Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "High precision inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

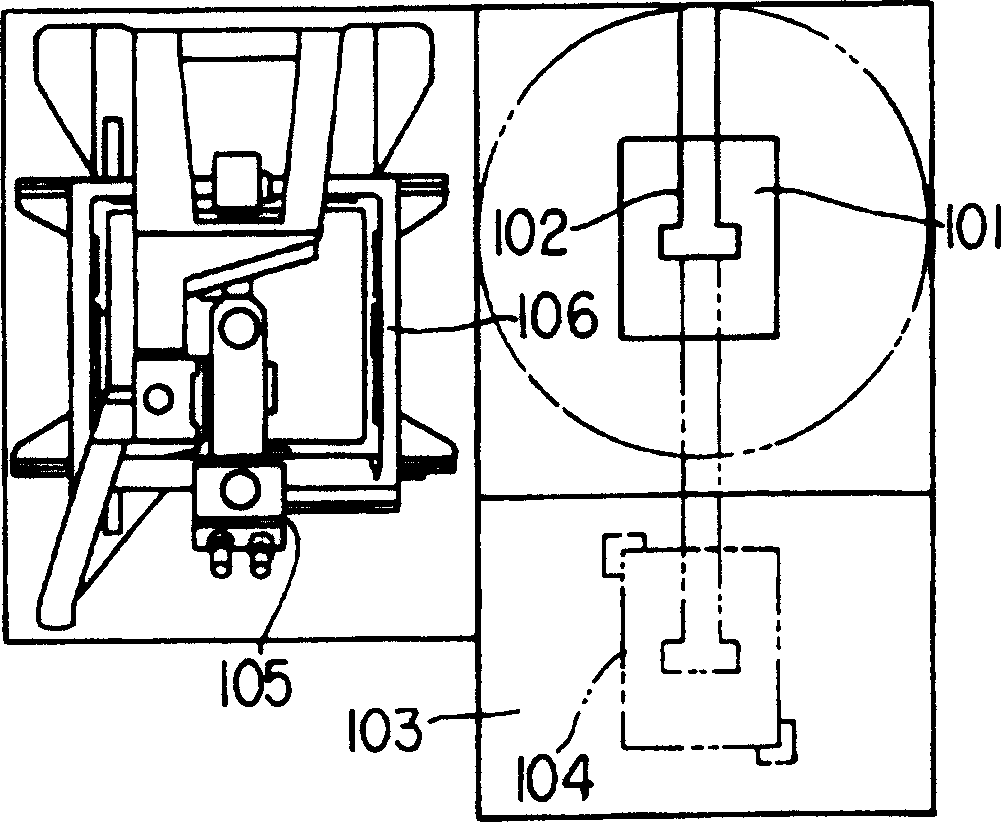

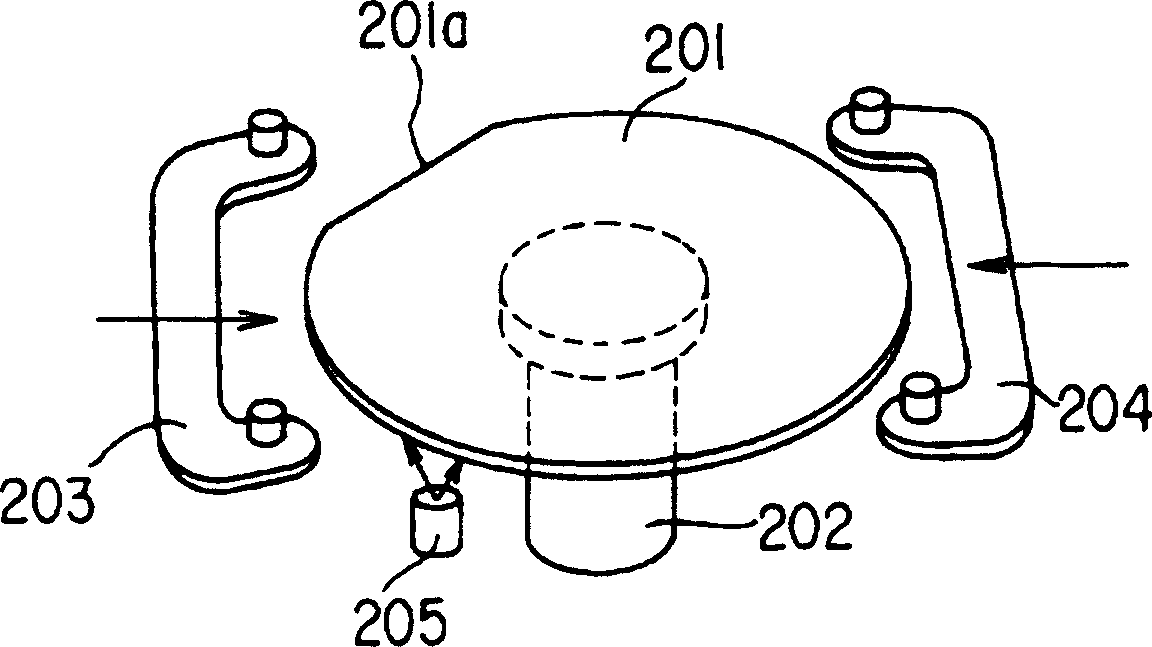

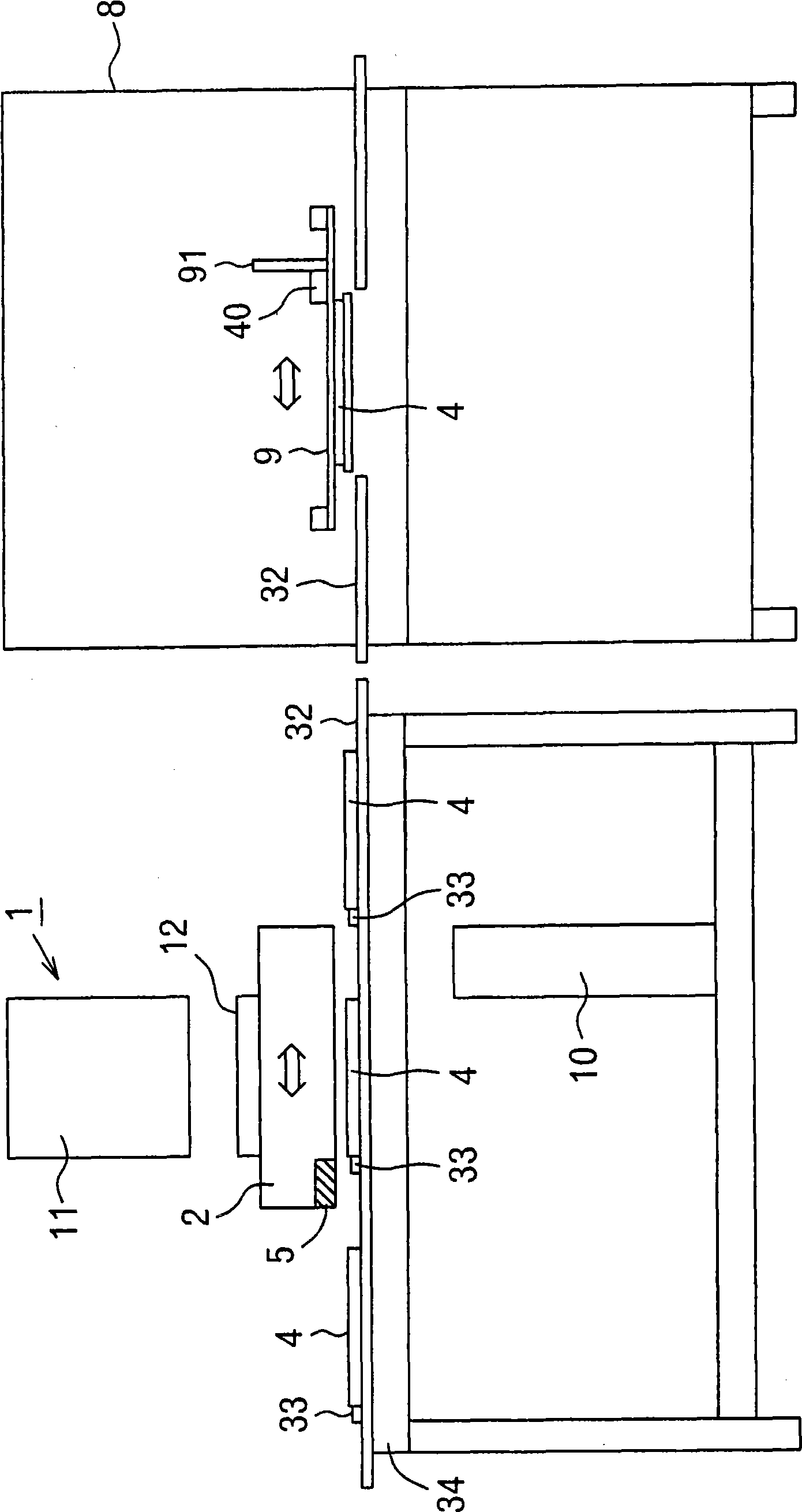

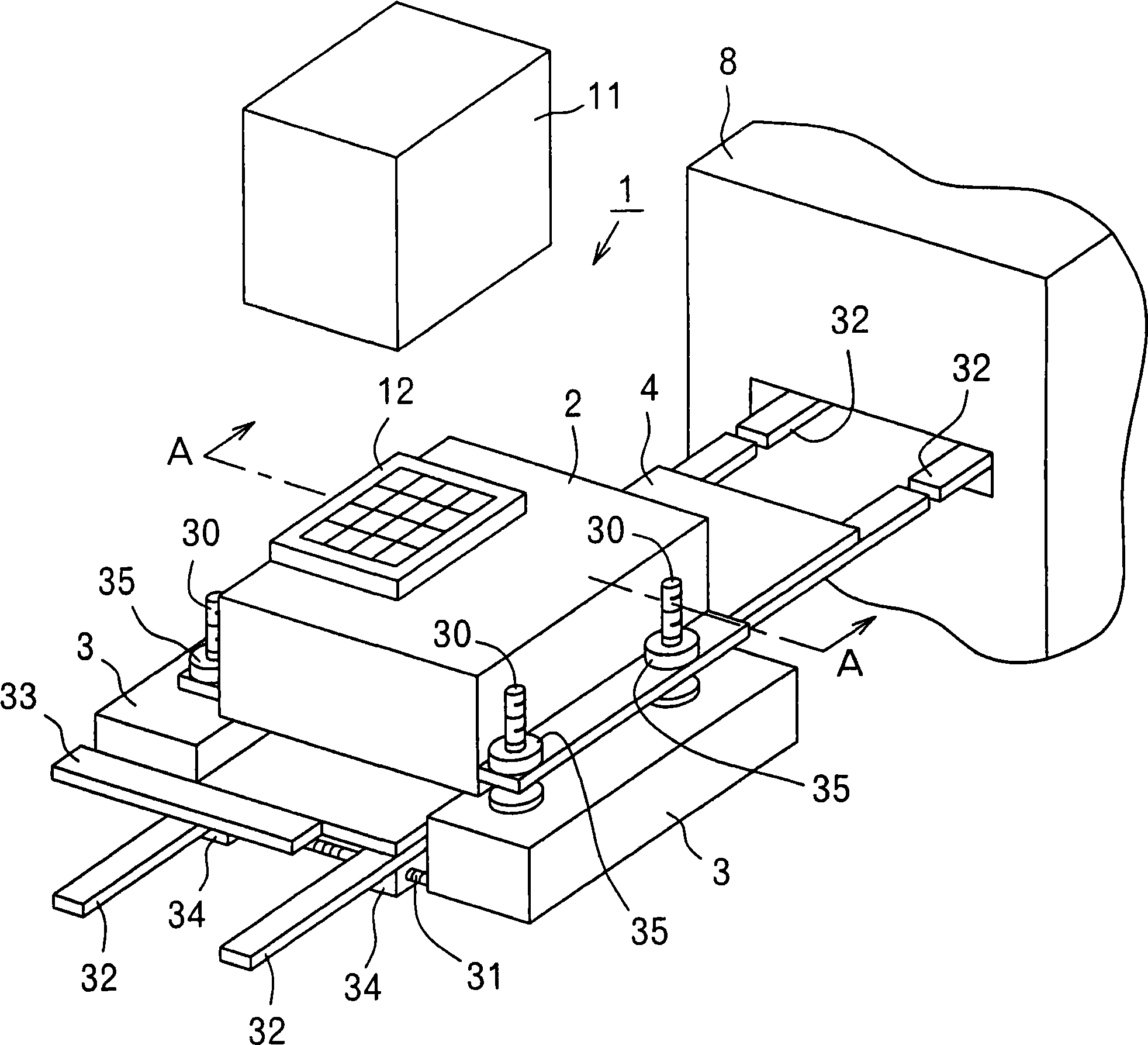

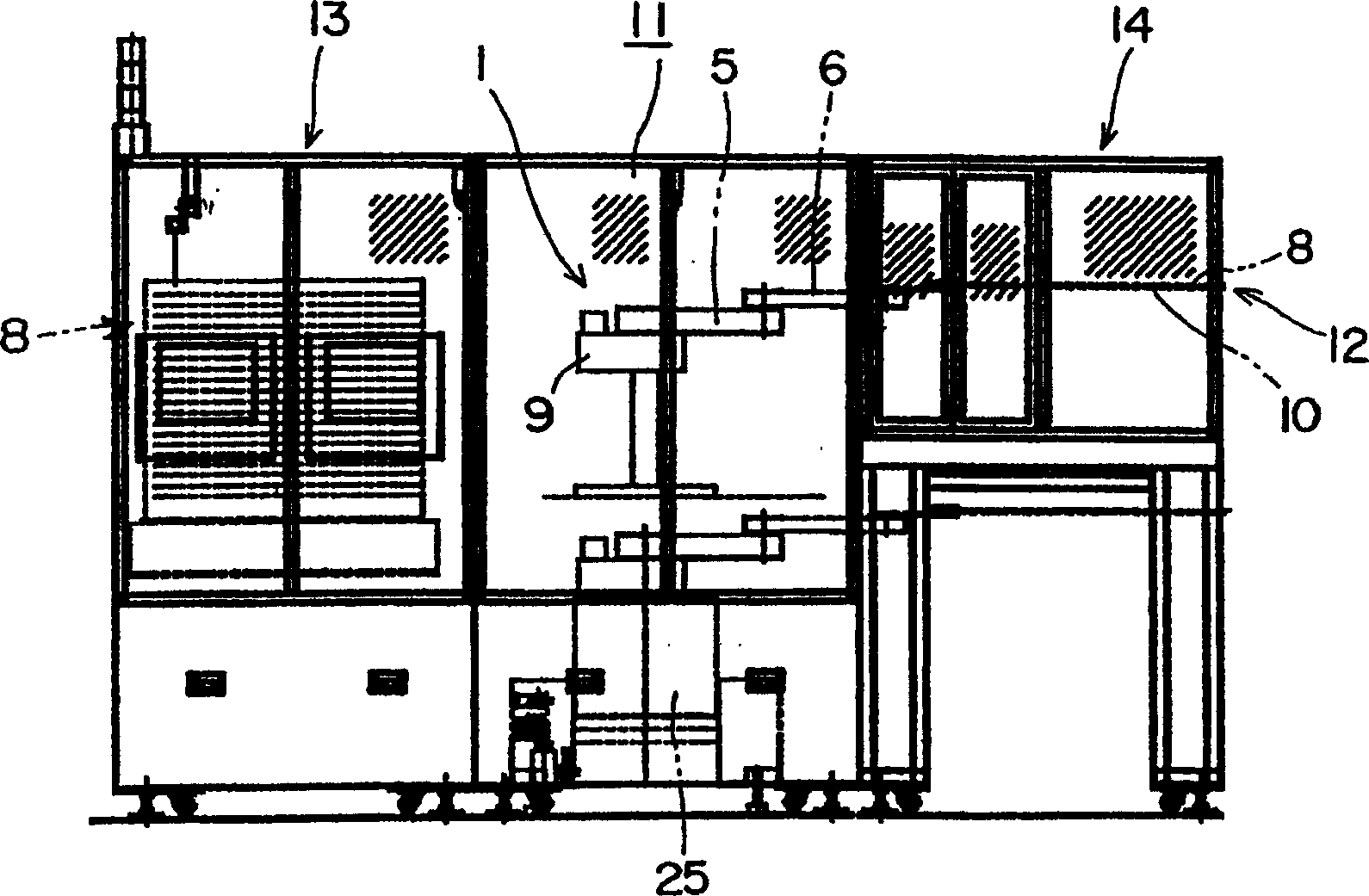

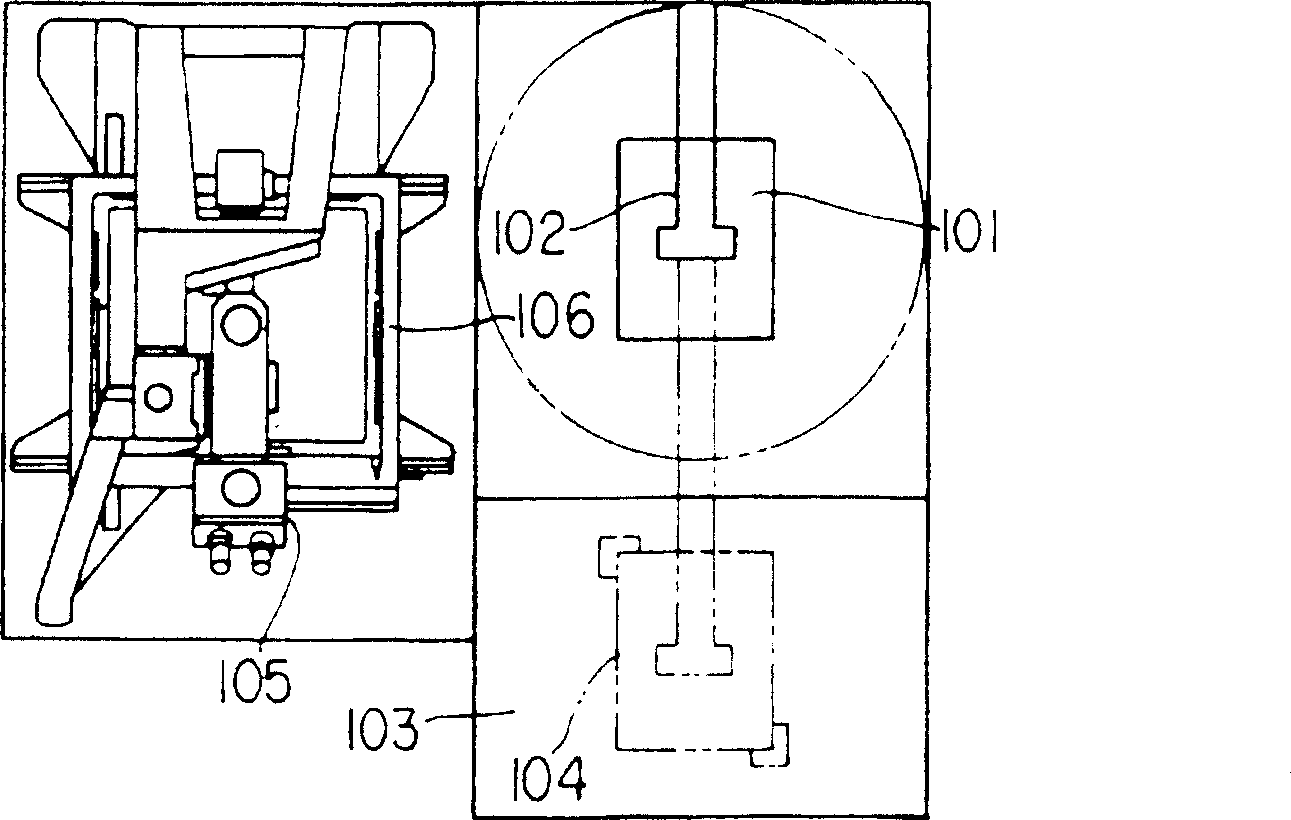

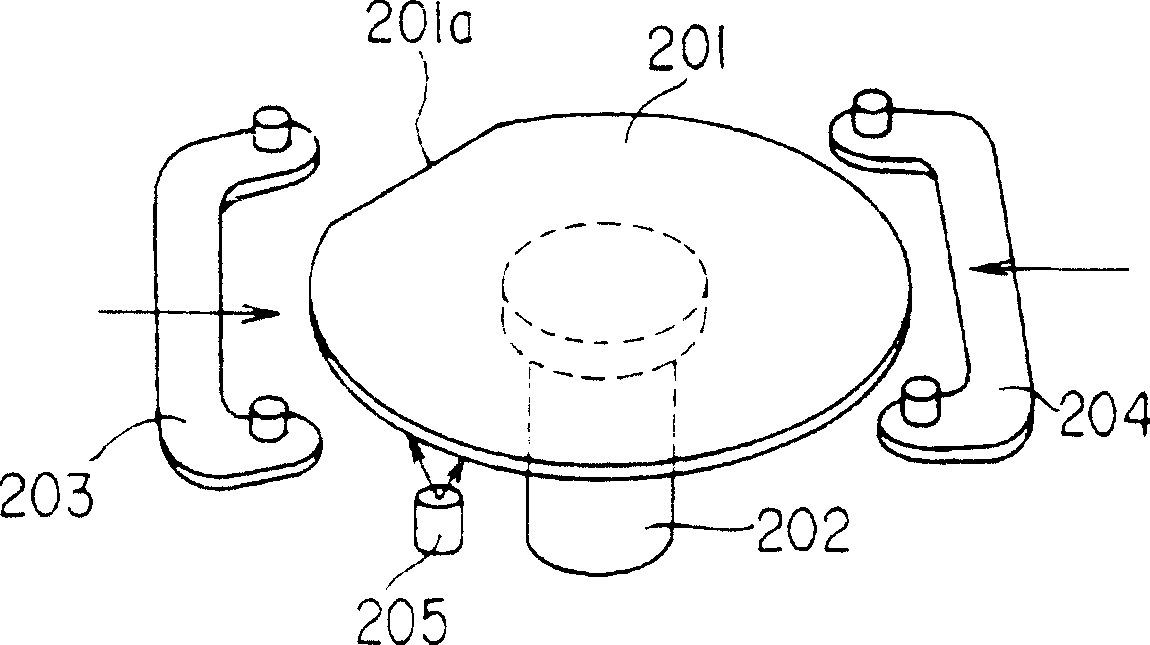

Chip check apparatus

InactiveCN1503340AThe equipment is compactLarge areaSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMicroscopeMechanical engineering

To provide a wafer inspection device which can realize an efficient configuration for suppressing an increase in footprint and can inspect a wafer with high accuracy.The wafer inspection device has a cassette part 2 and a wafer inspection part 3 including a microscope 6 and an XY stage 7 for moving the wafer 10. The cassette part 2 comprises a cassette 4 for holding the wafer 10 and an elevator 5. The wafer inspection part 3 comprises a carrying arm 18 that is arranged on the XY stage 7 to insert / extract the wafer 10 by arm pieces 181, 182 which can linearly move toward an opening of the cassette 4 and can be inserted between wafers 10 in the cassette 4, and a wafer rotary mounting base 22 which is vertically movable above the XY stage 7 to carry-in / carry-out the wafer to the carrying arm 18 by the vertical movement, a centering means for making the center of the wafer 10 and the rotary center of the wafer rotary mounting base 22 coincide with each other, and a detecting means for detecting the orientation of the wafer. (C)2004,JPO.

