Paper feeding and paper feeding structure of a scanner

A scanner and paper feeding technology, applied in the field of scanners, can solve the problems of reducing the scanning speed, reducing the scanning speed of the scanner, unable to guarantee the paper backward, etc., to achieve the effect of ensuring the scanning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

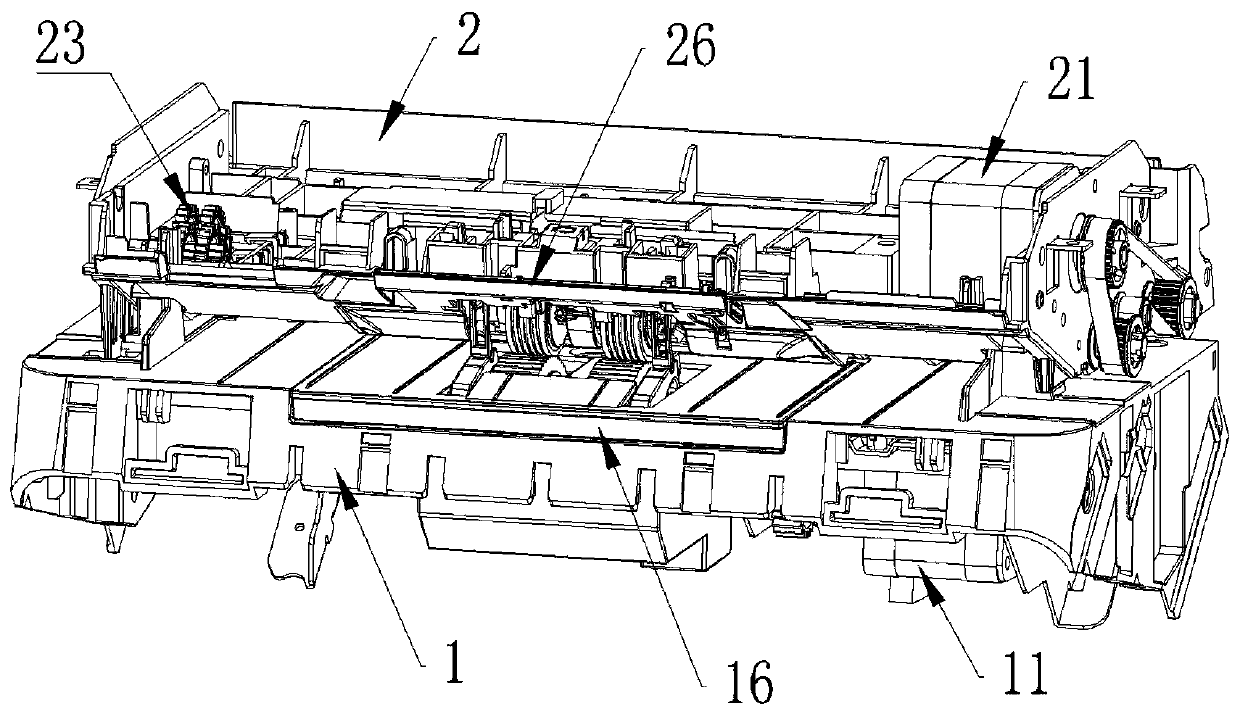

[0034] The embodiments of the present invention will be further described below in conjunction with the drawings.

