Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "High node strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

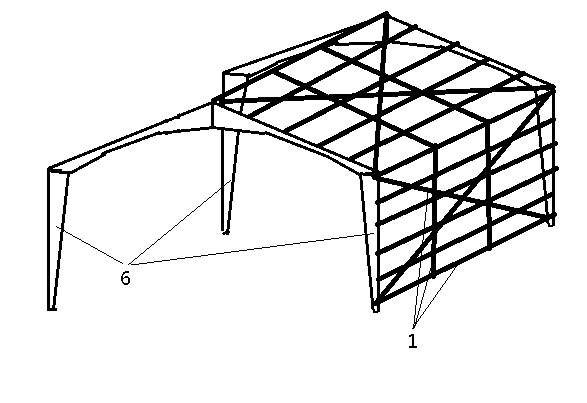

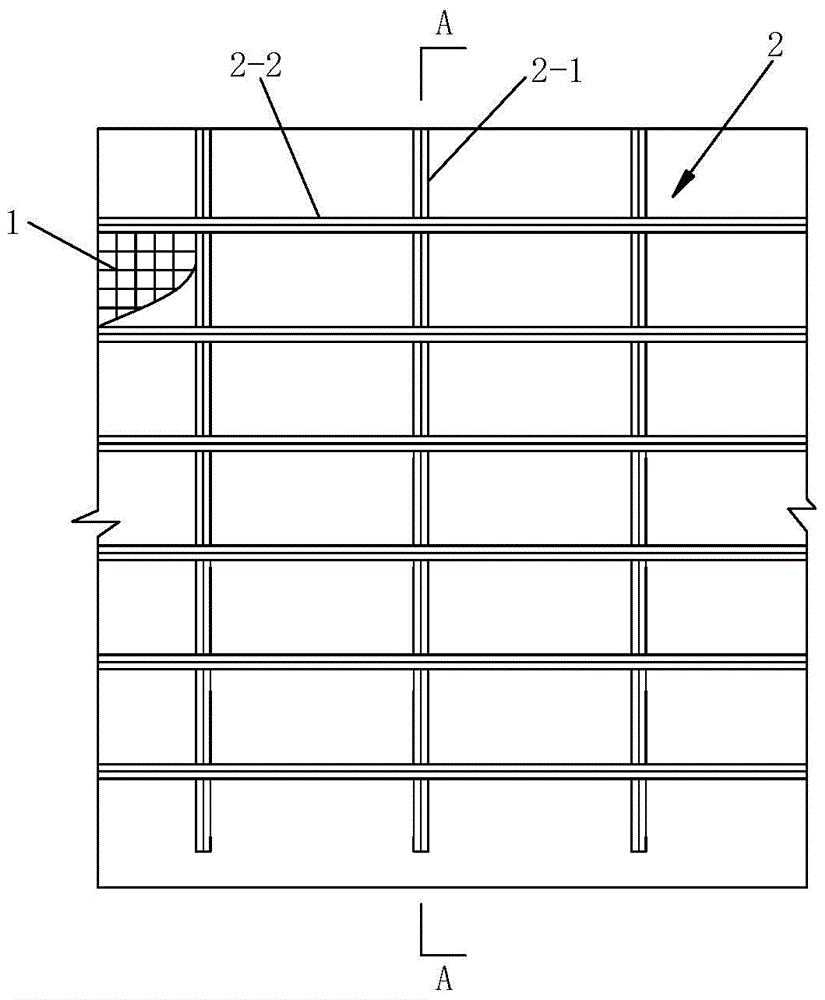

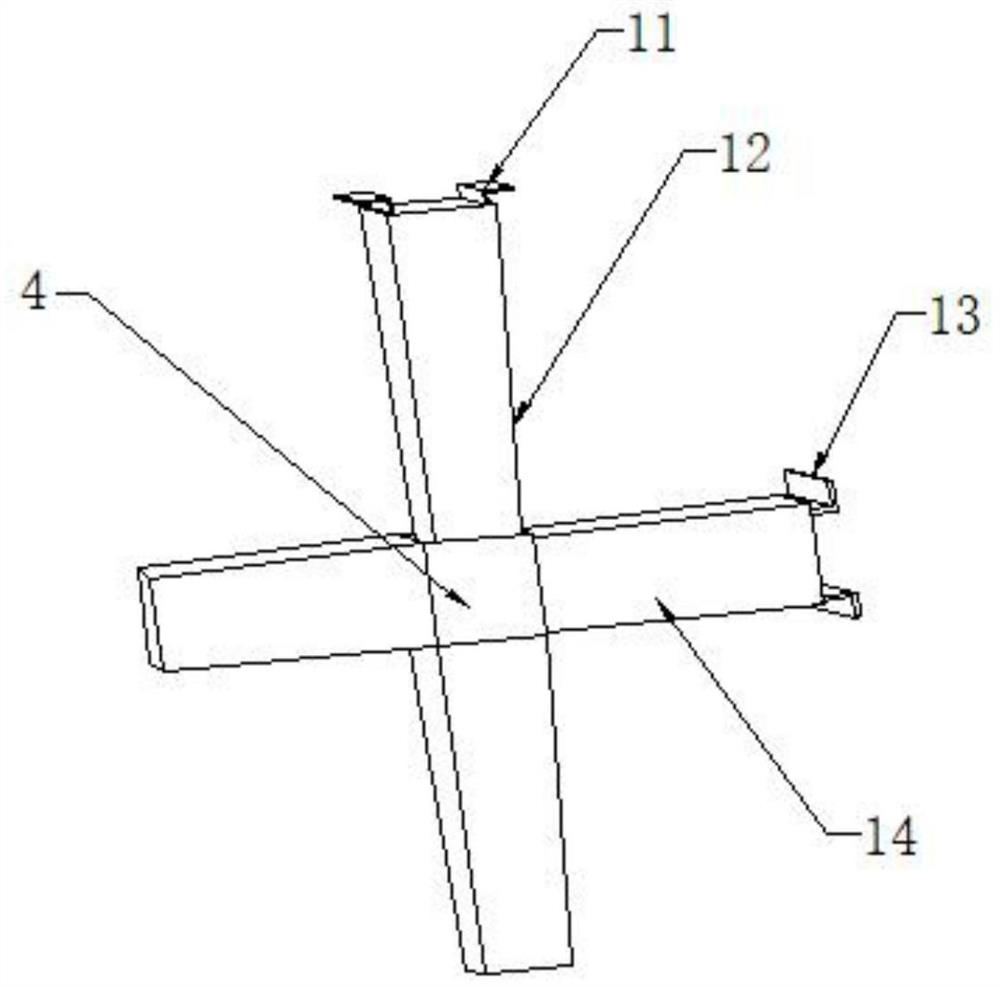

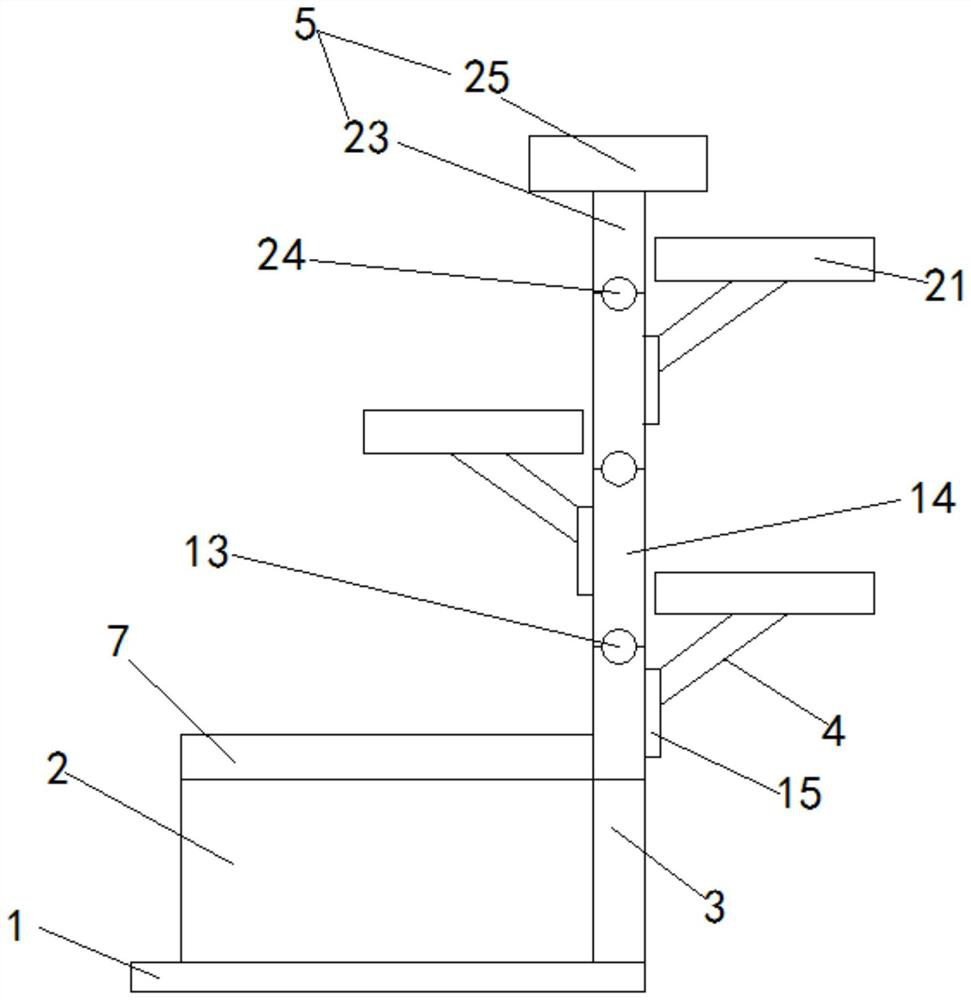

Portable shelter

InactiveCN104674949ASimple structureEasy to assemble and disassembleBuilding constructionsEngineeringStructural framework

The invention relates to a portable shelter. The portable shelter comprises a structural framework, a wall panel, a floor board and a roof panel, wherein the wall panel, the floor board and the roof panel are arranged on the structural framework; the structural framework comprises a bottom framework, a top framework, upright posts arranged between the bottom framework and the top framework, the wall panel, the floor board and the roof panel; the bottom framework is provided with a bottom end beam, a bottom side beam, a brace and a bottom frame basic node component; the bottom end beam and the bottom side beam are arranged on the bottom frame basic node component in an inserting