Owner:OLYMPUS CORP

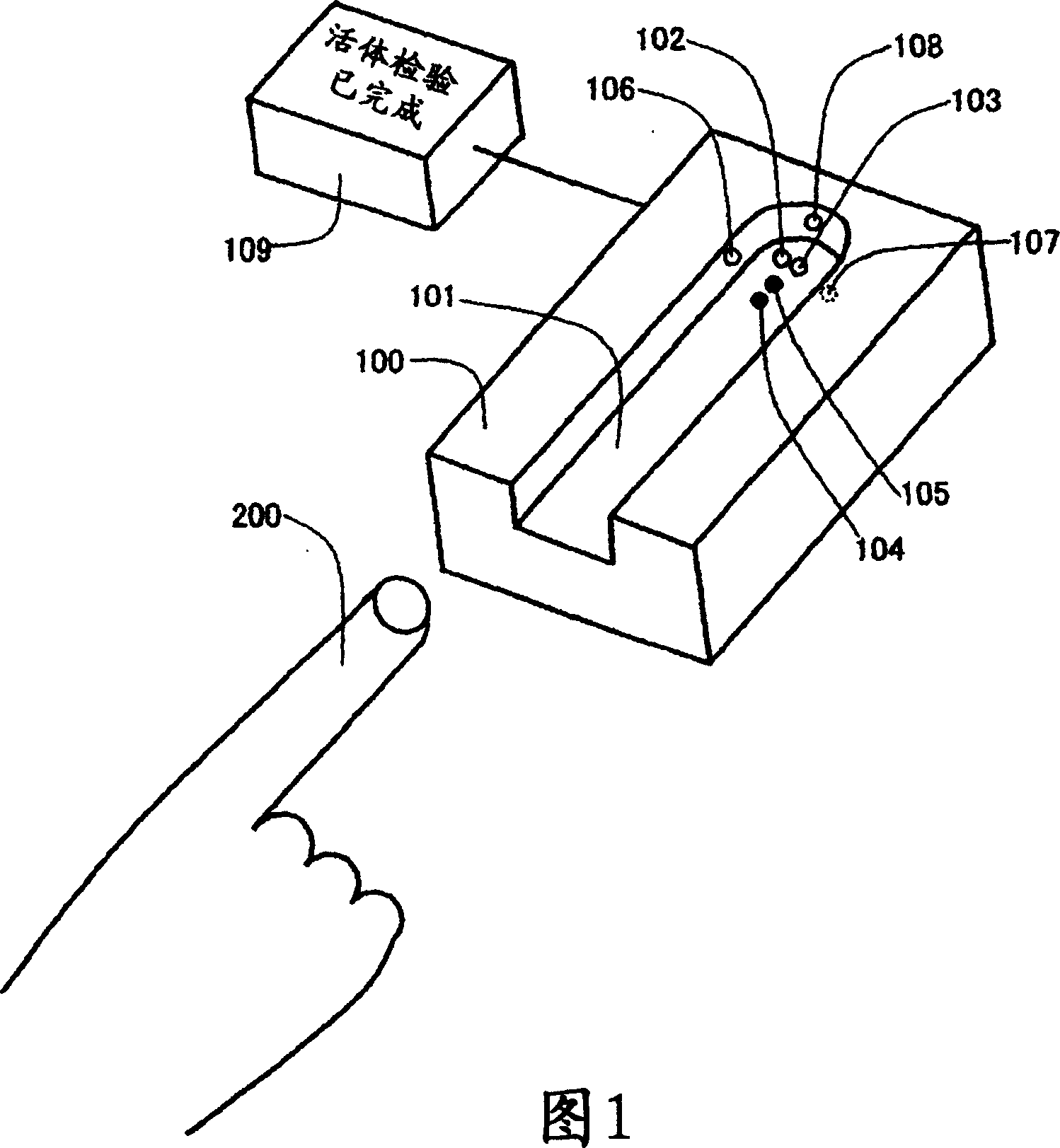

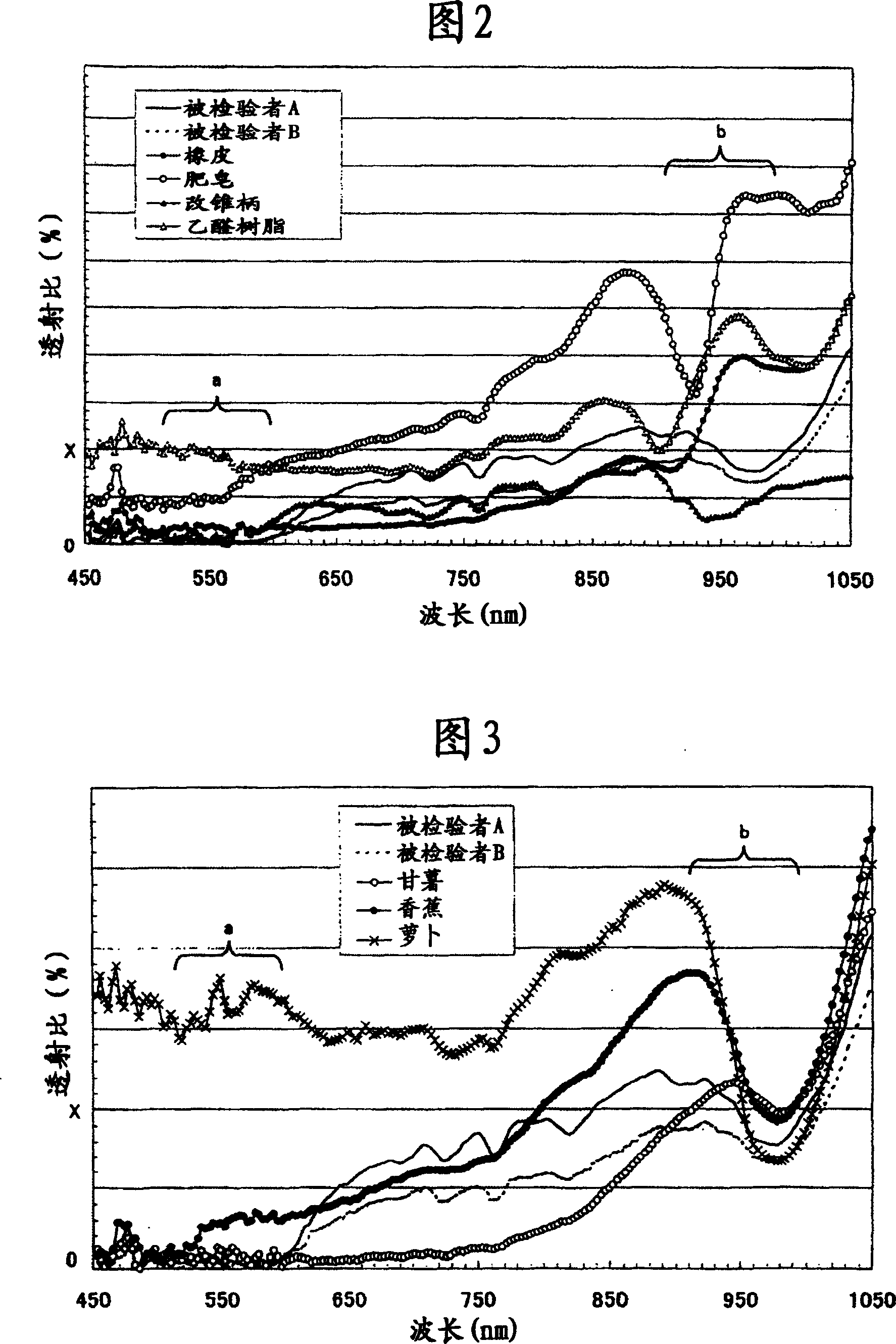

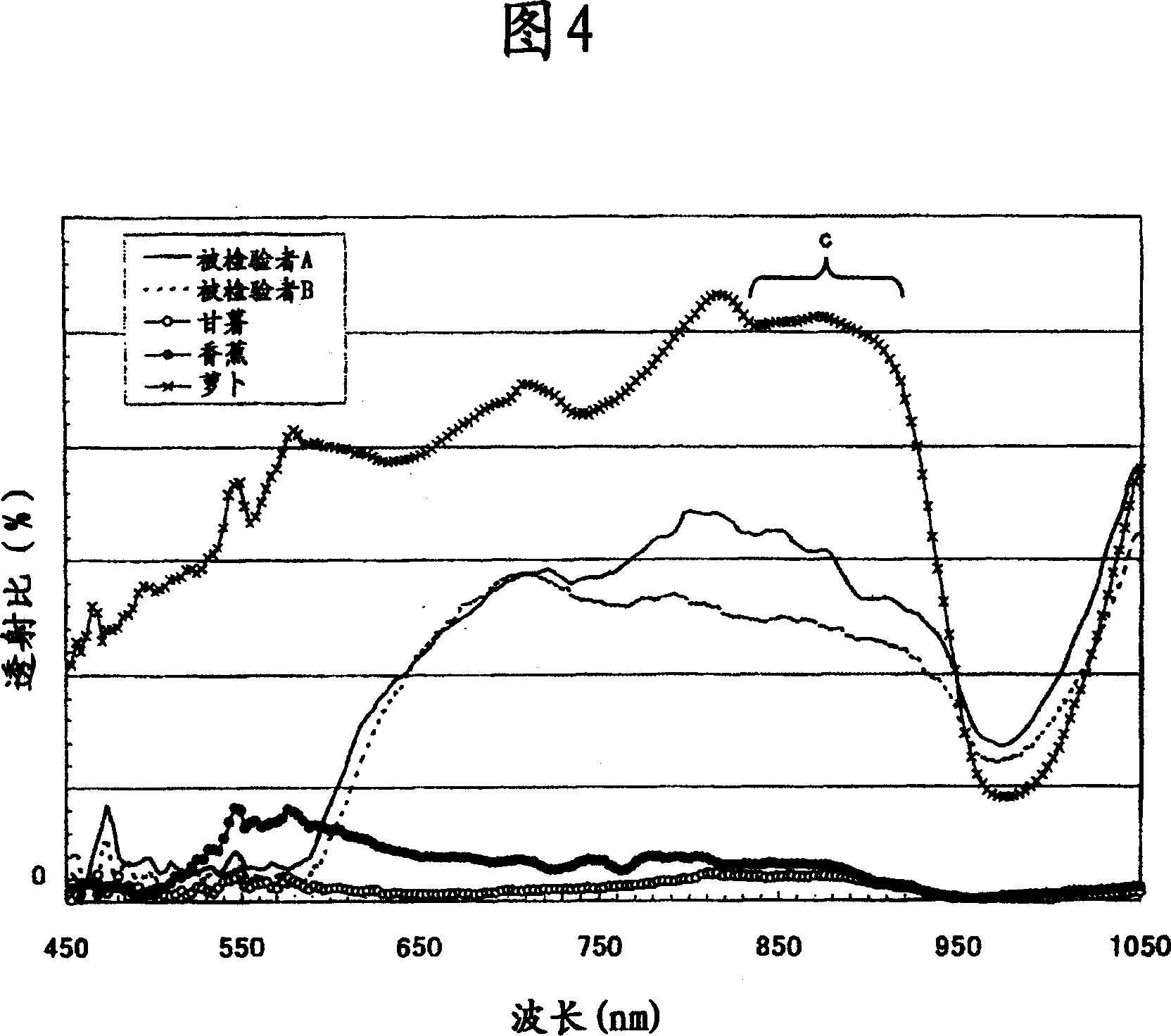

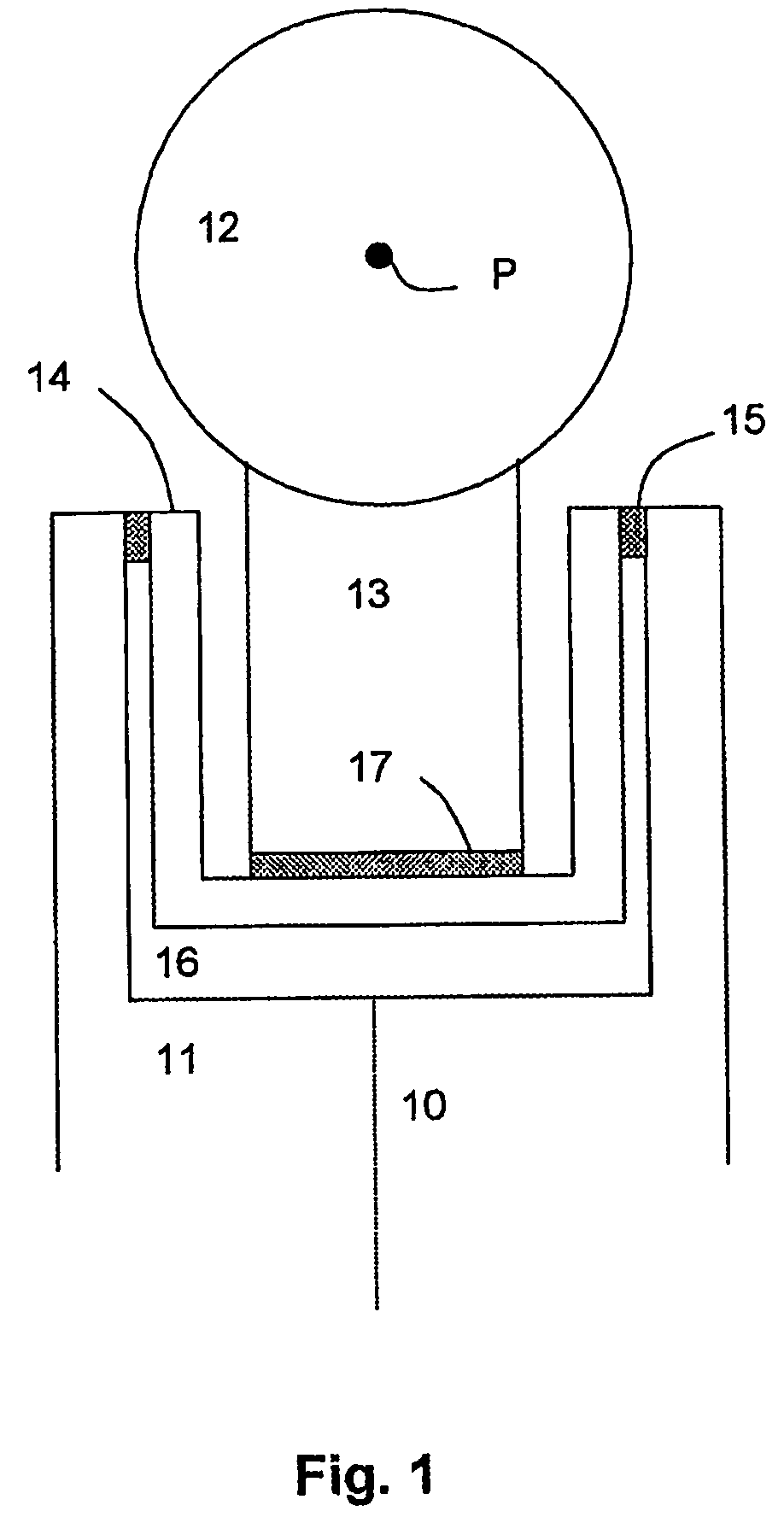

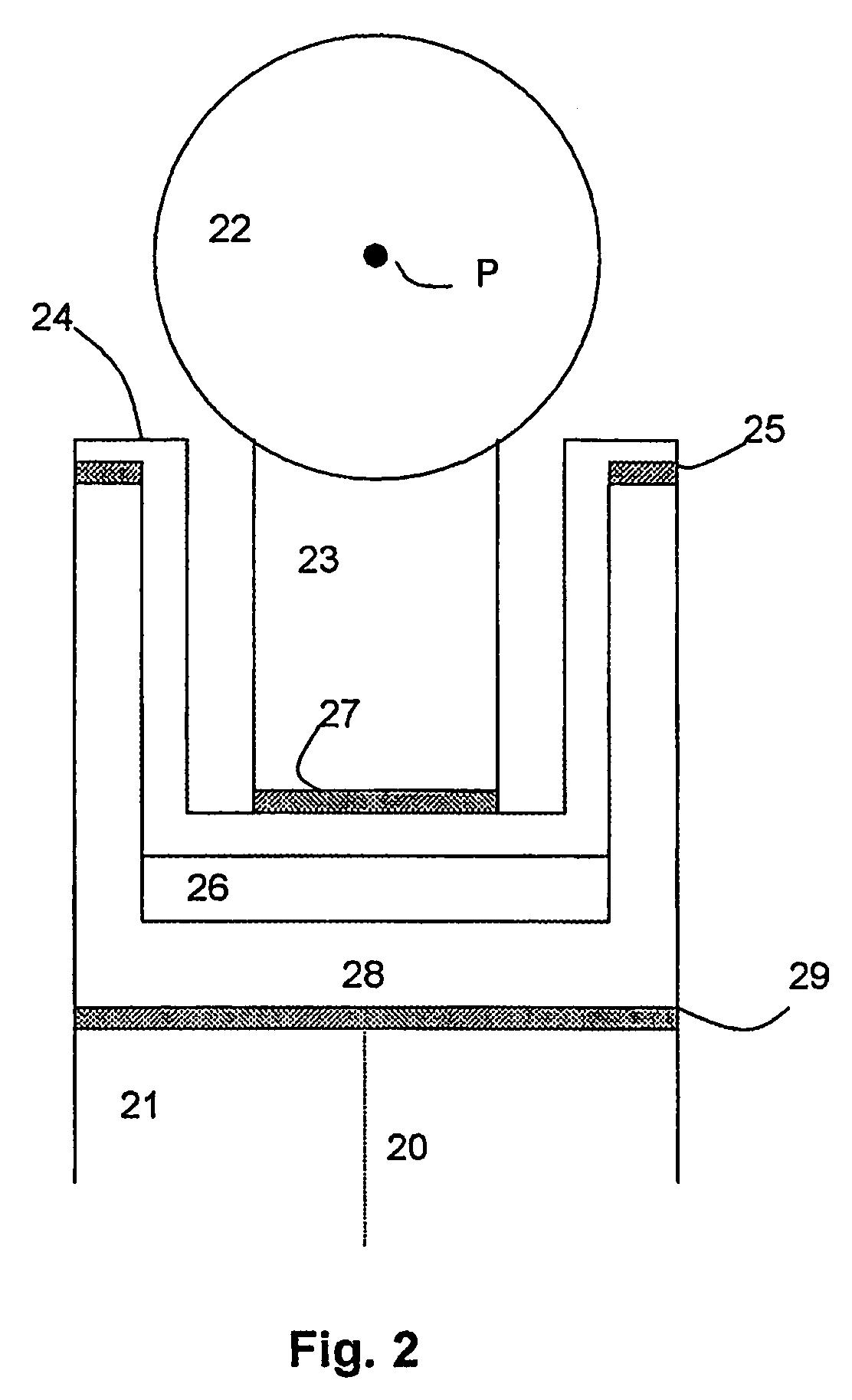

Biometric identification apparatus

InactiveCN101120879AHigh precision inspectionDiagnostics using lightPerson identificationTransmittanceLength wave

A biometric identification apparatus that can accurately and rapidly perform liveness detection with a simple structure. [Solution] The apparatus includes a plurality of light sources 102, 103, 106 , and 107 , each having a wavelength different from one another, for emitting light to a finger 200 as an object to be identified, and receivers 104 and 105 for detecting the light passing through the finger. The ratio of the light emitted from the light sources to the light detected with the receivers is obtained as transmittance. Determination in liveness detection is made by comparing the transmittance with a previously-set threshold of transmittance.

Owner:HITACHI MEDIA ELECTORONICS CO LTD

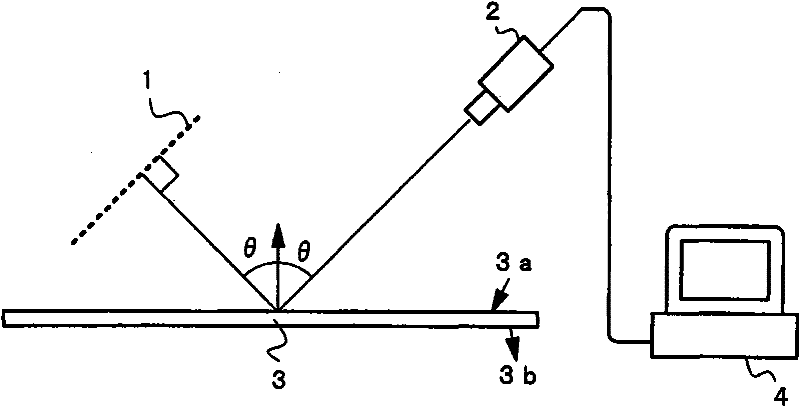

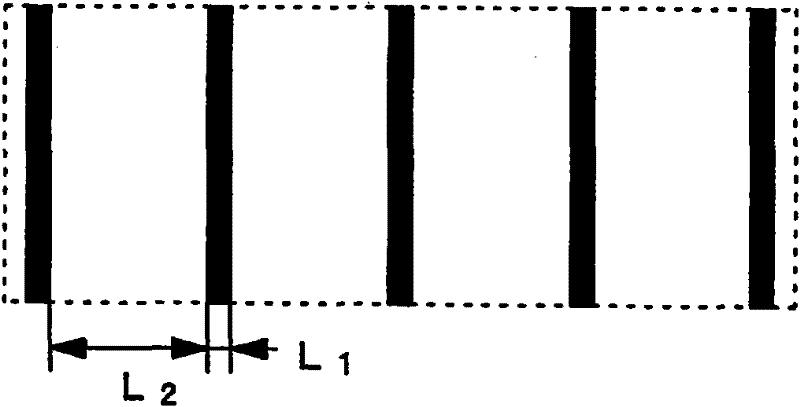

Detecting method and detecting device for surface shape

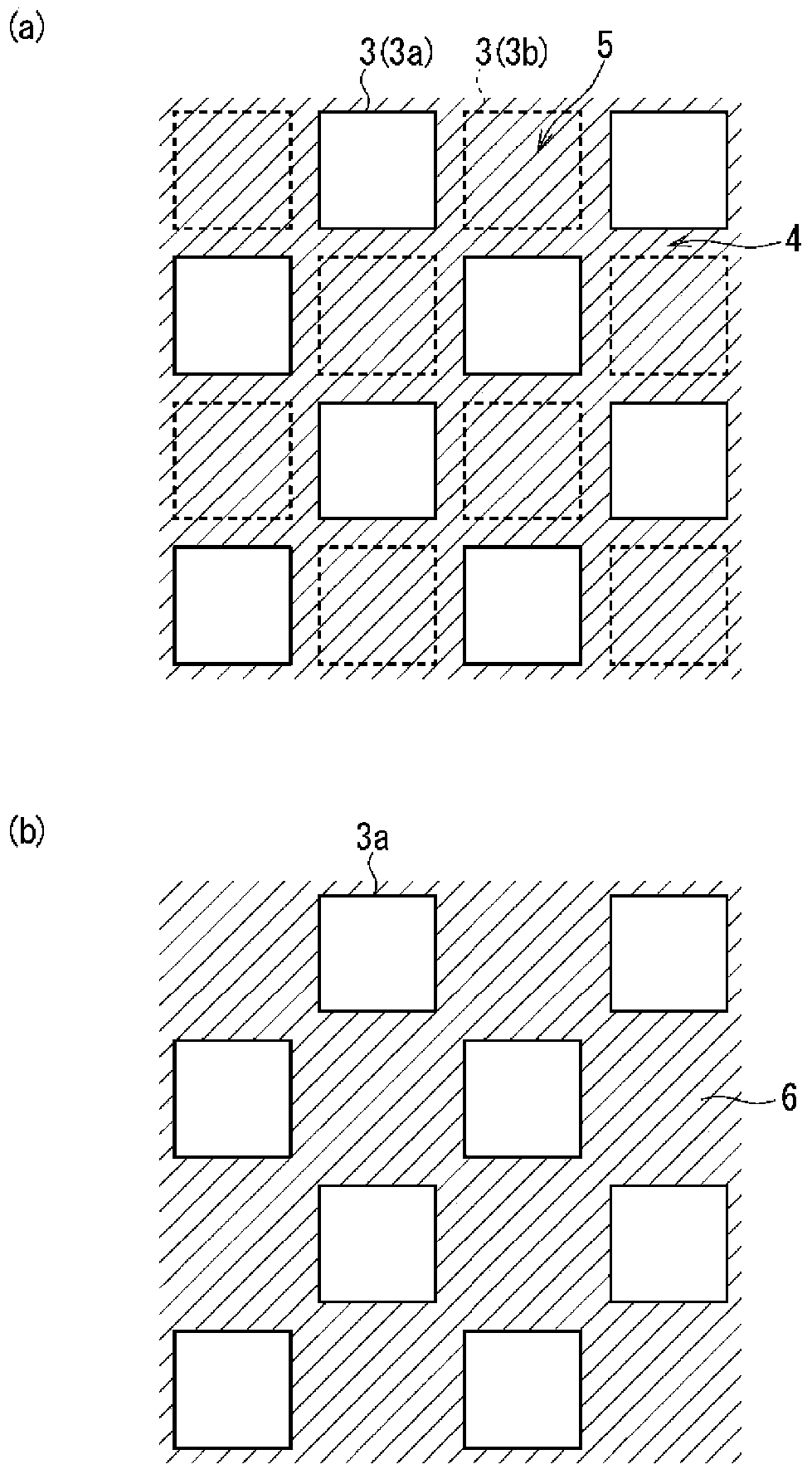

The invention provides a detecting method and a detecting device, which can remove the influences of back reflected image and detect the characteristics of surface shape with a high precision by a cheap device structure. The detecting method comprises the steps that: firstly, stripes applicable for a transparent plate-shaped body (3) (a detected object) are determined to be set in a separating manner in image signals which are acquired by photographing reflected images formed on the surface of the transparent plate-shaped body and the reflected images formed on the back surface of the transparent plate-shaped body; then, the determined stripes (1) are used, and the surface shape of the transparent plate-shaped body (3) is evaluated through image analysis only by the reflected images, which are formed on the surface of the transparent plate-shaped body (3), of the stripes (1).