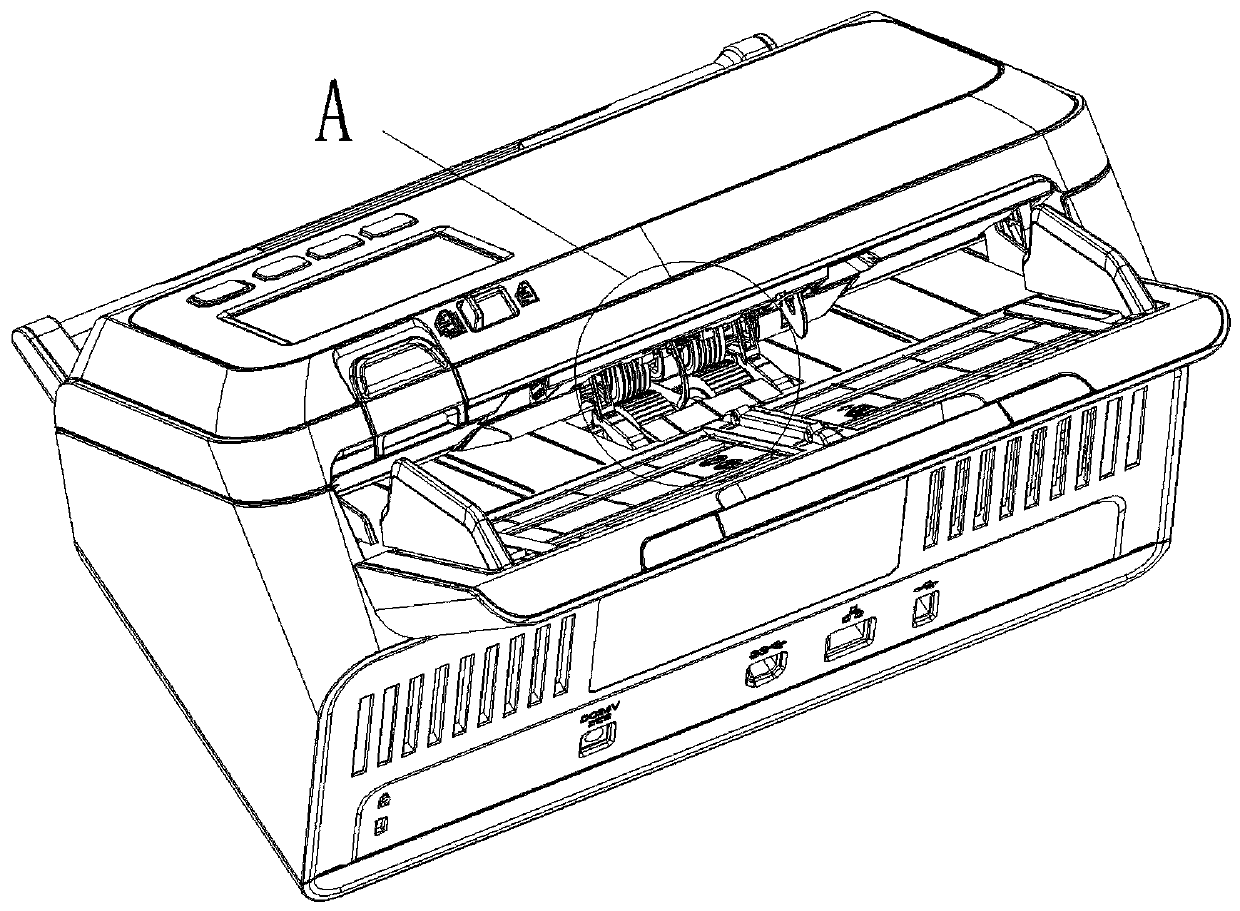

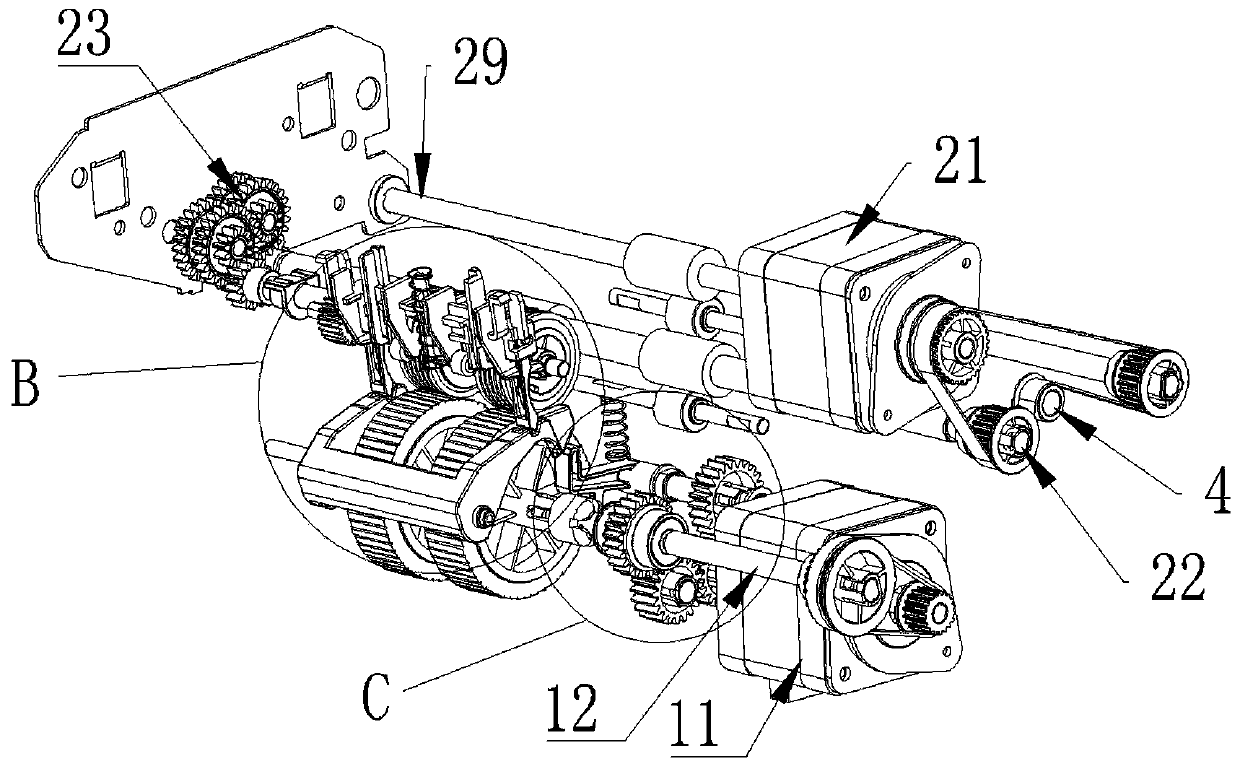

[0035] Such as Figure 1-3 As shown, this embodiment relates to a paper feeding and feeding structure of a scanner, including a paper pickup bracket 1 and a paper feeding bracket 2. The pickup bracket 1 is provided with a paper pickup motor 11, and the pickup motor 11 drives a paper pickup and feed The paper drive shaft 12 rotates, and the paper feed support 2 is provided with a paper feed motor 21, and the paper feed motor 21 drives the first paper feed roller 22 to rotate.

[0036] Such as Figure 6-7 As shown, in this embodiment, the first paper feed roller 22 is meshed and connected with a reduction gear set 23, and the reduction gear set 23 is connected to a paper feed rotating shaft sleeve 24 through a gear or a transmission rod. A torque limiter 241 is provided, the paper feed rotation shaft sleeve 24 drives the paper separation wheel 25 to rotate, and the pape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com