Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Image data is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

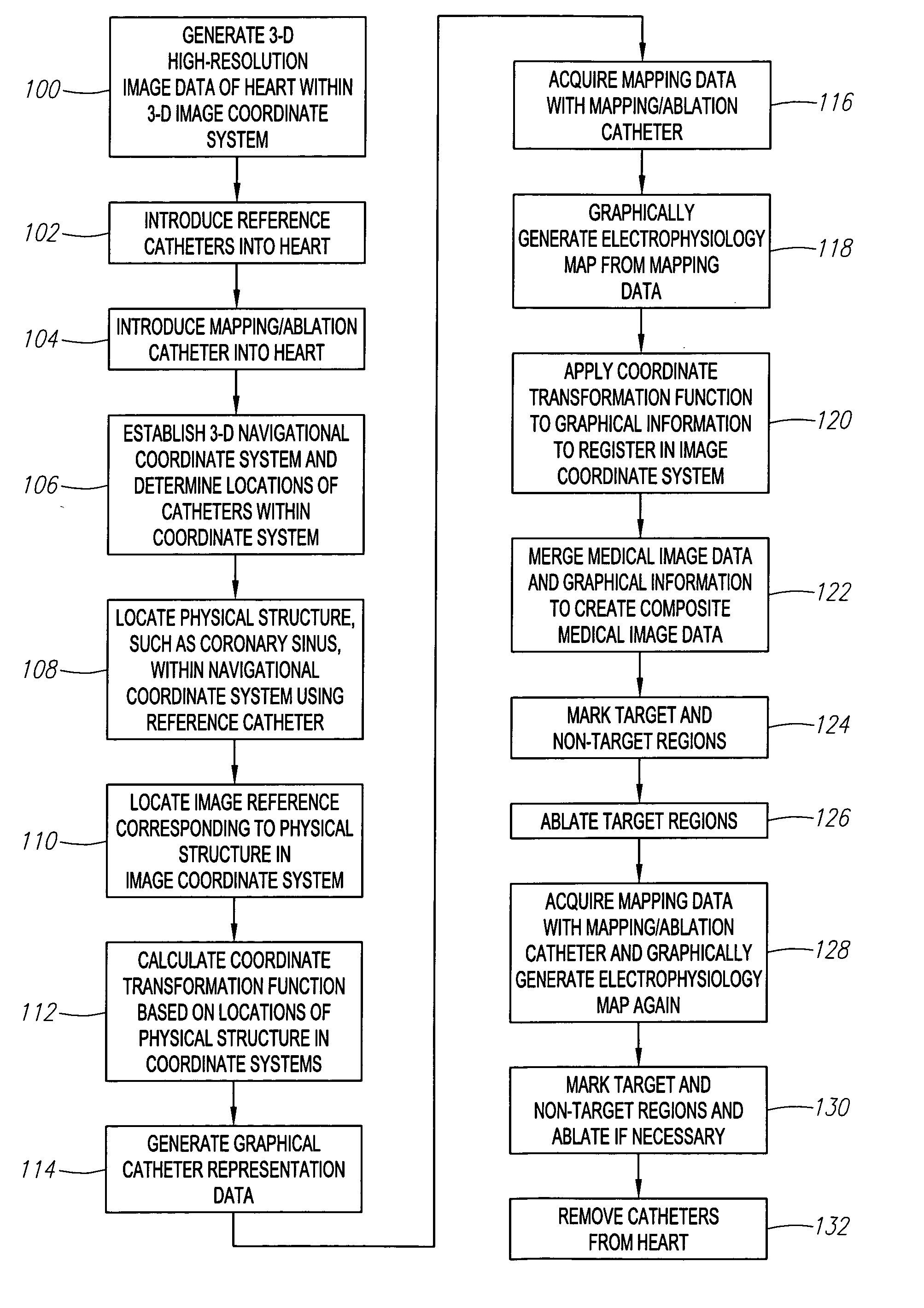

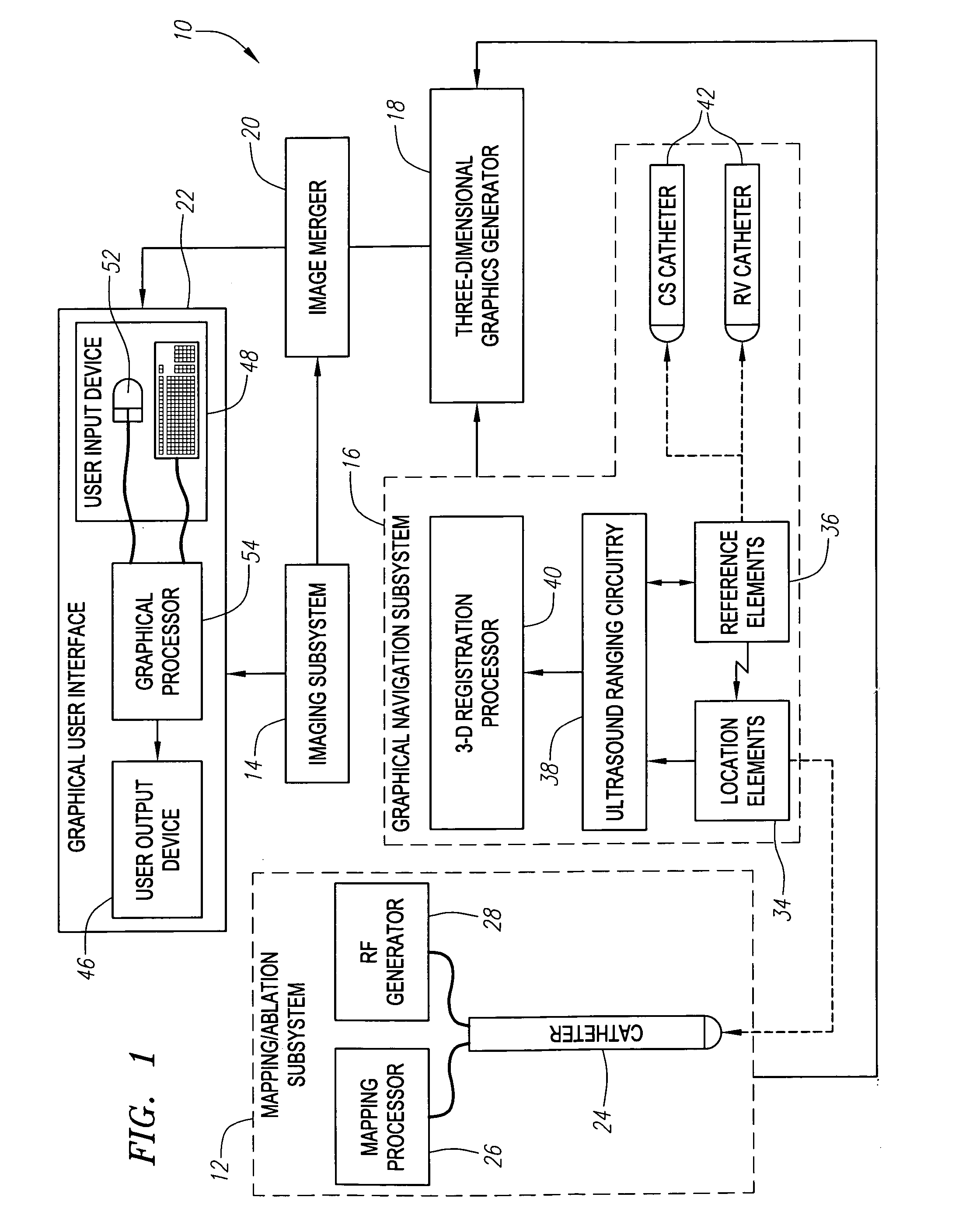

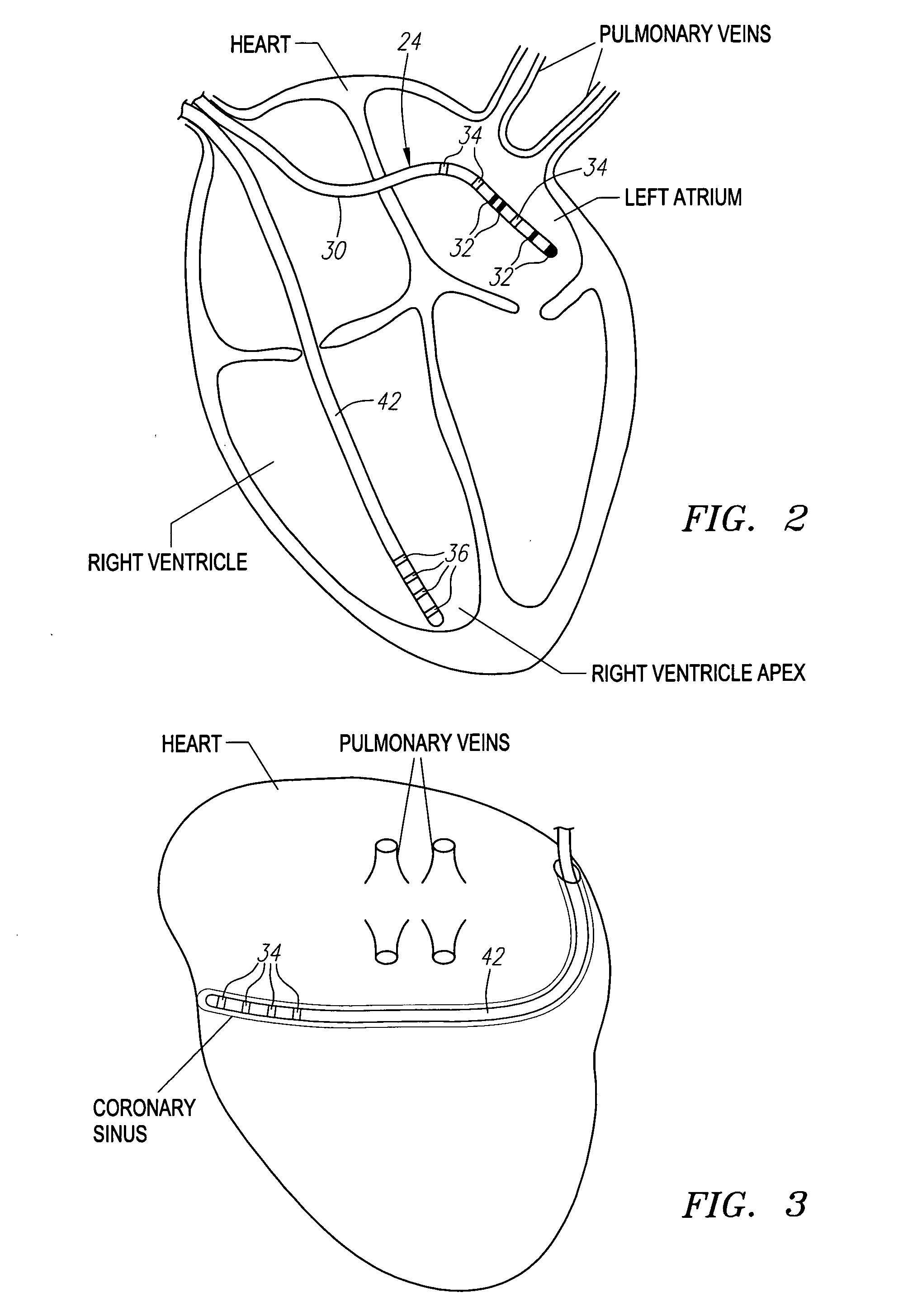

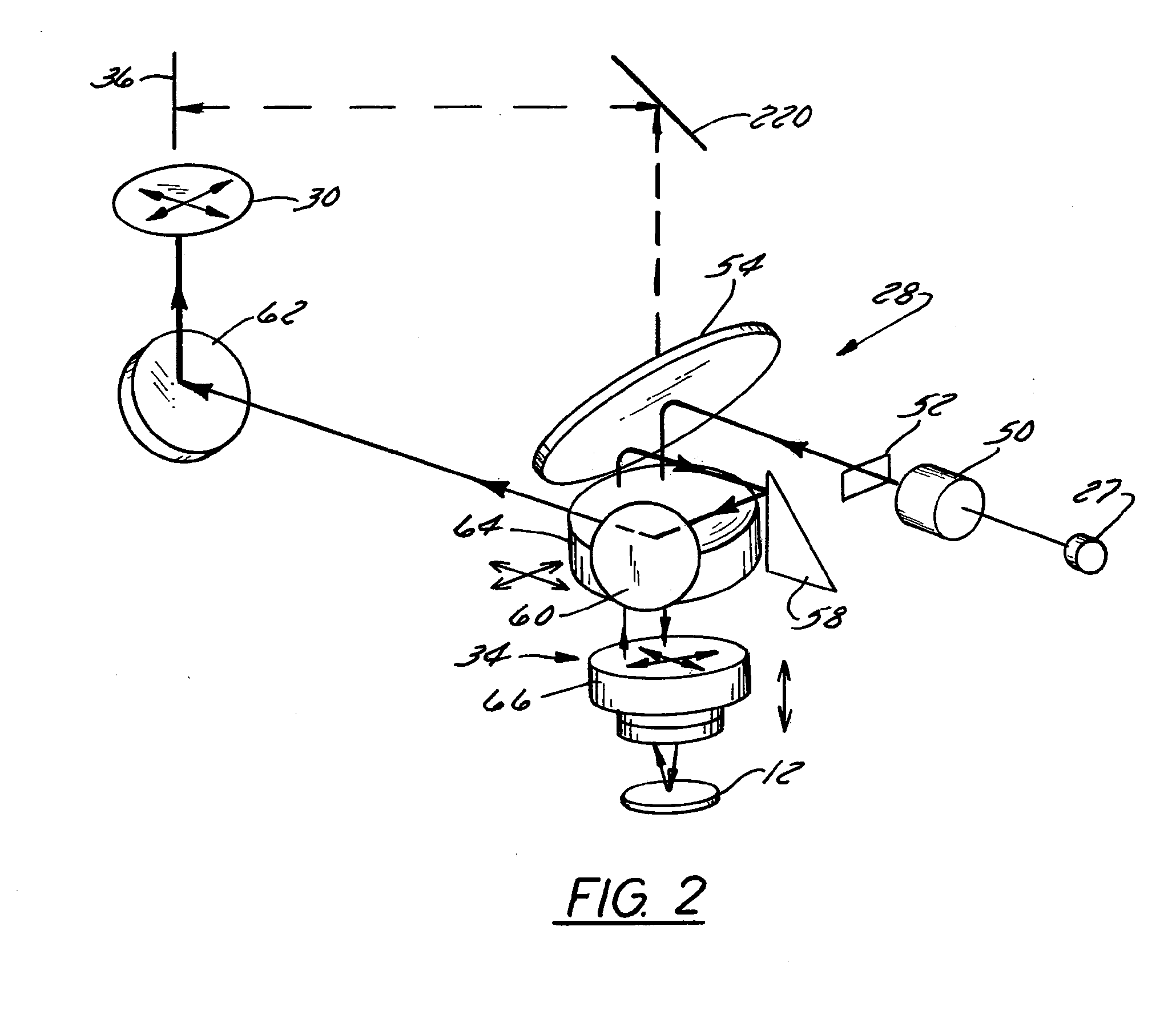

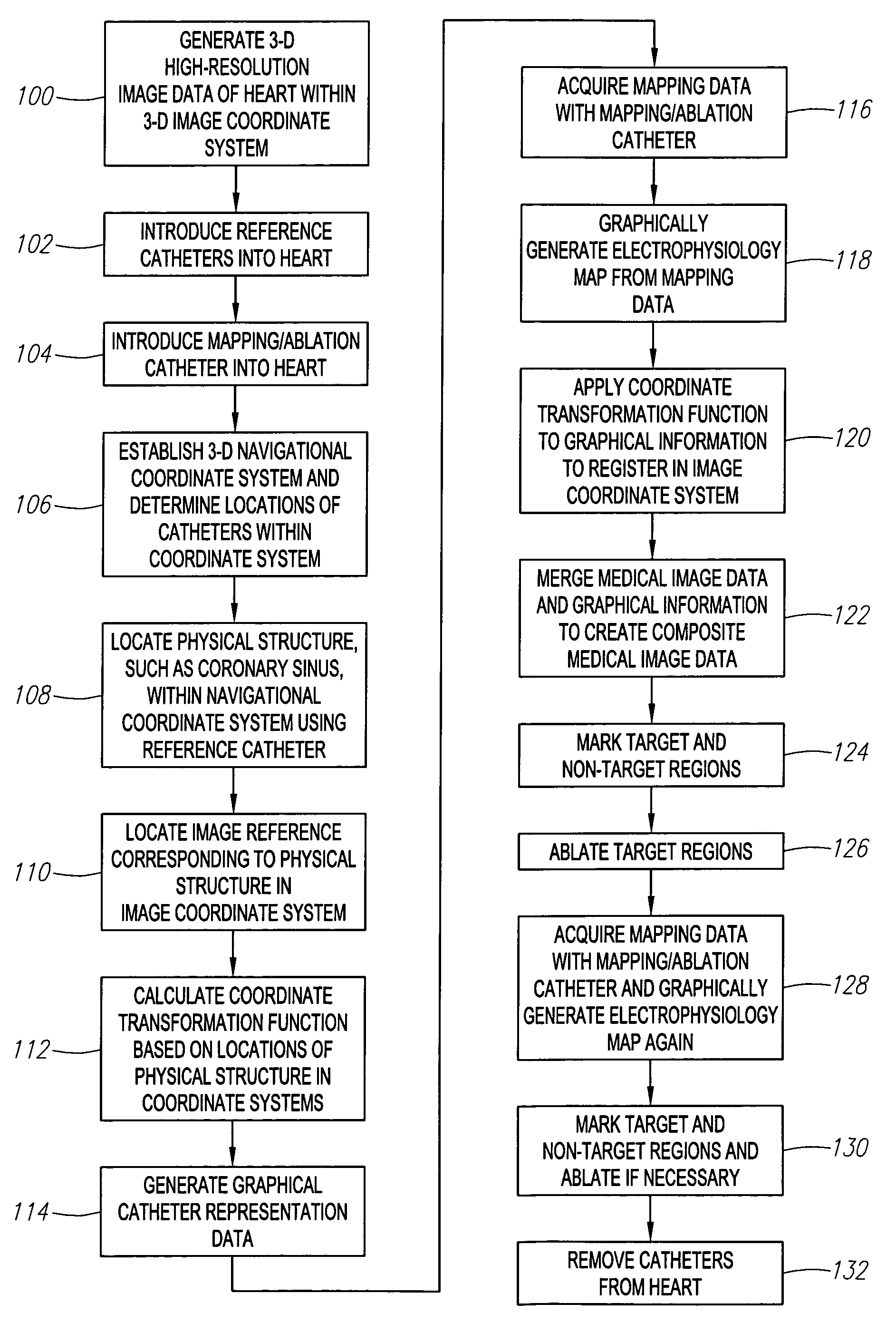

Method and system for registering an image with a navigation reference catheter

ActiveUS20060116575A1Timing errorImage data is accurateUltrasonic/sonic/infrasonic diagnosticsSurgeryGraphicsReference image

Methods and systems for processing and / or superimposing a medical image of an anatomical body (e.g., a heart) with graphical information are provided. Reference elements and / or reference catheter are placed in contact with the anatomical body. A physical structure within a navigational coordinate system is located using the reference elements and / or reference catheter. An image reference within an image coordinate corresponding to the physical structure is located. Location of the image reference can be accomplished, e.g., by displaying the medical image and electronically marking the displayed image reference, or by automatically locating image data corresponding to the image reference. The navigational and image coordinate systems are then registered based on the location of the physical structure within the navigational coordinate system and the location of the image reference within the image coordinate system, which allows graphical information to be accurately merged with the medical image data.