Owner:ASAHI GLASS CO LTD

Thermally compensated test piece for coordinate measuring machines

InactiveUS7188428B2High precision inspectionIncrease flexibilityTesting/calibration of speed/acceleration/shock measurement devicesMechanical measuring arrangementsLength variationCoordinate-measuring machine

Owner:METRONOM

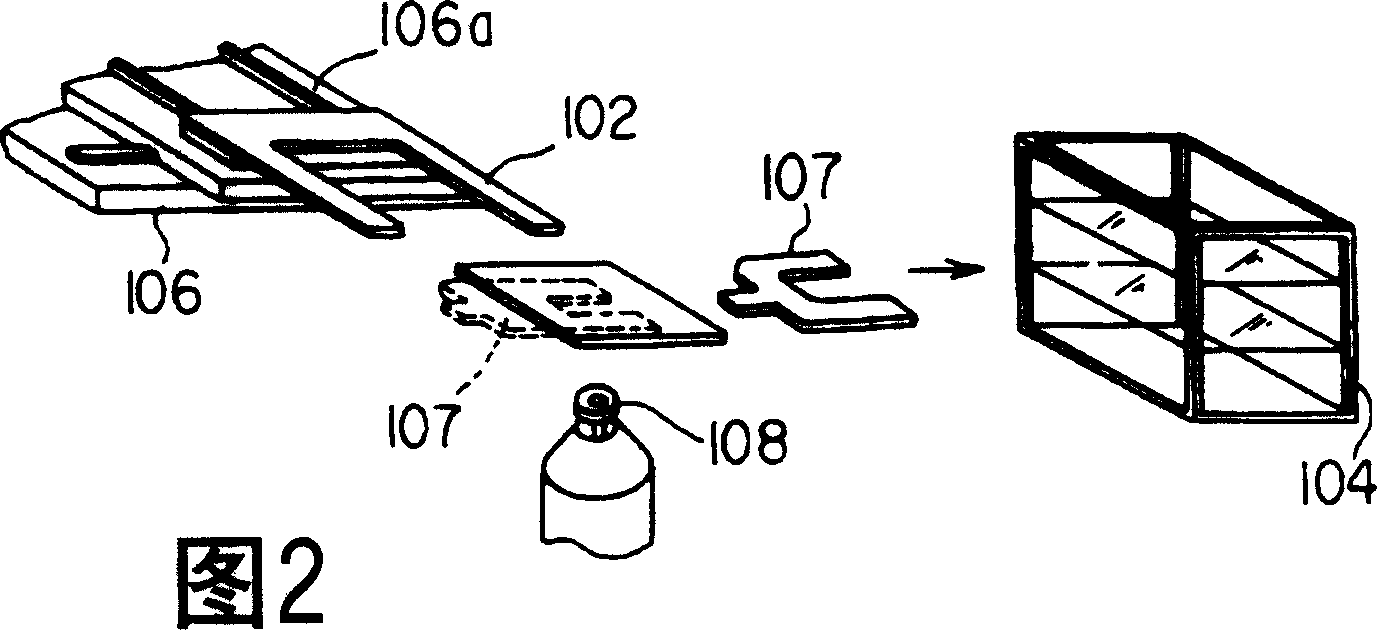

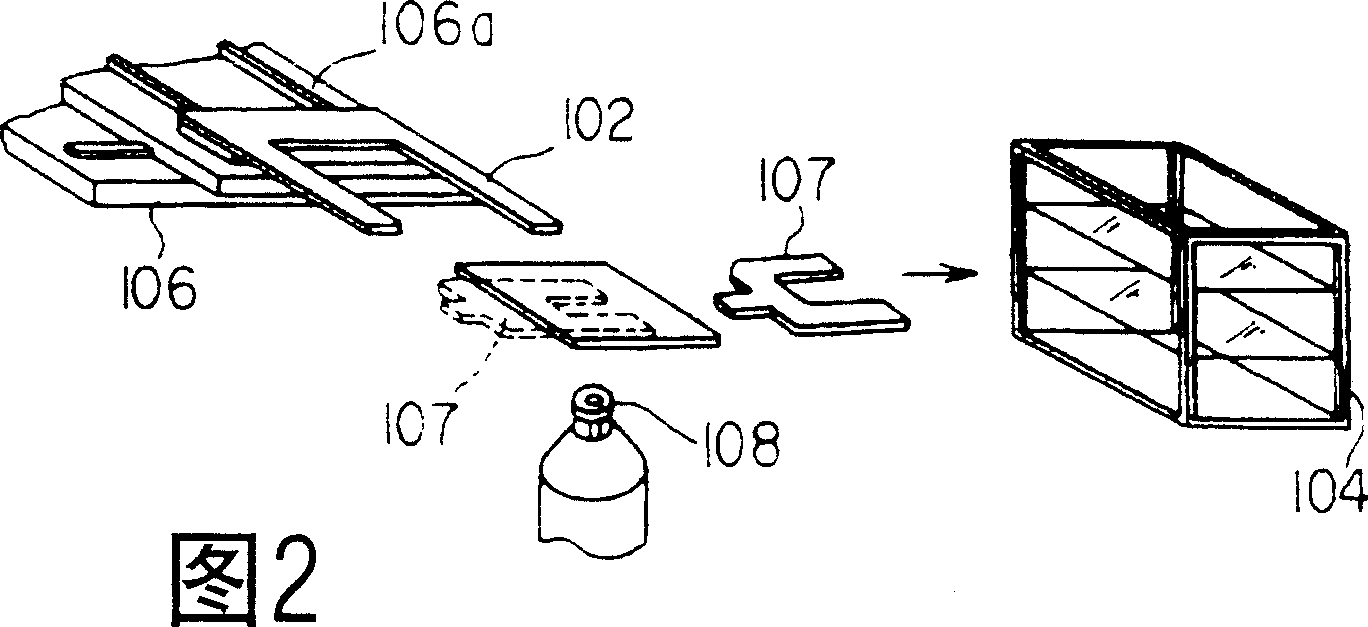

Box-manufacturing device

InactiveCN101549571ALow costReduce excess spaceBox making operationsPaper-makingIndustrial engineering

Owner:DAC ENG

Ceramic body defect inspecting device and defect inspecting method

ActiveCN109923402AReliable detectionShorten the recording timeImage enhancementImage analysisRadiation angleMechanical engineering

The invention provides a ceramic body defect inspecting device and a defect inspecting method. Around an image capturing unit which captures images of an inspection target region from a normal line direction thereof, a plurality of unit lights, which are at equiangular intervals from one another, and each of which radiates illuminating light obliquely, with the same radiation angle, toward the inspection target region from a different radiation direction, are successively turned on and off. Each time each of the plurality of unit lights is turned on, the image generating unit captures an imageof the inspection target region, thereby generating a plurality of sets of image-capture data. A determination image generating unit generates minimum brightness image data in which the minimum valueof the brightness at the same pixel position from among the plurality of sets of image-capture data is set as a brightness value at said pixel position, and generates determination image data on thebasis of the minimum brightness image data. A defect determining unit determines the presence or absence of a defect on the basis of the determination image data.

Owner:NGK INSULATORS LTD

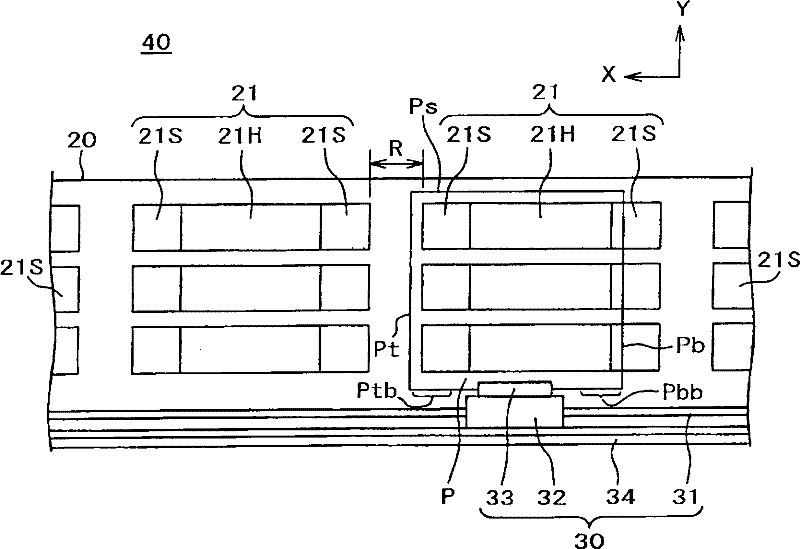

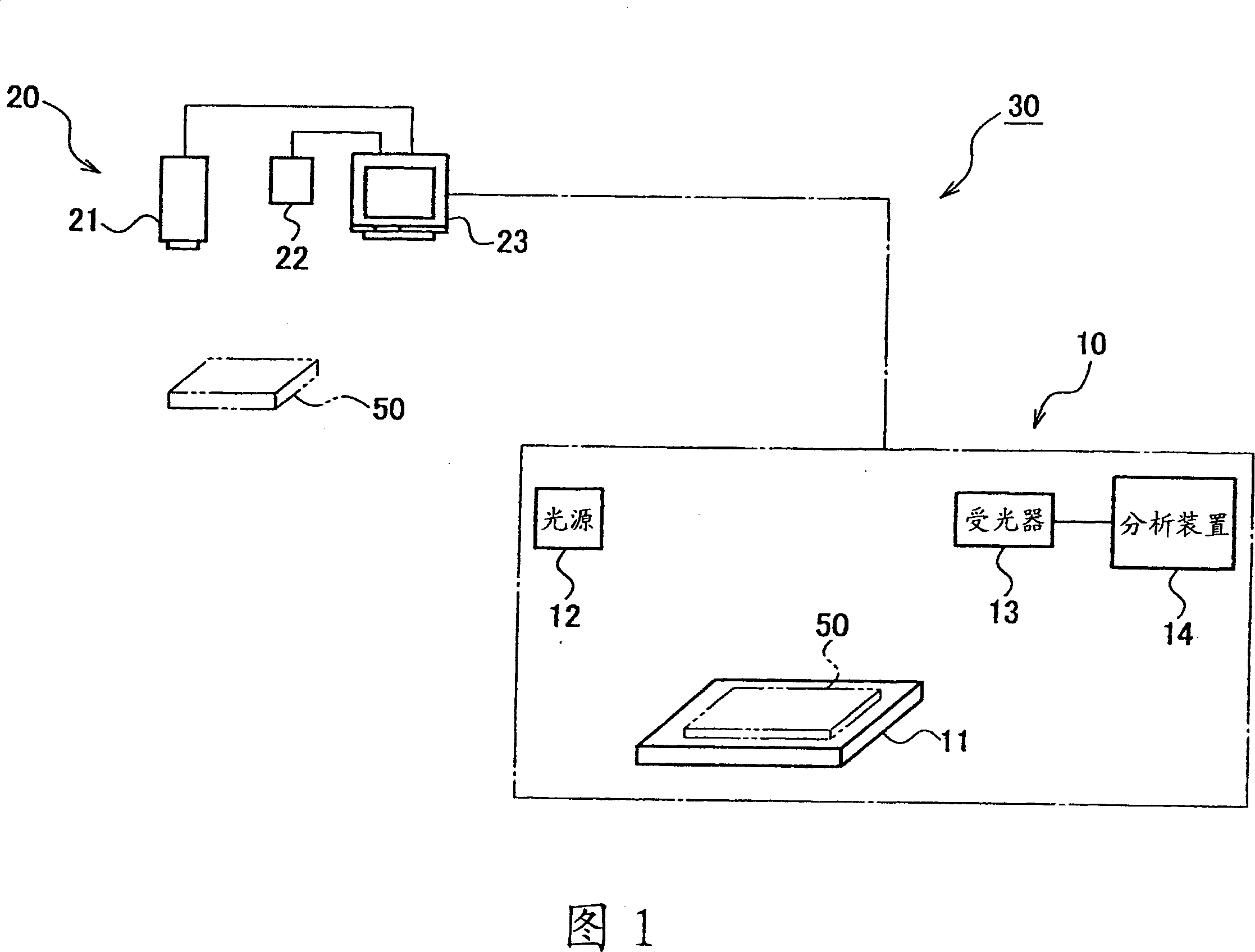

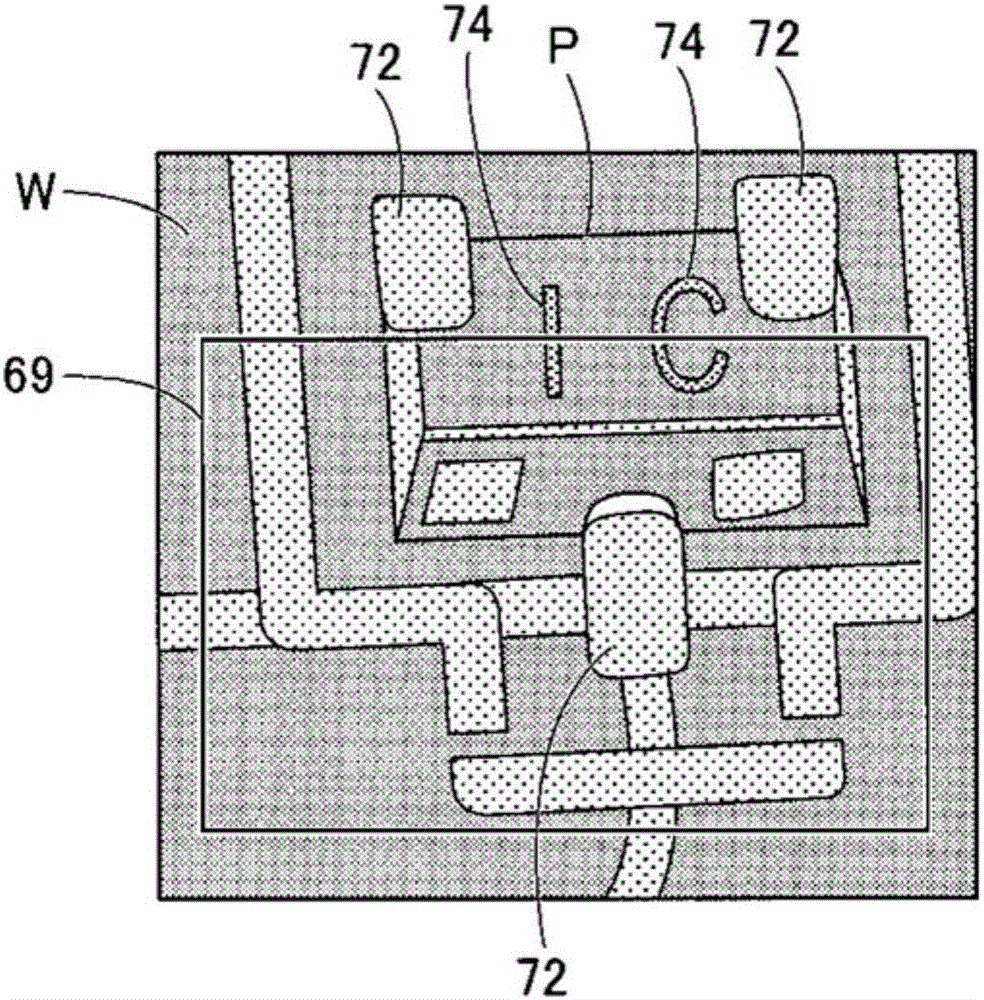

Method of inspecting an mura defect in a pattern and apparatus used for the same

InactiveCN1677097AStrong and weakUnevenness defects are clearly visibleDevices for pressing relfex pointsMaterial analysis by optical meansGraphicsRepeat pattern

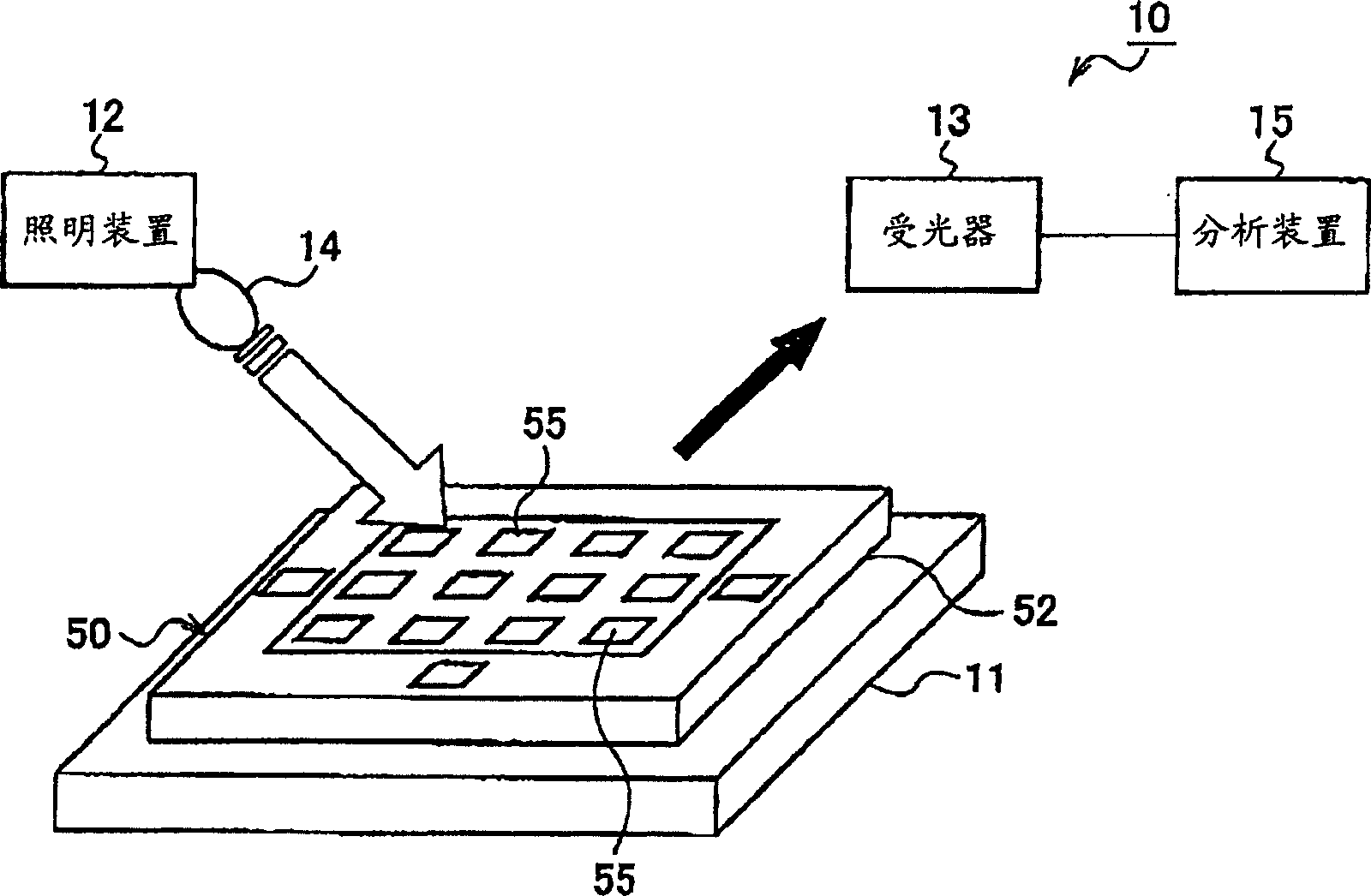

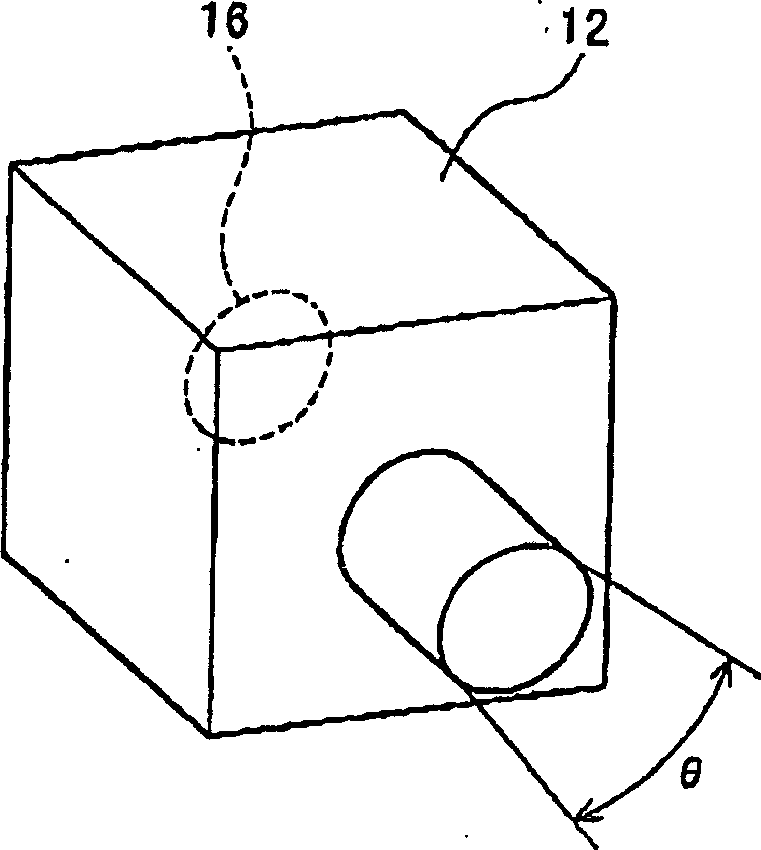

A mura defect inspection apparatus 10 having an illuminating unit 12 which irradiates light onto a photomask 50 having a chip 55 on the surface thereof, the chip is formed with a repeated pattern that a unit pattern is regularly arranged, and a photoreceptor 13 which receives scattered light generated at the edge part of the unit pattern of the repeated pattern on the chip of the photomask and converts it to received light data, wherein the received light data is analyzed to detect a mura defect generated in the repeated pattern, wherein the illuminating unit irradiates light that is emitted from an illumination light source and has a orientation property of the rays almost parallel, the light having a parallelism within an angle of 2°, for example, onto a repeated pattern 51 on the chip 55 of the photomask 50. This application claims foreign priority based on Japanese Patent application No. 2004 - 106462 , filed Mar. 31, 2004 , the contents of which is incorporated herein by reference in its entirety.

