Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "High olefin content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

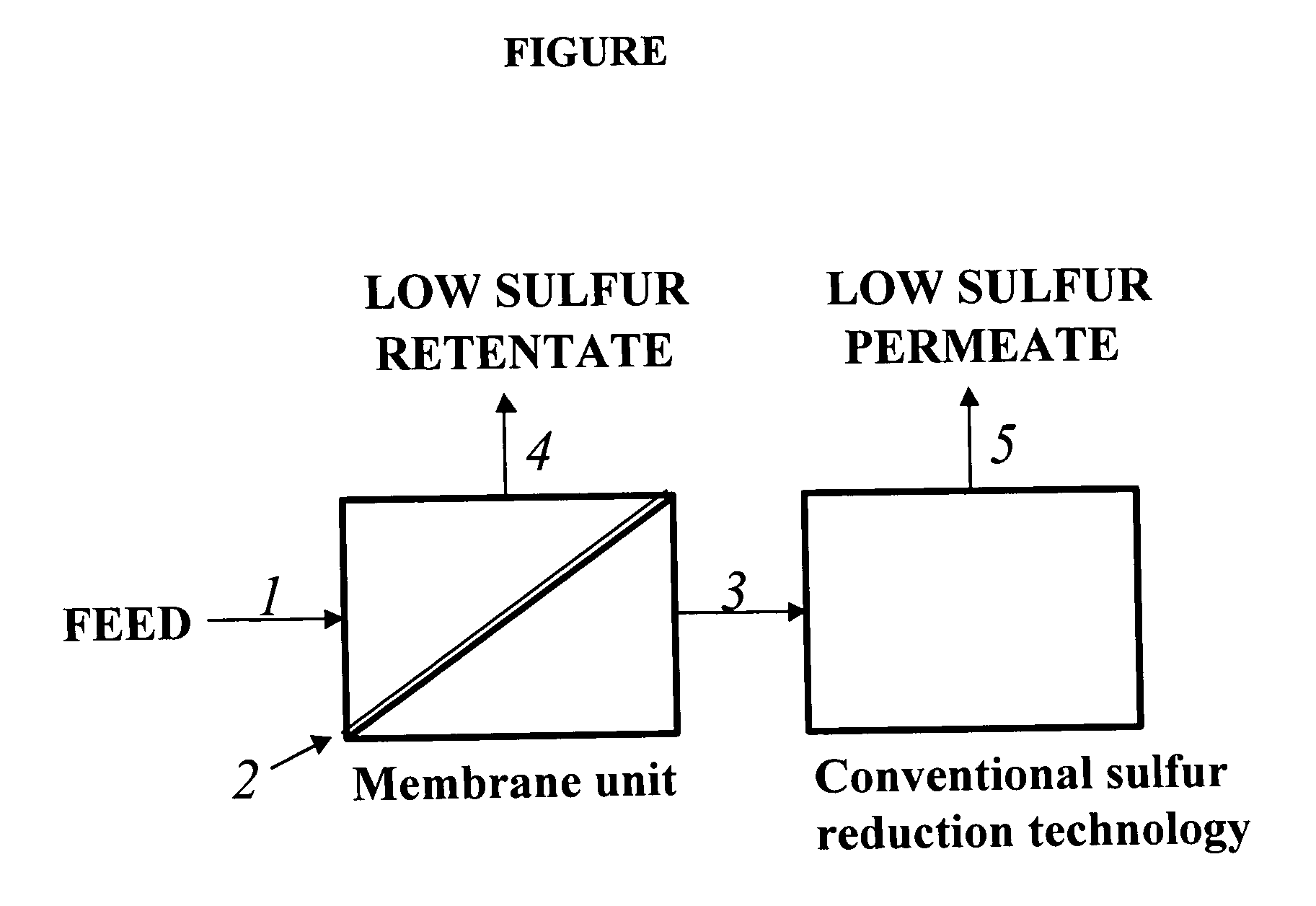

Membrane separation for sulfur reduction

InactiveUS6896796B2Improve economyMinimized volumeDialysisTreatment with plural serial refining stagesNaphthaGasoline

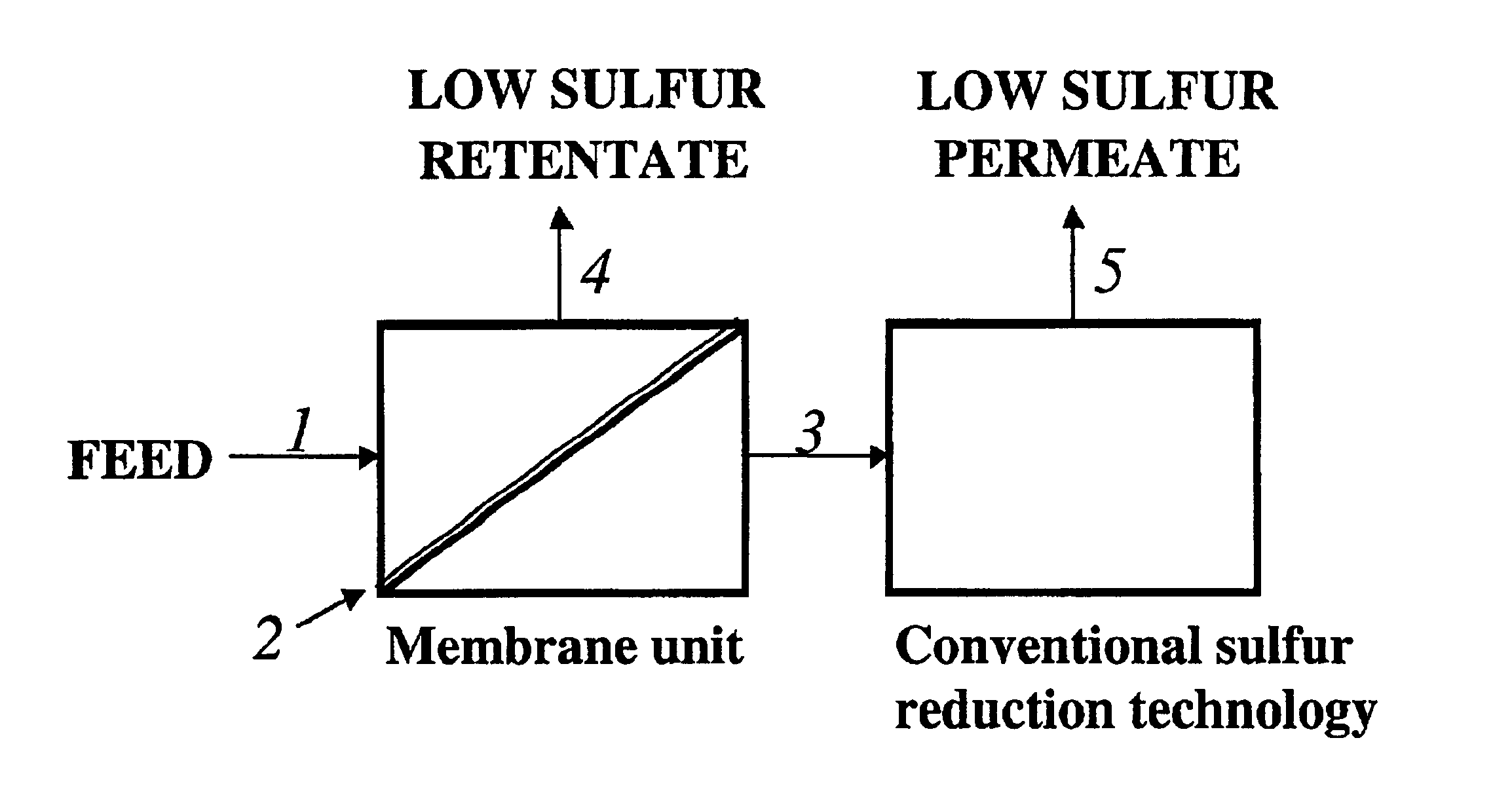

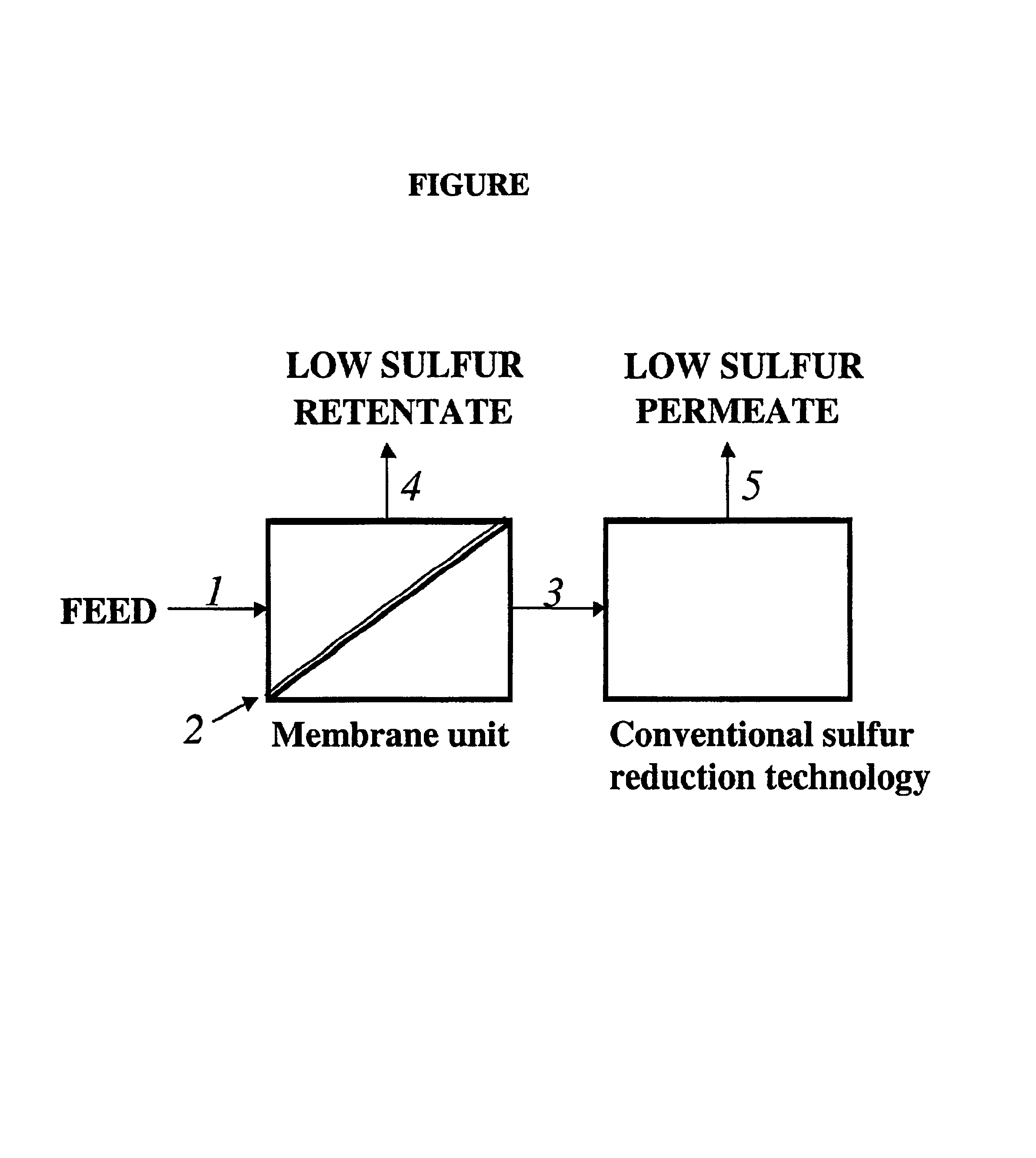

A membrane process for the removal of sulfur species from a naphtha feed, in particular, a FCC light cat naphtha, without a substantial loss of olefin yield is disclosed. The process involves contacting a naphtha feed stream with a membrane having sufficient flux and selectivity to separate a sulfur deficient retentate fraction from a sulfur enriched permeate fraction, preferably, under pervaporation conditions. Sulfur deficient retentate fractions are useful directly into the gasoline pool. Sulfur-enriched permeate fractions are rich in sulfur containing aromatic and nonaromatic hydrocarbons and are further treated with conventional sulfur removal technologies, e.g. hydrotreating, to reduce sulfur content. The process of the invention provides high quality naphtha products having a reduced sulfur content and a high content of olefin compounds.

Owner:WR GRACE & CO CONN

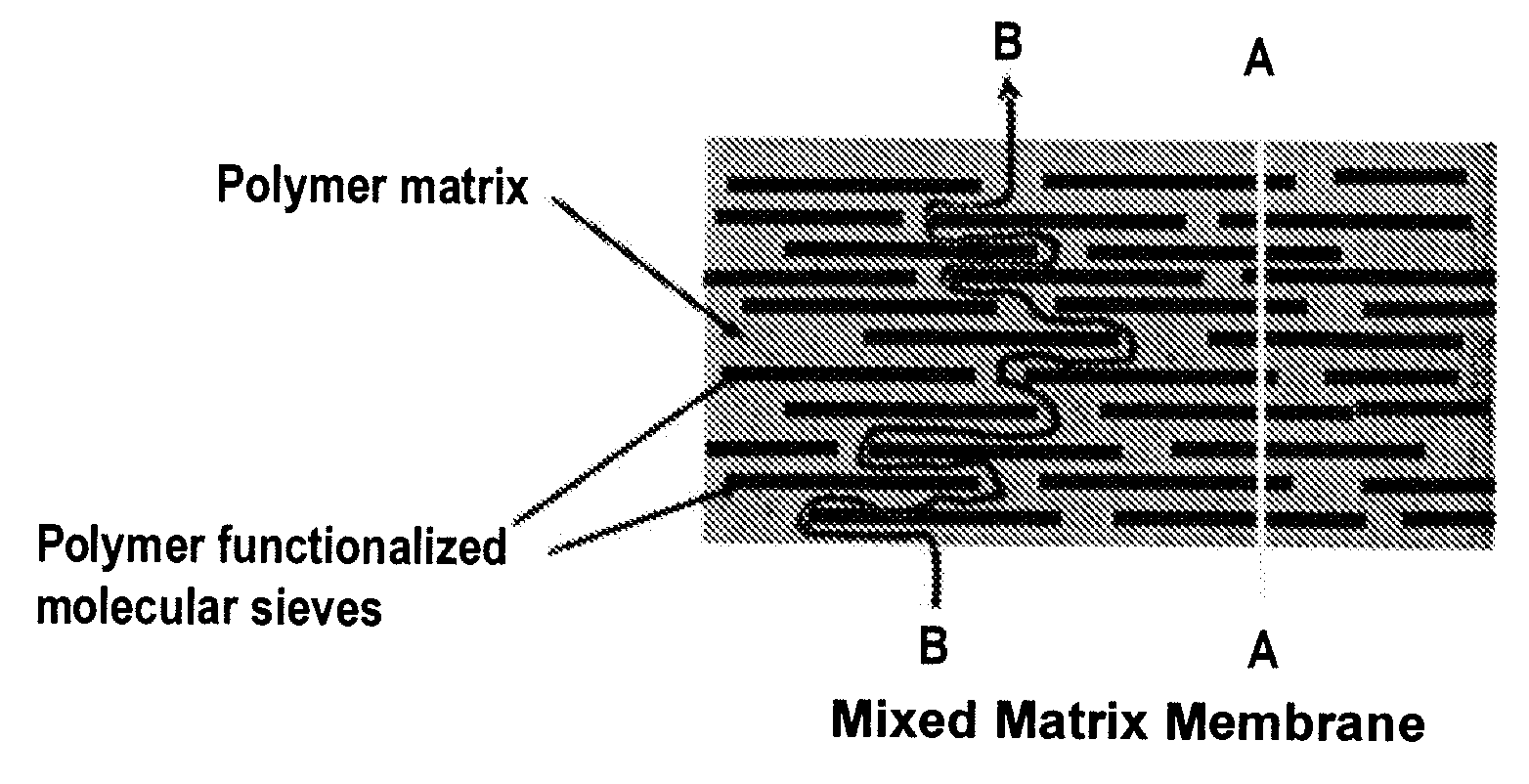

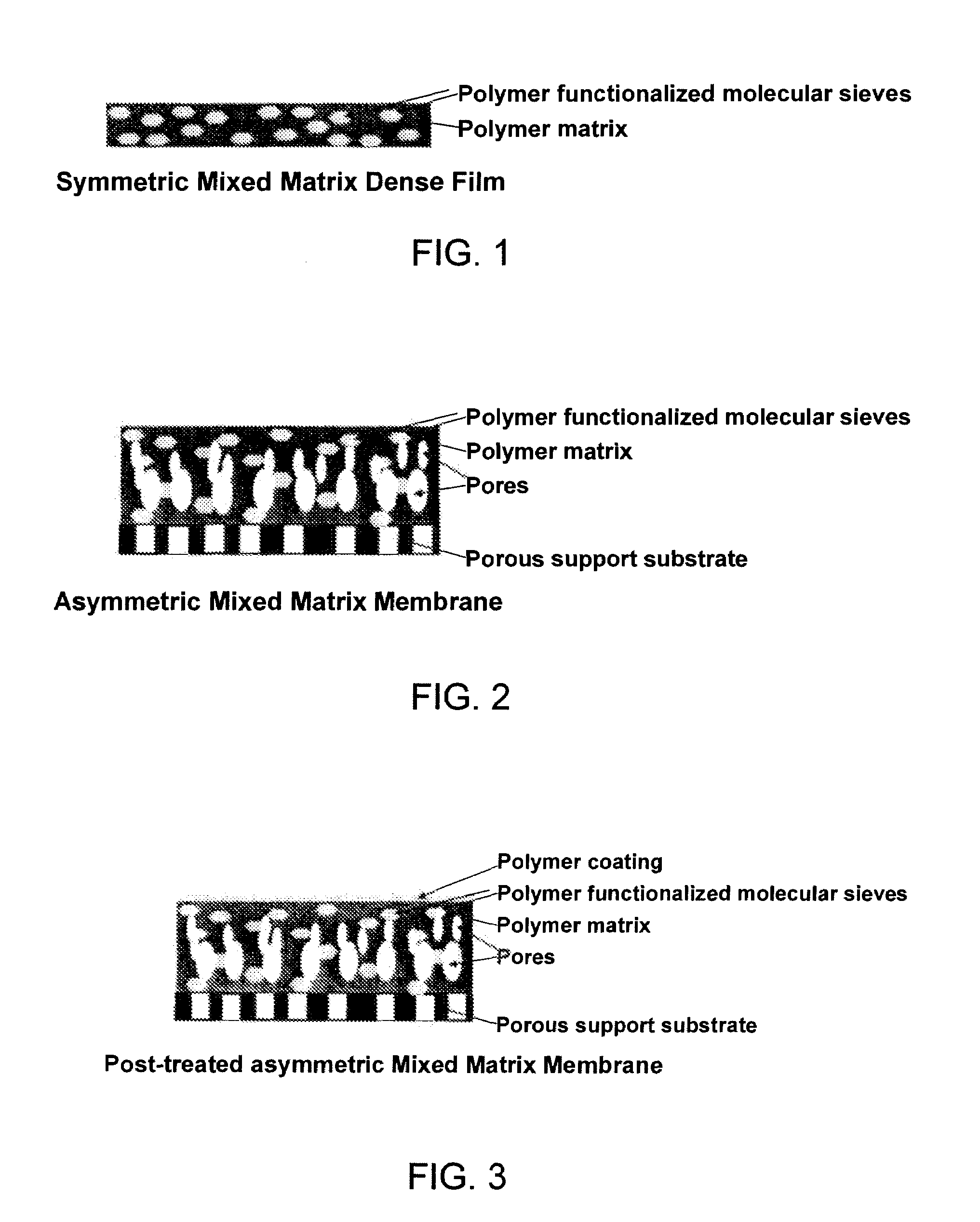

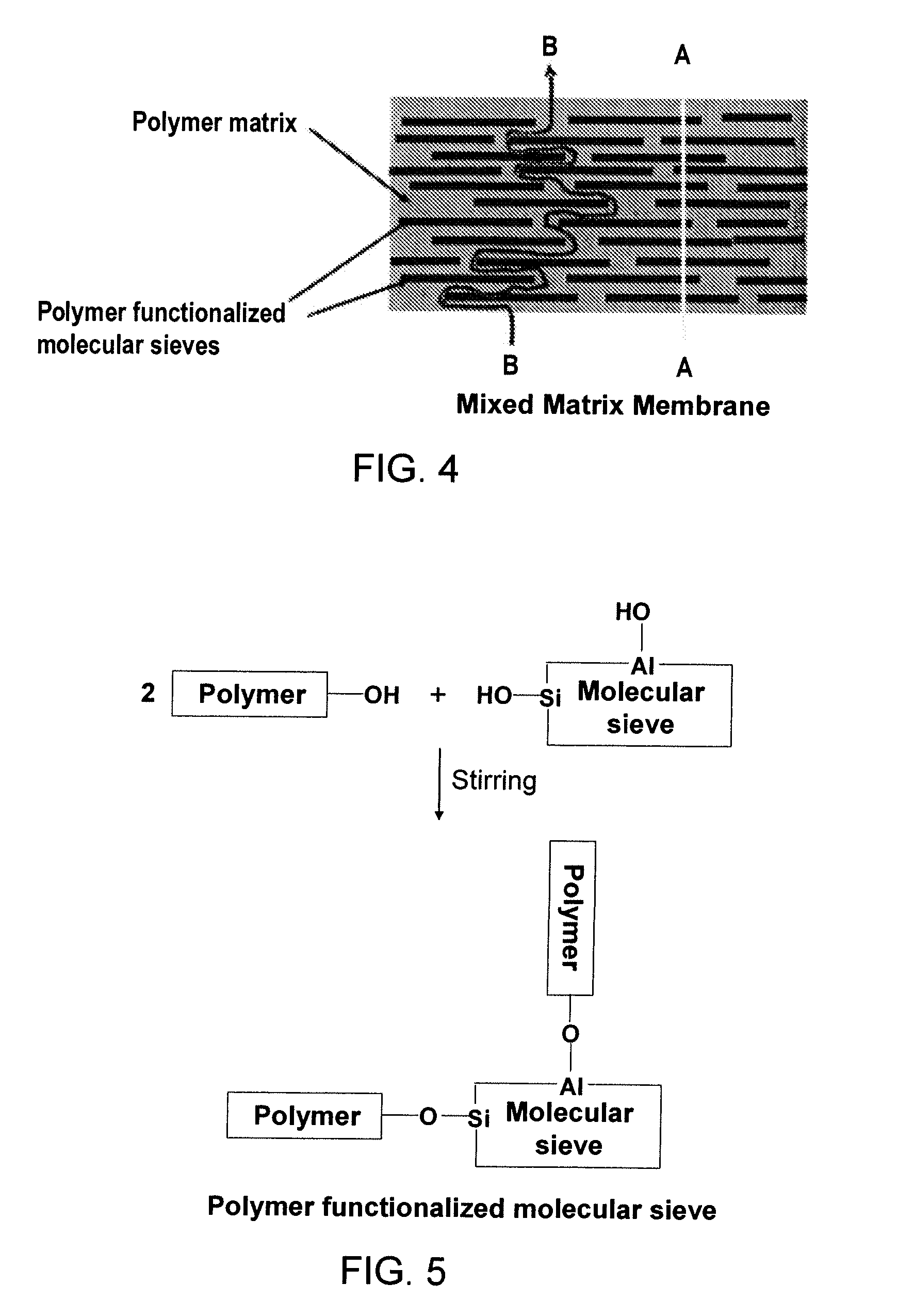

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes for sulfur reduction

InactiveUS20080295692A1Easy to separateAverage permeabilityMembranesSemi-permeable membranesCross-linkPolymer chemistry