Owner:BOSTON SCI SCIMED INC

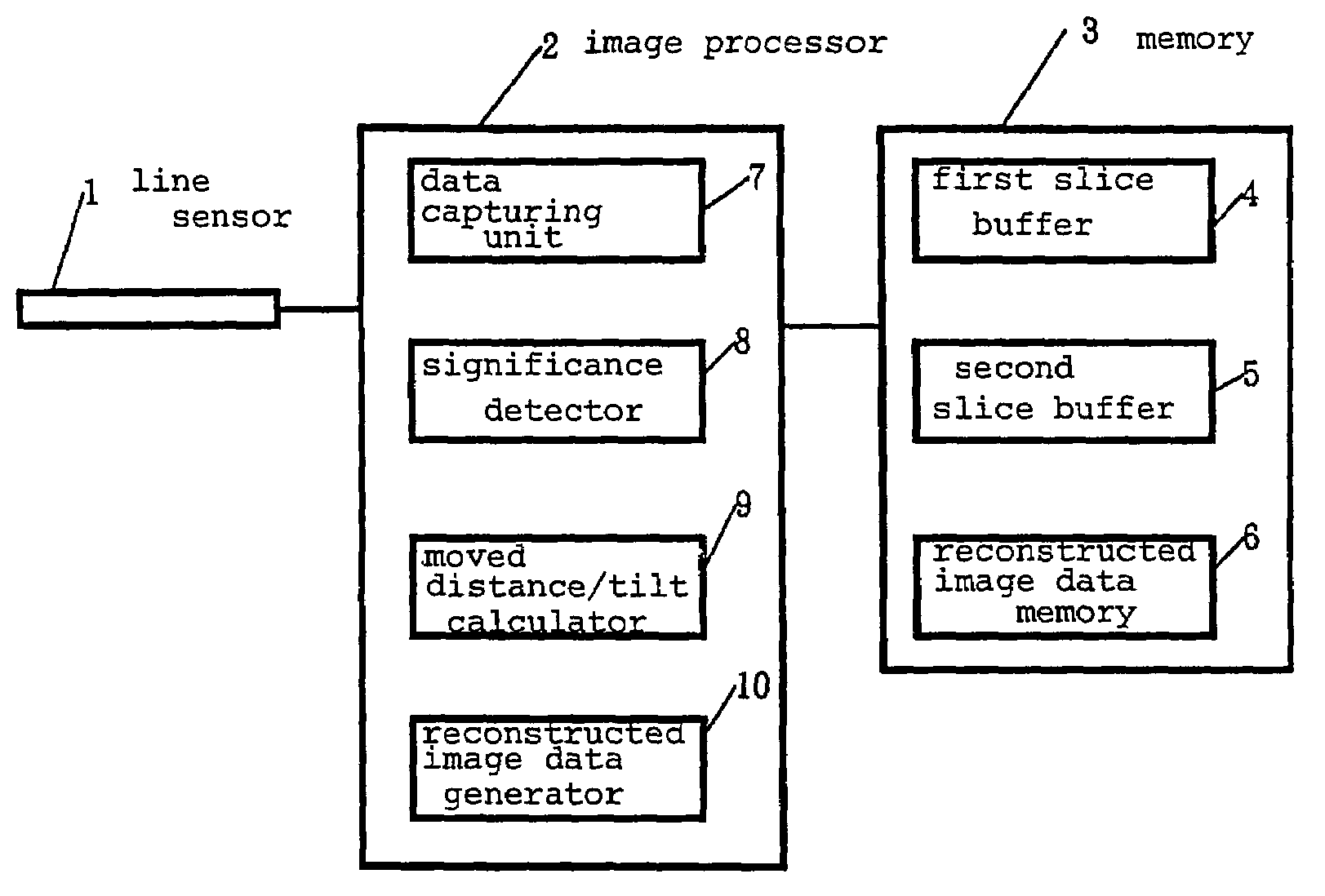

Generation of reconstructed image data based on moved distance and tilt of slice data

InactiveUS7263212B2Image data is accurateIncrease valueImage analysisGeometric image transformationImaging processingDistortion free

An image processing apparatus is capable of generating distortion-free accurate image data. The image processing apparatus has an image entering unit, an image processor, and a memory. Slice data read by the image entering unit is stored in the memory. The image processor determines whether the slice data stored in the memory is of significance or not. Then, the image processor calculates a moved distance and tilt of the slice data that has been detected as being of significance, and calculates positional coordinates of a reconstructed image area to which the slice data is to be projected, based on the moved distance and tilt of the slice data which have been calculated, and generates reconstructed image data. The generated reconstructed image data is stored in the memory.

Owner:NEC CORP

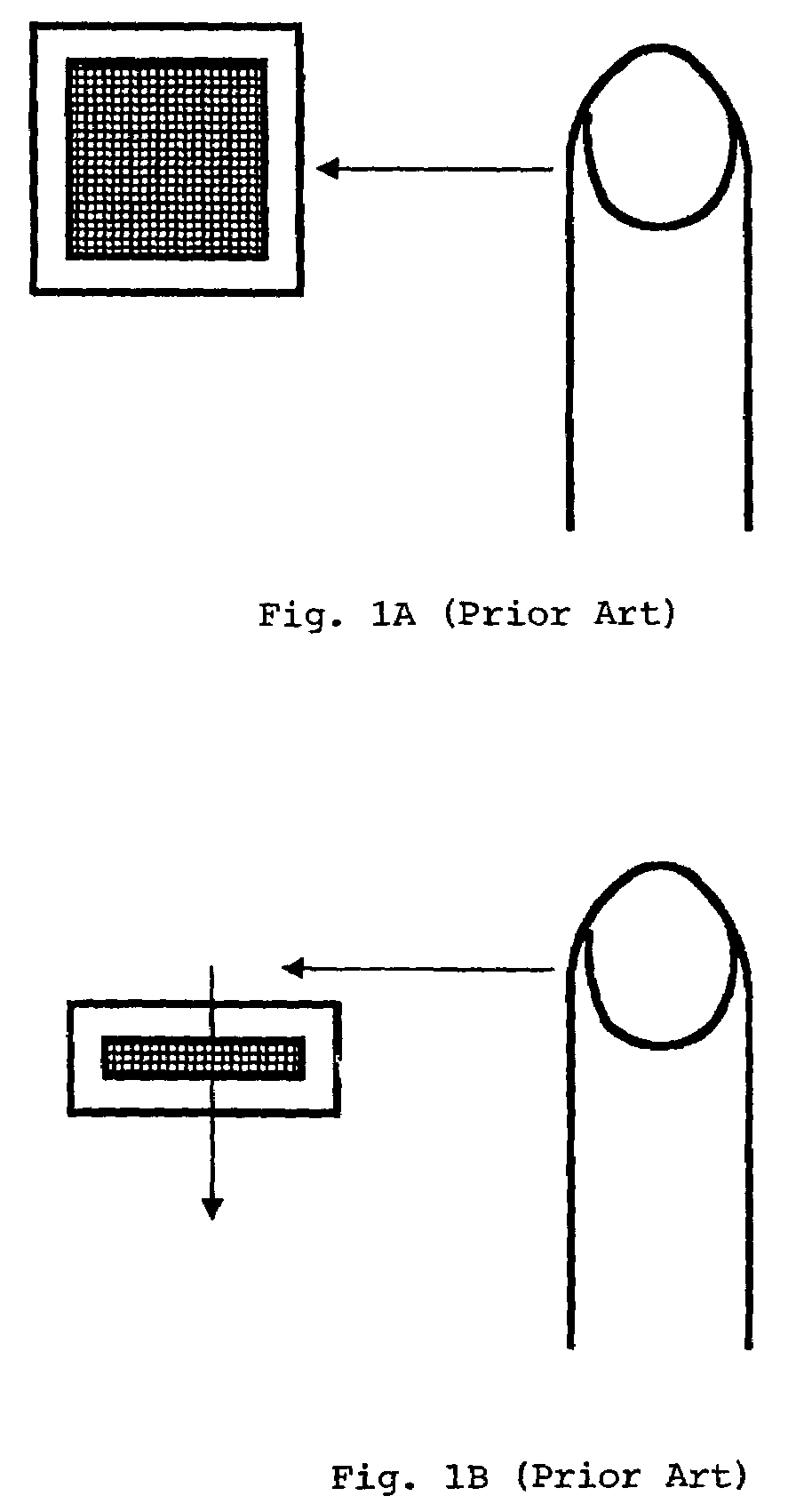

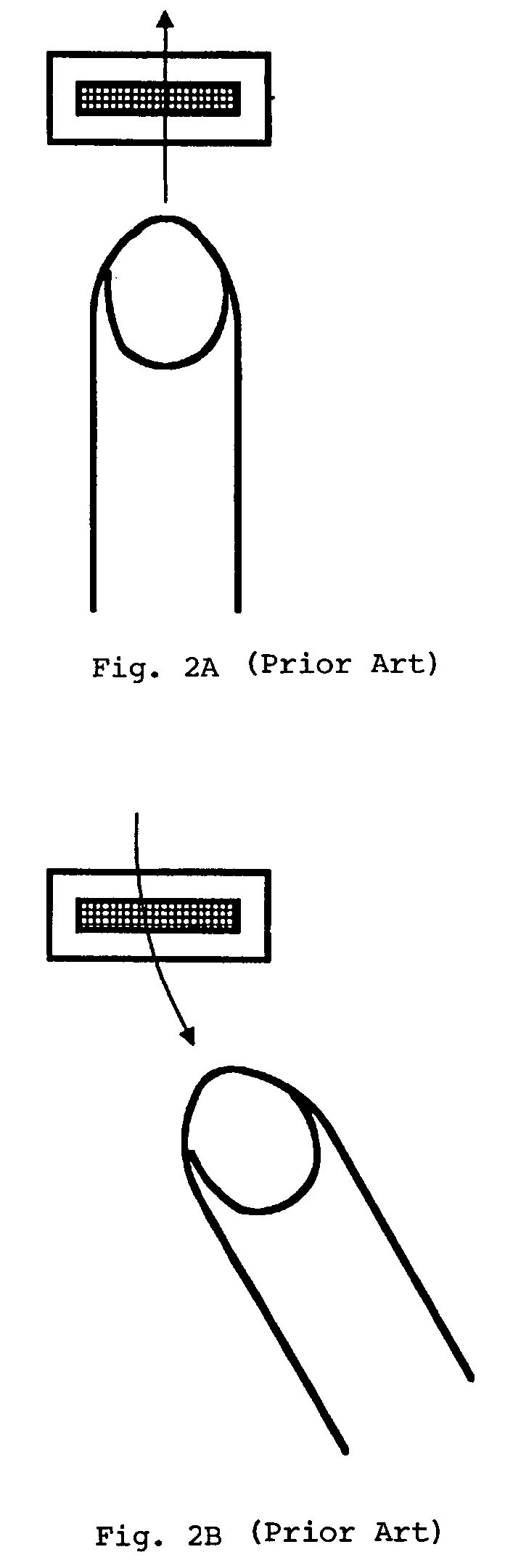

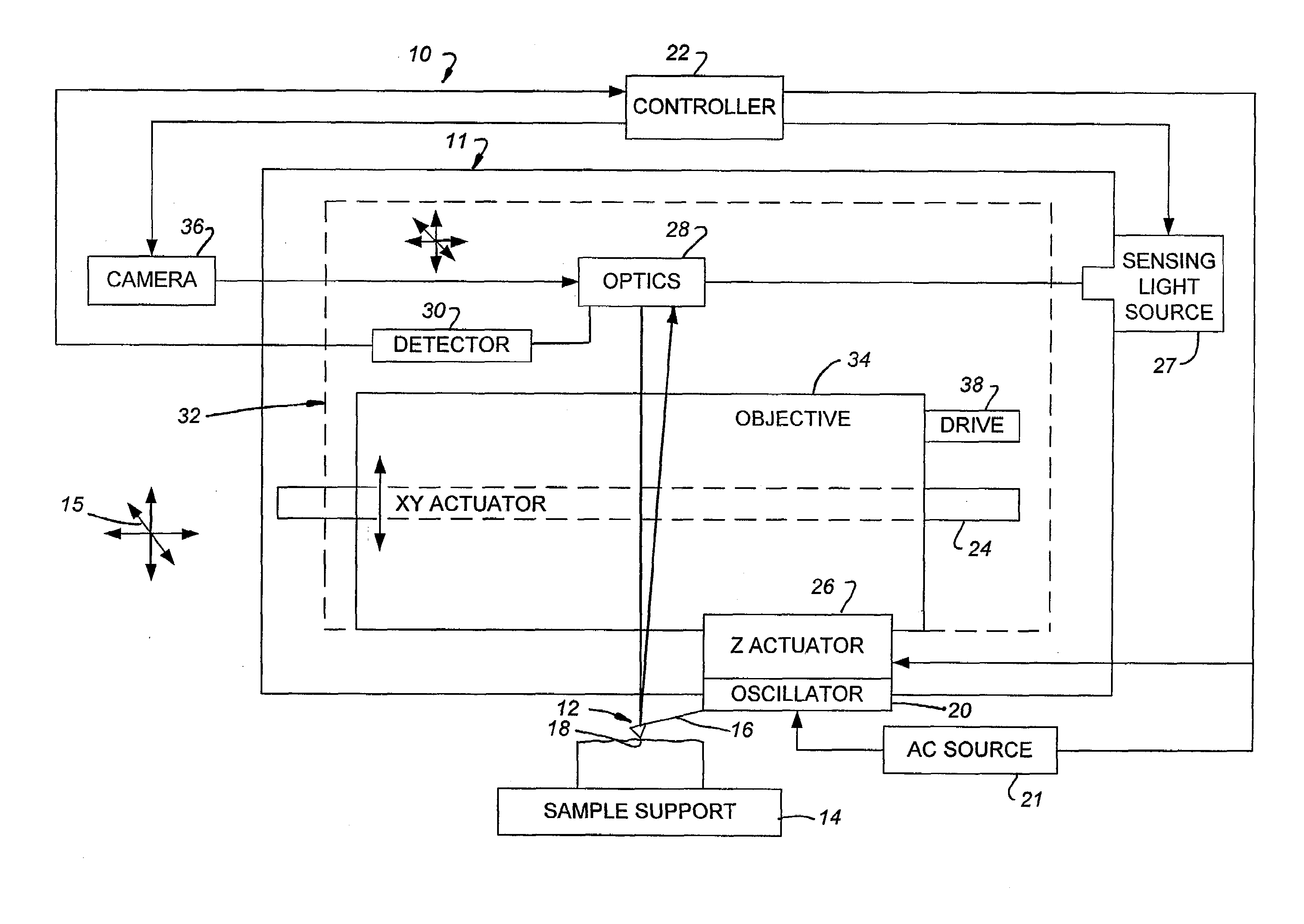

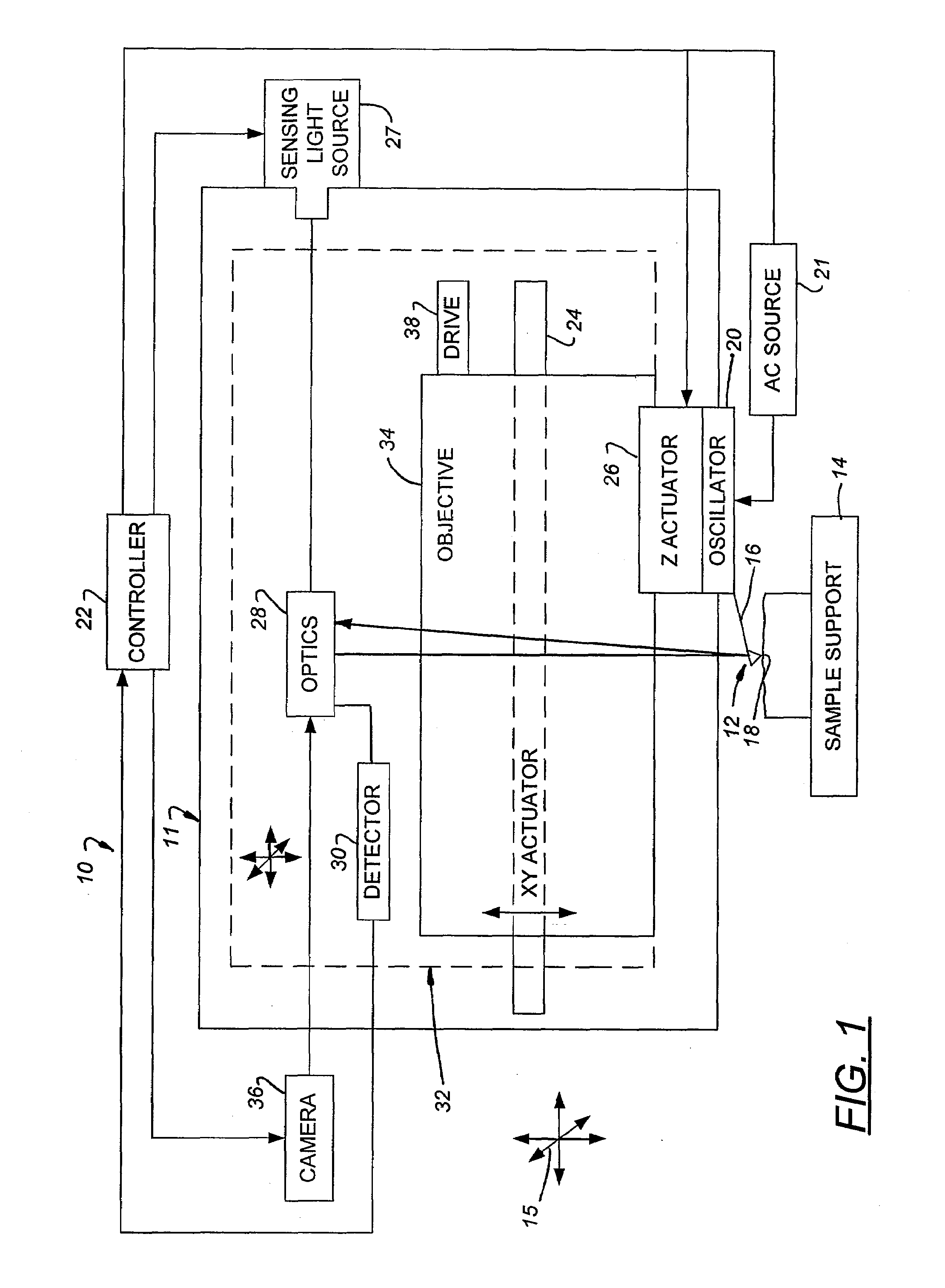

Fast-Scanning SPM Scanner and Method of Operating Same

ActiveUS20080223119A1Increased focus rangeImage data is accurateNanotechnologyMechanical roughness/irregularity measurementsHigh bandwidthImage resolution