way and are fastened to the bottom frame basic node component; the top framework is provided with a beam and a top frame basic node component; the beam is arranged on the top frame basic node component in an inserting way and is fastened to the top frame basic node component. The moveable room is simple in structure and convenient to assemble and disassemble, the space can be optionally expanded, and has certain strength and safety; meanwhile, cost can be also be saved, and the portable shelter is convenient to move; the space of the moveable room can be expanded by expanding the node components, so that the practicability is high; the portable shelter can be popularized in the actual life.

Owner:SHENYANG JIANZHU UNIVERSITY

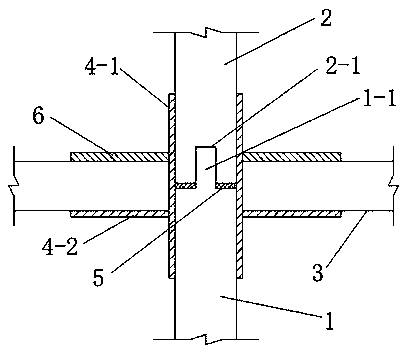

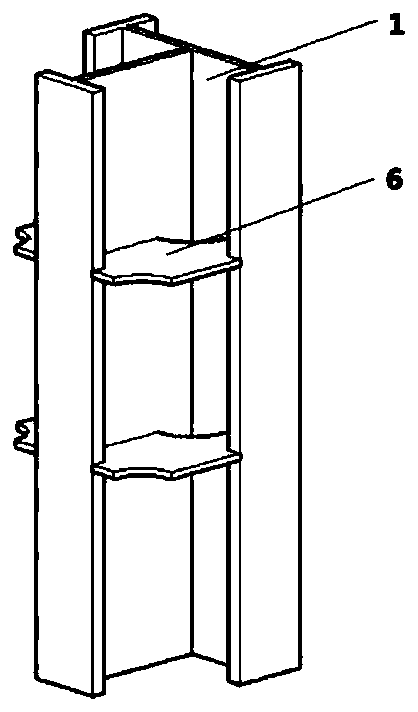

Wood beam column connecting structure

InactiveCN108678171AReduce labor intensityReduce workloadBuilding constructionsUltimate tensile strengthStructure building

The invention relates to a wood beam column connecting structure, and belongs to the field of wood structure buildings. The wood beam column connecting structure comprises a lower vertical column, anupper vertical column, a wood beam, a node connecting cylinder, an inner partition plate and a wedge-shaped cover plate, the node connecting cylinder comprises a box-shaped steel pipe and a U-shaped sleeve perpendicular to the outer surface of the box-shaped steel pipe, limit convex teeth are vertically pasted on two sides of an opening of the U-shaped sleeve, a wedge-shaped recessed portion is horizontally arranged on the U-shaped sleeve, grooves matched with the limit convex teeth are formed in the wood beam, the wedge-shaped cover plate is provided with a wedge-shaped projection matched with the wedge-shaped recessed portion, a tenon is arranged at the upper end of the lower vertical column, and a mortise matched with the tenon is formed in the lower end of the upper vertical column. According to the wood beam column connecting structure, a node is high in strength and industrialization degree, reliable to connect, convenient to assemble and rapid to construct, and the labor intensity and the workload of workers can be greatly relieved.

