Chip check apparatus

A technology for inspecting equipment and wafers, which is applied in the direction of instruments, semiconductor/solid-state device testing/measurement, and analyzing materials, etc. It can solve the problems of not being able to set up a swing stage, etc., and achieve increased occupied area, compact equipment structure, and high-precision wafer inspection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] An embodiment of the present invention will be described in detail below with reference to the drawings.

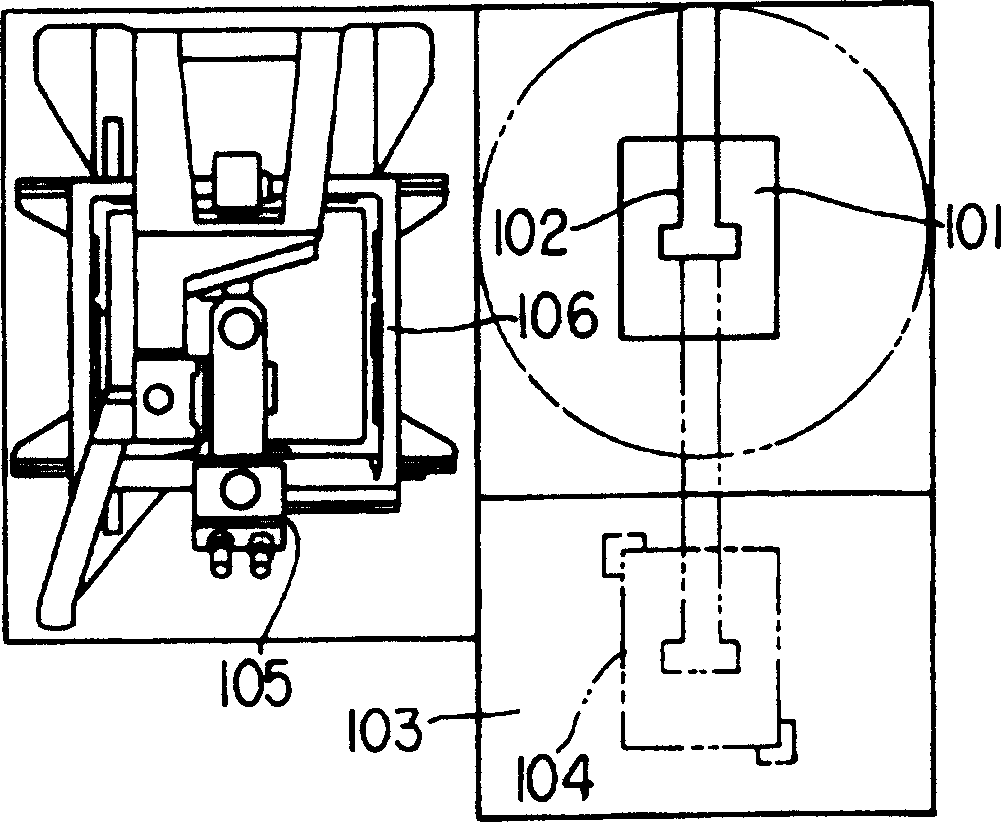

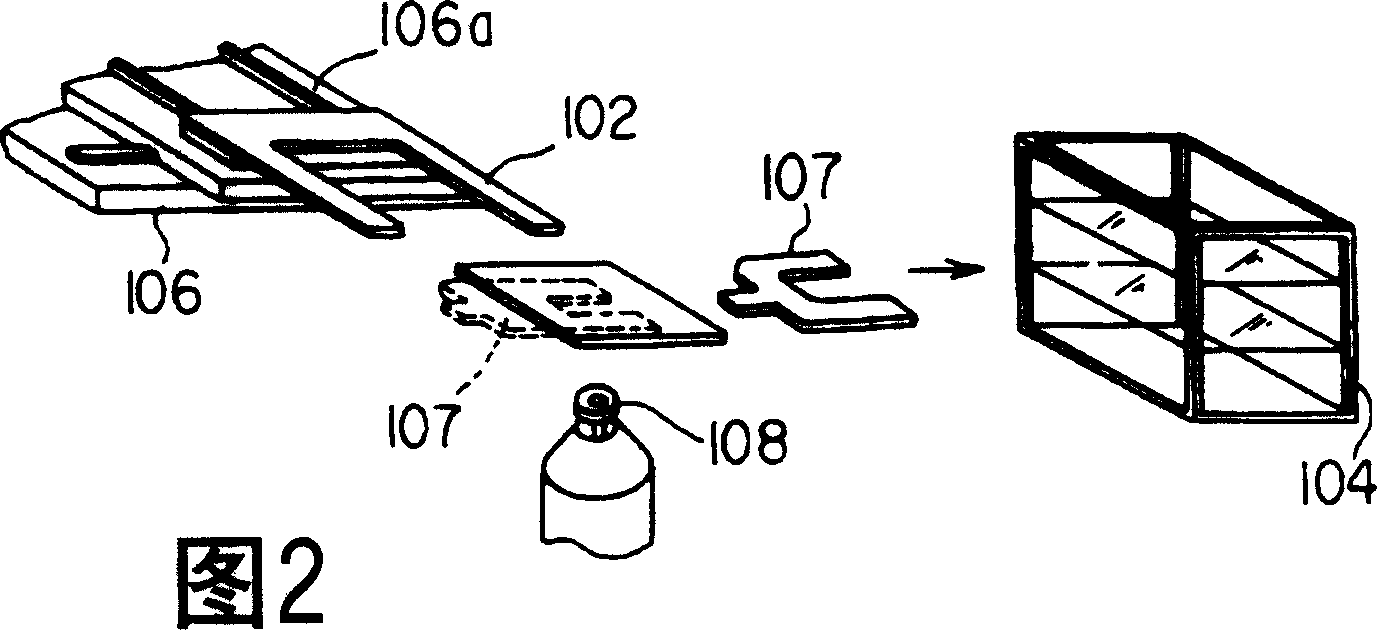

[0034] Figure 6A and FIG. 6B is a schematic diagram showing a structure of a wafer inspection apparatus according to an embodiment of the present invention, Figure 6A 6B is a front view, and FIG. 6B is a plan view.