A high-bandwidth SPM tip scanner is provided that additionally includes an objective that is vertically movable within the scan head to increase the depth of focus for the sensing light beam. Movable optics also are preferably provided to permit targeting of the sensing light beam on the SPM's probe and to permit the sensing light beam to track the probe during scanning. The targeting and tracking permit the impingement of a small sensing light beam spot on the probe under direct visual inspection of focused illumination beam of an optical microscope integrated into the SPM and, as a result, permits the use of a relatively small cantilever with a commensurately small resonant frequency. A high-bandwidth tip scanner constructed in this fashion has a fundamental resonant frequency greater than greater than 500 Hz and a sensing light beam spot minor diameter of less than 10 μm. Images can be scanned on large samples having a largest dimension exceeding 7 mm with a resolution of less than 1 Angstrom and while scanning at rates exceeding 30 Hz.

Owner:BRUKER NANO INC

Method and system for registering an image with a navigation reference catheter

ActiveUS7720520B2Image data is accurateTiming errorUltrasonic/sonic/infrasonic diagnosticsSurgeryGraphicsMarine navigation

Methods and systems for processing and / or superimposing a medical image of an anatomical body (e.g., a heart) with graphical information are provided. Reference elements and / or reference catheter are placed in contact with the anatomical body. A physical structure within a navigational coordinate system is located using the reference elements and / or reference catheter. An image reference within an image coordinate corresponding to the physical structure is located. Location of the image reference can be accomplished, e.g., by displaying the medical image and electronically marking the displayed image reference, or by automatically locating image data corresponding to the image reference. The navigational and image coordinate systems are then registered based on the location of the physical structure within the navigational coordinate system and the location of the image reference within the image coordinate system, which allows graphical information to be accurately merged with the medical image data.