Owner:SHENYANG JIANZHU UNIVERSITY

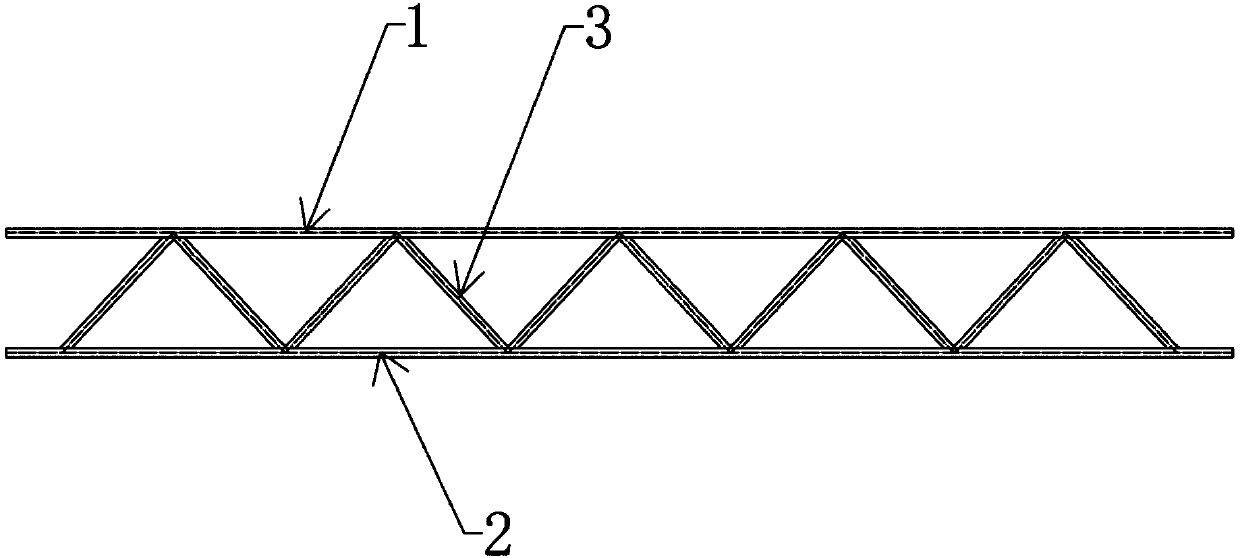

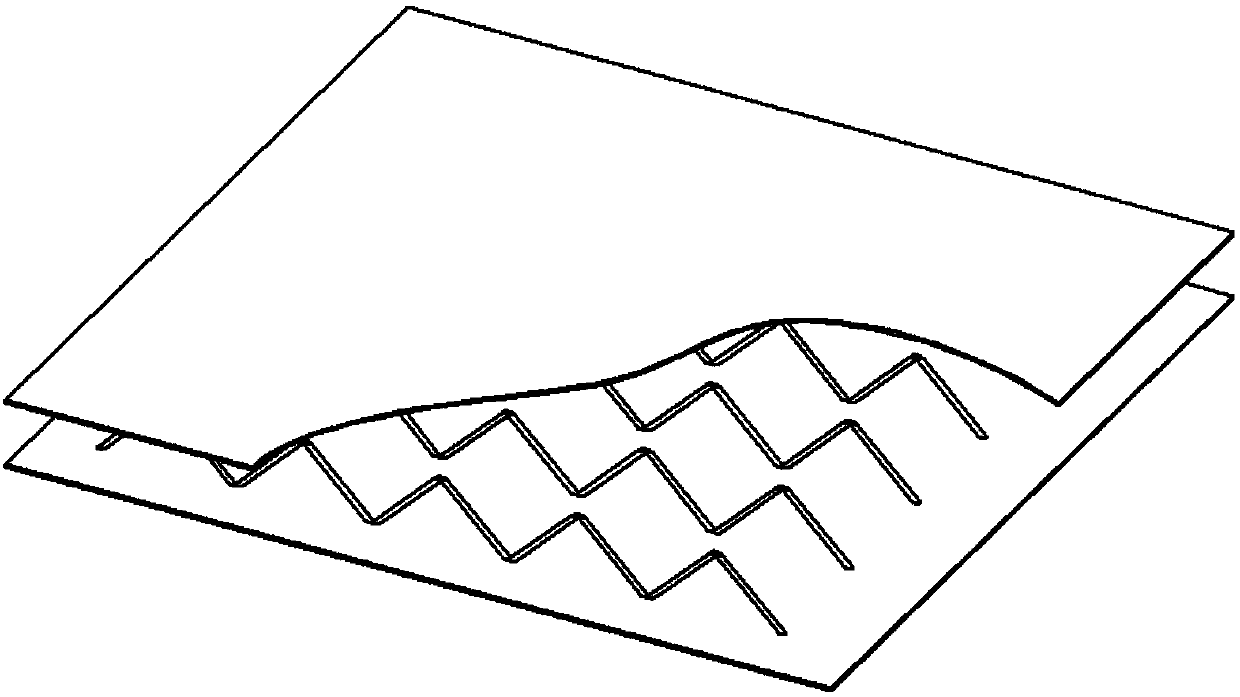

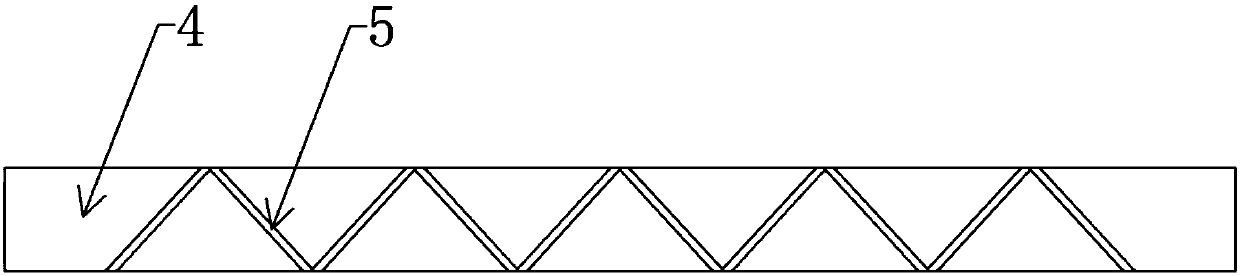

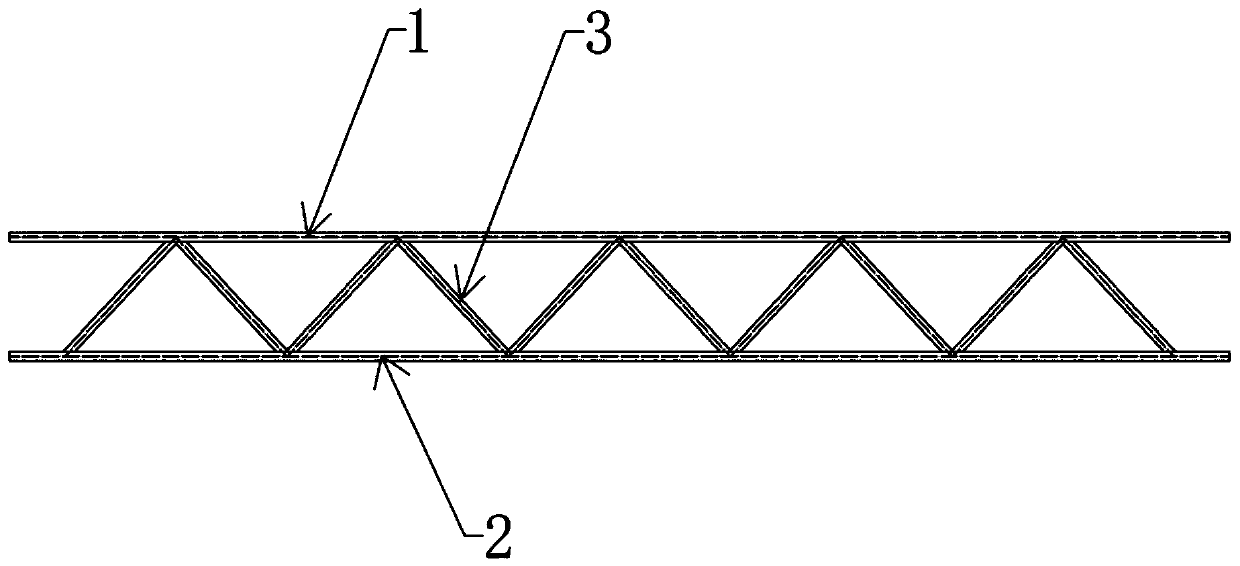

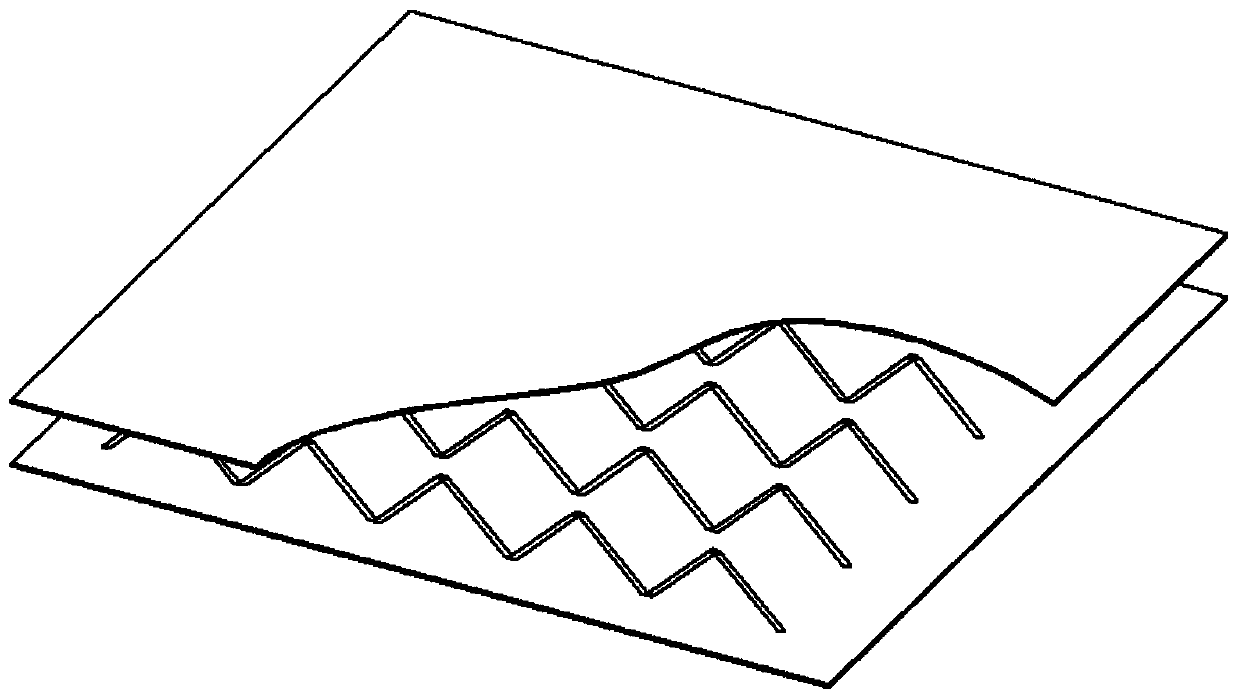

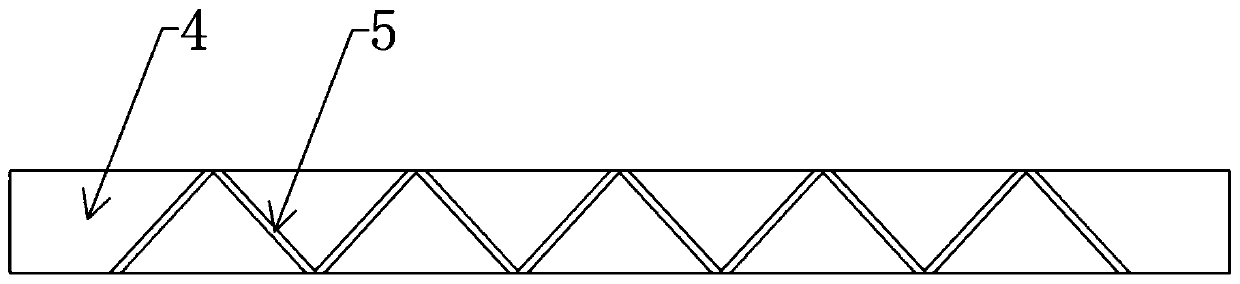

Composite lattice structure and preparation method

ActiveCN107599445AIncrease productivitySuitable for large-scale production of composite lattice structuresLayered productsFiberShell molding

The invention provides a composite lattice structure and a preparation method. The composite lattice structure is composed of an upper face plate, a lower face plate and a lattice core arranged between the upper face plate and the lower face plate. The lattice core is formed in the manner that lattice core triangular fibers and trapezoidal fibers are interlaced. Foam interlayers are arranged in the upper face plate and the lower face plate. A specific injection manner is applied to the composite lattice structure for VARTM formation. The preparation method of the composite lattice structure comprises the seven steps of (1) preparing a fusible alloy mold core; (2) inserting the triangular fibers; (3) laying fibers on the bottom layers of the upper face plate and the lower face plate; (4) inserting the trapezoidal fibers; (5) arranging the face plate interlayers and laying surface fibers of the face plates; (6) conducting VARTM (vacuum assisted resin transfer molding) formation; (7) heating and melting the fusible alloy mold core. The composite lattice structure and the preparation method effectively solve the connection problem between a composite lattice core and the face plates, integrated formation is achieved, the quality is reliable, the technology is simple, and the node strength is high.

