Synthesis of organic polysulfide

A polysulfide and synthesis method technology, applied in the field of additives, can solve the problems of low cost of sulfurized olefins, insufficient product purity, environmental pollution, etc., and achieve the effects of being conducive to environmental protection, simple synthesis process route, and wide decomposition temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

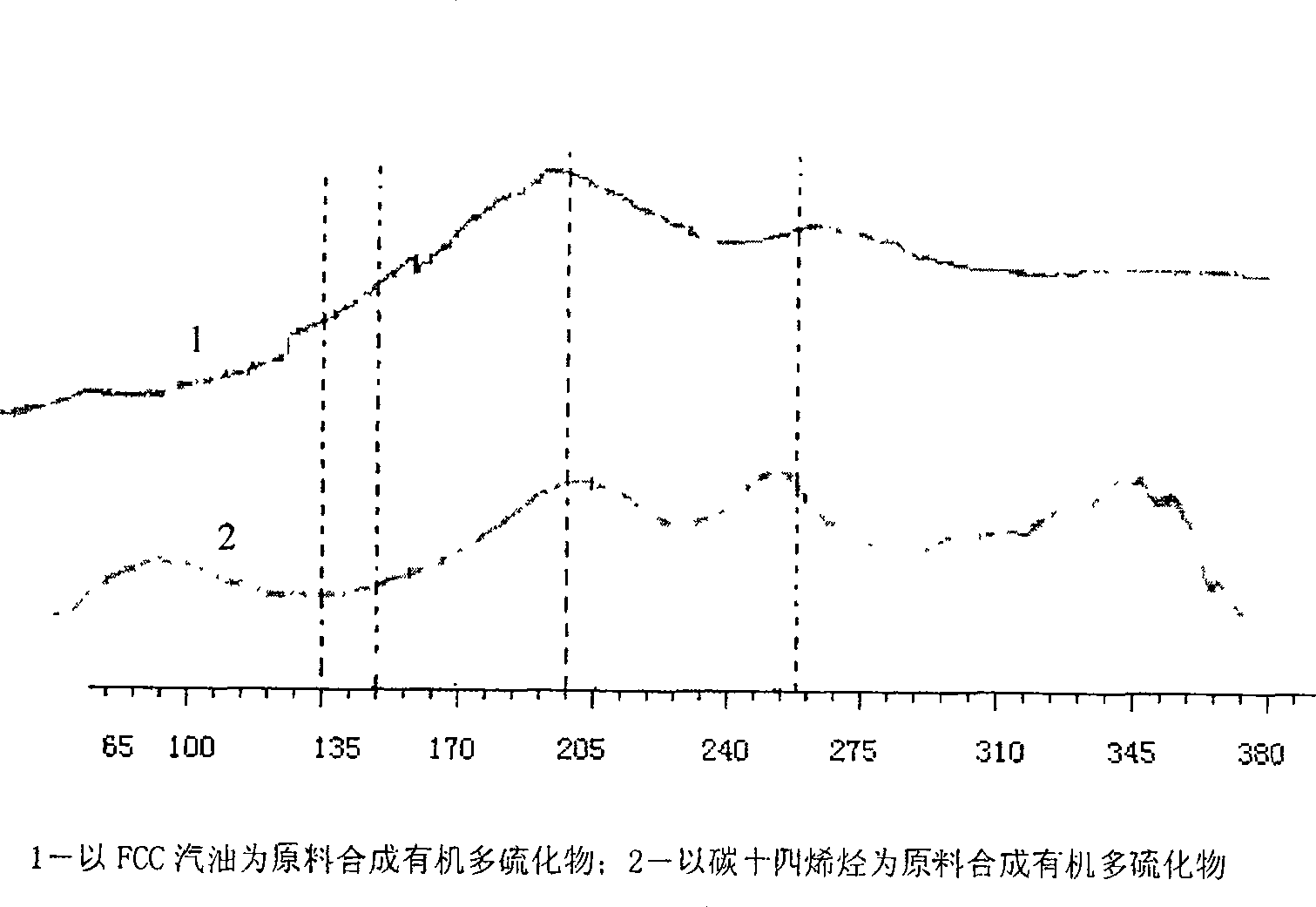

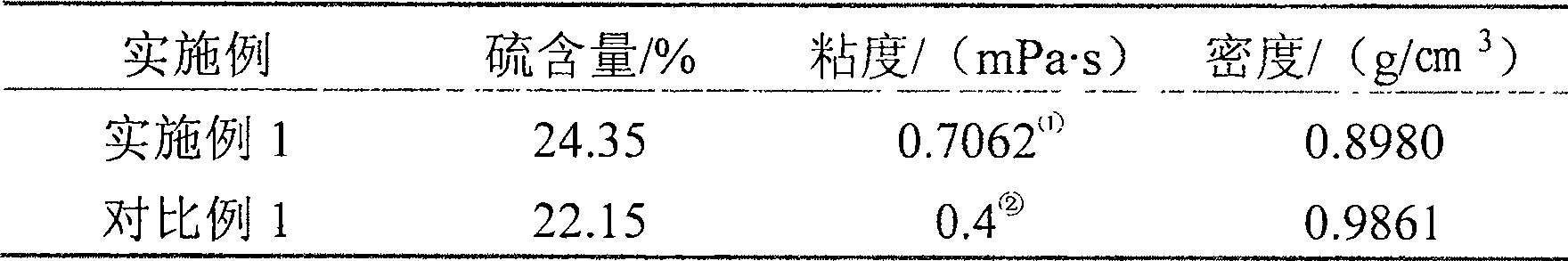

[0016] Embodiment 1, adopt the atmospheric distillation method to cut the FCC gasoline cut of 70~140 ℃ (FCC gasoline is obtained by catalytic cracking process of straight-run vacuum residue), get 20.0g of this cut as reaction raw material, add 16.7g of elemental sulfur and 1.0g catalyst triethylamine, the three are mixed and placed in a 150ml stainless steel high-pressure reactor, the air in the reactor is replaced with nitrogen, and then the reactor is sealed. React at 170°C for 3 hours, distill triethylamine from the obtained product at 90°C, then place the mixture containing organic polysulfur and elemental sulfur in an ice-water mixture at about 0°C for 30 minutes, decant, and take the upper liquid as organic polysulfides. The obtained polysulfide was supported on alumina, and the sulfur content of the product was determined to be 24.35% by combustion neutralization titration. The synthesized organic polysulfide has a wide decomposition temperature range, high sulfur cont...

Embodiment 2

[0017] Embodiment 2, prepare organic polysulfide by the method for embodiment 1, difference is that distillate used is the FCC gasoline fraction of 60~120 ℃, and catalyst adopts the mixture of triethylamine and sodium hydroxide, and its mol ratio is 1.5: 1. The total mass added is 5% of the gasoline fraction mass, and the reaction time is 6h. The purified organic polysulfides have a sulfur content of 24.54%.

Embodiment 3

[0018] Embodiment 3, prepare organic polysulfide by the method for embodiment 1, difference is that distillate oil used is the FCC gasoline fraction of 60~140 ℃, and catalyst is the mixture of triethylamine, aniline and sodium carbonate, three molar ratios The ratio is 1:1:0.1, and the total amount added is 5% of the mass of the gasoline fraction. Purified by washing with organic polysulfides. The obtained polysulfide was supported on alumina, and the sulfur content of the product was determined to be 20.22% by combustion neutralization titration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com