Owner:BOSTON SCI SCIMED INC

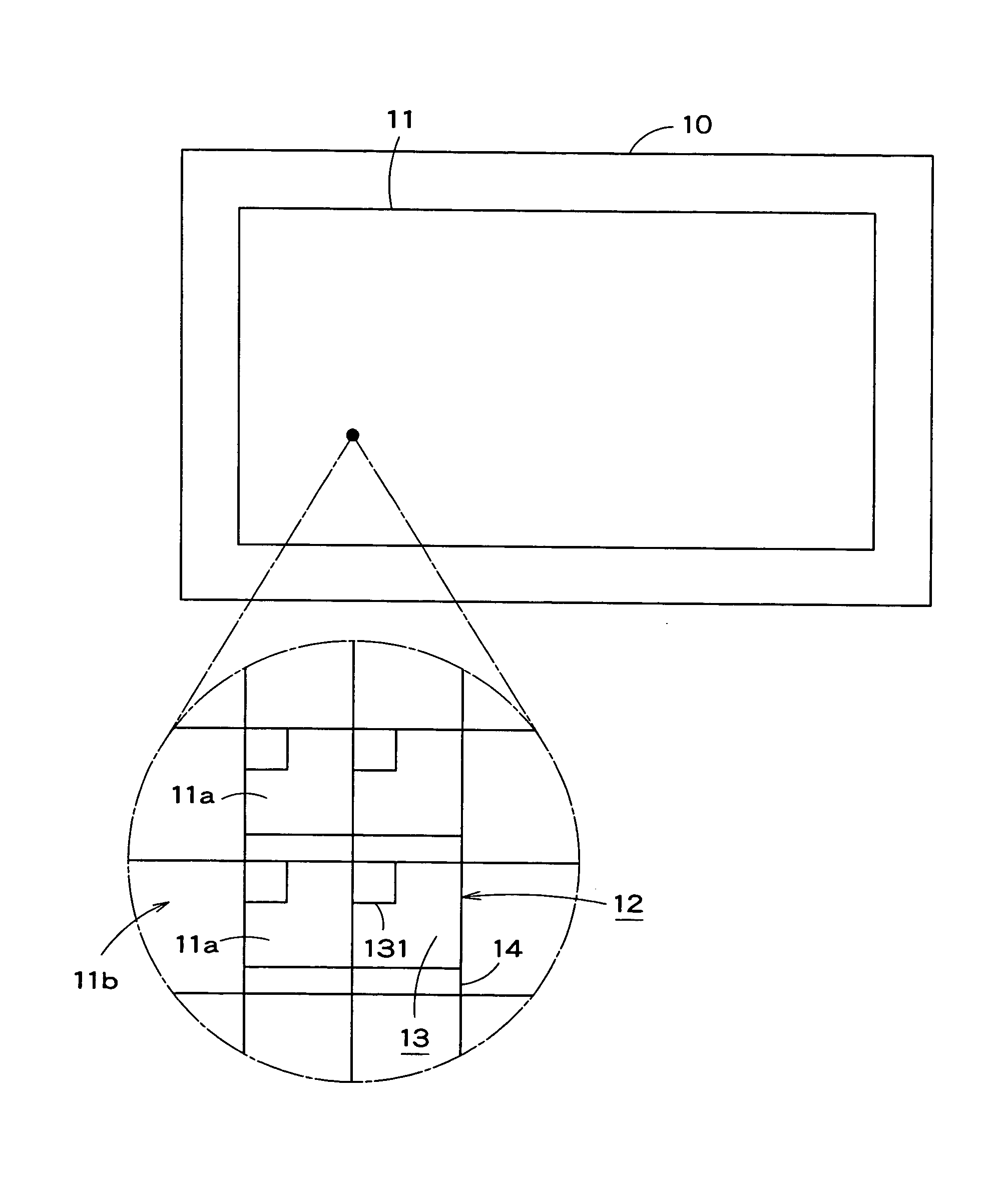

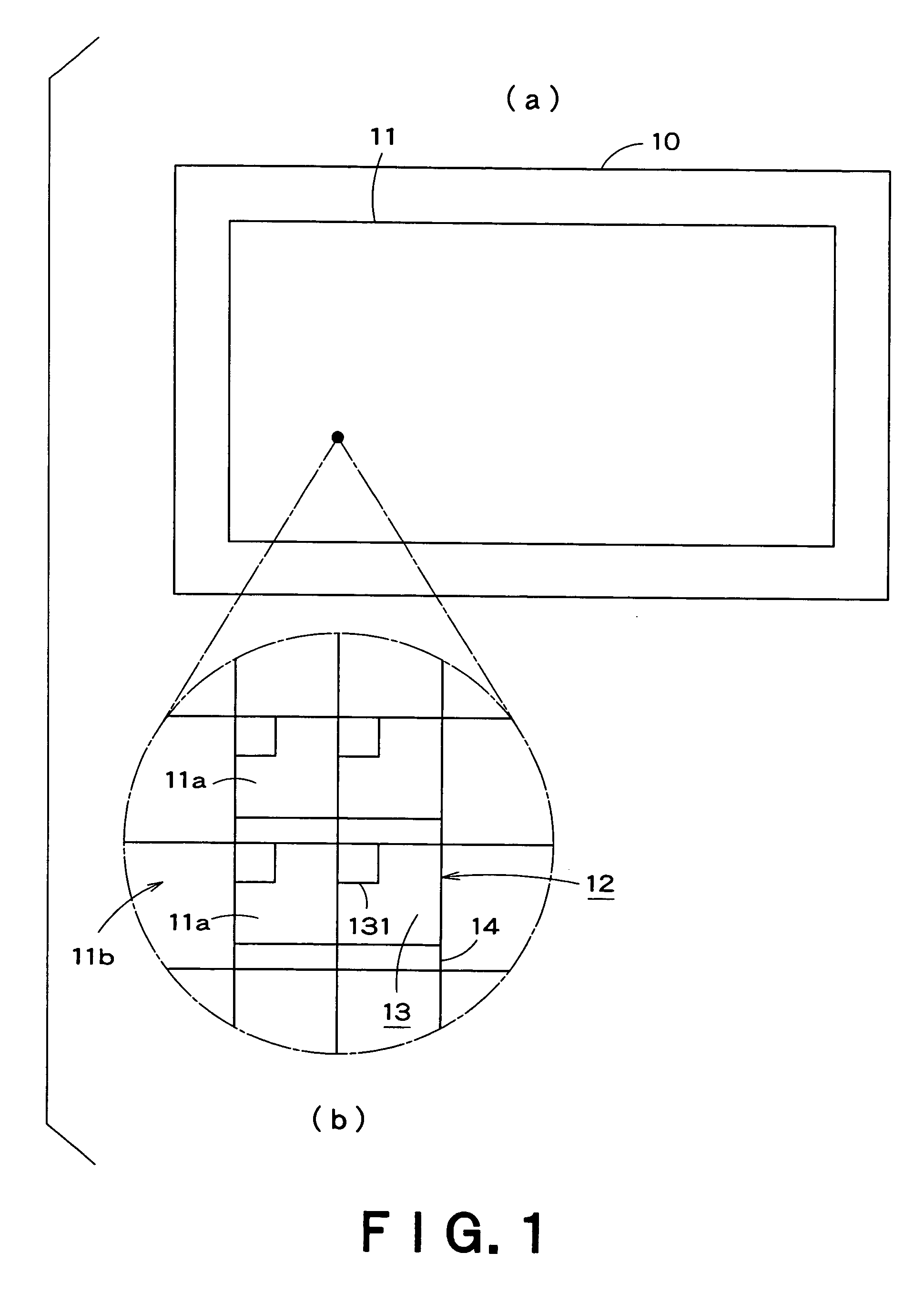

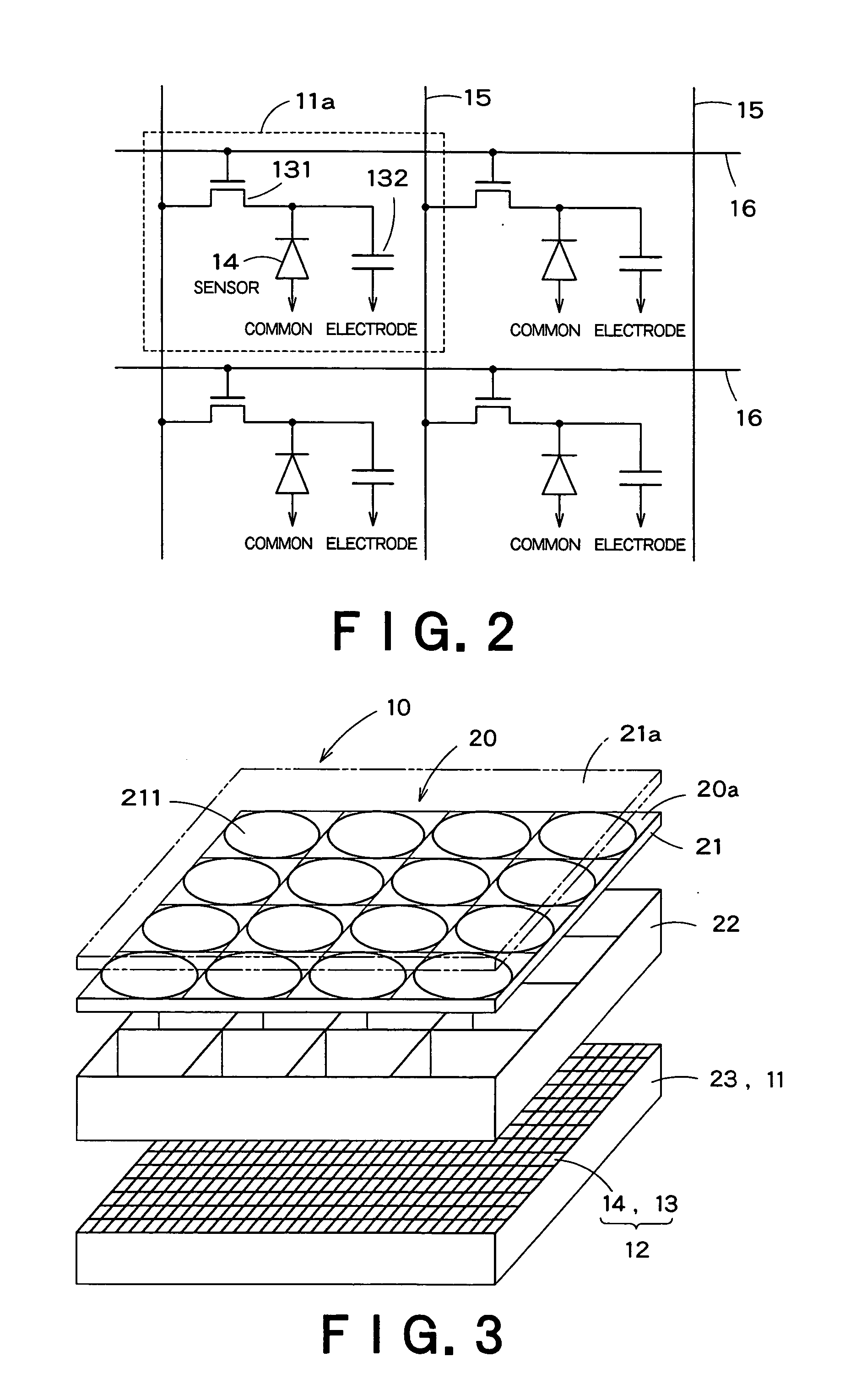

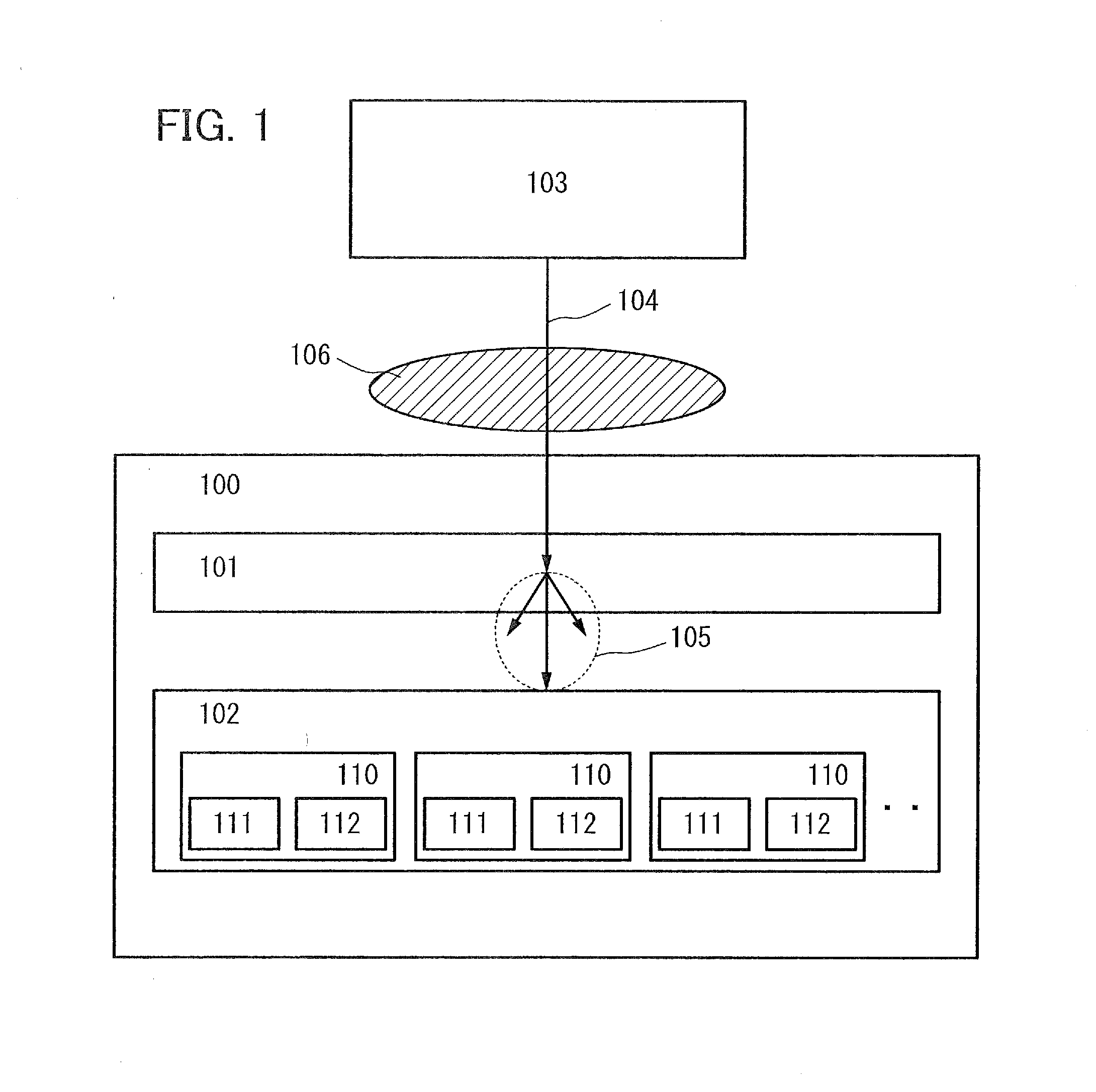

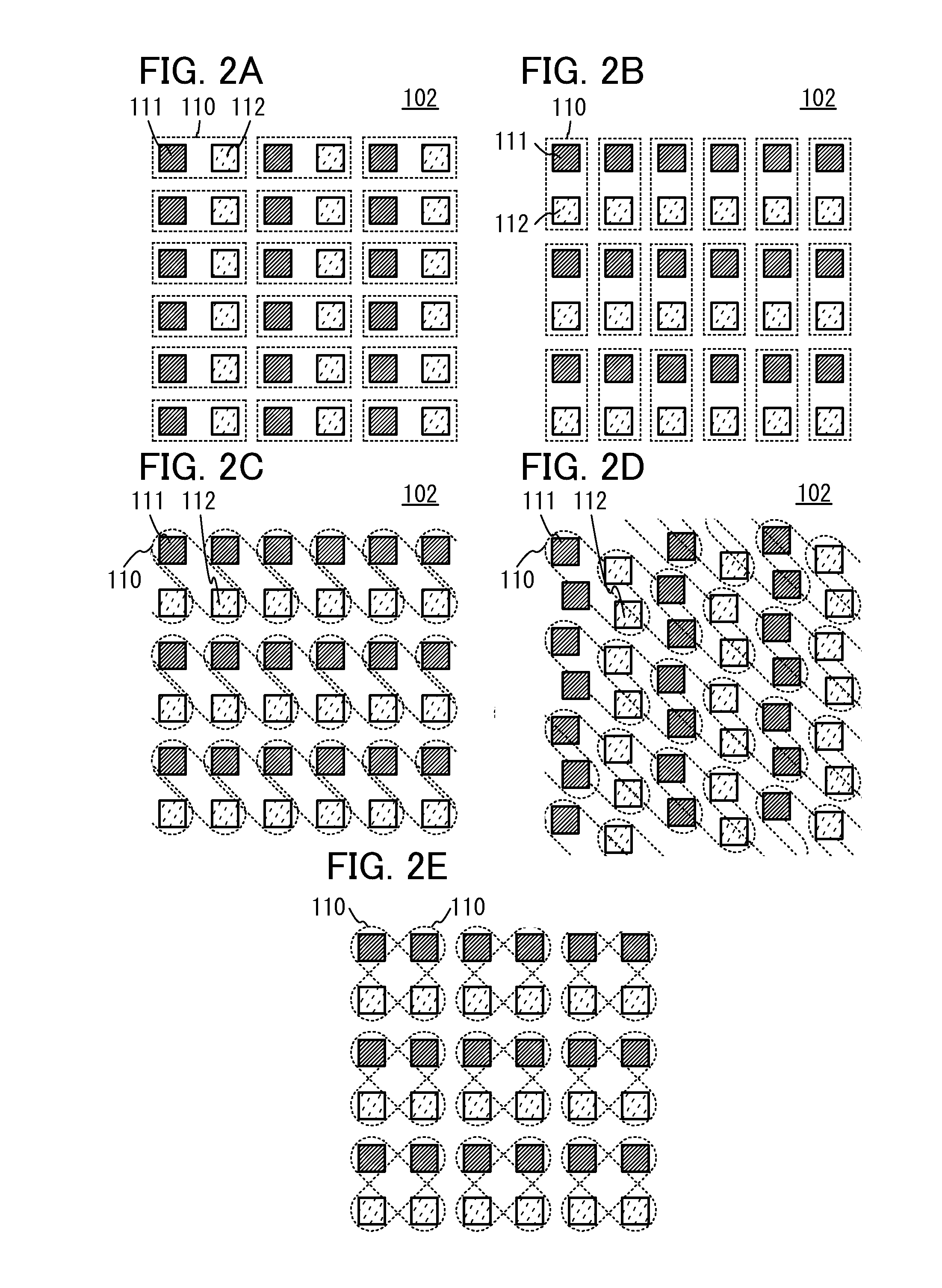

Display apparatus and display system

InactiveUS20050253834A1Realize functionEasy to operateCathode-ray tube indicatorsTelevision systemsSignal processing circuitsCompound imaging

A display apparatus 10 has a display screen 11 comprised of plurality of pixels displaying images based on image data, light sensors 14 to detect light entering the display screen 11 and arranged with display elements 13 to form the pixels, and compound imaging systems 20 comprised of imaging lenses 211 forming images of a subject in the light-receiving part of the light sensors 14. Images of a subject are output from the plurality of light sensors 14, and a signal processing circuit 35 synthesizes the image signals to generate image data. The image displayed by the display screen 11 is based on the image data output by the signal processing circuit 35.

Owner:DAI NIPPON PRINTING CO LTD

Image processing for image correction

InactiveUS7263221B1Image data is accurateImage enhancementCharacter and pattern recognitionImaging processingRadiology

In the processing of image data, image data are analyzed to determine a characteristic of the image, and the characteristic and a first correction parameter in correspondence to the characteristic are displayed in a screen of a display device. A second correction parameter may be set in the screen of the display device by a user. The image data is corrected with the first correction parameter, but when the user sets a second correction parameter, the image data are corrected with the second correction parameter. Alternatively, The image data are corrected automatically with the first correction parameter, and the characteristic of the image data is displayed in a screen after the image data have been corrected.

Owner:MINOLTA CO LTD

Mobile phone

InactiveCN102938796AIncrease profitHold video callsTelephone set constructionsStereo imageSystem hardware

The invention provides a mobile phone. The mobile phone comprises a mobile phone body, a rear camera and a front camera, the mobile phone body comprises a display screen, the rear camera is located on the rear surface of the mobile phone body, the front camera is located on the front surface of the mobile phone body, the front camera is connected to the mobile phone body through a rotating part, the rotating part is provided with a rotating initial position on the front surface of the mobile phone body, the rotating part is provided with a rotating stop position on the rear surface of the mobile phone body, and the front camera can rotate between the rotating initial position and the rotating stop position through the rotating part. The mobile phone has the advantages that by means of the rotatable cameras, the problem that the video call and the stereo image shooting can not simultaneously achieved in one mobile phone in prior art is solved, thereby the functions of the video call and the stereo image shooting can be simultaneously achieved in one mobile phone under the condition that hardware is not added, and the utilization ratio of system hardware resources is greatly improved.

Owner:ZTE CORP

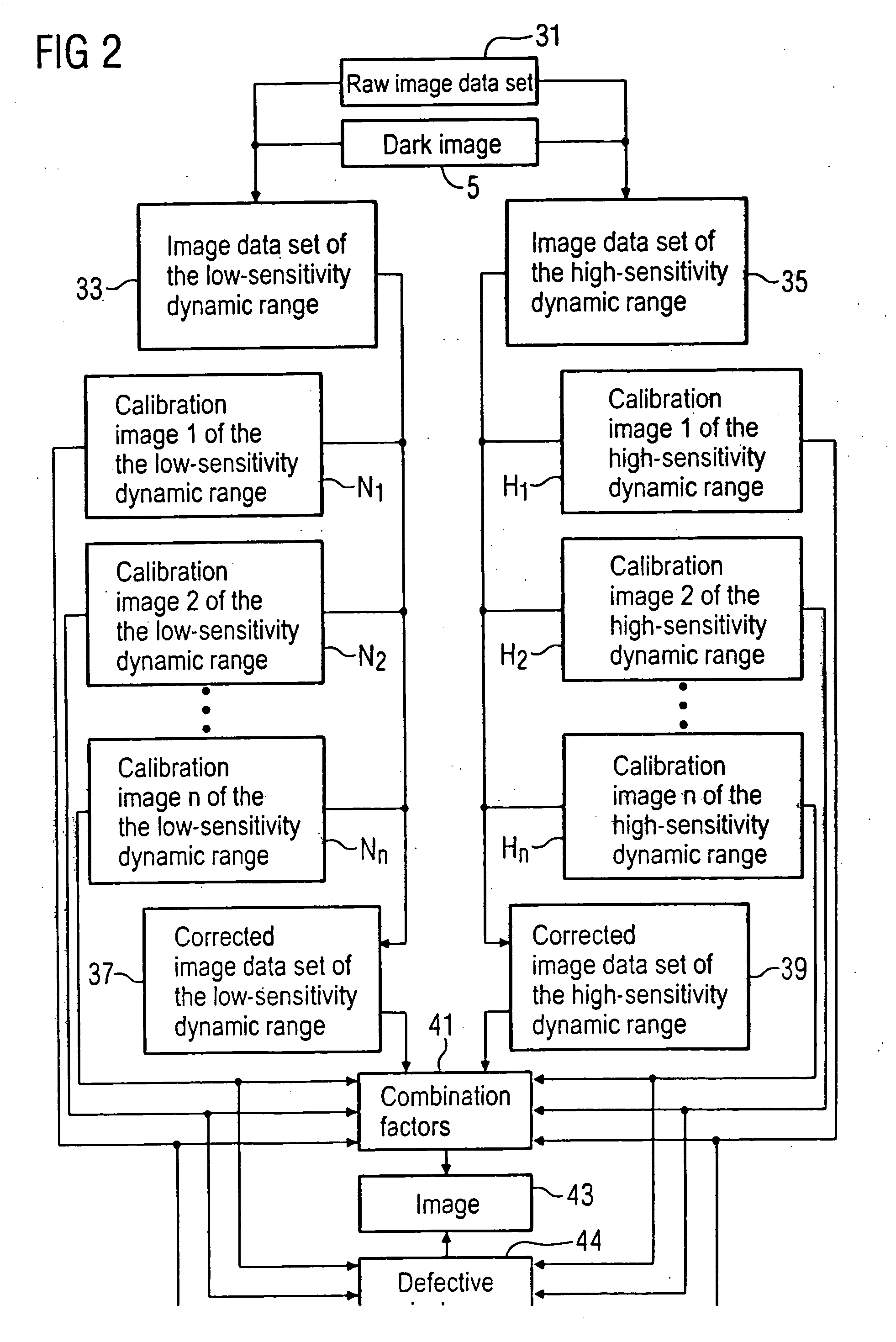

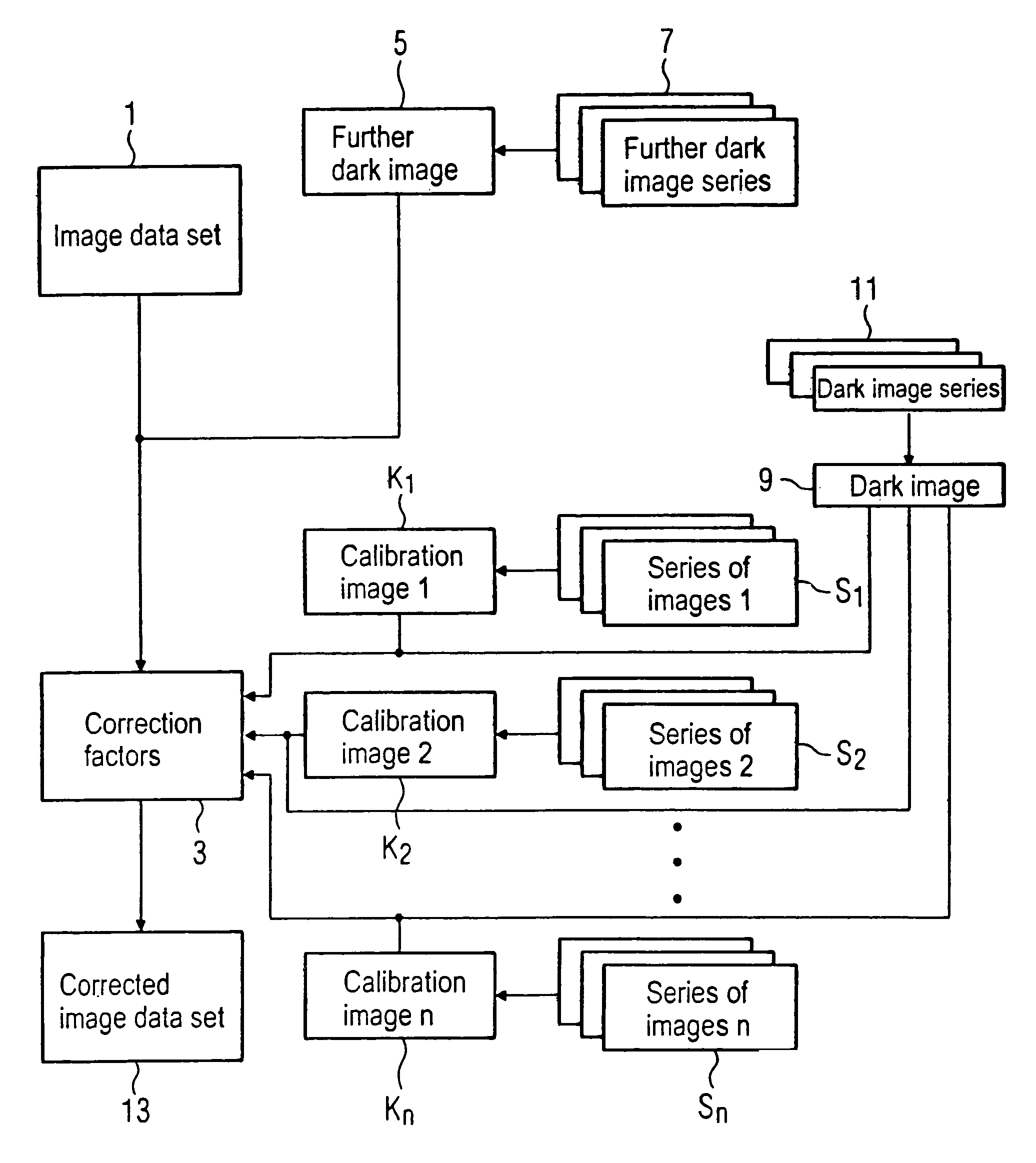

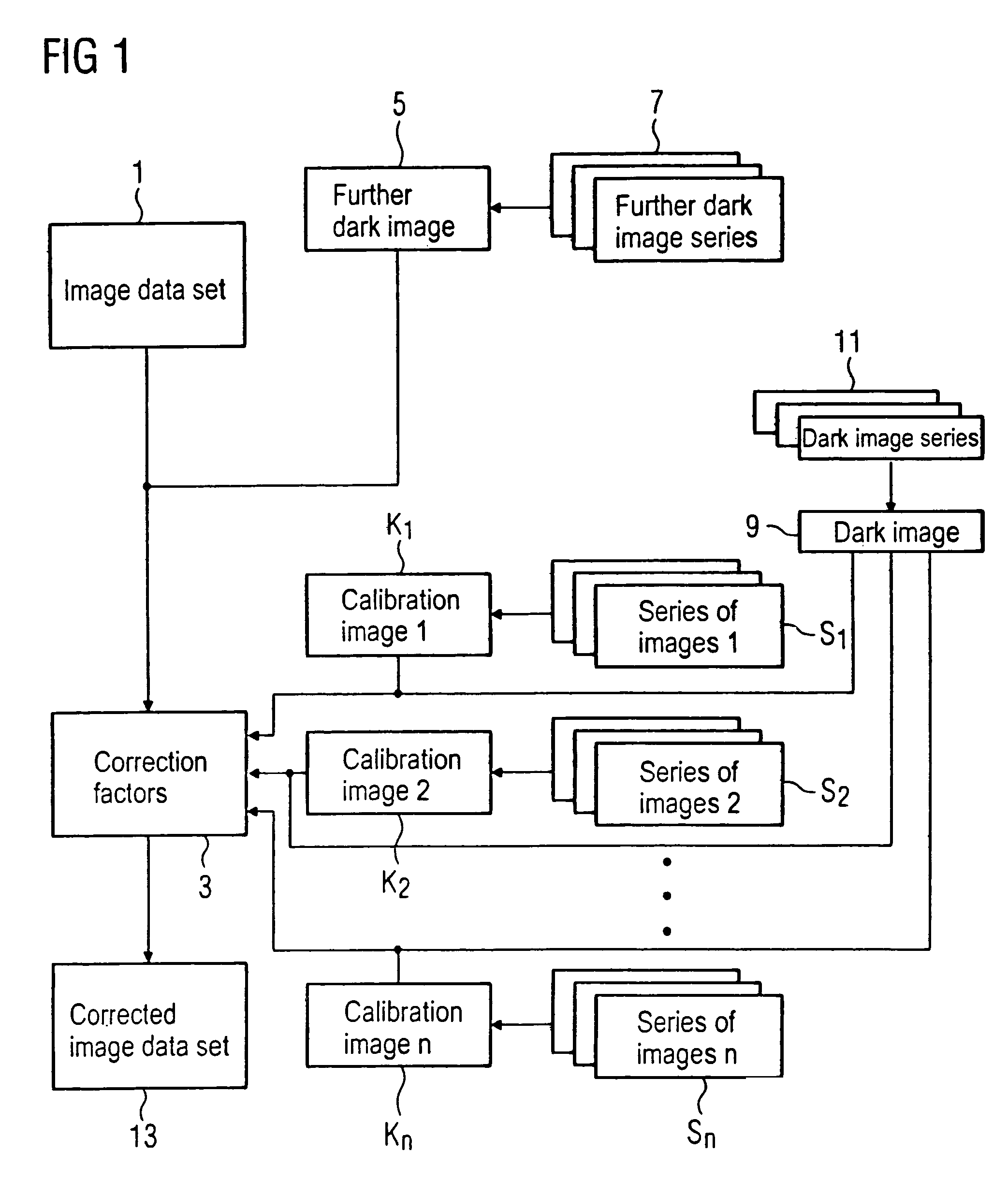

Method for correcting an image data set, and method for generating an image corrected thereby

InactiveUS20070065038A1Improve generation of imageImprove compromiseTelevision system detailsImage enhancementData setImaging data

In a method for correction of an image data set that was acquired with a planar image detector using at least two calibration images that were acquired in a preliminary procedure, as well as a method for generation of an image from a raw image data set that was acquired with a planar image detector with a high-sensitivity dynamic range and with a low-sensitivity dynamic range and which is composed of two image data sets, of which one was acquired in the high-sensitivity dynamic range and the other was acquired in the low-sensitivity dynamic range, at least two calibration images are generated in each dynamic range in a preliminary process. These calibration images are used in a correction procedure for the correction of the individual image data sets, as well as in a combination procedure to merge the two corrected image data sets into one image. In the combination procedure the two image data sets are conformed to one another using a comparison of the calibration images of the high-sensitivity dynamic range with the calibration images of the low-sensitivity dynamic range. The adjusted, corrected image data sets are added with weighting in a second step.

