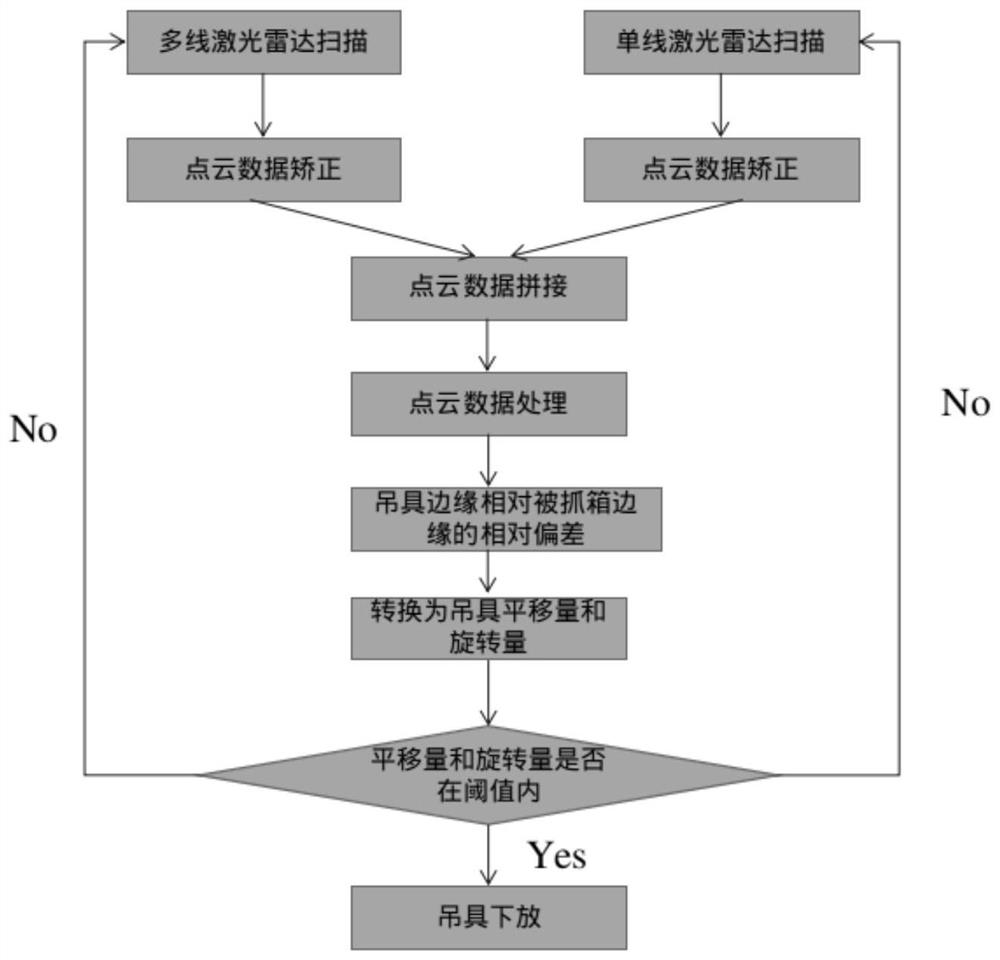

[0055] When carrying out the container grabbing process in the container area, the spreader runs to a certain height above the target container in the container area according to the instructions of the PLC shown in the figure, and then stops. Single-line laser scanning and multi-line laser scanning; after processing according to the above algorithm, the point cloud data of each side line of the spreader and the position of each side line of the container to be grabbed is obtained and converted into spatial coordinates in the world coordinate syste...

Embodiment 2

[0061] Example 2: The spreader adjustment process for stacking boxes in the box area: such as figure 1 combine Figure 5 and Figure 6 , the definition of the front, rear, left and right directions of the spreader movement is the same as that of embodiment 1;

[0062] When performing the container stacking process in the container area, the spreader and its loaded containers move synchronously to a certain height above the containers to be stacked and then stop. The four first laser radars and two second laser radars perform single-line laser detection on the bottom of the spreader respectively. Scanning and multi-line laser scanning; after processing according to the above algorithm, the point cloud data of each side line of the container loaded on the spreader and the position of each side line of the container to be stacked is obtained and converted into the spatial coordinates in the world coordinate system; according to the position of the side line Project the relation...

Embodiment 3

[0069] Embodiment 3: The process of grabbing boxes in the loading lane, such as figure 1 combine Figure 7 and Figure 8 As shown, the container grabbing operation process of the loading lane is that after the container truck, that is, the collection truck moves into place, the spreader walks to the designated row and lowers it to a fixed position above the target container to stop. According to the 4 single-line laser radar and 2 multi-line The lidar detects the offset distance between the edge of the spreader and the edge of the container on the truck, calculates the translation and rotation of the spreader, and continuously adjusts the attitude of the spreader in real time. When the translation and rotation enter the threshold range, the After the adjustment is completed, the spreader is lowered to grab the box.

[0070] The offset distance of the loading lane grabbing process includes the fifth offset shift_FB3, the sixth offset shift_LR3 and the third angle offset rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com