Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Implement curl" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

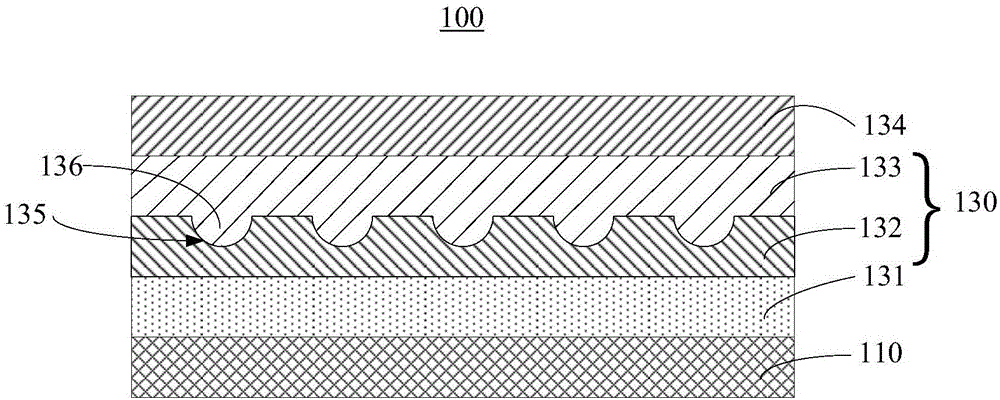

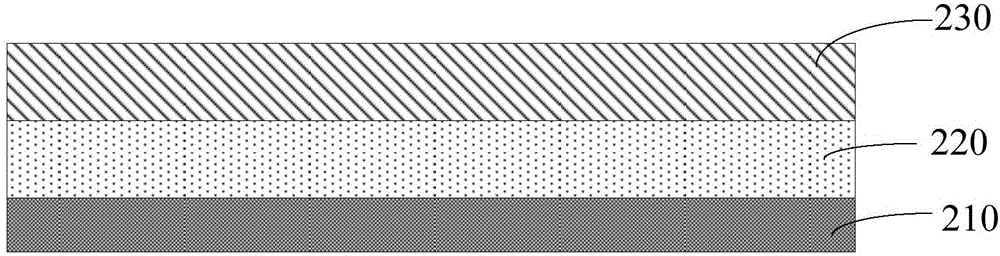

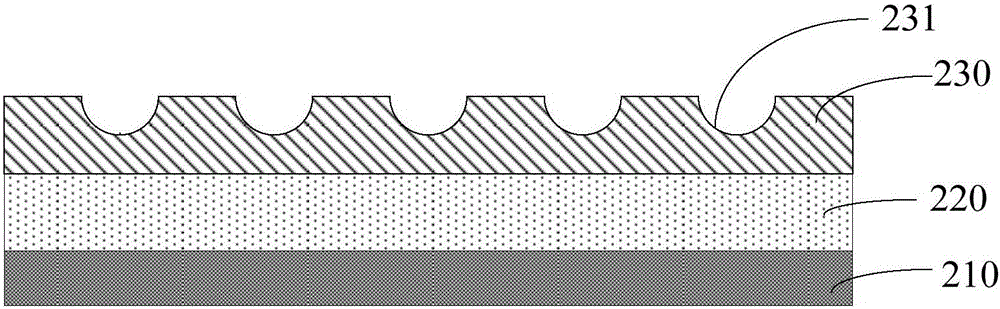

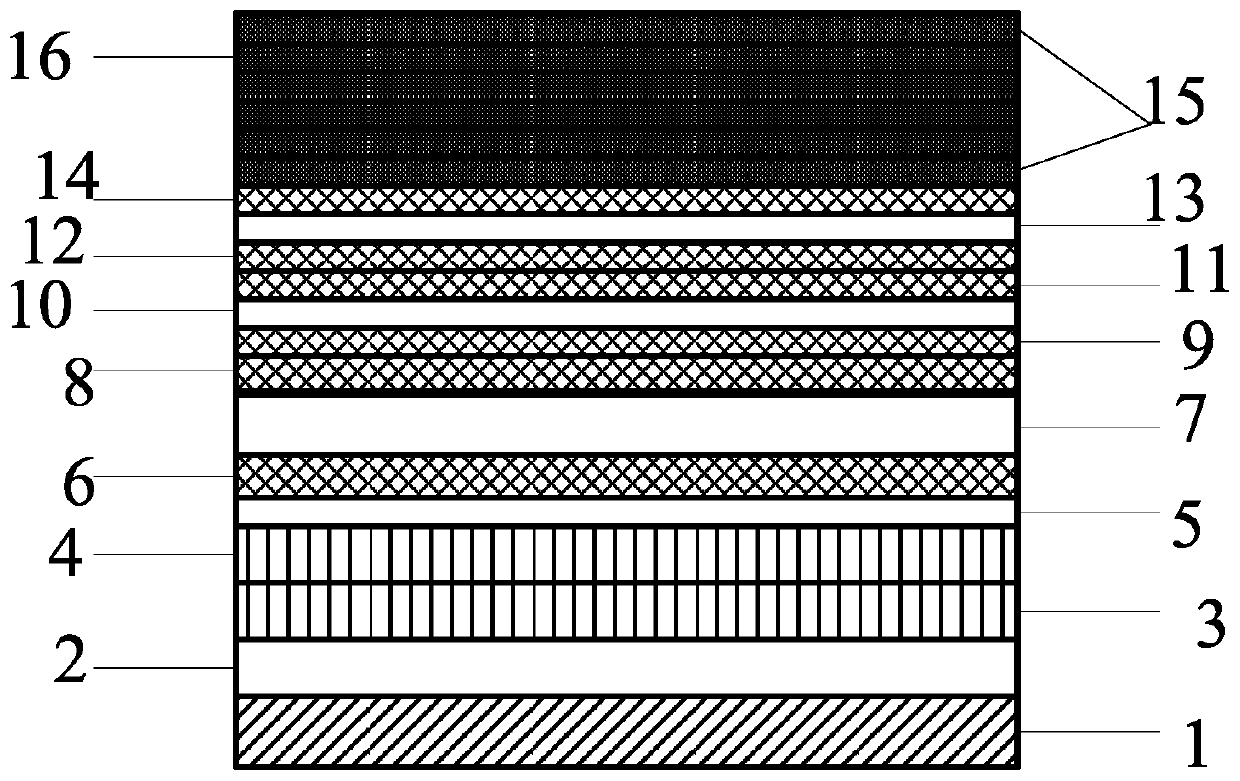

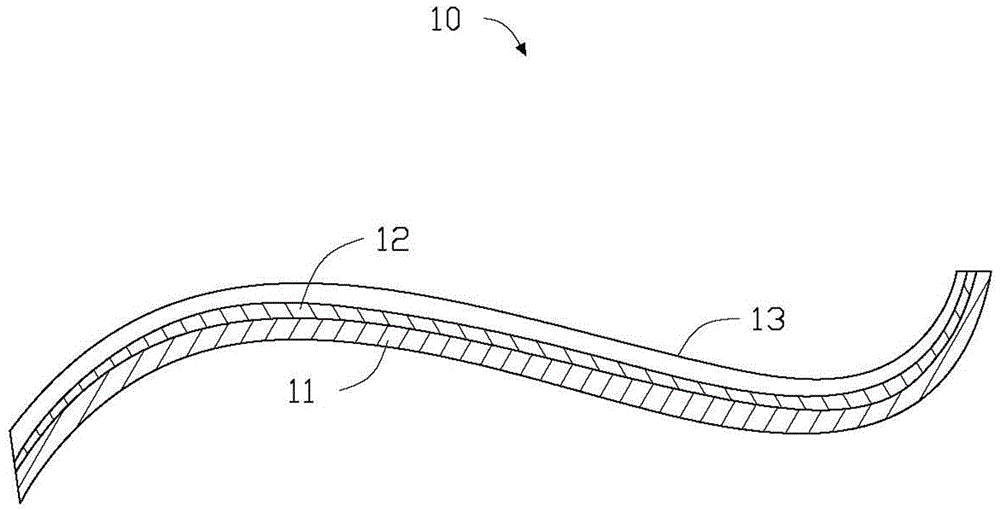

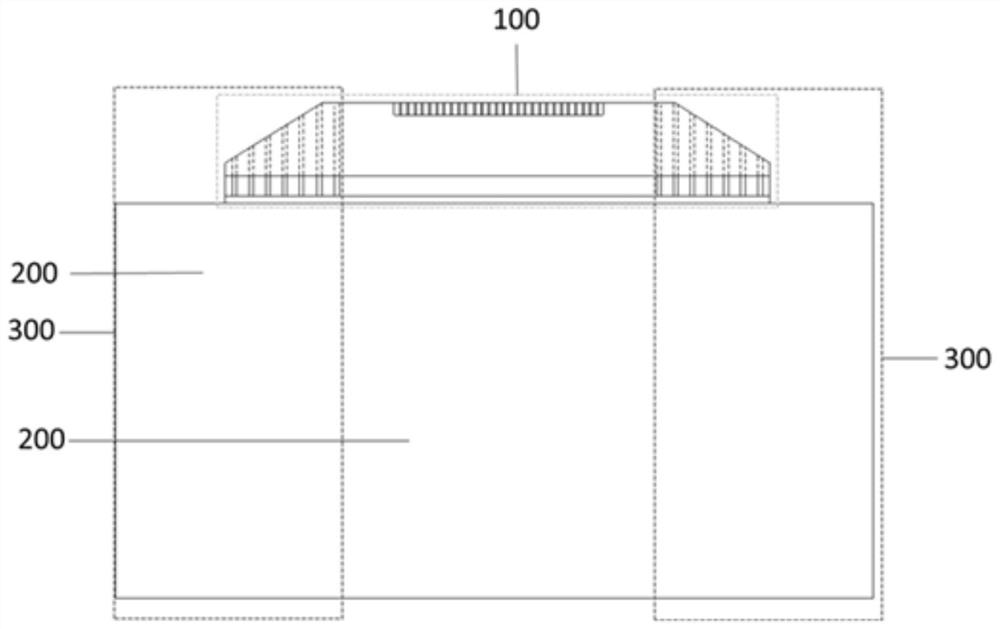

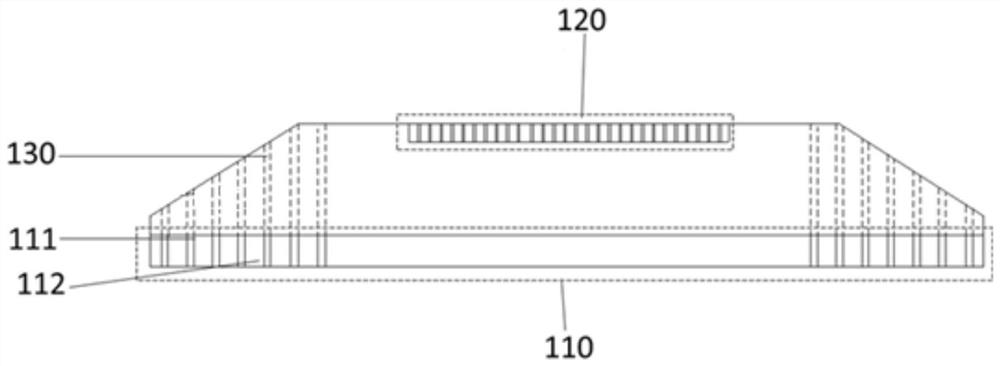

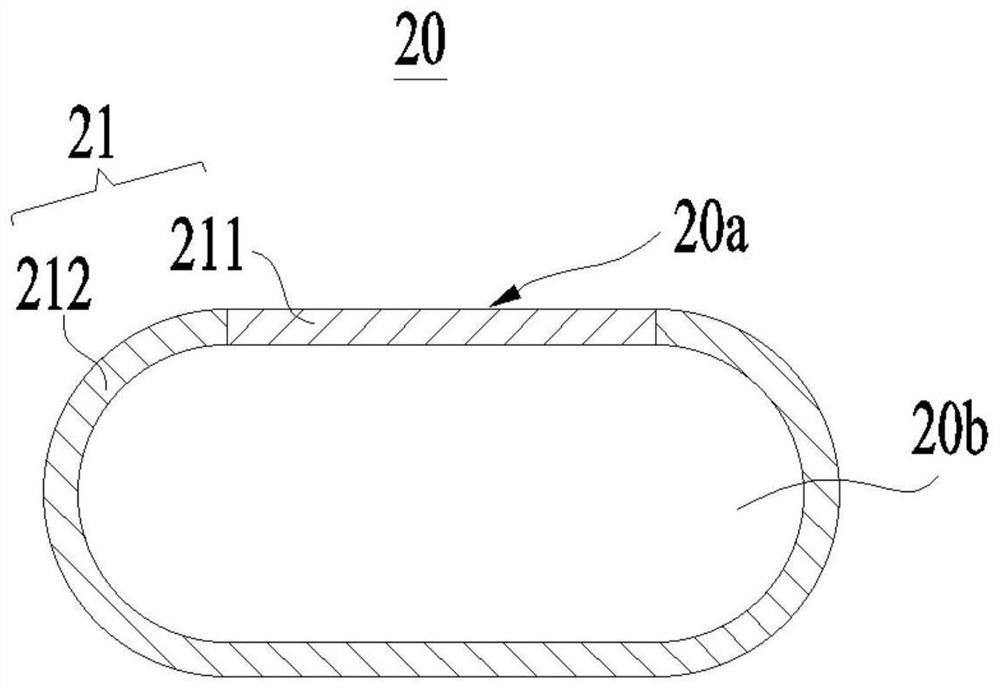

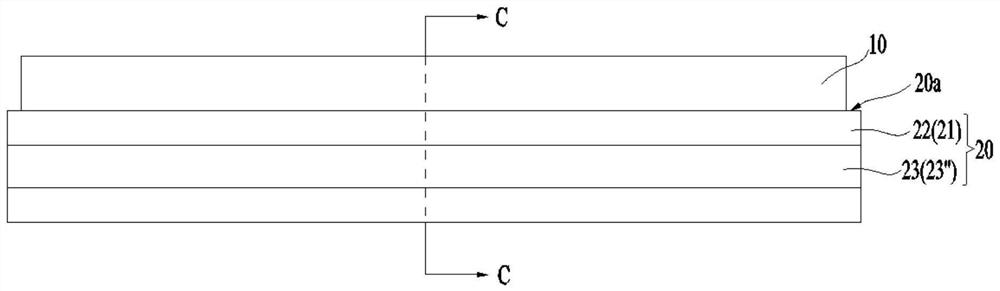

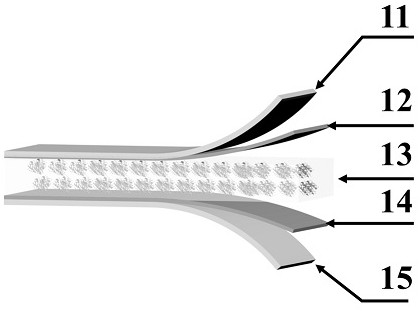

Packaging layer and packaging device

InactiveCN106410062AImprove liquidityImprove optical coupling outputSolid-state devicesSemiconductor/solid-state device manufacturingOptical couplingComputer science

The invention provides a packaging layer comprising a first inorganic functional layer and an organic buffer layer covering the first inorganic functional layer. A plurality of grooves are formed in the surface, in contact with the organic buffer layer, of the first inorganic functional layer and a plurality of protrusions corresponding to and matching the multiple grooves are arranged on the surface, in contact with the first inorganic functional layer, of the organic buffer layer, so that the multiple protrusions can be embedded into the corresponding multiple grooves respectively. In addition, the invention also provides a packaging device. According to the packaging layer, the optical coupling output of the packaging device can be improved effectively. Moreover, bending, folding, and even rolling of the packaging device can be realized, so that stability of the packaging device is improved and thus the service life of the packaging device is prolonged.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