Owner:SIEMENS HEALTHCARE GMBH

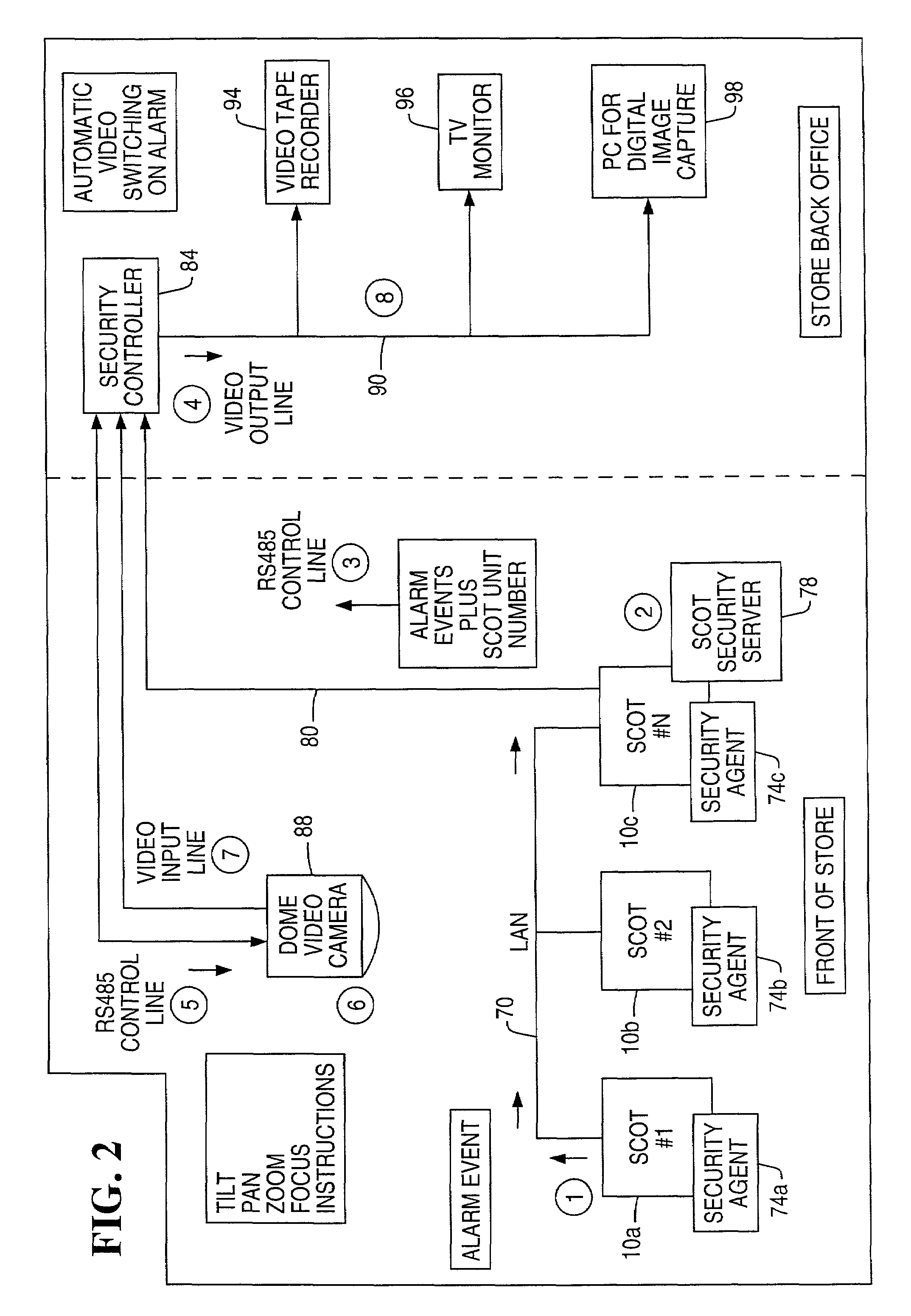

System and method for enhancing security at a self-checkout station

InactiveUS7034679B2Easy to recordIncrease opportunitiesSignalling system detailsColor television detailsData displayComputer terminal

A system controls security devices to enhance the security of self-checkout stations. The system includes security agent applications executing in the terminals of a plurality of self-checkout stations. The security agent software generates and transmits event messages regarding security events occurring at a station to a server. The server assigns a priority level to the event messages and sends the prioritized event messages as alert messages to a security controller. The security controller is coupled to security cameras, image data storage devices, and image data display devices and generates control messages for these devices in accordance with the alert messages received. The control messages for the security cameras operate the cameras to zoom, focus, tilt, or pan with respect to the events occurring at a station. Image data storage devices are coupled by the controller to cameras for the purpose of recording image data from the station in either a continuous or still image manner. The controller may insert visual alert indicators in the video stream of a camera directed to a monitor or an audible tone in the audio of the video stream to alert security personnel to the display of ongoing security events at a station. The controller may also be coupled to a paging system to generate pages for security personnel that identify a station where a security event is occurring so the security officer may observe the station during the incident.

Owner:NCR CORP

Semiconductor device

ActiveUS20110221945A1Highly accurate image dataImage pickup defectTransistorTelevision system detailsSemiconductorImaging data

A semiconductor device obtains highly accurate image data regardless of the intensity of incident light. The semiconductor device includes a first photo sensor provided in a pixel, a second photo sensor provided around the pixel, and a controller for setting the drive condition of the first photo sensor in accordance with the intensity of outside light obtained by the second photo sensor. An image is taken after the sensitivity of the first photo sensor is changed in accordance with the drive condition set by the controller. Thus, in the semiconductor device, an image can be taken using the first photo sensor whose sensitivity is optimized in accordance with the intensity of incident light.

Owner:SEMICON ENERGY LAB CO LTD

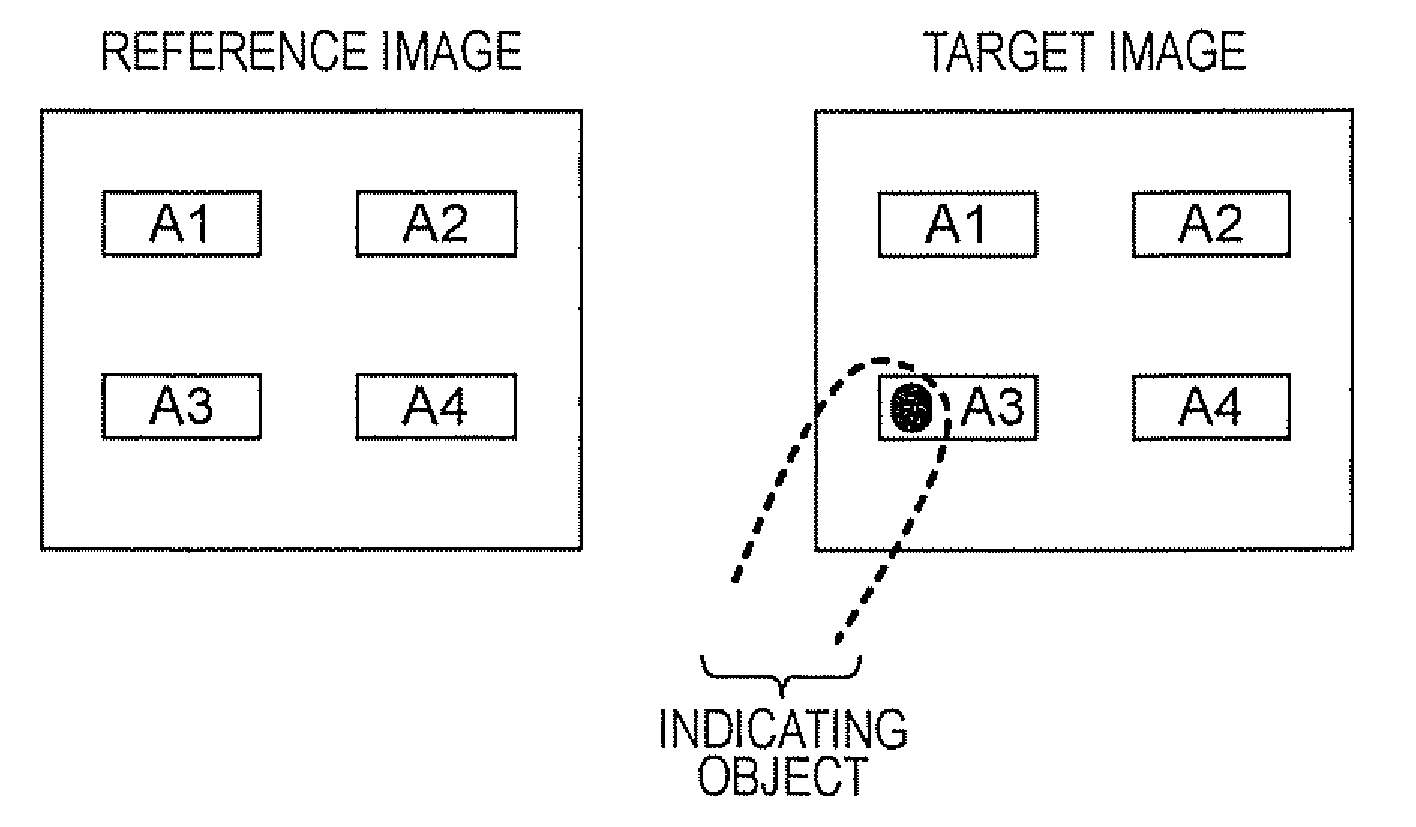

Electro-optical device, electronic apparatus and method of detecting indicating object

InactiveUS20090073141A1Improve accuracyImage data is accurateStatic indicating devicesPhotometry using electric radiation detectorsOptical propertyReference image

Provided is a device for driving first and second electrodes and an electro-optical element including a material having optical characteristics that vary with an applied voltage. The device includes: a driving unit which drives the electro-optical element between first and second driving states; a display unit which displays an image based on the optical characteristics of the electro-optical element; a pickup unit that outputs image data according to the amount of incident light; a first memory which fetches / stores the image data as reference image data; a second memory which fetches / stores the image data as target image data; a difference image data generating unit which generates difference image data from a difference between the reference and target image data; and a control unit which controls the write / read of the first and second memories such that the driving states corresponding to the reference image data and the target image data become equal.

Owner:SEIKO EPSON CORP

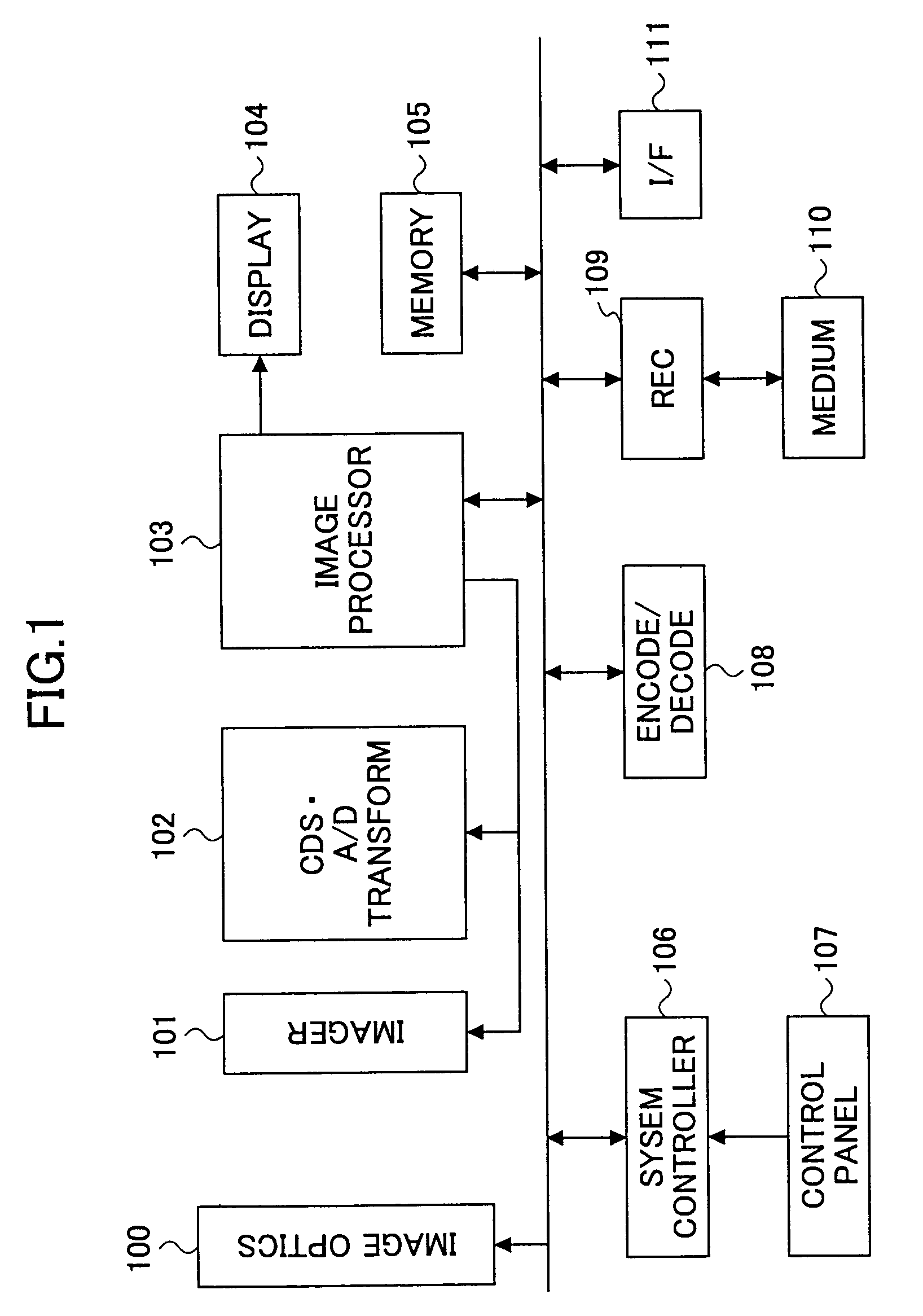

Video image capture device

InactiveUS20070109399A1Image data is accurateTelevision system detailsSolid-state devicesPhotoelectric conversionVideo image

A video image capture device of the present invention includes: an optical system having distortion characteristics which enlarge the center portion and compress the peripheral portions; an image sensor which performs photoelectric conversion of a subject image focused by the optical system to output as original image data; a distortion correction circuit which corrects distortion in the original image data; an instruction portion which sets the size of an extraction angle of view for the original image data before correction of distortion; and a recording device which, taking the angle of view of the original image data to be a first angle of view, stores in succession image data corresponding to the first angle of view of the original image data and, as pairs, image data corresponding to a second angle of view narrower than the first angle of view set by the instruction portion.

Owner:OLYMPUS CORP

Method and magnetic resonance system to correct distortions in image data

InactiveUS20110052031A1Easy to correctAvoid disadvantagesCharacter and pattern recognitionDiagnostic recording/measuringDiffusionResonance

In a method for correction of distortions in image data in a diffusion imaging, the image data are acquired with an imaging MRT measurement for a predetermined diffusion weighting and map a predetermined image segment. A diffusion model for the image segment is determined. Output image data are determined for the image segment such that the output image data are essentially free of distortions caused by diffusion weighting. Reference image data are estimated for the predetermined diffusion weighting for the image segment based on the output image data and the diffusion model. The acquired image data are compared with the reference image data and the acquired image data are corrected based on the comparison.