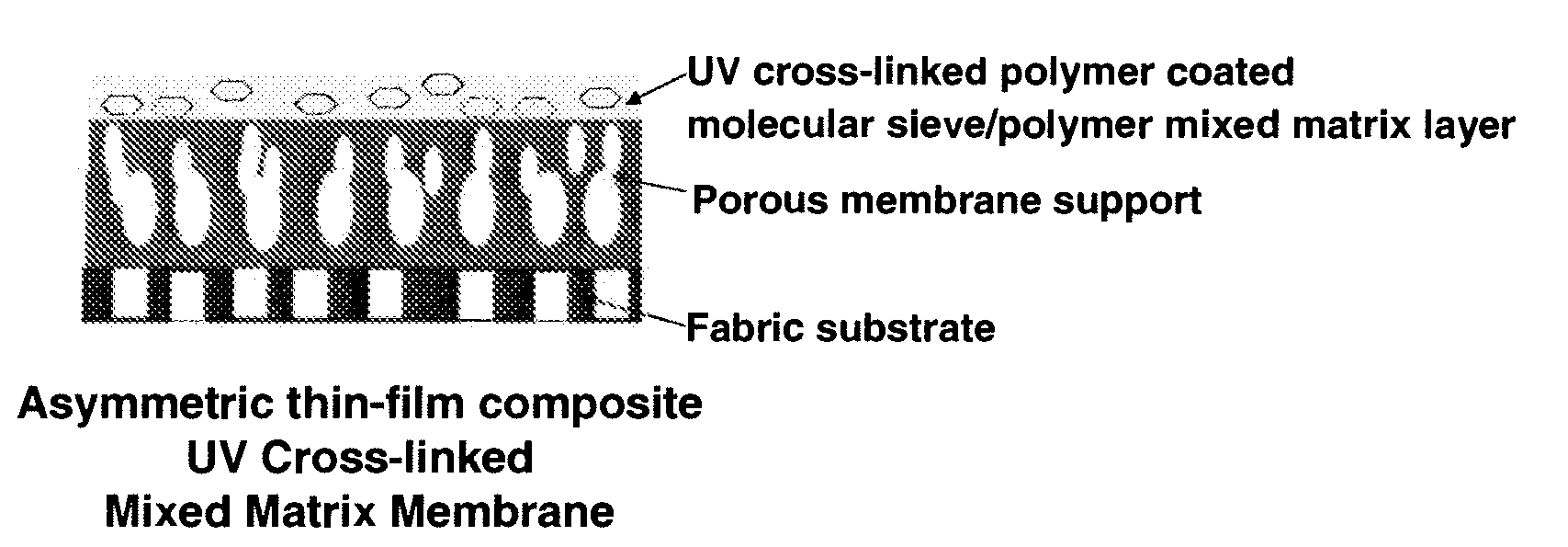

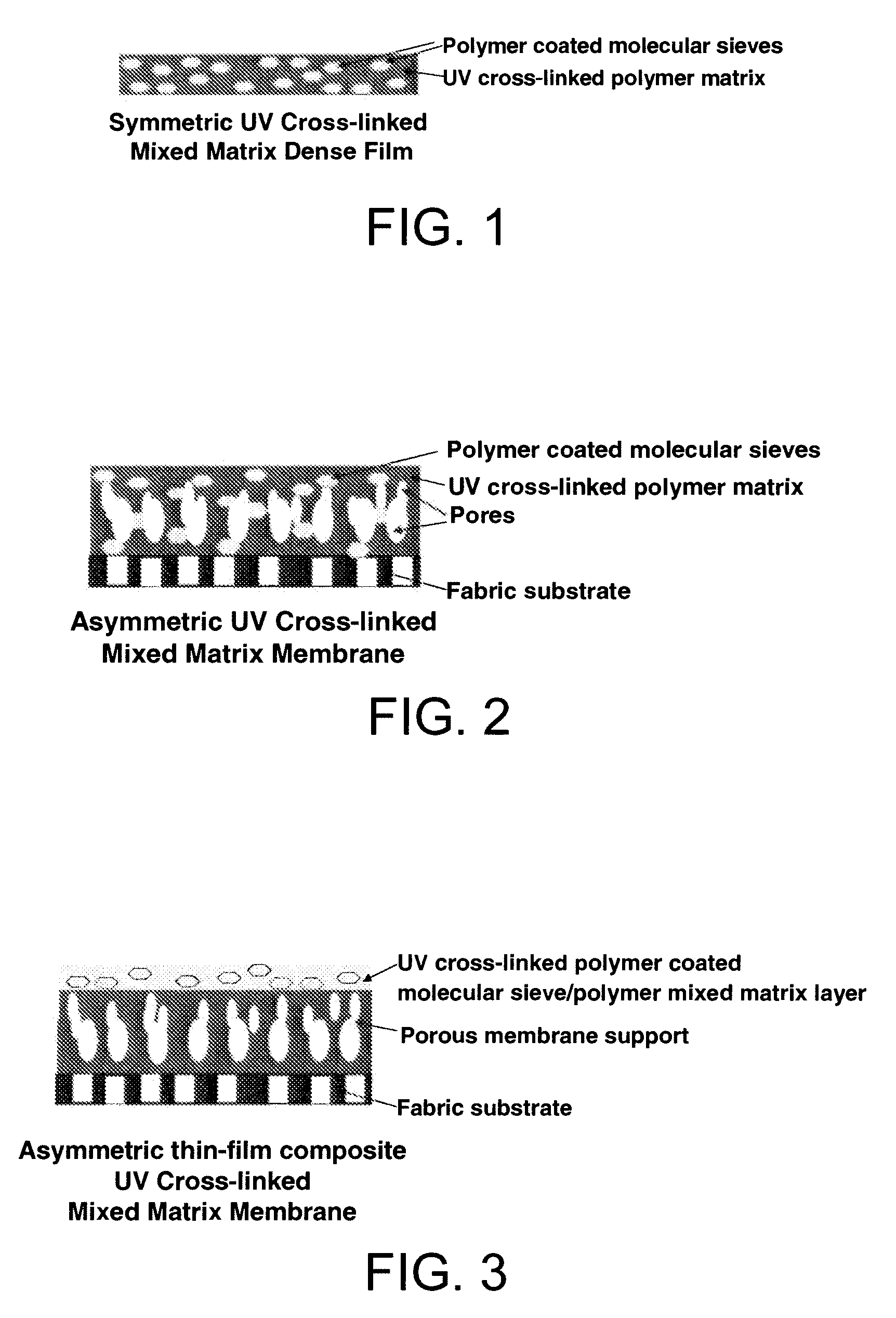

The present invention discloses high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs), the method of making these membranes, and the use of such membranes for separations. These UV cross-linked MMMs were prepared by incorporating polyethersulfone functionalized molecular sieves such as AlPO-14 and UZM-25 into a continuous UV cross-linkable polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes described in the current invention have good flexibility and high mechanical strength, and exhibit significantly enhanced selectivity and permeability over the polymer membranes made from the corresponding continuous polyimide polymer matrices for carbon dioxide / methane (CO2 / CH4) and hydrogen / methane (H2 / CH4) separations. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor separations such as deep desulfurization of gasoline and diesel fuels.

Owner:UOP LLC

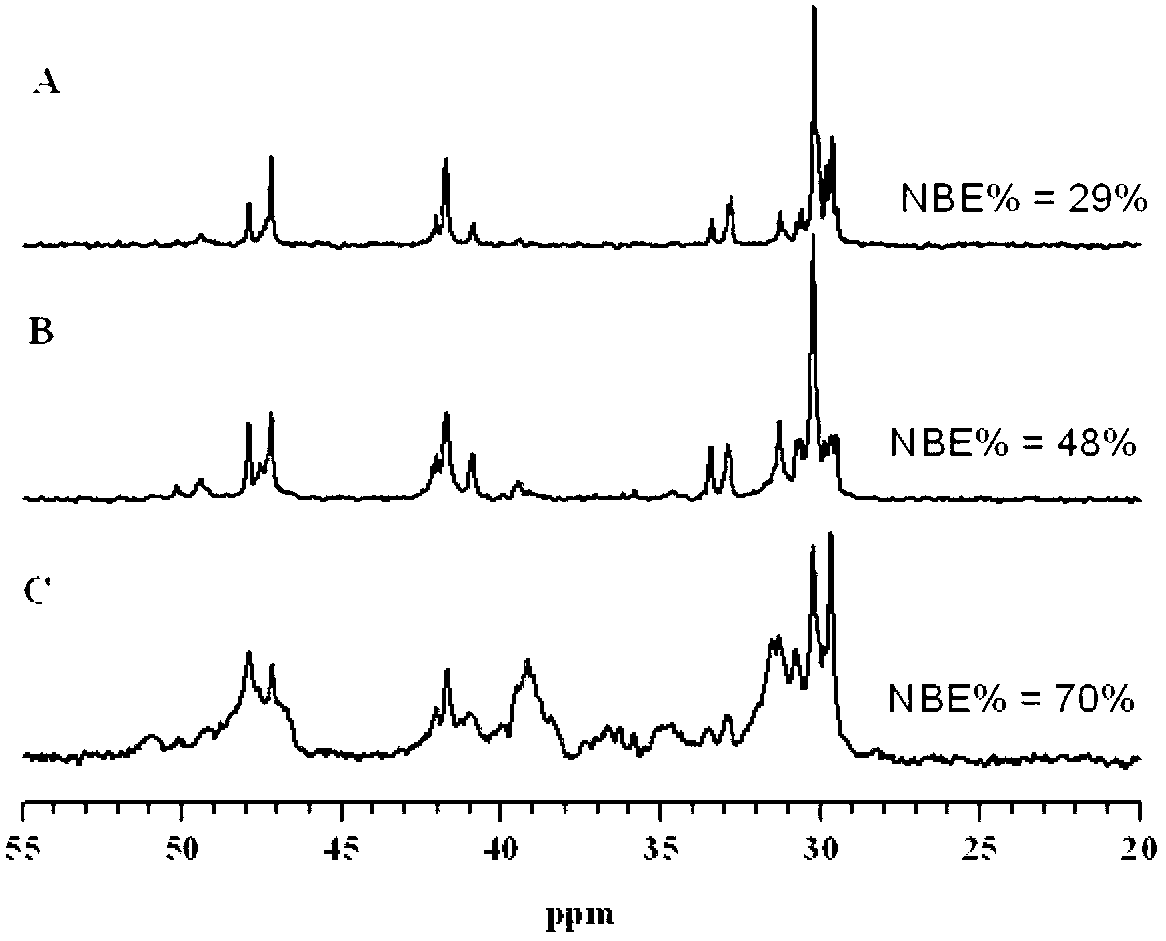

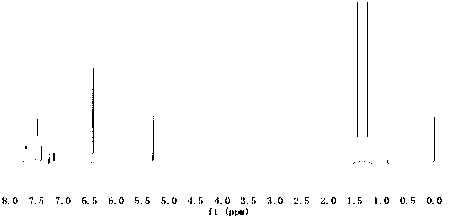

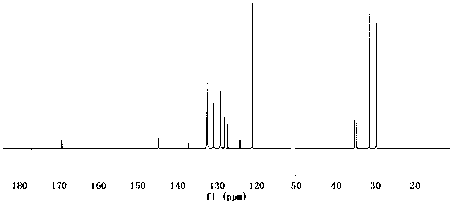

Preparation method of cycloolefin copolymers

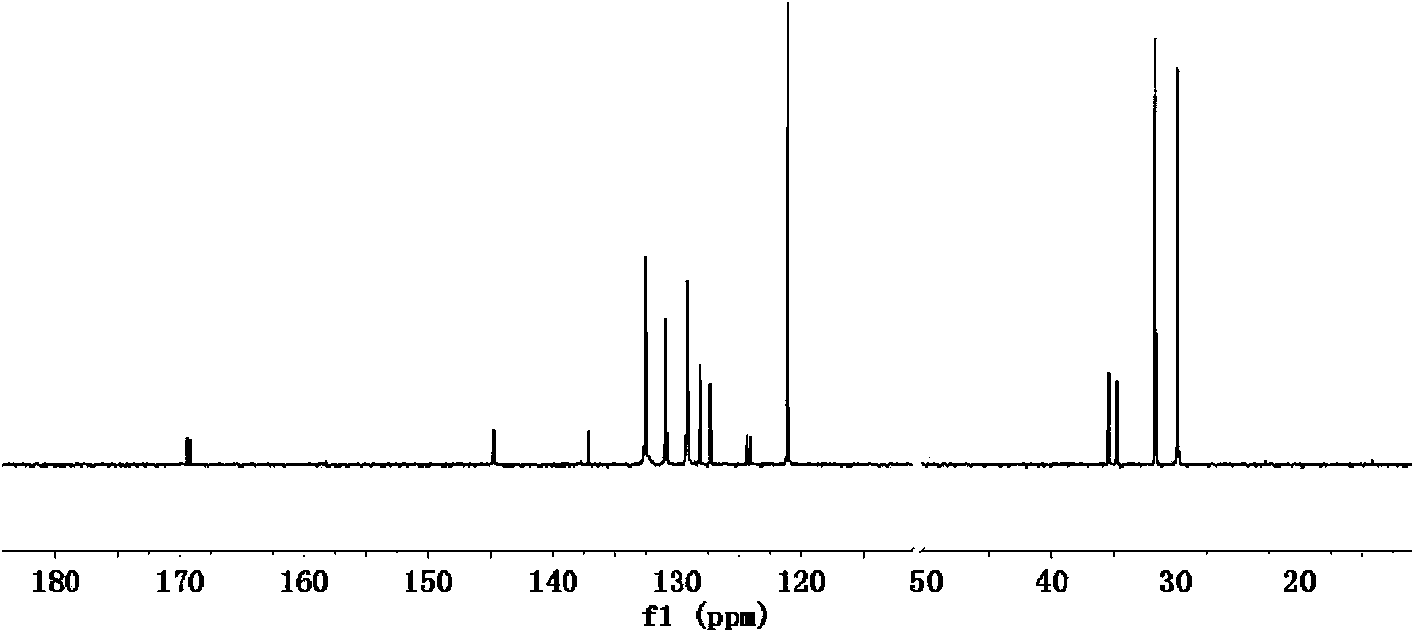

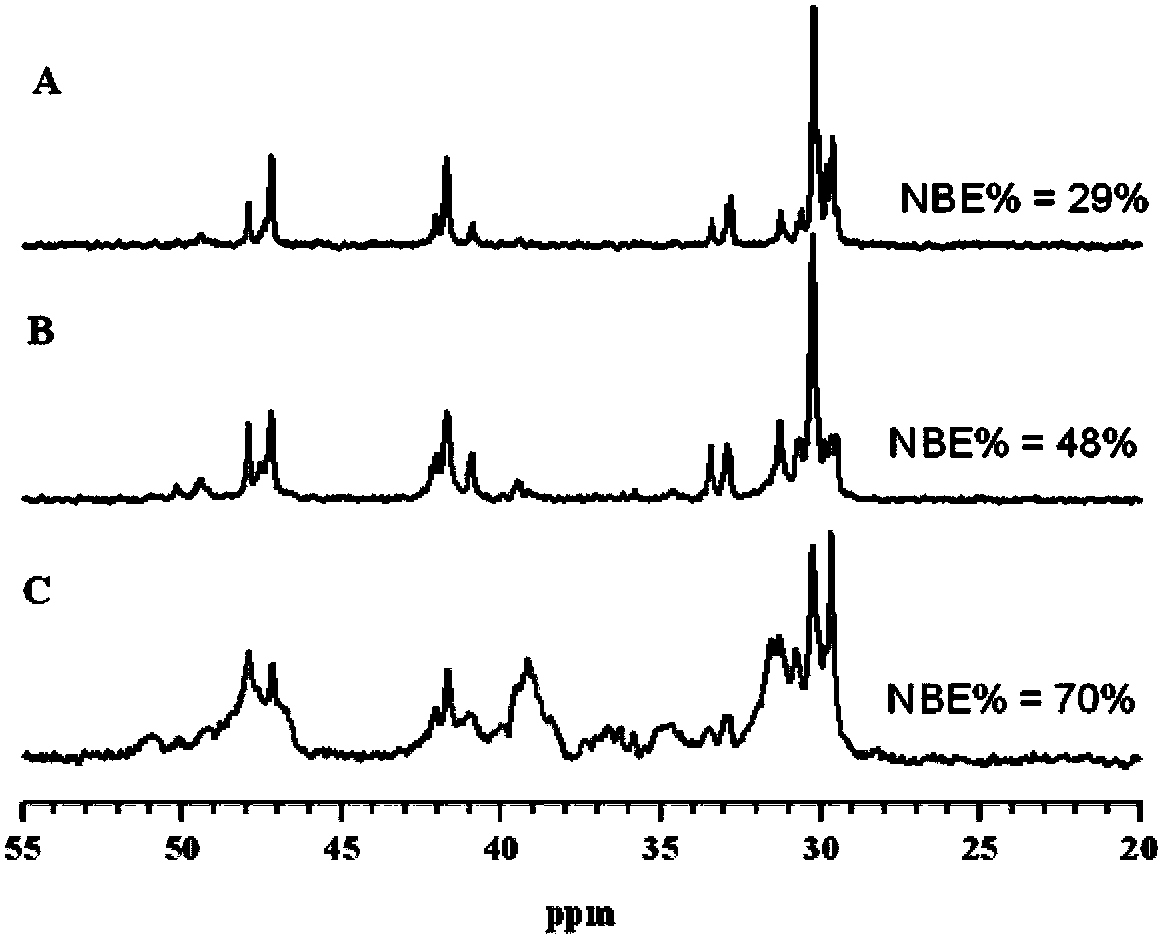

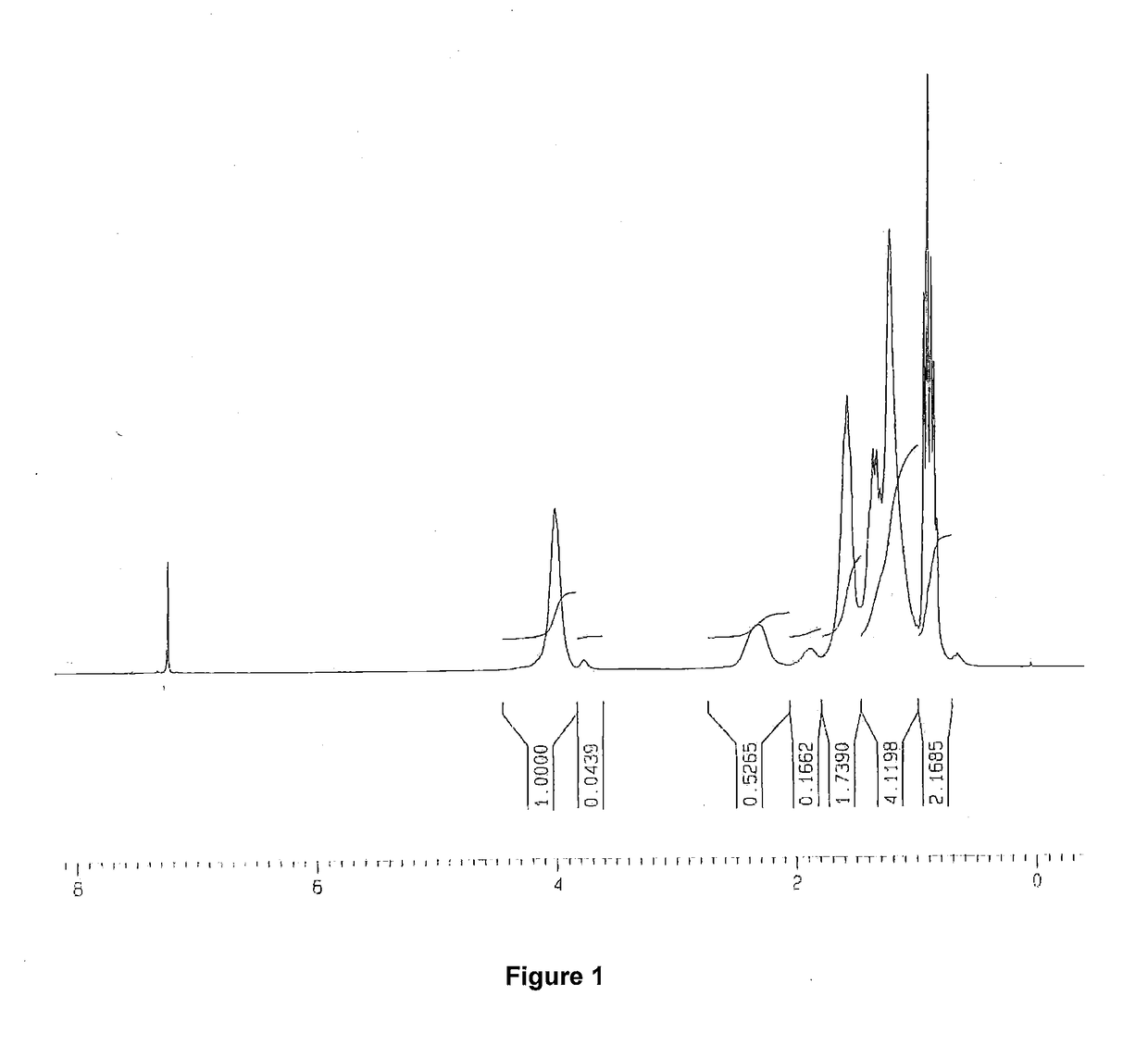

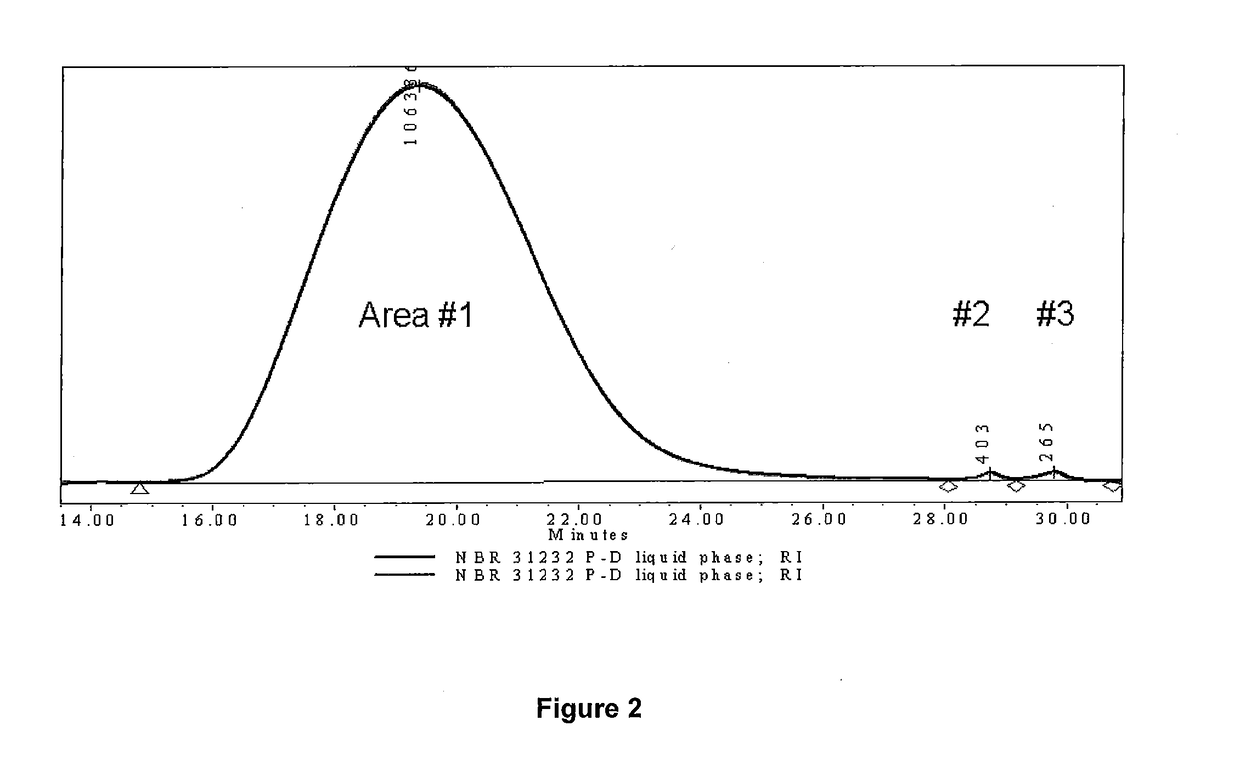

The invention provides a preparation method of cycloolefin copolymers. The preparation method comprises the steps of utilizing a half metallocene complex in a structure of a formula (I) as main catalysts, forming a salt ion active center after being acted with a cocatalyst, and thereby catalyzing the copolymerisation of ethylene and norbornene. On one hand, the existence of R in the half metallocene complex ensures the catalytic activity of a half metallocene system; the introduction of P, O or S atoms for the half metallocene complex improves the catalytic stability, therefore, the catalytic activity of the half metallocene complex is high; on the other hand, the introduction of aryloxy or aromatic sulfenyl further improves the charge properties and the space effects of a transition metal center, thereby being favorable for stabilizing a metal cation center; and the larger volume and an annual structure formed with the metal center also generate certain restriction to the spatial configuration of the half metallocene complex, therefore the generated cycloolefin copolymers through catalysis have high molecular weight, and at the same time, the method of the invention ensures that the content of the norbornene in the complex is high and can be regulated.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