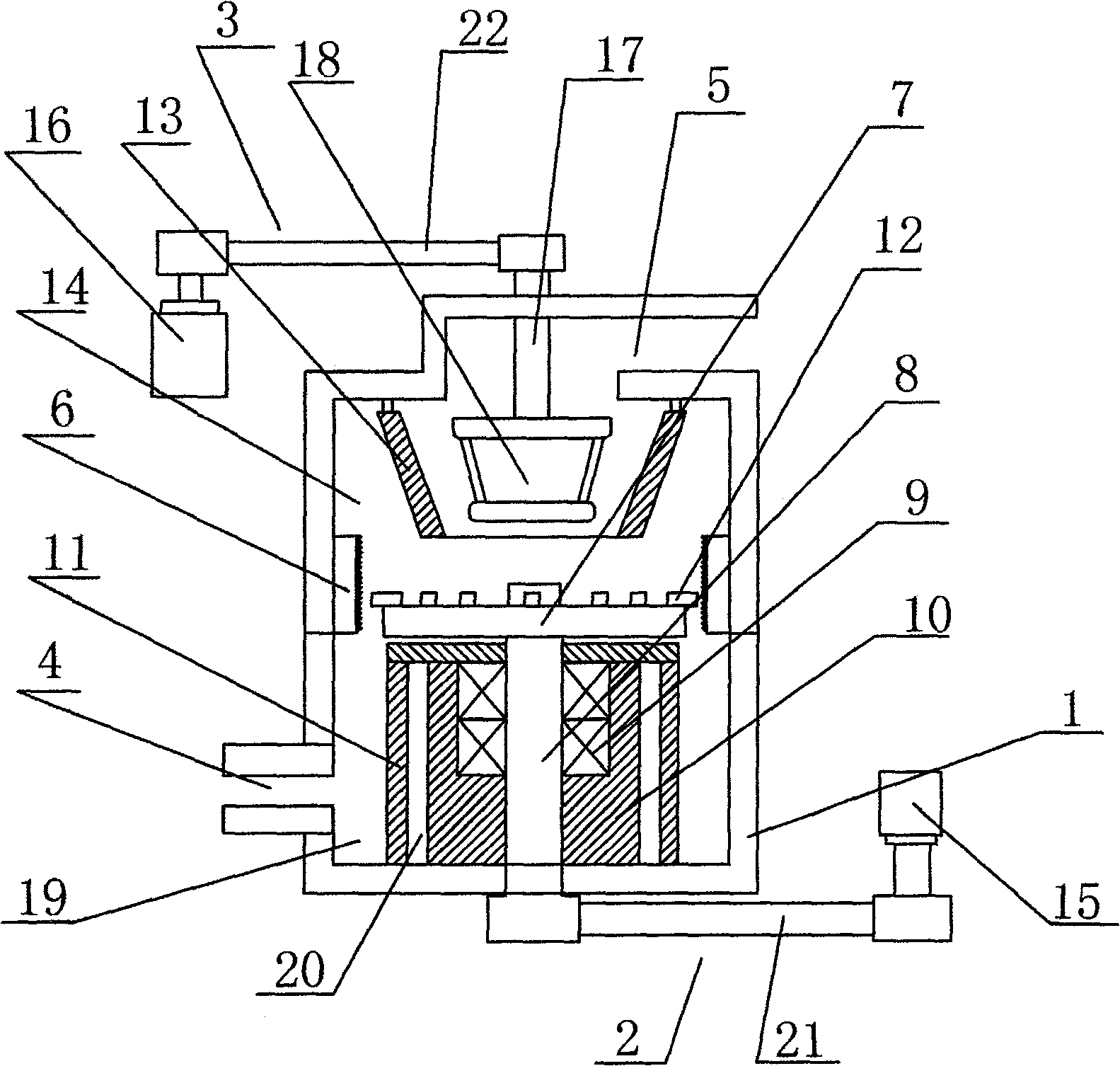

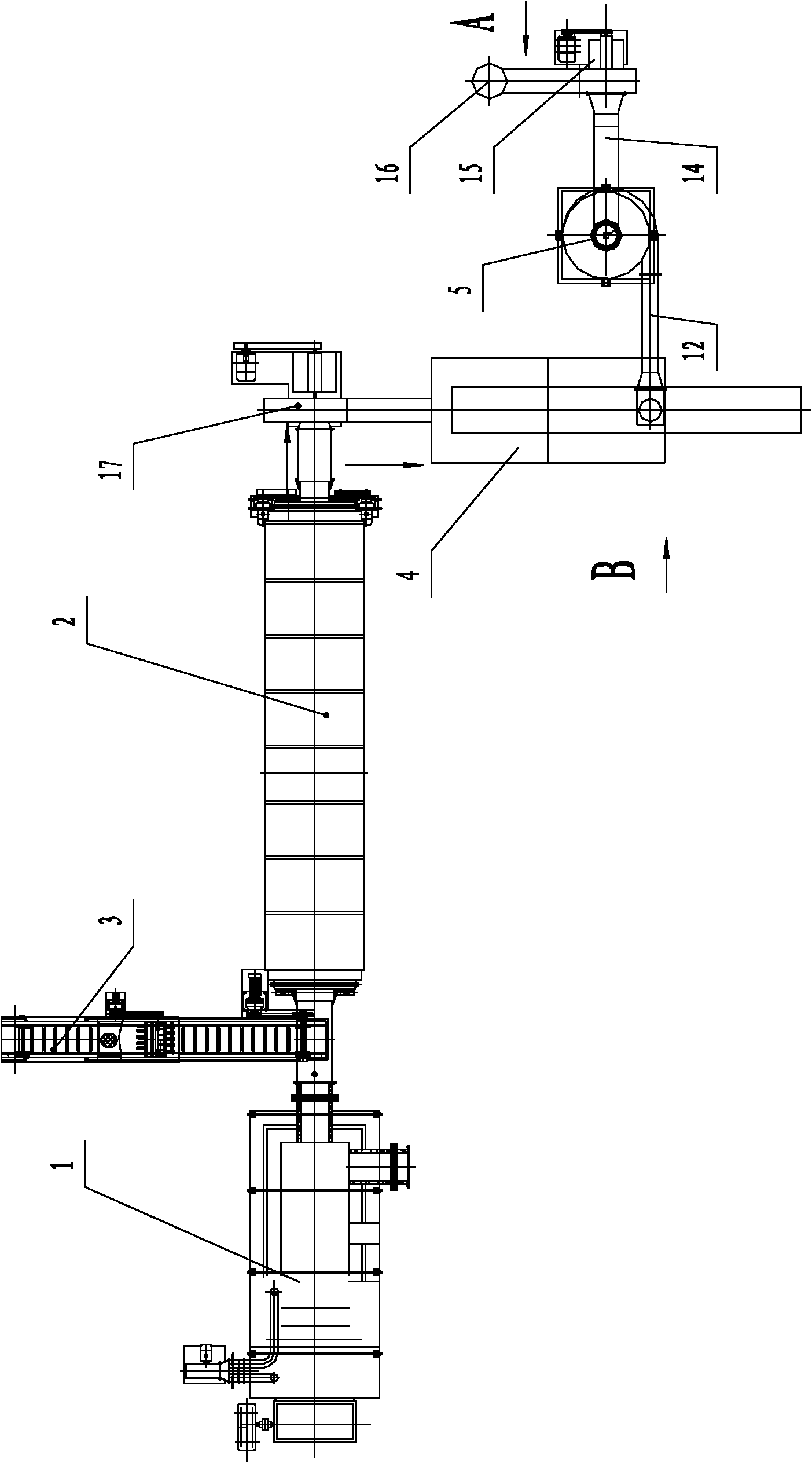

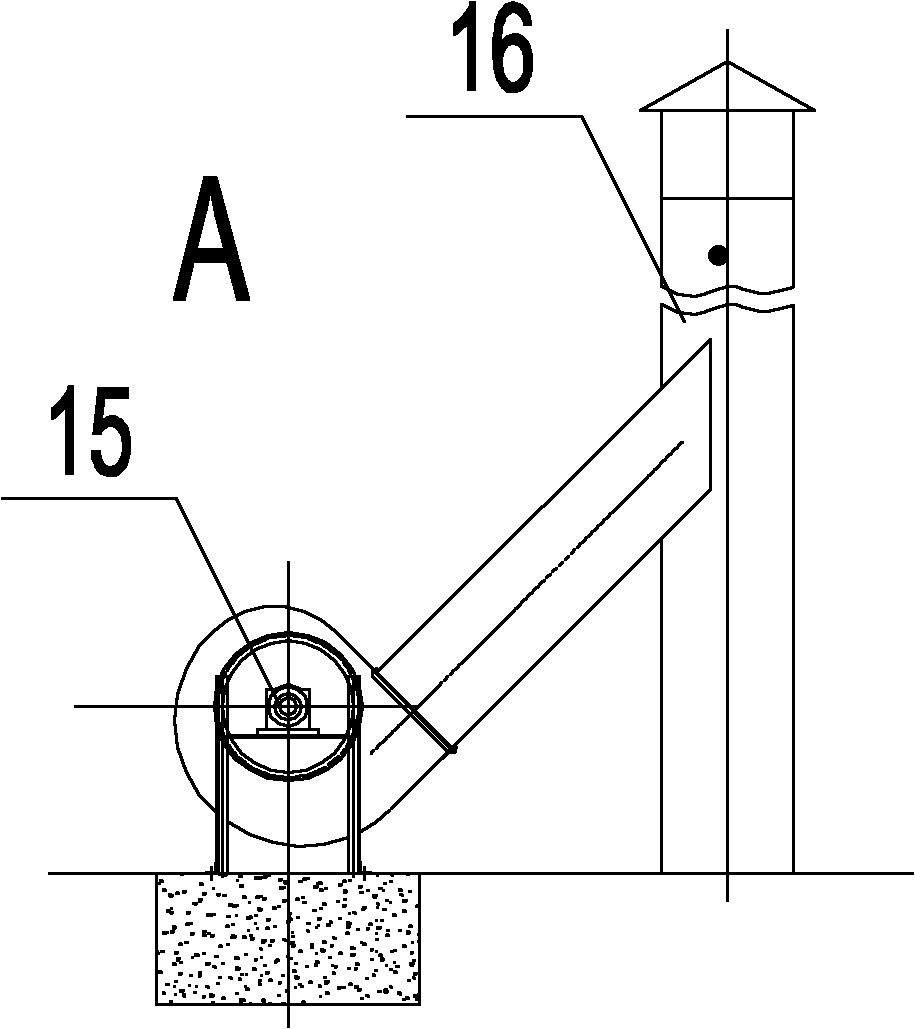

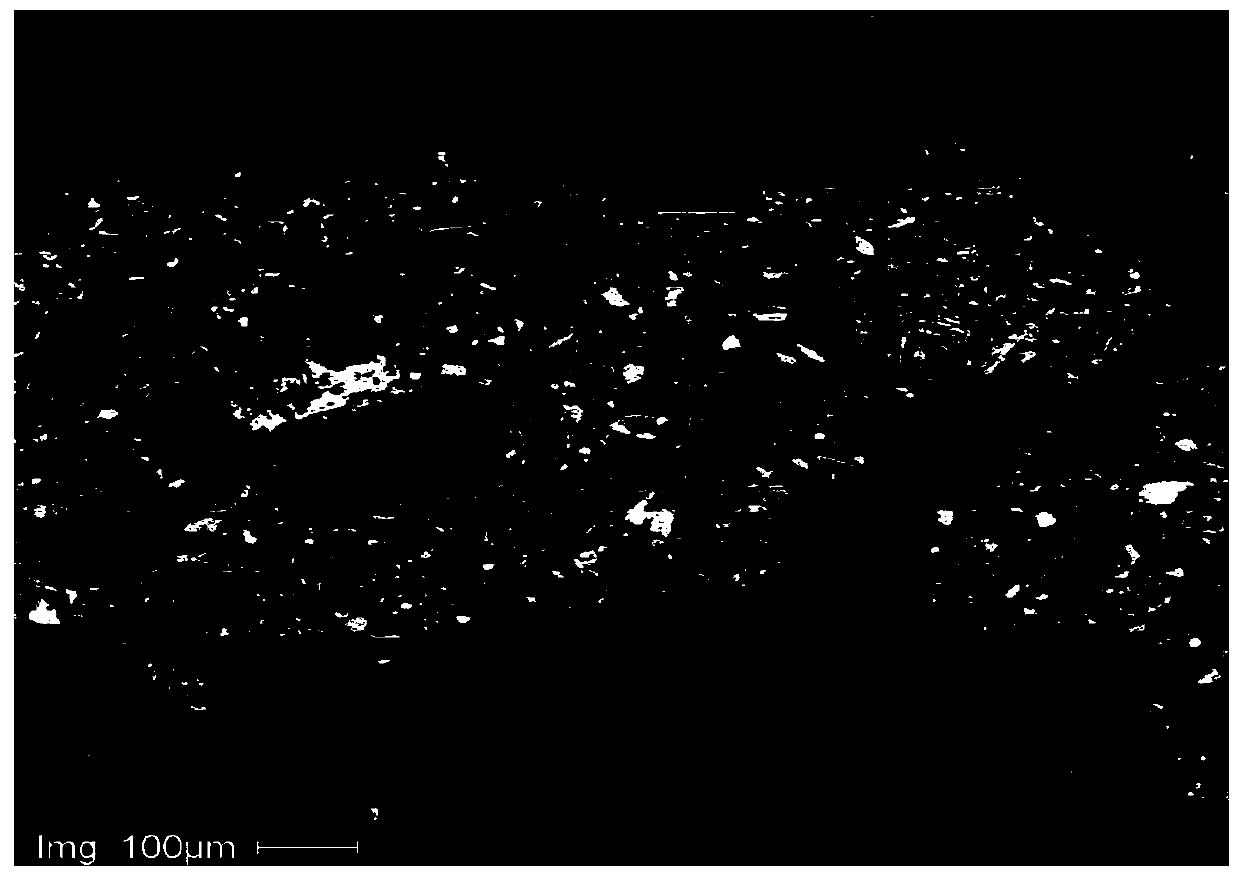

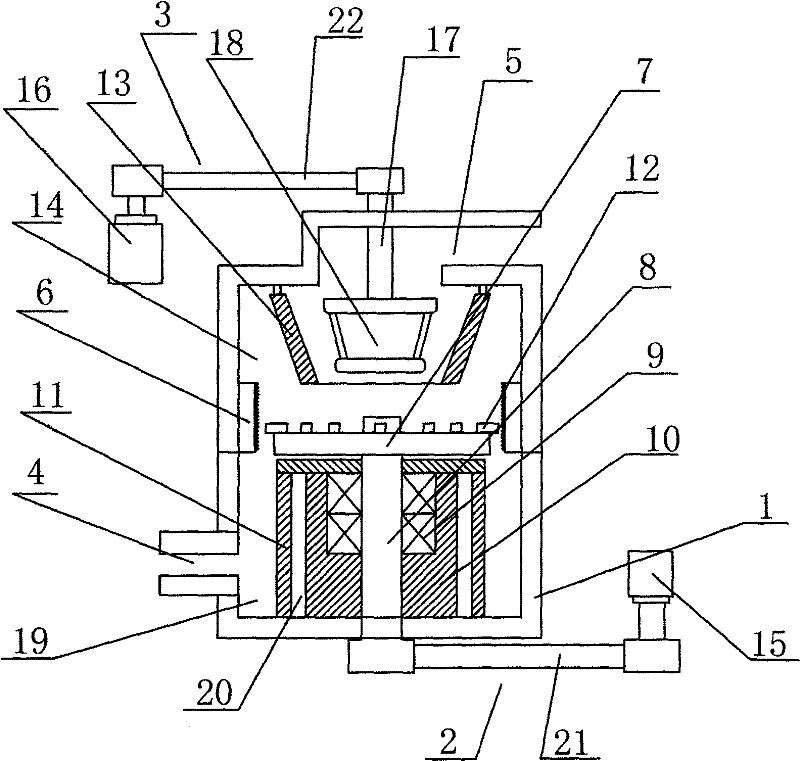

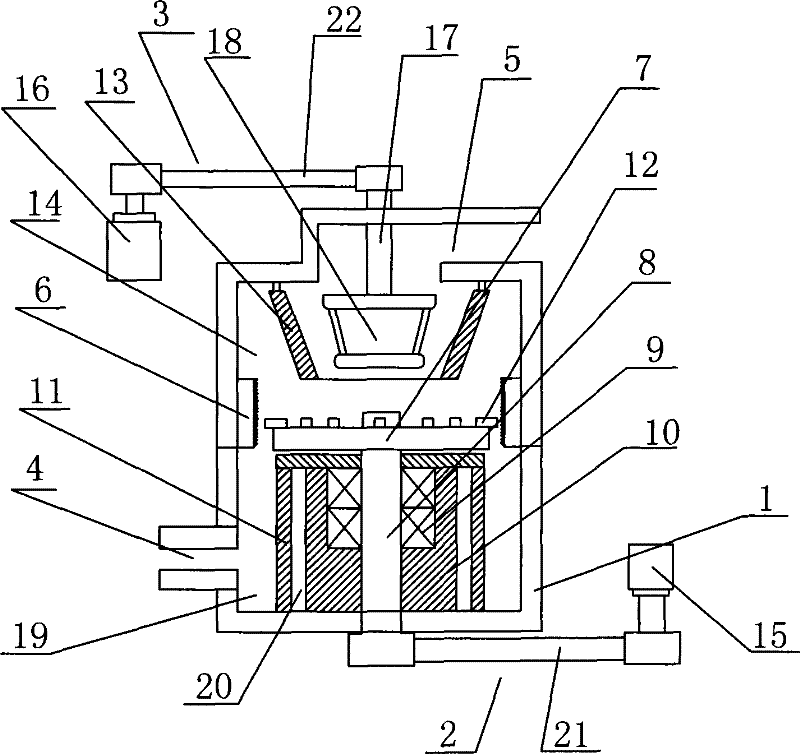

Air-flow vortex balling machine for producing spherical graphite

The invention discloses an air-flow vortex balling machine for producing spherical graphite, which consists of a machine body, a balling drive device and an internal classification machine drive device, wherein an internal classification machine, a powder balling module and a cooling system are arranged in the machine body. In the invention, an internal balling module and a classification module are rationally arranged, and thus, the air-flow vortex balling machine for producing the spherical graphite is provided. The air-flow vortex balling machine can ensure that the graphite powder undergoes the physical processes of thinning, shearing, collision, friction, coiling, uniting and densification in an air-flow vortex balling room or can realize the combination of a physical balling process and a mechanical powder thinning process to prepare the spherical product. The indexes, such as sphericity, grain fineness distribution, tap density, apparent density, actual density and special surface area, of the spherical graphite powder can be controlled in the range of pre-determined values; the quality is stable; the yield can be improved by over three times; and over 50 percent of energy consumption can be reduced.