Owner:HARBIN ENG UNIV

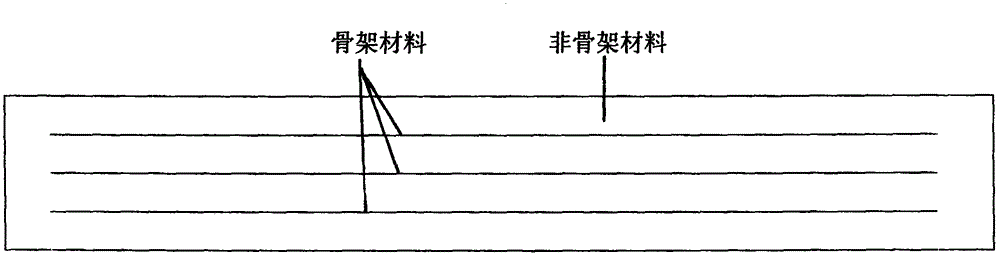

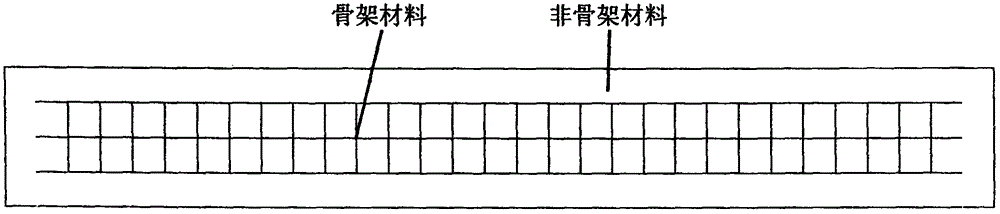

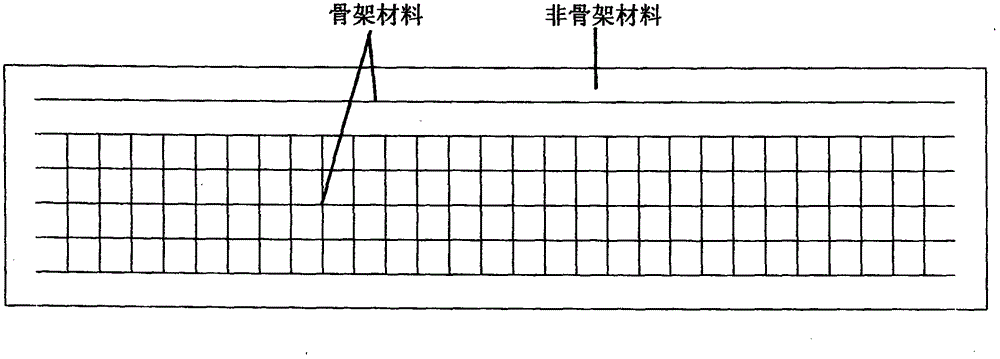

Method for manufacturing sandwich sheet and geocell manufactured through sandwich sheet

The invention discloses a method for manufacturing a sandwich sheet and a geocell manufactured through the sandwich sheet. The sandwich sheet is formed by high-strength high-melting-point materials serving as framework materials and low-melting-point thermoplasticity materials serving as non-framework materials through co-extrusion and thermal compounding or other machining methods; the framework materials can be composed of one or multiple materials; and the non-framework materials are the same homogeneous materials. Changing of strength of the sandwich sheet is achieved by changing the variety, specification, number and different combinations of the framework materials; and the high-strength geocell can be manufactured by the high-strength sandwich sheet and high-strength corrosion-resisting U-shaped nails through a weaving method.

Owner:何晓婷

Steel structure joint connection device and manufacturing method thereof

The invention provides a steel structure joint connection device and a manufacturing method thereof, and belongs to the field of steel structures. The problem that existing steel structure joints cannot be connected in a hidden mode is solved. The steel structure joint connection device is used for connecting six hollow steel pipes, a connection device comprises six connection parts, connection parts include outer connection pipes, inner join pipes, outer join pipes and inner connection pipes, connection boxes are arranged between outer connection pipes and inner connection pipes, the connection device further comprises baffles fixed on the inner walls of the top ends of the outer connection pipes, the bottom faces of the baffles abut against the top ends of the inner connection pipes in a sealing mode, grout-venting holes are formed in the baffles, any baffle is provided with a grouting opening, concrete mortar is poured into the connection parts through the grouting openings, and the six hollow steel pipes correspondingly sleeve six outer connection pipes in a matched mode and are fixed through fasteners. According to the steel structure joint connection device, the six hollow steel pipes can be connected in a high-intensive hidden mode.