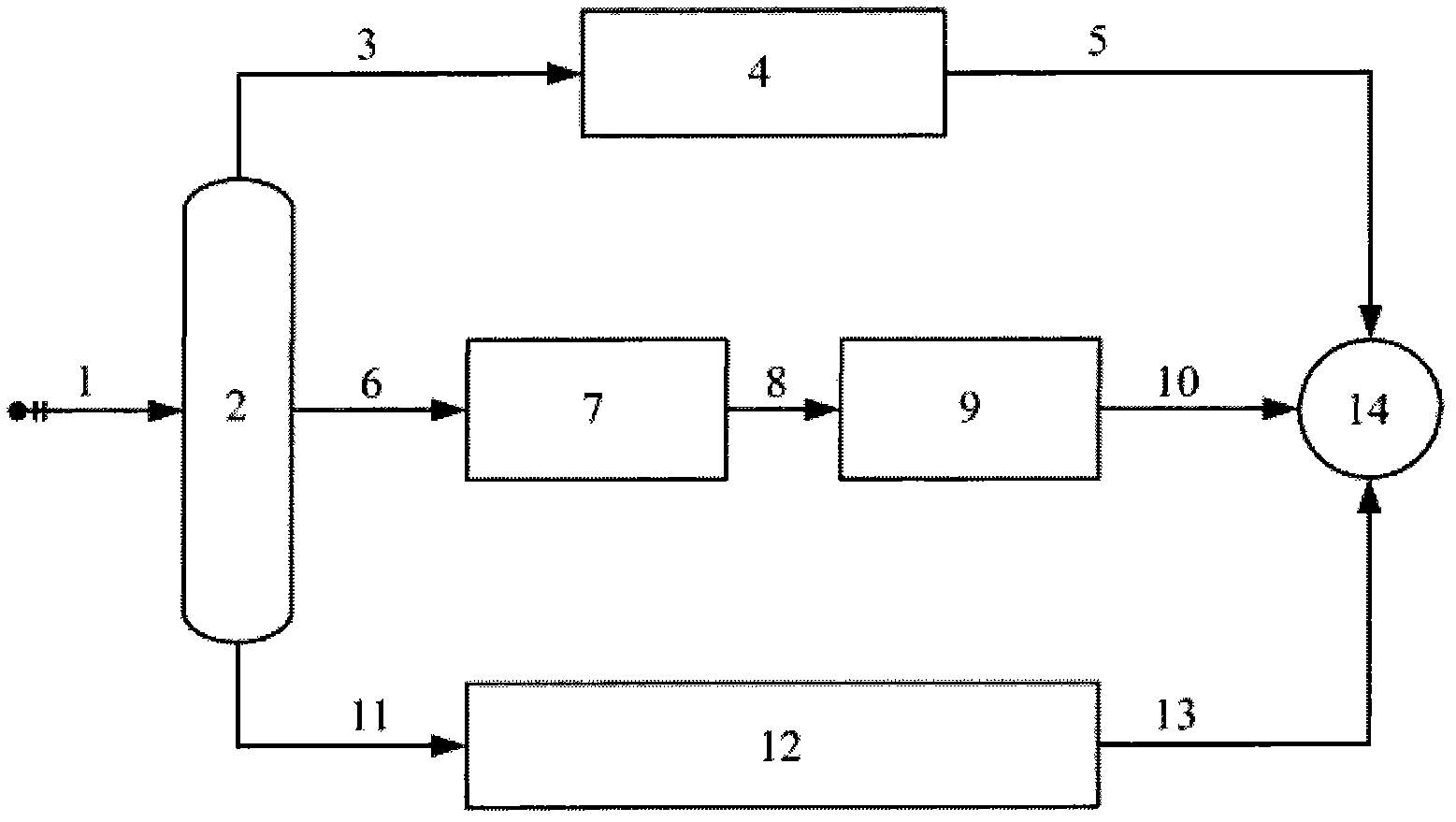

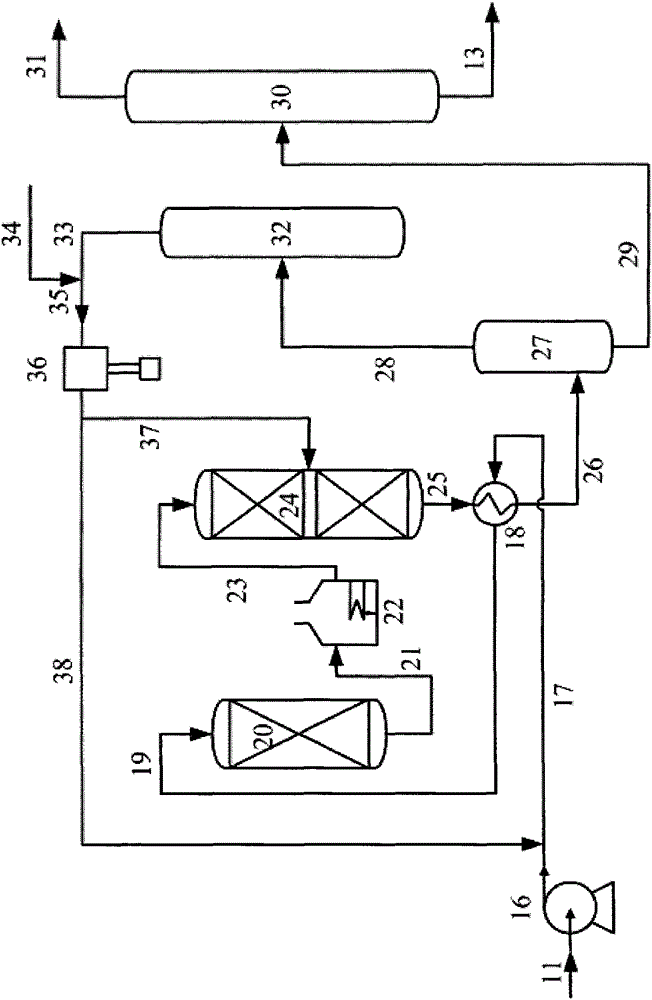

Integration of Cyclic Dehydrogenation Process with FCC for Dehydrogenation of Refinery Paraffins

ActiveUS20120071701A1Increase productionIncreased paraffinic contentCatalytic crackingCatalystsAlkaneParaffin wax

A process for increasing light olefin yields from the fluidized catalytic cracking process. The process combines small units to treat the paraffinic components in the product streams from the fluidized cracking process. The paraffins are dehydrogenated and light olefins are separated. Heavier olefins are passed to an olefin cracking unit for increasing the yields of ethylene and propylene.

Owner:UOP LLC

Polymer Functionalized Molecular Sieve/Polymer Mixed Matrix Membranes

InactiveUS20090127197A1Sufficient fluxAddressing Insufficient SelectivityGas treatmentUltrafiltrationMolecular sieveGasoline

The present invention discloses polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs) with either no macrovoids or voids of less than several Angstroms at the interface of the polymer matrix and the molecular sieves by incorporating polymer functionalized molecular sieves into a continuous polymer matrix. The MMMs exhibit significantly enhanced selectivity and / or permeability over the polymer membranes made from the corresponding continuous polymer matrices for separations. The MMMs are suitable for a variety of liquid, gas, and vapor separations such as deep desulfurization of gasoline and diesel fuels, ethanol / water separations, pervaporation dehydration of aqueous / organic mixtures, CO2 / CH4, CO2 / N2, H2 / CH4, O2 / N2, olefin / paraffin, iso / normal paraffins separations, and other light gas mixture separations.