Owner:LUOYANG GUANQI INDAL & TRADE

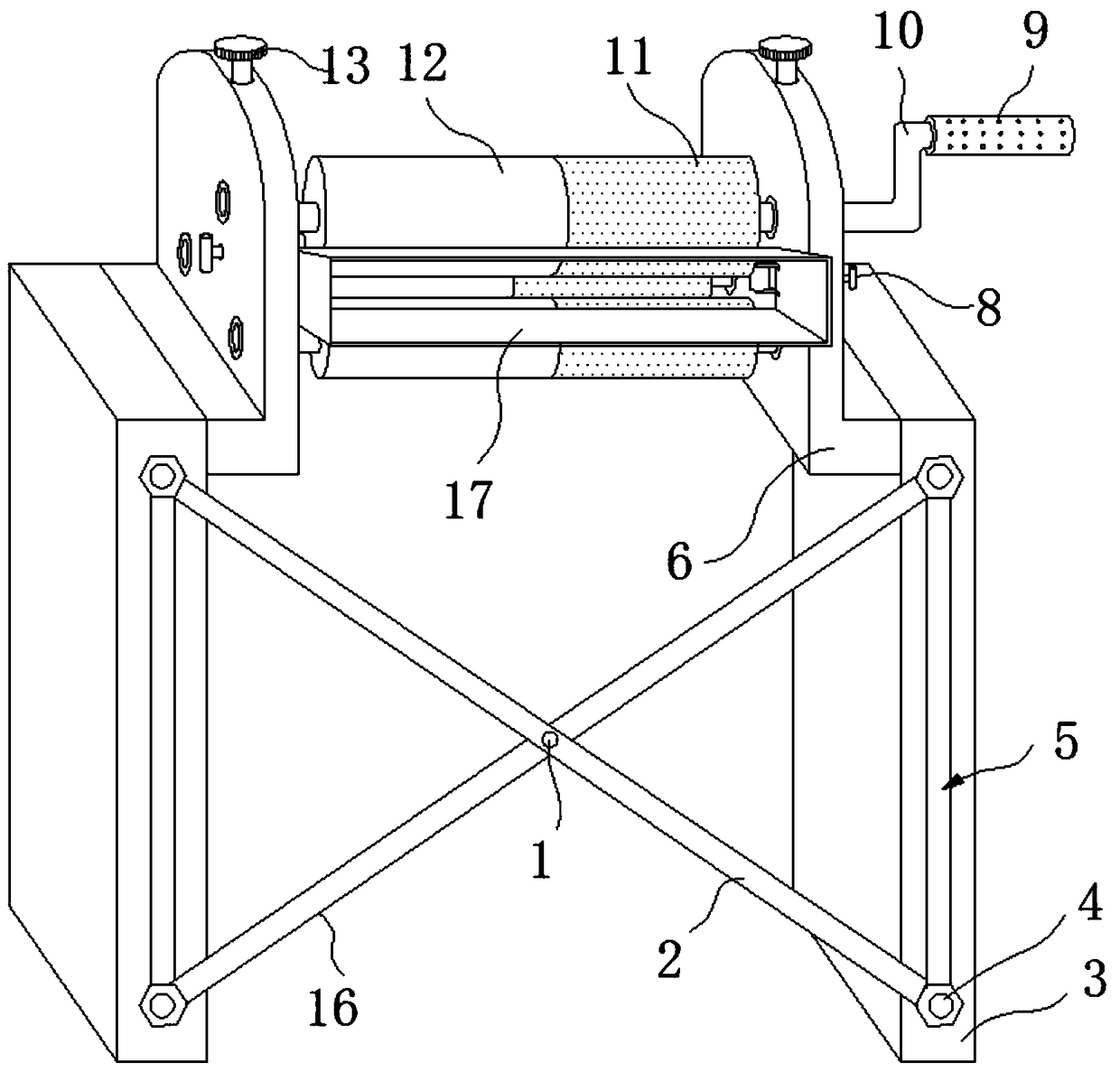

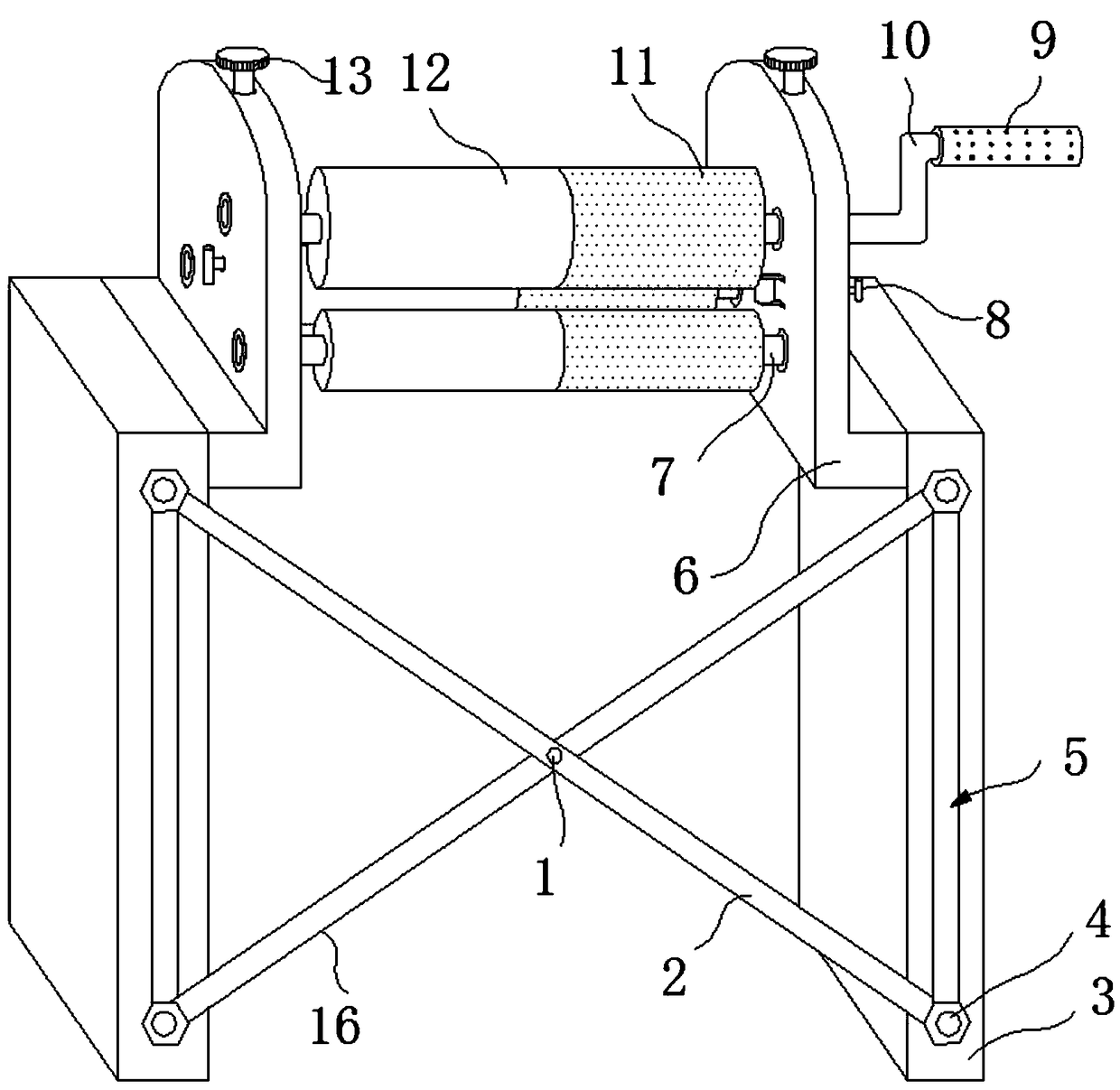

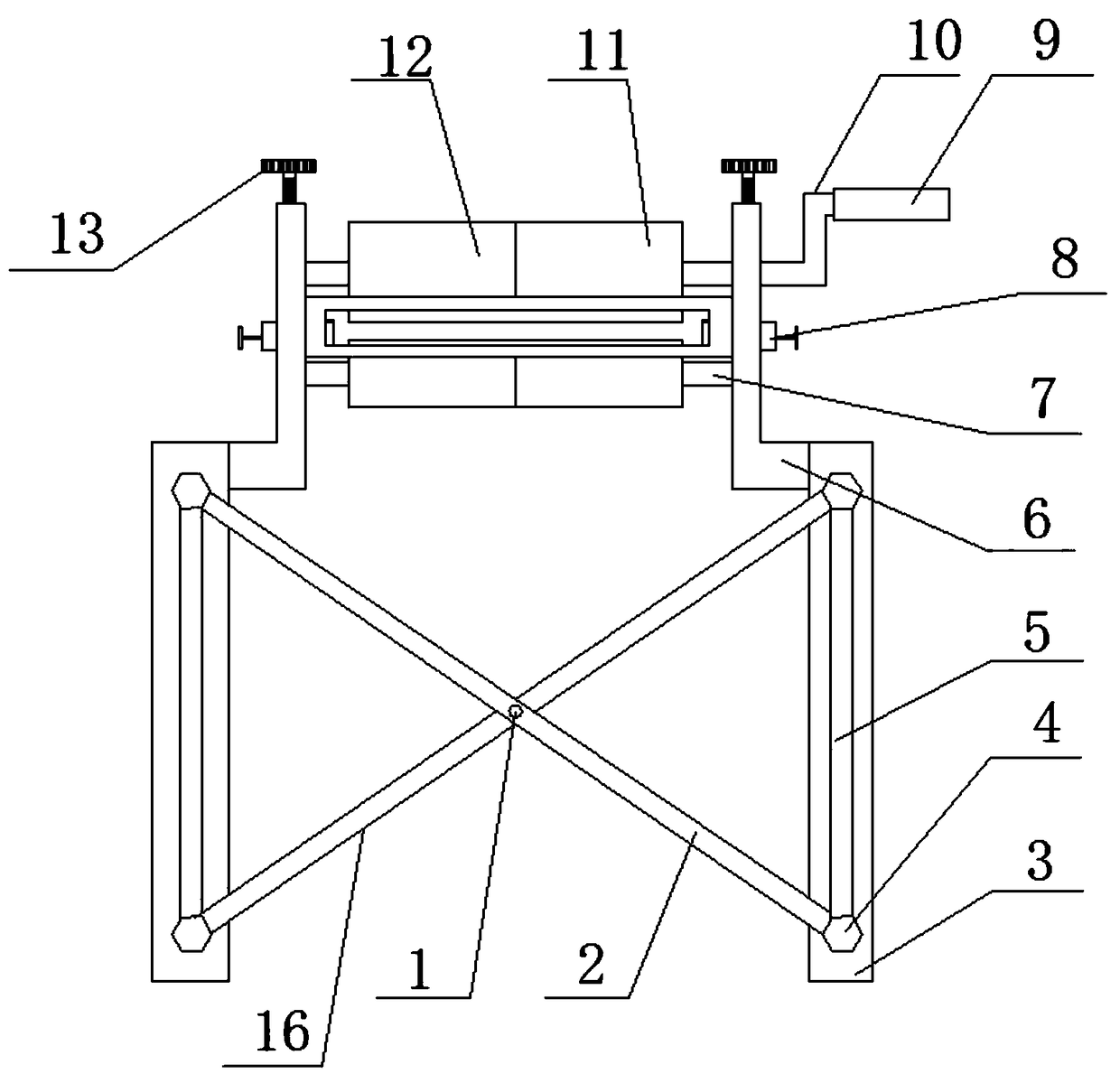

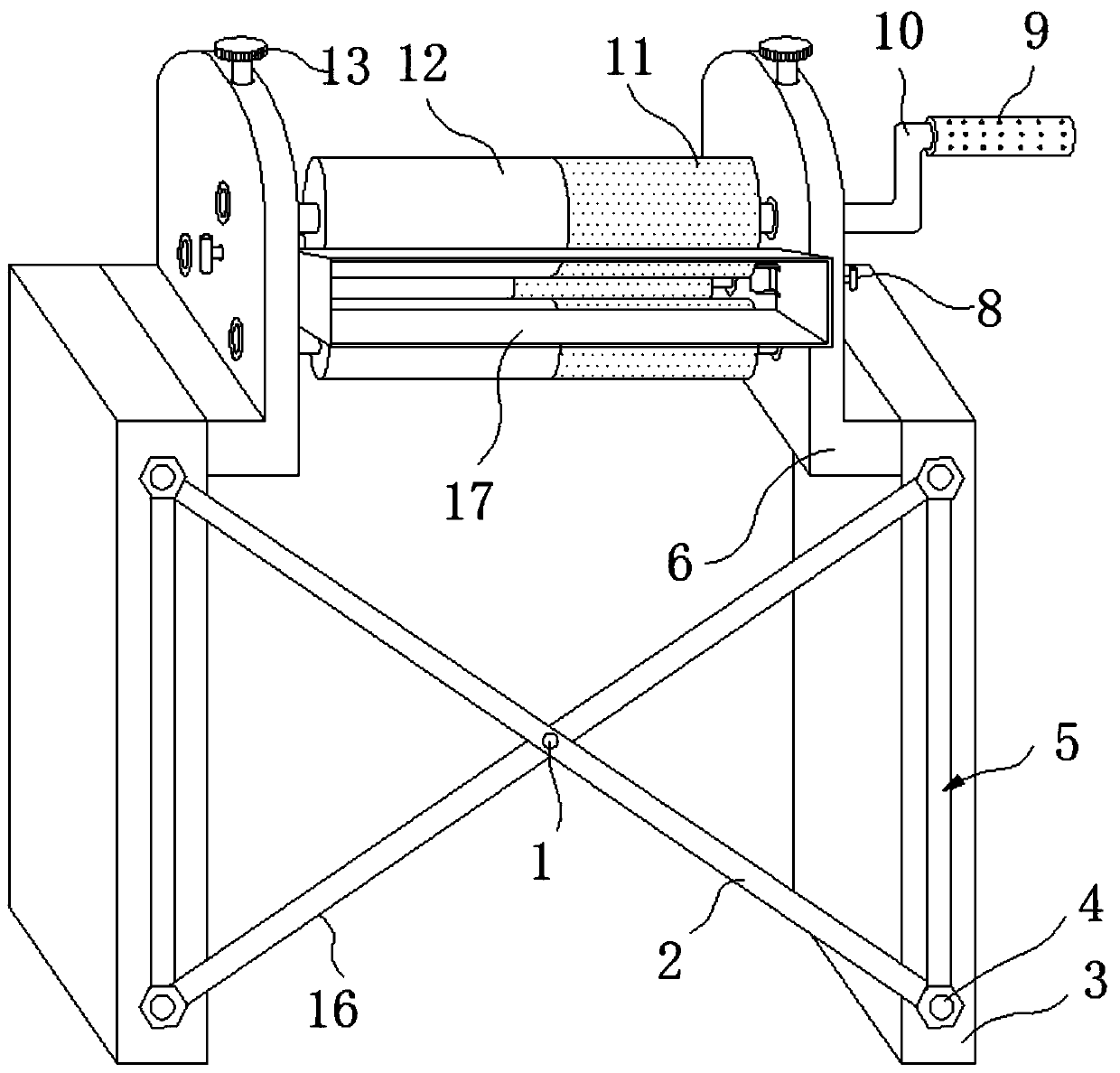

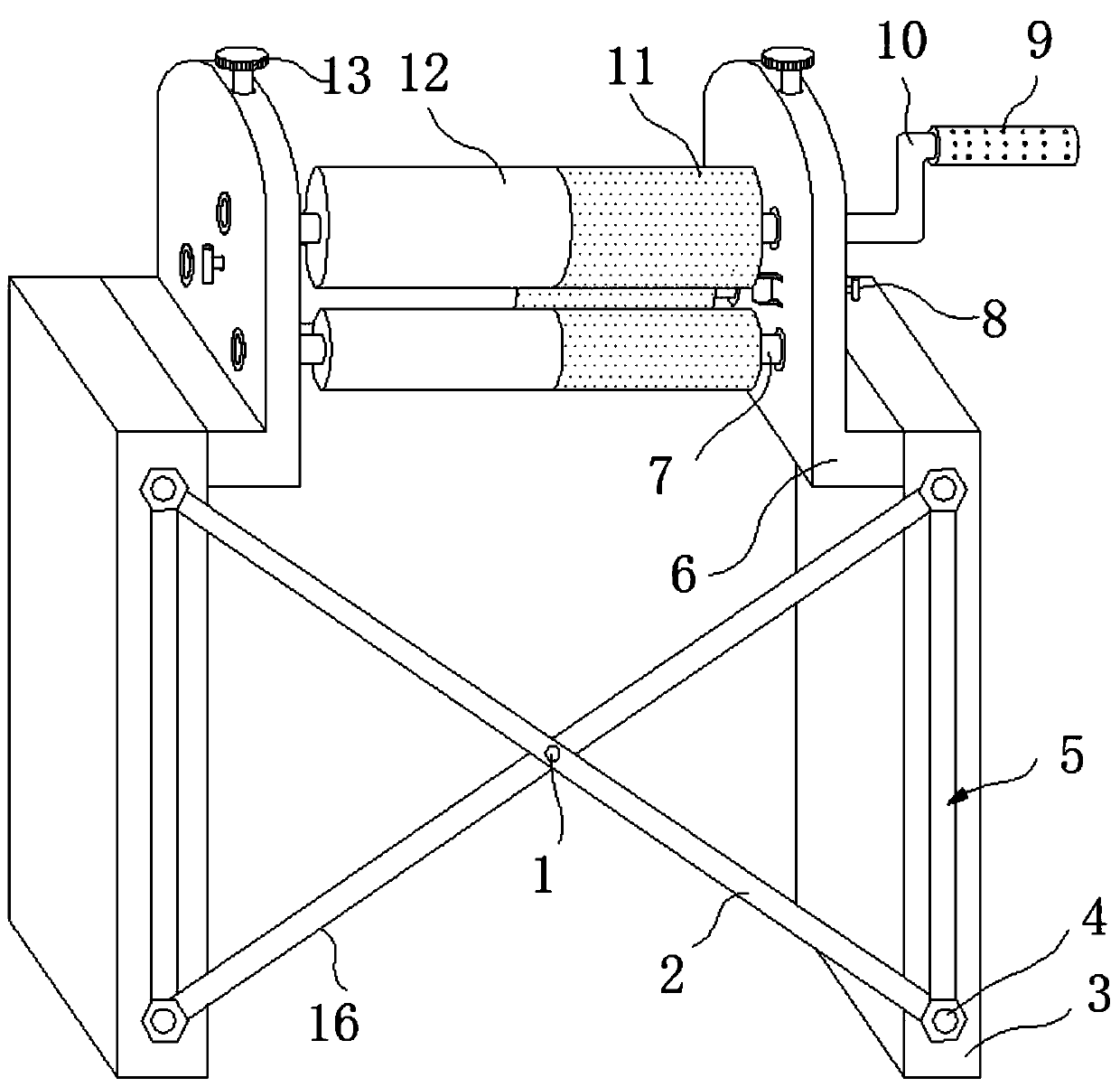

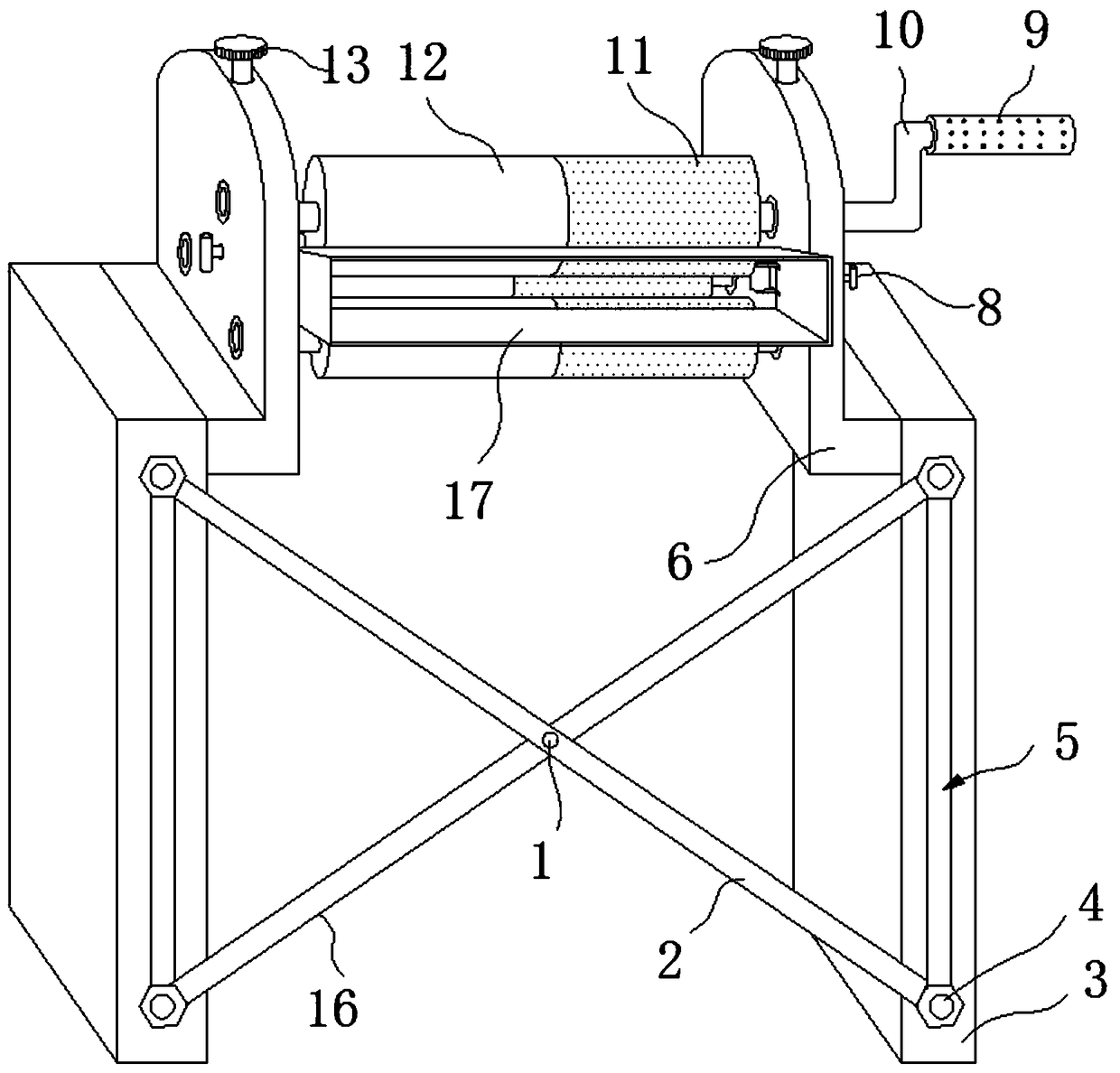

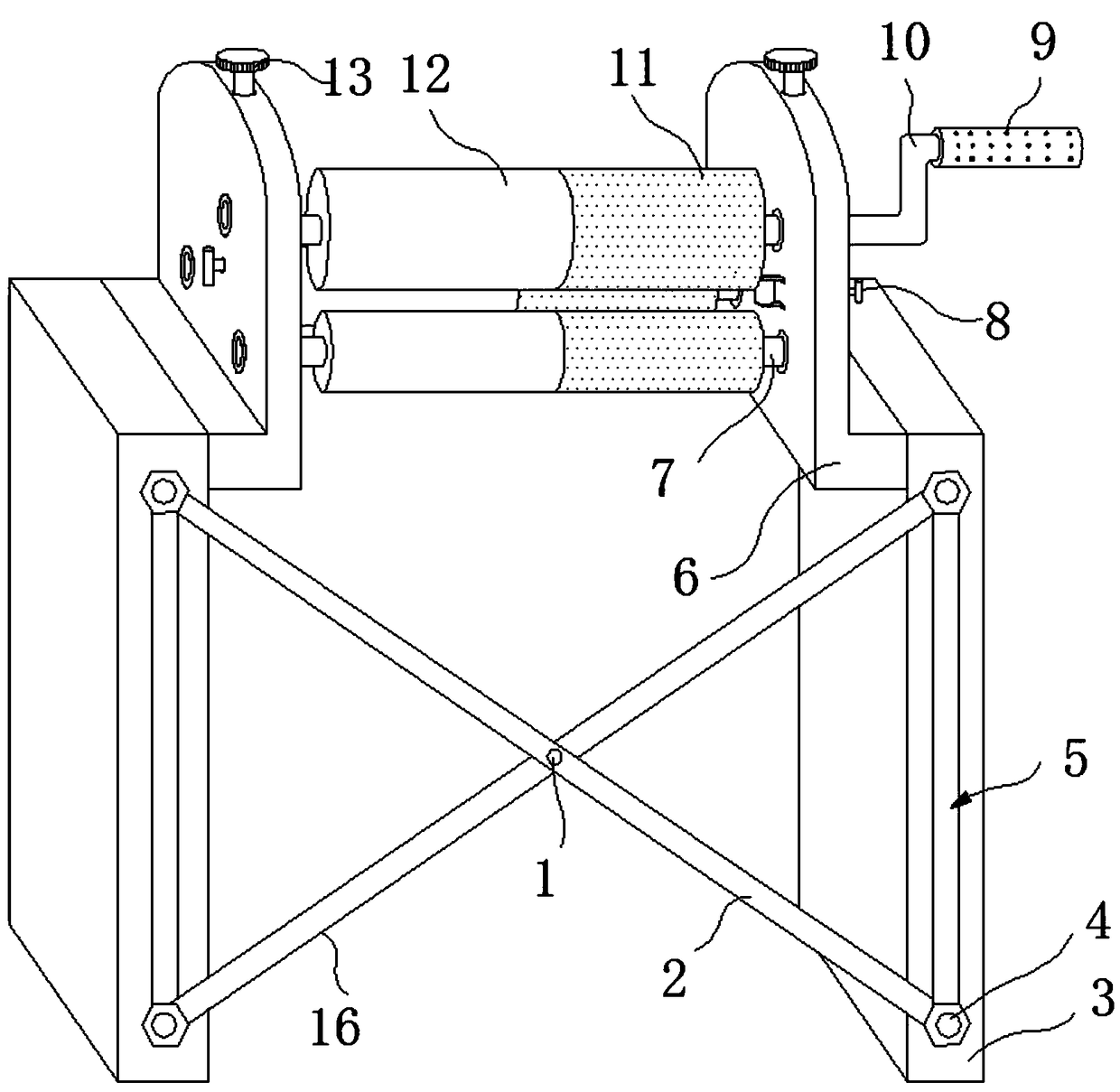

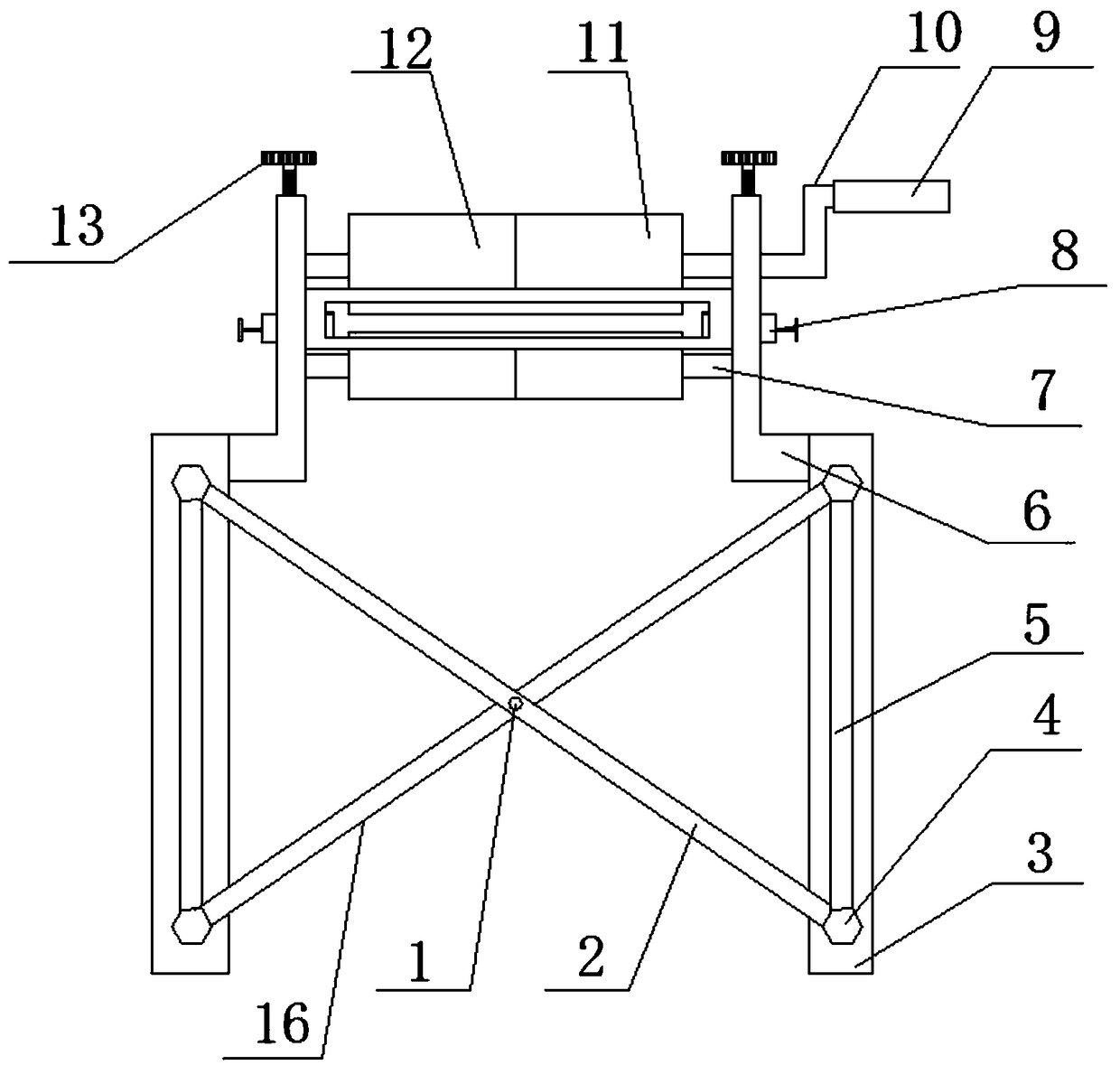

Three-roller symmetric type plate rolling machine

The invention relates to the field of cold working equipment and particularly relates to a three-roller symmetric type plate rolling machine. The three-roller symmetric type plate rolling machine comprises a screw, a first support, a side plate, a nut, a sliding groove, vertical plates, roller shafts, a limiting structure, a handle, a limiting block, a pulley, a ferrule, a dowel, an anti-slip sleeve, a crank, first press rollers, second press rollers, a locking nut, a bearing, a locating block, a second support, a feeding plate and a stop block. The sliding groove is arranged in the side plate, the sliding groove is in rotating connection with the first support and the second support through the nut, the two vertical plates are arranged at the top end of the side plate and symmetrically distributed, the three roller shafts are in rotating connection with the vertical plates through the bearing, one ends of the roller shafts are connected with the vertical plates, the ferrule is in rotating connection with the pulley through the dowel, and rolled materials can be guided by the pulley. The roller shafts are driven to rotate by rocking the crank with the hand, so that the coiling of the plate materials is facilitated. By arranging the first press rollers and the second press rollers on the roller shafts in a sleeving manner, the coiling of different plate materials is facilitated.

Owner:江苏中泰绿色建筑科技有限公司

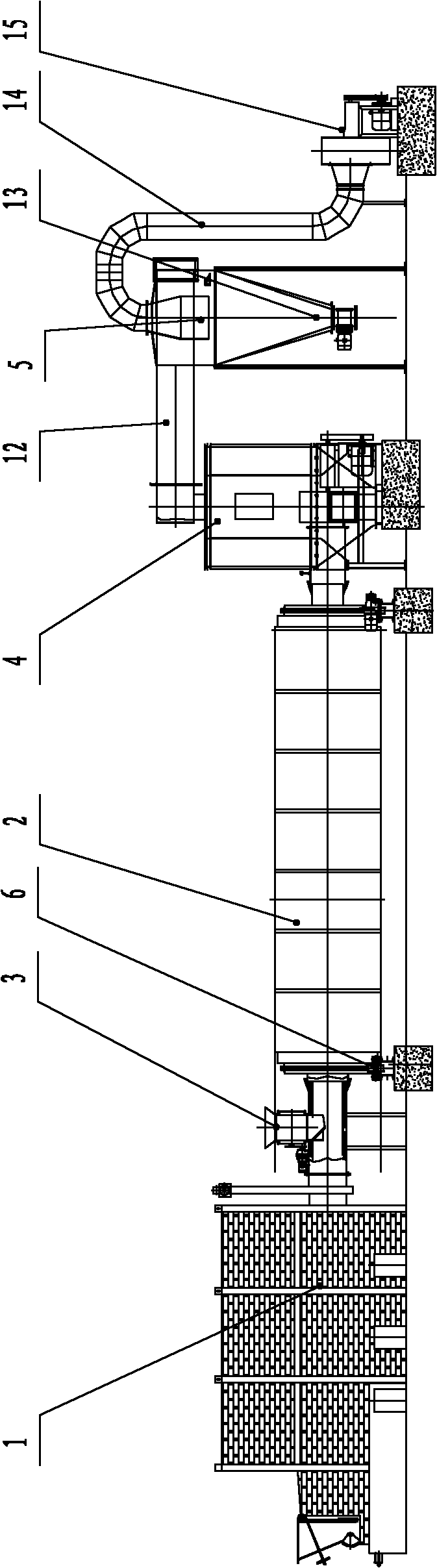

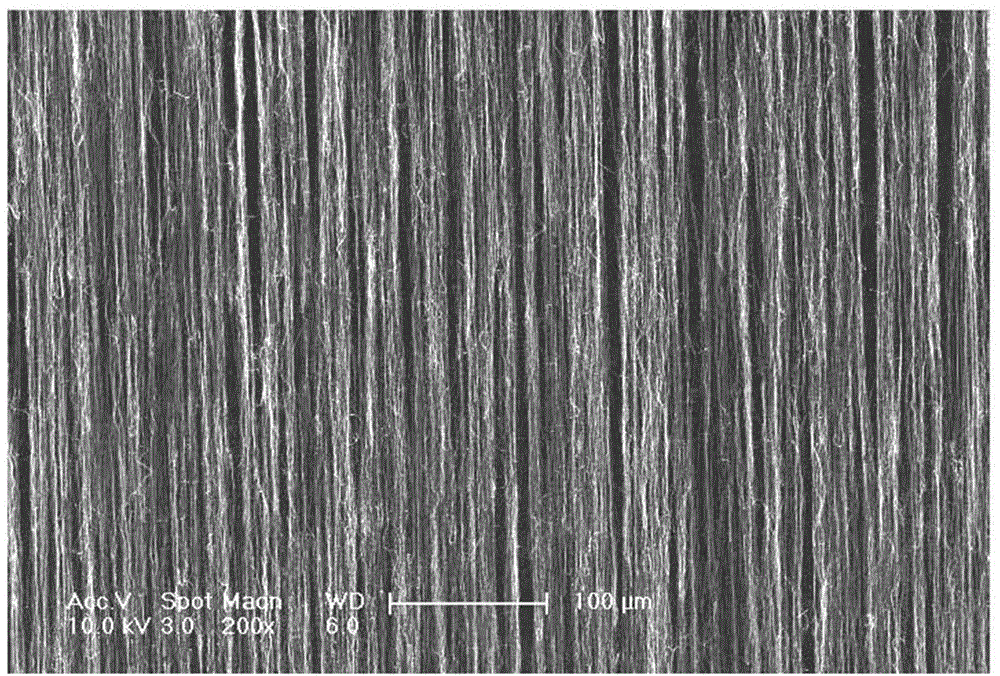

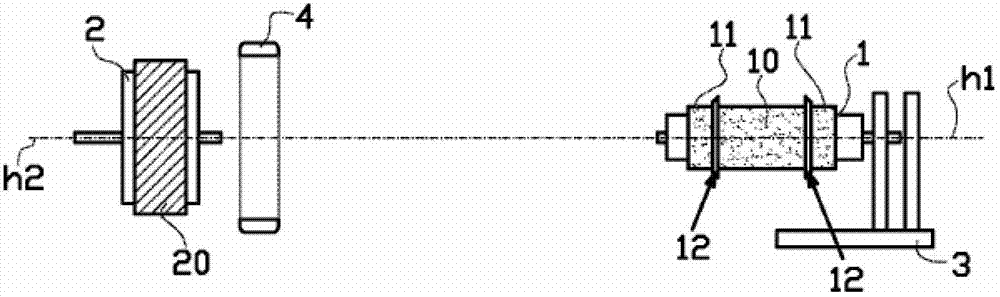

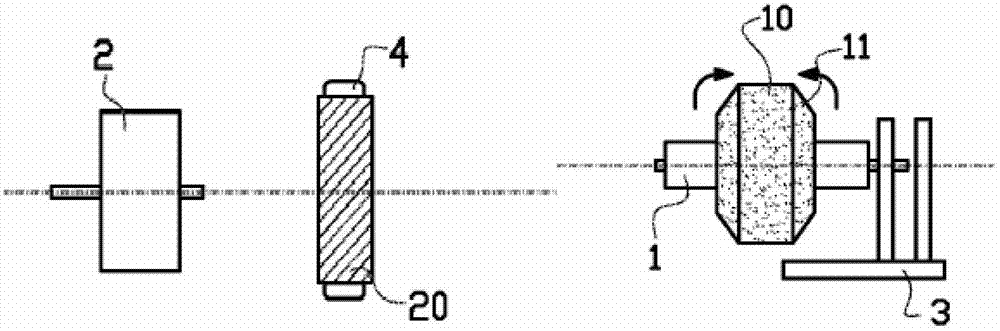

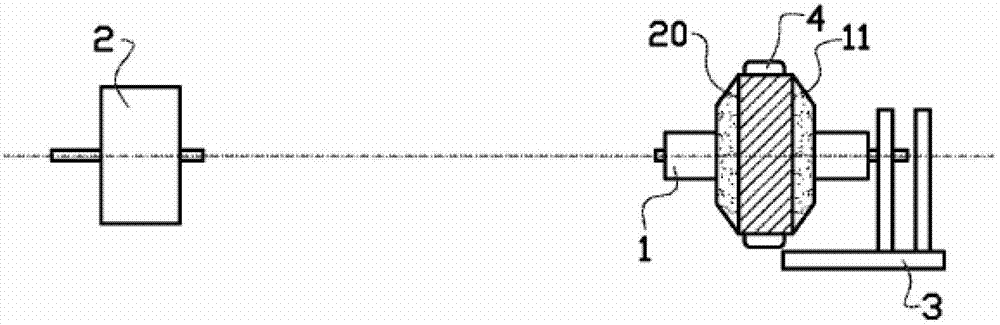

Method and device for drying plant fibers

InactiveCN102032758AGood drying effectReduce heat lossDrying solid materials with heatDrying gas arrangementsHot blastOil palm

The invention discloses a method and device for drying plant fibers, which is characterized in that hot air provided by a hot-blast stove (1) enters a drying roller (2), the plant fibers are fed into the drying roller (2) through a charging machine (3) on the drying roller (2), and the plant fibers in the drying roller (2) are overturned along with the drying roller (2), blown into a material bin (4) after being dried by the hot air and dedusted in the material bin (4) through a dust remover (5) to finish drying. In the drying method of the invention, the hot air and materials sufficiently contact, the drying effect is good, and the production cost is low and can be controlled at 500yuan / ton. The invention is adapted to the drying of various plant fibers, such as oil palms, coconut husks, hemp or bamboo fibers and the like.

Owner:GUIZHOU DAZIRAN TECH

Ancient mural holographic imitating and copying manufacturing method and holographic imitating and copying ancient mural obtained therethrough

ActiveCN110802980ATo achieve a high degree of simulation effectIncreased durabilitySpecial artistic techniquesEngineeringImage segmentation

The invention provides an ancient mural holographic imitating and copying manufacturing method and a holographic imitating and copying ancient mural obtained therethrough. The method comprises the following steps that data analysis and arrangement are performed according to cultural relic experimental investigation data so as to obtain a high-definition scanning image and a picture with the size ratio of 1:1 to an original mural as well as materials and structures used in an ancient mural original base layer and pigment used in the original wall painting; the high-definition scanning image isdivided into a plurality of parts, the size of each part is determined, image line drawing and copying are carried out, and bottom frame split manufacturing is carried out according to the size of each part; after a bottom frame is manufactured, single surface laying of a bottom lining plate is carried out, and then pure linen cloth is stretched and bound on the frame; according to the materials and the structures used in the ancient mural original base layer, a base layer and a surface layer are manufactured on the stretched linen cloth; pigment is selected according to the pigment used in the original wall painting, and a pigment blending liquid is prepared; the traditional drawing performance technique is applied to carry out ancient mural image information coping; and manufactured mural imitating and coping works are subjected to combined installation and gap filling.