Owner:HOYA CORP

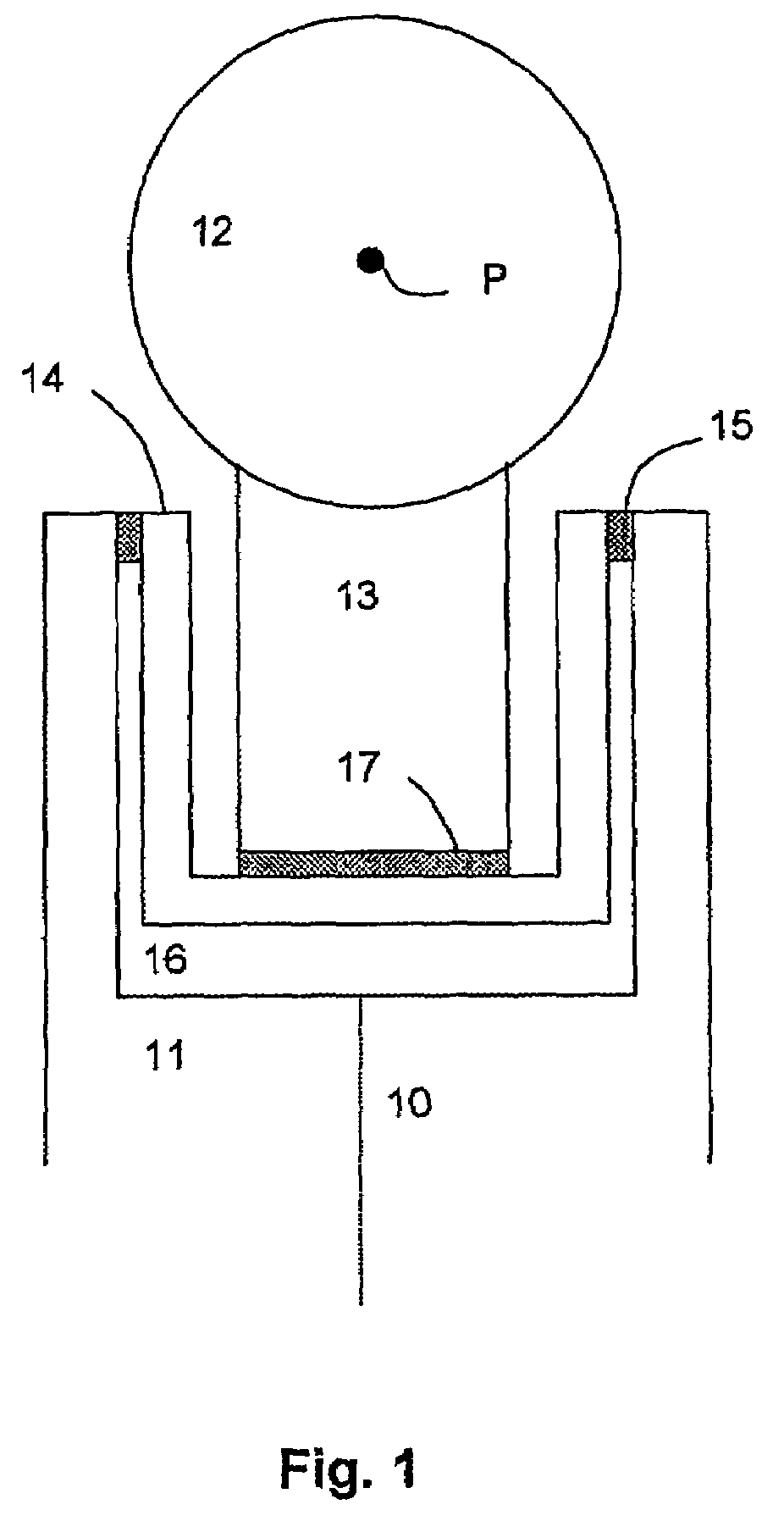

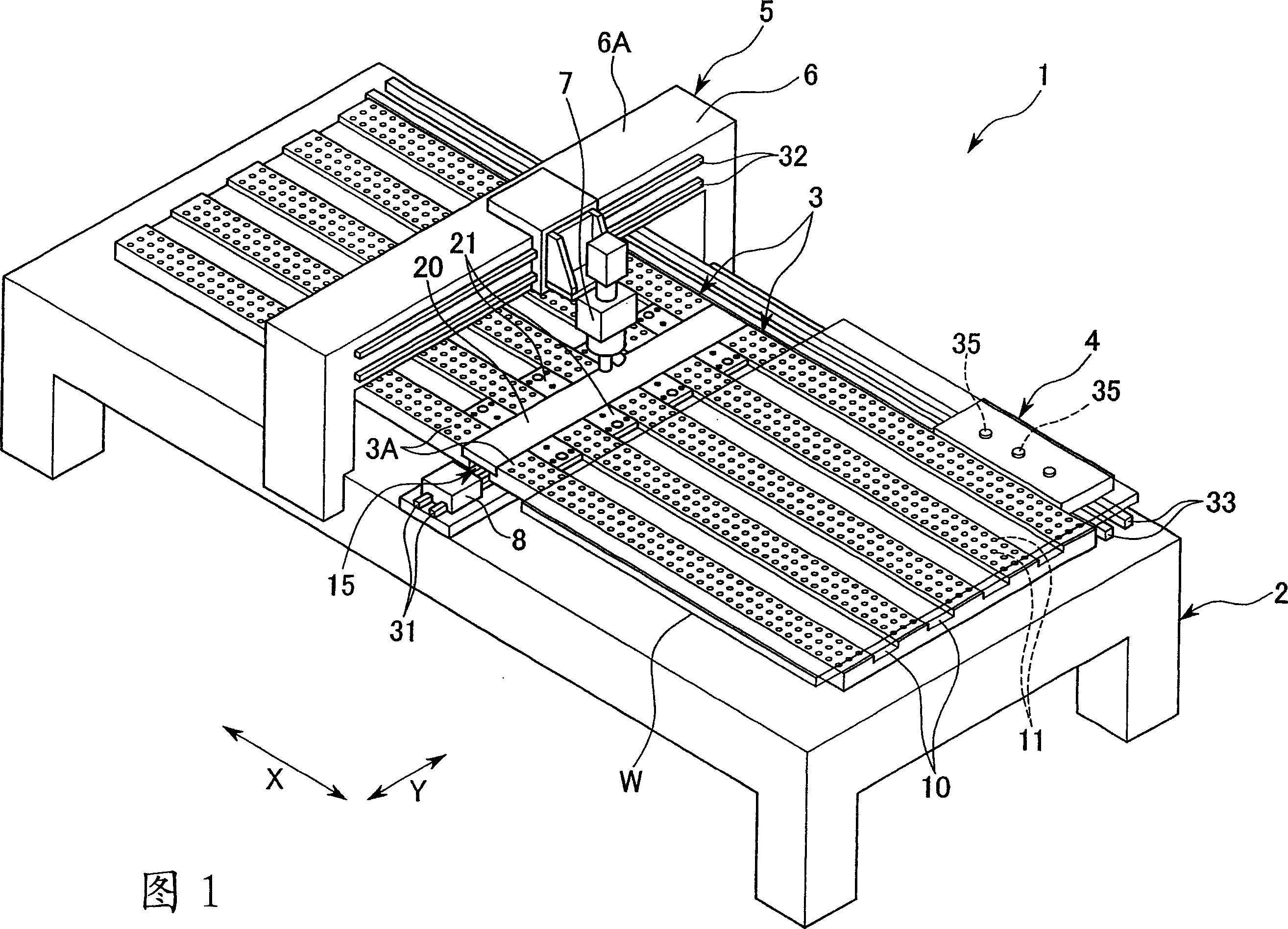

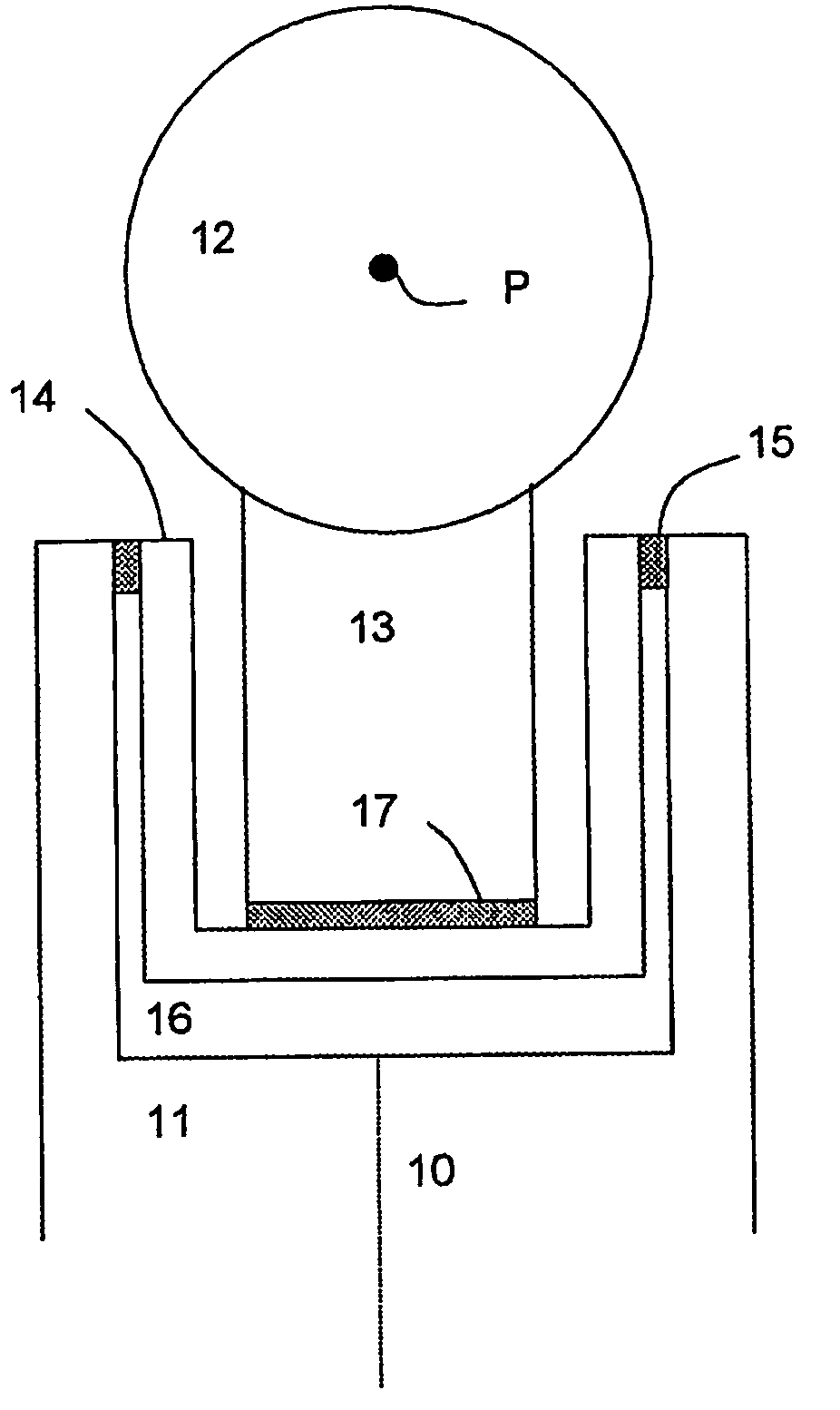

Glass substrate defect inspection device and glass substrate defect inspection method

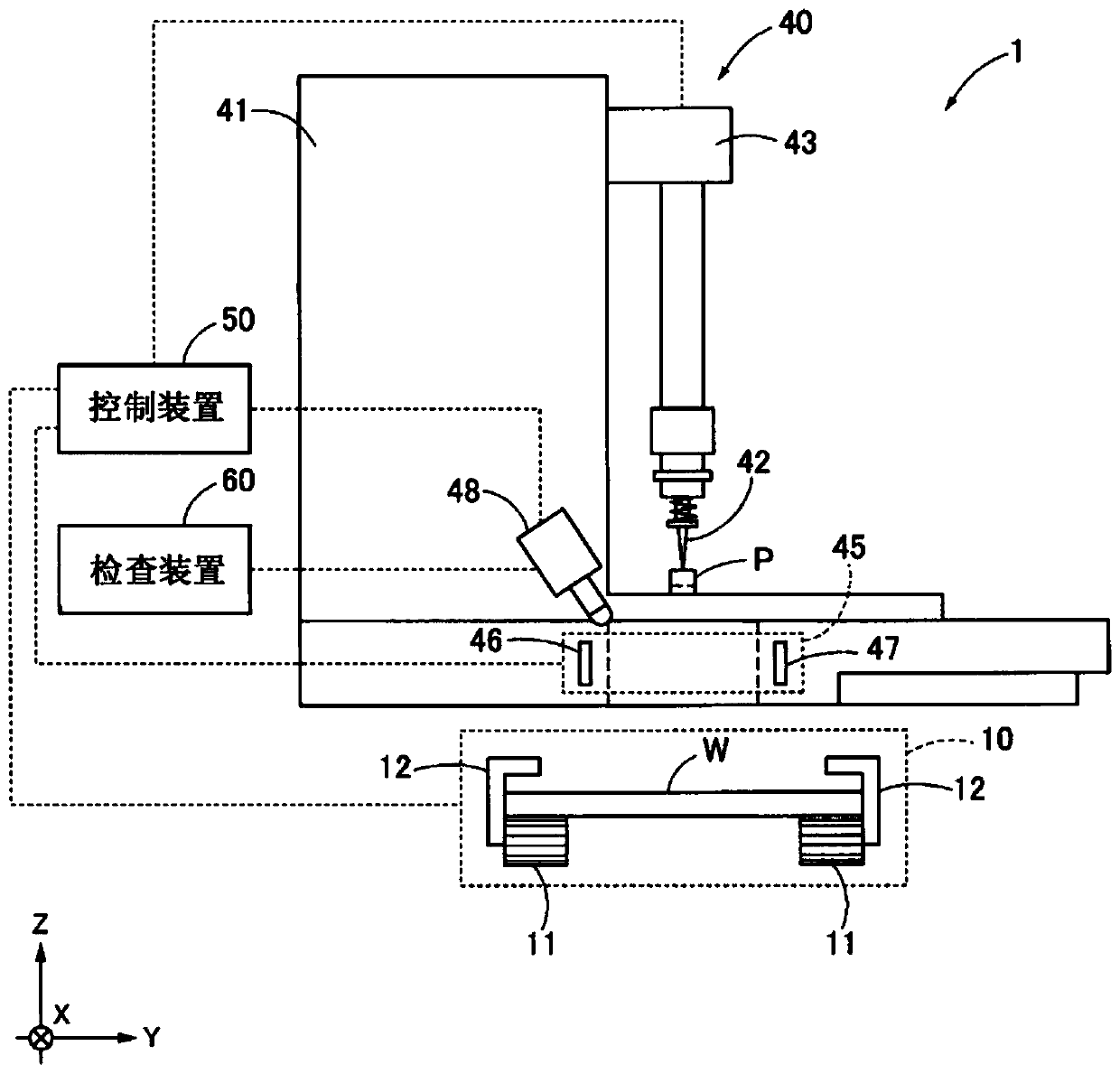

InactiveCN102565092AEnsure flatnessHigh precision inspectionMaterial analysis by optical meansUsing optical meansEngineeringInspection method

A glass substrate defect inspecting device and an inspection method thereof are provided to reduce or remove bouncing phenomenon and steadily perform an inspection by reducing the corrected amount during the inspection. A glass substrate (100) comprises a lifting device, a transfer device, and an optical inspection device. The lifting device lifts up a glass substrate(P) using air. The transfer device transfers the glass substrate to an inspection area where the lifting device is absent. The optical inspection device takes a picture of the glass substrate, thereby performing an inspection. A glass substrate defect inspecting device comprises a reduction device. The reduction device reduces the displacement caused by the bouncing of an end part of the glass substrate toward a transferring direction.

Owner:HITACHI HIGH-TECH CORP

Substrate checking device

InactiveCN1862319AHigh precision inspectionKeep the height roughly constantConveyorsOptically investigating flaws/contaminationOptoelectronicsLight source

Owner:OLYMPUS CORP

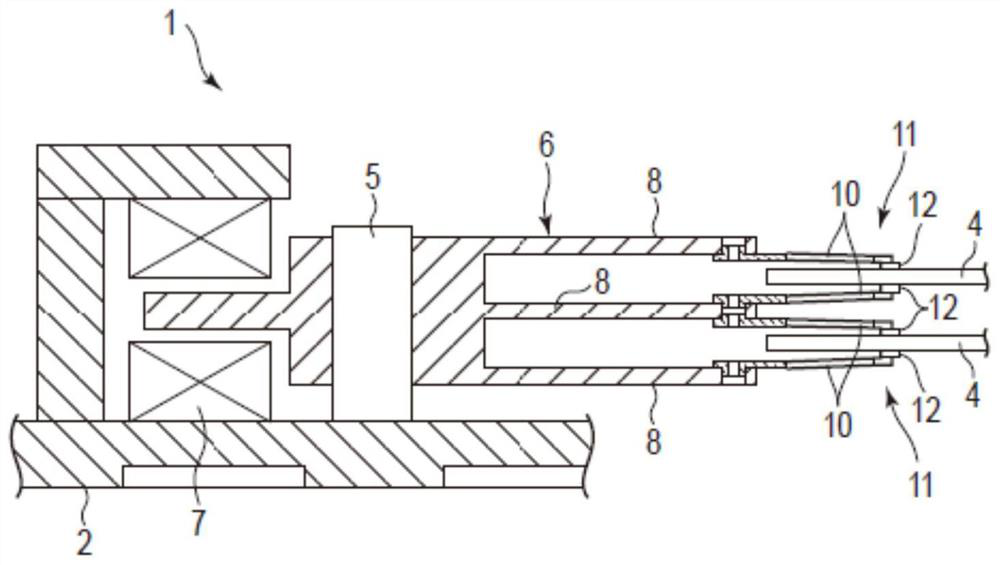

Evaluation apparatus and probe position inspection method

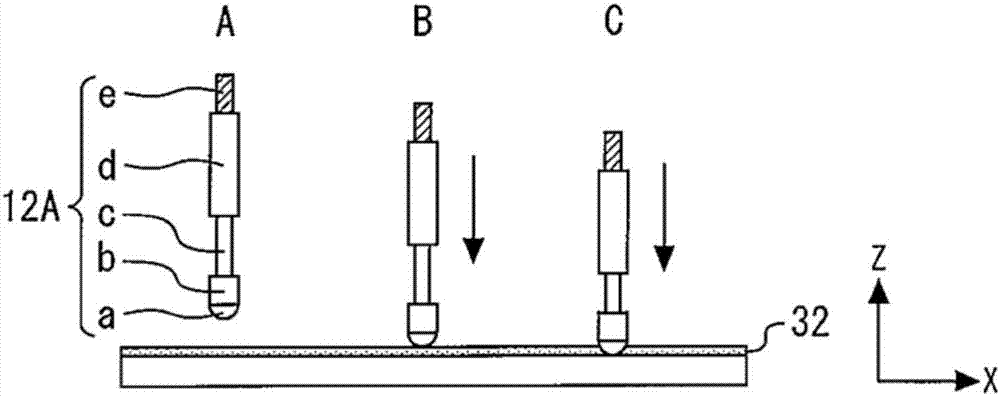

ActiveCN106960804AHigh precision inspectionSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsPrismSemiconductor

An evaluation apparatus comprising: a supporting unit configured to fix a semiconductor device in place and cause an upper surface and a lower surface of the semiconductor device to be exposed; a first insulating plate provided above the supporting unit; a second insulating plate provided below the supporting unit; a plurality of first probes fixed to the first insulating plate; a plurality of second probes fixed to the second insulating plate; and a probe position inspection apparatus attached to the supporting unit, wherein the probe position inspection apparatus comprises: a casing including a first transparent member on a side of the first insulating plate and a second transparent member on a side of the second insulating plate; an internal prism provided in the casing; a prism rotating unit for rotating the internal prism in the casing; and an imaging unit provided outside the casing to take an image of any of the plurality of first probes contacting the first transparent member and the plurality of second probes contacting the second transparent member through the internal prism.

Owner:MITSUBISHI ELECTRIC CORP

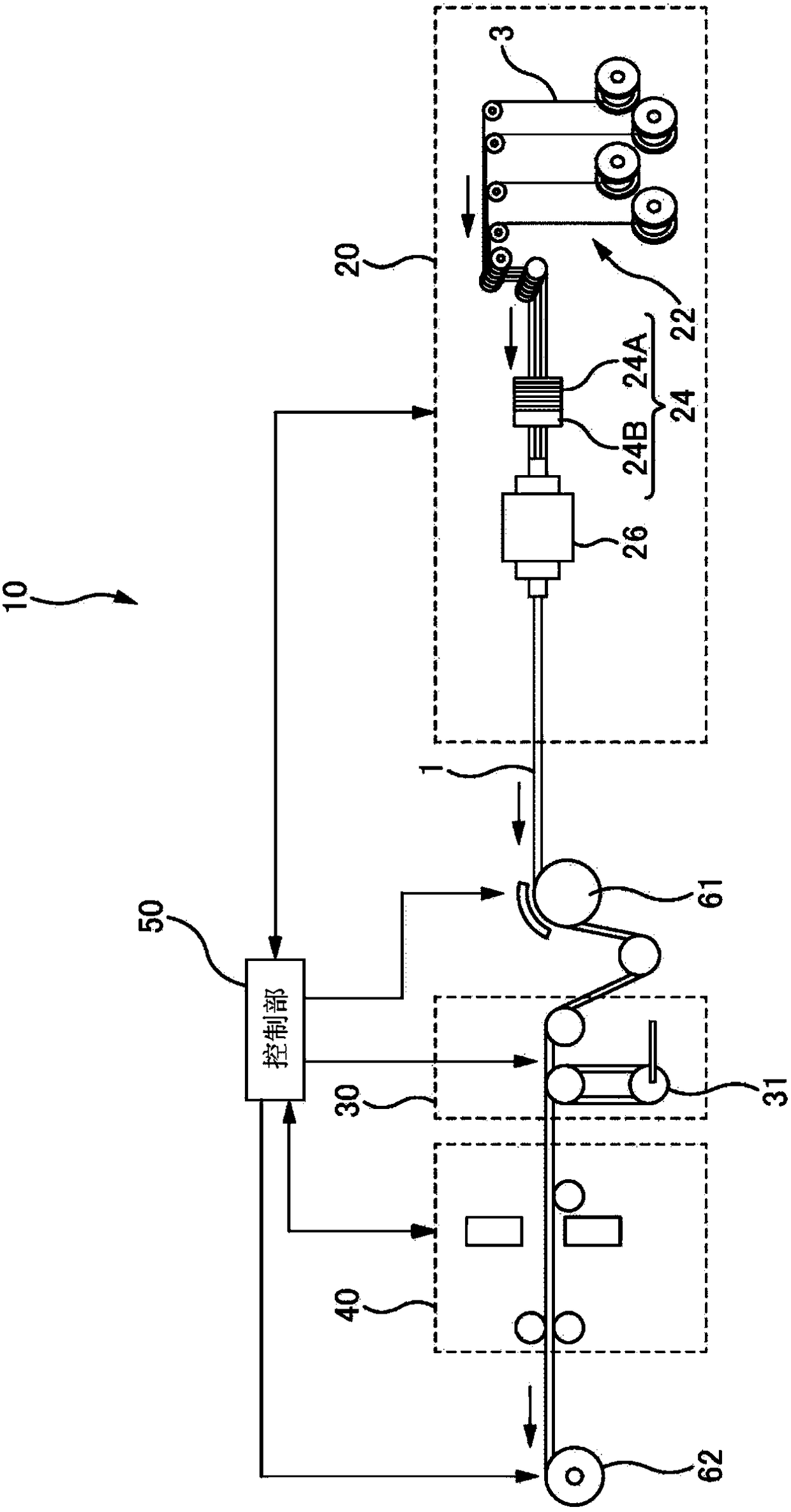

Method and system for detecting corrugation defect and manufacturing method of photomask

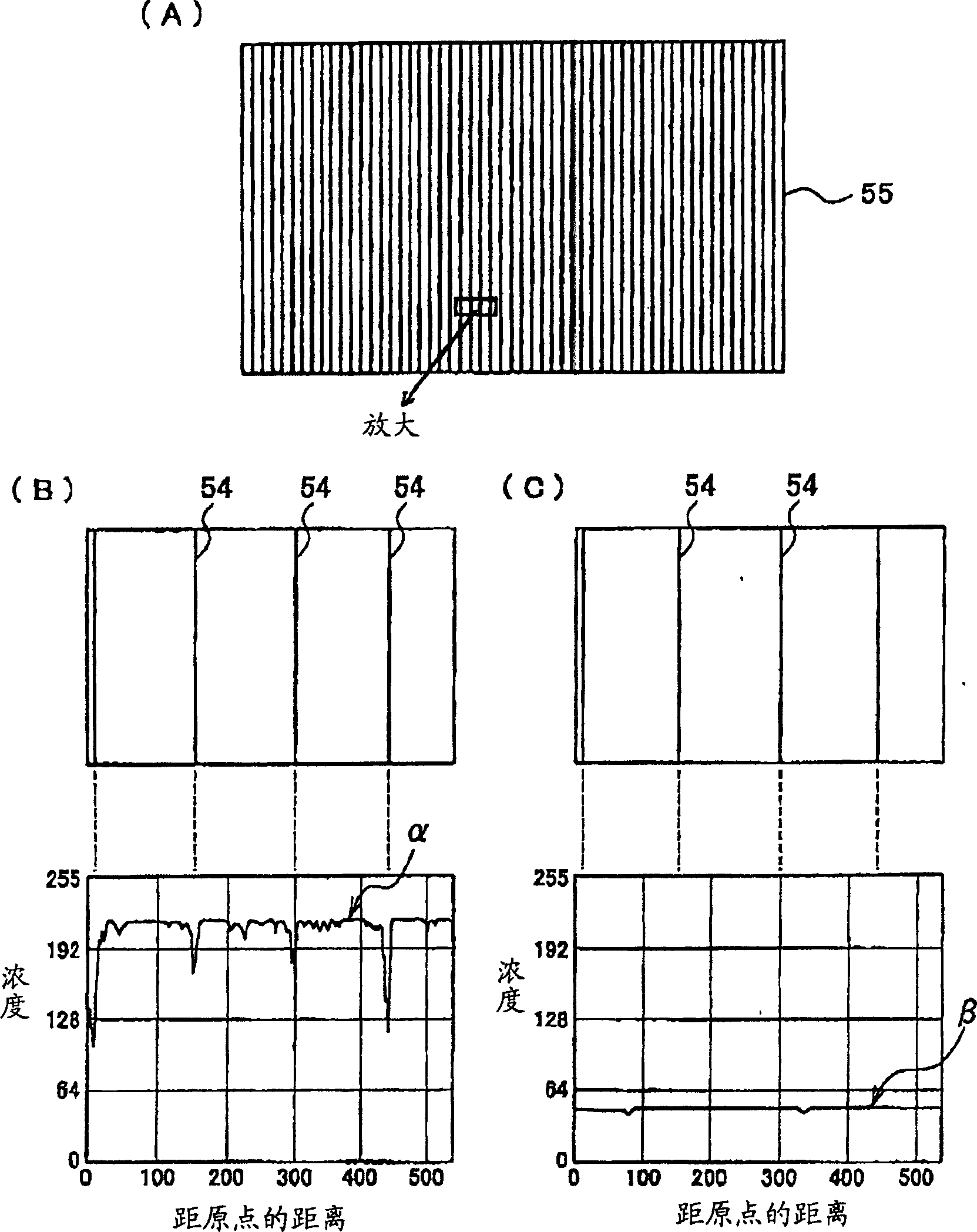

InactiveCN1983023ACheck condition optimizationValid checkOptically investigating flaws/contaminationUsing optical meansRepeat patternEngineering

An irregular flaw inspection method and system, and a fabricating method of a photomask are provided. The subject of the invention is to provide an irregular flaw inspection method capable of efficiently inspect an irregular flaw with high precision. In the irregular flaw inspection method for inspecting the irregular flaw produced in the repeating pattern of a photomask (50) having the repeating pattern wherein a large number of unit patterns are arranged regularly, a region having the repeating pattern becoming the inspection target of the irregular flaw is designated as an inspection area from the whole image of the photomask taken by the imaging camera (21) of a pattern data acquiring device (20) and the pattern data of the repeating pattern is acquired from the image, which is taken by a microscope (22), of the repeating pattern in the inspection area. The inspection condition of the irregular flaw due to an irregular flaw inspection device (10) is determined on the basis of the pattern data and the inspection of the irregular flaw is performed on the basis of the inspection condition by the irregular flaw inspection device.

Owner:HOYA CORP

Method and device for inspecting intermittently connected optical fiber tape, and manufacturing method

ActiveCN108351273AHigh precision inspectionMaterial analysis by optical meansTesting fibre optics/optical waveguide devicesConnection typeEngineering

The invention provides a method and device for inspecting intermittently connected optical fiber tape, and a manufacturing method. In order to inspect an intermittent-connection-type optical fiber tape with high precision despite an increased number of cores in the intermittent-connection-type optical fiber tape. This method for inspecting an intermittent-connection-type optical fiber tape comprises: repeatedly capturing an image of an intermittent-connection-type optical fiber tape along the width direction thereof, the intermittent-connection-type optical fiber tape in which connecting partsfor connecting adjacent optical fibers are intermittently arranged, while moving the optical fiber tape in the longitudinal direction thereof, and accumulating one-dimensional images in the width direction of the optical fiber tape; and arranging the accumulated plurality of one-dimensional images in a first direction in which pixels constituting part of the primary images are arranged and a second direction orthogonal to the first direction, and creating a two-dimensional image of the optical fiber tape.

