Nylon zipper curling and tooth fusing machine and nylon zipper curling and tooth fusing method thereof

A zipper and hemming technology, which is applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of product quality and quality impact, the cloth core is easy to detach from the cloth tape, and the cloth core is easy to fall off, etc., so that the zipper tape is firm, Time-saving and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] This embodiment provides a nylon zipper crimping tooth melting machine.

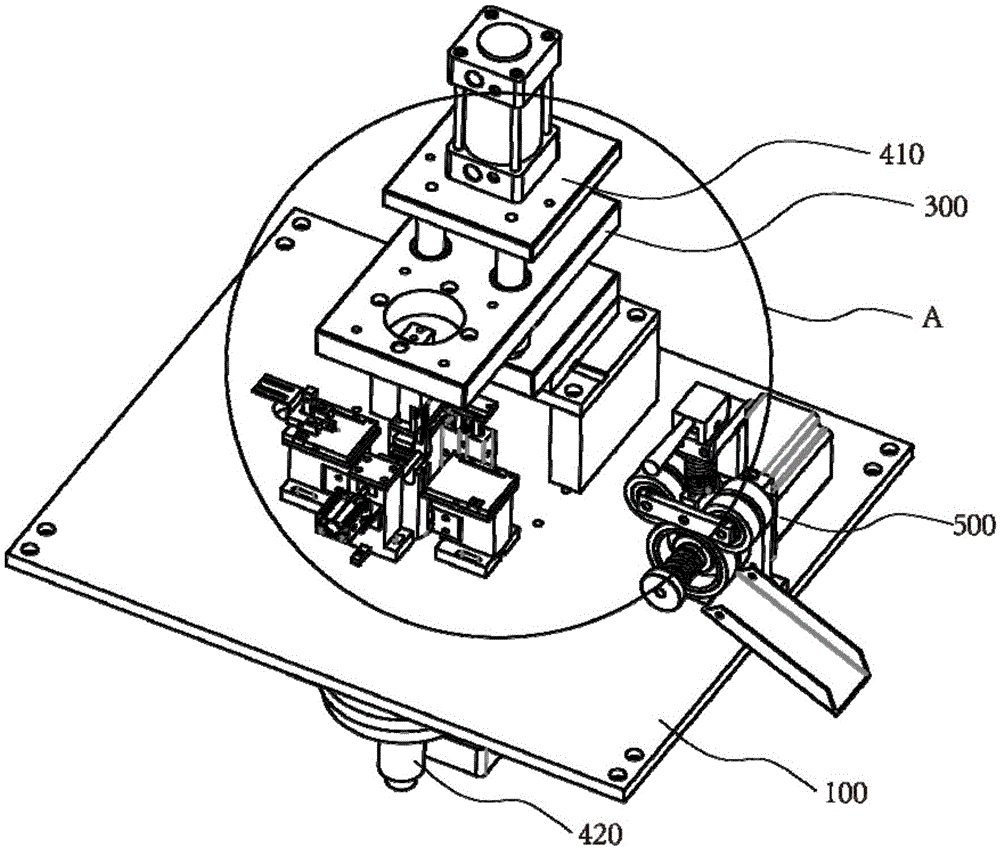

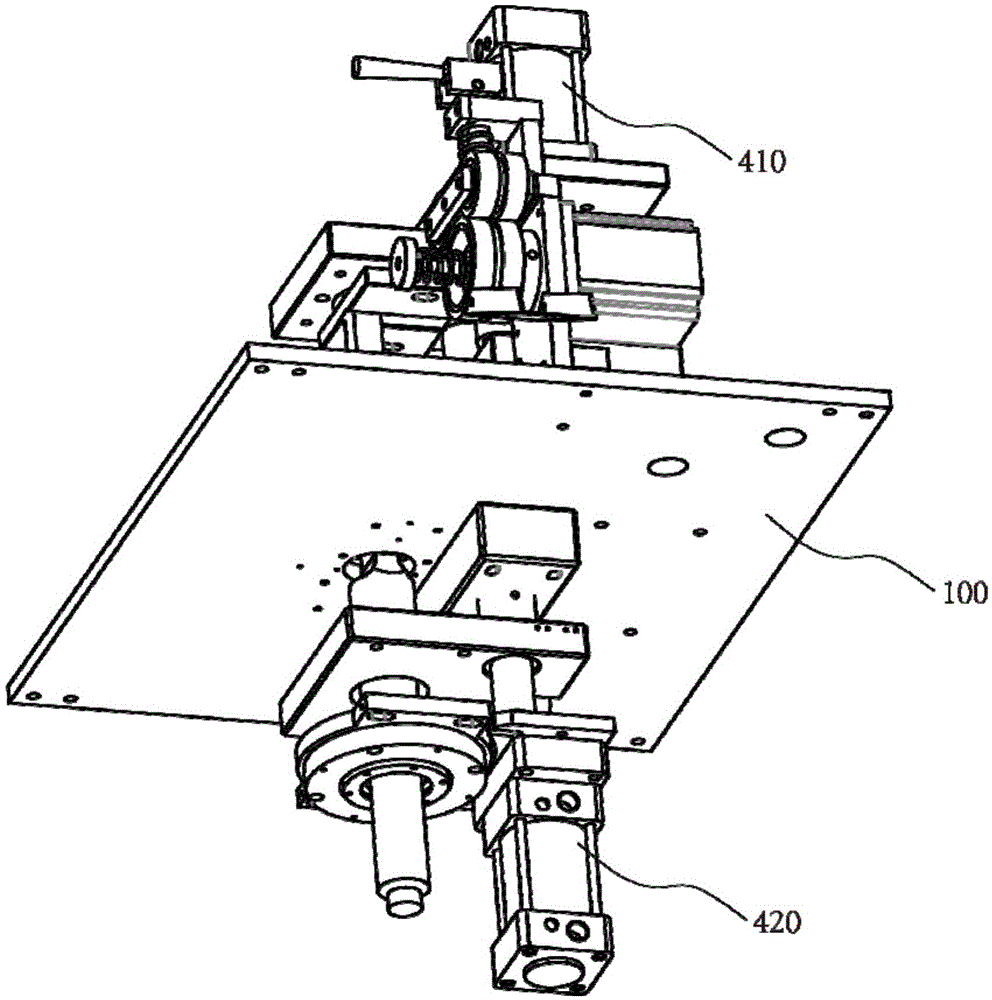

[0026] see figure 1 and figure 2 As shown, a crimping tooth melting machine includes a machine table 100, a welding device 300, an ultrasonic device, a dragging device 500, a detection device 600 and a hook device.