Owner:宋志旭

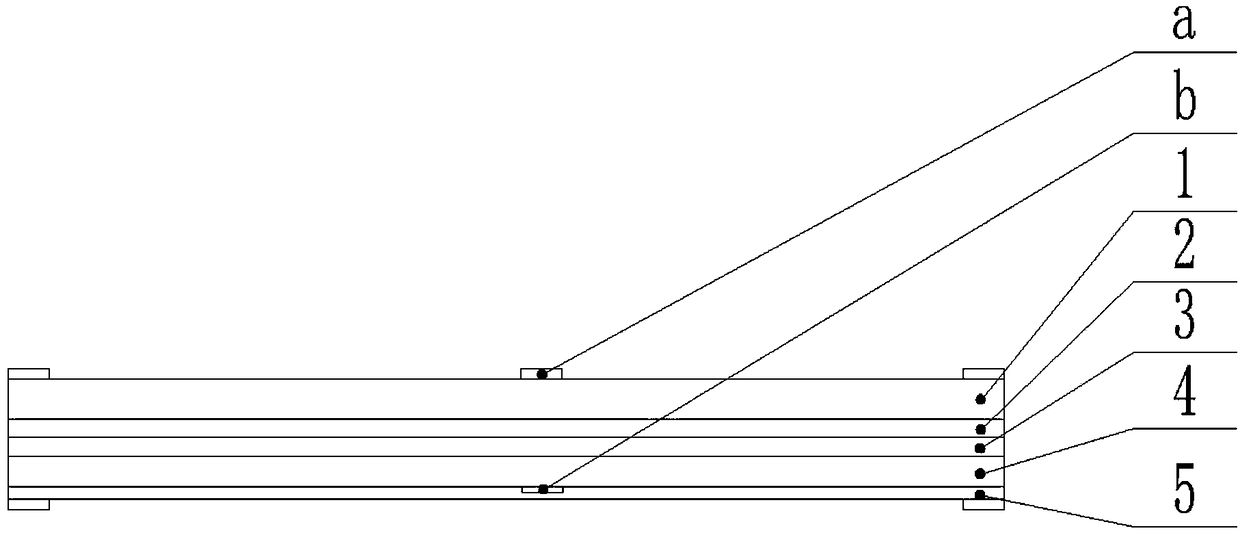

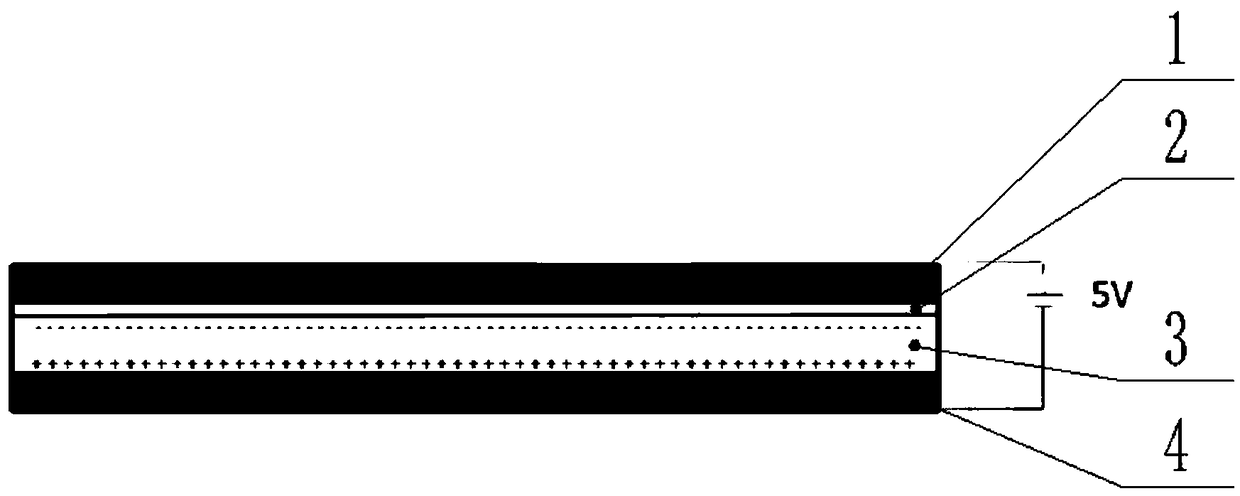

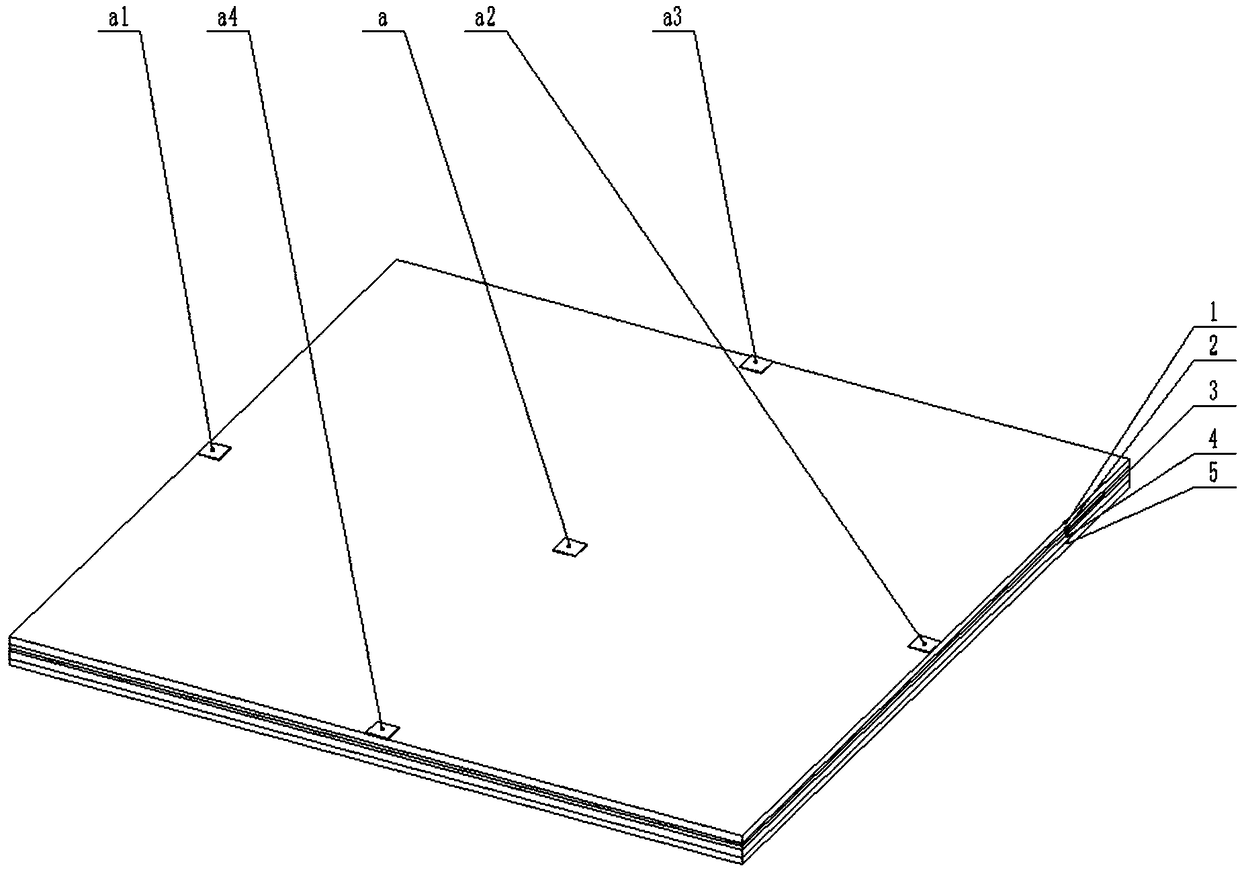

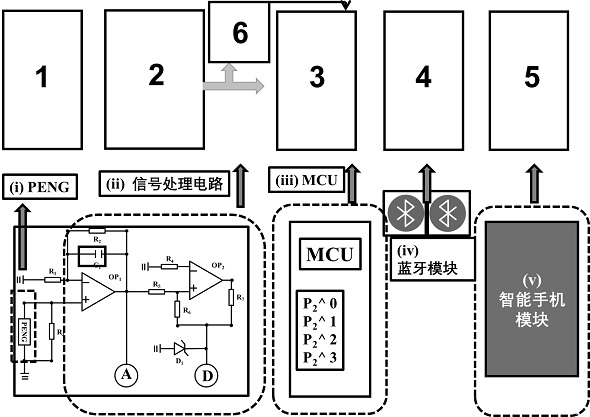

Non-array type super-capacitive tactile sensor and application

ActiveCN109323782AImprove flexibilityAchieve stretchForce measurementPositive pressureTactile sensor

The invention provides a non-array type super-capacitive tactile sensor and an application. The sensor comprises an upper electrode layer, a lower electrode layer, an ionic gel layer and an air layer,wherein the ionic gel layer and the air layer are located between the two electrode layers; the air layer is arranged between the upper electrode layer and the ionic gel layer; the ionic gel layer can collect positive and negative charges on the upper surface and the lower surface when being electrified; the upper electrode layer is connected with the positive electrode a of a power supply; thelower electrode layer is connected with the ground b; two groups of measuring electrodes are arranged on the upper surface of the upper electrode layer in transverse and longitudinal directions; eachgroup of the measuring electrodes comprises two measuring electrodes; and the distances between the two measuring electrodes and the center of the upper electrode layer are the same. The sensor adoptsa non-array type structure; the ionic gel layer and air are adopted as intermediate layers; large-area accurate positioning of a positive pressure is realized; and the upper electrode layer and the ionic gel layer are in contact with each other to form a super-capacitor when the positive pressure is received, so that the position of the positive pressure is determined.