Owner:UOP LLC

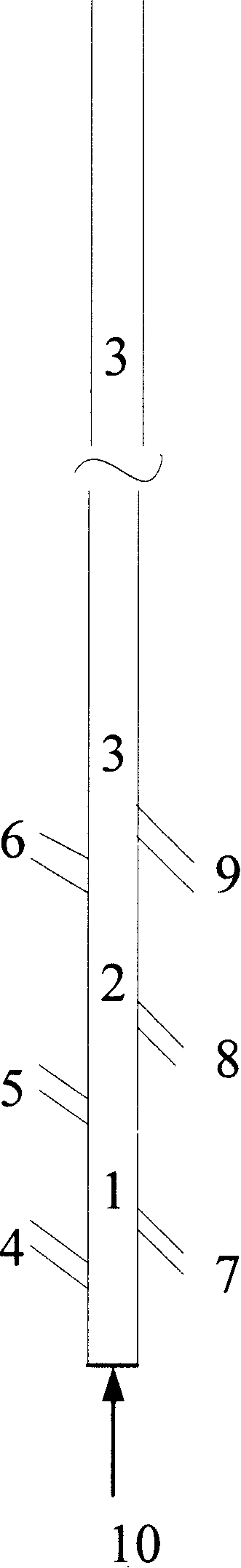

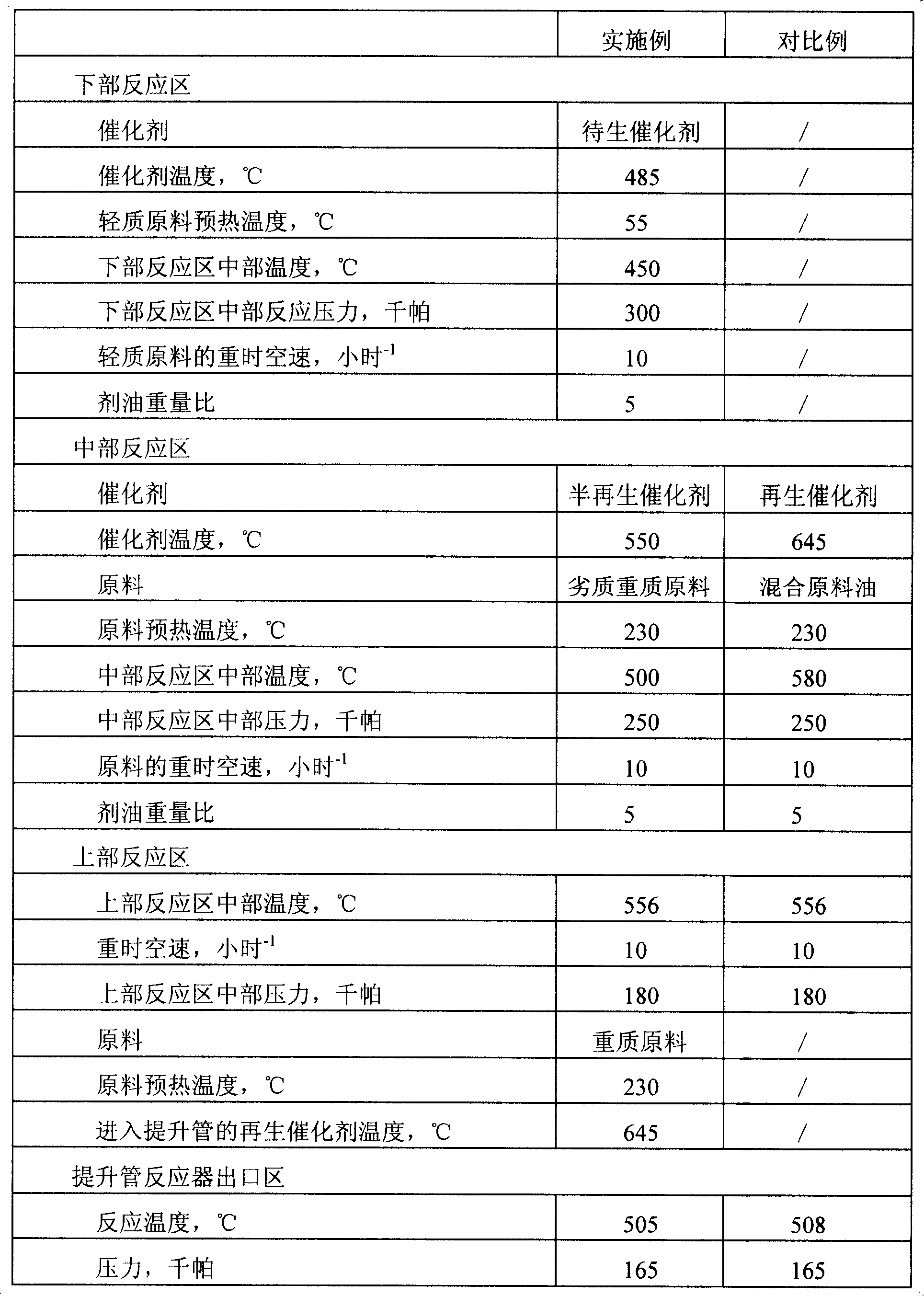

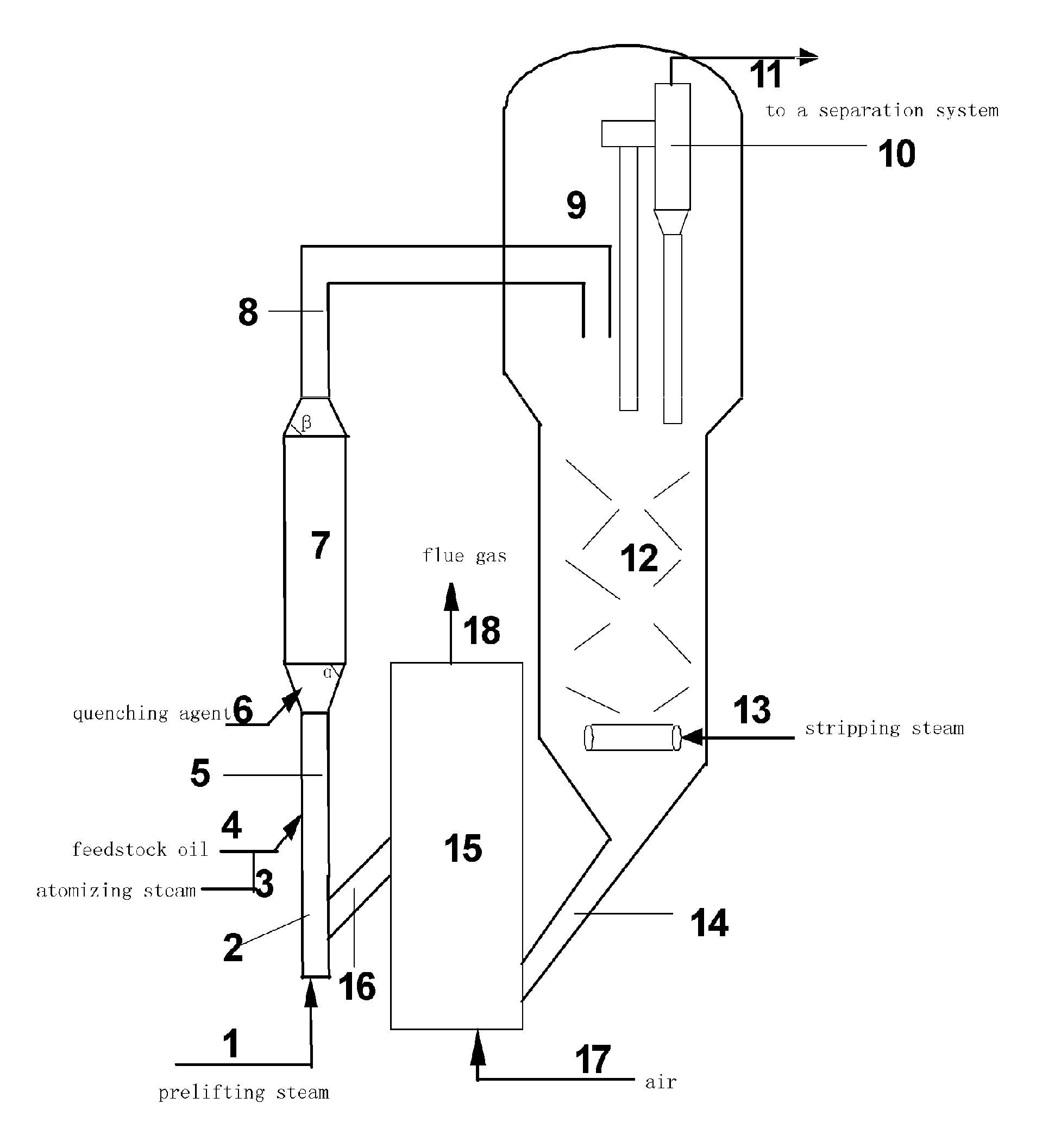

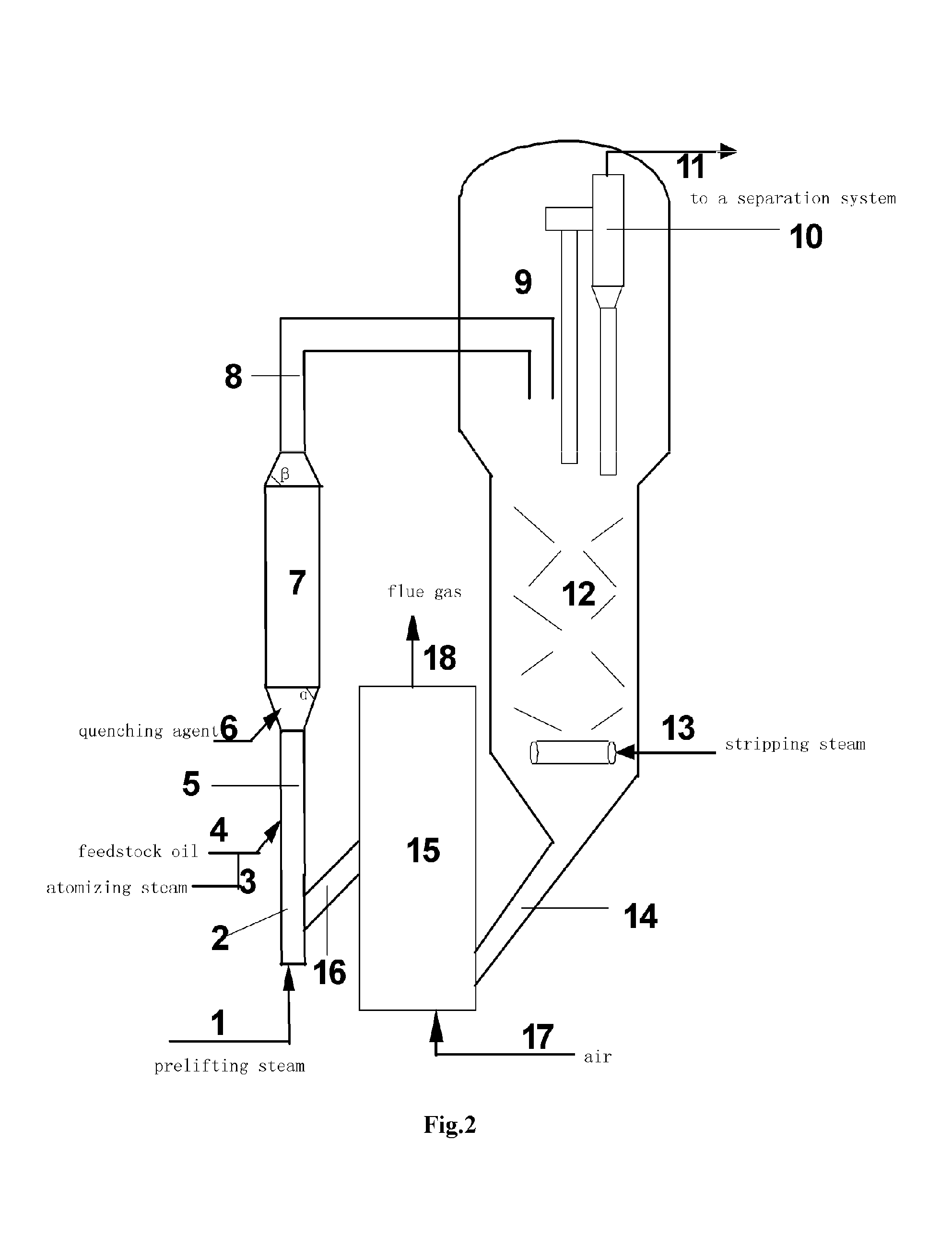

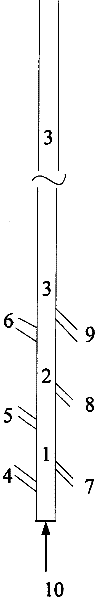

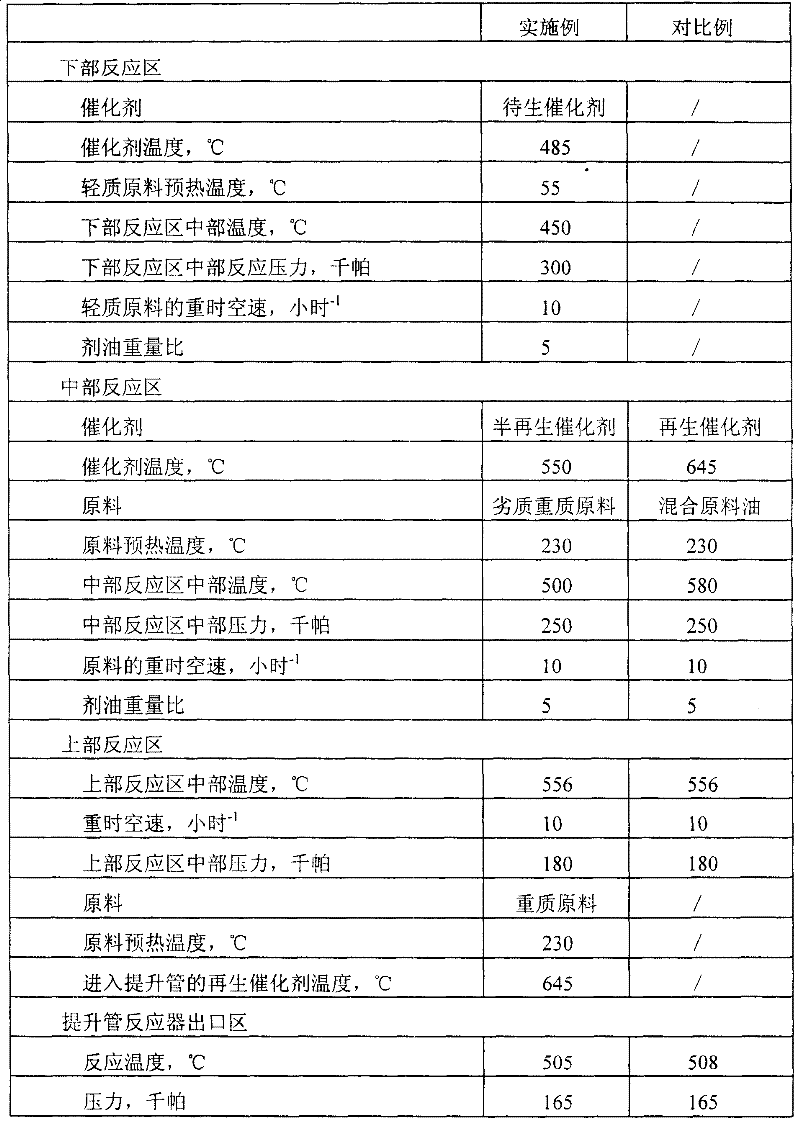

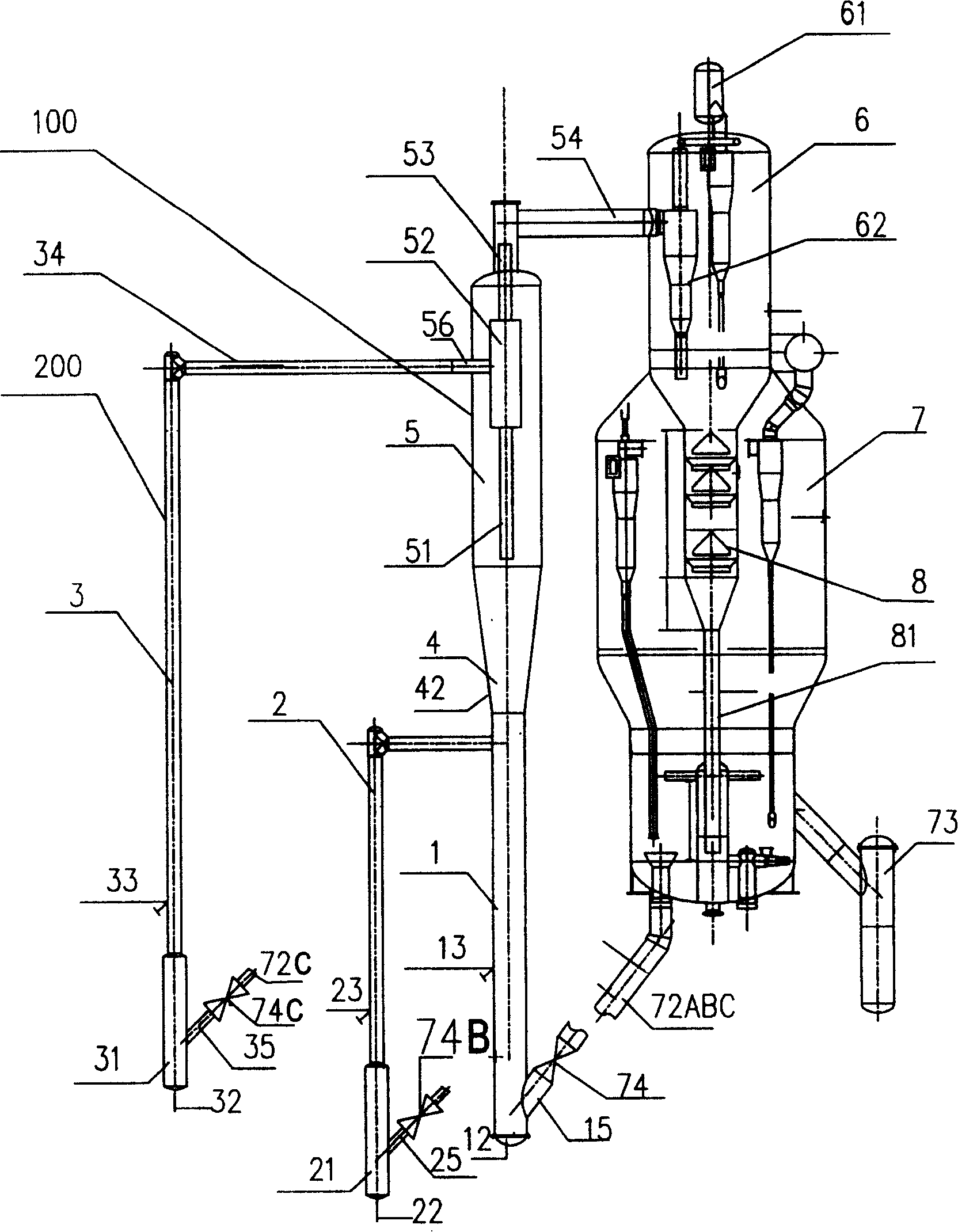

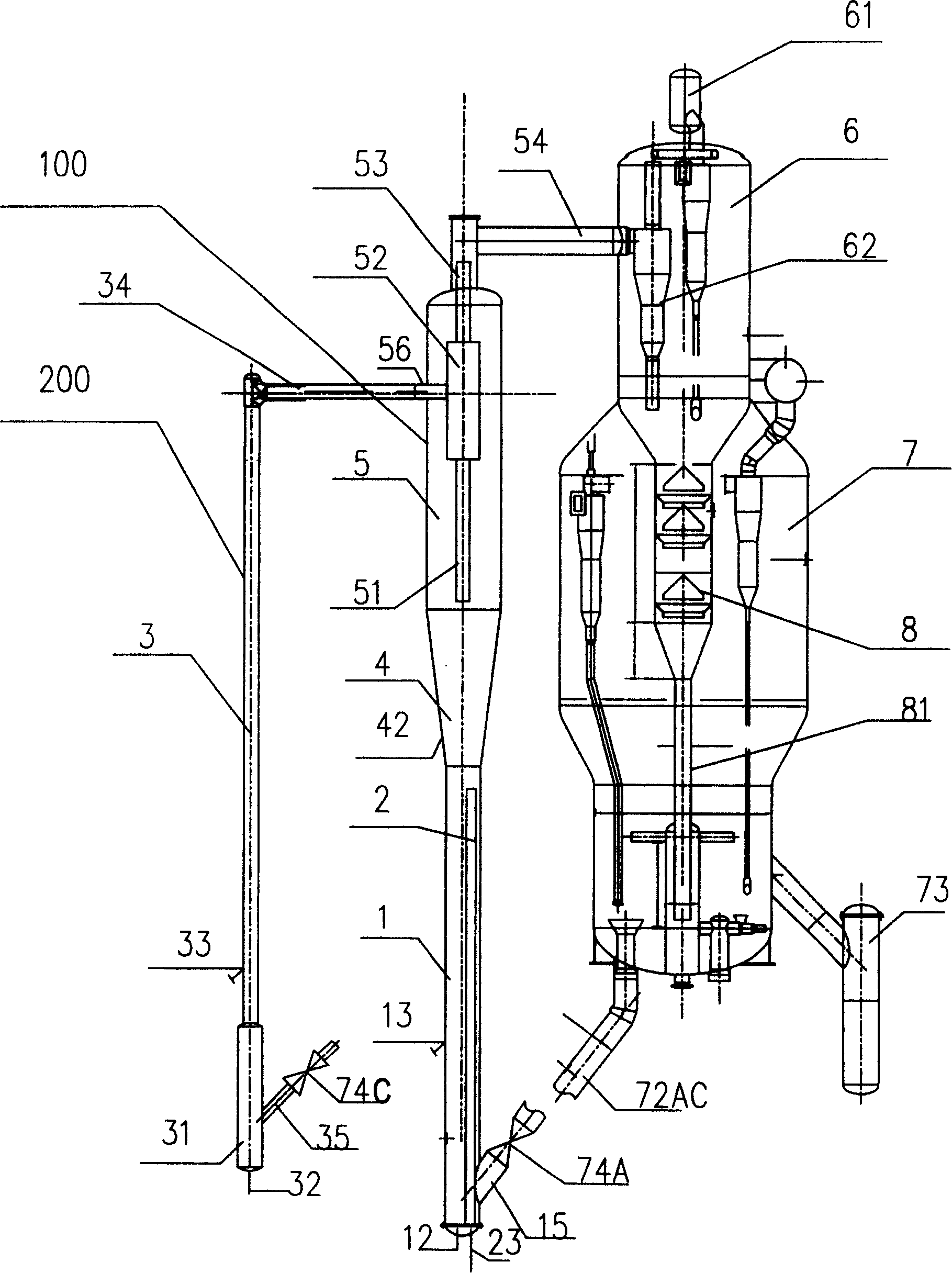

Cracking method for hydrocarbon oil

The invention discloses a hydrocarbon oil cracking method which comprises that: in a riser reactor comprising a plurality of reaction areas, the hydrocarbon oil raw material and the cracking catalyst are made a contact reaction in each reaction area under the condition of cracking reaction, the catalyst is separated from the reaction product to obtain the cracking product and spent catalyst, at least partial spent catalyst is regenerated to obtain the semi-regenerated catalyst and the regenerated catalyst, wherein, the reaction areas comprise at least one middle reaction area and at least one upper reaction area, the upper reaction area is positioned above the middle reaction area; the inferior heavy raw material and the semi-regenerated catalyst are imported in the middle reaction area to allow the heavy raw material to contact the semi-regenerated catalyst; the heavy raw material and the regenerated catalyst are imported in the upper reaction area to allow the heavy raw material to contact the regenerated catalyst. At least one item of the carbon residue content, the content of metal nickel and vanadium, the bitumencarb content and the basic nitrogen content of the inferior heavy raw material is higher than that of the heavy raw material. The method can optimize the cracking conditions of the hydrocarbon oil and improve the distribution of products.

Owner:CHINA PETROLEUM & CHEM CORP +1

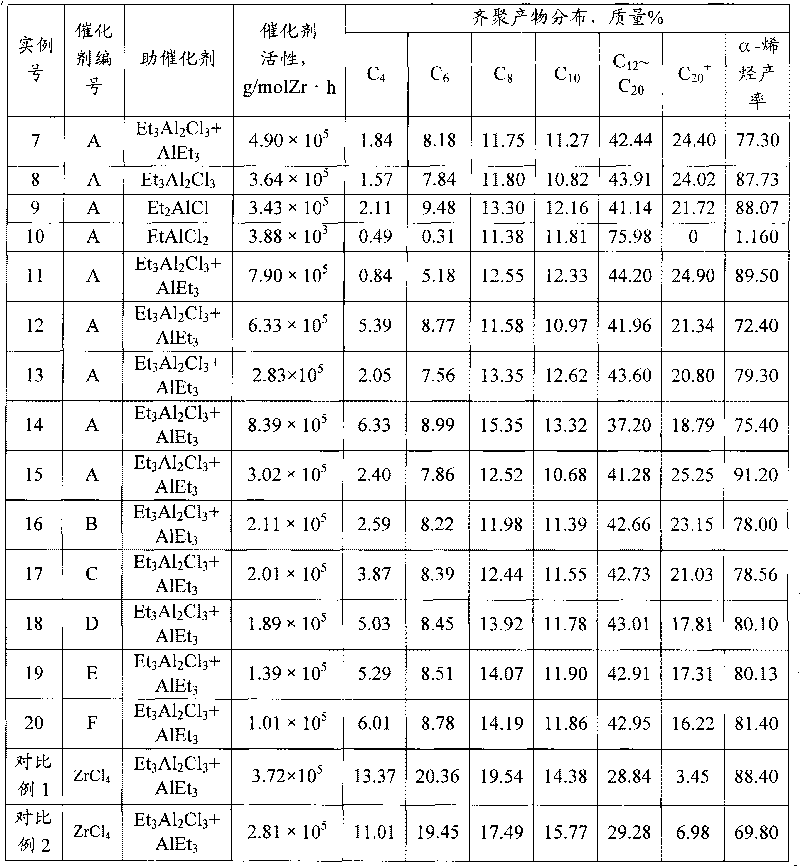

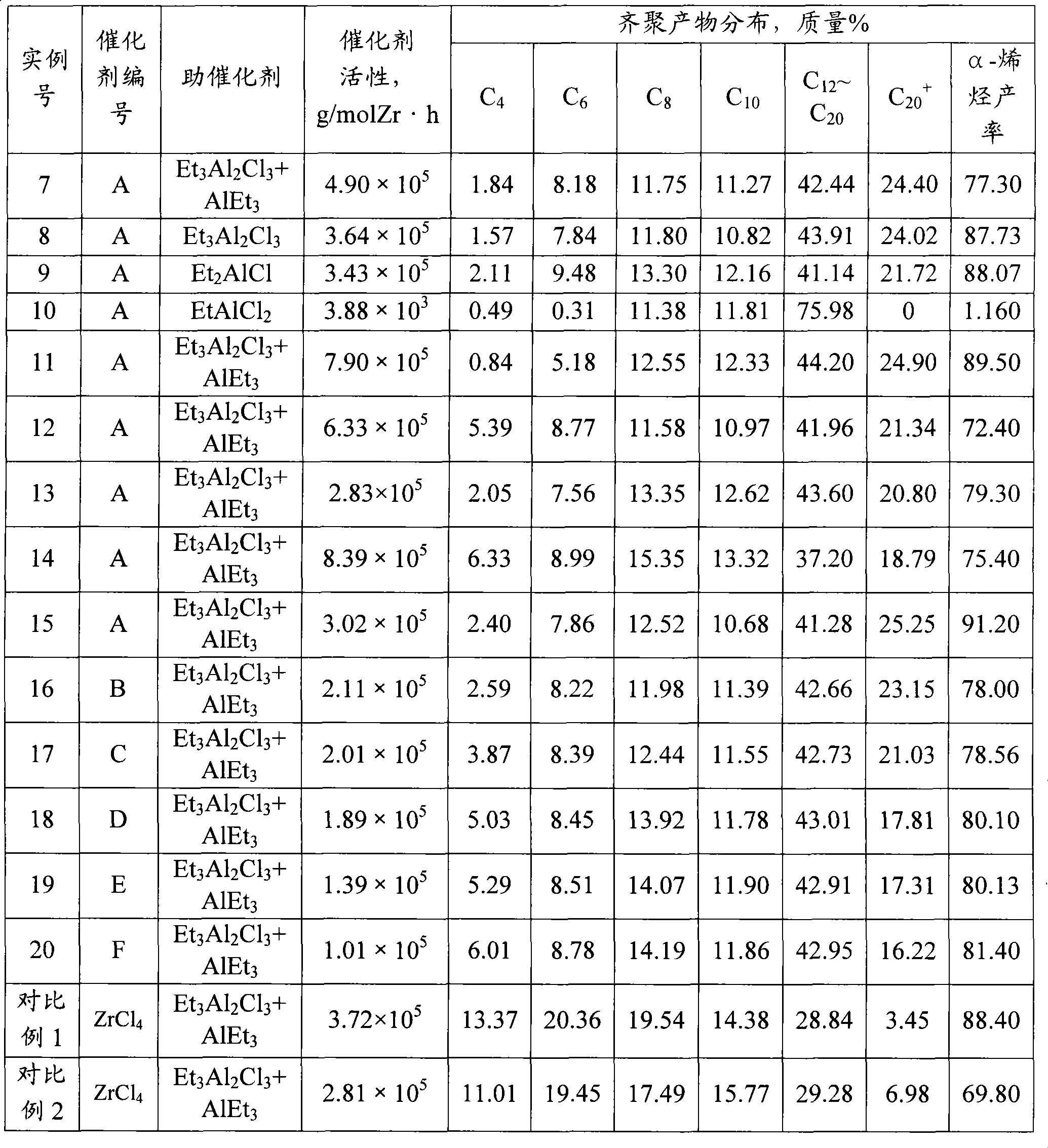

Olefin oligomerization catalyst and preparation method and application thereof

ActiveCN101745422AHigh catalytic activityLow carbon oligomersOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsOligomerAdduct

The invention relates to an olefin oligomerization catalyst, which comprises an ethylchloride zirconyl alcohol adduct with the general formula of Zr (OR) mCl4-m . nROH, wherein m is an integer from 1 to 3, n is 2 to 8, and R is C3 to C8 chain alkyl. The preparation method of the catalyst is simple, the catalyst has higher oligomerization activity when being matched with an organic aluminum catalyst, the content of oligomer in the oligomerization product is low, the content of C12 to C20 olefin is higher, and the yield of alpha-olefin is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Membrane separation for sulfur reduction

InactiveUS7018527B2Minimized volumeHigh olefin contentDialysisTreatment with plural serial refining stagesNaphthaGasoline

A membrane process for the removal of sulfur species from a naphtha feed, in particular, a FCC light cat naphtha, without a substantial loss of olefin yield is disclosed. The process involves contacting a naphtha feed stream with a membrane having sufficient flux and selectivity to separate a sulfur deficient retentate fraction from a sulfur enriched permeate fraction, preferably, under pervaporation conditions. Sulfur deficient retentate fractions are useful directly into the gasoline pool. Sulfur-enriched permeate fractions are rich in sulfur containing aromatic and nonaromatic hydrocarbons and are further treated with conventional sulfur removal technologies, e.g. hydrotreating, to reduce sulfur content. The process of the invention provides high quality naphtha products having a reduced sulfur content and a high content of olefin compounds.

Owner:WR GRACE & CO CONN

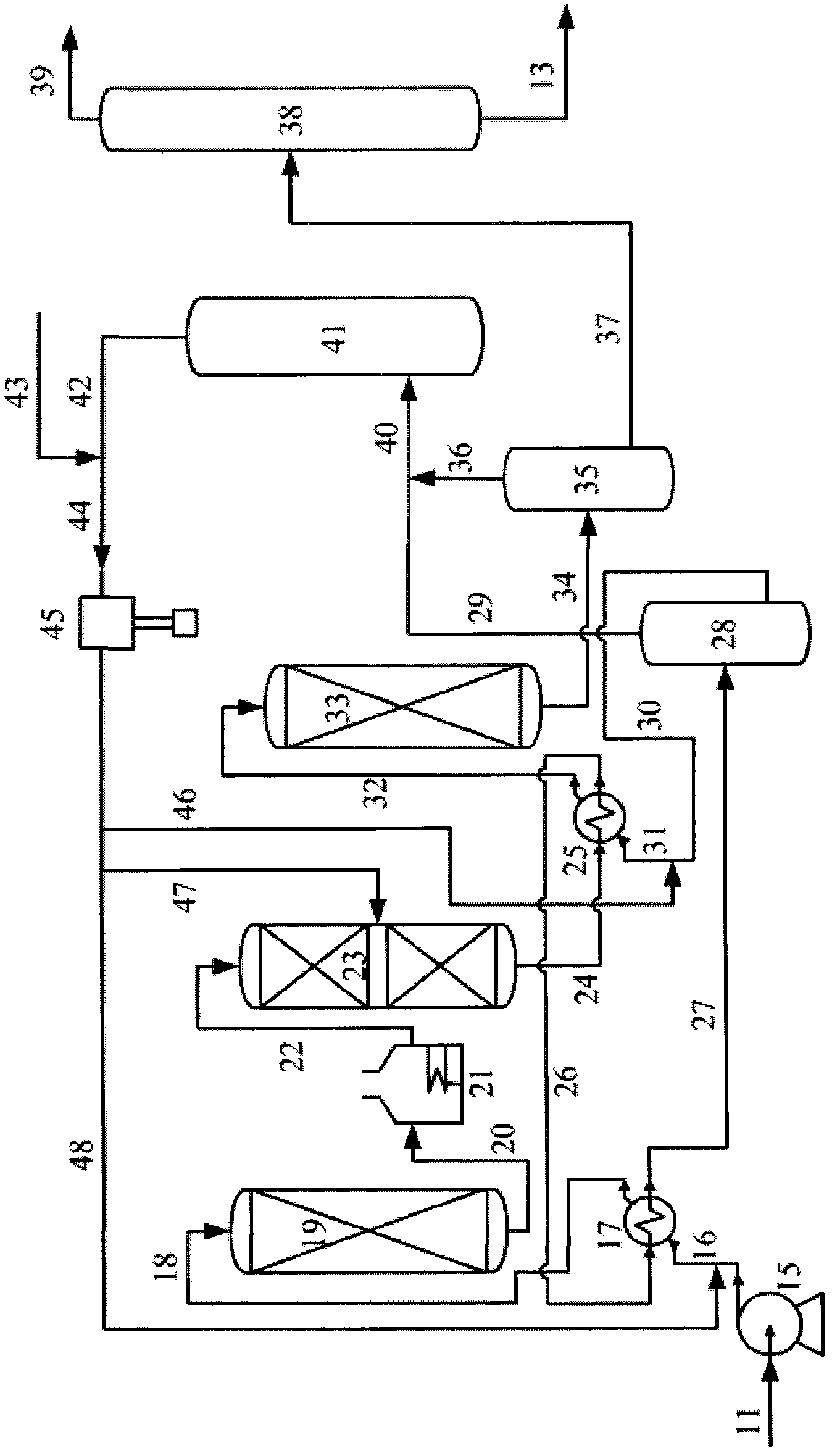

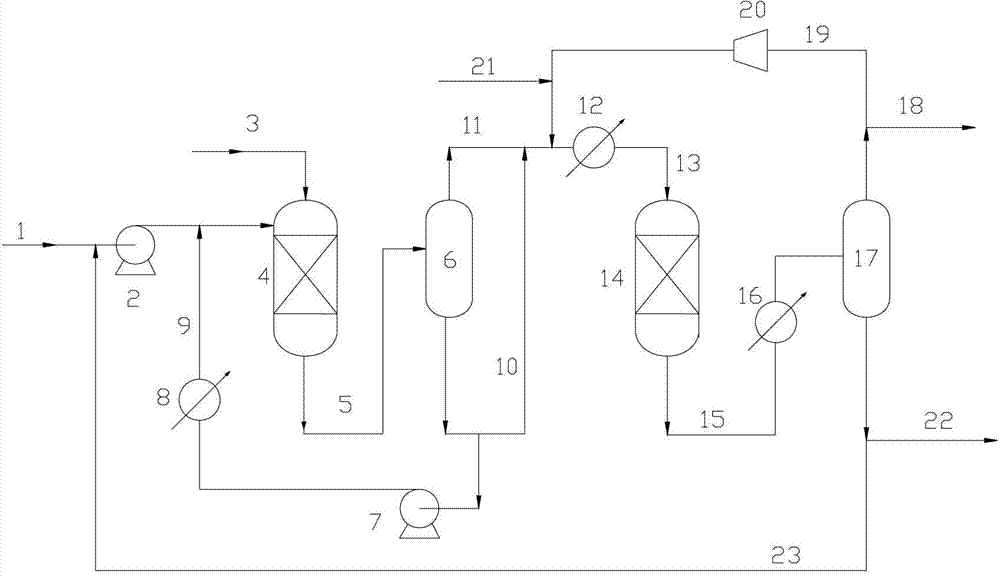

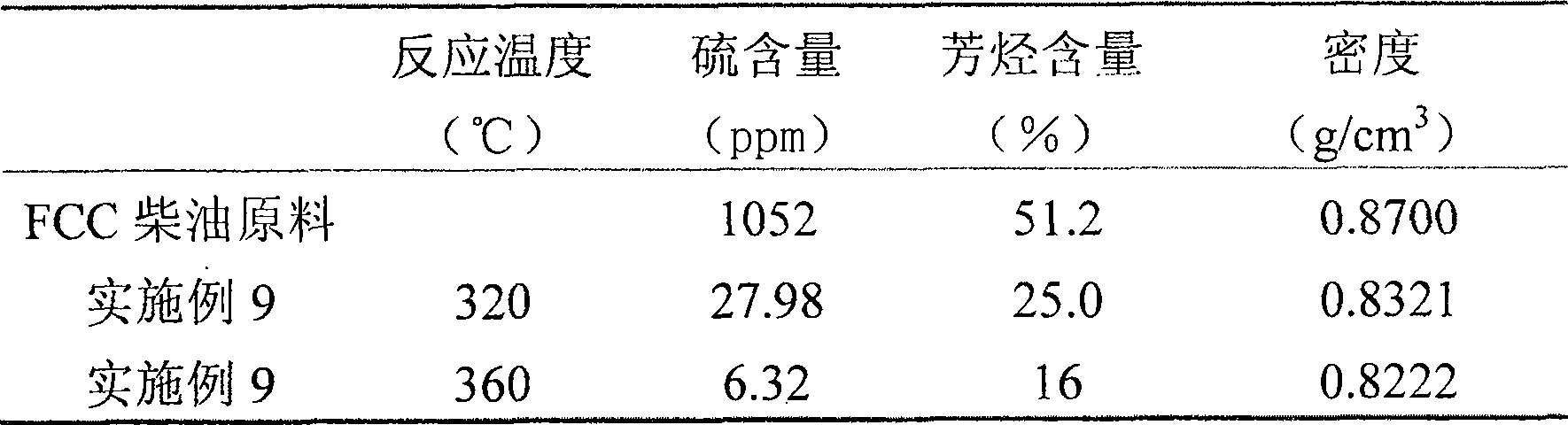

Method for reducing sulfur content in gasoline

ActiveCN103074106AHigh olefin contentReduce olefin contentTreatment with hydrotreatment processesCatalytic reformingHydrodesulfurization

