Multiposition and multifunctional pipe moving manipulator for submarine drilling machine

A manipulator and multi-functional technology, applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problem of lowering the success rate and work efficiency of core pipe lowering and recovery, failure and scrapping of drill pipe and drilling tools, and poor alignment and other issues, to achieve the effect of low cost, convenient operation and easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

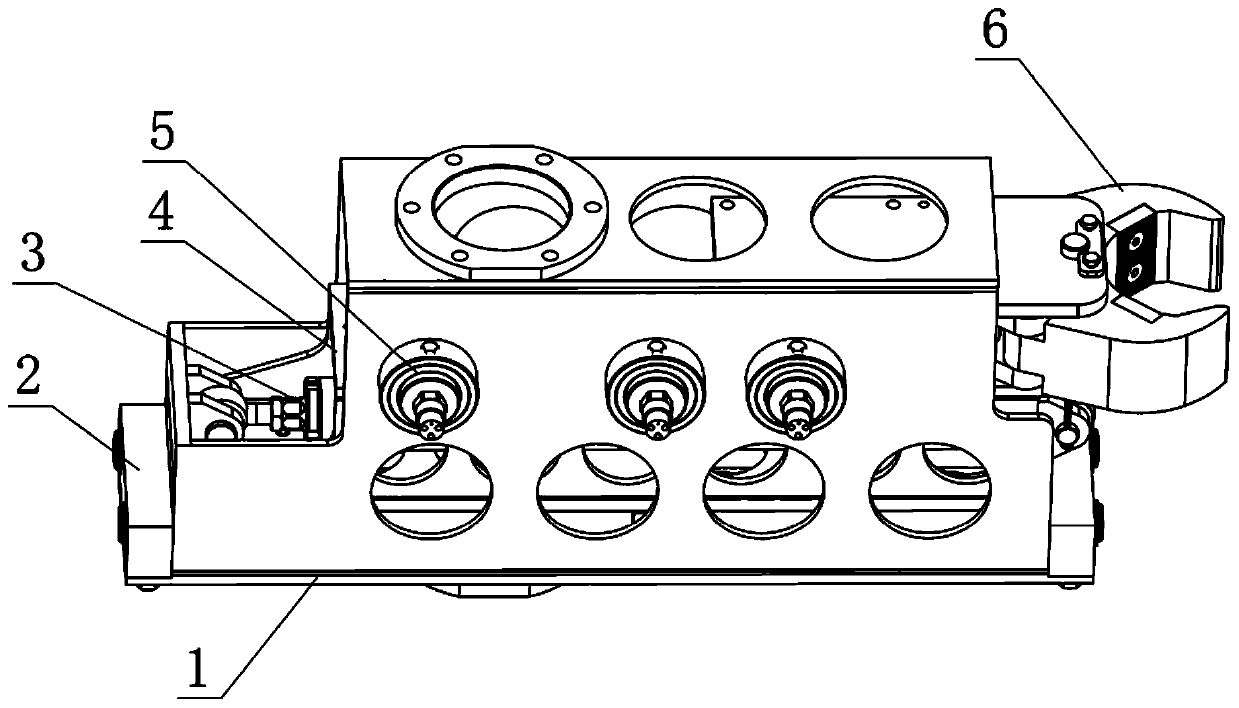

[0022] Such as figure 1 As shown, the present invention includes an outer frame 1, a guide rail 2, an outrigger cylinder 3, a telescopic arm assembly 4, a position sensor 5 and a manipulator assembly 6; the guide rail 2 is fixed on the outer frame 1; the telescopic arm assembly 4 is fixed on Guide rail slider 202, the guide rail slider is sleeved on the guide rail 2; one end of the outrigger cylinder 3 is hinged with the outer frame 1, and the other end is hinged with the telescopic arm assembly 4, and the axis of the outrigger cylinder 3 is parallel to the guide rail.

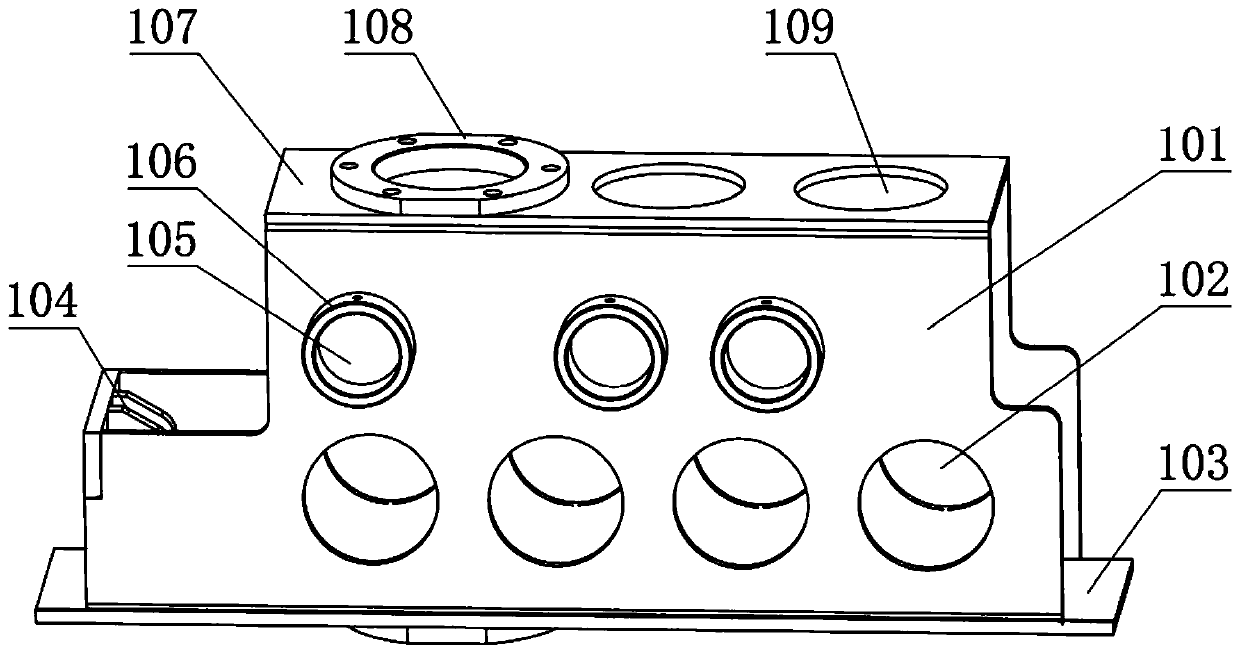

[0023] Such as figure 2 As shown, the outer frame 1 includes two outer frame side plates 101, side plate guide holes 102, outer frame bottom plate 103, telescopic arm cylinder ear I 104 and sensor fixing ring 106, two outer frame side plates 101, outer The frame top plate 106 and the outer frame bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com