Owner:HEBEI UNIV OF TECH

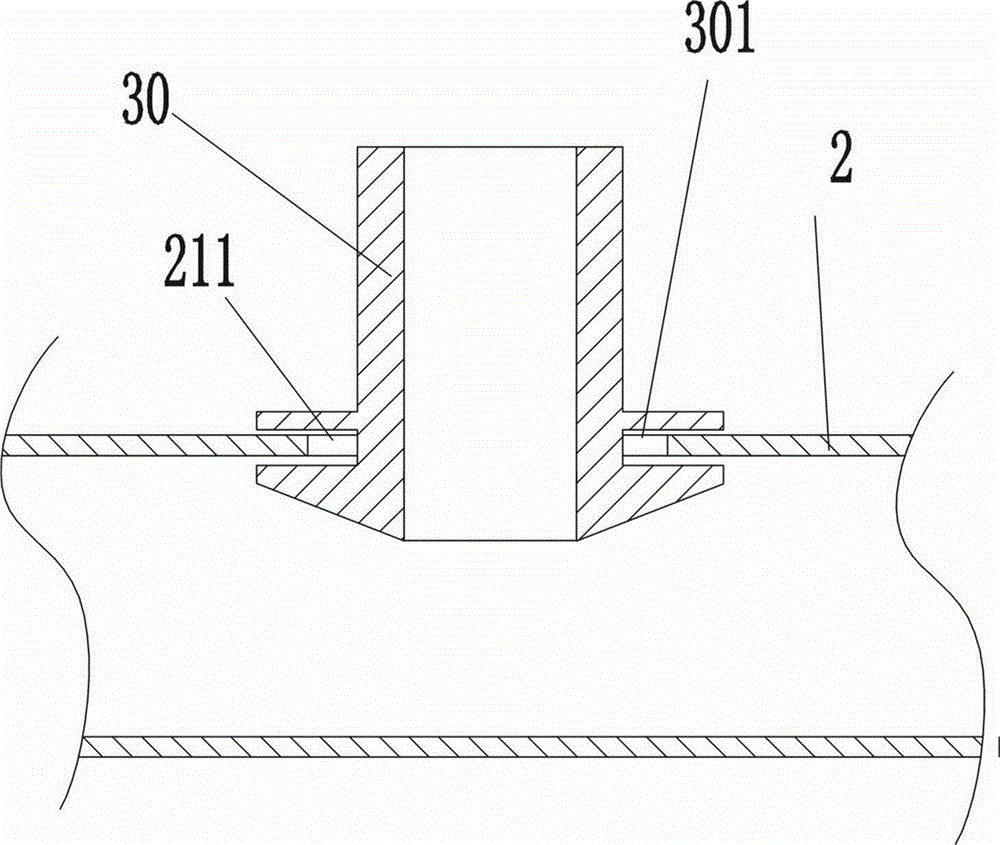

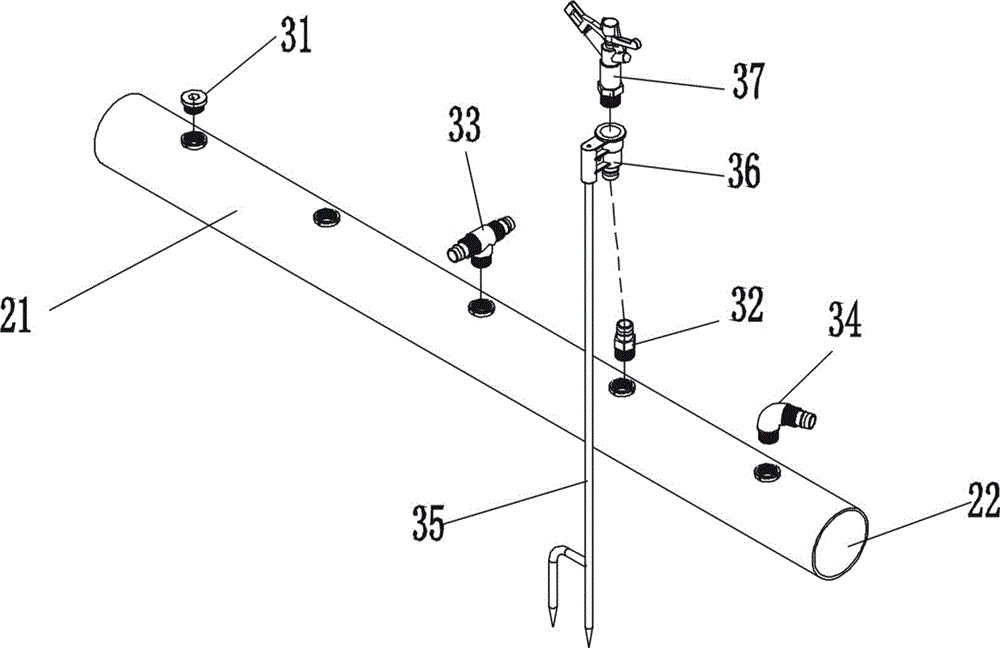

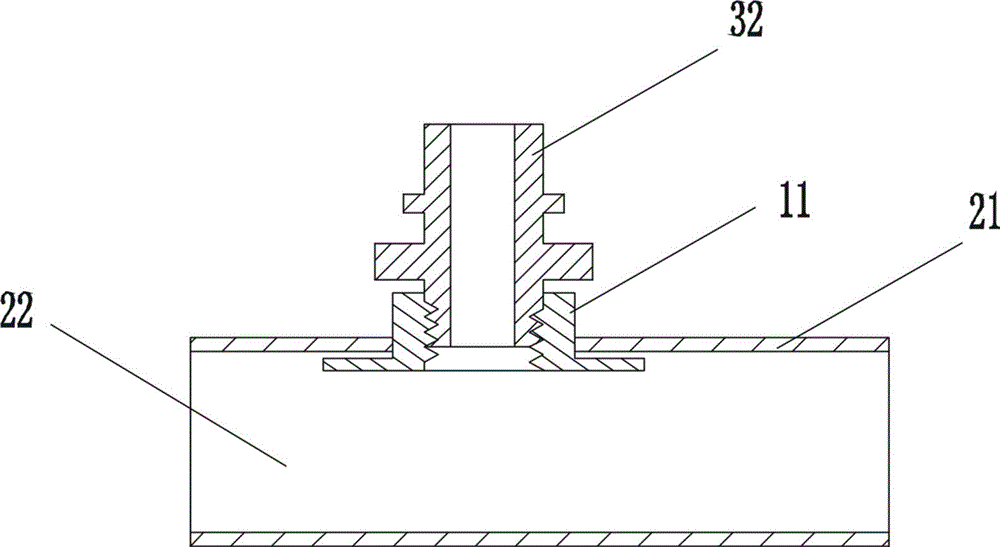

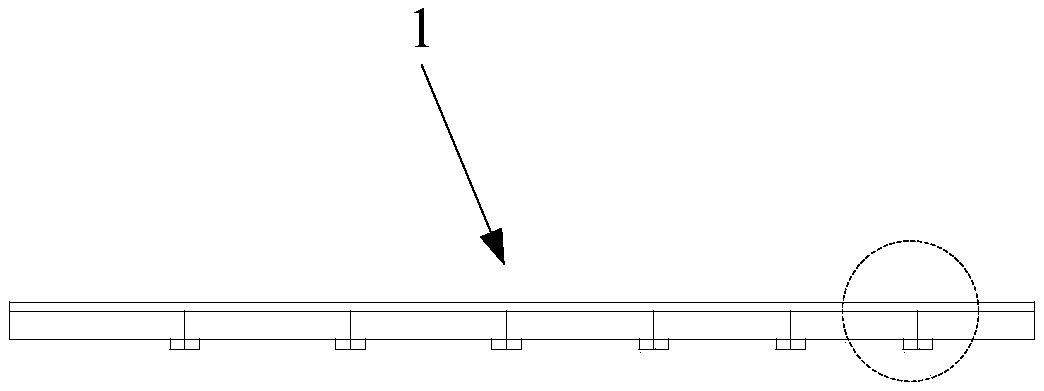

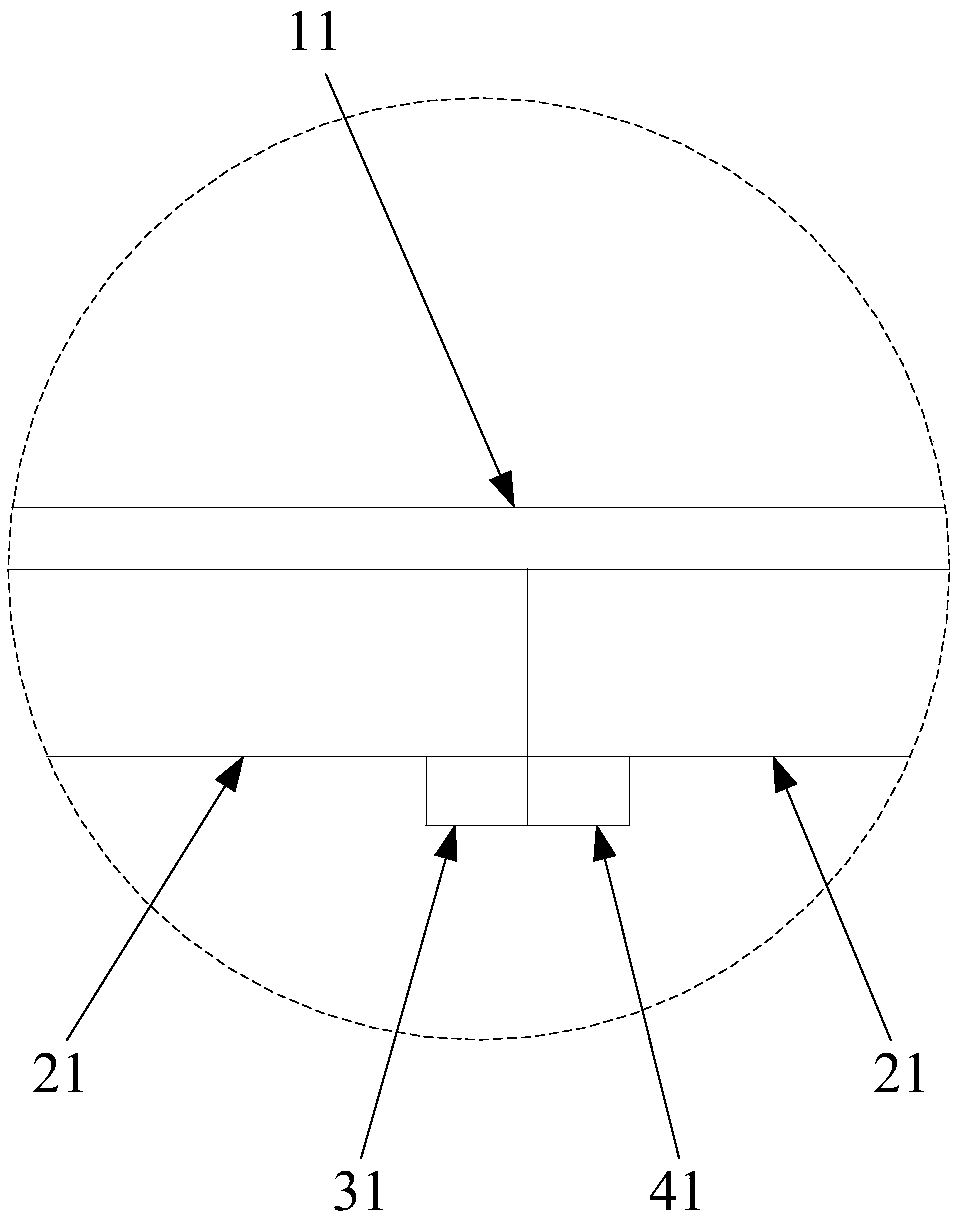

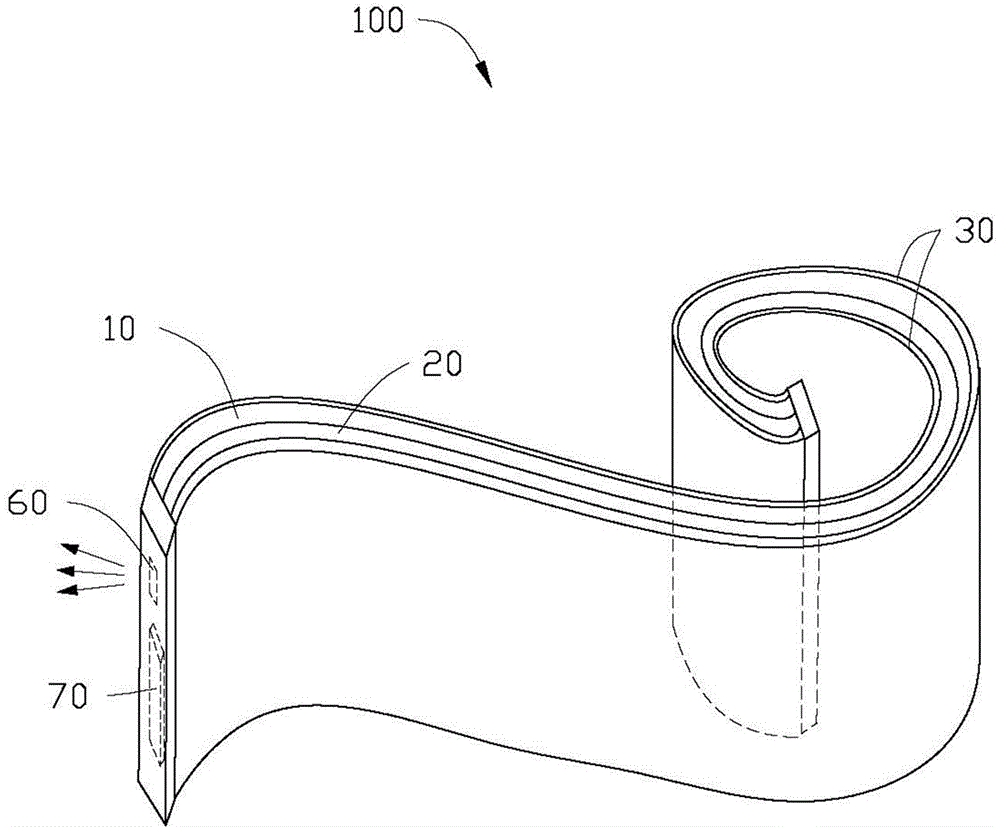

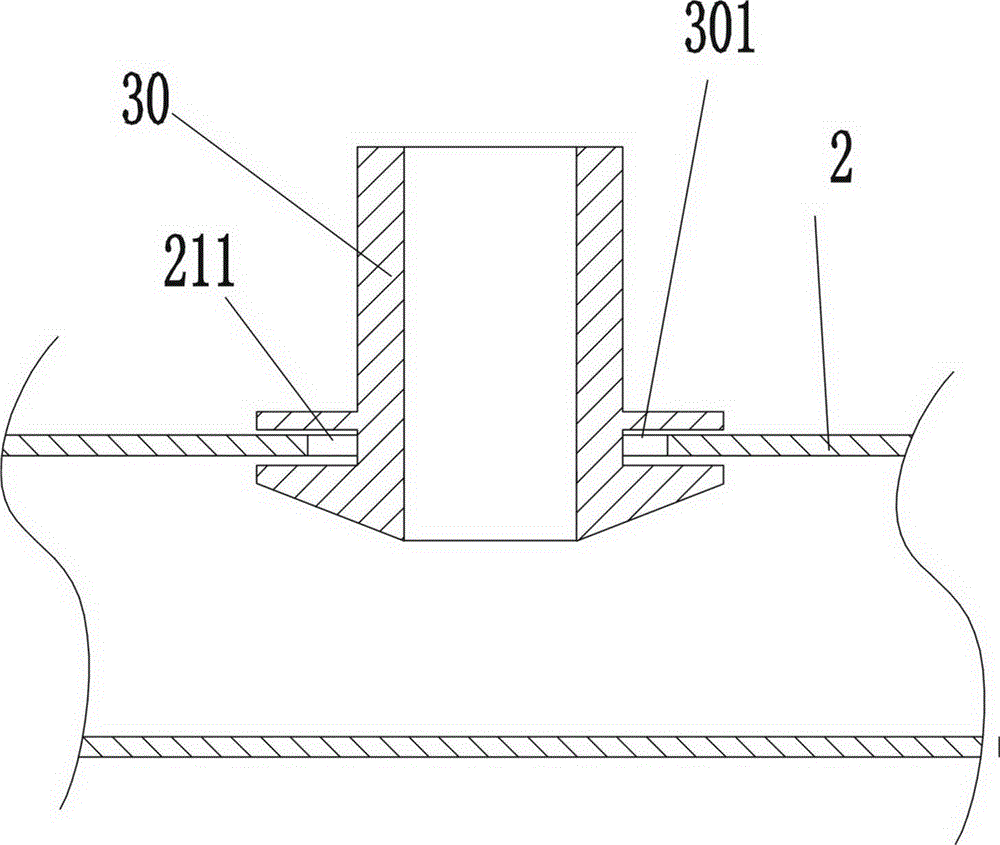

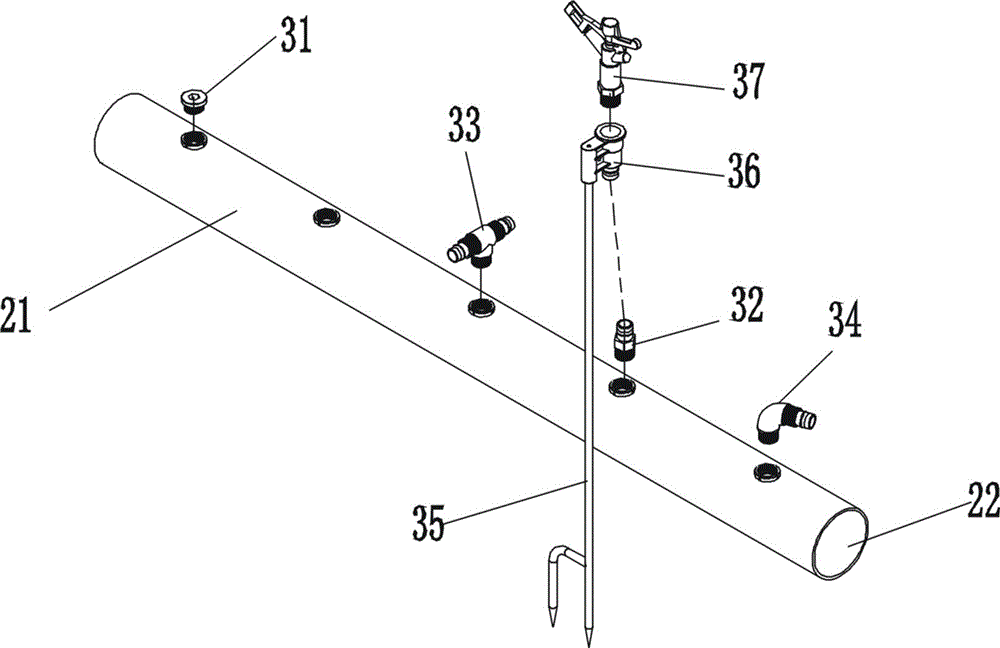

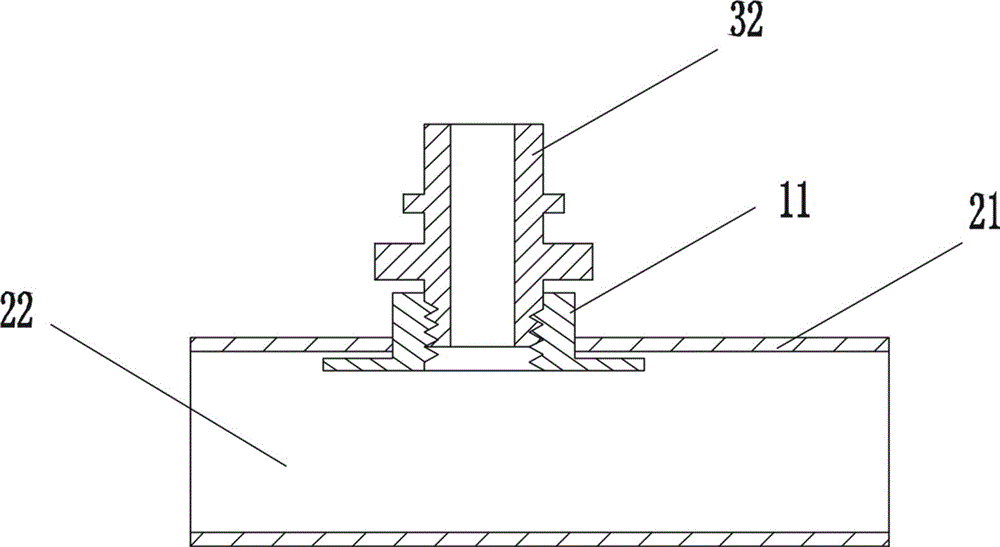

Irrigation plastic water hose and production process thereof

ActiveCN103999738AImplement curlReduce water leakageWatering devicesSpray nozzlesWater leakageLap joint

An irrigation plastic water hose comprises a hose wall made of plastic, and the hose wall is in lap joint end to end circumferentially to form a hose cavity. A plurality of through holes are formed in the hose wall, a plastic nut is matched with and arranged at each through hole correspondingly, the axial lengths of the plastic nuts are between 0.7cm and 2.0cm, and screw holes are formed in the center of plastic nut bodies. The plastic nuts are integrally injection molded to form circular protruding edges protruding and extending to the periphery, the circular protruding edges are disposed in a hose cavity of the plastic water hose, plastic nut bodies penetrate the through holes in the plastic water hose wall outwards, and the circular protruding edges are fused or bonded with the inner surfaces of the hose walls of the through hole edge areas. The invention further provides a production process of the irrigation plastic water hose. The irrigation plastic water hose can be recovered and wound conveniently, water guide tubes cannot be pushed outward by the water pressure easily to cause separation and water leakage even during large irrigation water pressure, and farmers can mount and dismount the water diversion tubes conveniently.

Owner:汕头市光华机械实业有限公司

Electronic equipment and display equipment thereof

PendingCN108803786AAchieve foldingImplement curlDigital data processing detailsBiomedical engineeringElectronic equipment

The invention discloses display equipment, which comprises a flexible body for displaying projected lights, and multiple supporting plates connected to the back surface of the flexible body, wherein any two adjacent supporting plates can be separated to realize folding and can be also assembled to support the flexible body in the same plane. In the display equipment, any two adjacent supporting plates can be separated from each other and can be also assembled; when the supporting plates are all separated, mutual folding can be realized, and then folding or curling of the whole display equipment is realized, so that the display equipment is convenient to carry; and when the supporting plates are all assembled, the flexible body can be supported in the same plane, so that the whole display equipment is a flat display plane and is laid on a non-white desktop to better display the projected lights. The invention further provides electronic equipment with the display equipment.

Owner:LENOVO (BEIJING) CO LTD

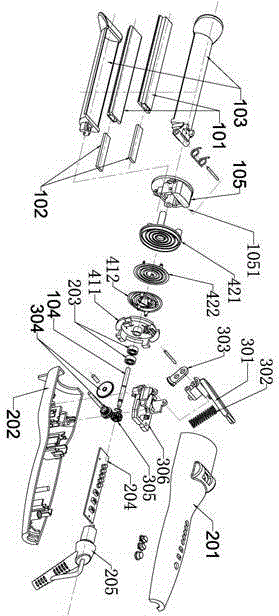

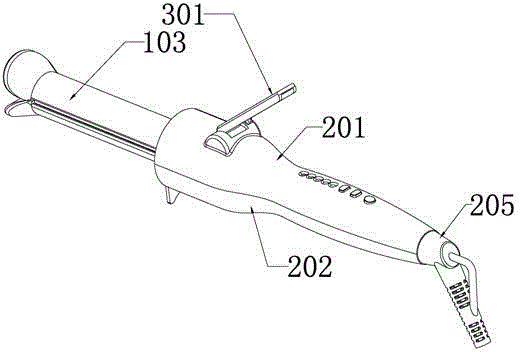

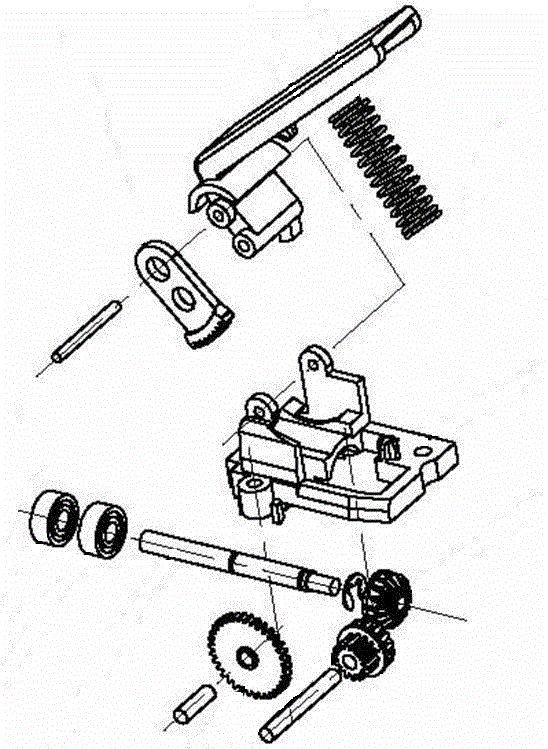

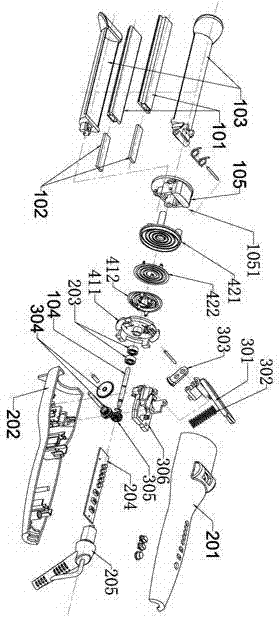

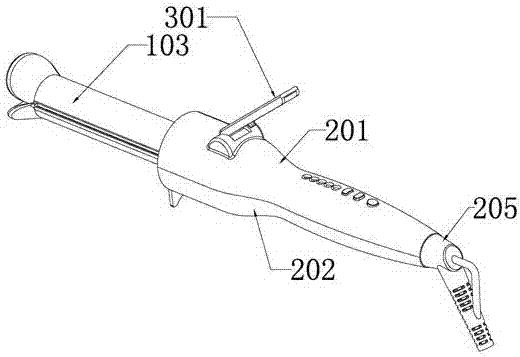

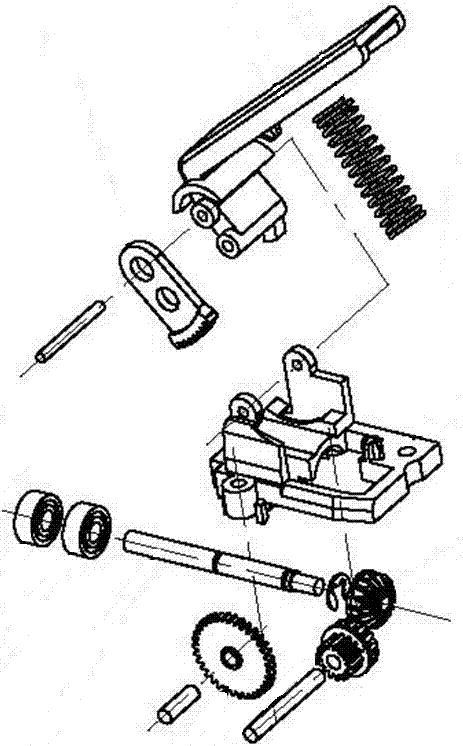

Hair curler

ActiveCN104665196ASave the trouble of wrapping around the heat pipeImplement curlCurling devicesEngineeringMechanical engineering

The invention relates to a hair curler, which comprises a hair curling assembly, a handle, a rotating mechanism assembly and a conductive assembly, wherein the rotating mechanism assembly is arranged on the handle, and the rotating mechanism assembly, the hair curling assembly and the conductive assembly form linked rotating matching. The hair curler has the beneficial effects that 1, an aluminum plate is arranged in the interior, so the scalding caused by false operation in the working process is avoided; 2, the hair curling assembly is driven by a press handle to rotate, so the trouble of winding hair on a heating pipe in the traditional method is avoided; 3, in the use process, the hair curling is started at the part requiring hair curling, and is stopped at the final part, so as to curl the hair of one part of area.

Owner:WENZHOU SHI LABO ELECTRICS CO LTD

Holographic copying painting base and production method thereof

PendingCN110509700ACrafting materials are not limitedIncrease the likelihood of performanceOrnamental structuresSpecial ornamental structuresUltravioletEngineering

The invention provides a holographic copying painting base and a production method thereof. The holographic copying painting base comprises a base substrate layer, a bottom glue layer, at least one layer of rock sand soil gluing layer and a cover cementing layer; the bottom glue layer covers the base substrate layer; the rock sand soil gluing layer is glued on the bottom glue layer; the cover cementing layer is glued on the rock sand soil gluing layer. The base is not constrained by the material, and the thickness of the base layer can be added according to requirements; a soft material can realize curling, the durability is extremely high, and portability is achieved; the installation method is simple and fast, and is not limited by conditions, in particular, the curved surface installation can be realized; the holographic copying painting base can also undergo overlay treatment of other auxiliary processes, so that properties of the base are added, and for example, the holographic copying painting base further has the functions of being waterproof, fireproof, antioxidant, corrosion-resistant and anti-ultraviolet and other functions and can be used indoors and outdoors; in addition, the holographic copying painting base is not limited by painting materials, and by using different blending agents, various painting materials can be applied for artistic expression.