The invention provides a method for reducing sulfur content in gasoline. According to the invention, full-fraction gasoline is fractionated to obtain a light gasoline fraction, an intermediate gasoline fraction and a heavy gasoline fraction, wherein the light gasoline fraction is subjected to alkali washing and refining so as to remove mercaptan sulfur therein, the intermediate gasoline fraction enters into a first hydrogenation unit for catalytic reforming so as to obtain a reformed intermediate gasoline fraction with an increased octane number, the heavy gasoline fraction enters into a second hydrogenation unit and contacts with a selective hydrodesulfurization catalyst for selective hydrodesulfurization, and the refined light gasoline fraction, the reformed intermediate gasoline fraction and the hydrogenated heavy gasoline fraction are mixed to obtain a full-fraction gasoline fraction with ultra low content of sulfur. The obtained full-fraction gasoline product has total sulfur content of less than 10 mu g / g, and compared with a full-fraction gasoline raw material, loss of the octane number ROC of the full-fraction gasoline product is less than 1.0 unit.

Owner:CHINA PETROLEUM & CHEM CORP +1

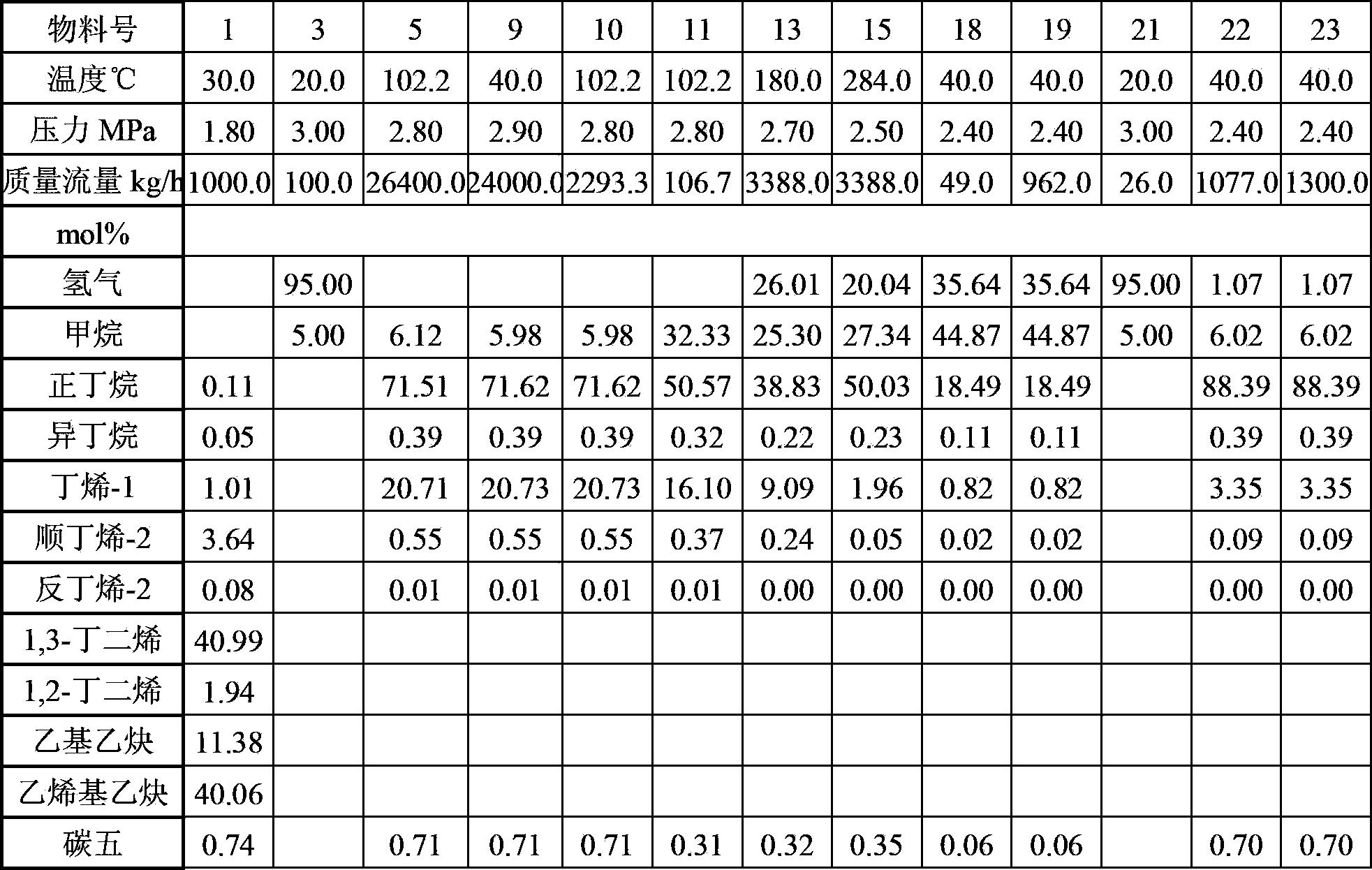

Butadiene tail gas hydrogenation device and method

ActiveCN103787813AExtended service lifeReduce olefin contentHydrocarbon by hydrogenationButadiene DioxideGas phase

The invention provides a method for hydrogenation of alkyne-rich tail gas of a butadiene extraction device. The alkyne-rich tail gas of a butadiene extraction device undergoes a liquid-phase hydrogenation reaction in the presence of an Ni-based catalyst using a titanium oxide-alumina compound as a carrier and undergoes a gas-phase hydrogenation reaction in the presence of an Ni-MO-based catalyst so that all alkynes and dialkenes in the raw material are subjected to hydrogenation conversion and most olefins are hydrogenated to form alkanes. The method realizes continuous and stable operation of the device and obviously reduces olefin content of the hydrogenation products to less than 5% so that requirements on cracking of the raw material of an ethylene production device are satisfied.

