Appearance inspection device and inspection method for component installation state

A technology for inspection devices and patterns, applied in measurement devices, electrical components, electrical components, etc., can solve the problems of inability to determine the color of solder, large color changes, and rising equipment costs, and achieve shortened program generation time, fewer production steps, and errors. Judgment less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0056] Hereinafter, an embodiment of the present invention will be described in detail using the drawings. First, the configuration of the inspection device will be described in detail.

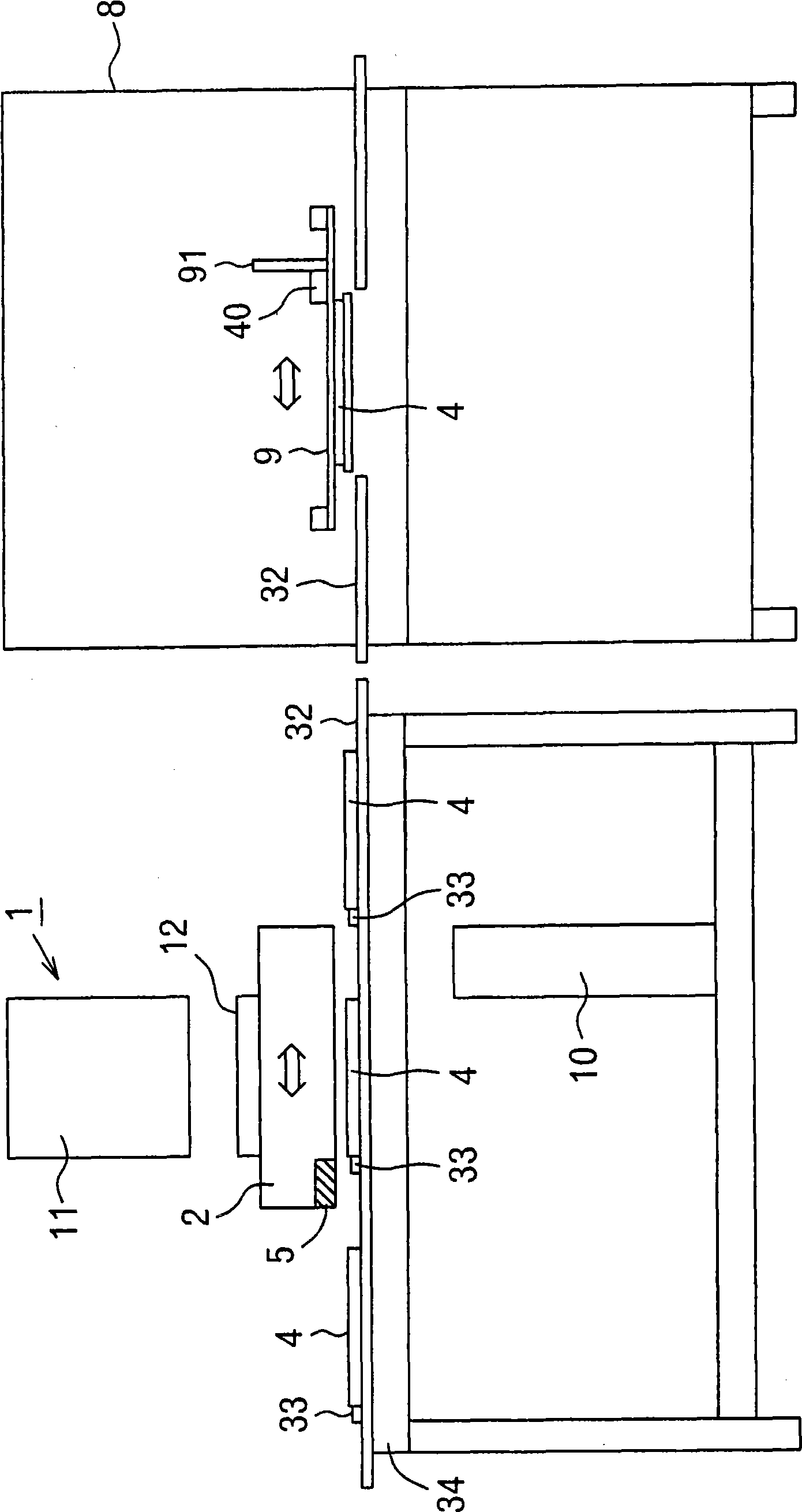

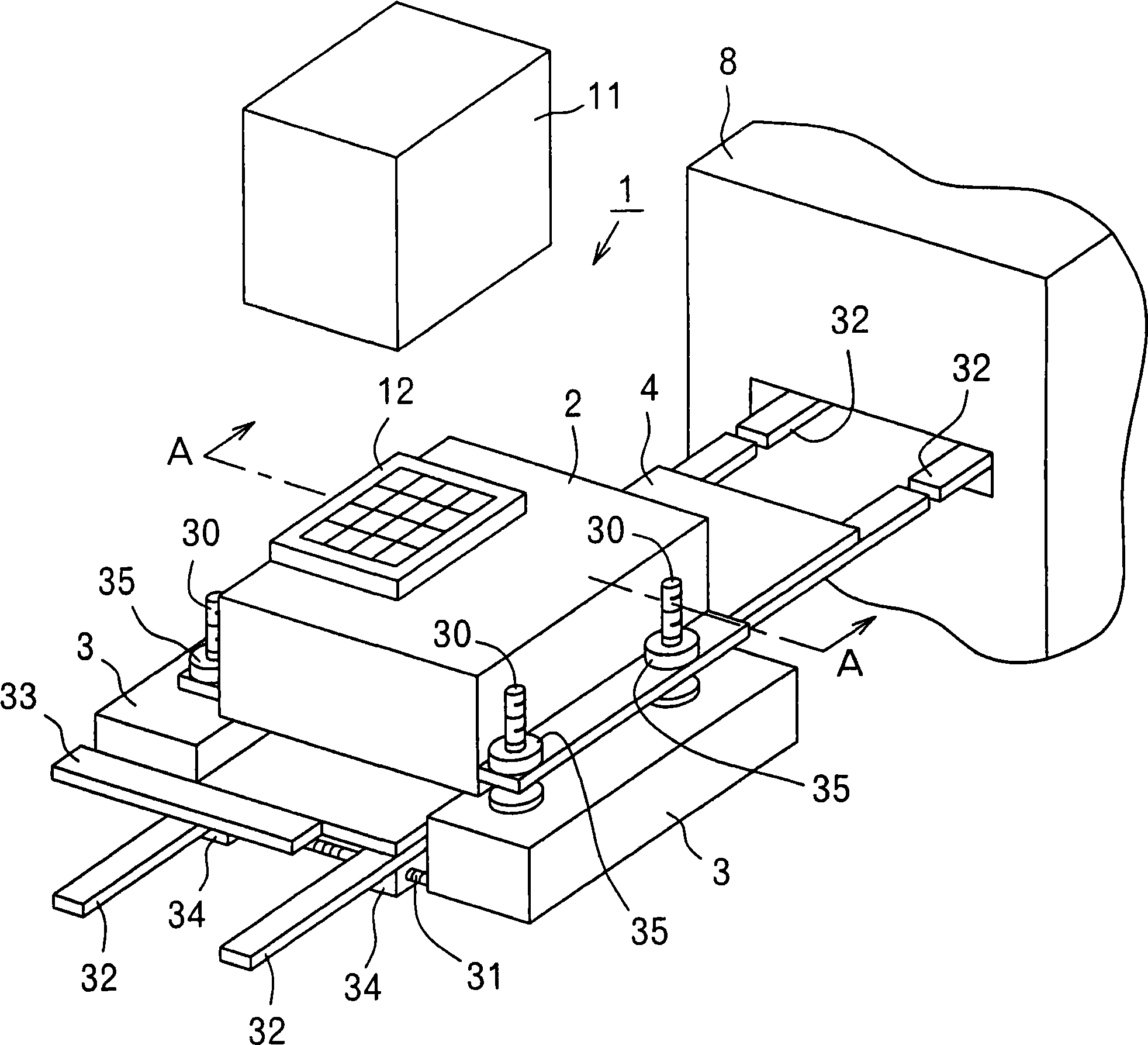

[0057] figure 1 It is a front view showing the outline of the inspection device 1 . figure 2 is a perspective view of the inspection device 1 .

[0058] The inspection device 1 is provided on a conveyor belt 32 extending left and right and driven intermittently, and a plurality of printed circuit boards 4 , 4 to be soldered are placed on the conveyor belt 32 to be separated from each other. A printing machine 8 is provided on the upstream side of the conveyor belt 32 from the inspection device 1 . An electronic component mounter for mounting electrons on the printed circuit board 4 and a reflow furnace (not shown) for thermally hardening solder are provided on the downstream side of the conveyor belt 32 from the inspection device 1 . The conveyor belt 32 of the printing press 8 and the ...

no. 2 example