Owner:马玉娟

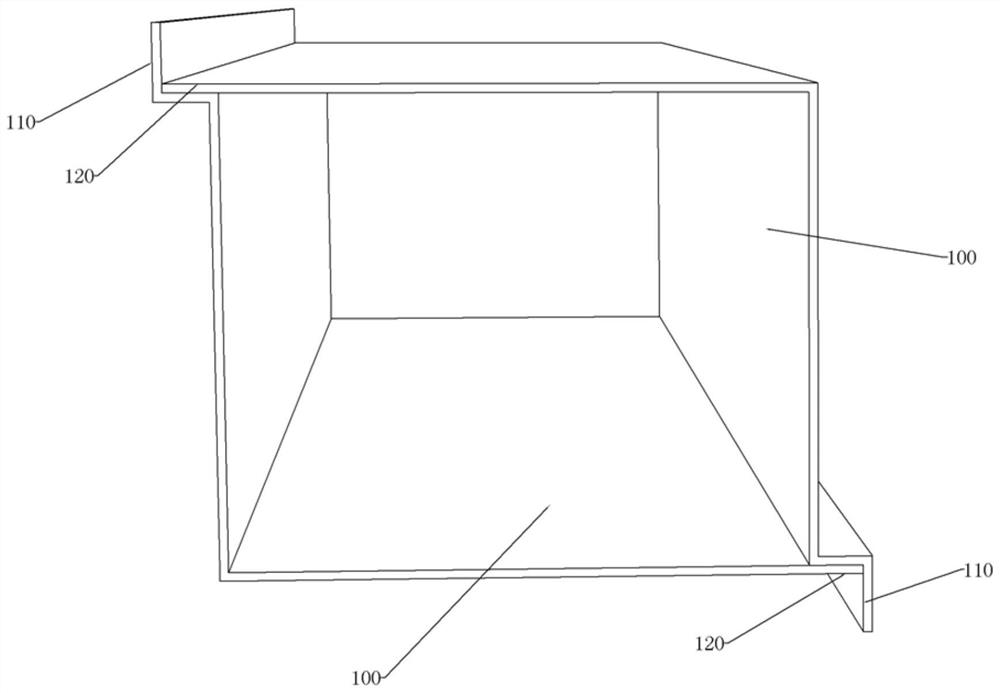

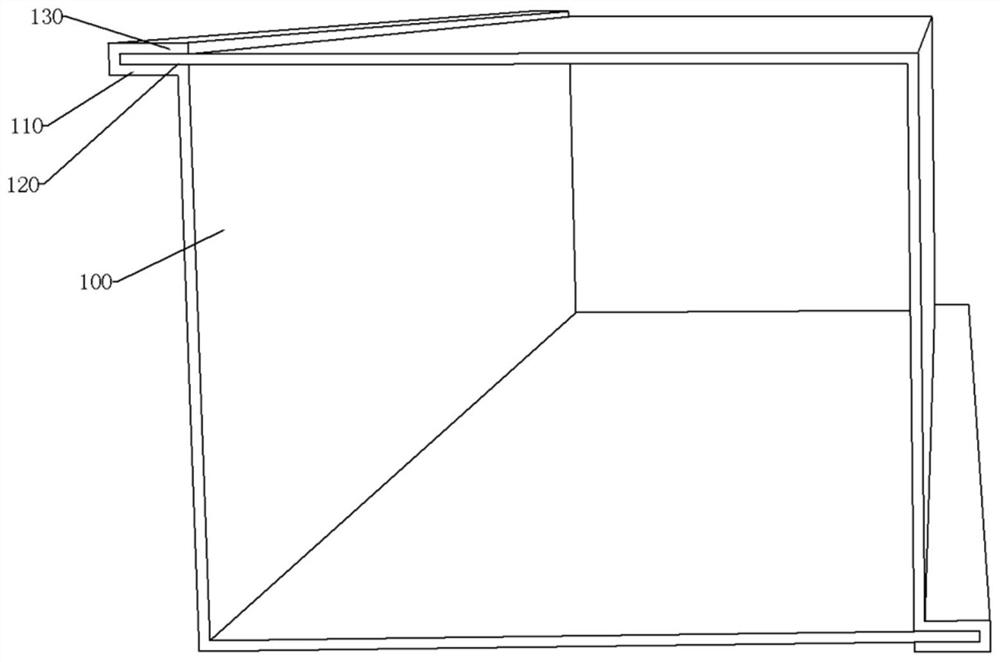

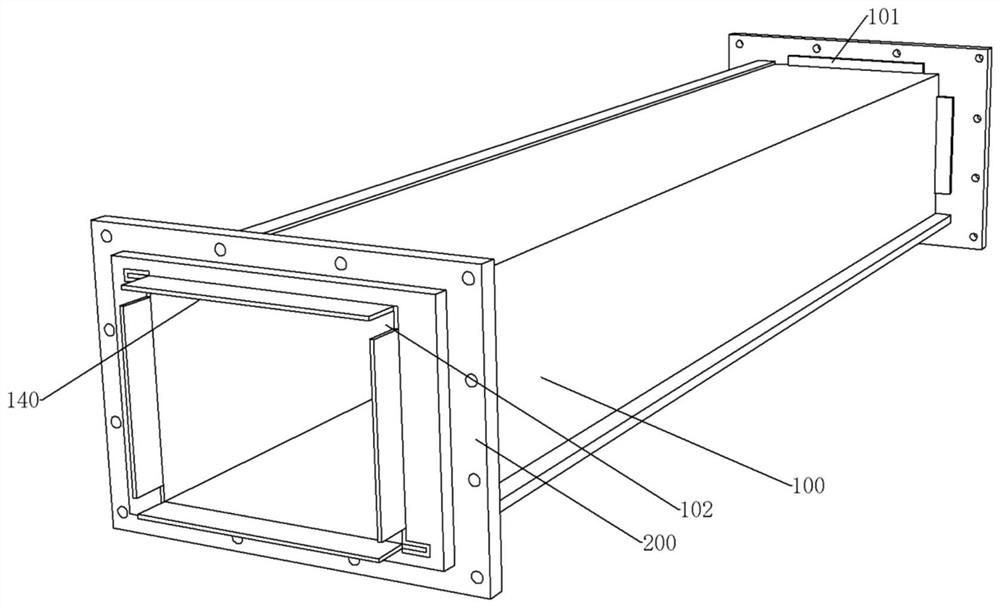

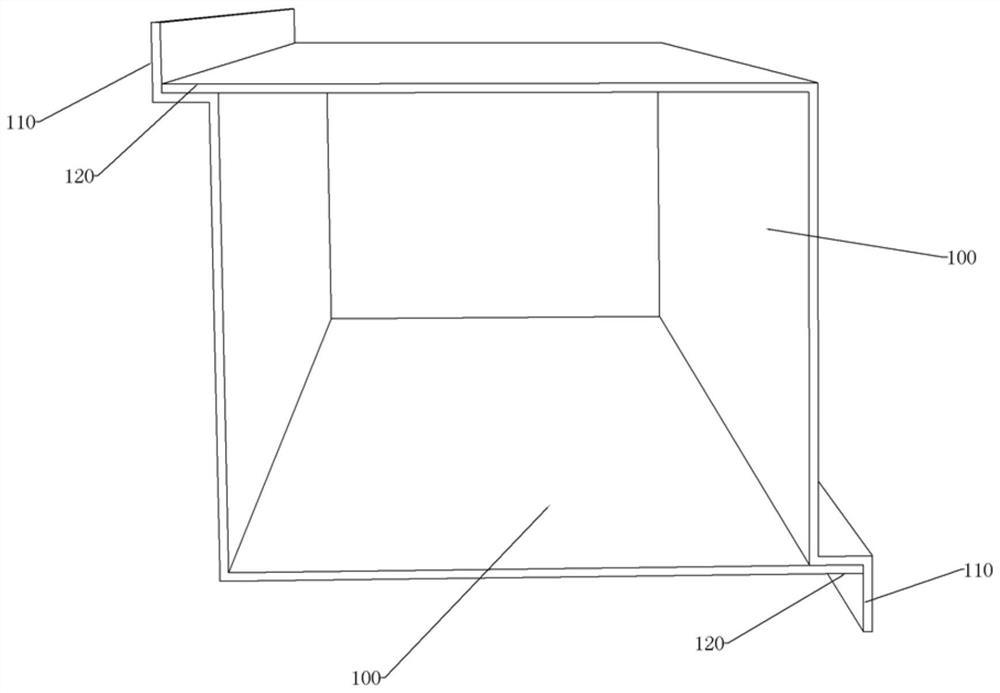

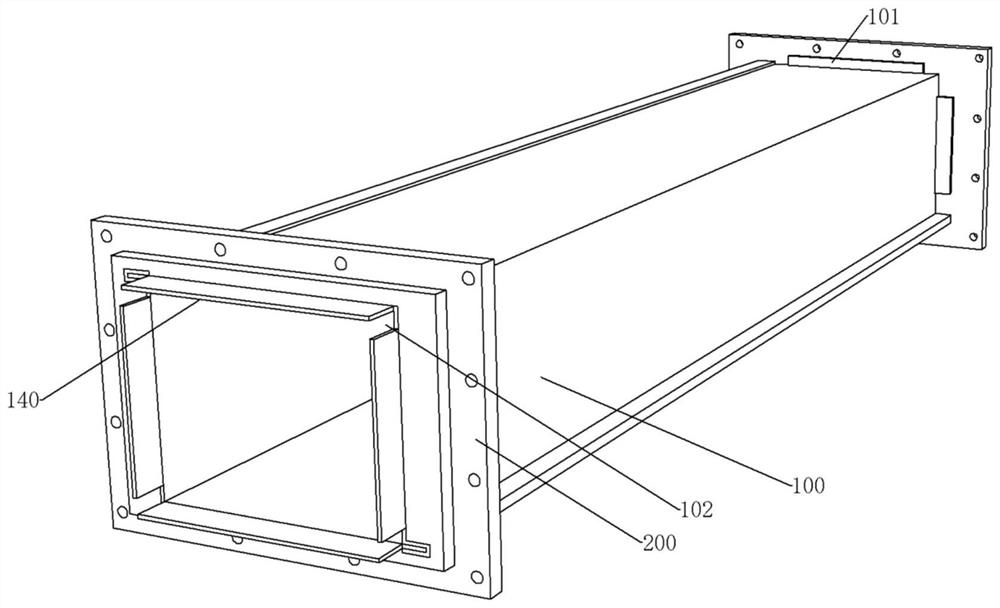

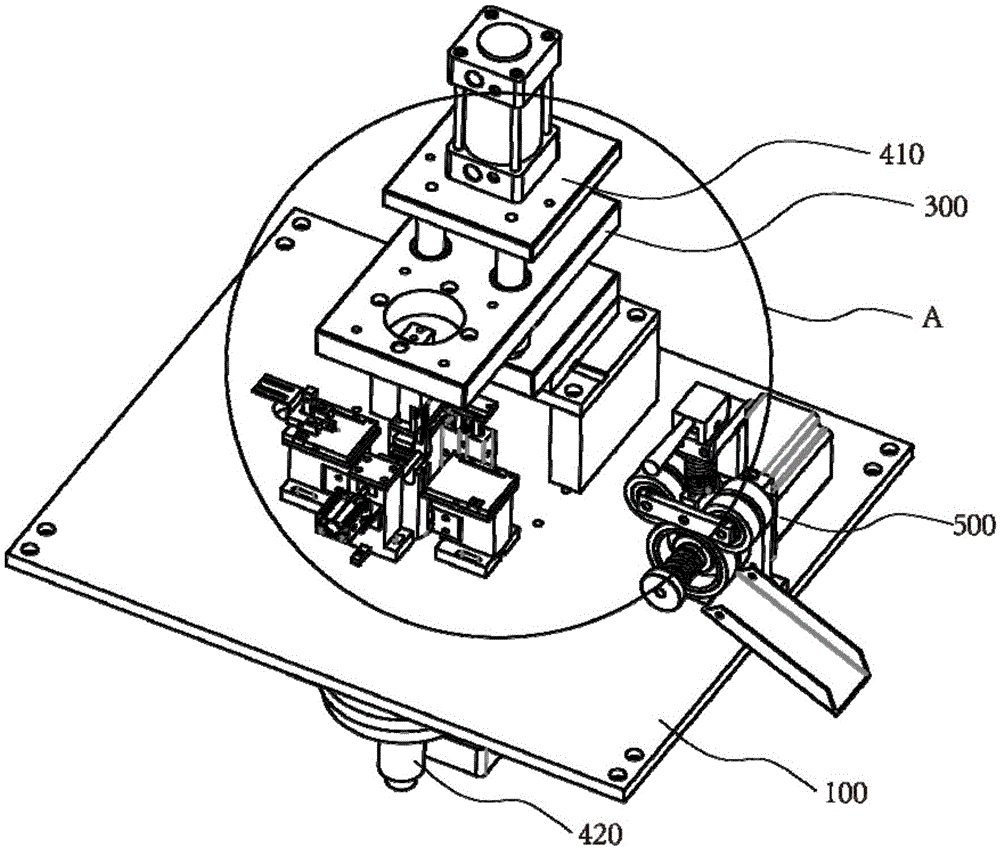

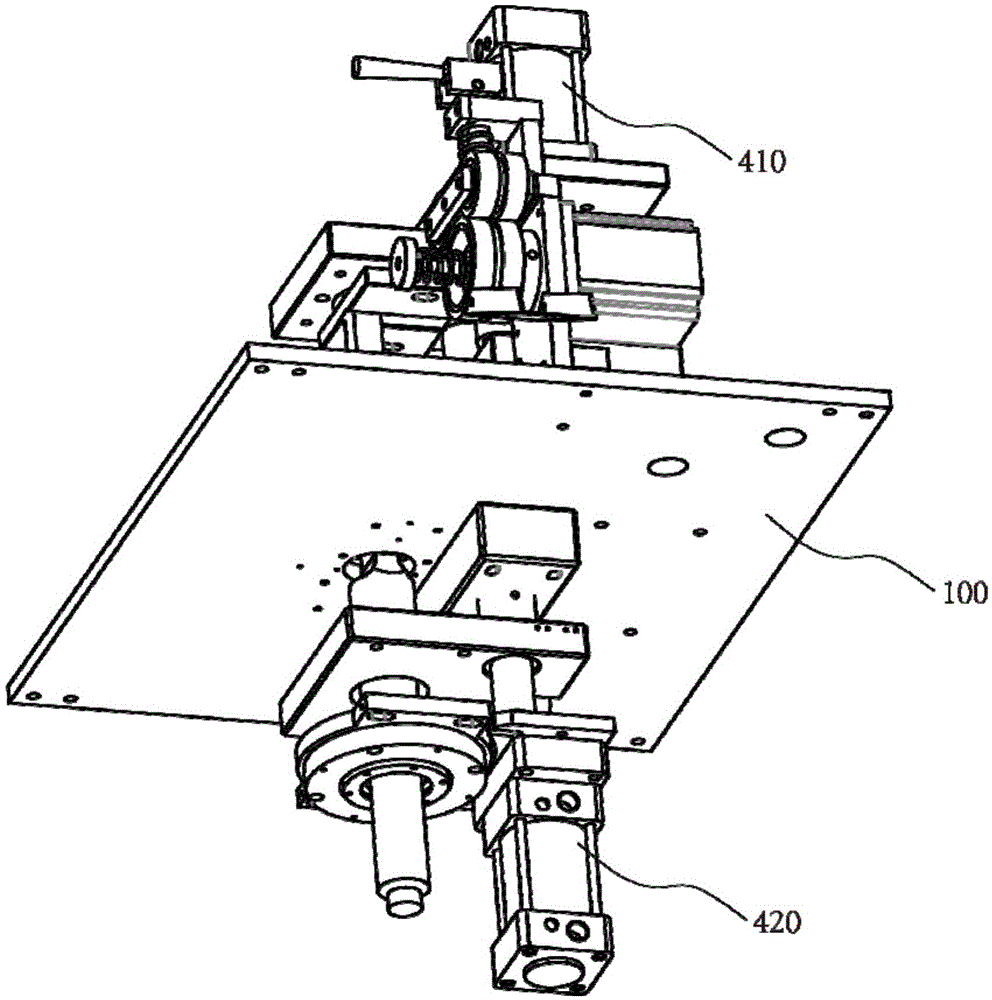

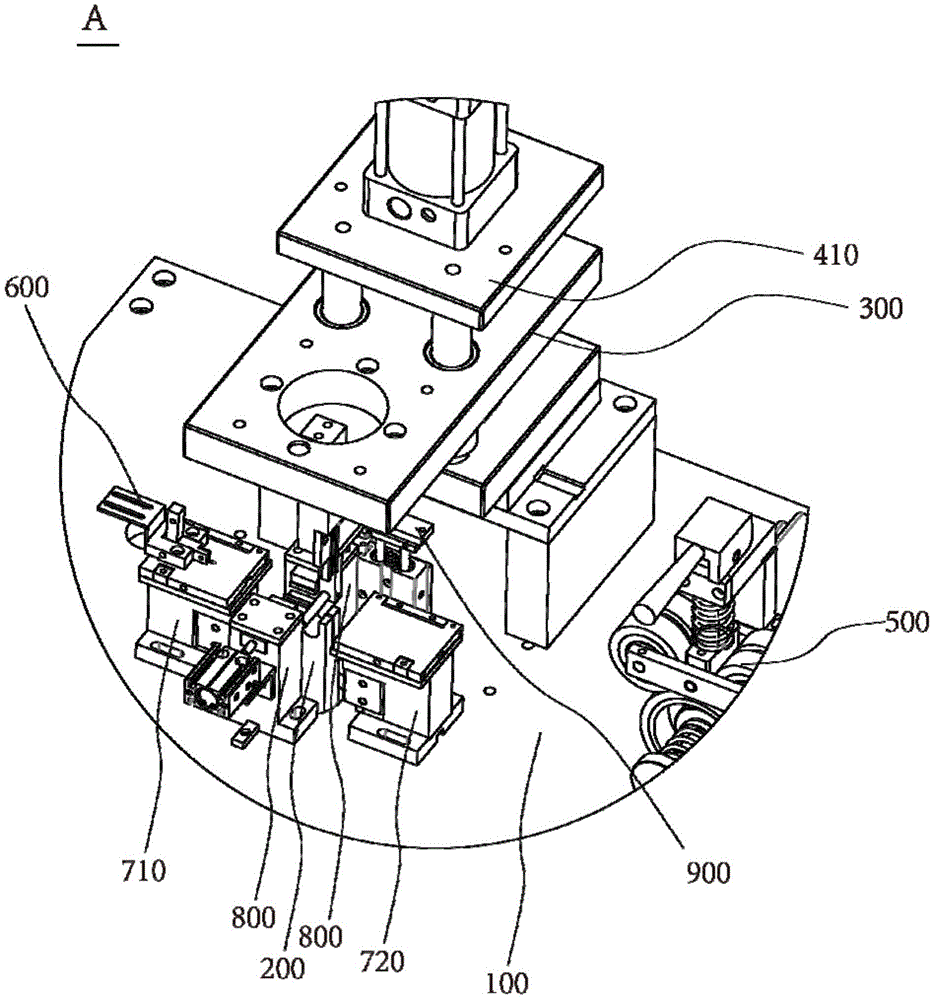

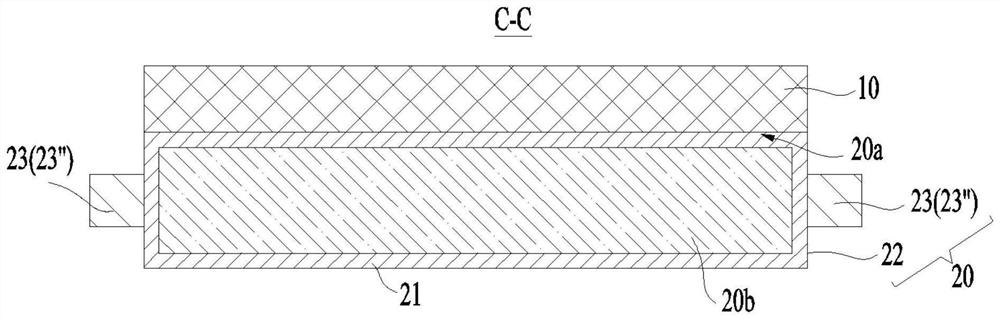

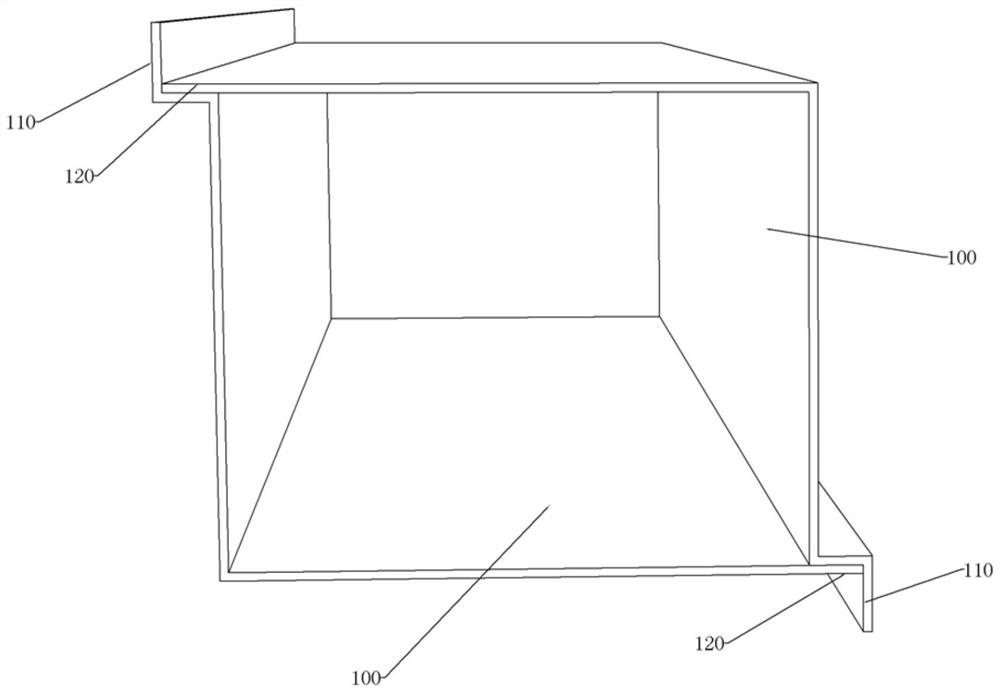

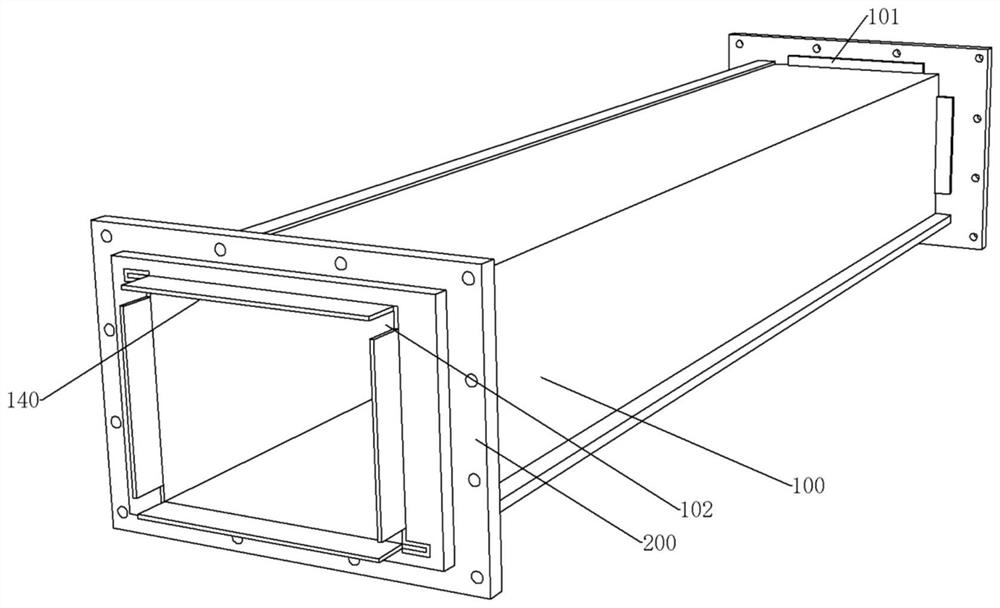

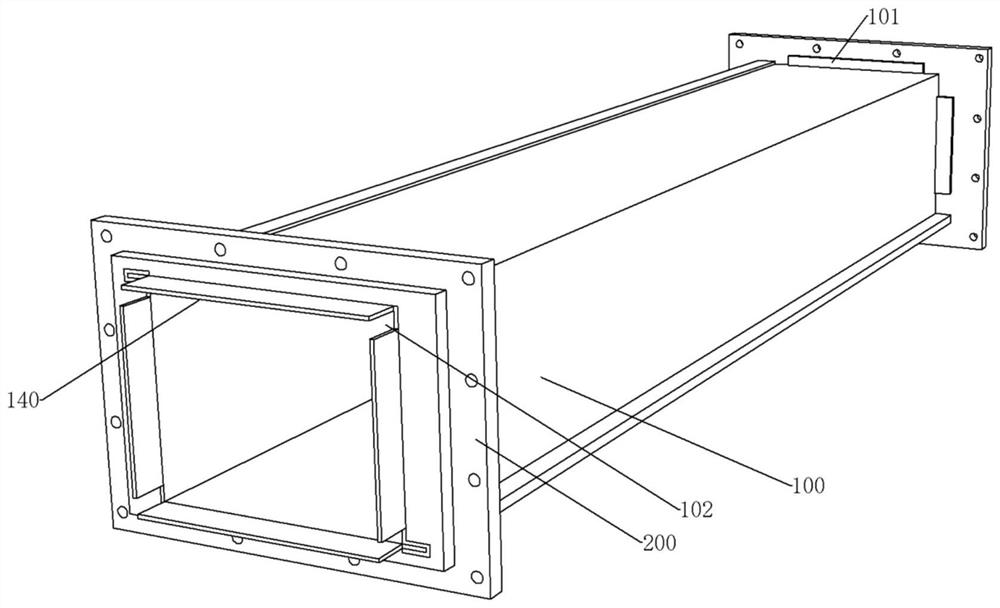

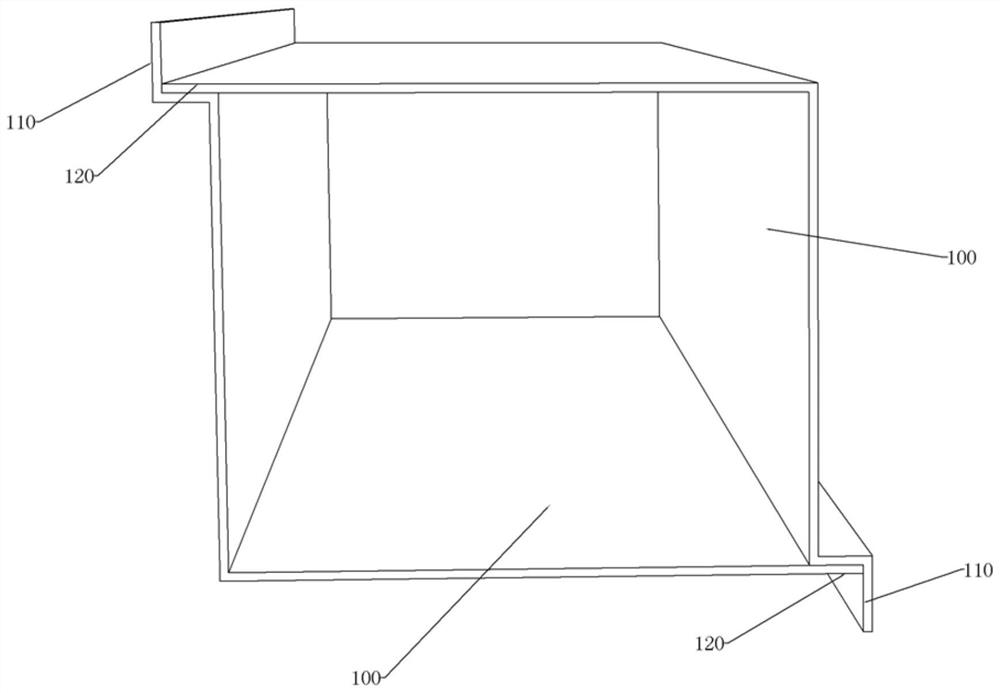

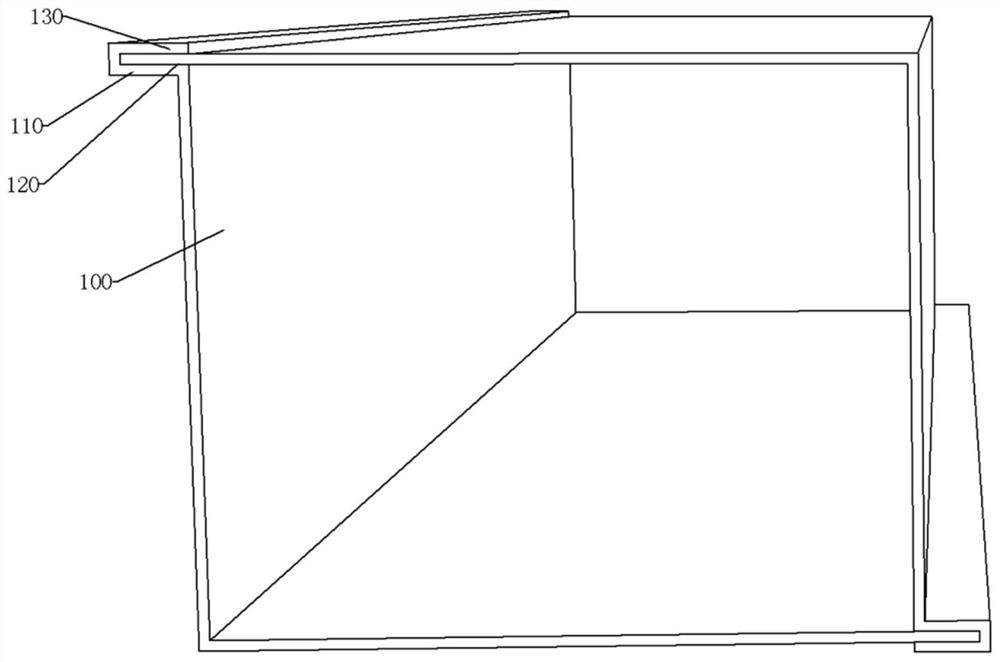

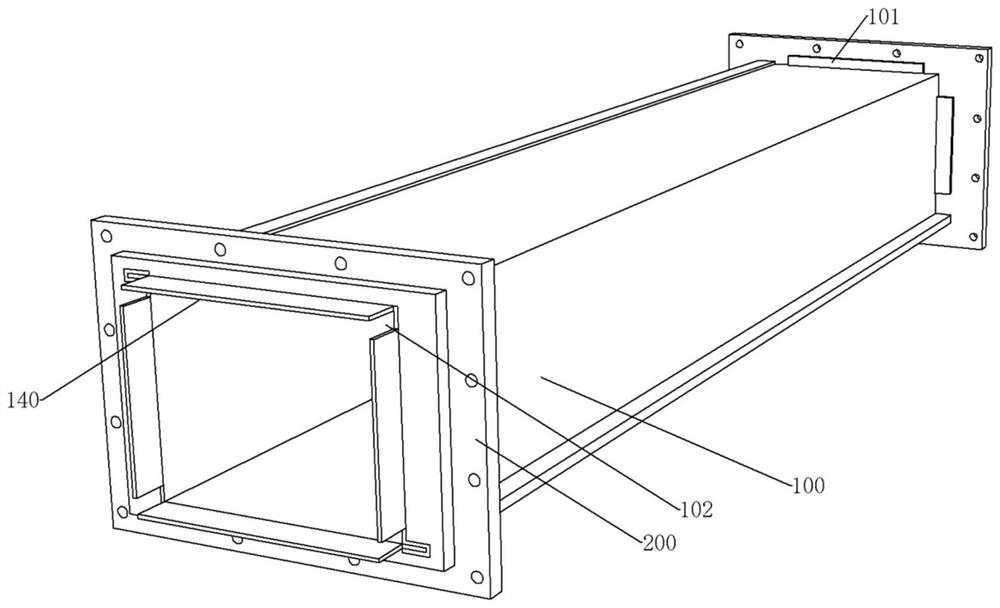

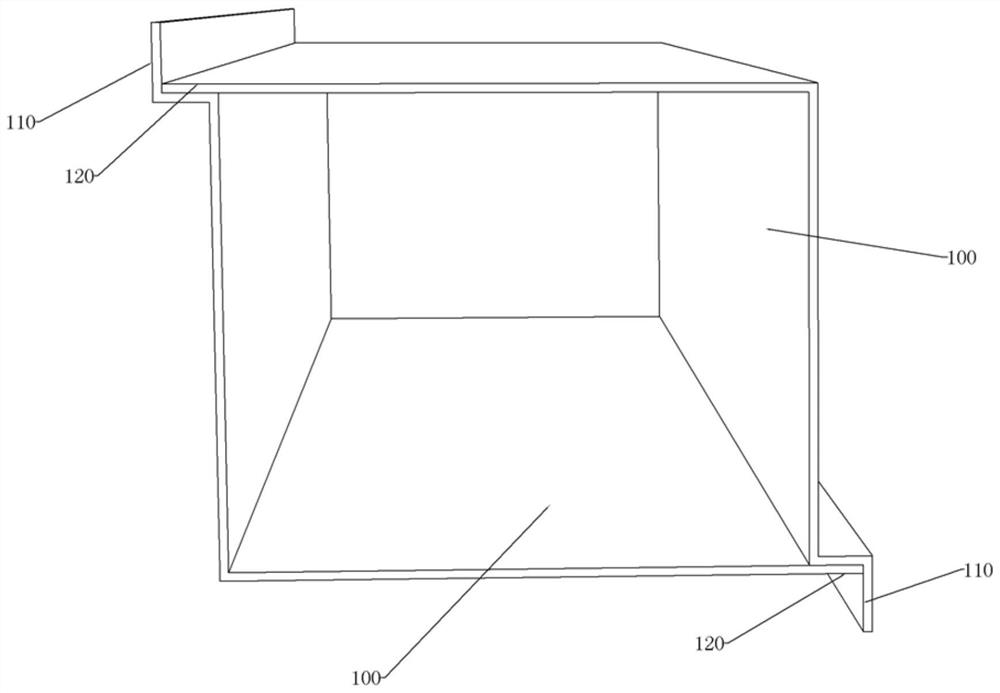

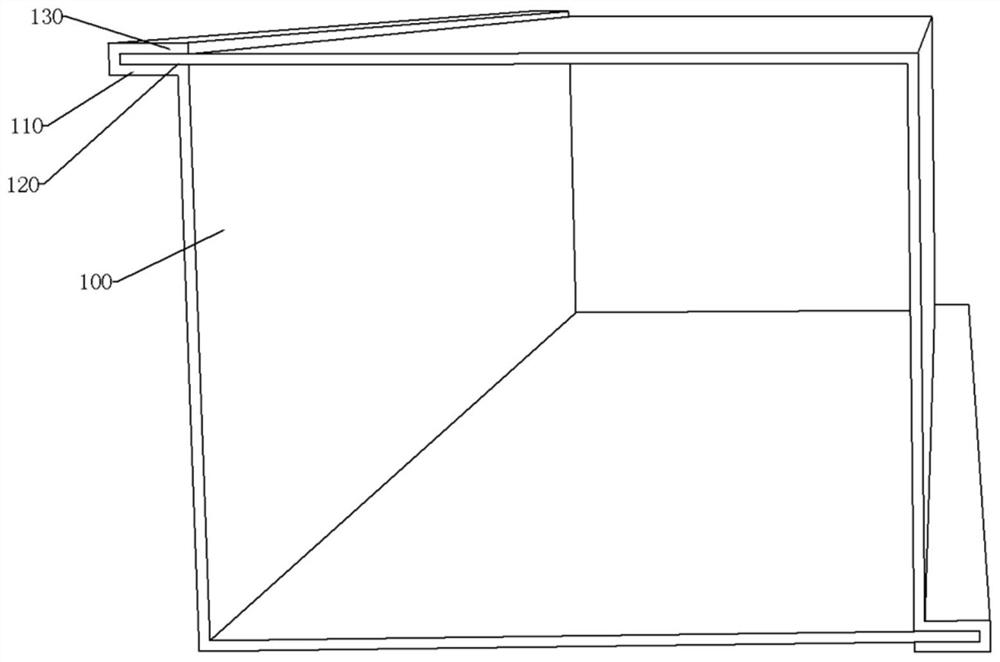

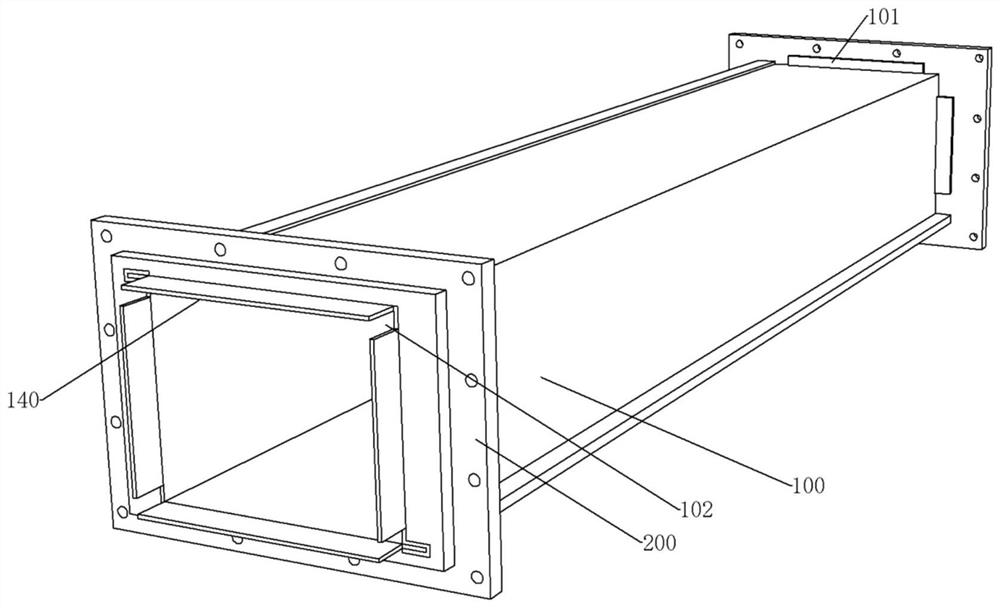

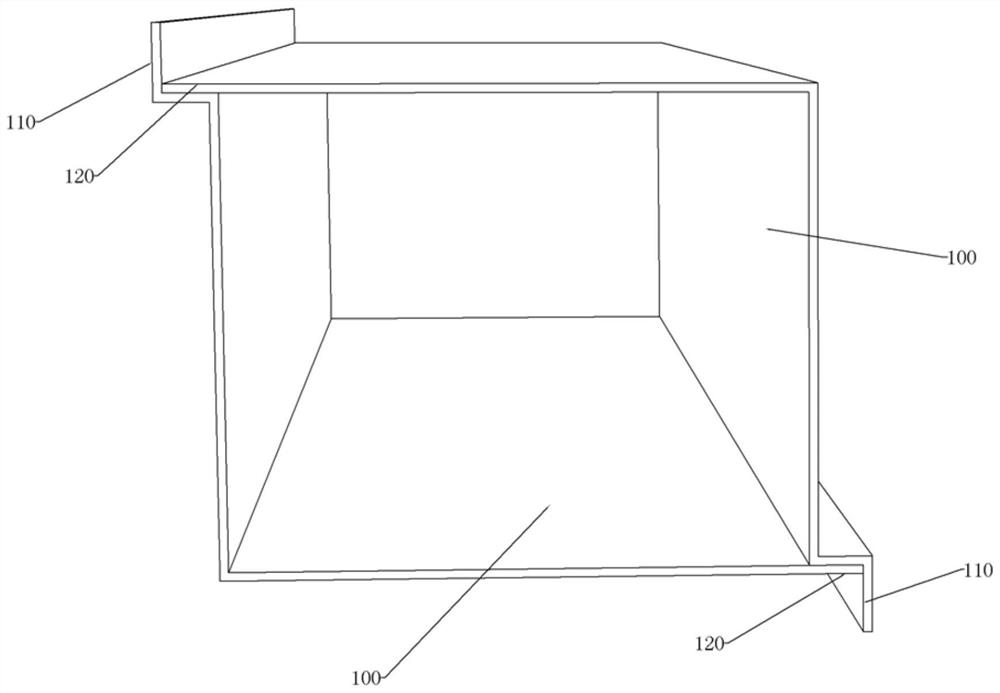

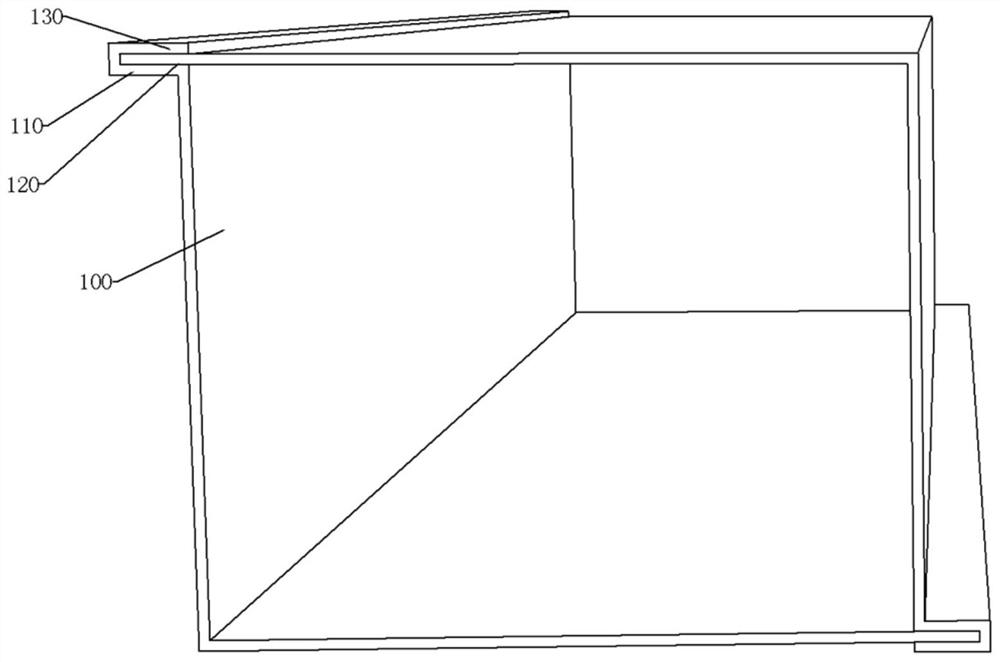

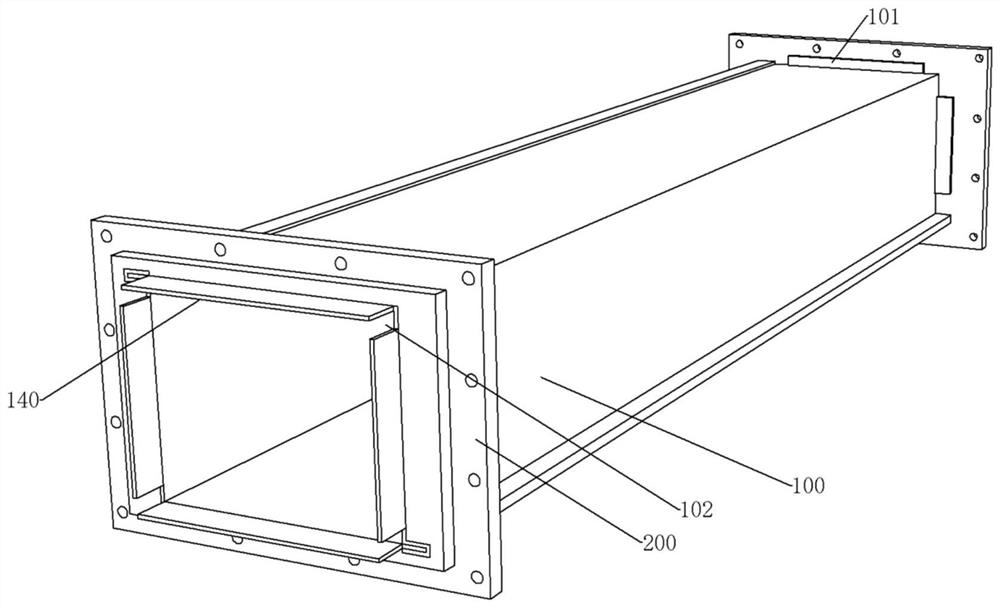

Conveying module and fire-fighting air duct production line thereof

ActiveCN112008432AIncrease productivitySimple structureOther manufacturing equipments/toolsMetal working apparatusEngineeringStructural engineering

The invention discloses a conveying module and a fire-fighting air duct production line thereof. The fire-fighting air duct production line of the conveying module comprises a platform module which isused for splicing and sewing a fire-fighting air duct, wherein the spliced fire-fighting air duct is a fire-fighting air duct with the edge sewn; a detection module used for detecting the flatness ofa sewn first hemming part; a grooving module used for cutting bending grooves in the two ends of the fire-fighting air duct correspondingly, wherein a second hemming part without hemming is obtained;a conveying module used for clamping the sewn fire-fighting air duct through a clamping mechanism and conveying the fire-fighting air duct; a flange sleeving module used for taking out a flange fromthe interior of a storage side plate and then respectively sleeving the two ends of the fire-fighting air duct with the flange; and a flange mounting module used for hemming the second hemming part which is not hemmed towards a clamping part, so that a second hemming part clamps and fixes the flange between a flange boss and the second hemming part. According to the conveying module and the fire-fighting air duct production line thereof, automatic sewing, detection, flange sleeving and flange fixing of the fire-fighting air duct can be realized.

Owner:CHONGQING VOCATIONAL INST OF ENG

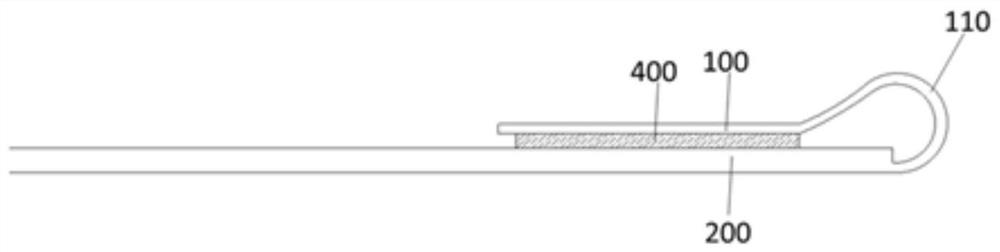

Thin type flexible electronic device

InactiveCN104978054AImplement curlAchieve distortionSecondary cellsDetails for portable computersElectricityInformation processing

A flexible electronic device comprises a shell, a touch module, a battery module, and an information processing and storage module. The touch module is located in the shell to sense input signals and convert the input signals into electronic signals. The battery module is used to supply power to the touch module, and all of the shell, the touch module, and the battery module are flexible. The information processing and storage module is capable of converting the electronic signals into control commands. The communication module is electrically connected to the information processing and storage module.

Owner:TIANJIN FUNA YUANCHUANG TECH

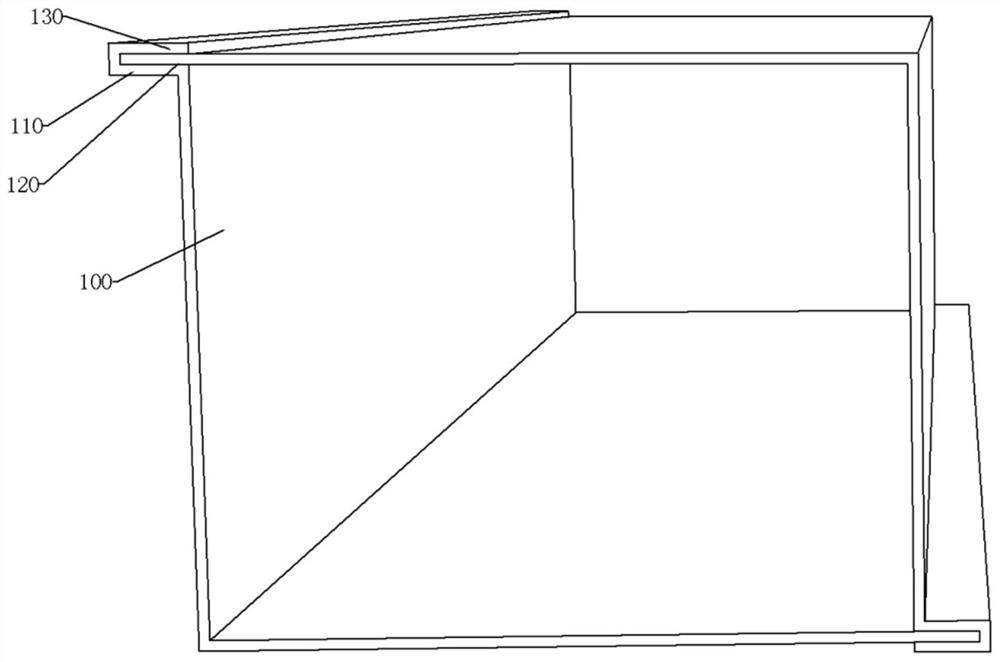

Flange installation module and fire-fighting air duct production line with flange installation module

ActiveCN112008374ARealize automatic stitchingIncrease productivityMetal sawing devicesMetal working apparatusProduction lineIndustrial engineering

The invention discloses a flange installation module and a fire-fighting air duct production line with the flange installation module. The fire-fighting air duct production line with the flange installation module comprises a platform module, a detection module, a grooving module, a conveying module, a flange sleeving module and the flange installation module. The platform module is used for splicing and sewing a fire-fighting air duct, wherein the spliced fire-fighting air duct is 100-1, and the hemmed fire-fighting air duct is 100-2. The detection module is used for detecting the flatness ofa sewn first hemming part. The grooving module is used for cutting bending grooves in the two ends of the fire-fighting air duct correspondingly, and a second hemming part without hemming is obtained. The conveying module is used for clamping the sewn fire-fighting air duct through a clamping mechanism and conveying the fire-fighting air duct. The flange sleeving module is used for taking out flanges from the interior of a storage side plate and then respectively enabling the flanges to sleeve the two ends of the fire-fighting air duct. The flange installation module is used for hemming the second hemming part without hemming towards a clamping part so that the second hemming part can clamp and fixe the flanges between flange bosses and the second hemming part. According to the flange installation module and the fire-fighting air duct production line, automatic sewing, detection, flange sleeving and flange fixing of the fire-fighting air duct can be realized.

Owner:CHONGQING VOCATIONAL INST OF ENG

Nylon zipper curling and tooth fusing machine and nylon zipper curling and tooth fusing method thereof

The invention discloses a nylon zipper curling and tooth fusing machine and a curing and tooth fusing method. The nylon zipper curling and tooth fusing machine comprises a machine platform, a tape protecting device, a fusion welding device, an ultrasonic device, a tape dragging device, a detection device and a crocheting device. The fusion welding device is arranged on the machine platform; the ultrasonic device is arranged on the machine platform and is opposite to the fusion welding device; the tape dragging device is arranged on the machine platform and is used for pulling a zipper tape onto the fusion welding device; the ultrasonic device is used for combining a zipper cloth core and a cloth edge, and is used for fusing zipper tooth heads on the zipper tape on a cloth tape; the detection device is arranged on the machine platform and is used for detecting the vacancy of the zipper tape; and the crocheting device is arranged on the machine platform, and is used for hooking the zipper tape and straightening and locating the zipper tape. A product produced by the curling and tooth fusing machine disclosed by the invention is good in quality.

Owner:广州市锦弘拉链机械有限公司

Display panel and display device

ActiveCN113707021ASolve the problem that the settings are prone to badSolve the problem that is prone to badSolid-state devicesPhotovoltaic energy generationDisplay deviceEngineering

The invention provides a display panel and a display device, which belong to the technical field of curled display, and can at least partially solve the problem that a wiring connection area of an existing sliding and rolling display panel is prone to badness. The display panel comprises a display part and a wiring part, the wiring part is located in the peripheral area of the display part; the wiring part is provided with a first wiring bending area and a second wiring bending area; the wiring part located in the first wiring bending area can be bent to the first surface side of the display part around a first axis; the wiring part located in the second wiring bending area can be bent to the first surface side of the display part around a second axis; the first axis intersects with the second axis, and the first wiring bending area and the second wiring bending area are overlapped; the wiring part comprises at least one first slot, and the first slot is located in an overlapping area of the first wiring bending area and the second wiring bending area; the first slot penetrates through the wiring part in the thickness direction of the wiring part, and the extension direction of the first slot is parallel to the second axis.

Owner:BOE TECH GRP CO LTD

Method and assembly for manufacturing a green tyre

Method and assembly for manufacturing a green tyre using a building drum (1) and a transfer device (3). The method comprises a step of arranging and forming a first tyre component assembly for the green tyre on a building drum (1), a step of placing the transfer device (3) around the building drum, a removal step of the first tyre component assembly for the green tyre being removed from the building drum (1) by the transfer device (3). After the removal step second tyre components for the same green tyre are arranged on the building drum (1), followed by a step of placing the transfer device (3) around the building drum (1), and a step of placing the first tyre component assembly on the second tyre components.

Owner:VMI HOLLAND BV

Flexible display device