Owner:CHINA PETROLEUM & CHEM CORP +1

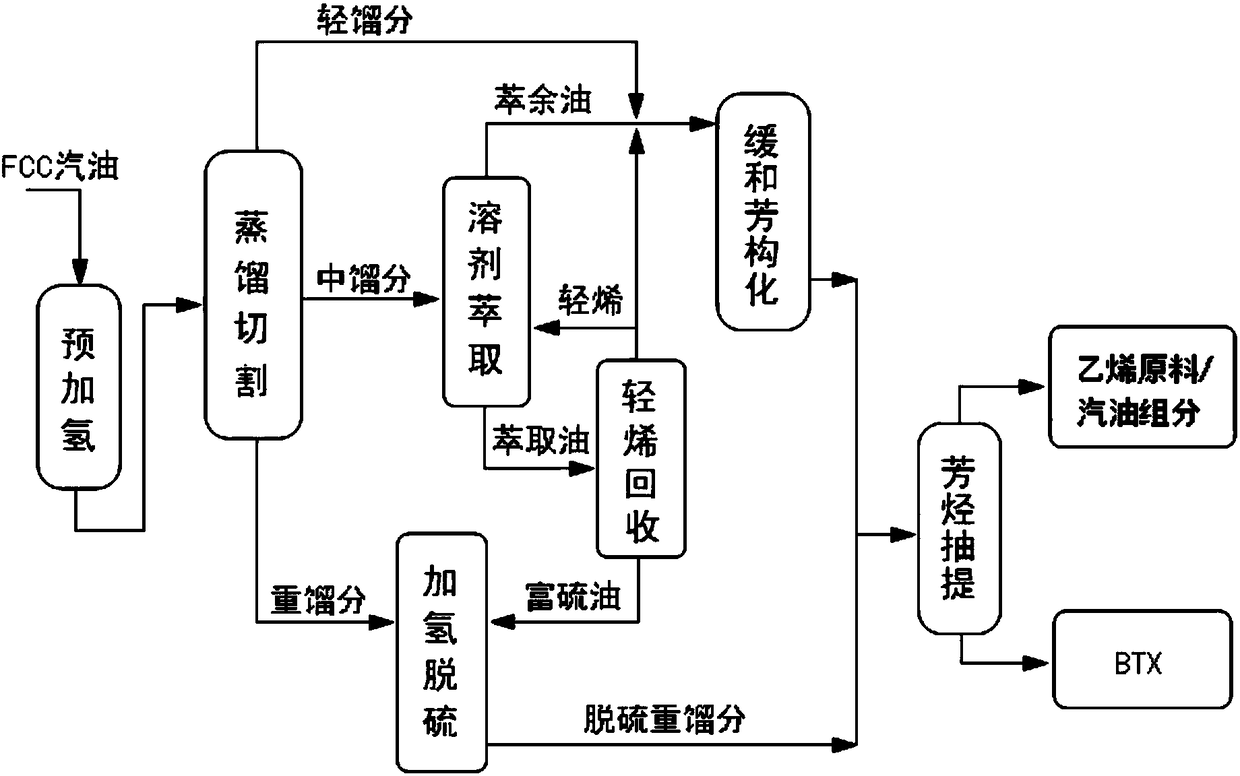

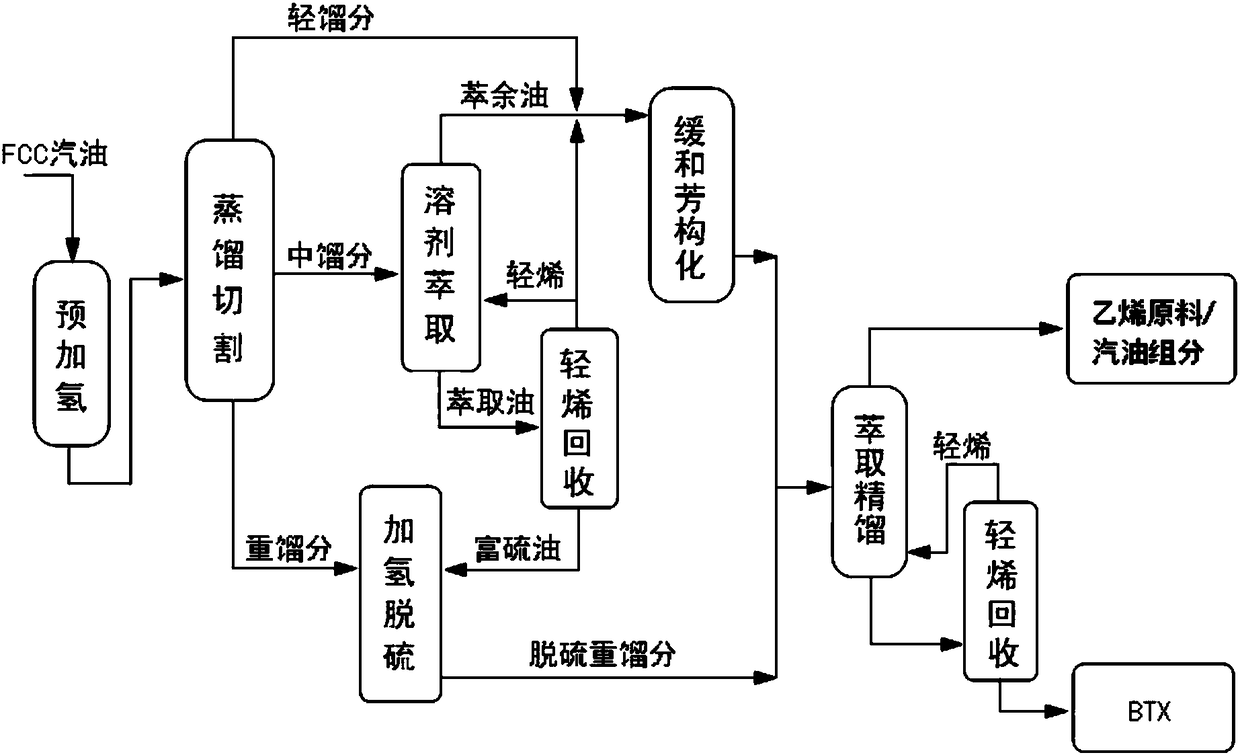

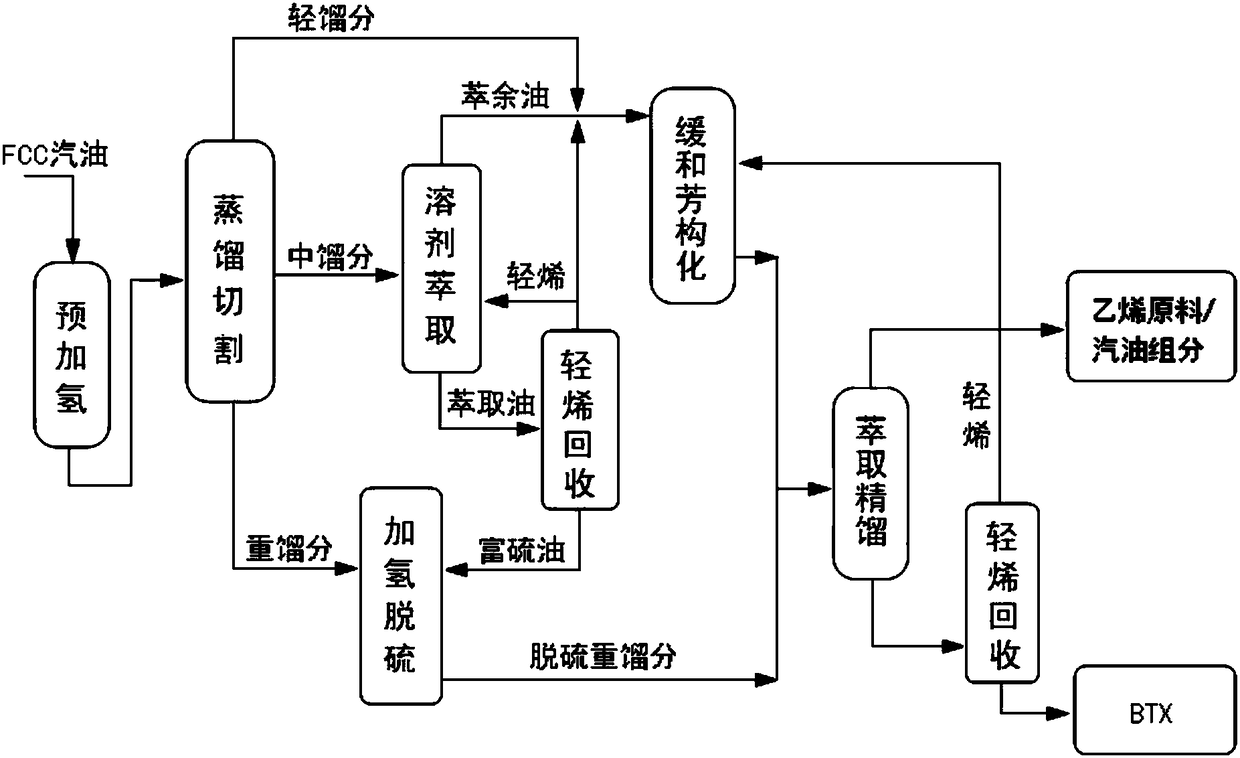

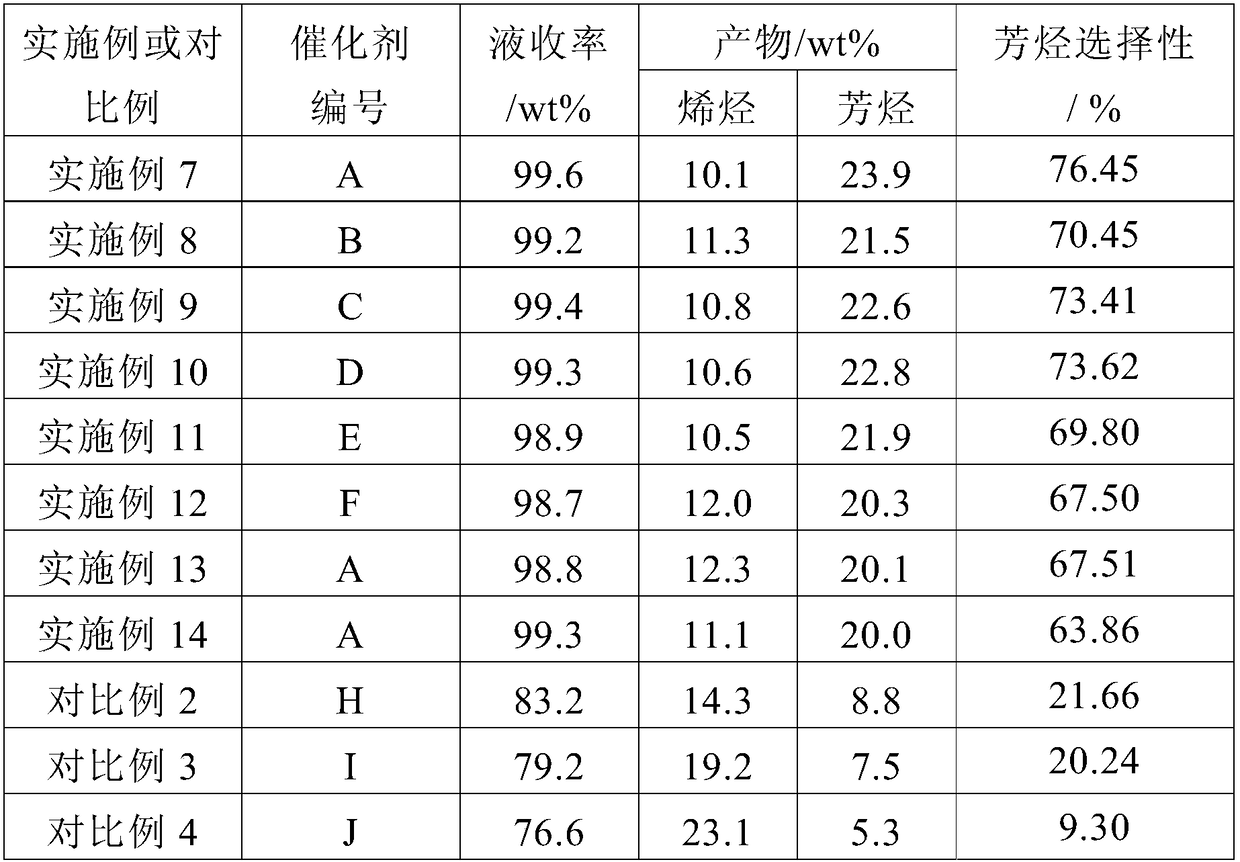

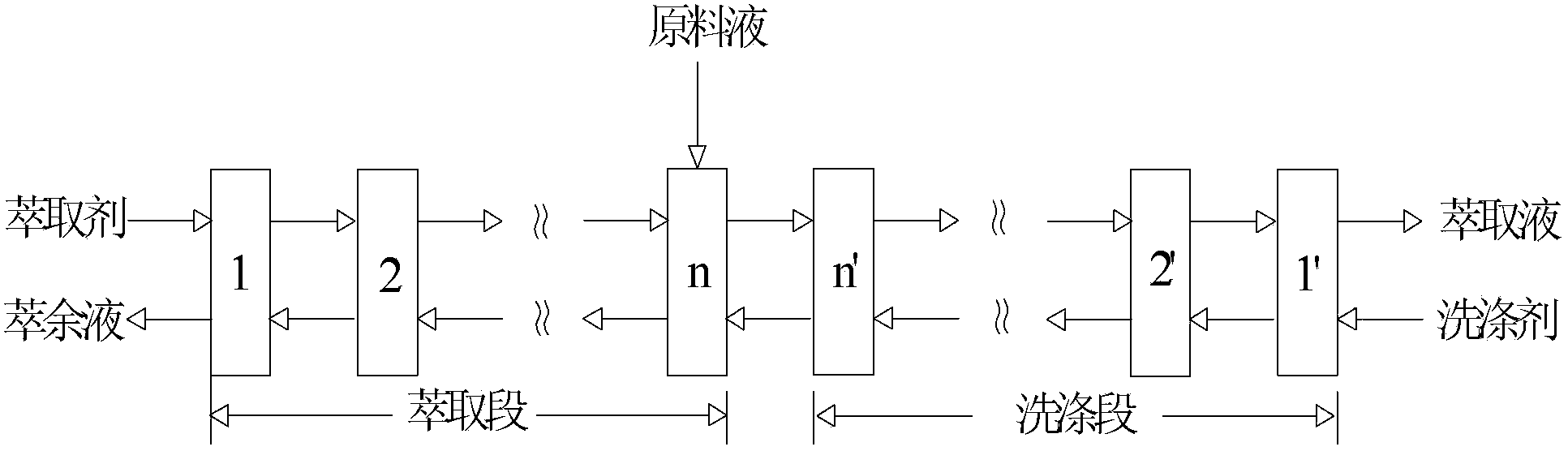

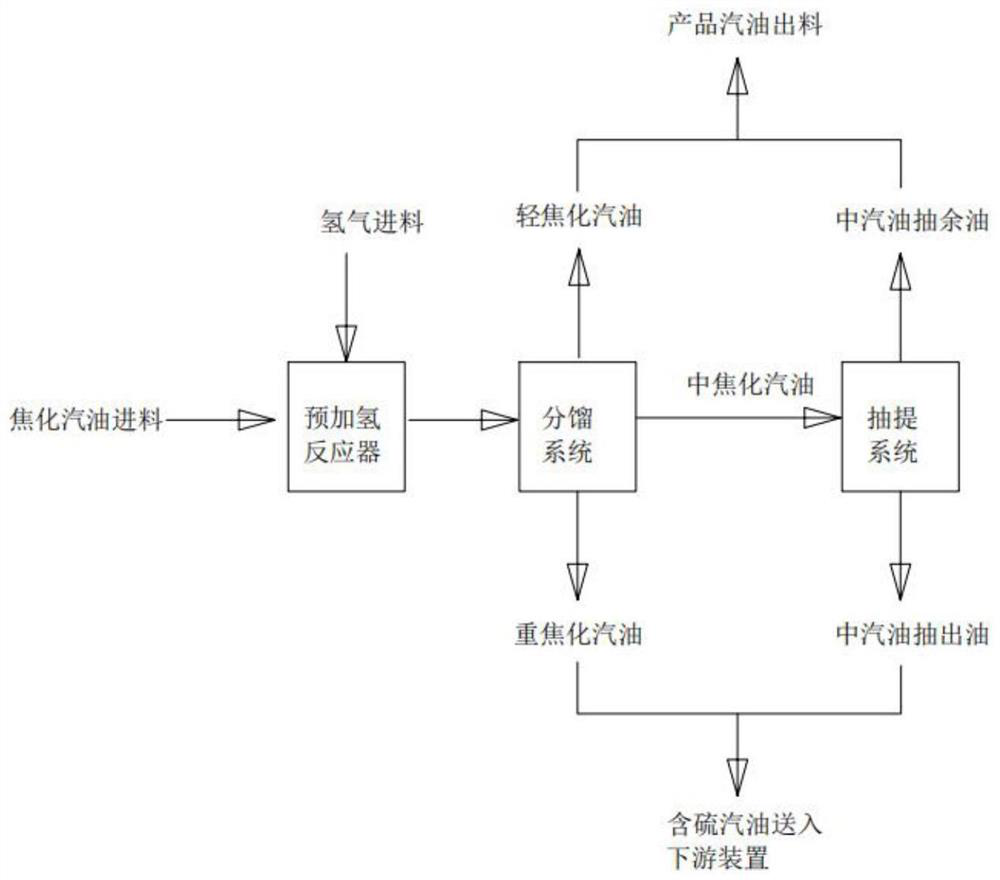

Method for maximally producing aromatic hydrocarbons from catalytic cracking gasoline

ActiveCN108485702AAchieve productionOvercome inability to prepareMolecular sieve catalystsTreatment with hydrotreatment processesHydrodesulfurizationSulfur

The invention provides a method for maximally producing aromatic hydrocarbons from catalytic cracking gasoline. The method comprises pre-hydrogenating catalytic cracking gasoline to obtain pre-hydrogenated catalytic cracking gasoline, dividing the pre-hydrogenated catalytic cracking gasoline into a light fraction, a middle fraction and a heavy fraction, extracting the middle fraction through a solvent to obtain olefin-rich raffinate and aromatic-rich extract, carrying out mild aromatization on the light fraction and the raffinate to obtain an aromatization product, recovering the light olefinfrom the extract to obtain a light olefin and sulfur-rich oil, carrying out selective hydrodesulfurization on the heavy fraction and the sulfur-rich oil to obtain a desulfurized heavy fraction, and carrying out aromatic extraction or extraction rectification on the aromatization product and the desulfurized heavy fraction. The method realizes olefin reduction, desulfurization and octane value increasing treatment on catalytically cracked gasoline and maximizes aromatic hydrocarbon production.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Aromatization catalyst and preparation method, regeneration method and aromatization method thereof

ActiveCN108479846AHigh aromatization activityImprove conversion rateMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveIon exchange

The invention provides an aromatization catalyst and a preparation method, regeneration method and aromatization method thereof. The preparation method comprises mixing a zeolite molecular sieve and abinder to obtain a catalyst precursor, orderly performing ion exchange modification and first modification treatment on the catalyst precursor, and after hydrothermal treatment, carrying out active metal loading and second modification treatment to obtain the aromatization catalyst. A modification element used in the first modification is at least one selected from metals in the group IA, group VA and lanthanide line in the periodic table, the active metal is at least one element selected from elements in the group VIIB, group VIII, group IB and group IIB, and the modifying element used for the second modification is at least one element selected from elements in the group VA and lanthanide line in the periodic table. The aromatization catalyst has good carbon deposition resistance and high aromatization activity, can complete the aromatization reaction under mild conditions, and has high aromatic selectivity and a liquid yield of 98.5% or more.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A butadiene tail gas hydrogenation device and method

ActiveCN103787813BExtended service lifeReduce olefin contentHydrocarbon by hydrogenationAlkaneButadiene Dioxide

The invention provides a method for hydrogenation of alkyne-rich tail gas of a butadiene extraction device. The alkyne-rich tail gas of a butadiene extraction device undergoes a liquid-phase hydrogenation reaction in the presence of an Ni-based catalyst using a titanium oxide-alumina compound as a carrier and undergoes a gas-phase hydrogenation reaction in the presence of an Ni-MO-based catalyst so that all alkynes and dialkenes in the raw material are subjected to hydrogenation conversion and most olefins are hydrogenated to form alkanes. The method realizes continuous and stable operation of the device and obviously reduces olefin content of the hydrogenation products to less than 5% so that requirements on cracking of the raw material of an ethylene production device are satisfied.

Owner:CHINA PETROLEUM & CHEM CORP +1

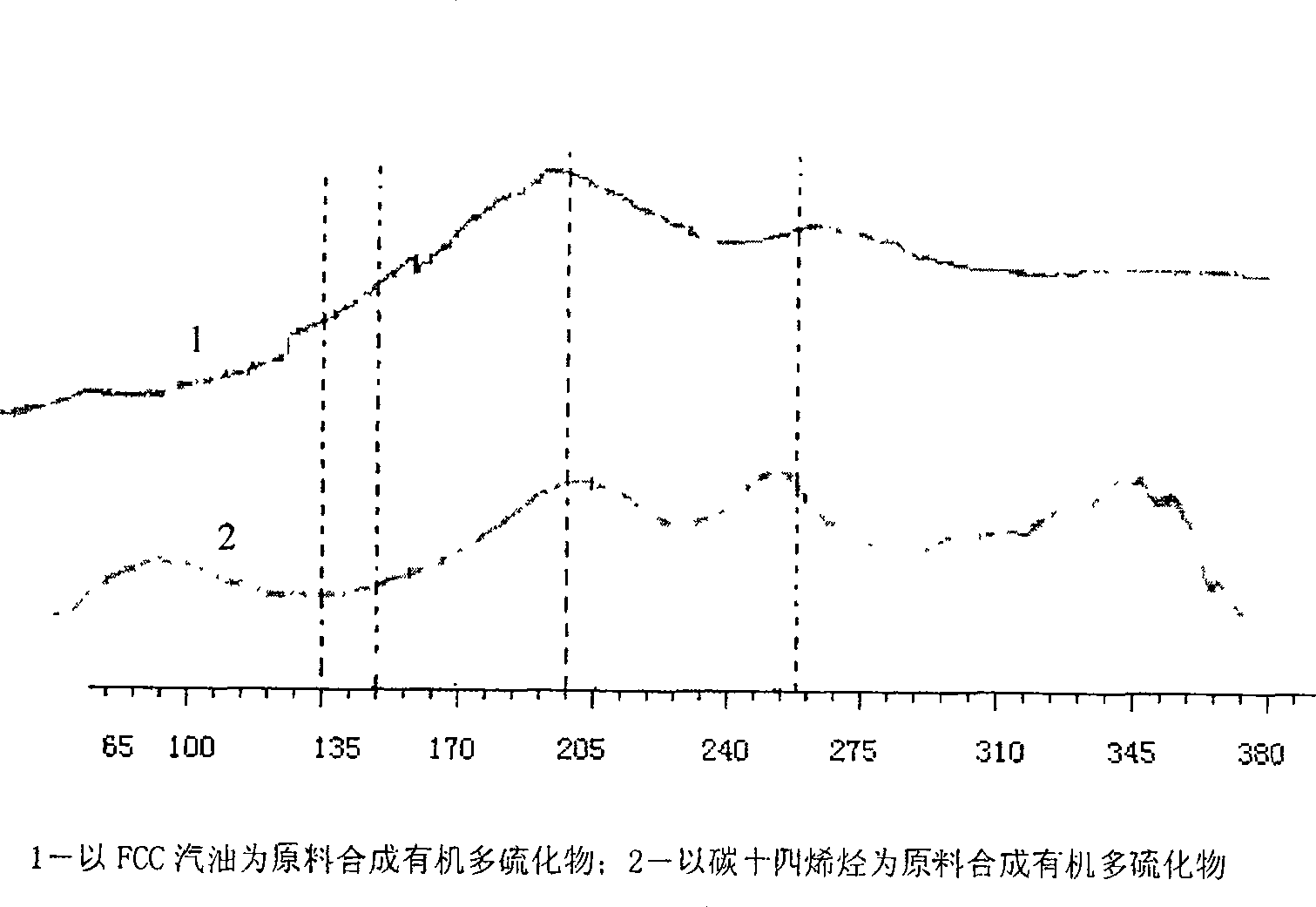

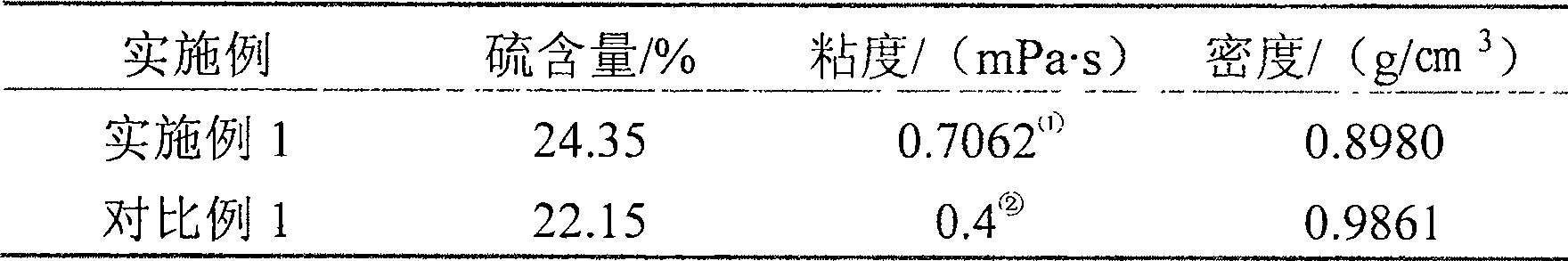

Synthesis of organic polysulfide

InactiveCN100509777CHigh yieldHigh olefin contentCatalyst activation/preparationHydropoly/poly sulfide preparationVulcanizationDouble bond

The invention discloses a synthesis method of an organic polysulfide used as a vulcanizing agent. In this method, the FCC distillate oil rich in olefins is used as a raw material. Under the action of a basic catalyst, the sulfur and the double bonds in the olefins undergo an addition reaction to form an adduct, and the unreacted elemental sulfur is separated by purification to obtain A mixture of relatively pure organic polysulfides. The organic polysulfide is mainly used as a vulcanizing agent for pre-sulfurization outside the hydrogenation catalyst. Its raw material has a wide range of sources and low cost, which can solve the problem of high production cost of the current organic vulcanizing agent; due to the use of mixed olefins as raw materials, the vulcanizing agent During application, the problem of excessively concentrated heat release can be alleviated; the process also has the advantages of simple preparation method and high sulfur content in the product, and has broad application prospects in the presulfurization process outside the hydrogenation catalyst.

Owner:大庆高新技术产业开发区南天实业有限公司

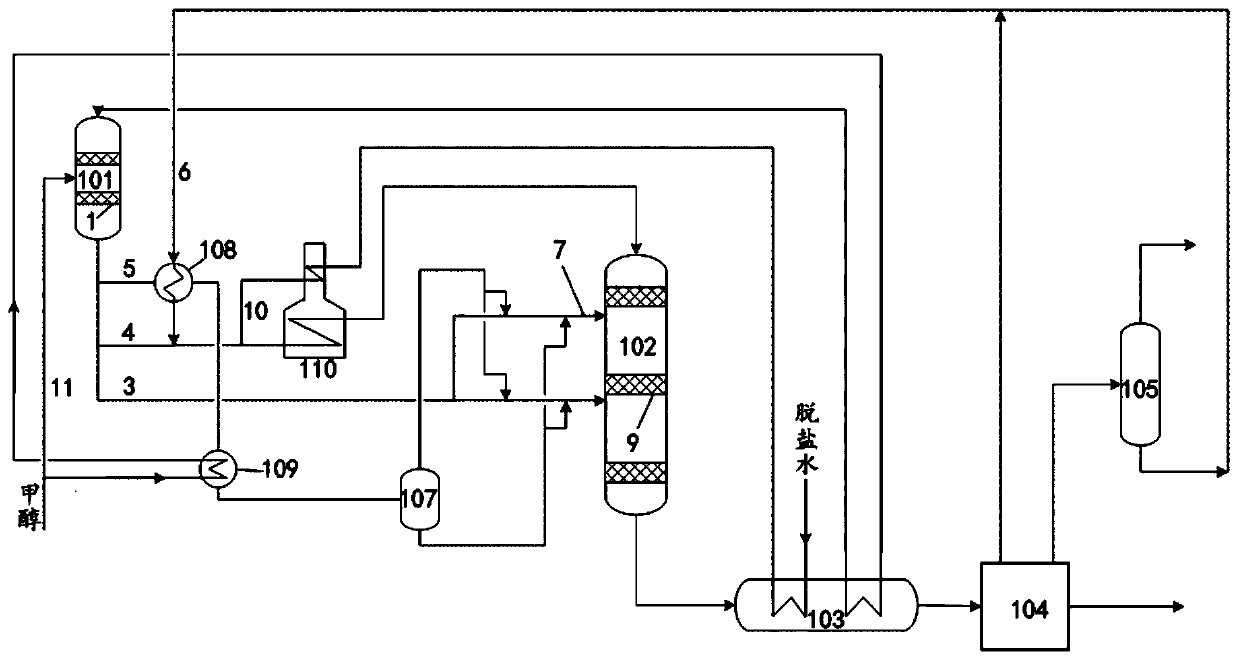

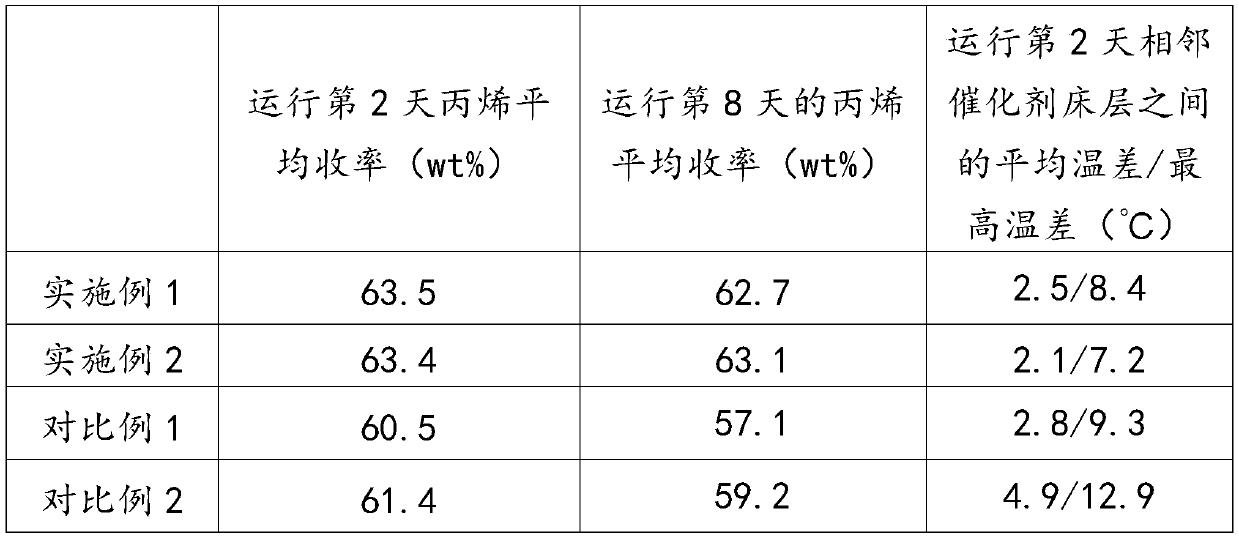

Device for preparing methanol into propylene

ActiveCN110054539AReduce runawayEfficient temperature control and stabilityMolecular sieve catalystChemical industryChemistryCooling Units

The invention discloses a device for preparing methanol into propylene. The device comprises a first reactor, a first material conveying pipe, a second material conveying pipe, a third material conveying pipe, a cooling unit, a dimethyl ether separation tower, a heating furnace, a second reactor, a separation unit, a C4 rectifying tower, a circulating hydrocarbon pipeline and a steam pipeline. Theinvention further discloses a corresponding method for preparing methanol into propylene. Isobutane is separated from circulating hydrocarbons, and a first product stream obtained by carrying out thereaction for preparing methanol into dimethyl ether in the first reactor is divided into three streams, so that the temperature flying phenomenon of the reactor can be reduced through dispersed feeding matched with different temperatures, and meanwhile, the high-efficiency temperature control of the reactor can be facilitated by adjusting the gas-liquid ratio fed from a side line.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