[0035] exist Figure 6A As shown in FIG. 6B , the apparatus main body 1 has a cassette unit 2 for storing wafers 10 described below as substrates, and a wafer inspection unit 3 for inspecting the wafers 10 .

[0036]The cassette unit 2 has a cassette 4 storing a plurality of wafers 10 . The film cassette 4 has an elevating device 5 for moving the entire film cassette 4 in the vertical direction.

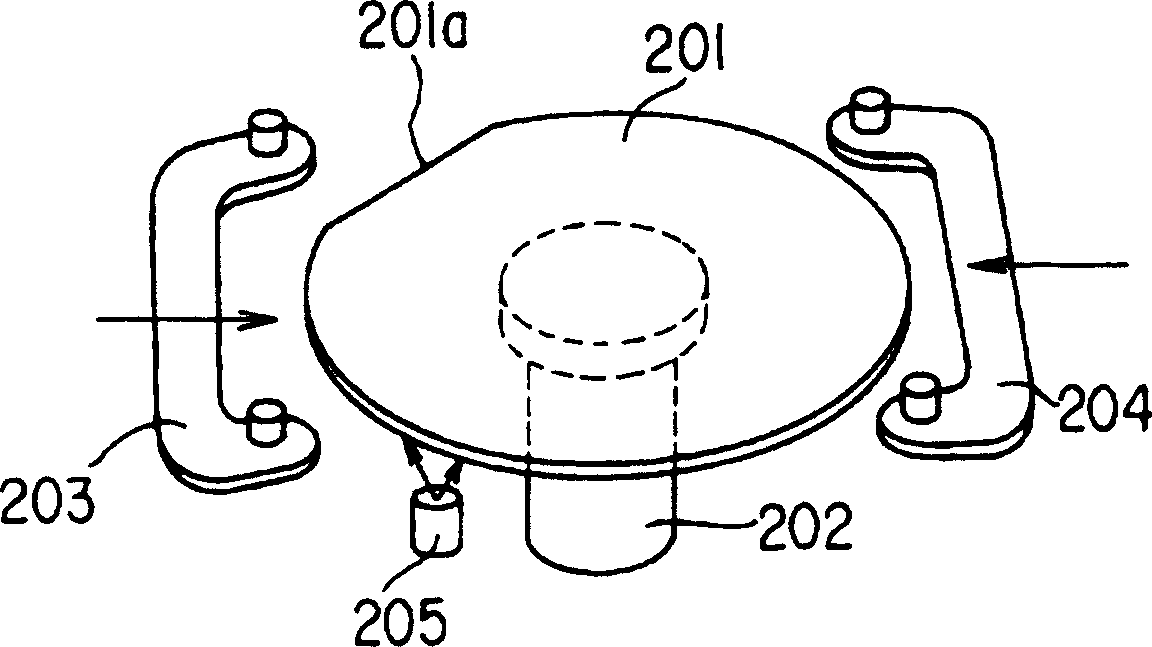

[0037] The wafer inspection unit 3 has a microscope 6 as an optical observation device for optically observing the wafer 10, and an XY stage 7 for placing the wafer 10 so as to be movable in the XY axis directions. This XY stage 7 has a wafer transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com