Owner:THE FUJIKURA CABLE WORKS LTD

Thermally compensated test piece for coordinate measuring machines

InactiveUS20050252017A1High precision inspectionIncrease flexibilityUsing mechanical meansTesting/calibration of speed/acceleration/shock measurement devicesLength variationEngineering

Owner:METRONOM

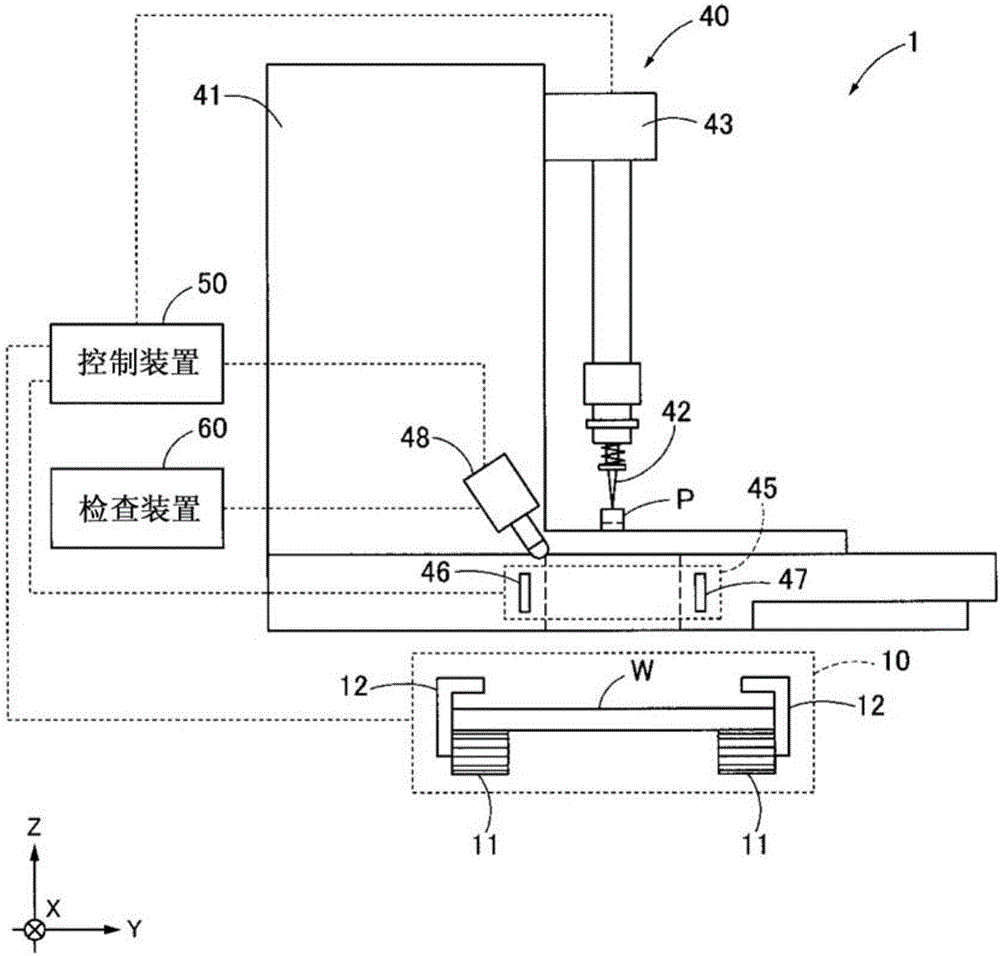

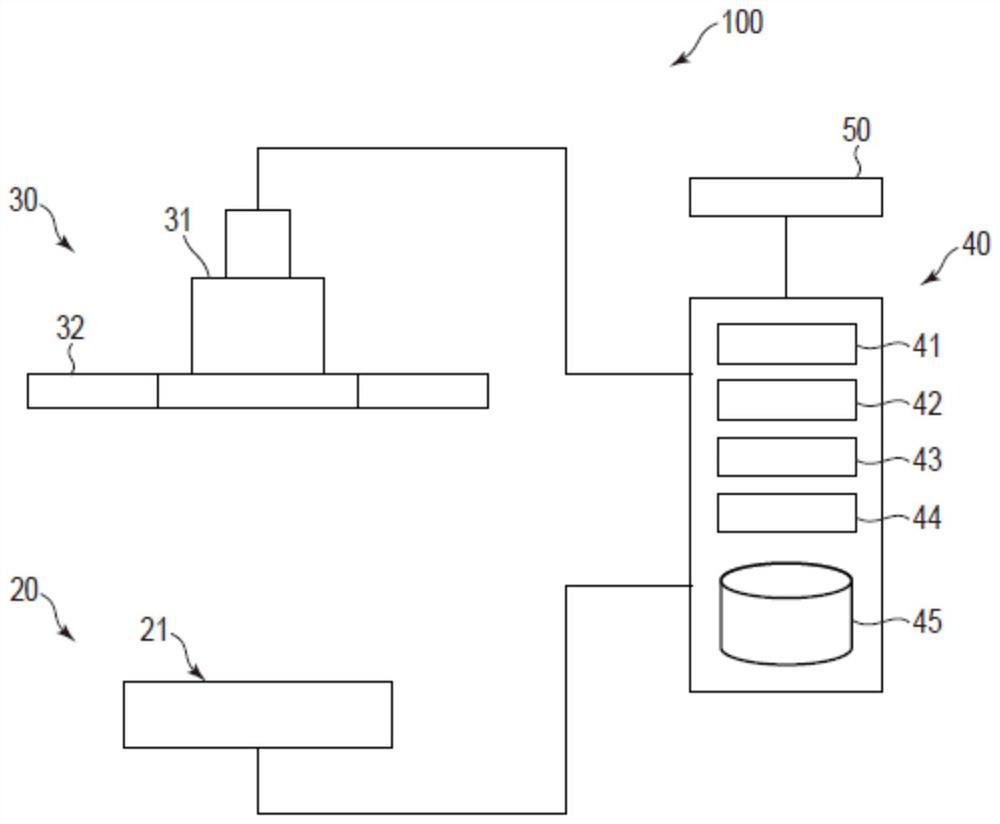

Inspection device, installation device, and inspecting method

ActiveCN106455478AHigh precision inspectionElectrical componentsComputer scienceBrightness perception

Whether a component is mounted on a substrate is inspected with high precision by simple processing. An inspection apparatus (60) inspects whether the component is mounted based on a pre-mounting image and a post-mounting image of the component taken before and after the component is mounted on a mounting surface of the substrate. The inspection device comprises a threshold setting section (62) for setting a threshold capable of recognizing the substrate according to the brightness value of the pre-mounting image; and a mask image generating section (63) for generating a mask image masking other than the substrate from the pre-mounting image according to the threshold. The specific areas corresponding to the mounting surface of the substrate of the pre-mounting image and the post-mounting image are compared with each other by employing the mask image, thereby inspecting whether the component is mounted or not.

Owner:JUKI CORP

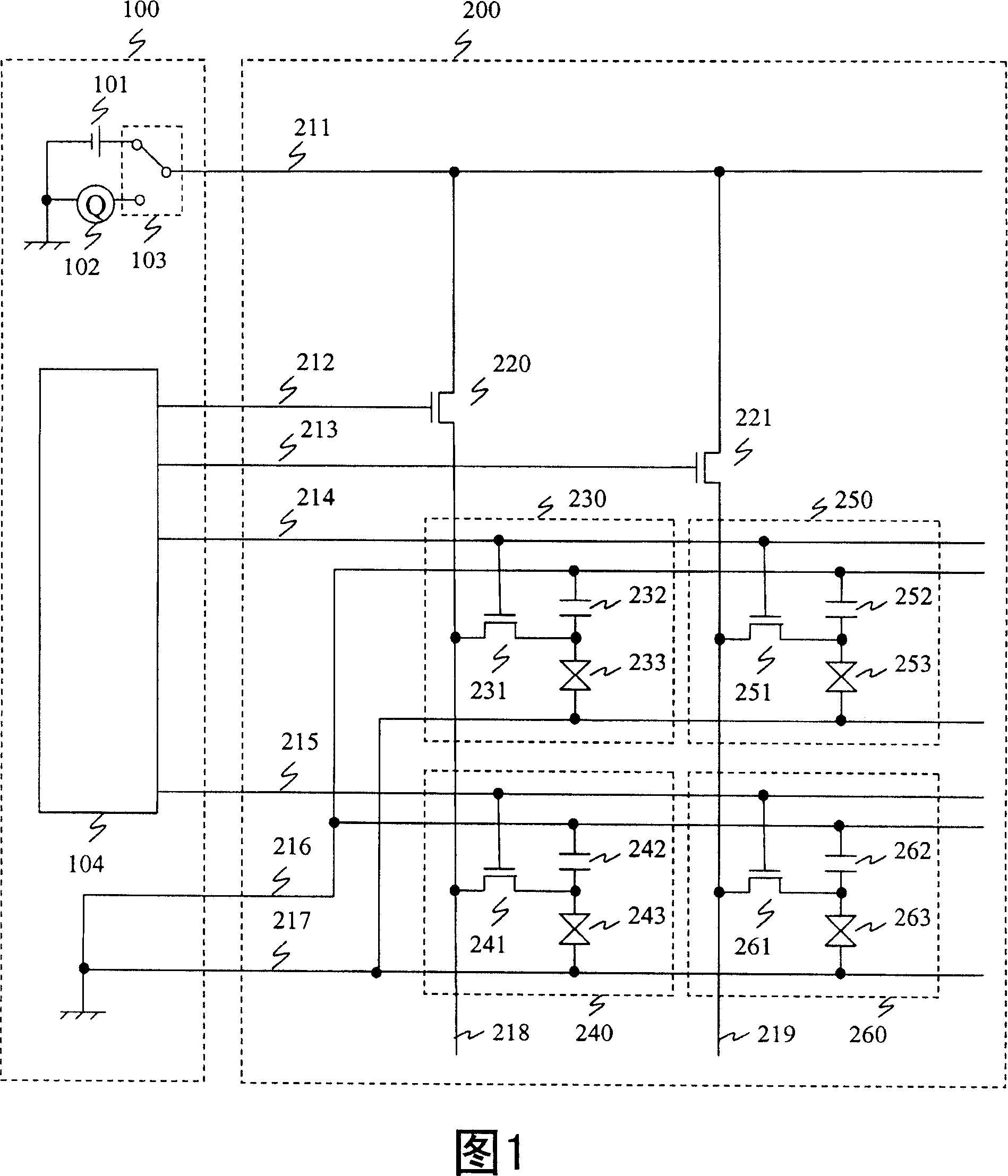

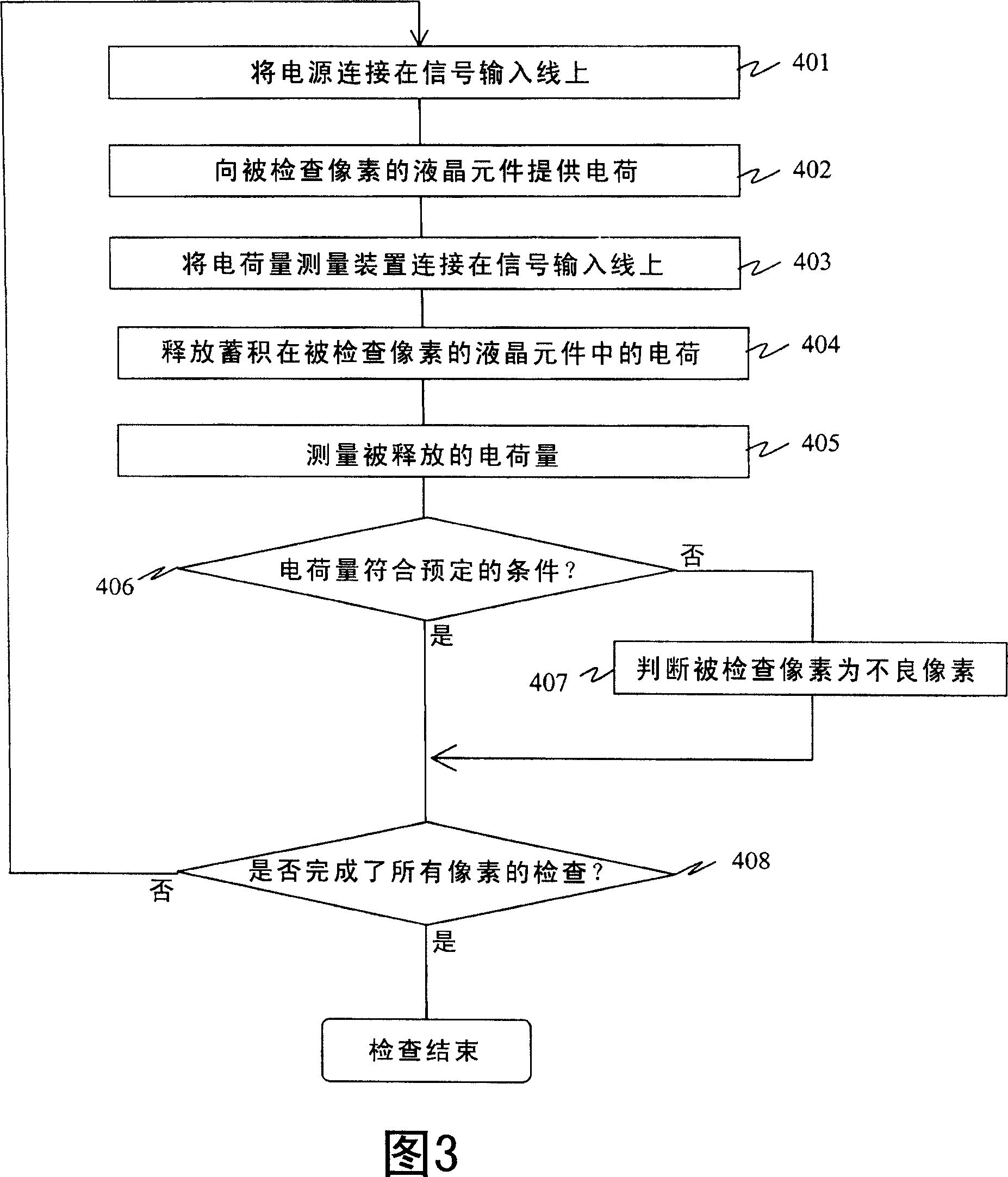

Method and apparatus for testing a liquid crystal cell

InactiveCN1987559AEfficient inspectionHigh precision inspectionStatic indicating devicesElectrical testingCharge dischargeEngineering

A test method for a liquid crystal display panel in which the pixels providing liquid crystal elements having sealed in liquid crystal material are arranged in a matrix between opposing electrodes is comprised of a charging process for supplying charge to the above-mentioned liquid crystal element of a pixel under test, a measurement process for discharging the charge from the above-mentioned charged liquid crystal element and measuring the amount of charge discharged, and a decision process for determining whether defects are present in the liquid crystal element of the above-mentioned pixel under test from the above-mentioned measurement results.

Owner:AGILENT TECH INC

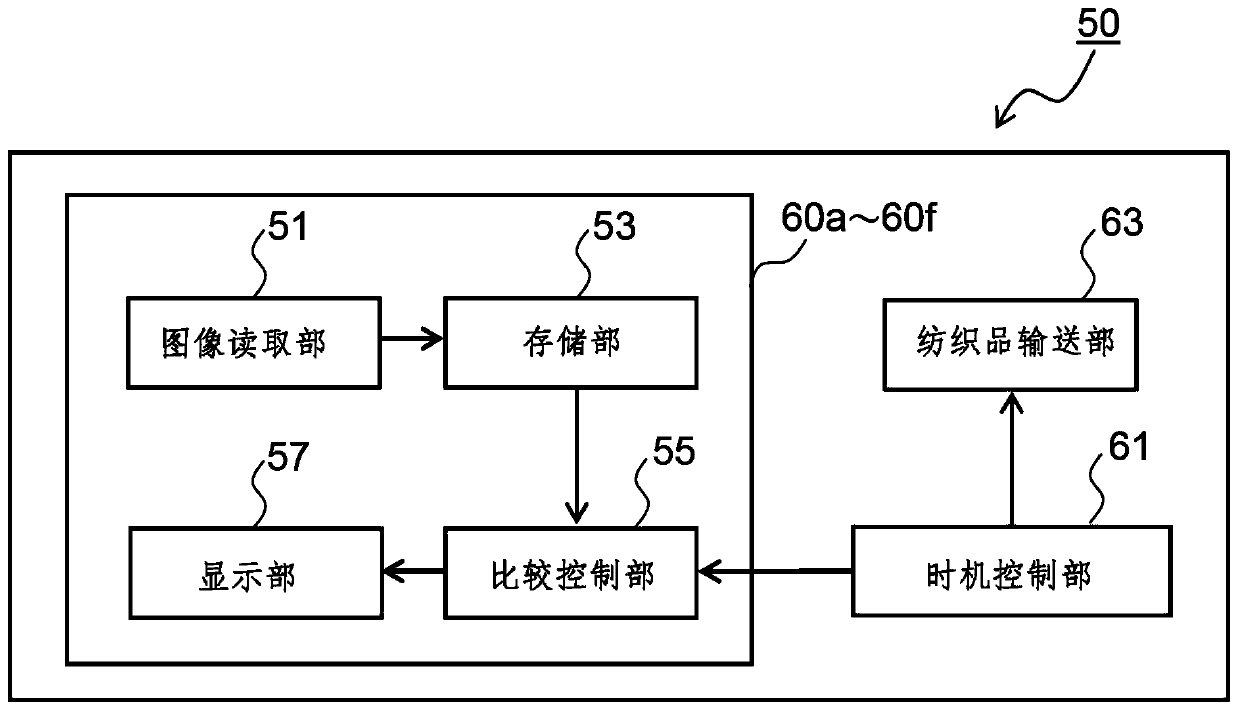

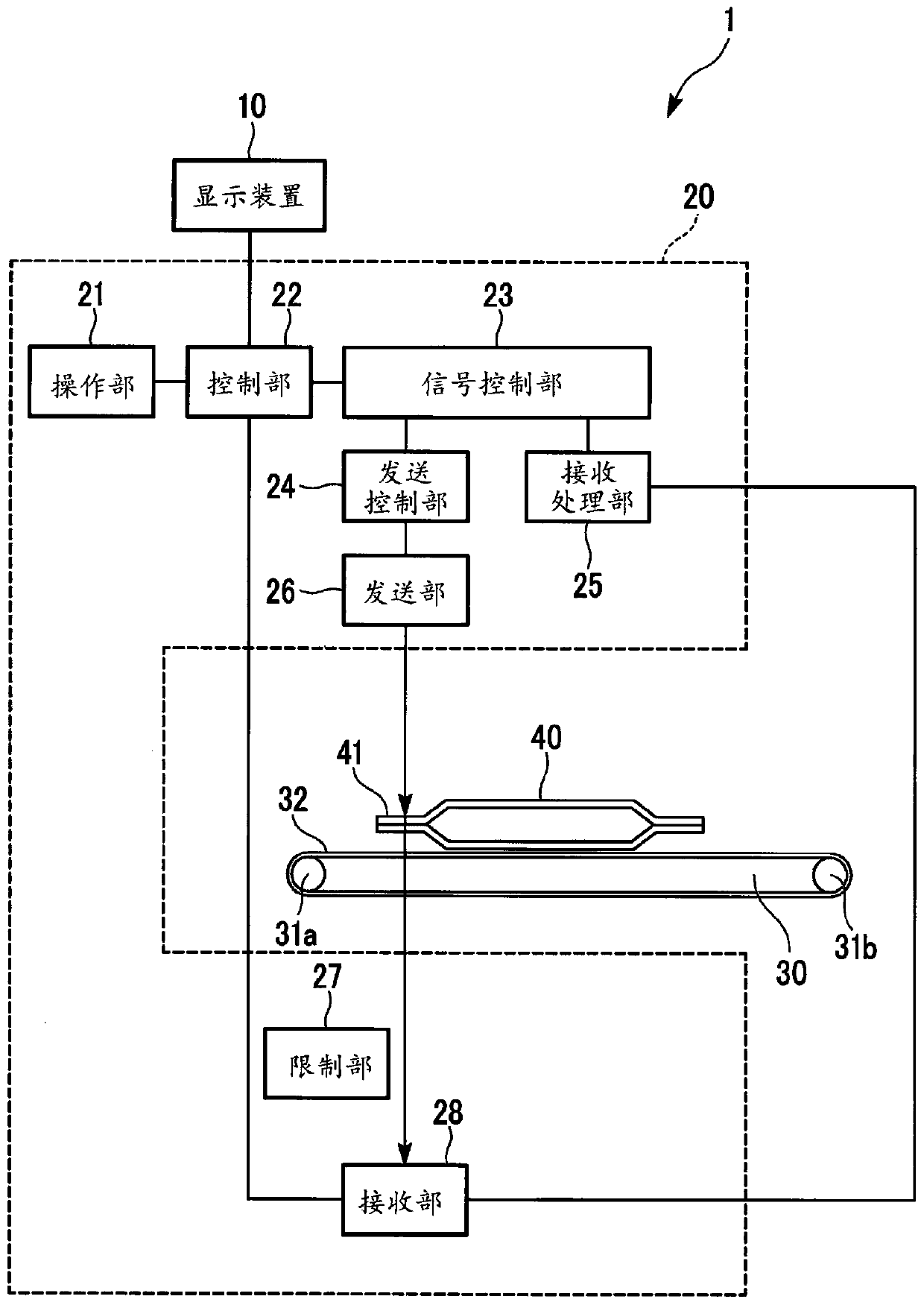

Inspection device and ink-jet printing device therewith

ActiveCN110924118AHigh precision inspectionSuppress false detectionImage enhancementImage analysisGraphicsReference image

The invention provides an inspection device and an ink-jet printing device therewith. The inspection device includes a sheet conveying portion, an image reading portion, a timing control portion, a storage portion, a comparing control portion, and a display portion. The image reading portion reads a plurality of images of the same pattern recorded repeatedly with a predetermined pitch on a recording sheet conveyed by the sheet conveying portion. The timing control portion regulates the timing of image reading by the image reading portion. The storage portion stores the plurality of images readby the image reading portion. The comparing control portion takes, out of the plurality of images stored in the storage portion, part of an image continuously recorded on the recording sheet corresponding to the forefront one pitch as a reference image and compares the image data of a comparison image recorded later than the reference image with image data of the reference image to check for image defects.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

