Glass substrate defect inspection device and glass substrate defect inspection method

A technology for inspection of glass substrates and defects, applied in measuring devices, optical devices, and material analysis through optical means, can solve problems such as no public solutions, jumping of the front end of the glass substrate, and no public solutions to problems, etc. Achieve high-precision inspection and ensure flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiment of the glass substrate defect inspection apparatus of this invention is demonstrated based on drawing.

[0025] figure 1 It is a block diagram showing the first embodiment of the glass substrate defect inspection apparatus 100 . The glass substrate defect inspection apparatus 100 roughly includes: an inspection unit 10 for inspecting a glass substrate P; unit 40; an air supply and suction unit 50 including a compressed air supply source 51 for supplying compressed air to the transport unit 40 and a vacuum supply source 52 for sucking in air; and an overall control unit 60 for monitoring and controlling the status of each part.

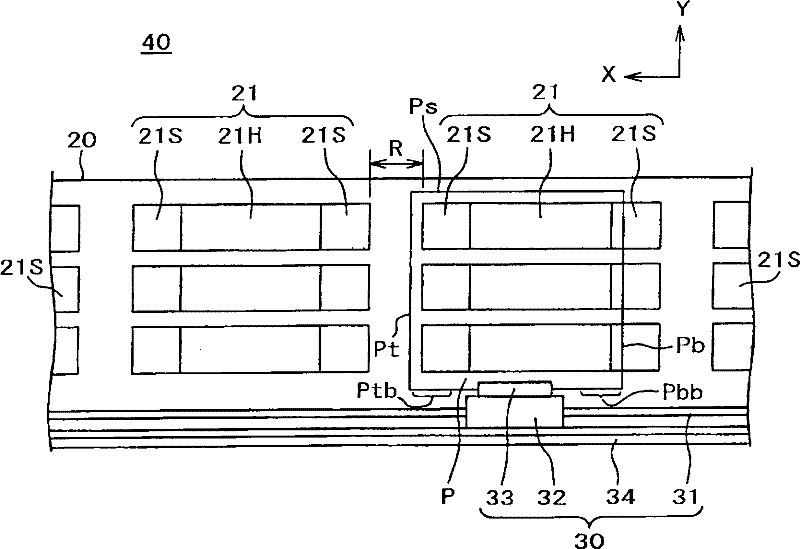

[0026] figure 2 It is a figure which shows the schematic structure seen from the upper part of the conveyance part 40 which concerns on 1st Embodiment of this invention. The air suspension stage 20 has a plurality of rectangular divided stages 21 arranged in the conveyance direction (X) and the direction Y perpendicul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com