Plastic hose for irrigation and its manufacturing process

A plastic and hose technology, applied in gardening, applications, watering devices, etc., can solve the problems of water seepage of water guide pipes, falling off of water guide pipes, expansion and spread of separated parts, etc., and achieve good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A manufacturing process of plastic hose for irrigation, comprising the following steps:

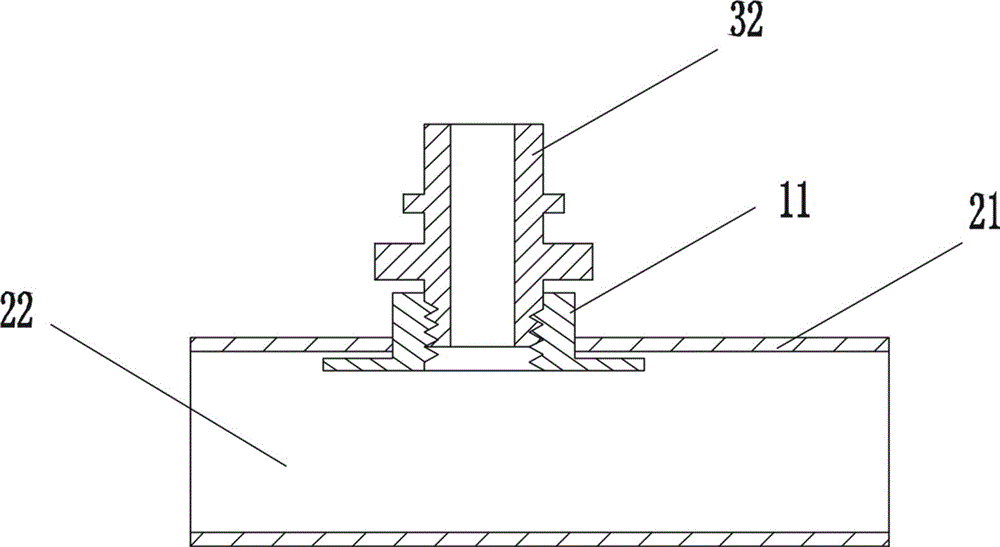

[0039] (1), prepare the circular plastic nut 1 that the axial length is 1.0 centimeters, make the plastic nut form the annular convex edge 12 that extends to all around, and annular convex edge 12 is close to one of the end faces of plastic nut body 11 (specifically in image 3 The center is the lower end surface), the plastic nut body 11 and the annular convex edge 12 are integrally formed by injection molding, and the center of the plastic nut body 11 is formed with a screw hole 13, such as image 3 , Figure 4 Shown; Prepare the blank 210 of plastic hose pipe wall, as figure 2 As shown, the blank 210 of the plastic hose pipe wall adopts PE woven fabric layer, and the blank 210 of the plastic hose pipe wall is cut into a long strip shape, and the width of the long strip shape (that is, the width in the short direction, figure 2 (shown in b) is equal to the perimeter of the pl...