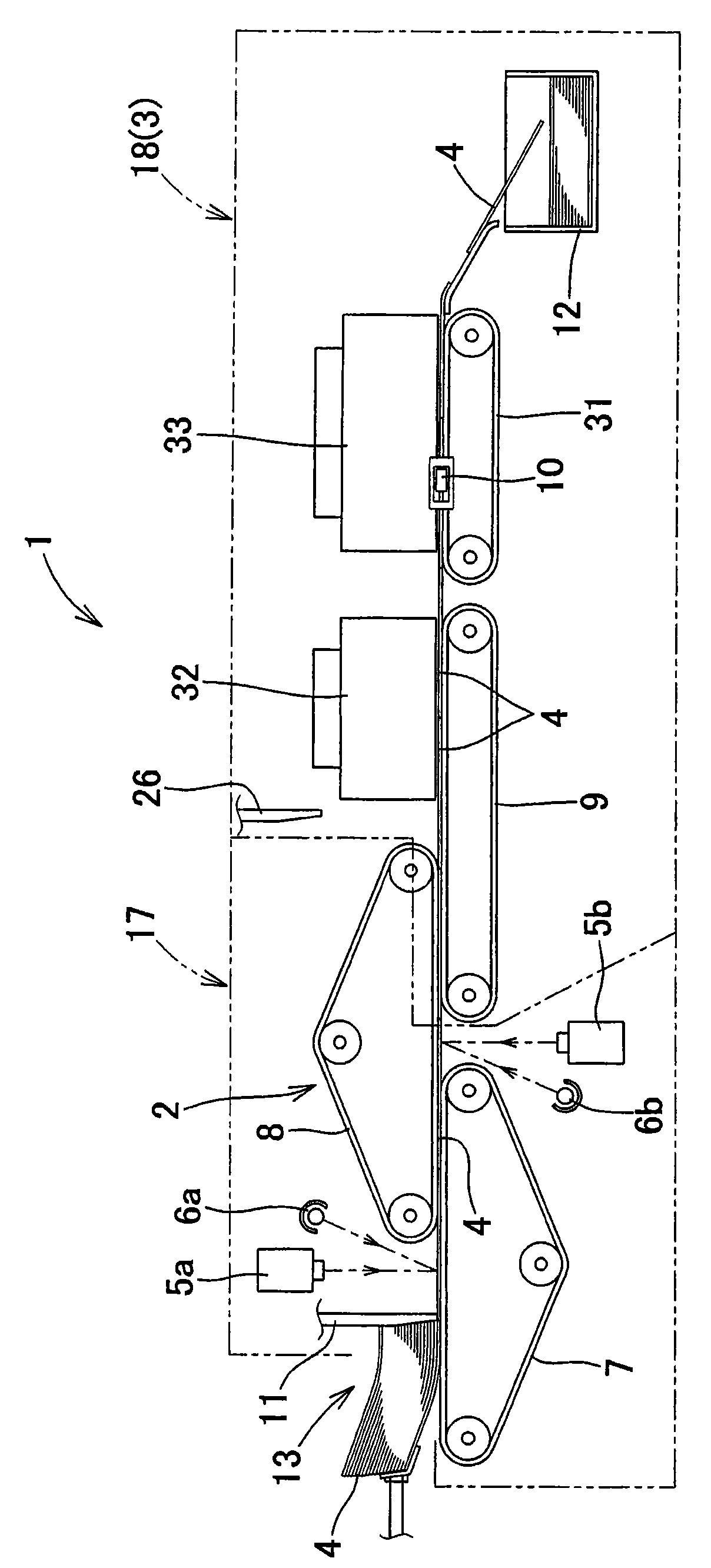

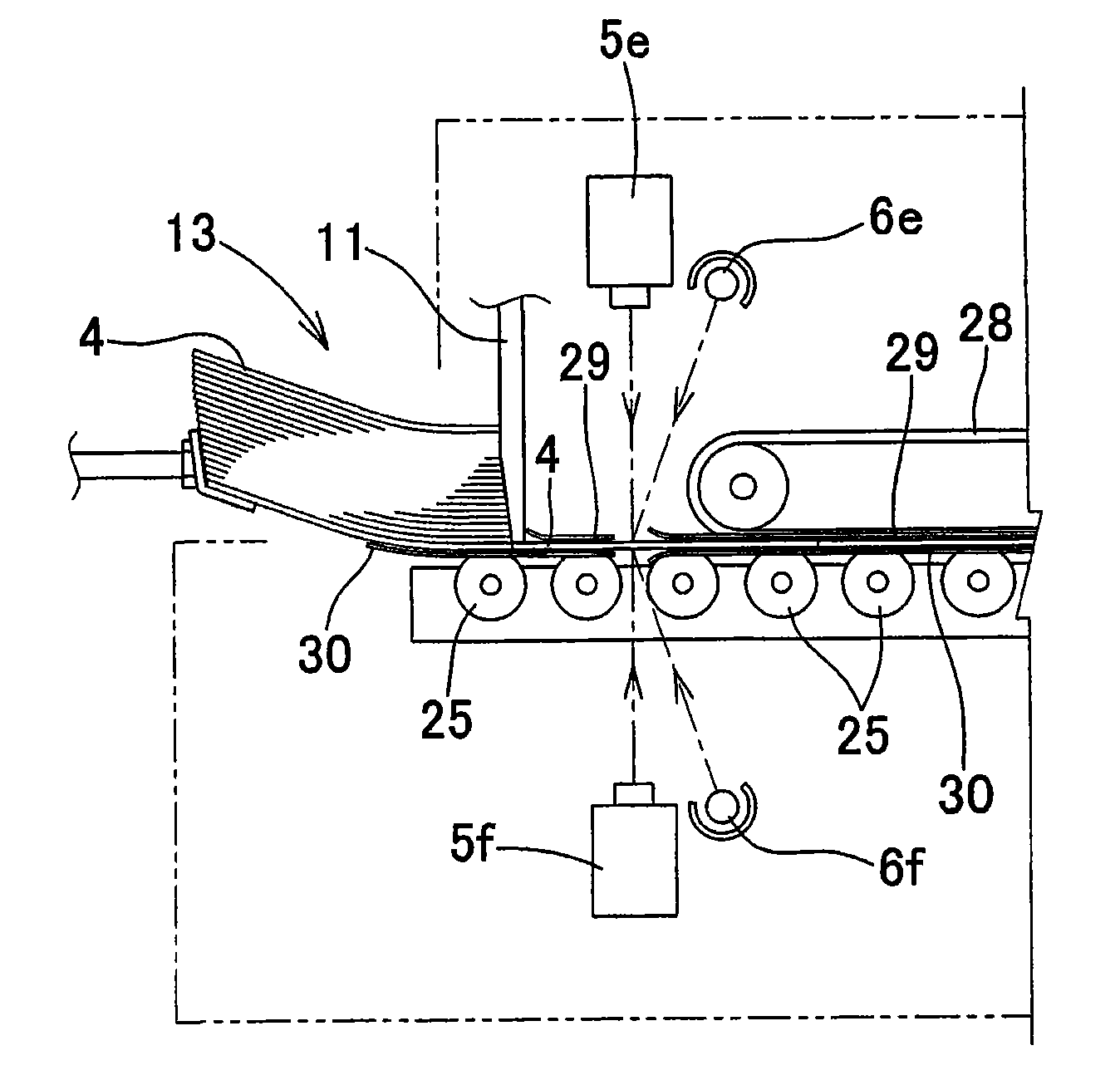

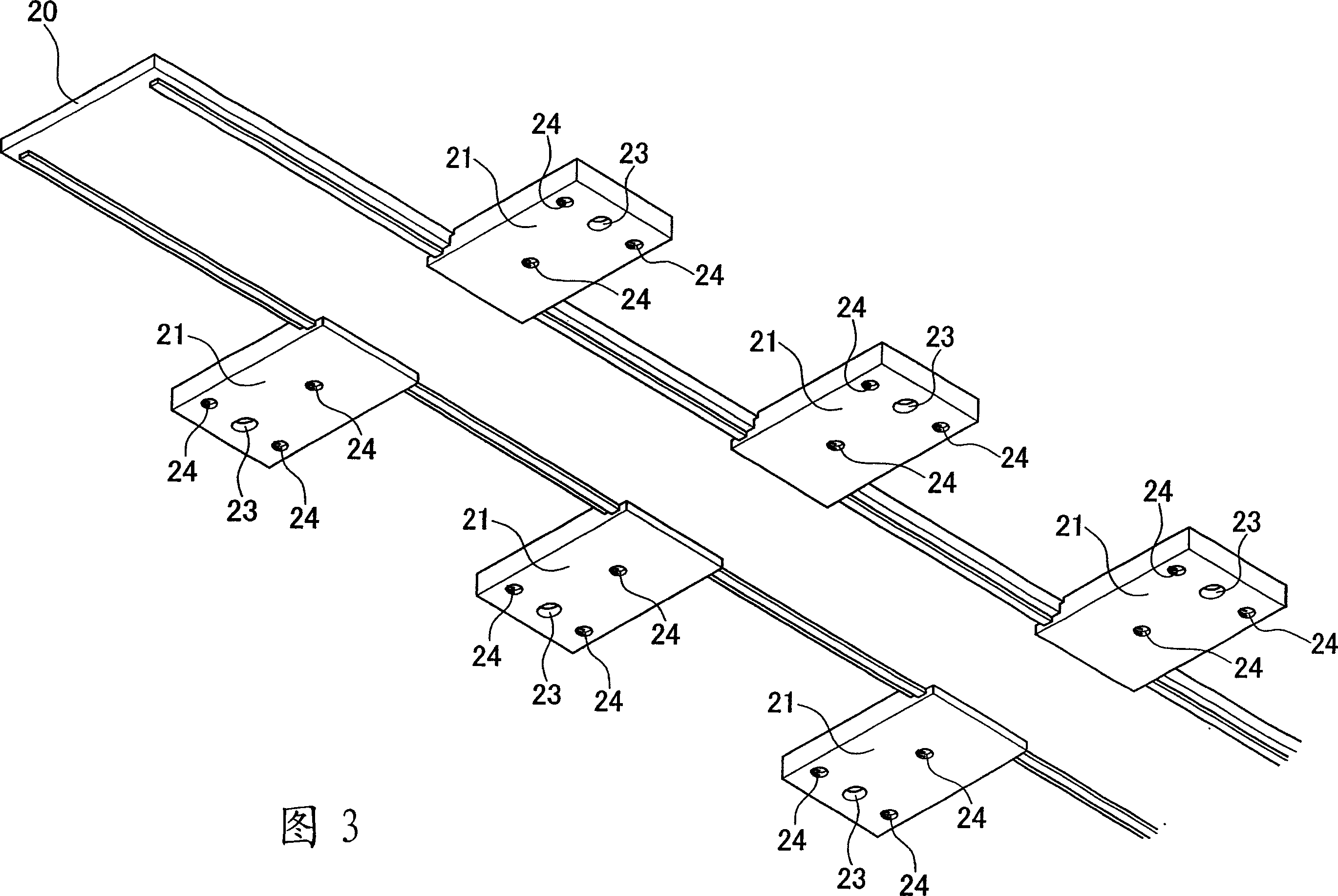

Appearance inspection device and inspection method for component installation state

InactiveCN101532966ASmooth scanScan accuratelySemiconductor/solid-state device manufacturingMaterial analysis by optical meansConveyor beltComputer engineering

Provided is an appearance inspection device and inspection method for a component installation state, wherein the inspection device (1) is provided with an image scanner (2), having at least a reading module (5) moving along a guide shaft (21) and making an image reading part (54) towards a lower side to scan an image, and a horizontal supporting member for supporting the reading module (5) horizontally; a conveyor belt (32), conveyed to the lower side of the image reading part (54) of the image scanner (2) as a printing substrate (4) of an inspection object; and a mechanism for processing the image scanned by the reading module (5) and displaying on a monitor (11).

Owner:北原明 +1

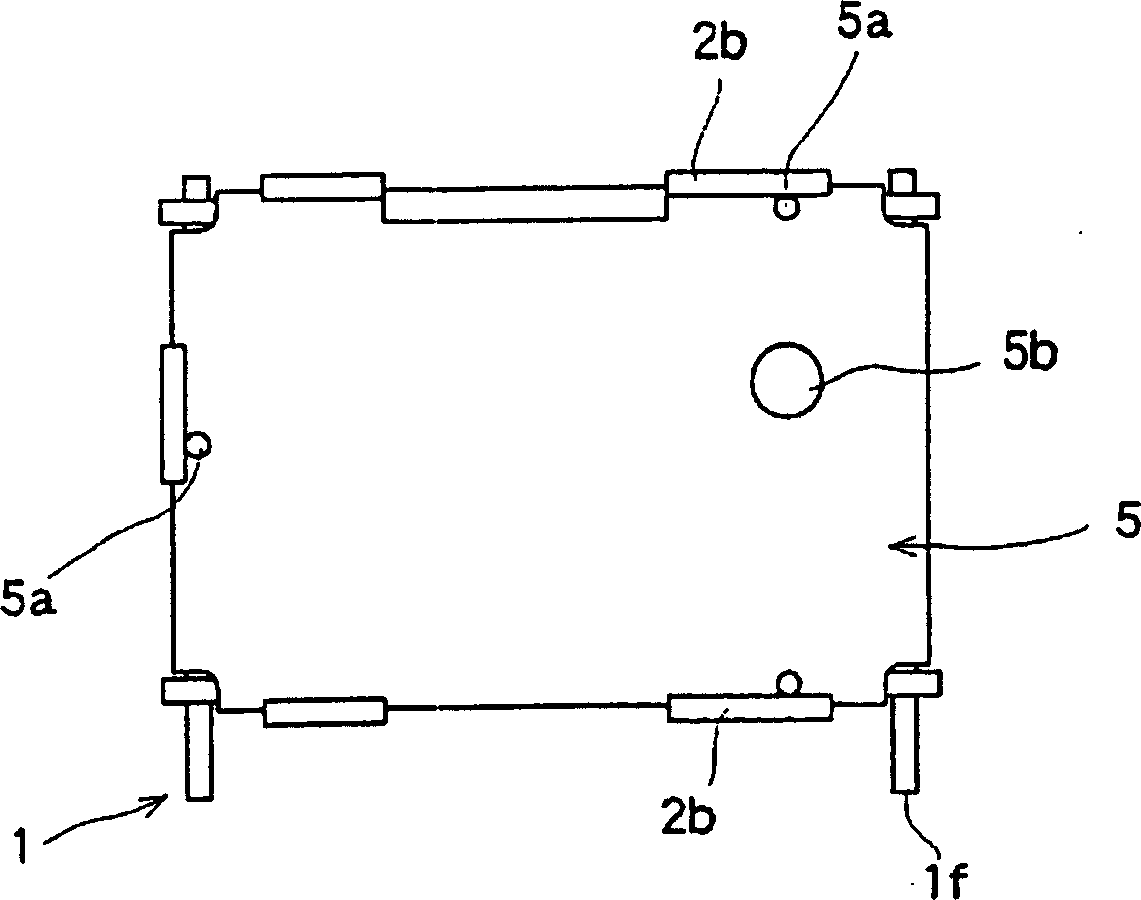

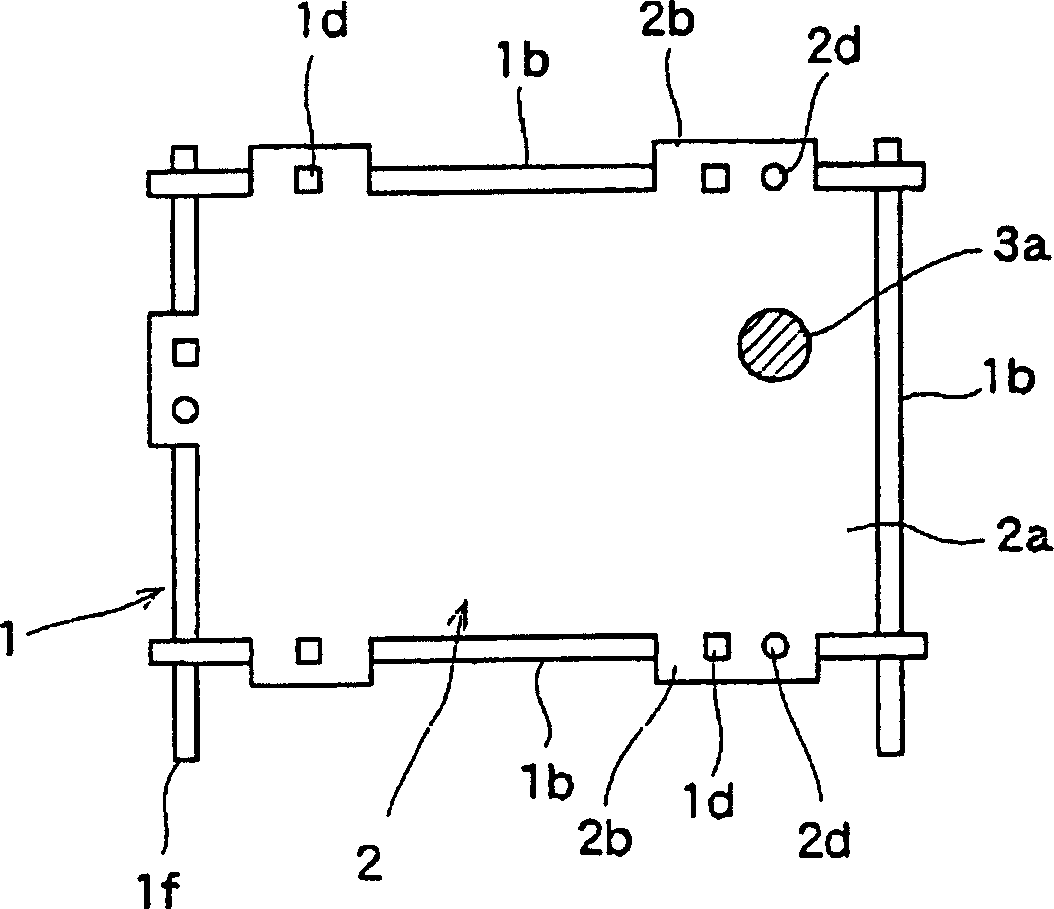

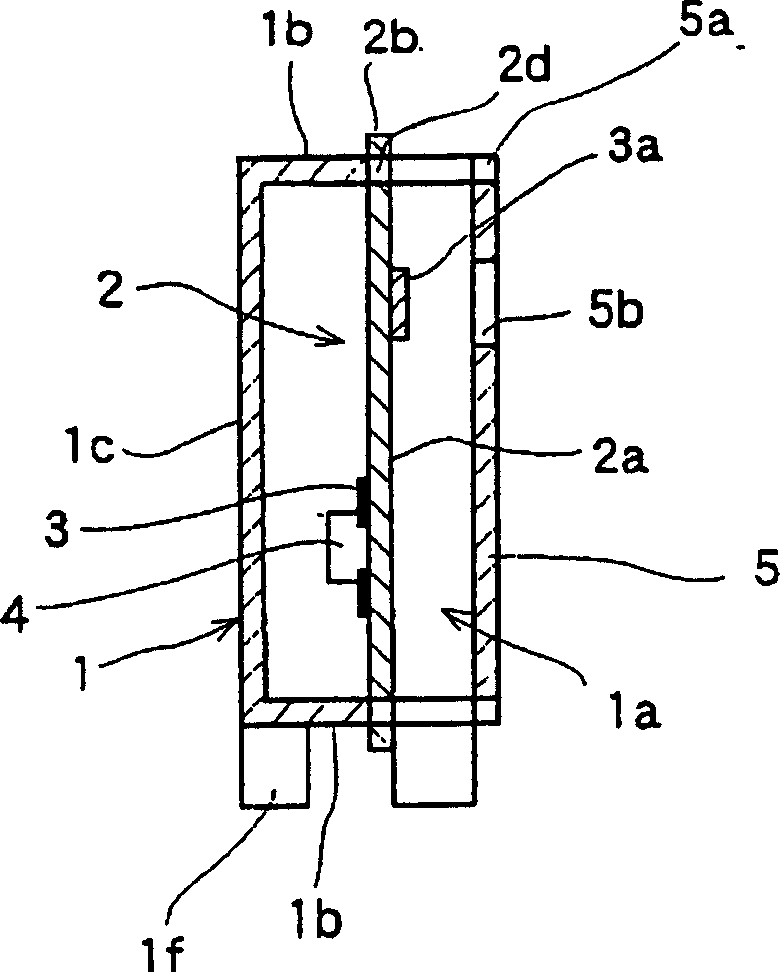

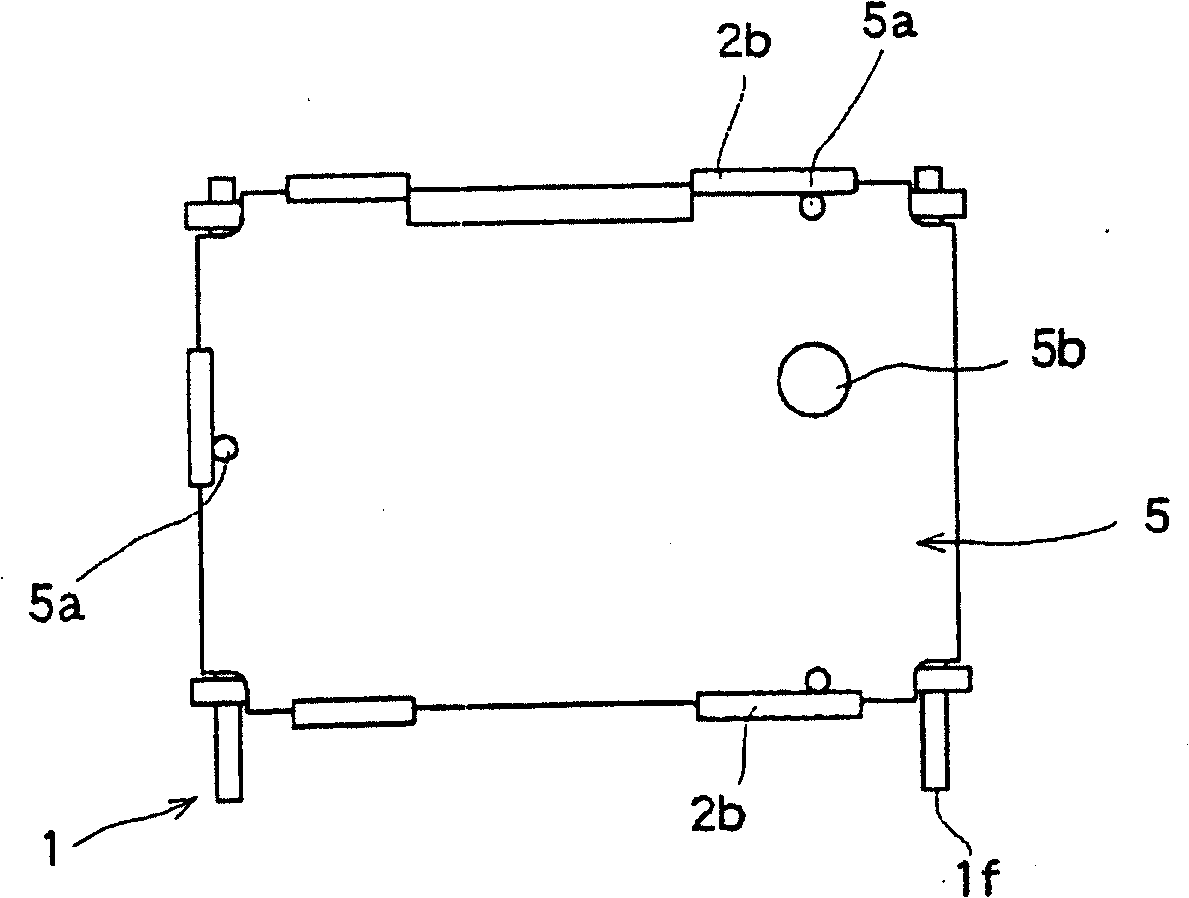

High-frequency apparatus

InactiveCN1747643APrecise positioningWell formedMagnetic/electric field screeningElectrical apparatus contructional detailsBand shapeElectrical and Electronics engineering

The invention provides a high frequency equipment which has an inexpensive circuit board and can be reliably inspected. In the high frequency equipment, the extension 2b of a circuit board 2 is provided with a mount hole 2c for receiving the projection 1d of a frame 1 thereinto and mounting the circuit board 2 thereto, and with a positioning hole 2d capable of receiving a guide rod 8 therein. Thus, when the device after being assembled is inspected, a probe 9 can be positioned with use of the positioning hole 2d having a wiring pattern 3 provided thereto as a reference, the position of the probe 9 relative to the wiring pattern 3 can be made accurate, and the device can be reliably inspected. Further, upon manufacturing the circuit board, the positioning hole 2d provided in the extension 2b of the circuit board 2 can be used also as a feed hole, a strip-shaped substrate 10 for use in manufacture of the circuit board 2 can be made small, and therefore an expensive circuit board can be obtained.

Owner:ALPS ALPINE CO LTD

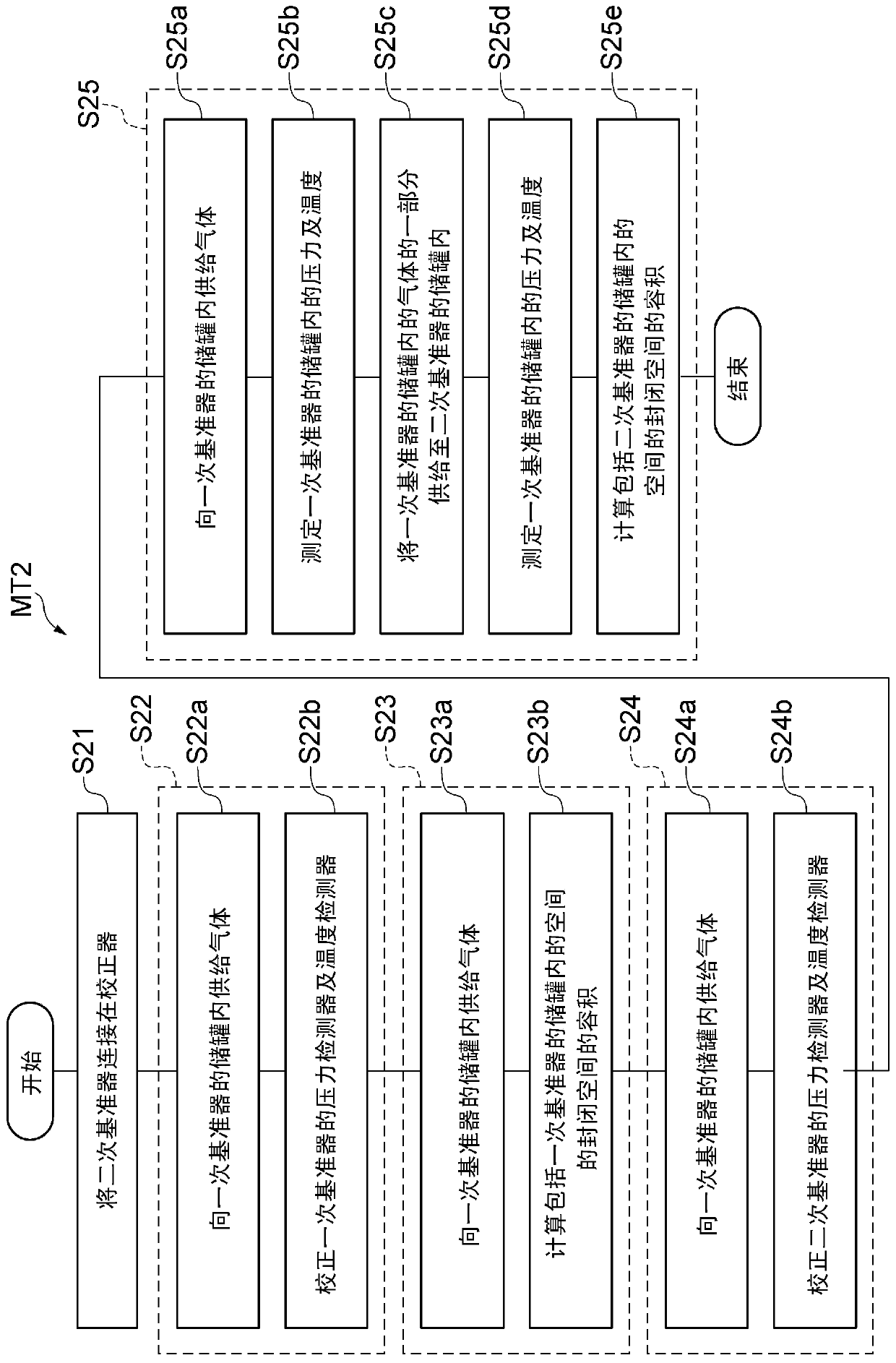

Inspection method of gas supply system, calibration method of secondary reference device

ActiveCN107831753BHigh precision inspectionProgramme controlVolume measurement apparatus/methodsEngineeringReference device

An object of the present invention is to inspect a gas supply system with high accuracy. The method related to one aspect of the present invention includes: a first step of connecting the reference device to the other end of the connecting pipe; a second step of supplying gas from a flow controller to the pipe; a third step of closing a first After the valve, obtain the measured values of the first pressure detector and the first temperature detector; in the fourth step, open the third valve and supply part of the gas in the piping to the storage tank; in the fifth step, obtain the first pressure measurement The measured value of the detector and the first temperature detector or the measured value of the second pressure detector and the second temperature detector; the sixth step uses Boyle-Charlie's law, and based on the measured value obtained in the third step, The volume of the piping is calculated from the measured value obtained in the fifth step and the volume of the closed space including the space in the storage tank when the third valve is closed.