[0027] The welding device 300 is disposed on the machine platform 100 , and the ultrasonic device is disposed on the machine platform 100 and is opposite to the welding device 300 .

[0028] see figure 1 and figure 2 As shown, the towing device 500 is arranged on the machine platform 100 for pulling the zipper tape to the welding device 300 . The towing device 500 has a roller and a towing driving part, the roller is arranged on the machine platform 100, the towing driving part is arranged on the machine platform 100 and is connected to the roller for driving the roller Rotating, the rollers drag the zipper tape into the welding device 300 .

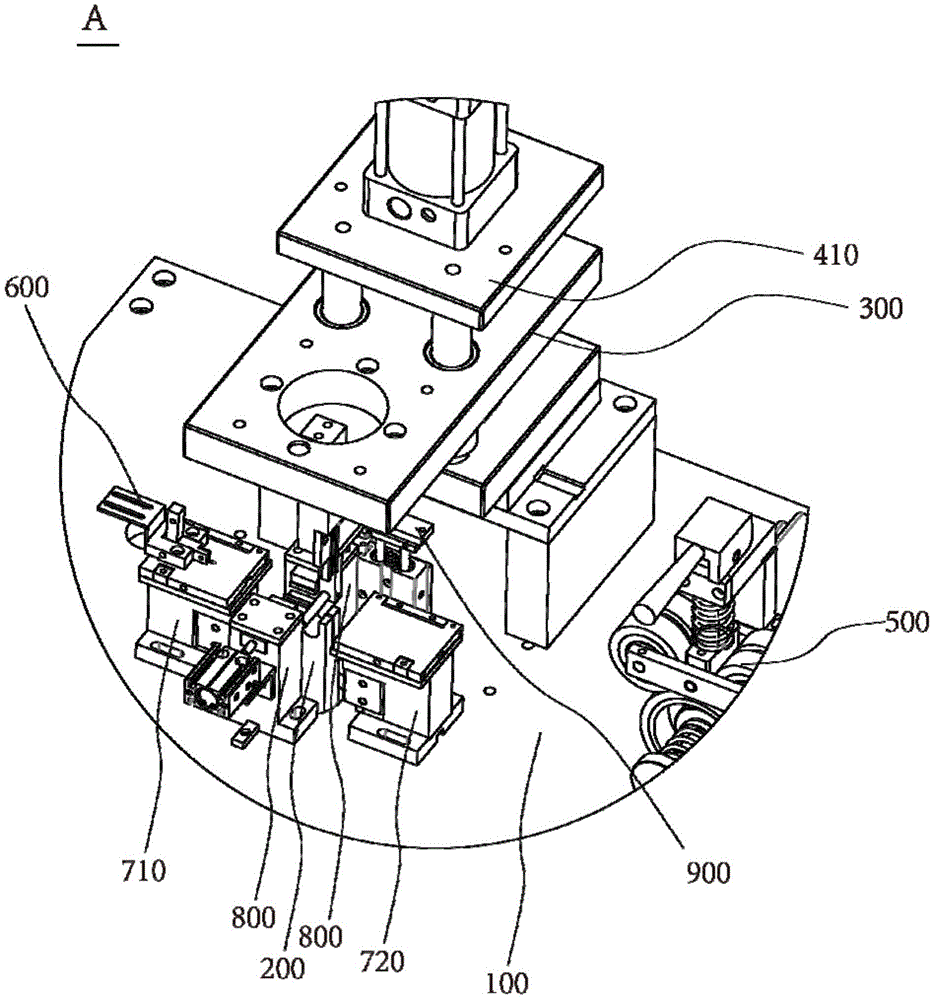

[0029] see image 3 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com