Olefin oligomerization catalyst and preparation method and application thereof

A catalyst, olefin technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of low carbon olefins, such as excess, decline, and excessive C activity. , to achieve the effect of high content of high-carbon olefins, improved catalytic activity, and high yield of α-olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

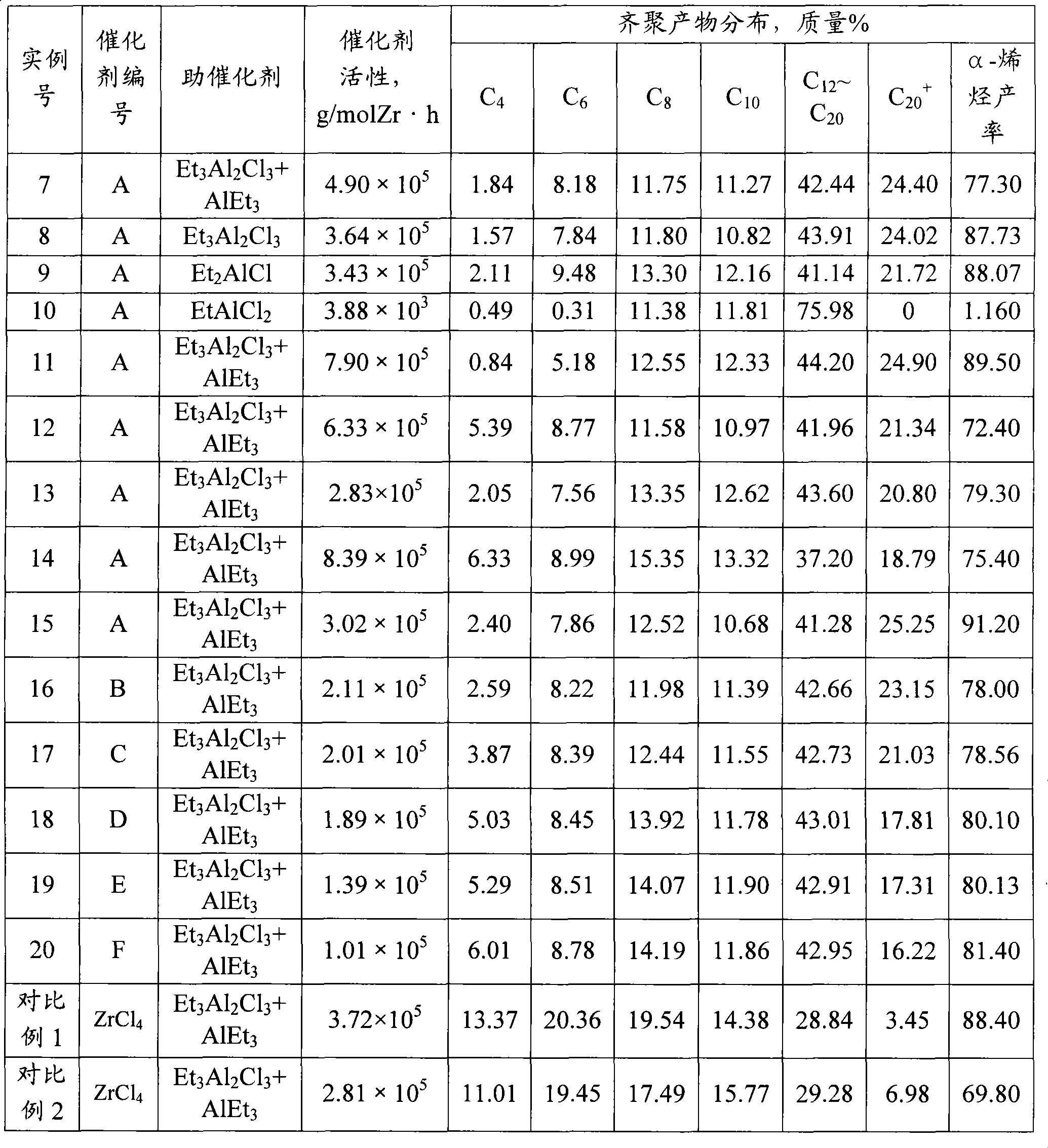

Examples

preparation example Construction

[0013] The preparation method of the catalyst provided by the invention comprises fully reacting zirconium tetrachloride in an aromatic hydrocarbon medium with an aliphatic alcohol having the general formula ROH, wherein R is C in the ROH 3 ~C 8 The chain alkyl group, the molar ratio of fatty alcohol and zirconium tetrachloride in the reaction is 3~9:1.

[0014] The reaction temperature is the reflux temperature of the aromatic hydrocarbons contained in the system, preferably 70-100°C.

[0015] The aliphatic alcohol reacted with zirconium tetrachloride in the present invention is preferably butanol, propanol or hexanol, and the aromatic hydrocarbon in the reaction medium is preferably benzene or toluene.

[0016] Carrying out the olefin oligomerization method with the catalyst provided by the invention is: Zr(OR) with the general formula of the present invention m Cl 4-m nROH's chlorinated alkoxyzirconium alkoxide as the main catalyst and organoaluminum as the co-catalyst e...

example 1

[0022] The following examples prepare the oligomerization catalysts described in this invention.

[0023] Suspend 10mmol of zirconium tetrachloride in 34.6g of toluene, stir at 70°C for 1 hour, add 30mmol of n-butanol, reflux at 85°C for 4 hours, and measure the generated HCl by quantitative analysis. The composition of butoxy zirconium alkoxide is: Zr(OBu)Cl 3 2C 4 h 9 Oh. After the reaction, the temperature of the system was lowered to 25°C, and 20 grams of toluene was added to prepare Zr(OBu)Cl with a zirconium concentration of 0.2 mol / liter. 3 2C 4 h 9 OH solution in toluene A.

example 2

[0025] Prepare chloroalkoxy zirconium alkoxide by the method for example 1, difference is the n-butanol that adds 40mmol, makes the alcoholate of chloro n-butoxy zirconium, and its composition is: Zr(OBu)Cl 3 ·3C 4 h 9 Oh. After the reaction was completed, the system was cooled down, and 18.9 grams of toluene was added to form Zr(OBu)Cl with a zirconium concentration of 0.2 mol / liter. 3 ·3C 4 h 9 OH solution in toluene B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com