Owner:TOKYO ELECTRON LTD

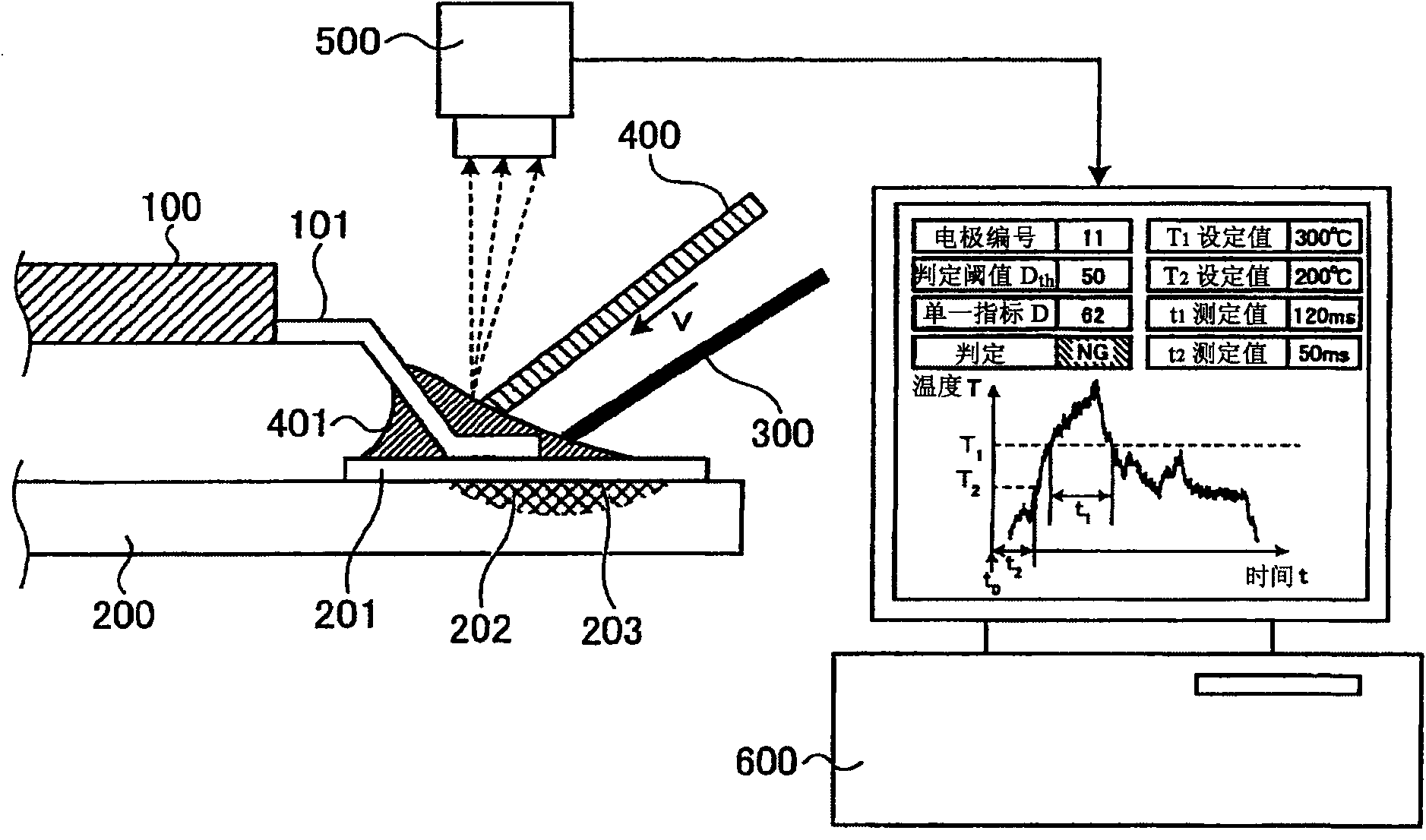

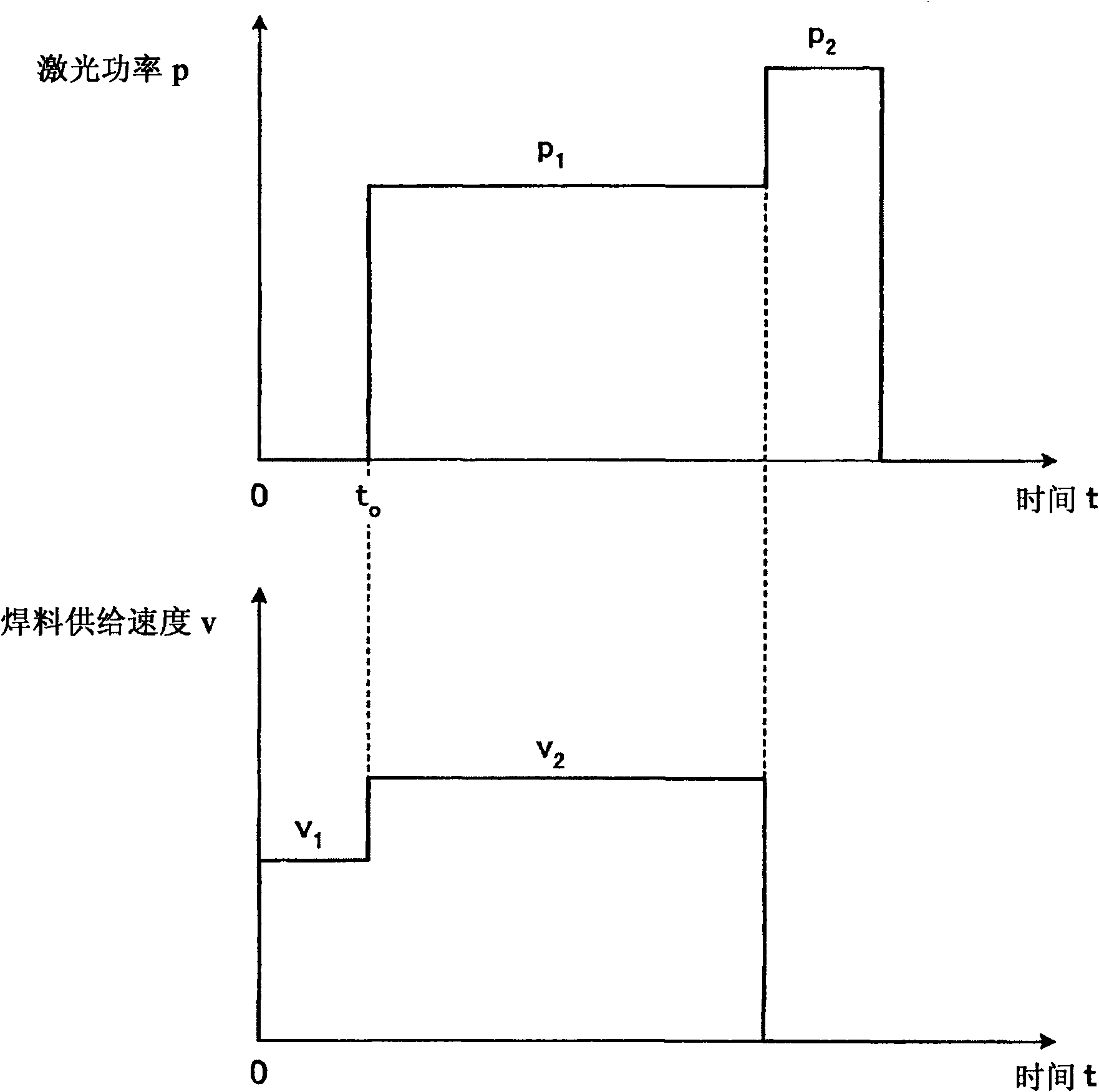

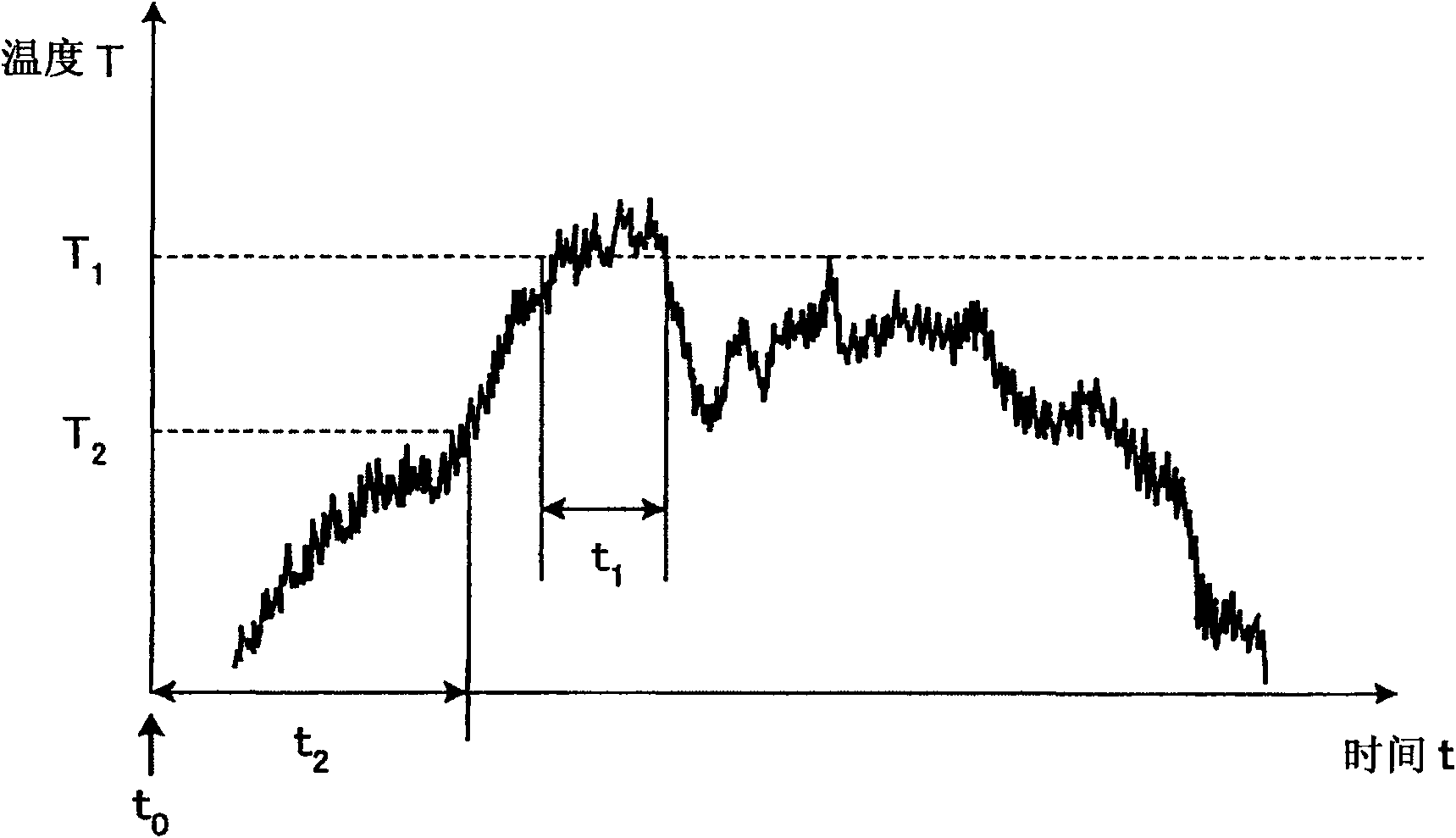

Quality control method for solder joint portion and quality control device

InactiveCN102209441BReal-time checkHigh precision inspectionPrinted circuit assemblingElectrical componentsNon destructiveVitrification

The invention provides a quality control method for solder a joint portion, enabling highly accurate quality inspection in a non-damaged manner at a real time bases without an extra inspection process. The quality control method for a joint portion formed when solder and partial heat energy are supplied to a resin substrate, includes measuring temperature of the joint portion varying with time during jointing process, calculating a plurality of characteristic values based on the measured values, obtaining a single value index based on the plurality of characteristic values, and determining whether the joint portion is qualified or not by comparing the value index with the predetermined threshold, wherein the characteristic values includes time t1 indicating the time when the temperature of the joint portion is higher or equal to the predetermined time T1 which satisfied the conditions of (substrate vitrification temperature- 50 DEG C) <= T1<= (substrate vitrification temperature+250 DEG C), and time t2 indicating the time from utilizing heat energy to the temperature of the joint portion reaching the predetermined time T2 which satisfied the conditions of (substrate vitrification temperature-50 DEG C) <= T2<= (substrate vitrification temperature+250 DEG C).

Owner:MITSUBISHI ELECTRIC CORP

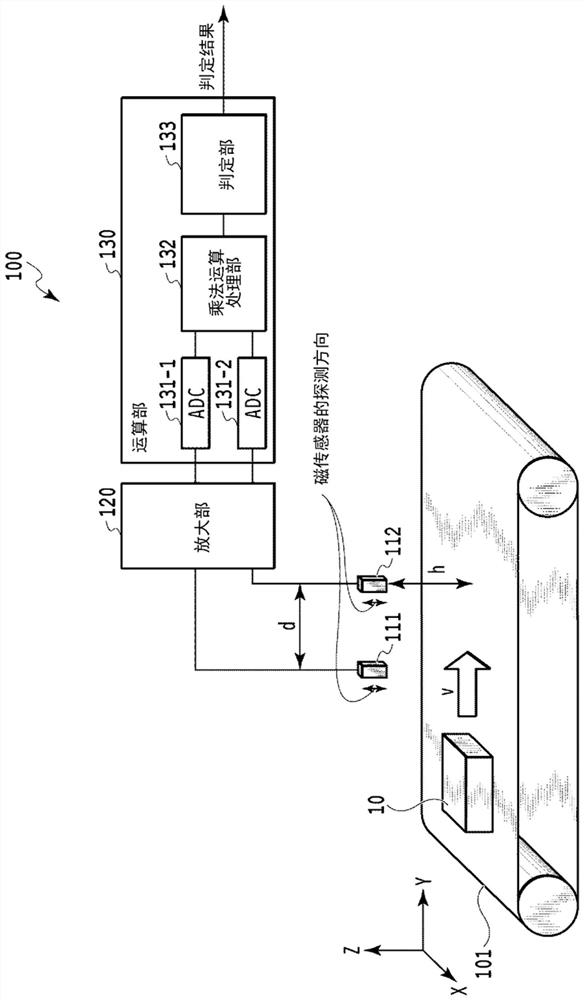

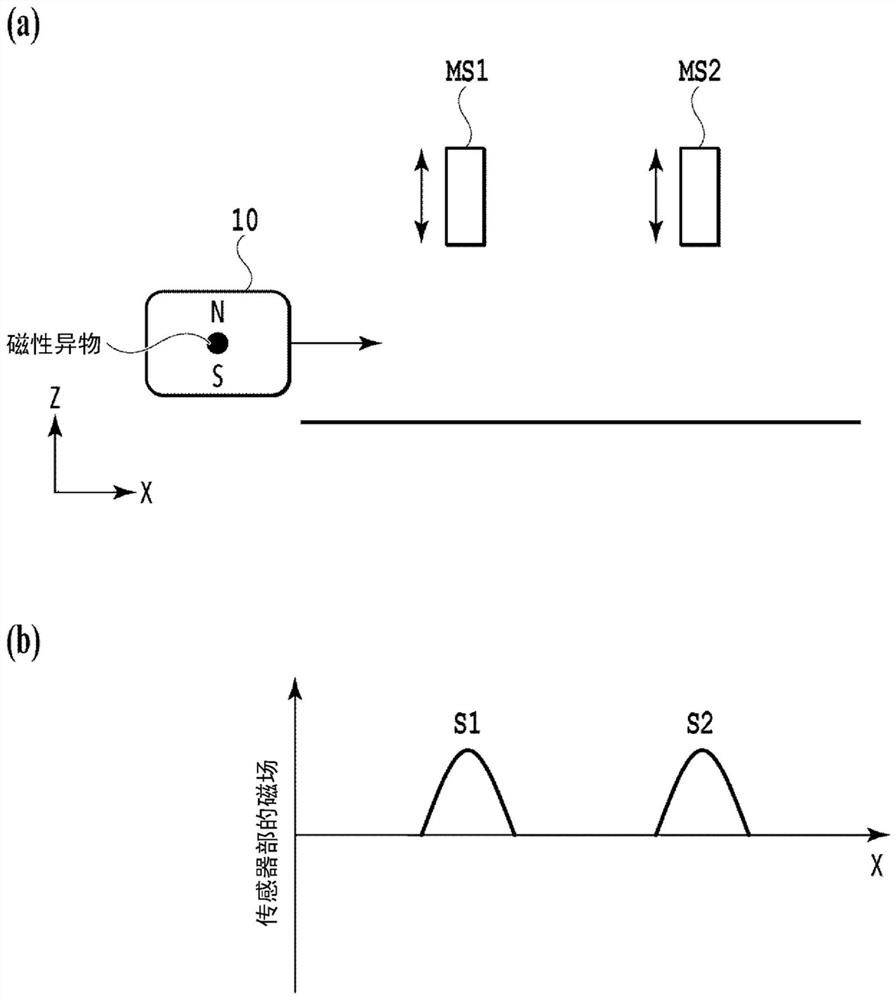

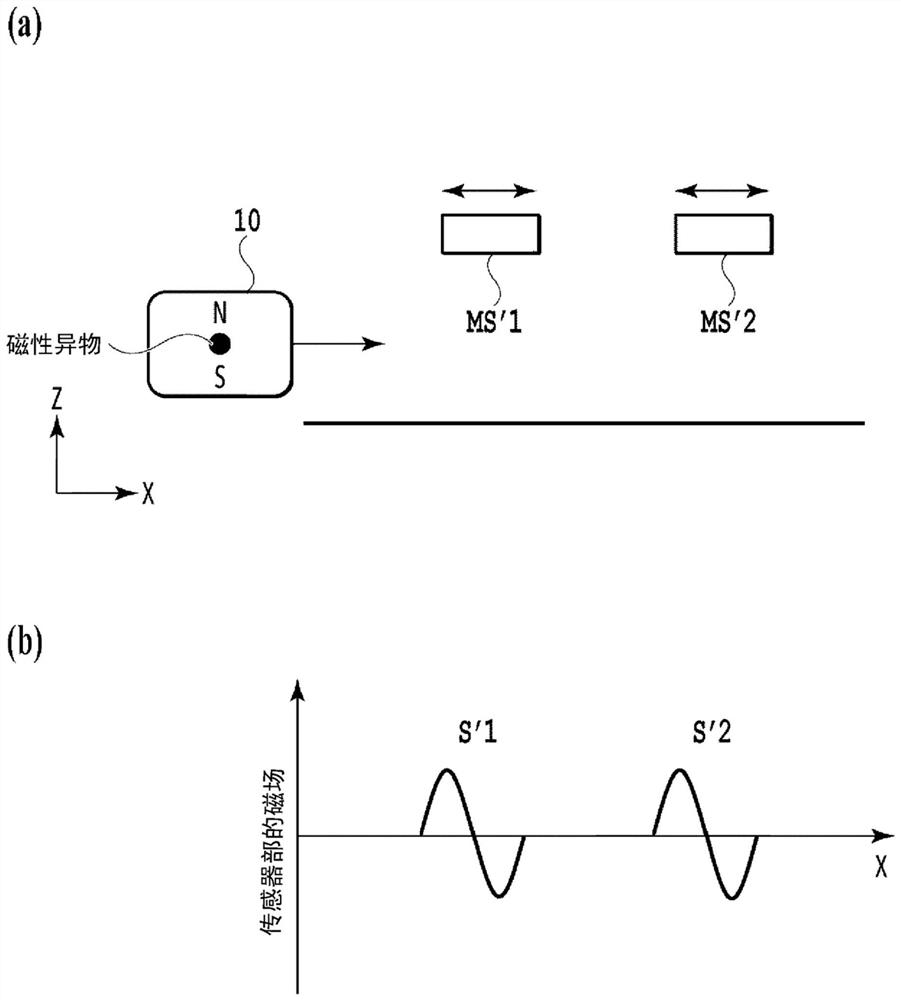

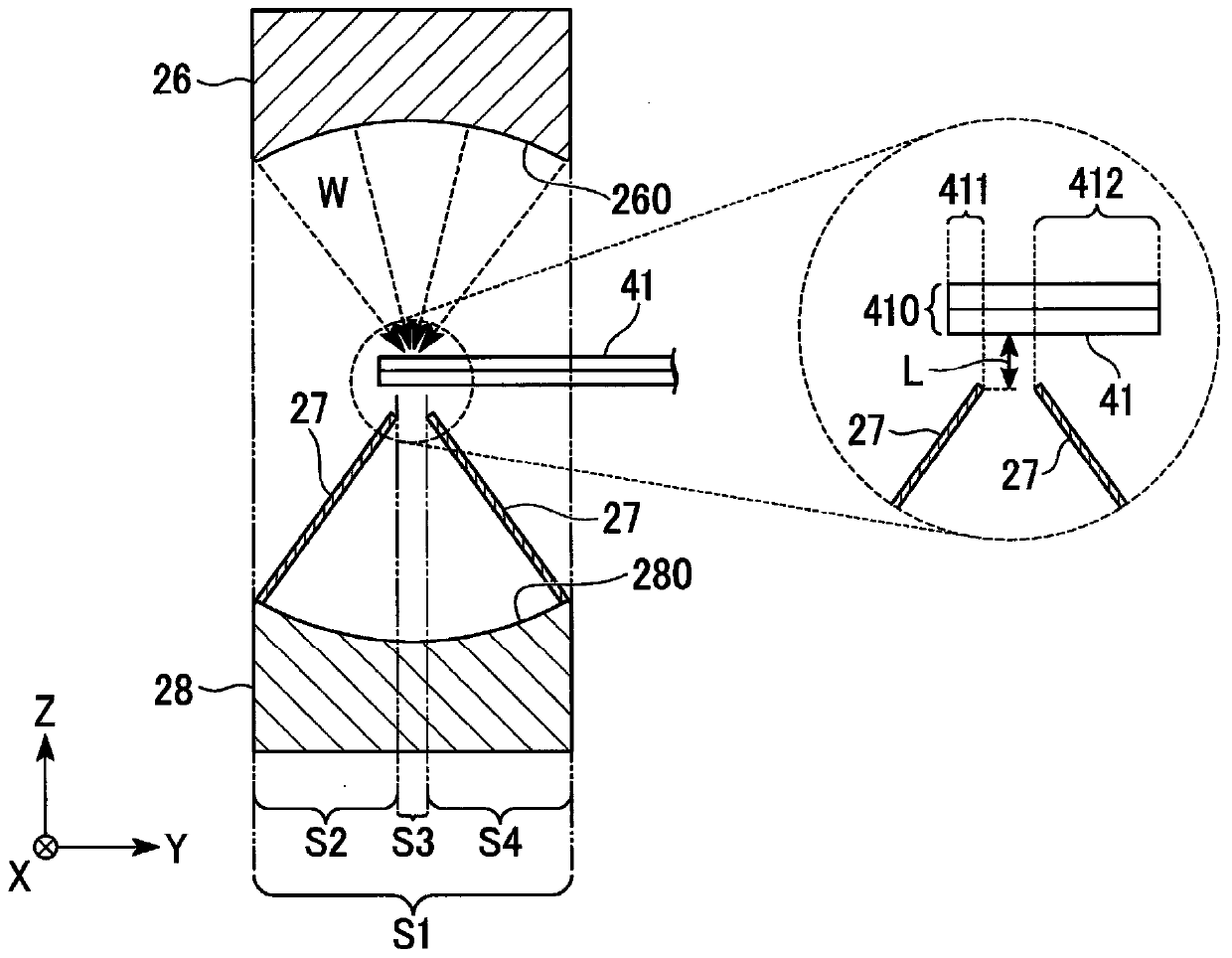

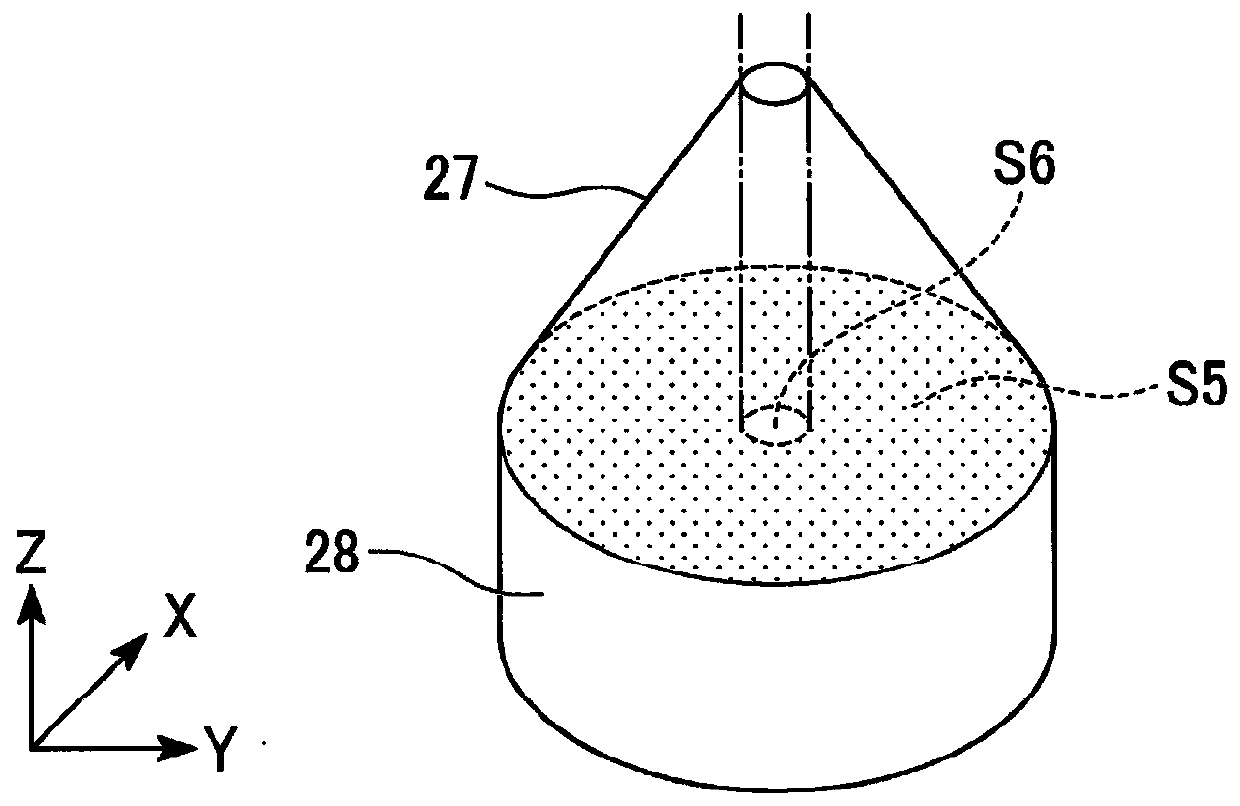

Inspection device

ActiveCN111670388AHigh precision inspectionMagnetisation measurementsVoltage-current phase angleForeign matterSignal wave

The purpose of the present invention is to provide an inspection device which, irrespective of the passing position of an inspection target, does not have a dead zone, does not have a change in polarity of a detection signal waveform, and can consecutively perform inspection. The inspection device (100) is provided with: a transport path (101) in which the inspection target is transported at a moving velocity v; a first magnetic detector (111) and a second magnetic detector (112) which detect the magnetism of magnetic foreign matter included in the inspection target (10); an amplifying unit (120) which amplifies each of detection signals from the first magnetic detector (111) and the second magnetic detector (112); and a calculation processing unit (130) which multiplies a signal, obtainedby delaying the detection signal from the first magnetic detector (111), by the detection signal from the second magnetic detector (112). The first magnetic detector (111) and the second magnetic detector (112) respectively have magnetic sensors which are paired. One magnetic sensor MS1 of the first magnetic detector, which has a vertical magnetic field detection direction, is disposed at a height h from the transport surface, and one magnetic sensor MS2 of the second magnetic detector is disposed at a distance d from the magnetic sensor MS1.