ActiveCN113362713AImplement curlAchieve flatteningPhotovoltaic energy generationIdentification meansEngineeringFlexible display

The invention provides a flexible display device. The flexible display device comprises a flexible display panel and a curling assembly, wherein the flexible display panel is provided with a display surface and a back surface which are opposite, the curling assembly comprises a wall part and a containing cavity defined by the wall part, at least part of the surface of the side, back to the containing cavity, of the wall part is a binding face, the back face of the flexible display panel is bound to the binding face, the curling assembly has a stretching state and a reset state, the curling assembly drives the flexible display panel to be curled in the reset state, and the curling assembly is converted into the stretching state from the reset state according to the increase of the internal pressure of the containing cavity so as to drive the flexible display panel to be unfolded. According to the flexible display device provided by the invention, the curling assembly is arranged to have the stretching state and the resetting state, so that the target that the flexible display panel is repeatedly switched between the flattening state and the curling state can be achieved; and the flexible display device is simple in overall structure and has high operation reliability.

Owner:HEFEI VISIONOX TECH CO LTD

Air-flow vortex balling machine for producing spherical graphite

The invention discloses an air-flow vortex balling machine for producing spherical graphite, which consists of a machine body, a balling drive device and an internal classification machine drive device, wherein an internal classification machine, a powder balling module and a cooling system are arranged in the machine body. In the invention, an internal balling module and a classification module are rationally arranged, and thus, the air-flow vortex balling machine for producing the spherical graphite is provided. The air-flow vortex balling machine can ensure that the graphite powder undergoes the physical processes of thinning, shearing, collision, friction, coiling, uniting and densification in an air-flow vortex balling room or can realize the combination of a physical balling processand a mechanical powder thinning process to prepare the spherical product. The indexes, such as sphericity, grain fineness distribution, tap density, apparent density, actual density and special surface area, of the spherical graphite powder can be controlled in the range of pre-determined values; the quality is stable; the yield can be improved by over three times; and over 50 percent of energy consumption can be reduced.

Owner:LUOYANG GUANQI INDAL & TRADE

A production line of a conveying module and its fire-fighting air duct

ActiveCN112008432BRealize automatic stitchingIncrease productivityOther manufacturing equipments/toolsMetal working apparatusProduction lineStructural engineering

The invention discloses a conveying module and a production line for fire-fighting air ducts. The production line for fire-fighting air ducts includes: a platform module for splicing and sewing fire-fighting air ducts; The air cylinder; the detection module, used to detect the flatness of the stitched first hemming part; the grooving module, used to cut out bending grooves at both ends of the fire-fighting air cylinder respectively, to obtain the unhemmed second hemming part; Conveyor module, used to clamp and sew the fire-fighting blower through the clamping mechanism, and transport the fire-fighting blower; sleeve flange module, used to take out the flange from the storage side plate, and then set them on both ends of the fire-fighting blower The flange module is used to crimp the uncrimped second crimping part to the engaging part, so that the second crimping part fastens and fixes the flange between the flange boss and the second crimping part between. The invention can realize the automatic sewing, detection, fitting flange and fixing flange of the fire-fighting air duct.

Owner:CHONGQING VOCATIONAL INST OF ENG

A grooving module and its fire-fighting air duct production line

ActiveCN112008431BRealize automatic stitchingIncrease productivityOther manufacturing equipments/toolsProduction lineStructural engineering

Owner:CHONGQING VOCATIONAL INST OF ENG

A kind of sleeve flange module and its fire-fighting air duct production line

ActiveCN112008375BRealize automatic stitchingIncrease productivityMetal sawing devicesMetal working apparatusProduction lineIndustrial engineering

The invention discloses a flange module and its production line for fire-fighting air ducts. The production line for fire-fighting air ducts includes: a platform module for splicing and sewing fire-fighting air ducts; The fire-fighting air cylinder; the detection module is used to detect the flatness of the stitched first hemming part; the grooving module is used to cut out bending grooves at both ends of the fire-fighting air cylinder respectively to obtain the second hemming without hemming part; delivery module, used to clamp and sew the fire blower through the clamping mechanism, and transport the fire blower; sleeve flange module, used to take out the flange from the storage side plate, and then set them on the fire blower respectively Both ends; equipped with flange modules, used to crimp the uncrimped second crimping part to the engaging part, so that the second crimping part can fasten and fix the flange on the flange boss and the second crimping between sections. The invention can realize the automatic sewing, detection, fitting flange and fixing flange of the fire-fighting air duct.

Owner:CHONGQING VOCATIONAL INST OF ENG

Detection module and fire-fighting air duct production line thereof

InactiveCN112108535ARealize automatic stitchingIncrease productivityElectric/magnetic roughness/irregularity measurementsMetal working apparatusProduction lineStructural engineering

The invention discloses a detection module and a fire-fighting air duct production line thereof. The fire-fighting air duct production line comprises a platform module, a detection module, a groovingmodule, a conveying module, a flange sleeving module and a flange mounting module, wherein the platform module is used for splicing and sewing a fire-fighting air duct; the spliced fire-fighting air duct is a fire-fighting air duct on which hemming is finished; the detection module is used for detecting the flatness of a sewn first crimping part; the grooving module is used for cutting bending grooves in the two ends of the fire-fighting air duct respectively to obtain a second crimping part which is not crimped; the conveying module is used for clamping the sewn fire-fighting air duct througha clamping mechanism and conveying the fire-fighting air duct; the flange sleeving module is used for taking out flanges from a storage side plate and then respectively sleeving the two ends of the fire-fighting air duct with the flanges; and the flange mounting module is used for crimping the second crimping part which is not crimped towards a clamping part, so that the second crimping part clamps and fixes the flanges between flange bosses and the second crimping part. According to the fire-fighting air duct production line, automatic sewing, detection, flange sleeving and flange fixing ofthe fire-fighting air duct can be realized.

Owner:CHONGQING VOCATIONAL INST OF ENG

A three-roller symmetrical plate rolling machine

The invention relates to the field of cold working equipment and particularly relates to a three-roller symmetric type plate rolling machine. The three-roller symmetric type plate rolling machine comprises a screw, a first support, a side plate, a nut, a sliding groove, vertical plates, roller shafts, a limiting structure, a handle, a limiting block, a pulley, a ferrule, a dowel, an anti-slip sleeve, a crank, first press rollers, second press rollers, a locking nut, a bearing, a locating block, a second support, a feeding plate and a stop block. The sliding groove is arranged in the side plate, the sliding groove is in rotating connection with the first support and the second support through the nut, the two vertical plates are arranged at the top end of the side plate and symmetrically distributed, the three roller shafts are in rotating connection with the vertical plates through the bearing, one ends of the roller shafts are connected with the vertical plates, the ferrule is in rotating connection with the pulley through the dowel, and rolled materials can be guided by the pulley. The roller shafts are driven to rotate by rocking the crank with the hand, so that the coiling of the plate materials is facilitated. By arranging the first press rollers and the second press rollers on the roller shafts in a sleeving manner, the coiling of different plate materials is facilitated.