[0083] Figure 11 It is a plan view showing an image scanner 2 of another embodiment. A general commercially available scanner reads A4 size (length 21 cm x width 30 cm) at the maximum, and if the size of the printed circuit board 4 is increased in resolution by A4 size, the scanning time will become longer. In this example, three reading modules, namely, the first reading module 5 , the second reading module 50 and the third reading module 51 are provided in the image scanner 2 . For ease of illustration, the guide shafts 21, 21 are not shown. The 1 / 3 area from the upstream side of the printed substrate 4, that is, the right side, is scanned by the first reading module 5, and the 1 / 3 area from the downstream side of the printed substrate 4, that is, the left side, is scanned by the second reading module 50. image. which is, Figure 12 Among them, the image of area X is scanned by the first reading module 5 , and the image of area Y is scanned by the second reading module ...

no. 3 example

[0088] Figure 14 It is a plan view showing an image scanner 2 of another embodiment. In this example, with multiple Figure 14 In the middle are ten vertical reading modules 52, 52, which do not move. Instead, the printed substrate 4 on the conveyor belt 32 moves. This requires inspection at a high resolution of about 5 to 10 micrometers in the inspection of damage, stains, foreign matter, and patterns on the printed circuit board 4 , which is considerably time-consuming. Therefore, by providing a plurality of vertical reading modules 52, 52 with a smaller planar area than the horizontal type, the inspection surface is divided, the moving distance of the printed circuit board 4 is shortened, and the scanning time is reduced. Furthermore, the number of vertical reading modules 52, 52 is not limited to Figure 14 the number shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com