Owner:CANON DENSHI KK

High-frequency apparatus

InactiveCN100442965CPrecise positioningWell formedMagnetic/electric field screeningElectrical apparatus contructional detailsElectrical and Electronics engineeringHigh frequency

Owner:ALPS ALPINE CO LTD

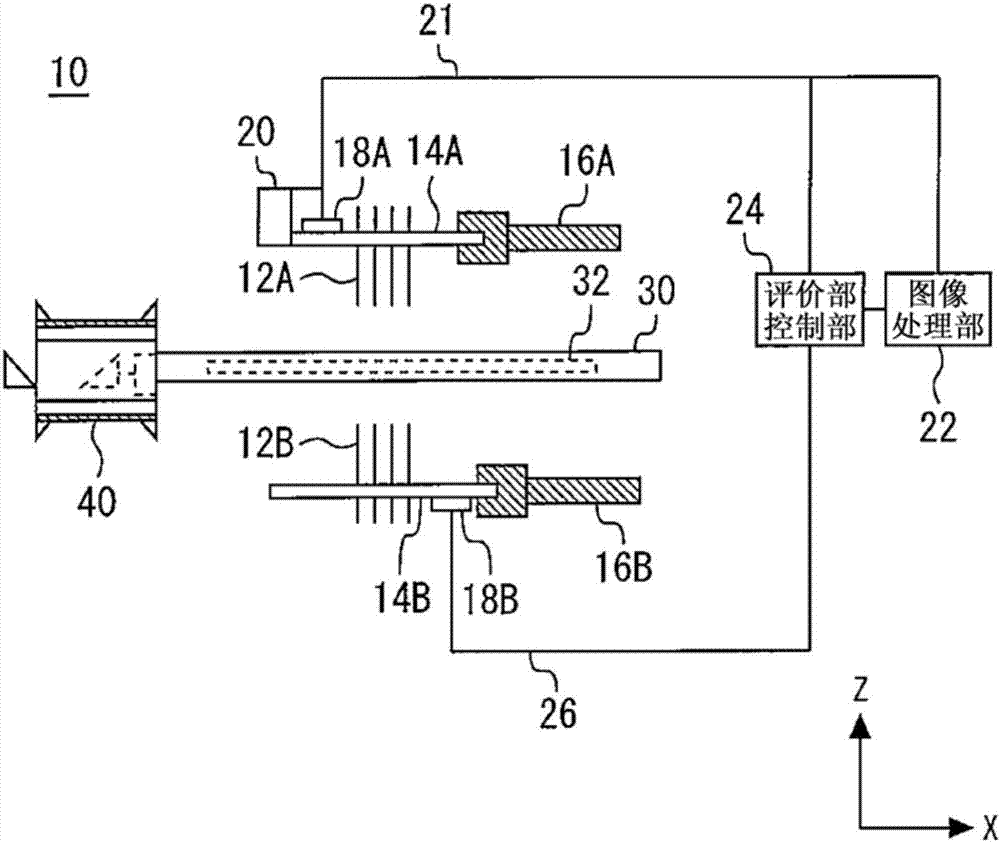

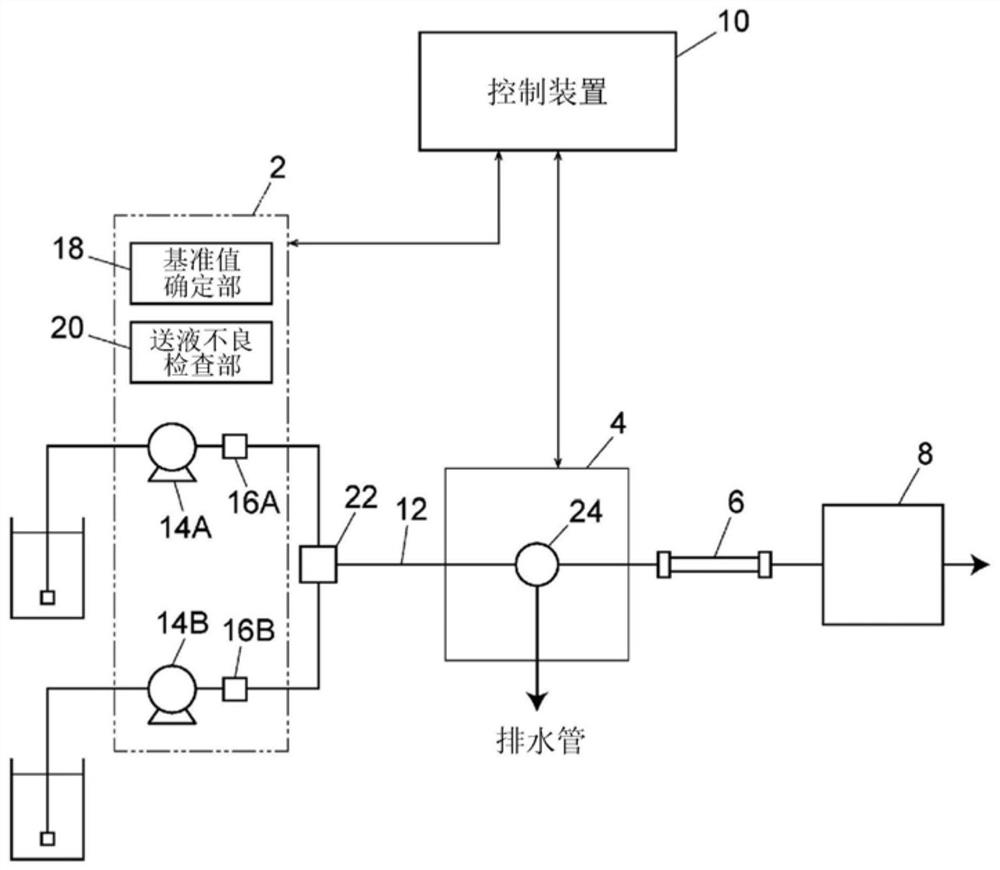

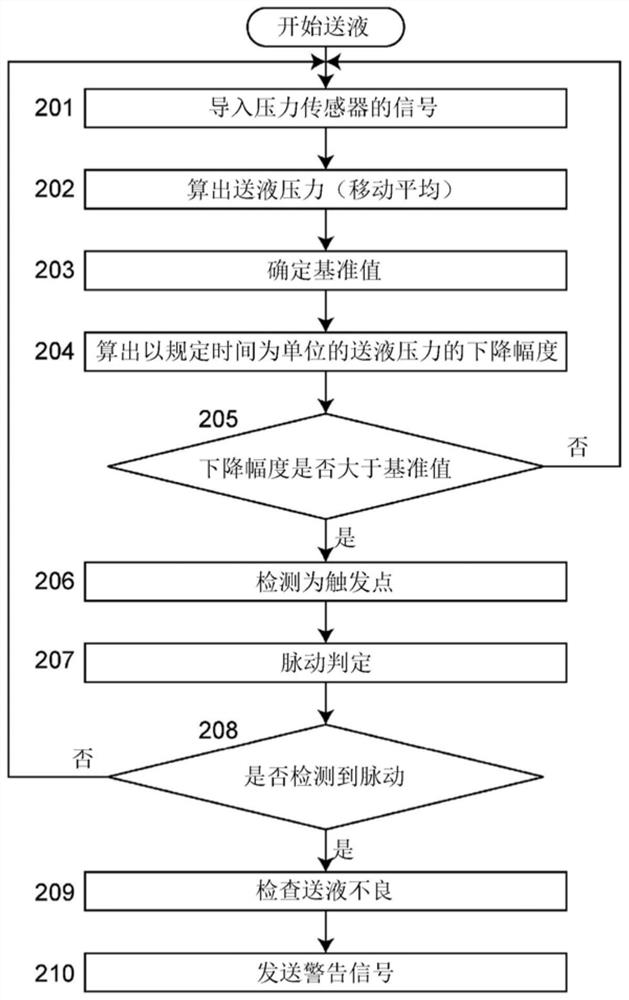

Liquid feeding system for liquid chromatography

A liquid feeding system (2, 2') is provided with a plurality of liquid feeding pumps (14A, 14B) which operate independently of each other and feed a liquid as a mobile phase through a common flow channel (12); pressure sensors (16A, 16B) for detecting the pressure of the liquid being fed in the flow channel (12); and a liquid feeding failure detection unit (20, 28) that is configured to cyclically obtain the pressure of the liquid being fed, detected by the pressure sensors (16A, 16B), and to detect, through detection of variation in the pressure of the liquid being fed in relation to the respective drive cycles of the plurality of liquid feeding pumps (14A, 14B), failure in liquid feeding by either of the plurality of liquid feeding pumps (14A, 14B).

Owner:SHIMADZU SEISAKUSHO CO LTD

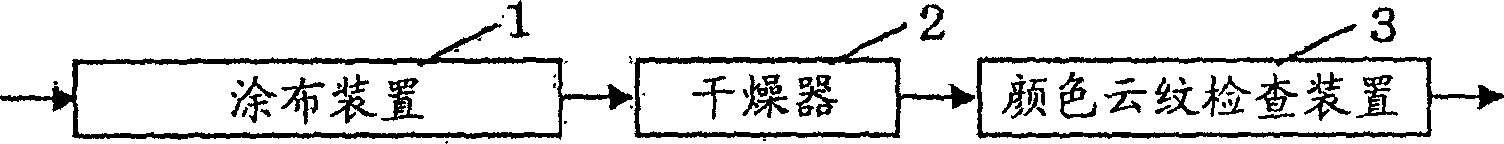

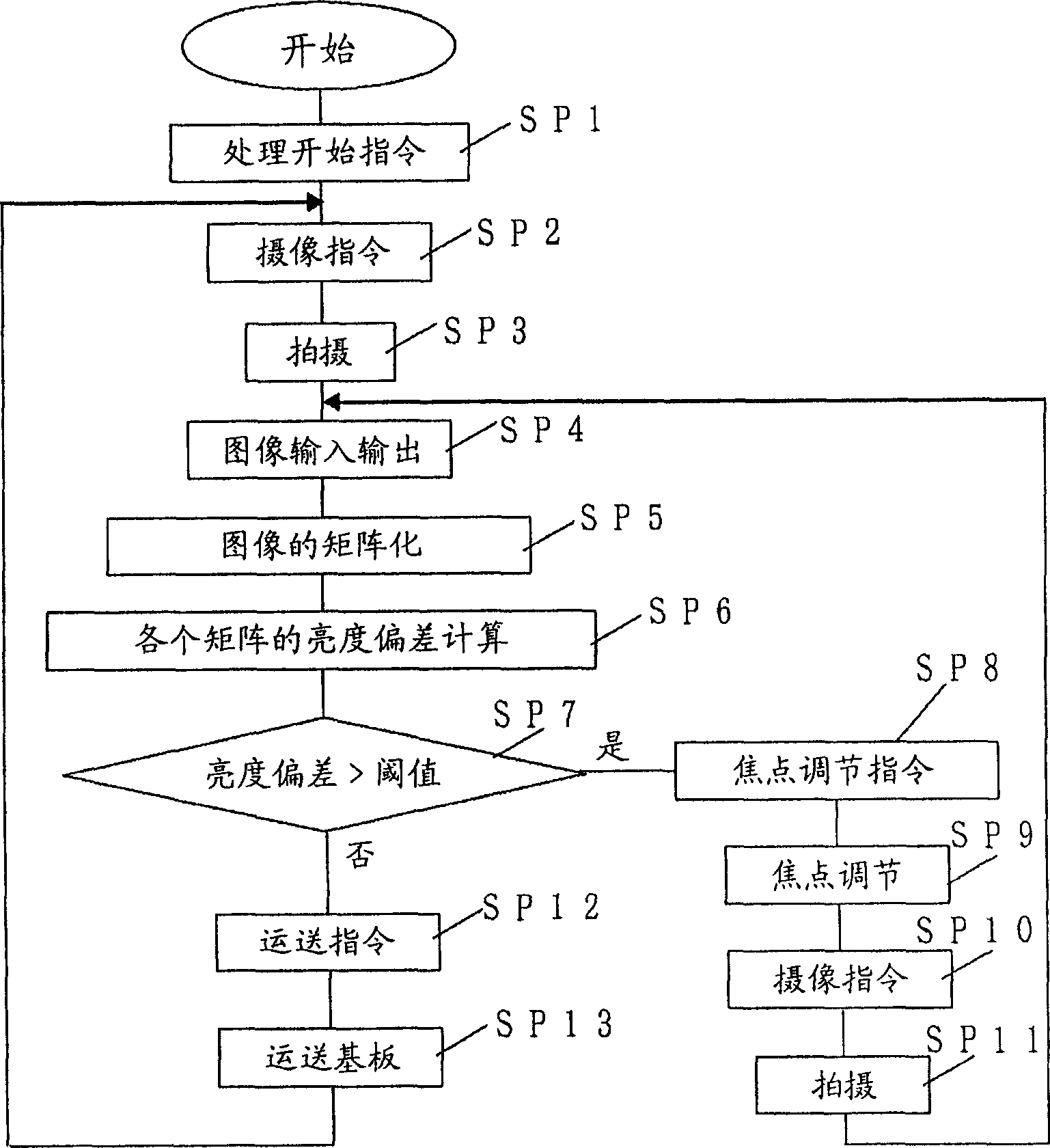

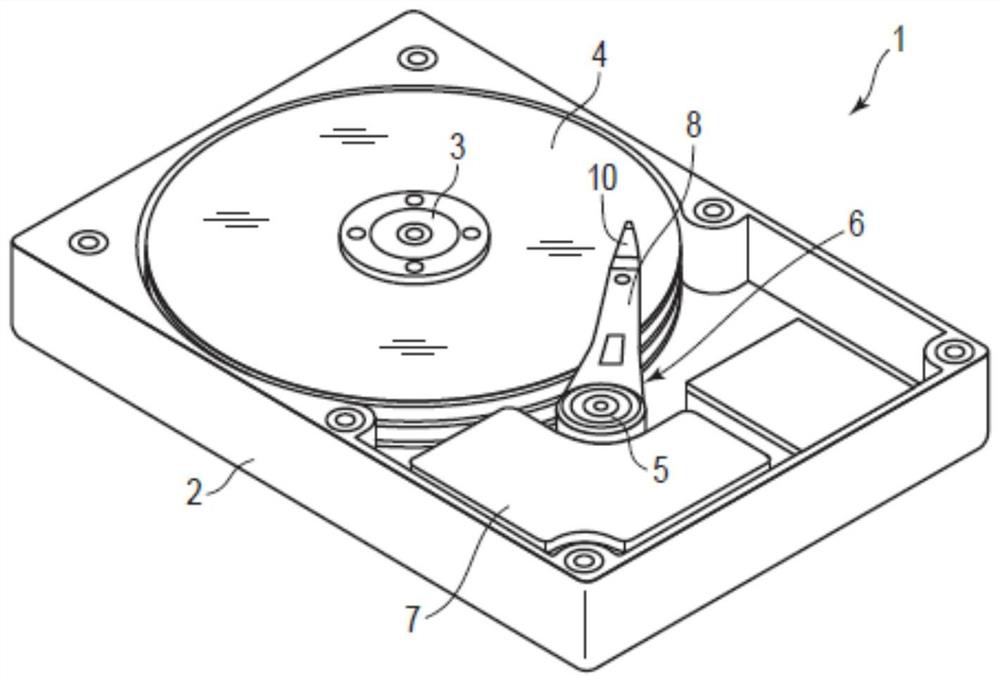

Jp2006234470

InactiveCN1834733AHigh precision inspectionOptical discsRecord information storageVideo cameraInspection method

The present invention provides a color blur inspection method and the apparatus thereof, which could inspect the existence and level of color blur in high precision without the influence by personal difference and status difference of individual. The present invention could eliminate the Mohr's stripes, adjust the focus of focusing optical system 34, employ a video camera device 35 to capture the substrate 31, and inspect the existence and level of color blur according to the photo data.

Owner:TORAY ENG CO LTD

Inspection device, installation device and inspection method

Owner:JUKI CORP

Inspection method of examination system and examination system

An inspection method for an examination system configured to image an object and make a good / defective determination of the object on the basis of an image acquired by the imaging comprises displaying a sample image of the object, imaging the displayed sample image by a camera, and making a good / defective determination of the object indicated by the sample image on the basis of the image acquired by imaging of the camera.

Owner:NHK SPRING CO LTD

Ultrasonic inspection device

ActiveCN110824001AExtension of timeHigh precision inspectionAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationEngineeringAcoustics

Owner:YAMAHA FINE TECHNOLOGIES CO LTD

Industrial robot

ActiveCN1265943CInhibitionHigh precision inspectionGripping headsScattering properties measurementsEngineeringLaser beams

An industrial robot which works in a clean room can measure the amount of particles of dust and the like in the clean room with high precision and immediate. A light-scattering type particle counter measures the amount of particles in the clean room. The particle counter is provided on a hand portion of the industrial robot and a counter inlet is arranged on the tip of the hand portion. A laser beam used in the particle counter is formed a belt-shaped.

Owner:NIDEC SANKYO (ZHEJIANG) CORPORATION +1

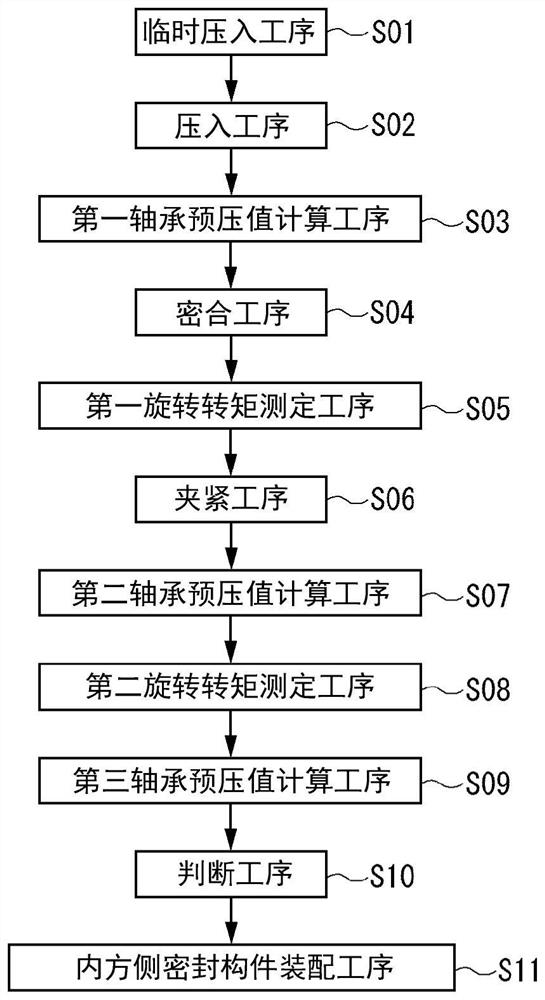

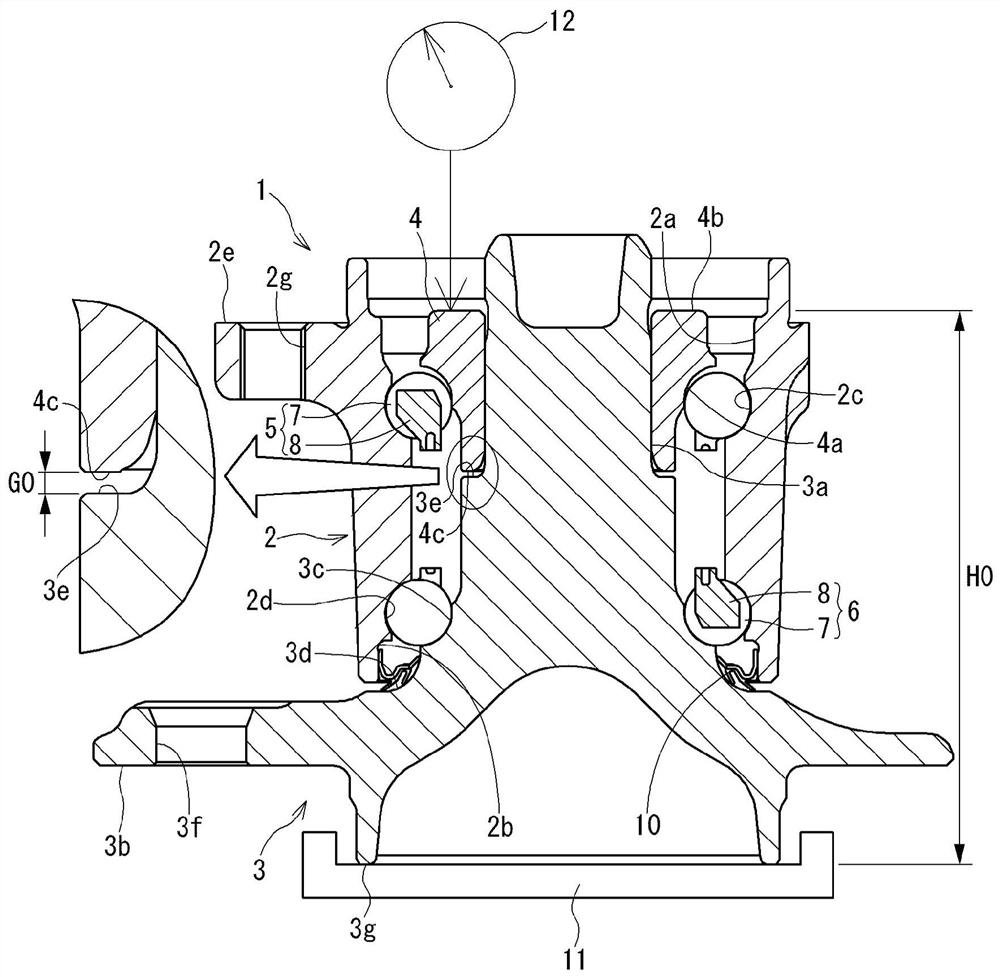

Preload inspection method and assembly method for wheel bearing device

PendingCN113366292AHigh precision inspectionRolling contact bearingsBearing assemblyClassical mechanicsControl theory

Provided is a preload inspection method for a wheel bearing device enabling more accurate checking of preload. The invention comprises: a press-fitting step (S02) for press-fitting an inner ring (4) to a small-diameter stepped part (3a); a first bearing preload value calculation step (S03) for calculating a first bearing preload value (P1) on the basis of a first axial direction negative clearance (G1); a first rotating torque measurement step (S05) for measuring a first rotating torque Ta after the press-fitting step; a swaging step (S06) for swaging the small-diameter stepped part to the inner ring after the first rotating torque measurement step; a second bearing preload value calculation step (S07) for calculating a second bearing preload value (P2) on the basis of a second axial direction negative clearance (G2); a second rotating torque measurement step (S08) for measuring a second rotating torque Tb after the swaging step; a third bearing preload value calculation step (S09) for calculating a third bearing preload value (P3) by adding, to the first bearing preload value, a preload change amount (Delta P) based on a differential torque (Delta T) between the first rotating torque and the second rotating torque; and a determination step (S10) for determining the suitability of the preload from the second bearing preload value and the third bearing preload value.

Owner:NTN CORP

Chip check apparatus

InactiveCN100472743CCompact structureReduced footprintSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

To provide a wafer inspection device which can realize an efficient configuration for suppressing an increase in footprint and can inspect a wafer with high accuracy.The wafer inspection device has a cassette part 2 and a wafer inspection part 3 including a microscope 6 and an XY stage 7 for moving the wafer 10. The cassette part 2 comprises a cassette 4 for holding the wafer 10 and an elevator 5. The wafer inspection part 3 comprises a carrying arm 18 that is arranged on the XY stage 7 to insert / extract the wafer 10 by arm pieces 181, 182 which can linearly move toward an opening of the cassette 4 and can be inserted between wafers 10 in the cassette 4, and a wafer rotary mounting base 22 which is vertically movable above the XY stage 7 to carry-in / carry-out the wafer to the carrying arm 18 by the vertical movement, a centering means for making the center of the wafer 10 and the rotary center of the wafer rotary mounting base 22 coincide with each other, and a detecting means for detecting the orientation of the wafer. (C)2004,JPO.

Owner:OLYMPUS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com