Owner:SIEMENS HEATHCARE GMBH

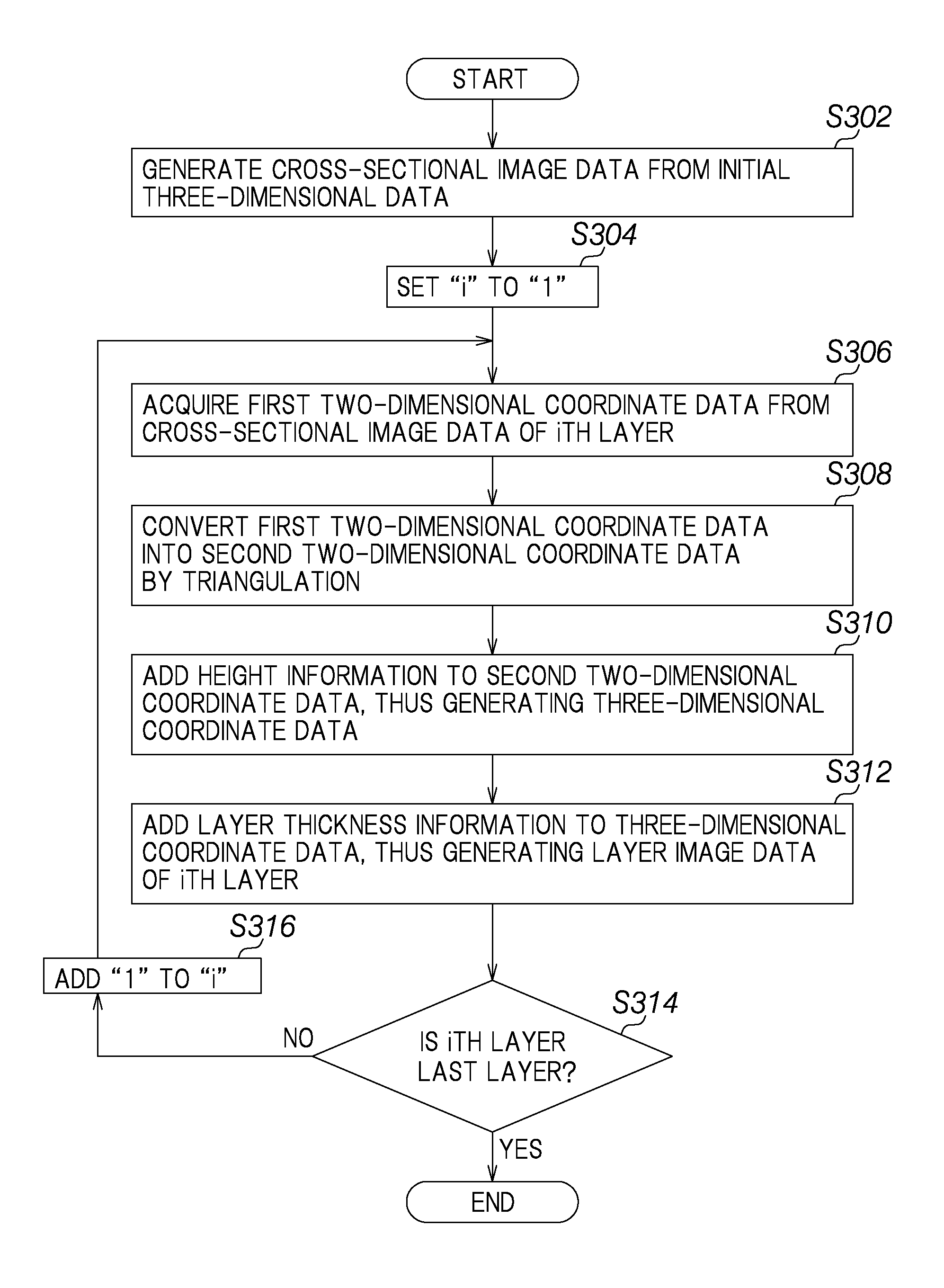

Three-dimensional object preview device, three-dimensional printing apparatus, and three-dimensional object preview method

ActiveUS20150205553A1Image data is accurateWell formedAdditive manufacturing apparatus3D object support structuresComputer graphics (images)Triangulation

A three-dimensional object preview device includes a cross-sectional image data generation section configured to generate cross-sectional image data representing a cross-sectional shape of each layer of a three-dimensional object, a two-dimensional coordinate data acquisition section configured to acquire first two-dimensional coordinate data from the cross-sectional image data, a two-dimensional coordinate data conversion section configured to convert, using triangulation, the first two-dimensional coordinate data into second two-dimensional coordinate data, a three-dimensional coordinate data generation section configured to add Z-axis coordinate information to the second two-dimensional coordinate data to generate three-dimensional coordinate data, a layer image data generation section configured to add layer thickness information to the three-dimensional coordinate data, thus generating layer image data, a printing image data generation section configured to generate, using the layer image data, printing image data representing a three-dimensional model, and a display section configured to cause a display device to display the three-dimensional model.

Owner:ROLAND DG CORP

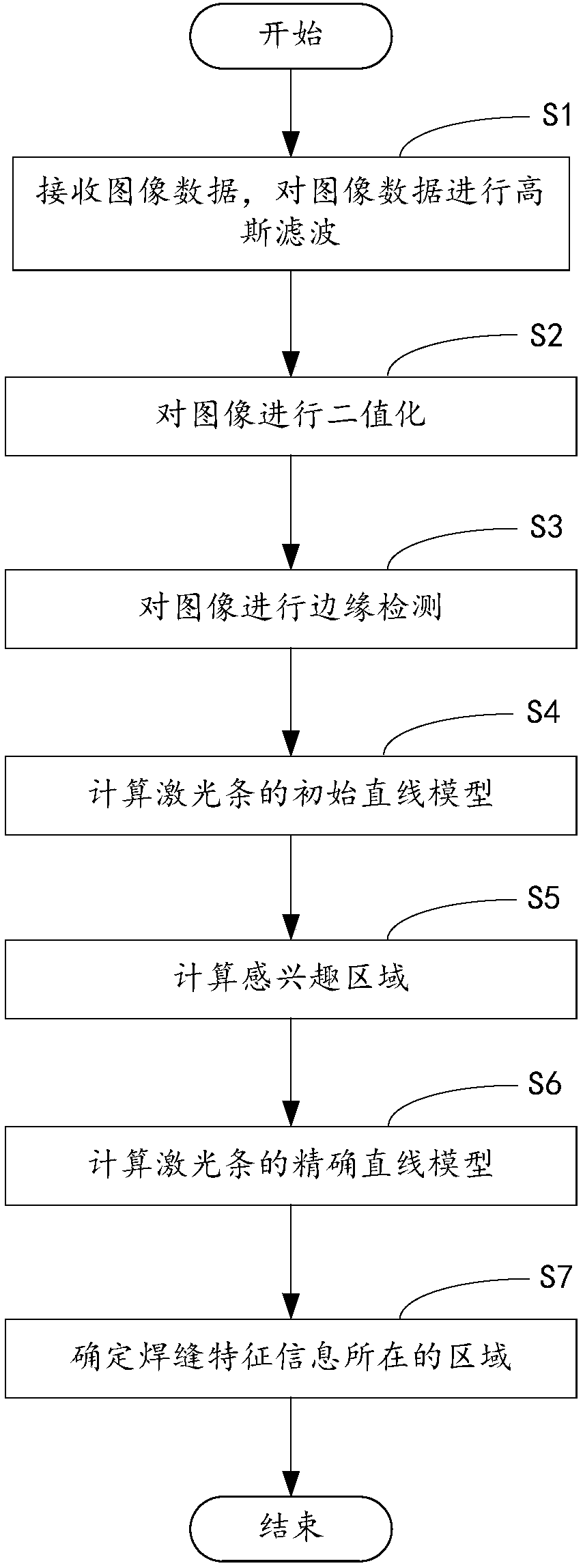

Welding seam image identification method, computer device and computer readable storage medium

InactiveCN108280829AImprove recognition efficiencyQuick fixImage enhancementImage analysisWeld seamImaging data

The invention discloses a welding seam image identification method, a computer device and a computer readable storage medium. The method includes the steps: receiving image data, performing Gaussian filtering on the received image data, and performing binarization processing on the image data after Gaussian filtering; performing edge detection on an image after binarization, and calculating a structural light center line in the image after binarization; calculating an initial straight line model of a laser bar in the image after edge detection by the aid of a random sampling consistency algorithm, calculating an interest area based on the initial straight line model, calculating an accurate straight line model of a laser bar in the image in the interest area by the aid of the random sampling consistency algorithm again, and calculating an area of welding seam characteristic information in the interest area. The invention further provides a computer device for implementing the method and a computer readable storage medium. According to the method, the welding seam characteristic information in the image can be rapidly identified, and the identifying efficiency of welding seam characteristics is improved.

Owner:广东省海洋工程装备技术研究所 +1

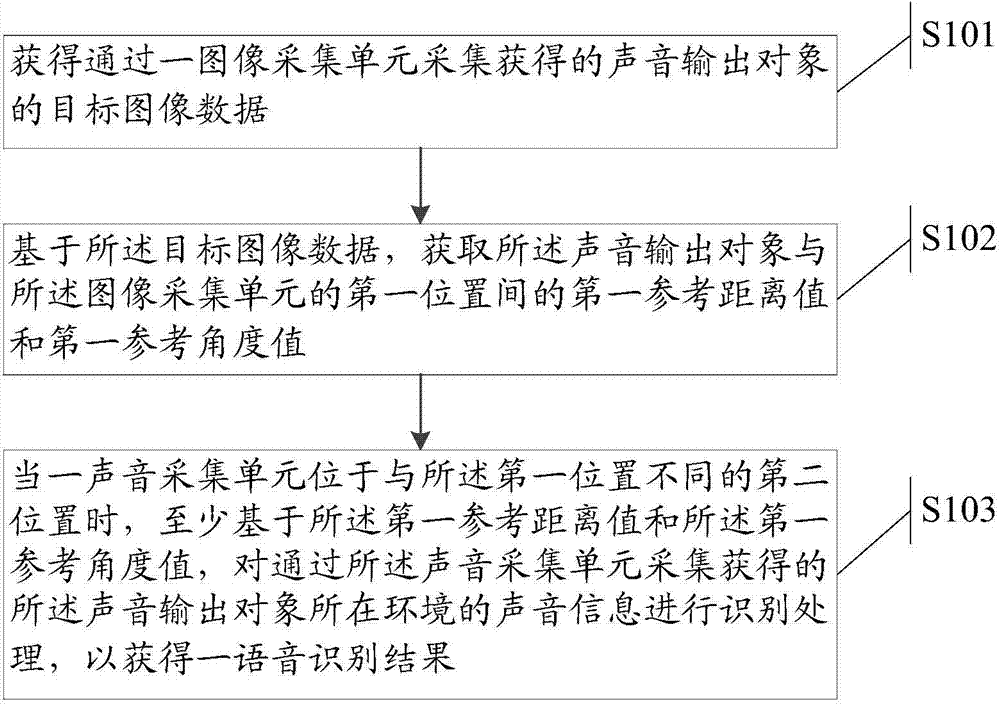

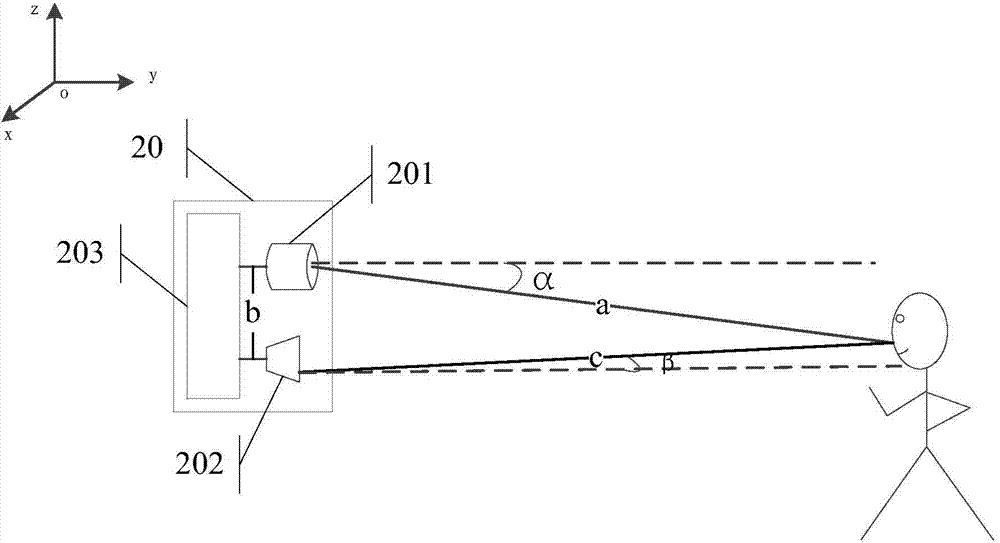

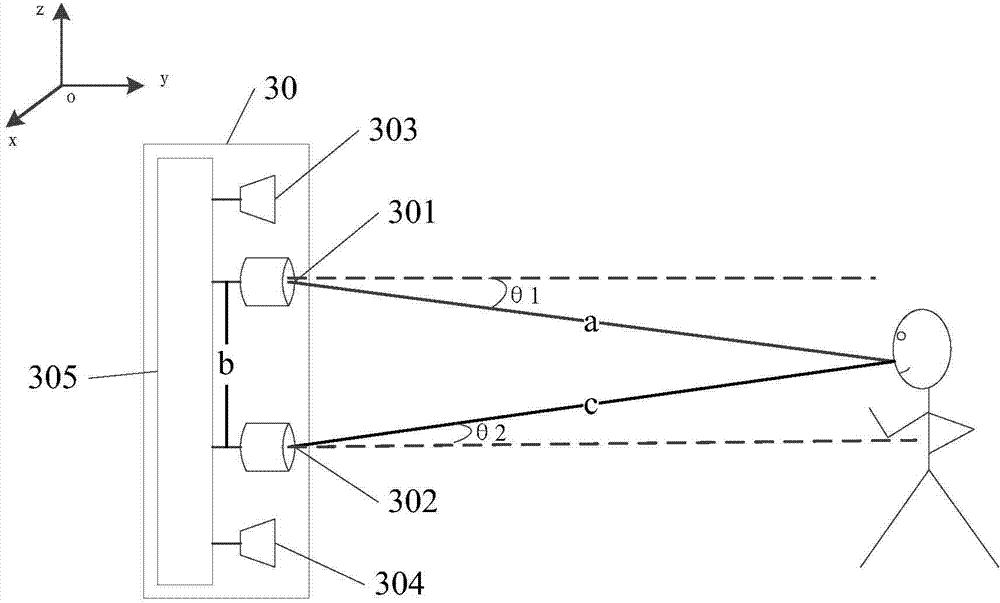

Data processing method and electronic device

ActiveCN104715753AImprove speech recognition rateSolve technical problems that are difficult to achieve a high recognition rateSpeech recognitionInput/output processes for data processingEnvironmental noiseComputer science

The invention discloses a data processing method and an electronic device, so as to solve the technical problem that in the case of large environmental noise in the prior art, a voice recognition system is hard to achieve a high recognition rate. The method comprises steps: target image data, acquired and obtained by an image acquisition unit, of a sound output object are acquired; on the basis of the target image data, a first reference distance value and a first reference angle value between the sound output object and a first position of the image acquisition unit are acquired; when a sound acquisition unit is located at a second position different from the first position, recognition processing is carried out on sound information of the environment of the sound output object acquired and obtained by the sound acquisition unit at least on the basis of the first reference distance value and the first reference angle value so as to acquire a voice recognition result.