Owner:江苏中泰绿色建筑科技有限公司

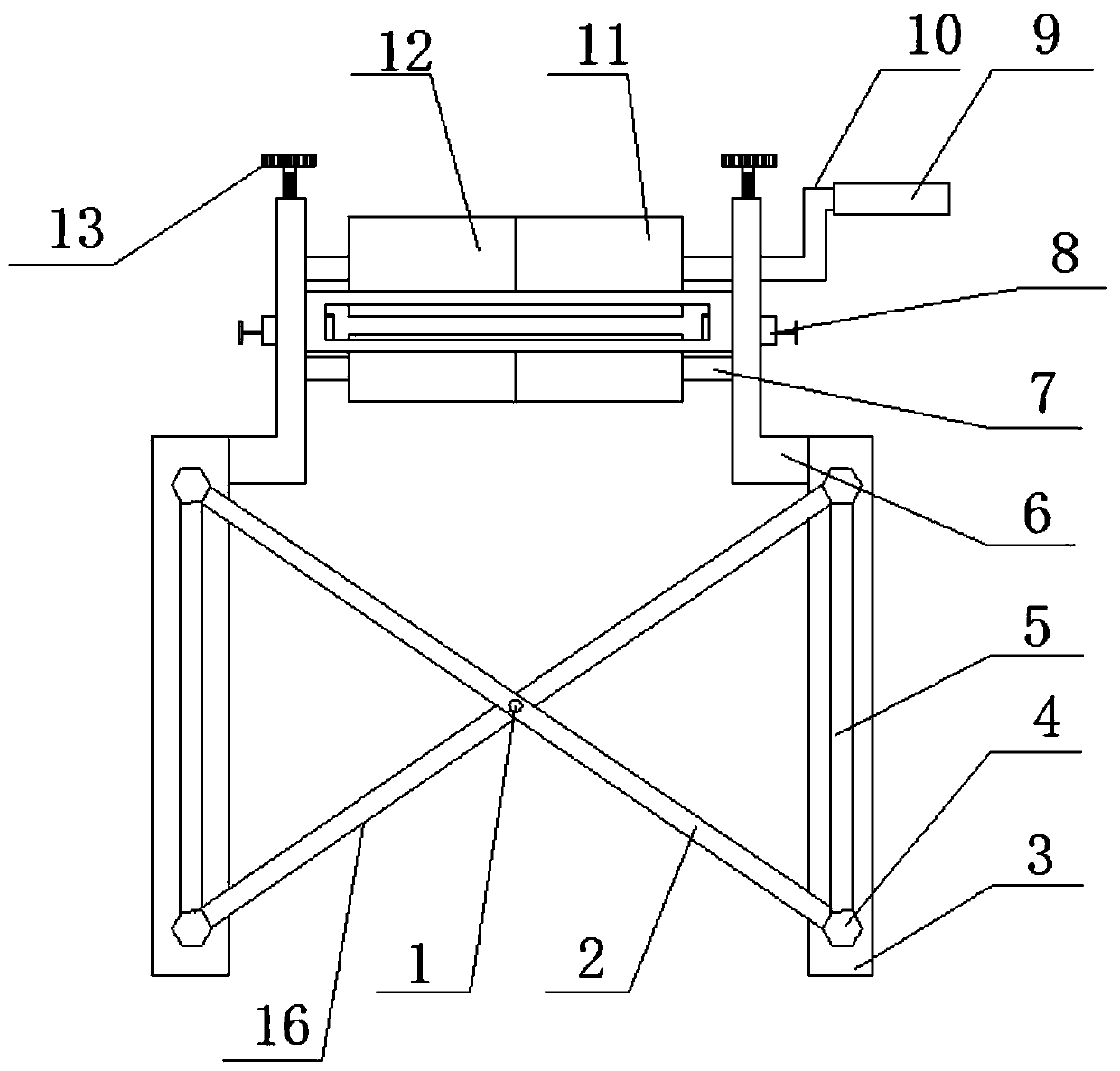

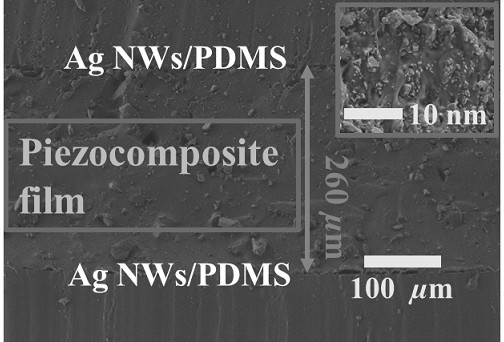

Robot electronic skin simulation touch device based on piezoelectric nano-generator

ActiveCN112461412AFit closelyAchieve full bendingBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesSignal processing circuitsRobot hand

The invention provides a robot electronic skin simulation touch device based on a piezoelectric nano-generator, and the device comprises a piezoelectric power generation module which is installed on amechanical arm of a robot, and is connected with an information feedback system through a wireless module. The piezoelectric power generation module comprises a flexible piezoelectric nano-generator,a signal processing circuit, a micro-control unit and a storage battery; the piezoelectric nano-generator is connected with the signal processing circuit and the storage battery, the signal processing circuit is connected with the micro-control unit, and the micro-control unit is connected with the wireless module; the information feedback system comprises an information processing unit, and thewireless module is connected with the information processing unit. The piezoelectric nano-generator can realize full bending and curling, is simple to manufacture, convenient to use and low in cost, and better fits the surface of a human body or a machine; different responses can be generated for different mechanical forces to serve as the touch sense of the robot, and the sensitivity and the reflection degree of the touch sense of the robot are greatly improved.

Owner:HENAN UNIVERSITY

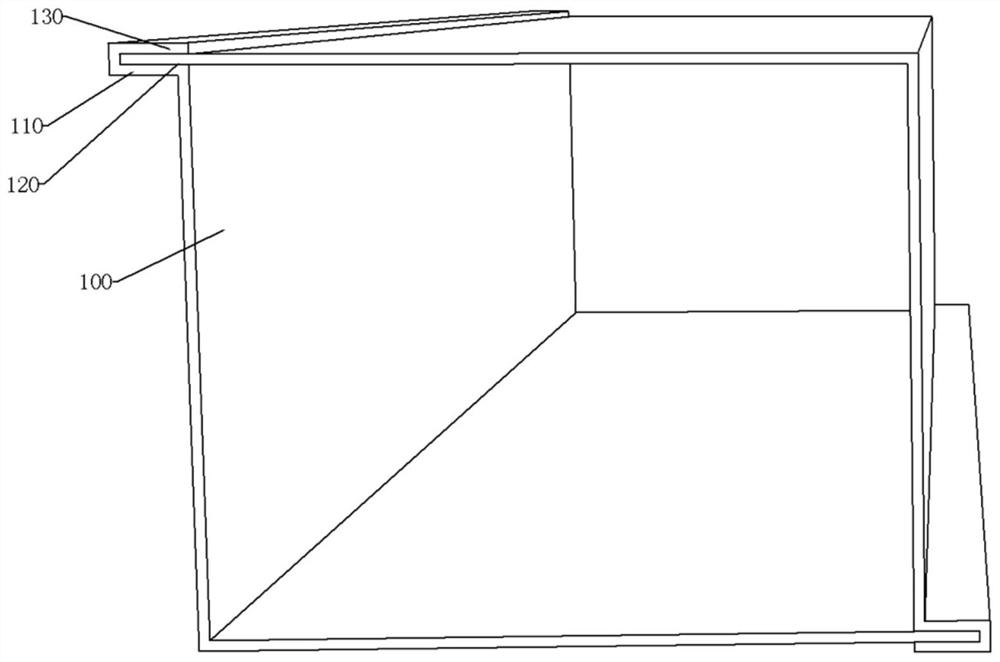

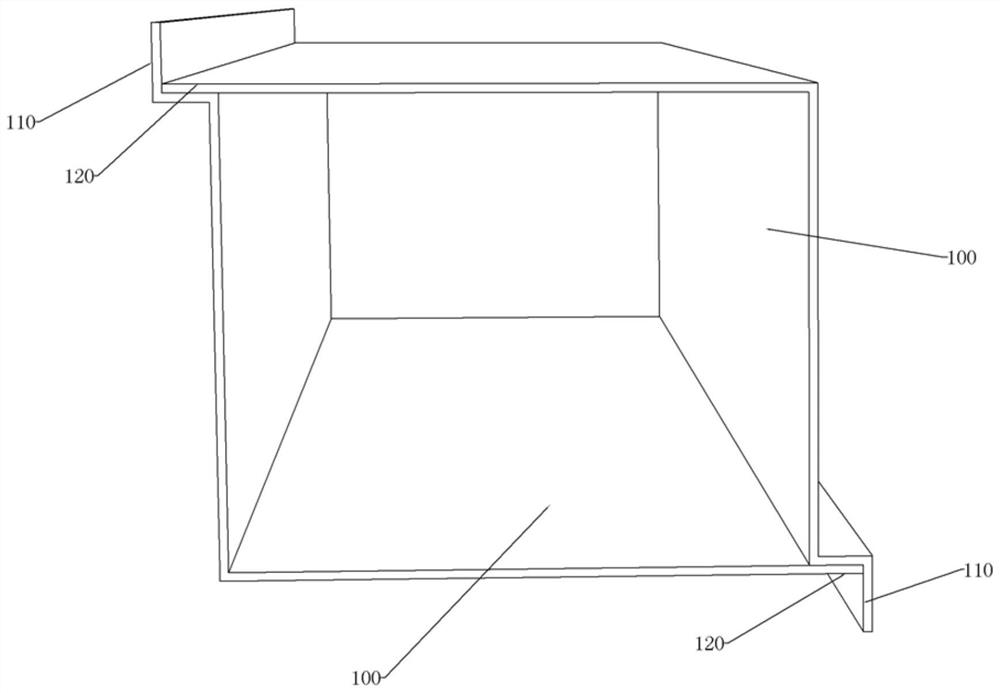

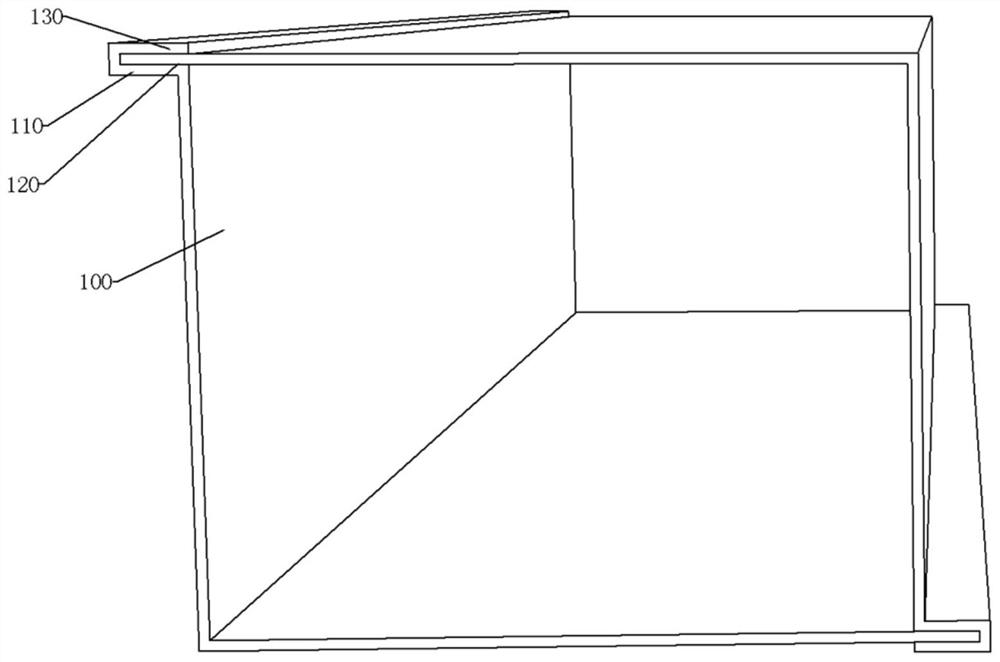

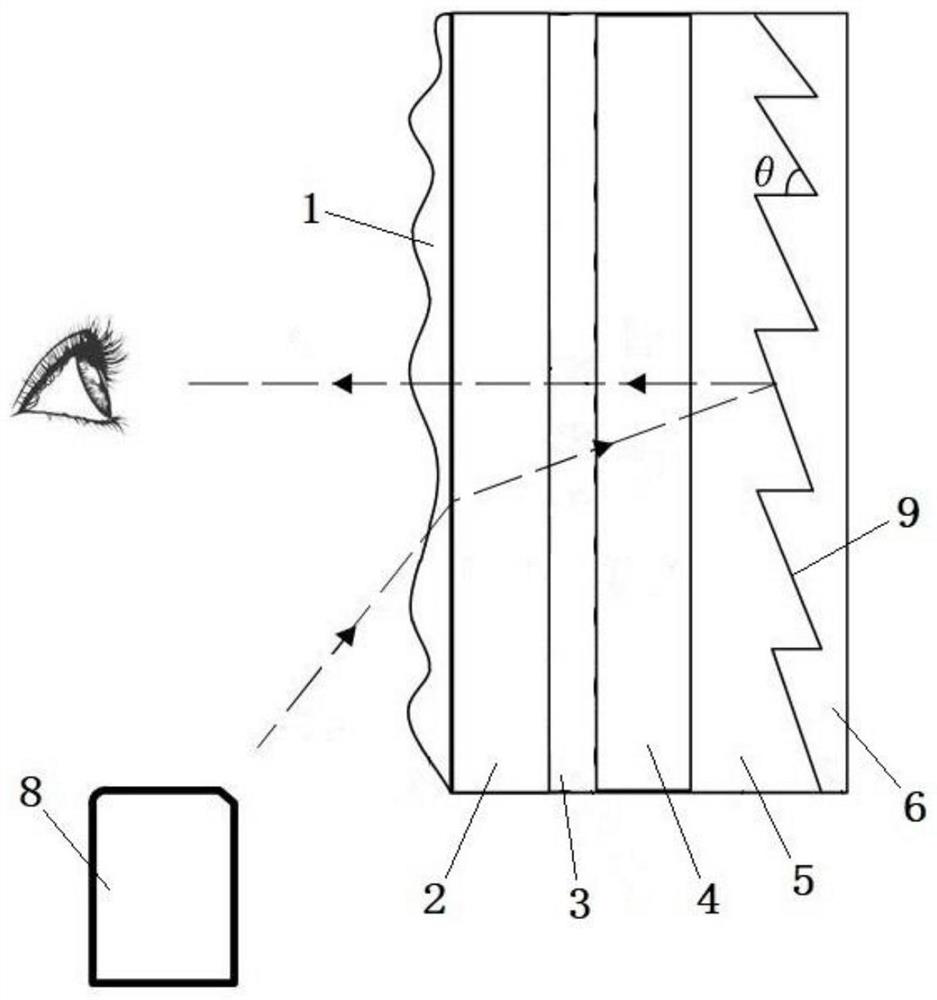

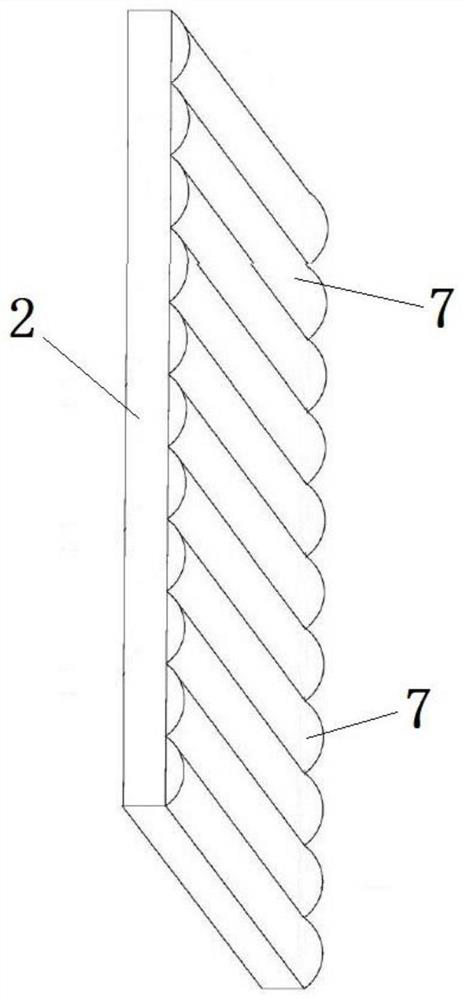

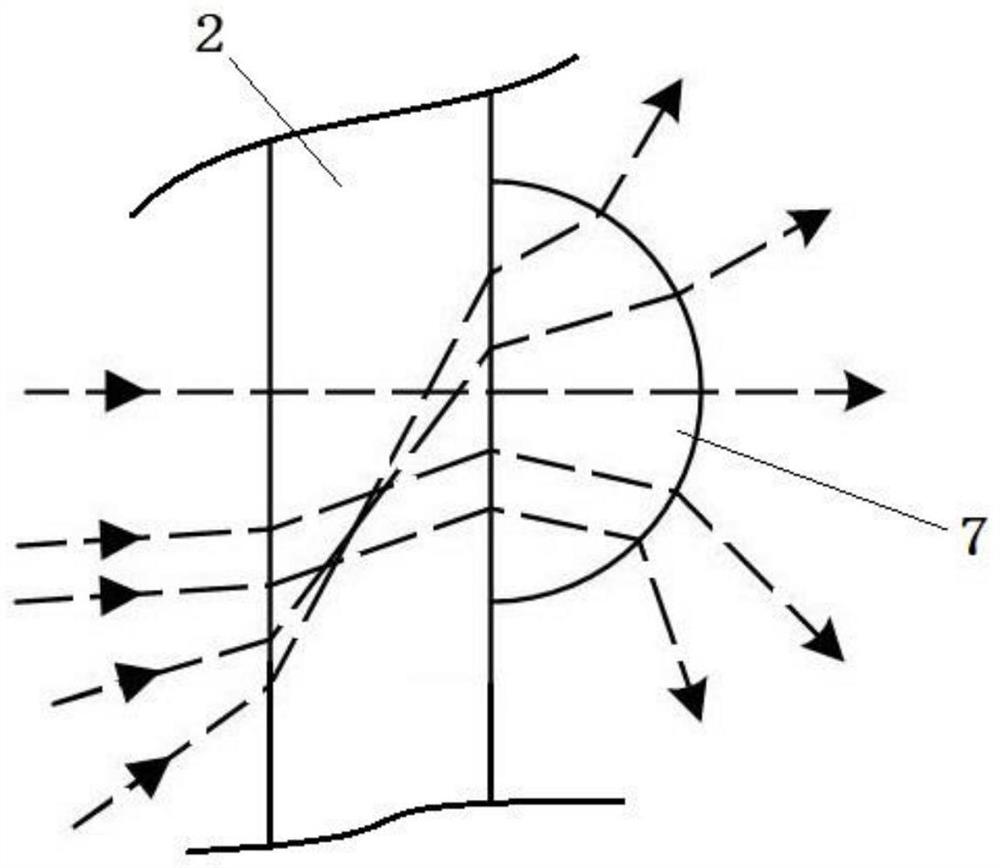

Ceiling reflection resistant projection screen and projection system

The invention discloses a ceiling reflection resistant projection screen and a projection system, relates to the technical field of projection screens, and is used for solving the problem of poor definition of a projection screen in the prior art. The projection system comprises a projector and an anti-ceiling reflection projection screen, wherein the anti-ceiling reflection projection screen comprises a surface layer, a diffusion layer, a Fresnel lens layer and a reflection layer which are sequentially stacked and arranged; the haze value of the surface, away from the diffusion layer, of the surface layer is greater than or equal to 20%; the diffusion layer comprises a light diffusion layer and two supporting layers, the light diffusion layer is arranged between the two supporting layers, the light diffusion layer is provided with a light transmitting face used for diffusing light, the light transmitting face is provided with a gradually-shrinking part and / or a gradually-expanding part in the direction away from the surface layer, and a cavity used for containing air is defined by the gradually-shrinking part and / or the gradually-expanding part and the supporting layers.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

Plastic hose for irrigation and its manufacturing process

An irrigation plastic water hose comprises a hose wall made of plastic, and the hose wall is in lap joint end to end circumferentially to form a hose cavity. A plurality of through holes are formed in the hose wall, a plastic nut is matched with and arranged at each through hole correspondingly, the axial lengths of the plastic nuts are between 0.7cm and 2.0cm, and screw holes are formed in the center of plastic nut bodies. The plastic nuts are integrally injection molded to form circular protruding edges protruding and extending to the periphery, the circular protruding edges are disposed in a hose cavity of the plastic water hose, plastic nut bodies penetrate the through holes in the plastic water hose wall outwards, and the circular protruding edges are fused or bonded with the inner surfaces of the hose walls of the through hole edge areas. The invention further provides a production process of the irrigation plastic water hose. The irrigation plastic water hose can be recovered and wound conveniently, water guide tubes cannot be pushed outward by the water pressure easily to cause separation and water leakage even during large irrigation water pressure, and farmers can mount and dismount the water diversion tubes conveniently.

Owner:汕头市光华机械实业有限公司

A kind of making method of source and flow new type of painting and obtained source and flow new type of painting

ActiveCN110802980BTo achieve a high degree of simulation effectIncreased durabilitySpecial artistic techniquesComputer graphics (images)Algorithm

The invention provides a method for making a new type of original mural painting and the obtained new type of mural painting. The method includes: analyzing and organizing data according to the experimental investigation data of cultural relics to obtain a high-definition mural with a size ratio of 1:1. Scanned images and photos, as well as the materials and structure used in the original layer of ancient murals, and the pigments used in the original murals; divide the high-definition scanned image into several parts, determine the size of each part, and make a line drawing copy of the image, and follow the instructions The size of each part is made separately for the bottom frame; after the bottom frame is made, the bottom liner is laid on one side, and then the pure linen is stretched on the frame; according to the materials and structure used in the original floor of the ancient mural, Make the ground layer and surface layer on the stretched linen; select pigments according to the pigments used in the original murals and make a pigment blending solution; apply traditional painting expression techniques to copy the image information of ancient murals; combine the produced mural reproductions Installation and gap filling.

Owner:宋志旭

a curling iron

ActiveCN104665196BSave the trouble of wrapping around the heat pipeImplement curlCurling devicesEngineeringMechanical engineering

Owner:WENZHOU SHI LABO ELECTRICS CO LTD

Manufacturing method of petroleum oil pipe

The invention relates to the field of cold machining equipment, in particular to a manufacturing method of a petroleum oil pipe. A plate rolling machine adopted by the invention comprises a screw, a first support, a side plate, a nut, a sliding groove, vertical plates, roller shafts, a limiting structure, a handle, a limiting block, a pulley, a clamping sleeve, a pin, an anti-skid sleeve, a crank,a first compression roller, a second compression roller, a tight locking nut, bearings, a positioning block, a second support, a feeding plate and a stop dog; according to the method, through the arrangement of the sliding groove in the side plate, the sliding groove is rotationally connected with the first support and the second support through the nut, the vertical plates are arranged at the top end of the side plate, and the vertical plates are arranged two, and the two vertical plates are symmetrically distributed; the roller shafts are rotationally connected with the vertical plates through the bearings, and three roller shafts are arranged; and one ends of the roller shafts are connected with the vertical plates, the clamping sleeve is rotationally connected with the pulley throughthe pin, and the pulley can guide and correct a coiled material. Through the manual rotation of the crank to drive the roller shafts to rotate, a plate which can be conveniently rolled is facilitated,a first pressing roller and a second pressing roller sleeve the roller shafts, and curling of different plates can be facilitated.

Owner:DONGYING RUIAO IND & TRADE CO LTD

A flange-mounted module and its production line for fire-fighting air ducts

ActiveCN112008374BRealize automatic stitchingIncrease productivityMetal sawing devicesMetal working apparatusProduction lineIndustrial engineering

The invention discloses a flange mounting module and a production line for fire-fighting air ducts. The production line for fire-fighting air ducts includes: a platform module for splicing and sewing fire-fighting air ducts; The fire-fighting air cylinder; the detection module is used to detect the flatness of the stitched first hemming part; the grooving module is used to cut out bending grooves at both ends of the fire-fighting air cylinder respectively to obtain the second hemming without hemming part; delivery module, used to clamp and sew the fire blower through the clamping mechanism, and transport the fire blower; sleeve flange module, used to take out the flange from the storage side plate, and then set them on the fire blower respectively Both ends; equipped with flange modules, used to crimp the uncrimped second crimping part to the engaging part, so that the second crimping part can fasten and fix the flange on the flange boss and the second crimping between sections. The invention can realize the automatic sewing, detection, fitting flange and fixing flange of the fire-fighting air duct.

Owner:CHONGQING VOCATIONAL INST OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com