Embodiment 2

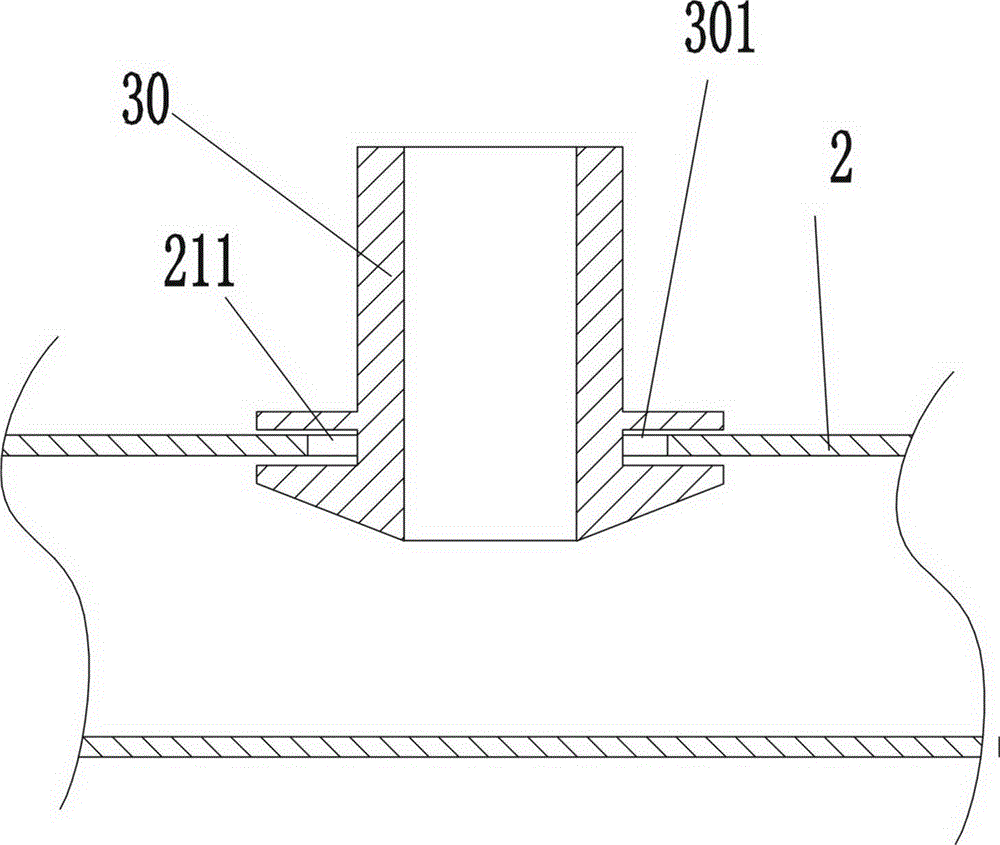

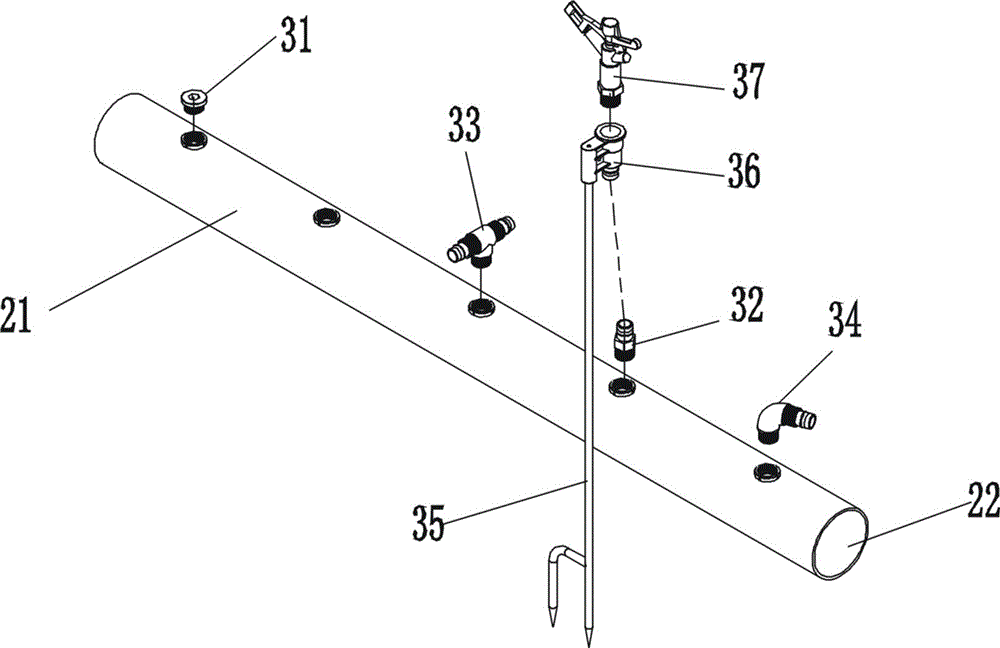

[0044] Image 6 , Figure 7 , Figure 8 , Figure 9 As shown, the plastic hose 2 for irrigation is made by the method of Embodiment 1, and includes a pipe wall 21 made of PE plastic material braided. The pipe wall 21 is overlapped end to end in the circumferential direction to form a lumen 22; There are multiple vias 211 (see via figure 2 shown), each through hole 211 is correspondingly equipped with a circular plastic nut 1, as image 3 , Figure 4 Shown, the axial length of the plastic nut 1 ( image 3 (shown in h) is 1.0 cm, and the plastic nut is integrally formed with an annular convex edge 12 protruding and extending around, and the annular convex edge 12 is close to one of the end surfaces of the plastic nut body 11 (specifically in image 3 The center is the lower end surface), the annular convex edge 12 is located in the tube cavity 22 of the plastic hose, the annular convex edge 22 is ultrasonically welded to the inner surface of the tube wall, and the plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com