Method and assembly for manufacturing a green tyre

A technology of components and raw tires, applied in tires, applications, household appliances, etc., can solve problems such as tire structures that cannot be manufactured, and achieve the effects of rapid market trends, shortened adjustment time, and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

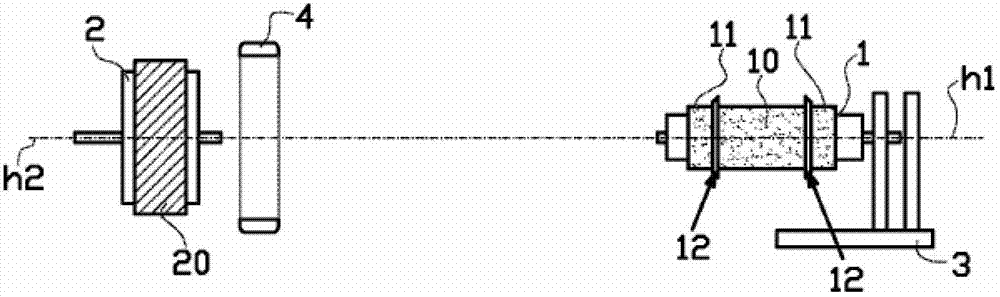

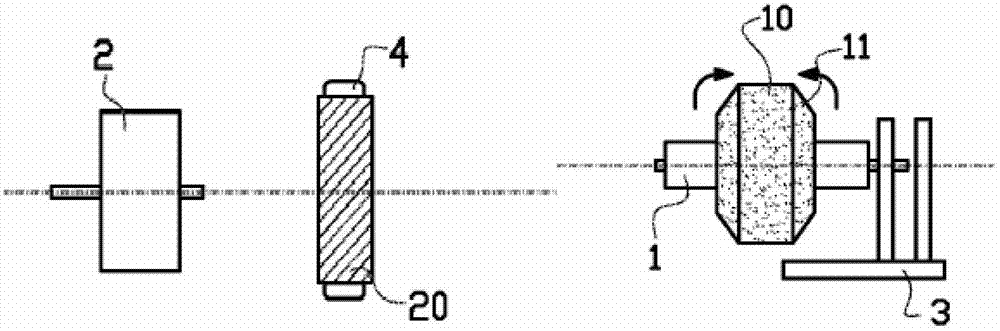

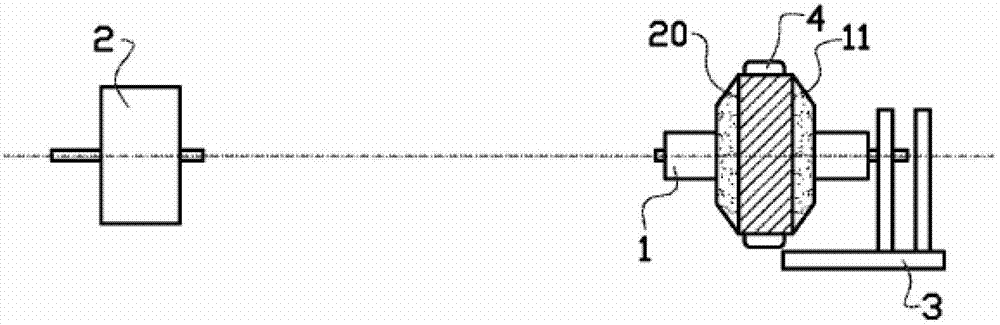

[0032] Figure 1A Schematically shows a side view of a plant for manufacturing green tires. The plant has a first building drum 1 , a second building drum 2 and a transfer device 3 and a transfer ring 4 .

[0033]In the example shown, the first building drum 1 is a combined carcass and building drum (building and building drum). Said substantially cylindrical building drum 1 having a substantially horizontal outer circumferential surface has a crimping device, known per se, for crimping edge portions of tire components arranged on the drum in the direction of the center of the drum 1 . Said other crimping devices are known, for example, from patent publication WO 01 / 68356, which uses radially extending articulated arms for this purpose, or WO 03 / 013835, which uses radially expandable articulated arms for this purpose. The inflatable rubber bladder is not further described here so as not to unnecessarily obscure the subject matter of the present invention.

[0034] In the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com