Owner:LENOVO (BEIJING) LTD

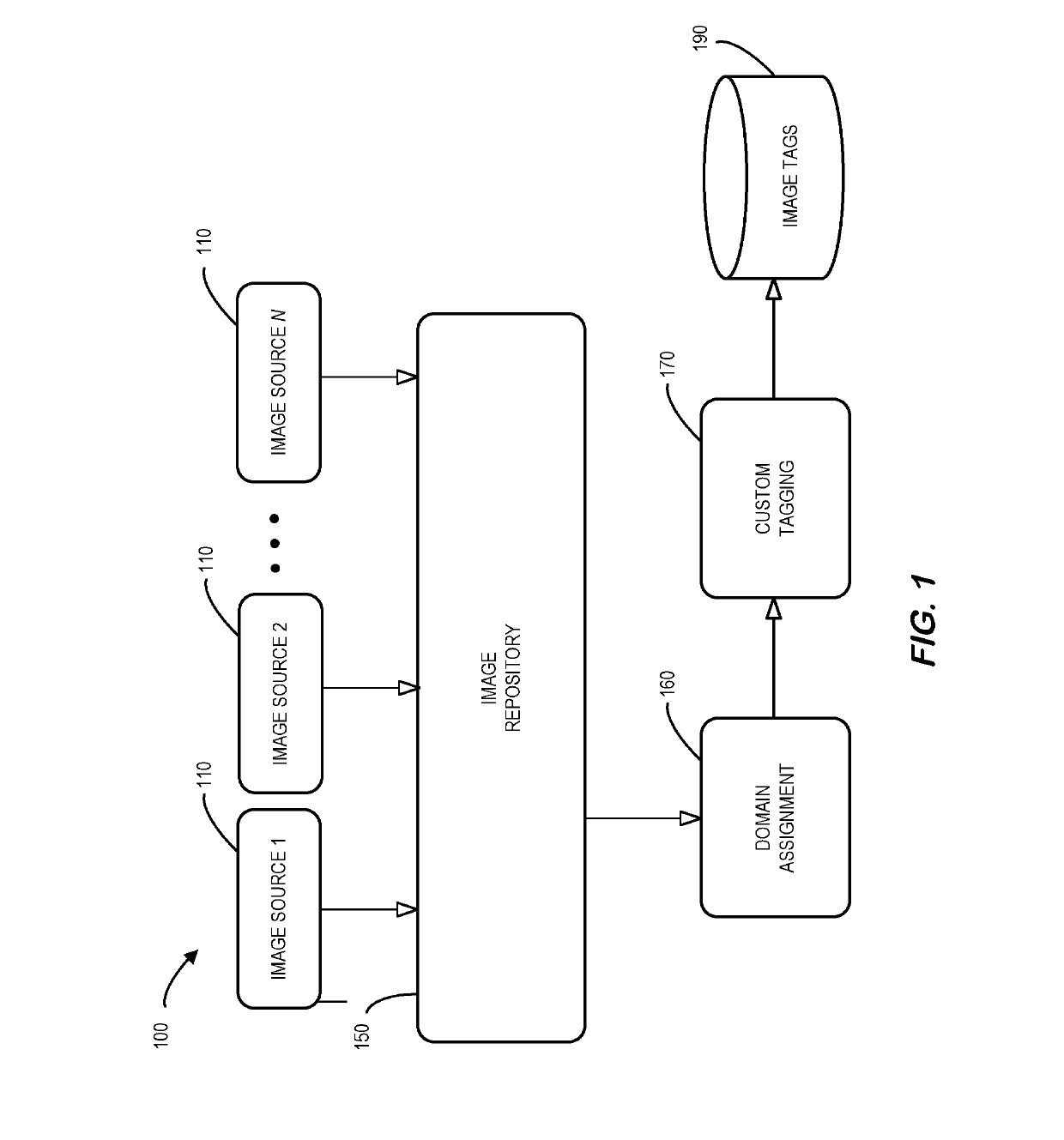

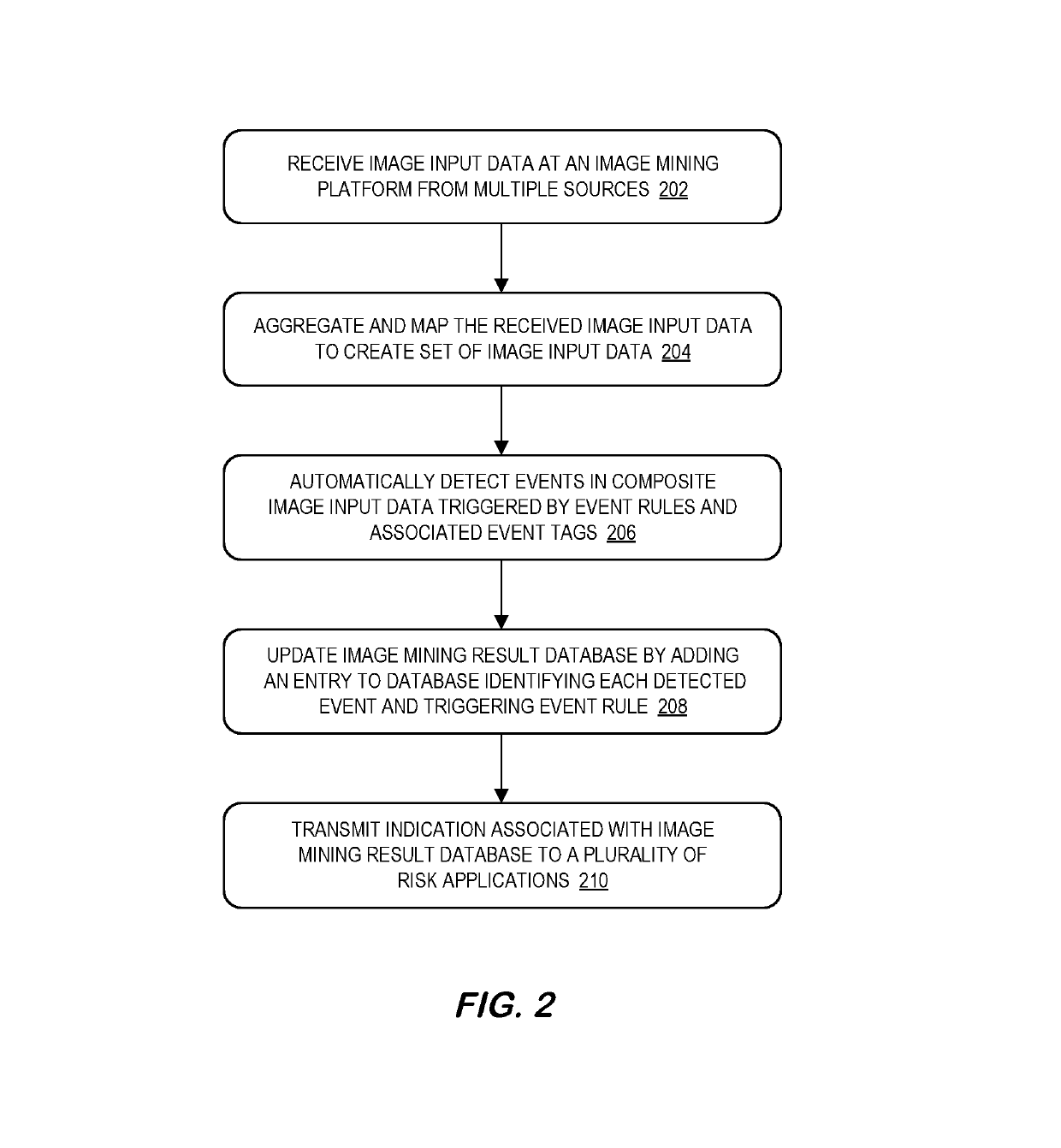

System and method for evaluating images to support multiple risk applications

ActiveUS20190171986A1Promote resultsImage data is accurateFinanceCharacter and pattern recognitionApplication softwareData mining

In some embodiments, image input data is received from multiple sources. The received image input data may then be aggregated and mapped to create a set of image input data. An event in the set of image input data may be automatically detected, such as by being triggered by a rule and an associated tag. An image mining result database may be updated by adding an entry to the database identifying each detected event and the triggering rule. An indication associated with the image mining result database may then be transmitted to a plurality of risk applications.

Owner:HARTFORD FIRE INSURANCE

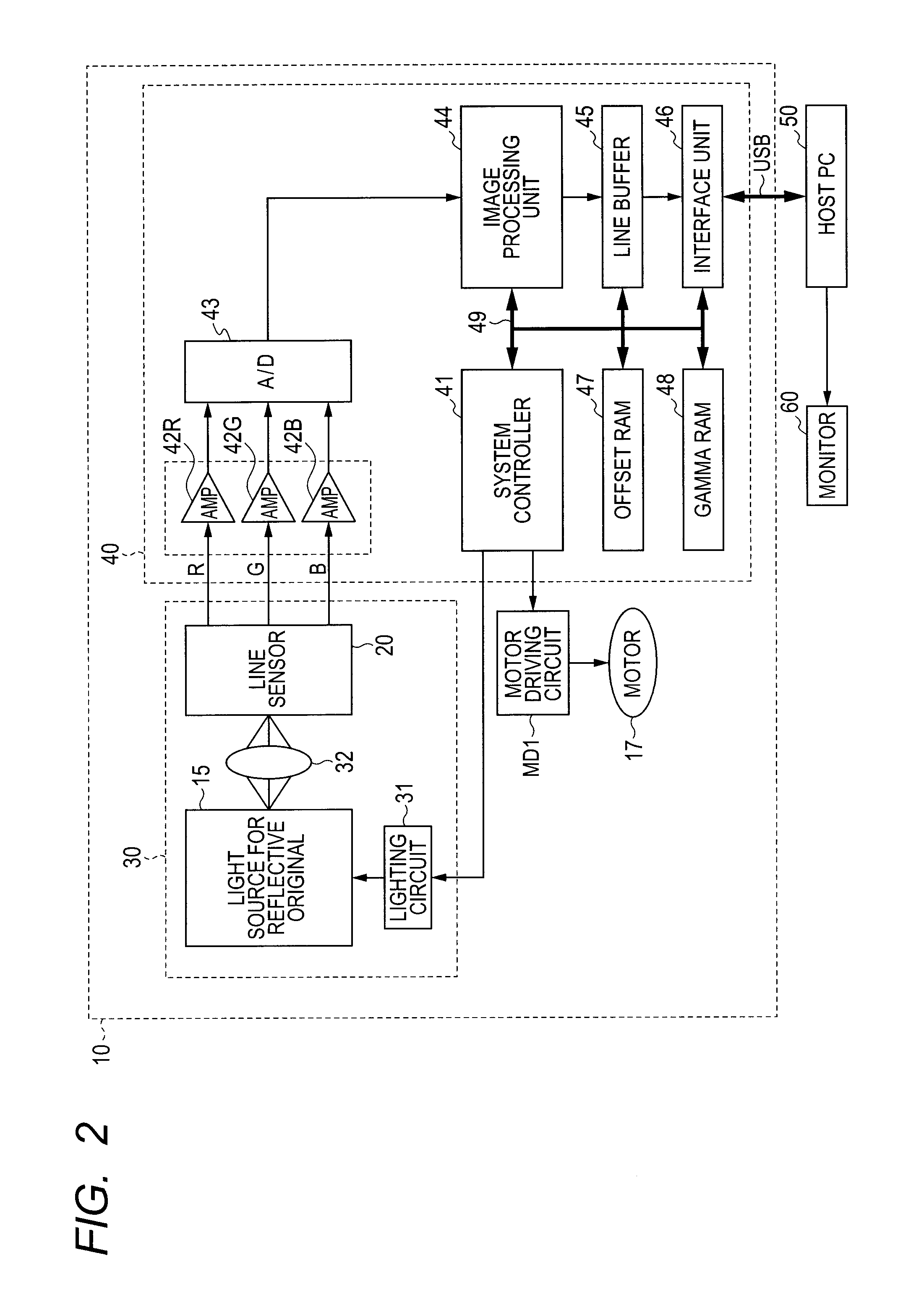

Image processing scheme

InactiveUS7013049B2Effectively reduced hue changeSimple apparatus configurationCharacter and pattern recognitionImage codingImaging processingImaging data

At least the deviation on a pixel having a value deviating from a predetermined range through inverse transform of image data from a frequency domain is reduced, wherein a pixel which should have a value changed in a direction reverse to the deviation is determined based on a character of the inverse transform.

Owner:RICOH KK

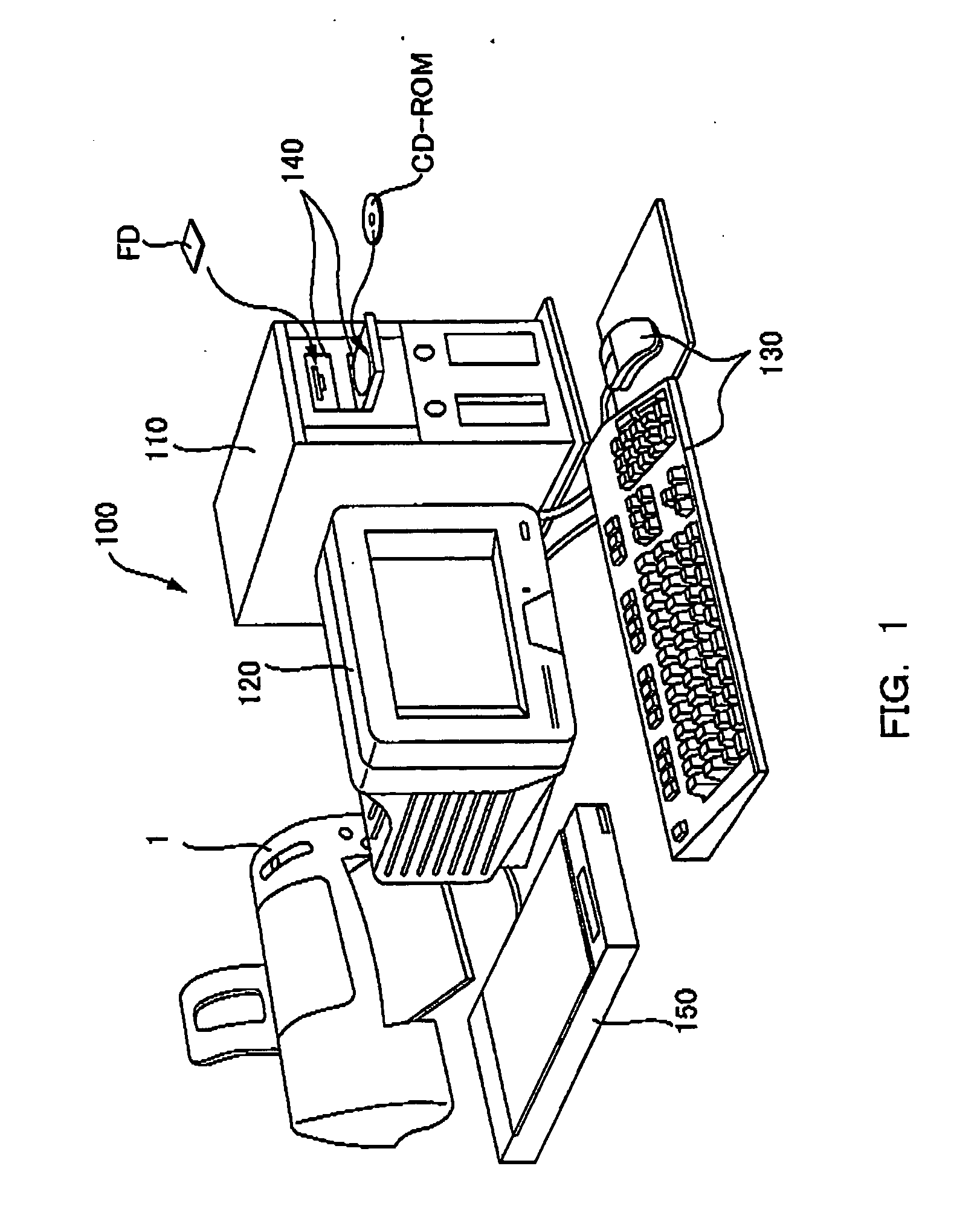

Image processing apparatus, image processing method, and image processing program recorded recording medium

It is an object to provide an image processing apparatus which can properly obtain an original area even when there is one original or when there are a plurality of originals, an image processing method, and a recording medium in which an image processing program has been recorded. An image processing apparatus for deciding an image data area of an original from read image data obtained by being read by an image reading apparatus has: an extracting unit for extracting a plurality of image areas from the read image data; and a discriminating unit for discriminating whether or not tilt angles of the image areas extracted by the extracting unit are equal. If one or more tile angles of the image areas are not equal as a result of the discrimination by the discriminating unit, it is determined that each of the image areas is an image data area of the original on the assumption that there are a plurality of originals.

Owner:CANON KK

Radiation detection panel, radiation imaging device, and diagnostic imaging device

ActiveUS20140056405A1Reduce afterglowReduce adverse effectsTelevision system detailsMaterial analysis by optical meansRadiation imagingTransducing Unit

To achieve a radiation detection panel capable of outputting a signal for generating an accurate pixel signal regardless of the performance of a conversion unit, a detection circuit that outputs a signal used for generating a pixel signal includes a first output circuit that outputs a signal due to afterglow, and a second output circuit that outputs a signal including both a signal based on radiation emission and a signal due to afterglow. Transistors using an oxide semiconductor material for a channel formation region are used as some transistors included in the first and second output circuits. In the radiation detection panel having this structure, the signal (a first signal or a second signal) can be held in each output circuit; therefore, after all output circuits hold the signal (the first signal or the second signal), the first signal and the second signal can be sequentially output from detection circuits.

Owner:SEMICON ENERGY LAB CO LTD

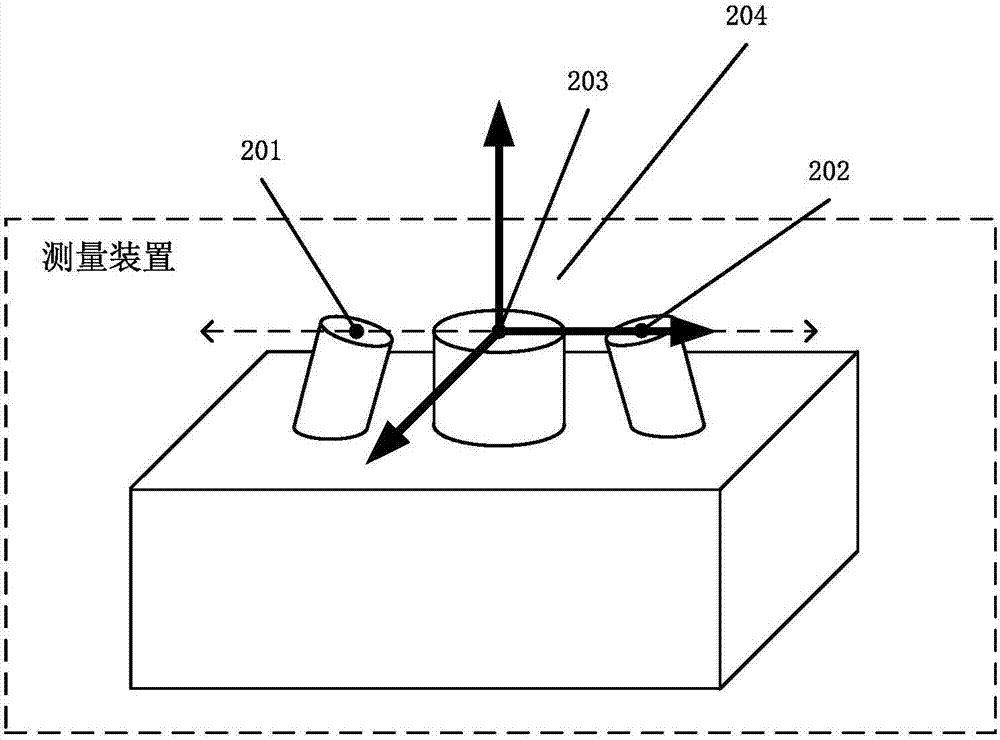

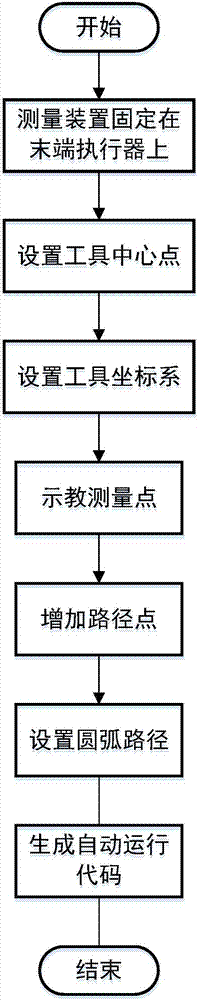

Automatic three dimensional morphology measurement device and method for high temperature object

ActiveCN106908015AMeasuring Motion Path Optimization ImprovementsImage data is accurateUsing optical meansThree dimensional morphologyMeasurement device

The invention discloses a three dimensional morphology measurement device comprising an industrial robot, a clock synchronization controller, a projector, two CCD cameras, an image collecting card and a computer, wherein the two CCD cameras are respectively arranged on two sides of the projector in a symmetric manner, an included angle formed by a photocenter axis of each CCD camera and a photocenter axis of the projector ranges between 20 degrees and 60 degrees, the two CCD cameras and the projector form a measurement device which is arranged on a tail end executor of the industrial robot, a tool center point of the industrial robot is set as a center for an end face of a lens of the projector, a tool coordinate system is parallel to the photocenter axis of the projector, the clock synchronization controller is controlled by the industrial robot and is connected with the projector and the two CCD cameras, the projector is connected with the computer, and the two CCD cameras are connected with the computer via the image collecting card. The invention also discloses a corresponding measurement method. According to the measurement device and method disclosed in the invention, optimized layout of the measurement device and optimized processing of a measurement route are realized, and three dimensional morphology of a high temperature object can be measured accurately.