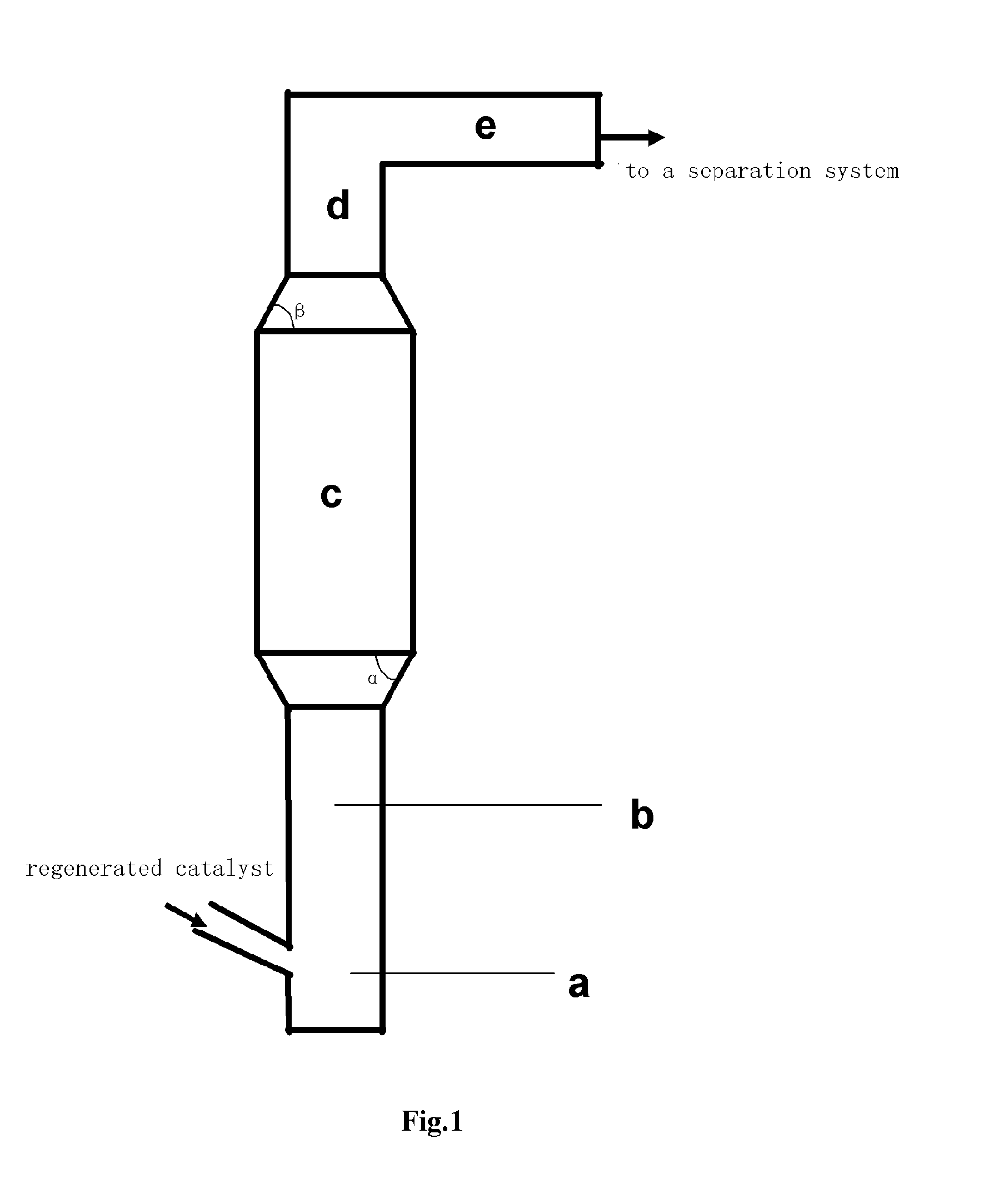

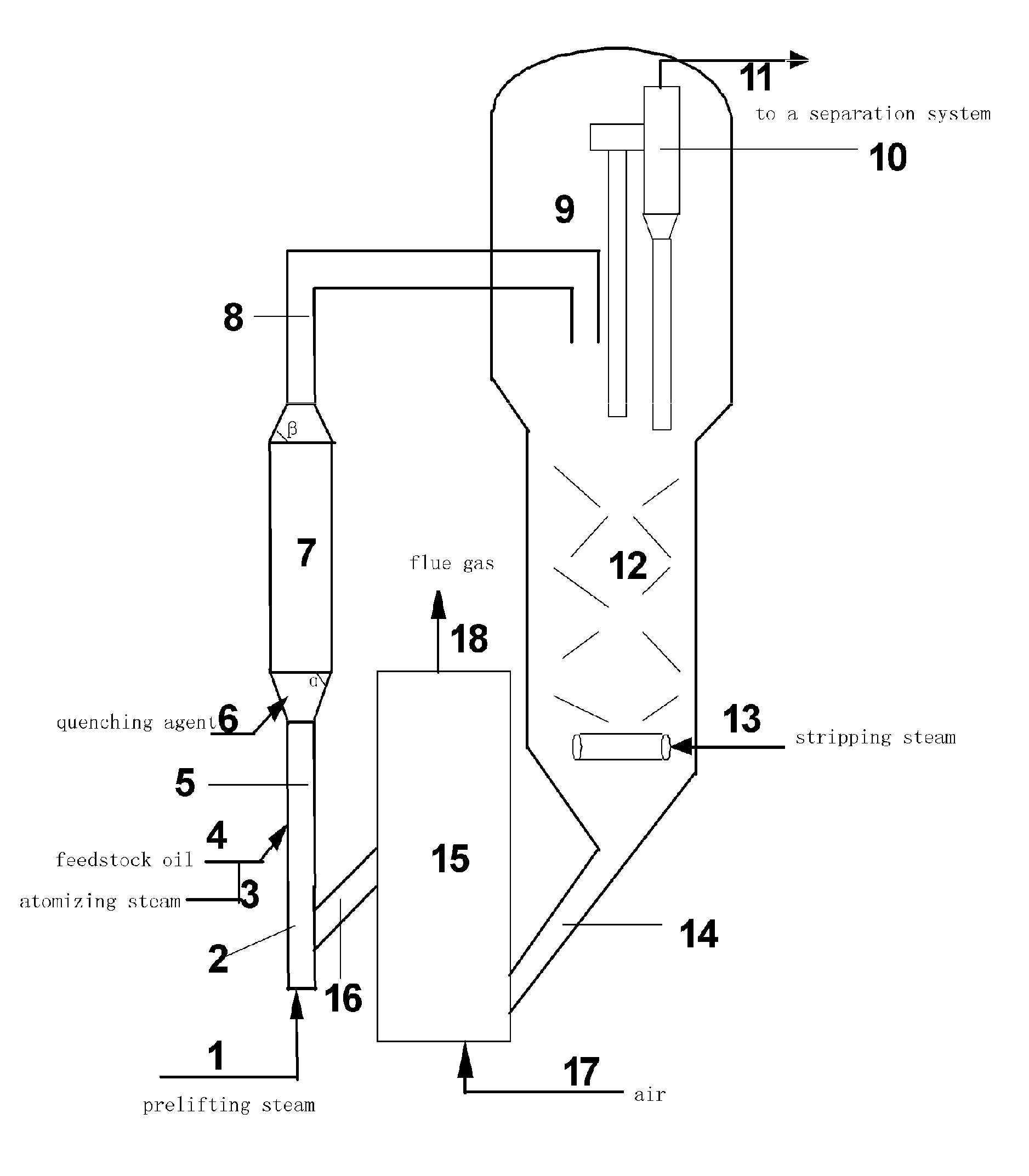

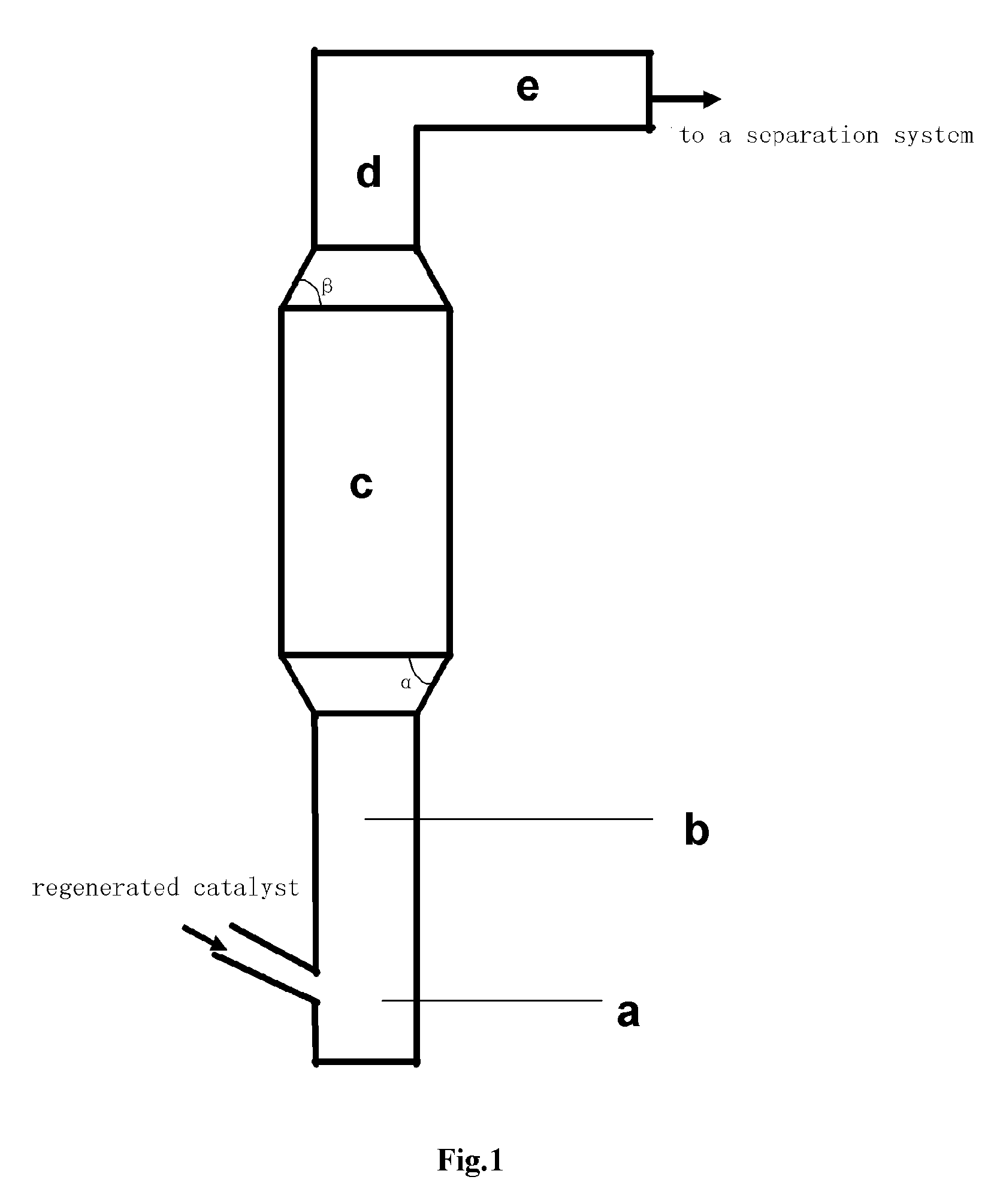

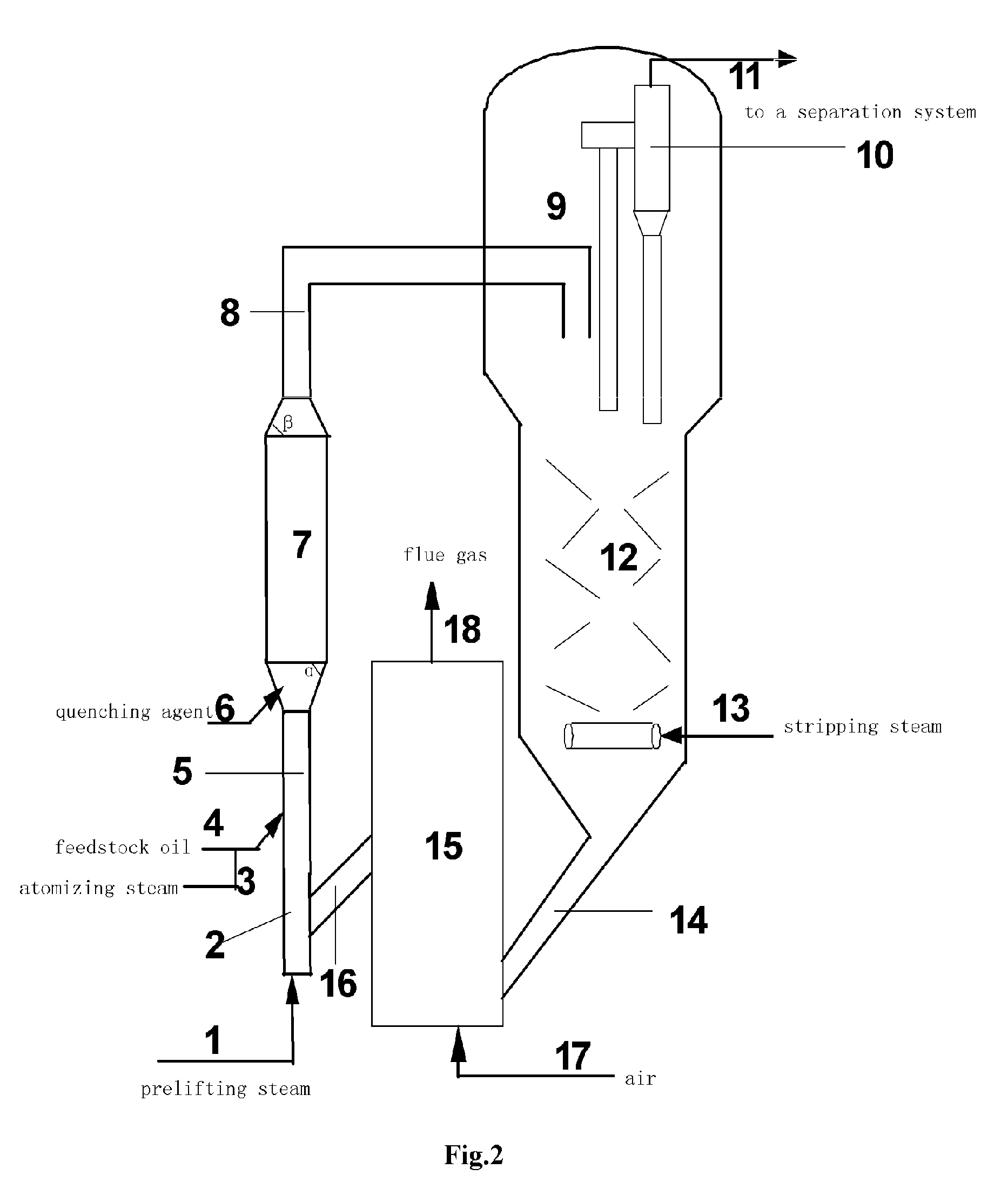

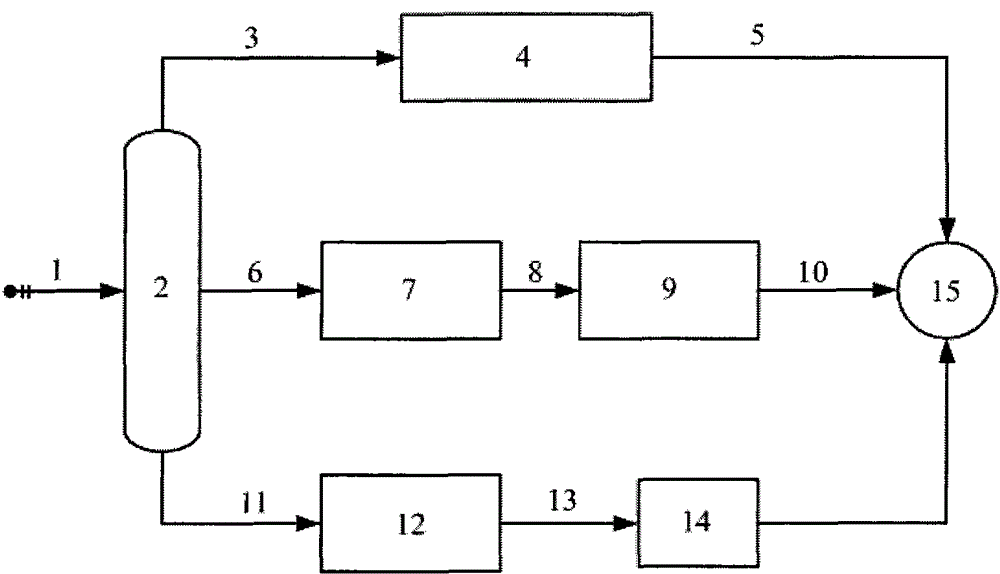

Catalytic conversion method for improving product distribution

ActiveUS20130211167A1Improve product distributionIncreasing isobutene contentCatalytic crackingHydrocarbonsPtru catalystCracking reaction

The present invention relates to a catalytic conversion process for improving the product distribution, characterized in that a feedstock oil of good quality is contacted with a hot regenerated catalyst having a lower activity in a reactor to carry out a cracking reaction, the reaction product is separated from the spent catalyst to be regenerated, then the reaction product is fed into a separation system, and the spent catalyst to be regenerated is stripped, regenerated and recycled in the process. The isobutene content in the liquefied petroleum gas (LPG) produced by the process is increased by a factor of more than 30%, and the olefin content in the gasoline composition may be increased to more than 30 wt. %. The product distribution is optimized, and the yields of dry gas and coke are decreased, so as to sufficiently utilize the petroleum resources.

Owner:RES INST OF PETROLEUM PROCESSING SINOPEC +1

An aromatization catalyst and its preparation method, regeneration method and aromatization method

ActiveCN108479846BHigh aromatization activityImprove conversion rateMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveIon exchange

The invention provides an aromatization catalyst and a preparation method, regeneration method and aromatization method thereof. The preparation method comprises mixing a zeolite molecular sieve and abinder to obtain a catalyst precursor, orderly performing ion exchange modification and first modification treatment on the catalyst precursor, and after hydrothermal treatment, carrying out active metal loading and second modification treatment to obtain the aromatization catalyst. A modification element used in the first modification is at least one selected from metals in the group IA, group VA and lanthanide line in the periodic table, the active metal is at least one element selected from elements in the group VIIB, group VIII, group IB and group IIB, and the modifying element used for the second modification is at least one element selected from elements in the group VA and lanthanide line in the periodic table. The aromatization catalyst has good carbon deposition resistance and high aromatization activity, can complete the aromatization reaction under mild conditions, and has high aromatic selectivity and a liquid yield of 98.5% or more.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

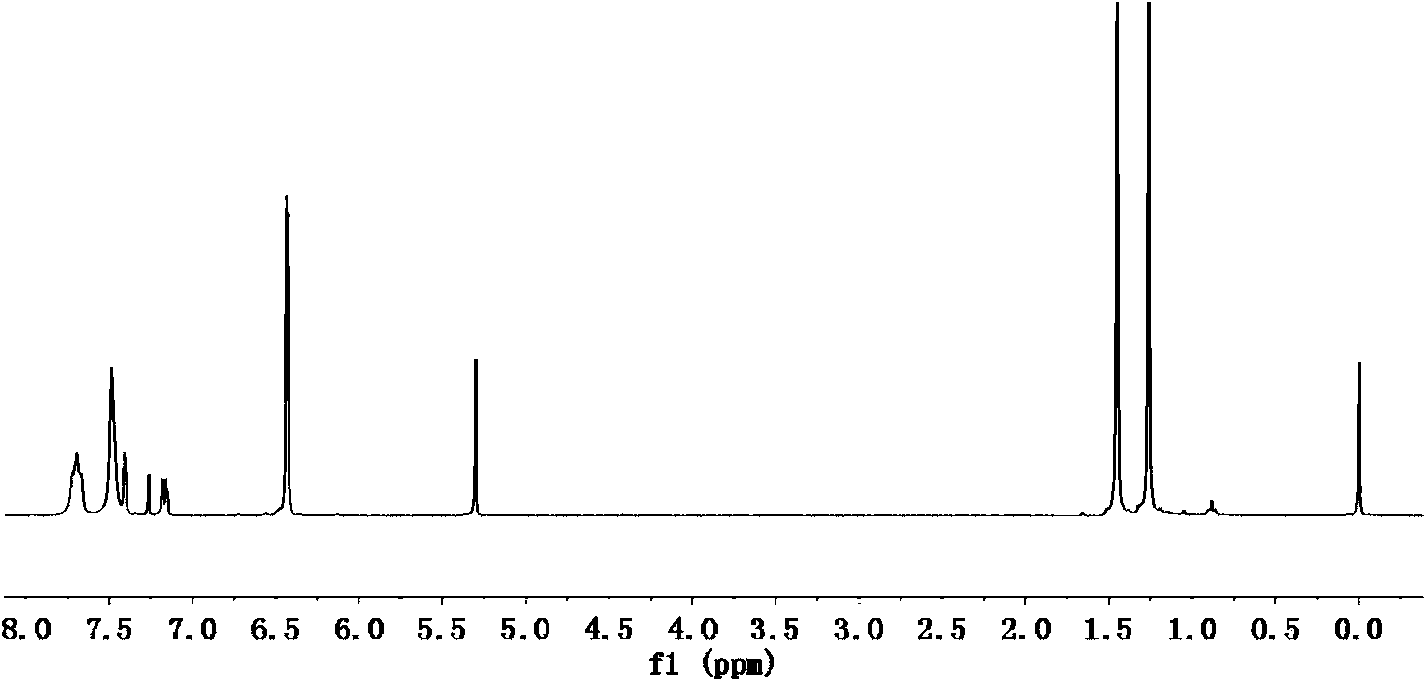

Method for extracting and separating liquid olefin and alkane mixture by adopting functional ionic liquid

ActiveCN102701895BImprove thermal stabilityLow steam pressureExtraction purification/separationSolventIonic liquid

Owner:ZHEJIANG UNIV

Preparation method of cycloolefin copolymers

The invention provides a preparation method of cycloolefin copolymers. The preparation method comprises the steps of utilizing a half metallocene complex in a structure of a formula (I) as main catalysts, forming a salt ion active center after being acted with a cocatalyst, and thereby catalyzing the copolymerisation of ethylene and norbornene. On one hand, the existence of R in the half metallocene complex ensures the catalytic activity of a half metallocene system; the introduction of P, O or S atoms for the half metallocene complex improves the catalytic stability, therefore, the catalytic activity of the half metallocene complex is high; on the other hand, the introduction of aryloxy or aromatic sulfenyl further improves the charge properties and the space effects of a transition metal center, thereby being favorable for stabilizing a metal cation center; and the larger volume and an annual structure formed with the metal center also generate certain restriction to the spatial configuration of the half metallocene complex, therefore the generated cycloolefin copolymers through catalysis have high molecular weight, and at the same time, the method of the invention ensures that the content of the norbornene in the complex is high and can be regulated.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

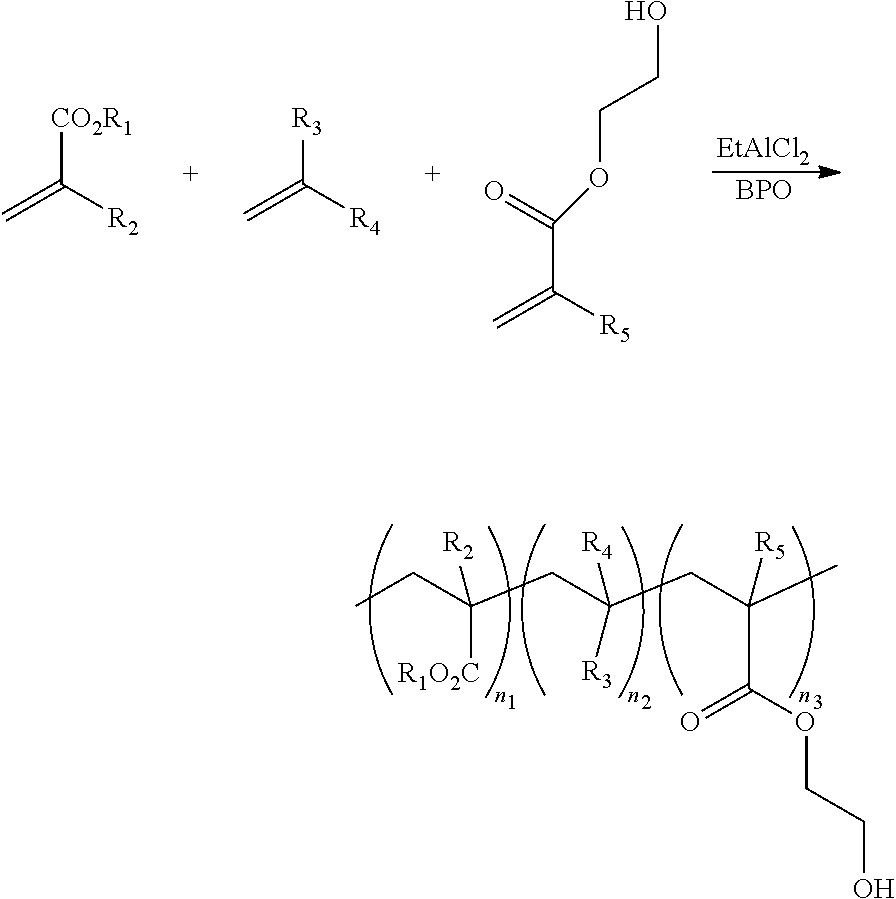

Olefin-acrylate copolymers with pendant hydroxyl functionality and use thereof

ActiveUS20180305480A1High olefin contentImprove water vapor barrier performanceLayered productsAdhesivesBackbone chainAlkene

Copolymers prepared by a reaction of (1) an unactivated olefin, (2) an activated olefin, and (3) a hydroxyl functional activated olefin and / or a hydroxyl functional unactivated olefin are described. The copolymers have a backbone of polar vinyl monomers and non-polar alkene monomers, with pendant hydroxyl functional groups. The copolymers are well suited for optically clear, pressure sensitive, polyurethane and / or barrier adhesives.