Owner:WUHAN POWER3D TECH

Camera system, color conversion device and method employed thereupon, and recording medium for color conversion program

ActiveUS20150245009A1Simple photographingAccurate conversionImage enhancementImage analysisComputer graphics (images)Imaging data

A camera system includes: a database which stores a plurality of stereoscopic color profiles, in which conversion relationships calculated from second image data obtained by photographing a plurality of reference color stereoscopic objects assigned with reference colorimetric values in advance and the reference colorimetric values corresponding to the second image data are associated with a plurality of illumination conditions in photographing; a selection unit which, based on an illumination condition at the time of photographing of a stereoscopic subject, selects a stereoscopic color profile corresponding to the illumination condition; and a color conversion unit which performs color conversion from first image data of a photographed image of the stereoscopic subject to colorimetric values, based on the selected stereoscopic color profile.

Owner:FUJIFILM CORP

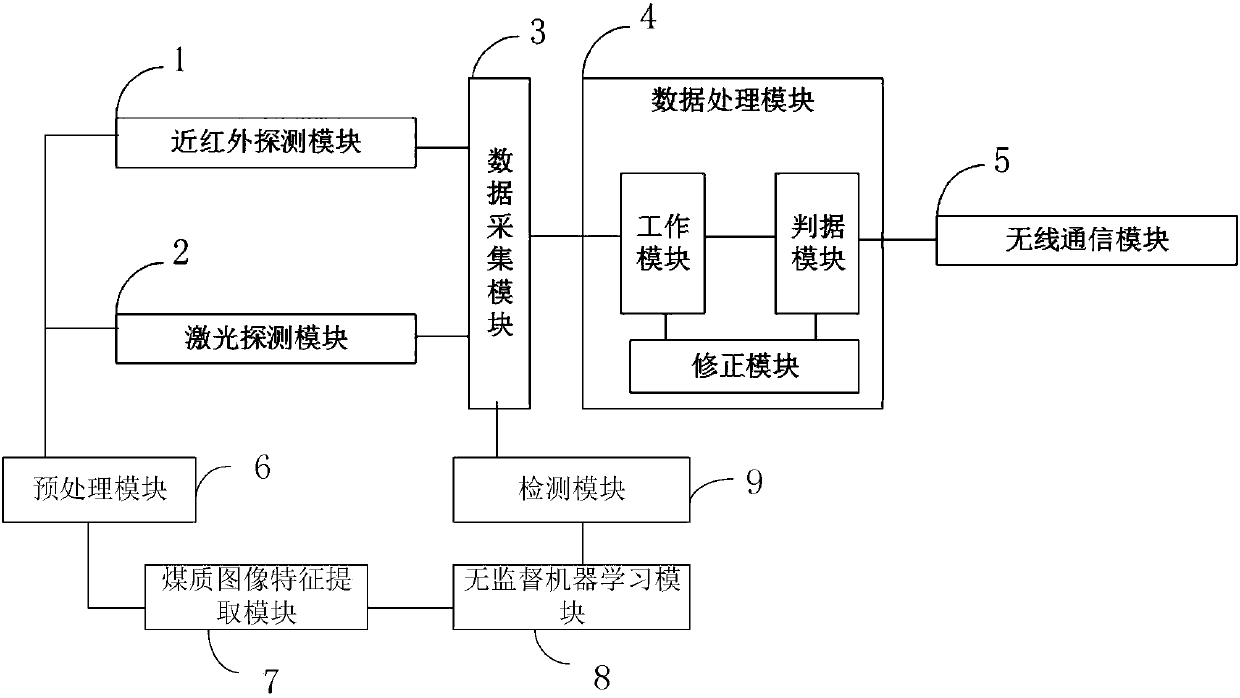

Coal quality online detection and analysis method based on regression analysis

InactiveCN107589093ARealize full elemental analysisImprove stabilityMaterial analysis by optical meansCharacter and pattern recognitionFault toleranceFeature extraction

The invention belongs to the field of coal quality detection and discloses a coal quality online detection and analysis method based on regression analysis. Graphic features of various areas in coal are automatically extracted by regression analysis algorithm of machine learning for image characteristics extraction; and a coal quality online detection result is provided based on the extracted image characteristics by machine learning, and the detection result is displayed through a display module. the method of the invention comprises the following specific steps: a coal scanned image is acquired through data acquisition equipment with built-in near-infrared detection module and laser detection module; the coal scanned image is pretreated by the use of a pretreatment module, and the coal scanned image is divided into multiple blocks. Coal quality data information detection is carried out through the near-infrared detection module and the laser detection module, and the detection data is accurate. By component network for nonlinear prediction, the method of the invention has advantages of strong adaptability, good fault tolerance and the like. All elements analysis of coal quality can be realized, and measurement accuracy also can be enhanced.

Owner:邓雷

Method for correcting an image data set, and method for generating an image corrected thereby

InactiveUS7729527B2Improve generation of imageImprove compromiseImage enhancementTelevision system detailsData setImaging data

In a method for correction of an image data set that was acquired with a planar image detector using at least two calibration images that were acquired in a preliminary procedure, as well as a method for generation of an image from a raw image data set that was acquired with a planar image detector with a high-sensitivity dynamic range and with a low-sensitivity dynamic range and which is composed of two image data sets, of which one was acquired in the high-sensitivity dynamic range and the other was acquired in the low-sensitivity dynamic range, at least two calibration images are generated in each dynamic range in a preliminary process. These calibration images are used in a correction procedure for the correction of the individual image data sets, as well as in a combination procedure to merge the two corrected image data sets into one image. In the combination procedure the two image data sets are conformed to one another using a comparison of the calibration images of the high-sensitivity dynamic range with the calibration images of the low-sensitivity dynamic range. The adjusted, corrected image data sets are added with weighting in a second step.

Owner:SIEMENS HEALTHCARE GMBH

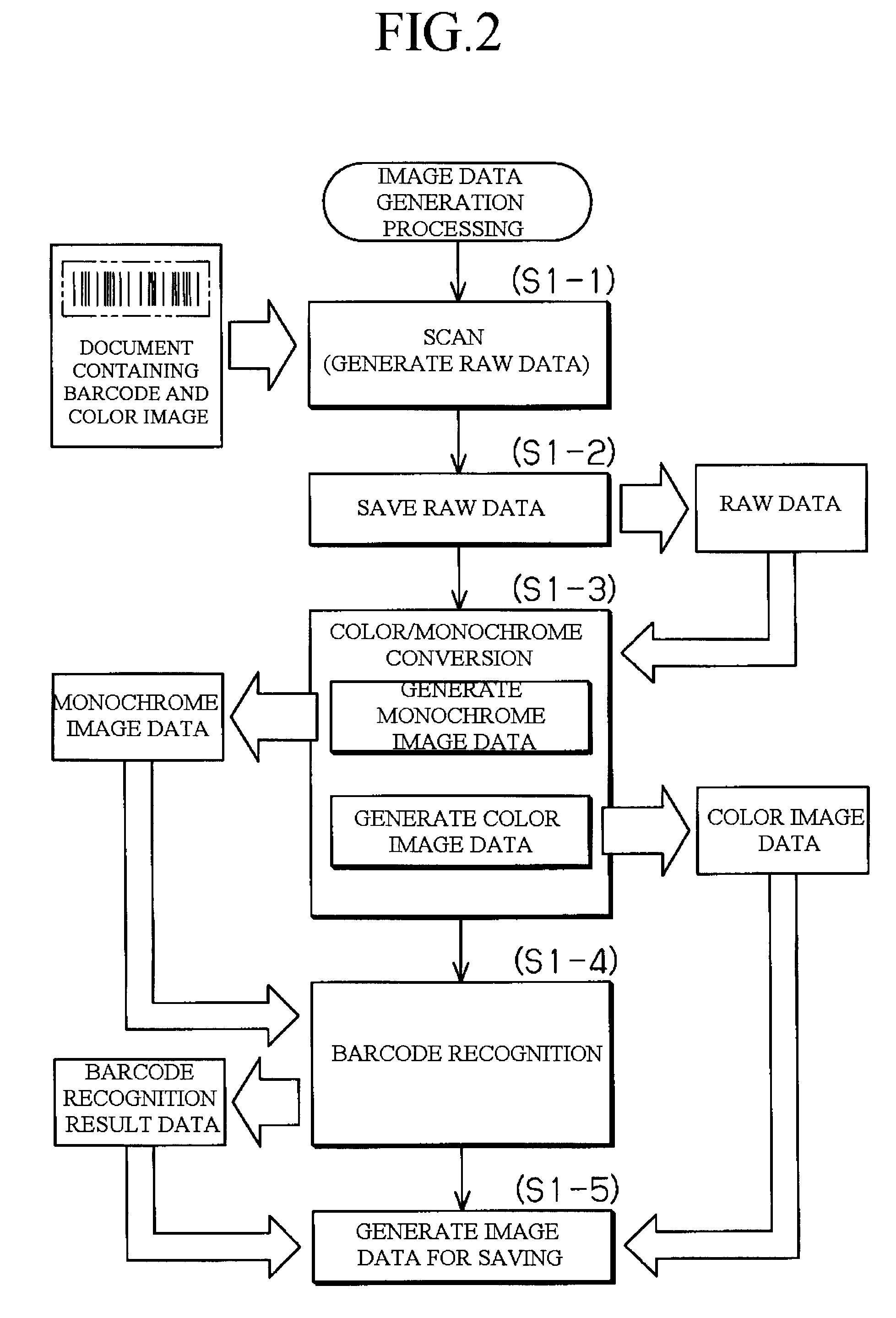

Image data generating device, image data generating method, and computer-readable storage medium

InactiveUS20080309960A1Accurate collectionAccurate identificationCo-operative working arrangementsPictoral communicationPattern recognitionMonochromatic color

Upon receiving a scan command via an operation panel 22, the controller 21 of a multi-function device 20 activates a scanner 23 and generates RAW data, the RAW data being recorded to a hard disk memory 24. The controller 21 then generates monochrome image data and color image data from the RAW data. From the generated monochrome image data, the controller 21 conducts recognition processing on a barcode contained in the scanned original to acquire barcode recognition result data. The controller 21 then associates the barcode recognition result data to the generated color image data as the filename thereof to generate image data for saving. The image data for saving is then recorded to the hard disk memory 24.

Owner:RICOH KK

Fast-scanning SPM scanner and method of operating same

ActiveUS8166567B2Increased focus rangeImage data is accurateNanotechnologyMechanical roughness/irregularity measurementsHigh bandwidthImage resolution

A high-bandwidth SPM tip scanner is provided that additionally includes an objective that is vertically movable within the scan head to increase the depth of focus for the sensing light beam. Movable optics also are preferably provided to permit targeting of the sensing light beam on the SPM's probe and to permit the sensing light beam to track the probe during scanning. The targeting and tracking permit the impingement of a small sensing light beam spot on the probe under direct visual inspection of focused illumination beam of an optical microscope integrated into the SPM and, as a result, permits the use of a relatively small cantilever with a commensurately small resonant frequency. A high-bandwidth tip scanner constructed in this fashion has a fundamental resonant frequency greater than greater than 500 Hz and a sensing light beam spot minor diameter of less than 10 μm. Images can be scanned on large samples having a largest dimension exceeding 7 mm with a resolution of less than 1 Angstrom and while scanning at rates exceeding 30 Hz.

Owner:BRUKER NANO INC

Imaging device, image processing method, and recording medium

InactiveUS7359549B2Small sizeImprove compression efficiencyCharacter and pattern recognitionSignal generator with single pick-up deviceColor planeImaging data

An image processing method includes obtaining raw image data of an object by generating the object by an imager that generates an image of the object with color decomposition, decomposing the raw image data into a plurality of color planes such that each of the color planes comprises pixel information of a color pertinent to the color plane, and compressing data of each color plane.

Owner:RICOH KK

Image processing method, correction-value acquiring method, and printing method

InactiveUS20060262330A1Image data is accurateDigitally marking record carriersDigital computer detailsImaging processingPaper document

An image processing method, includes: a first reading step of reading, as image data, a scale with a scanner; a second reading step of reading, as image data, a document with the scanner; and a correction step of correcting the image data of the document using the image data of the scale.

Owner:SEIKO EPSON CORP

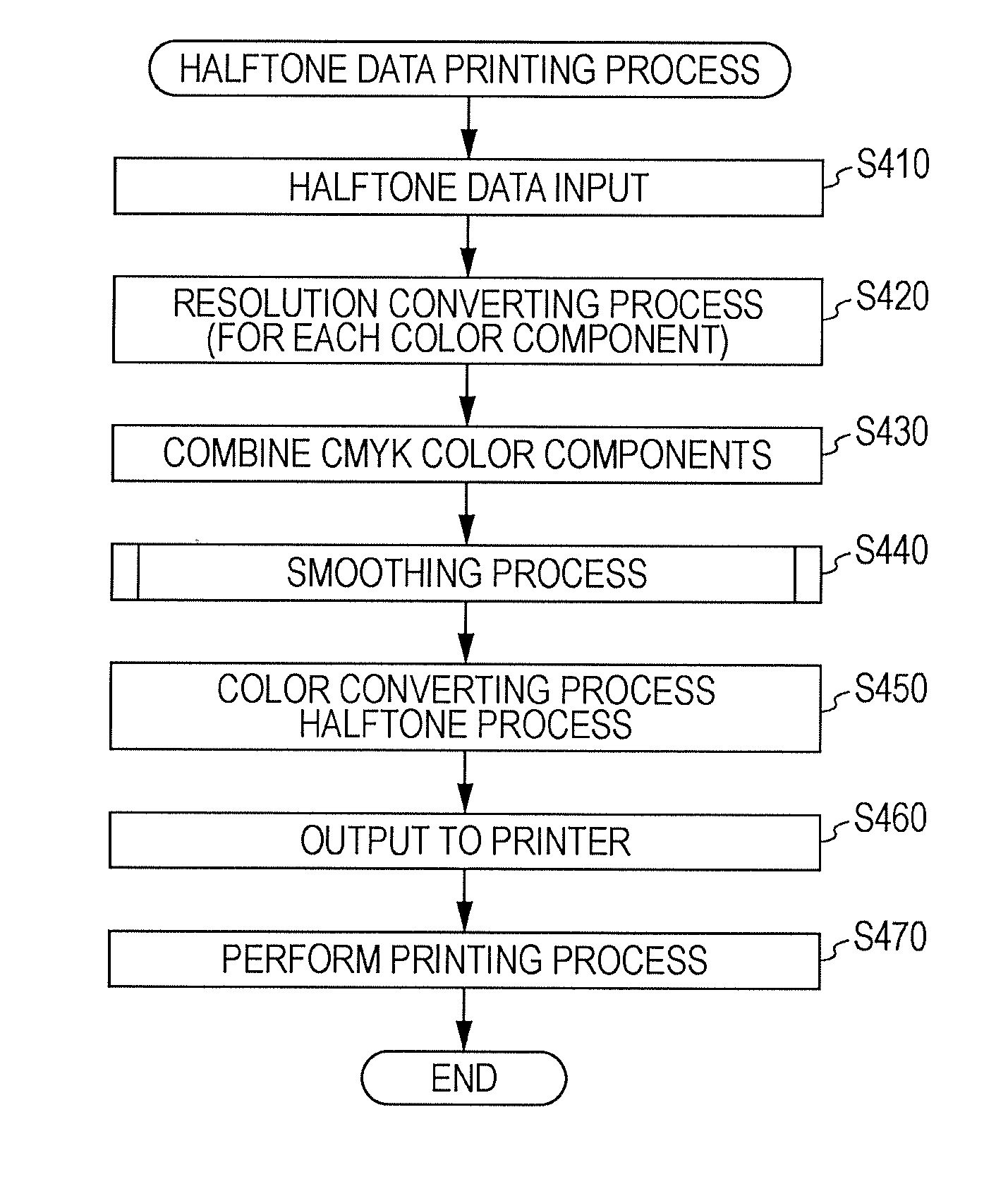

Ink jet printing apparatus and printing method

InactiveUS20100259791A1Image data is accurateVisual presentationPictoral communicationColor toneInkjet printing

Provided is an ink jet printing apparatus capable of printing halftone image data representing a halftone image including at least color components of cyan, magenta, and yellow, the ink jet printing apparatus including: an input unit which is used to input the halftone image data; a smoothing unit which creates smoothing image data by performing a smoothing process only on the yellow component in the halftone image data or performing a smoothing process having a smoothing degree relatively stronger than those of other color components on the yellow component; and a printing control unit which controls execution of a printing process on the basis of the smoothing image data.

Owner:SEIKO EPSON CORP

Food data analysis method based on cloud computing

InactiveCN107273886AUnderstand the processImprove supervisionCharacter and pattern recognitionComputer terminalMulti aspect

The invention belongs to the field of food inspection technology, and discloses a food data analysis method based on cloud computing. The food data analysis method based on the cloud computing includes the steps of photographing information of a food production process by a camera unit; processing, by a processing unit, information transmitted by the camera unit; the processing unit identifying the information through a built-in image identification and determination module; transmitting the processing unit information to a monitoring unit through a wireless routing unit; the monitoring unit monitoring the information transmitted by the routing unit through a network cloud server; sending out a warning prompt on illegal information; and carrying on multi-aspect control through data sharing between the network cloud server and the monitoring unit by using a mobile terminal. According to the invention, the supervision is greatly enhanced, a more accurate understanding of the processing process of a factory is gained, the processing process is more transparent, opportunistic and irregular production methods are eliminated, and black-hearted manufacturers are also restrained from producing harmful foods; and at the same time, the examination work is better facilitated.

Owner:湖北泰拓物联科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com