Owner:HENKEL KGAA

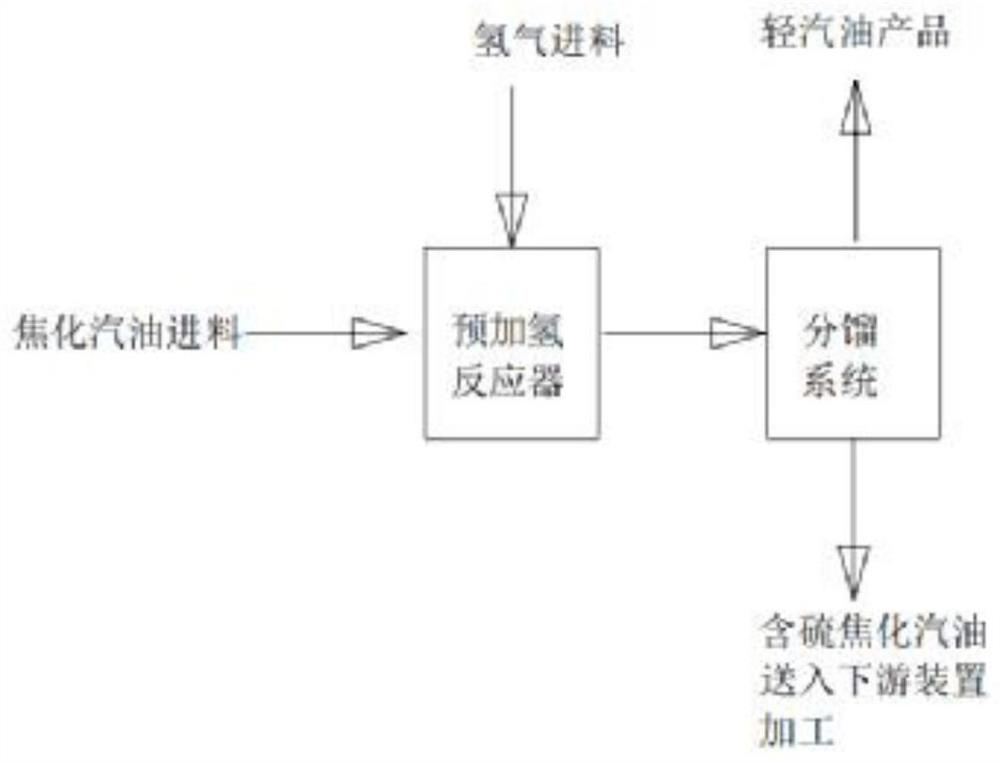

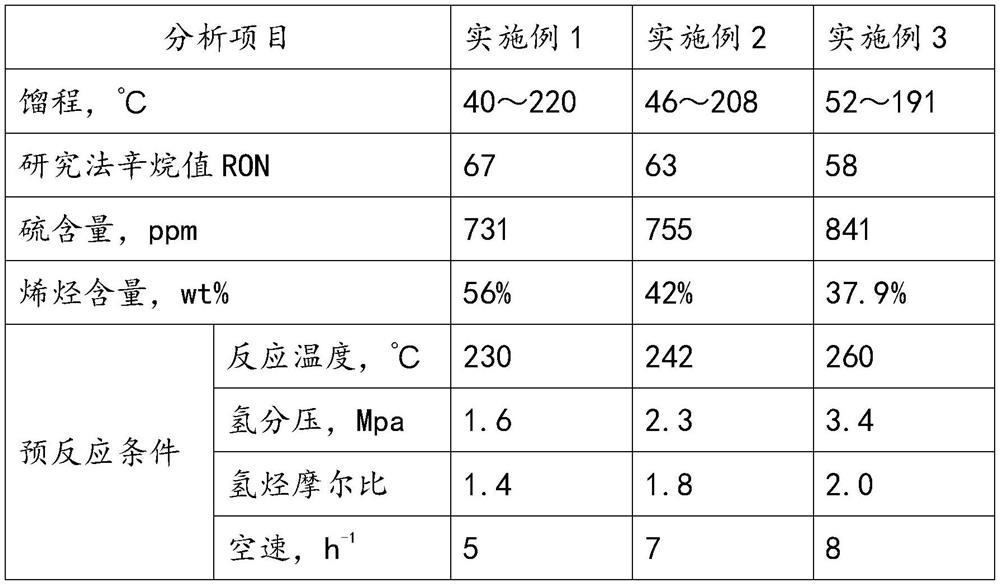

Coker gasoline processing technology

InactiveCN111778068AHigh olefin contentBoost octaneTreatment with hydrotreatment processesChemistryProcess engineering

The invention relates to a coking gasoline processing technology, and belongs to the technical field of gasoline processing. The technology comprises carrying out a pre-hydrogenation reaction processon coker gasoline, wherein monoolefine in the coker gasoline is reserved in the step, fractionating the coker gasoline subjected to the pre-reaction to obtain gasoline with light fraction, medium fraction and heavy fraction, respectively treating according to the properties of each fraction, wherein the light fraction gasoline is directly used as a gasoline blending component, separating the medium fraction gasoline to obtain raffinate oil and extract oil, wherein the raffinate oil as a gasoline blending component, and sending the extract oil and the heavy fraction gasoline into a downstream device for reprocessing. According to the process, the characteristics of high olefin content and high octane number in the coking gasoline light component are fully considered, the yield of the high-octane number light component is increased through the sulfur transfer function of the pre-reaction, the processing flow is shortened, the processing energy consumption is reduced, and the process canbe used as an effective way for coking gasoline utilization.

Owner:盘锦浩业化工有限公司 +1

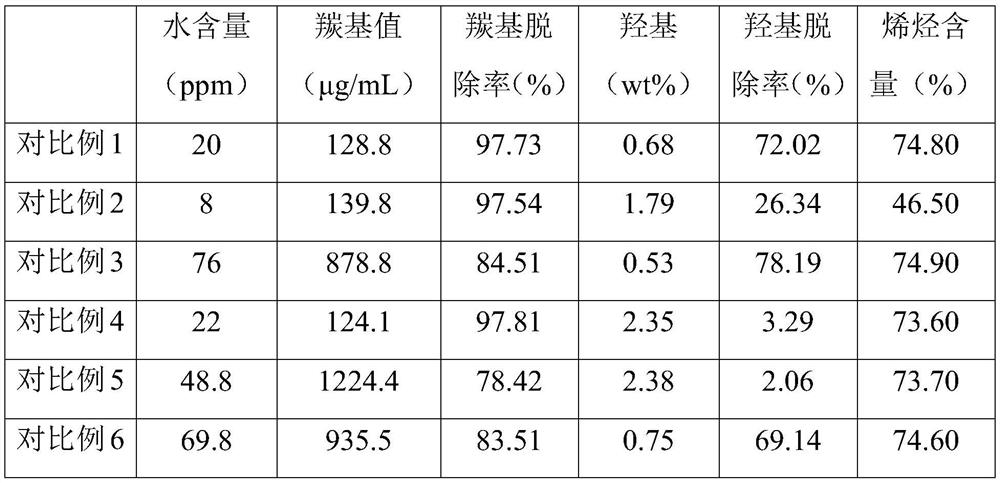

Method for removing oxygen-containing compounds in Fischer-Tropsch synthetic oil

PendingCN114479914AExtended service lifeLittle impact on purityTreatment with plural serial refining stagesRefining to eliminate hetero atomsFixed bedOxygen compound

The invention discloses a method for removing oxygen-containing compounds in Fischer-Tropsch synthetic oil, and belongs to the technical field of Fischer-Tropsch oil treatment. The method comprises the following steps: in a fixed bed reaction device, removing oxygen-containing compounds in Fischer-Tropsch synthetic oil to be treated by using sulfonic acid resin; the weight ratio of the sulfonic acid resin to the Fischer-Tropsch synthetic oil to be treated is 1: (100-200). According to the method, sulfonic acid resin and Fischer-Tropsch synthetic oil are subjected to a reaction, so that oxygen-containing compounds in the Fischer-Tropsch synthetic oil can be removed through the reaction under the condition of ensuring no loss of straight-chain olefins, and additional straight-chain olefins are generated at the same time, so that the olefin content in an oil product is greatly improved. In addition, the method is beneficial to prolonging the service life of the sulfonic acid resin, few by-products are generated, the influence on the purity of olefin is small, the energy consumption is low, and the economic benefit is high.

Owner:INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD

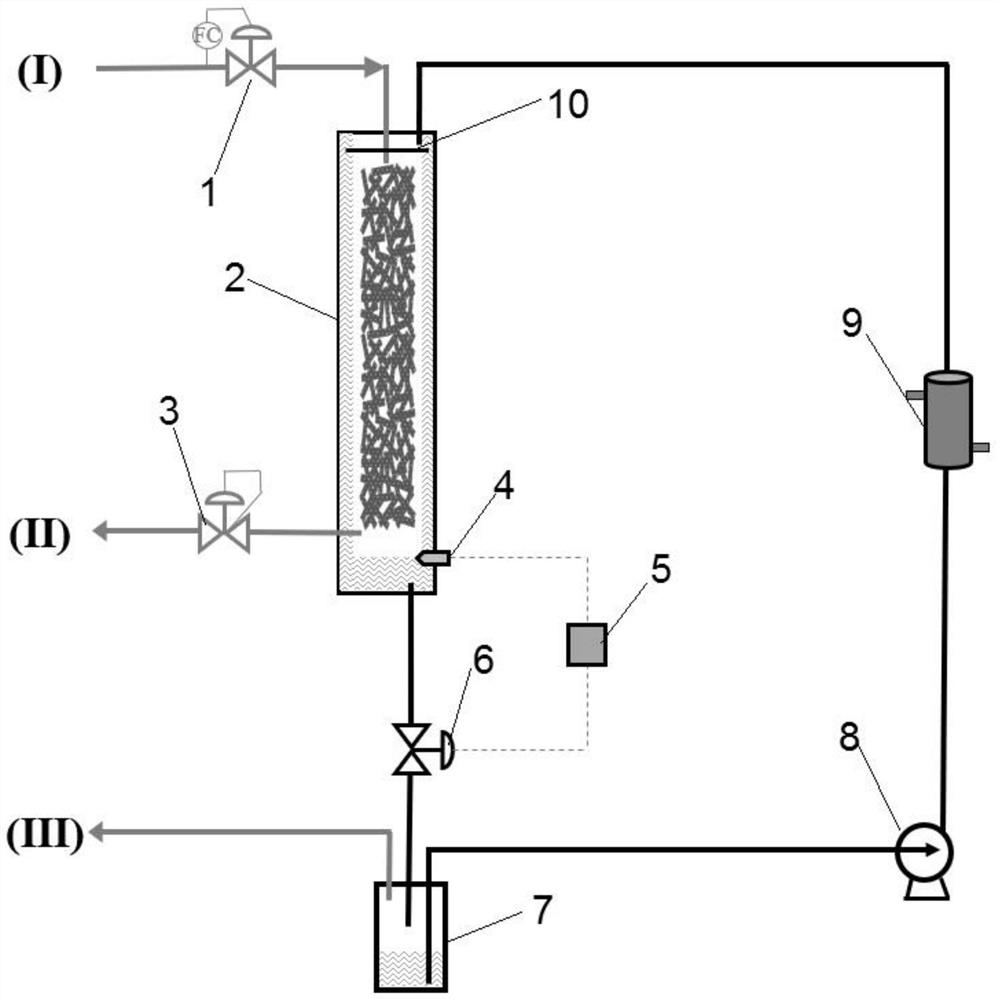

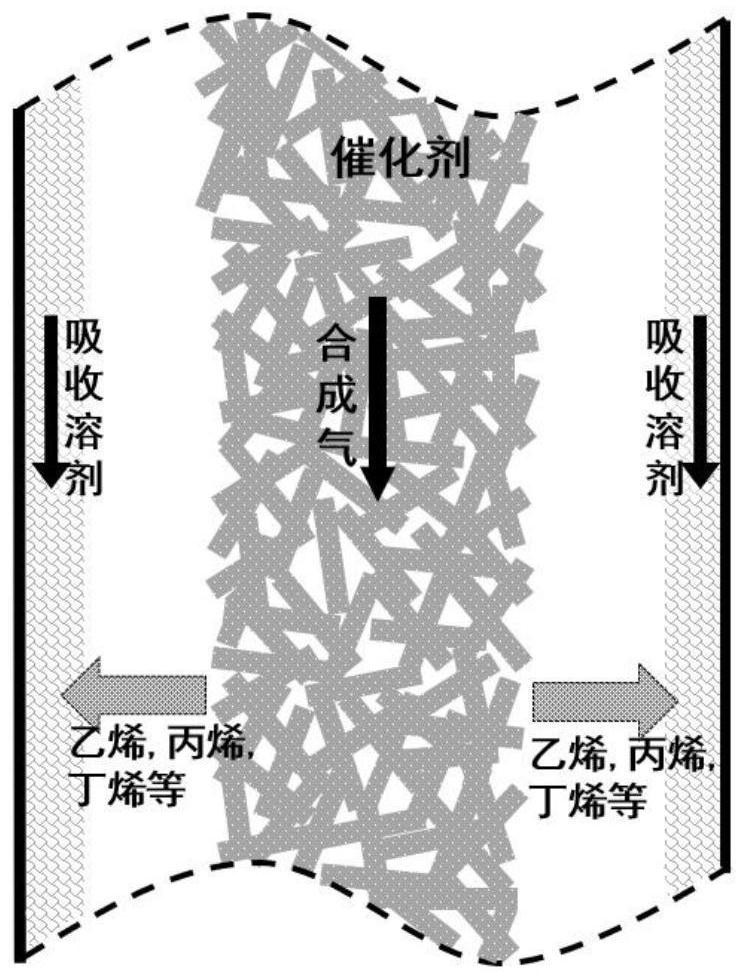

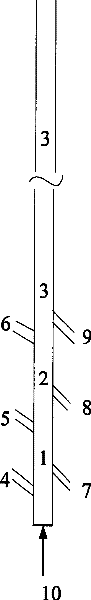

Method for preparing olefin from synthesis gas and reaction and separation integrated reaction device

PendingCN114773137AImprove conversion rateHigh olefin contentGas treatmentHydrocarbon from carbon oxidesPtru catalystReactive separation

Owner:JISHOU UNIVERSITY +1

Cracking method for hydrocarbon oil

The invention discloses a hydrocarbon oil cracking method which comprises that: in a riser reactor comprising a plurality of reaction areas, the hydrocarbon oil raw material and the cracking catalyst are made a contact reaction in each reaction area under the condition of cracking reaction, the catalyst is separated from the reaction product to obtain the cracking product and spent catalyst, at least partial spent catalyst is regenerated to obtain the semi-regenerated catalyst and the regenerated catalyst, wherein, the reaction areas comprise at least one middle reaction area and at least one upper reaction area, the upper reaction area is positioned above the middle reaction area; the inferior heavy raw material and the semi-regenerated catalyst are imported in the middle reaction area to allow the heavy raw material to contact the semi-regenerated catalyst; the heavy raw material and the regenerated catalyst are imported in the upper reaction area to allow the heavy raw material to contact the regenerated catalyst. At least one item of the carbon residue content, the content of metal nickel and vanadium, the bitumencarb content and the basic nitrogen content of the inferior heavy raw material is higher than that of the heavy raw material. The method can optimize the cracking conditions of the hydrocarbon oil and improve the distribution of products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Three section type catalystic conversion method of petroleum hydrocarbon raw material and its device

InactiveCN100393845CReduce olefin contentGood modification effectCatalytic crackingThree stageGasoline

The invention relates to a three-stage petroleum hydrocarbon raw material catalytic conversion method and the reactor thereof, belonging to petroleum hydrocarbon catalytic conversion process field. And the method makes raw oil, back-refined oil, and gasoline react separately and not interfere with one another; the catalytic cracking reacting region of a heavy oil reactor uses regenerated catalyst, and the modifying reacting region supplements low temperature catalyst after gasoline reaction, forming second reacting region; after the gasoline reaction ends, the extracted catalyst is fed into the second reaction region of heavy oil reaction and continues being used; the gasoline reaction and back-refined oil cracking reaction adopt regenerated catalyst temperature lowering solution, implementing high solvent-oil ratio working condition. And the reactor is a combined reactor composed of heavy oil reacting part and parallel and interconnected gasoline reacting parts. And it separately refines different materials and makes gasoline and heavy oil cooperate with each other and their advantages complementary; and raises reacting efficiency and improves product quality.

Owner:洛阳石化设备研究所

Integration of cyclic dehydrogenation process with FCC for dehydrogenation of refinery paraffins

ActiveUS9150465B2Increase productionIncreased paraffinic contentCatalytic crackingCatalystsAlkaneDehydrogenation

A process for increasing light olefin yields from the fluidized catalytic cracking process. The process combines small units to treat the paraffinic components in the product streams from the fluidized cracking process. The paraffins are dehydrogenated and light olefins are separated. Heavier olefins are passed to an olefin cracking unit for increasing the yields of ethylene and propylene.

Owner:UOP LLC

Catalytic conversion method for improving product distribution

ActiveUS9580664B2Increase contentOptimize allocationCatalytic crackingTreatment with hydrotreatment processesLow activityGasoline

The present invention relates to a catalytic conversion process for improving the product distribution, characterized in that a feedstock oil of good quality is contacted with a hot regenerated catalyst having a lower activity in a reactor to carry out a cracking reaction, the reaction product is separated from the spent catalyst to be regenerated, then the reaction product is fed into a separation system, and the spent catalyst to be regenerated is stripped, regenerated and recycled in the process. The isobutene content in the liquefied petroleum gas (LPG) produced by the process is increased by a factor of more than 30%, and the olefin content in the gasoline composition may be increased to more than 30 wt. %. The product distribution is optimized, and the yields of dry gas and coke are decreased, so as to sufficiently utilize the petroleum resources.

Owner:RES INST OF PETROLEUM PROCESSING SINOPEC +1

Olefin oligomerization catalyst and preparation method and application thereof

ActiveCN101745422BHigh catalytic activityHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsAlcoholOligomer

The invention relates to an olefin oligomerization catalyst, which comprises an ethylchloride zirconyl alcohol adduct with the general formula of Zr (OR) mCl4-m . nROH, wherein m is an integer from 1 to 3, n is 2 to 8, and R is C3 to C8 chain alkyl. The preparation method of the catalyst is simple, the catalyst has higher oligomerization activity when being matched with an organic aluminum catalyst, the content of oligomer in the oligomerization product is low, the content of C12 to C20 olefin is higher, and the yield of alpha-olefin is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for producing ultra-low sulfur full distillate gasoline products

ActiveCN103074107BReduce lossesHigh olefin contentTreatment with hydrotreatment processesCatalytic reformingHydrodesulfurization

The invention provides a production method for a full-fraction gasoline product with ultralow sulfur. Full-fraction gasoline is fractionated into a light gasoline fraction, a medium gasoline fraction and a heavy gasoline fraction; the light gasoline fraction is subjected to alkali washing and refining so as to remove mercaptan sulfur therein; the medium gasoline fraction enters into a first hydrogenation unit and undergoes catalytic reforming so as to obtain a reformed medium gasoline fraction with an improved octane number; the heavy gasoline fraction enters into a second hydrogenation unit, successively enters into two hydrotreatment reaction zones and respectively undergoes selective hydrogenation for removal of diene and selective hydrodesulfurization so as to obtain a hydrogenated heavy gasoline fraction, and the hydrogenated heavy gasoline fraction undergoes oxidation for removal of mercaptan sulfur so as to obtain a low-sulfur heavy gasoline fraction. The refined light gasoline fraction, the reformed medium gasoline fraction and the low-sulfur heavy gasoline fraction are mixed so as to obtain the full-fraction gasoline product with ultralow sulfur. The obtained full-fraction gasoline product has total sulfur content of less than 10 mu g / g; and compare with a full-fraction gasoline raw material, loss of the octane number RON of the full-fraction gasoline product is less than 1.0 unit.

Owner:CHINA PETROLEUM & CHEM CORP +1

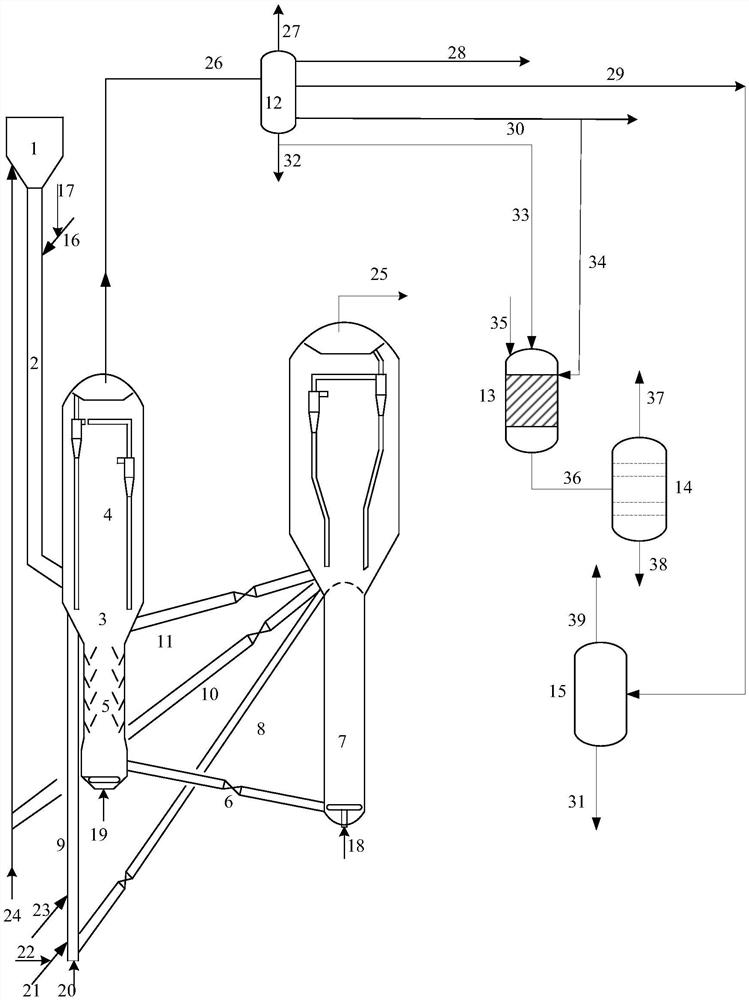

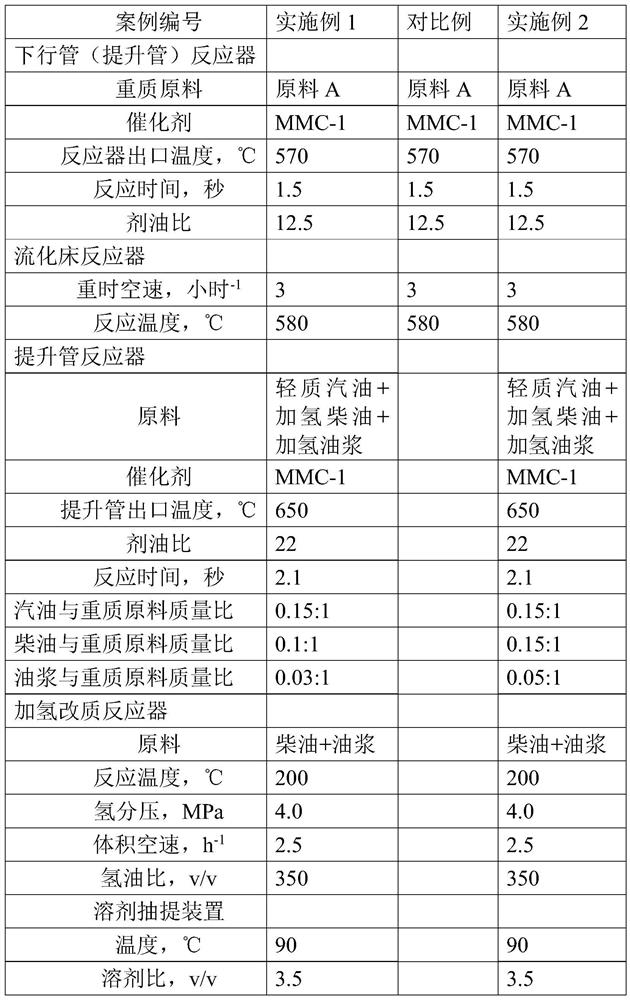

Catalytic cracking method and system

ActiveCN113897216AImprove conversion ratePromotes re-lysisCatalytic crackingHydrocarbon oils treatment productsProcess engineeringAromatic hydrocarbon

The invention relates to a catalytic cracking method and a system. The catalytic cracking method comprises a combined process of catalytic cracking, hydro-upgrading and aromatic hydrocarbon extraction. According to the process, benzene, methylbenzene and xylene can be co-produced while low-carbon olefin is produced to the maximum extent, and product distribution is optimized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com