Owner:东阳市智林科技有限公司

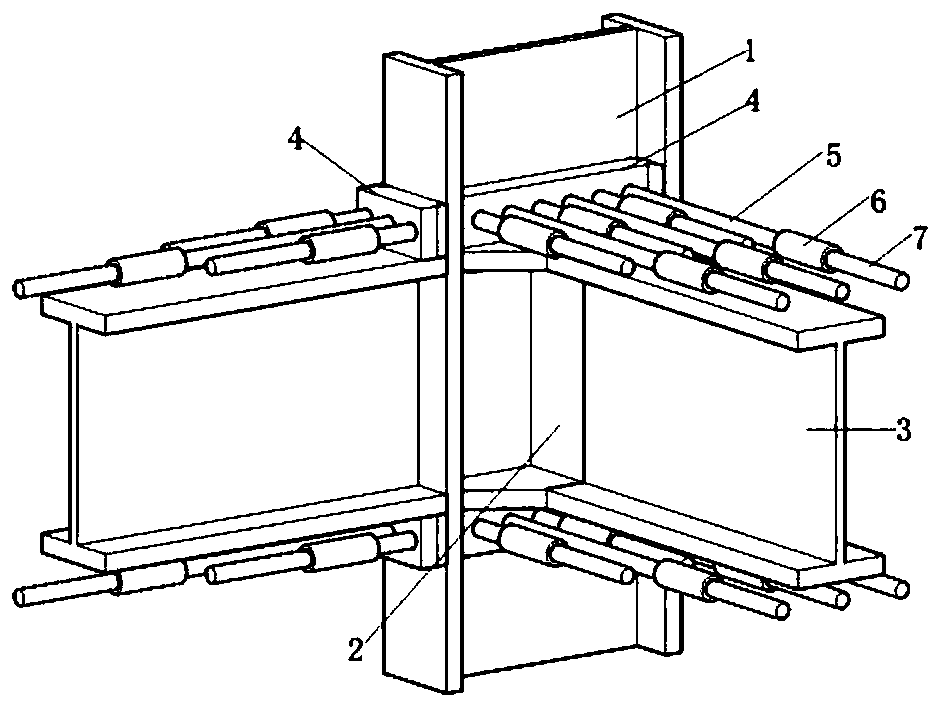

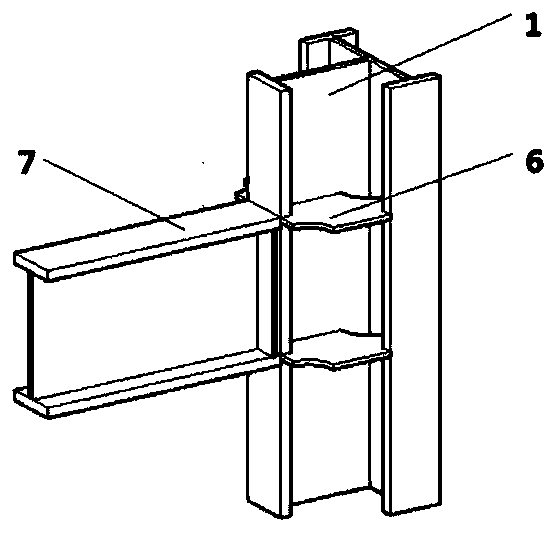

Quick-split type H-shaped steel concrete beam column connection node

PendingCN109914598AImprove assembly rateIncrease productivityBuilding material handlingRebarSteel columns

The invention relates to a quick-split type H-shaped steel concrete beam column connection node, comprising H-shaped steel columns, connecting plates, stiffening members, H-shaped steel beams and reinforcing ribs, wherein the H-shaped steel beam is fixedly and vertically arranged on any flange surface of each H-shaped steel column; the connecting plates are respectively and fixedly arranged at theflanges of the H-shaped steel columns at the parts where the flanges of the H-shaped steel columns are contacted with upper and lower flanges of the H-shaped steel beams; the H-shaped steel beams arevertically and fixedly arranged on webs at any sides of the H-shaped steel columns by means of the stiffening members; the webs of the H-shaped steel columns at the two ends of the stiffening membersare respectively provided with the connecting plates; the connecting plates are provided with a plurality of threaded holes, and the plurality of reinforcing ribs are vertically arranged on the connecting plates. The quick-split type H-shaped steel concrete beam column connection node is high in assembly rate. All the components, including the section steel columns, the connecting plates, studs,sleeves and reinforcing steel bars, of the node are pre-fabricated in a factory, and can be produced in a modular way, so that the production efficiency is high; furthermore, the efficiency of site construction is improved, and the construction quality is guaranteed, so that the connection node is higher in economic benefit.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

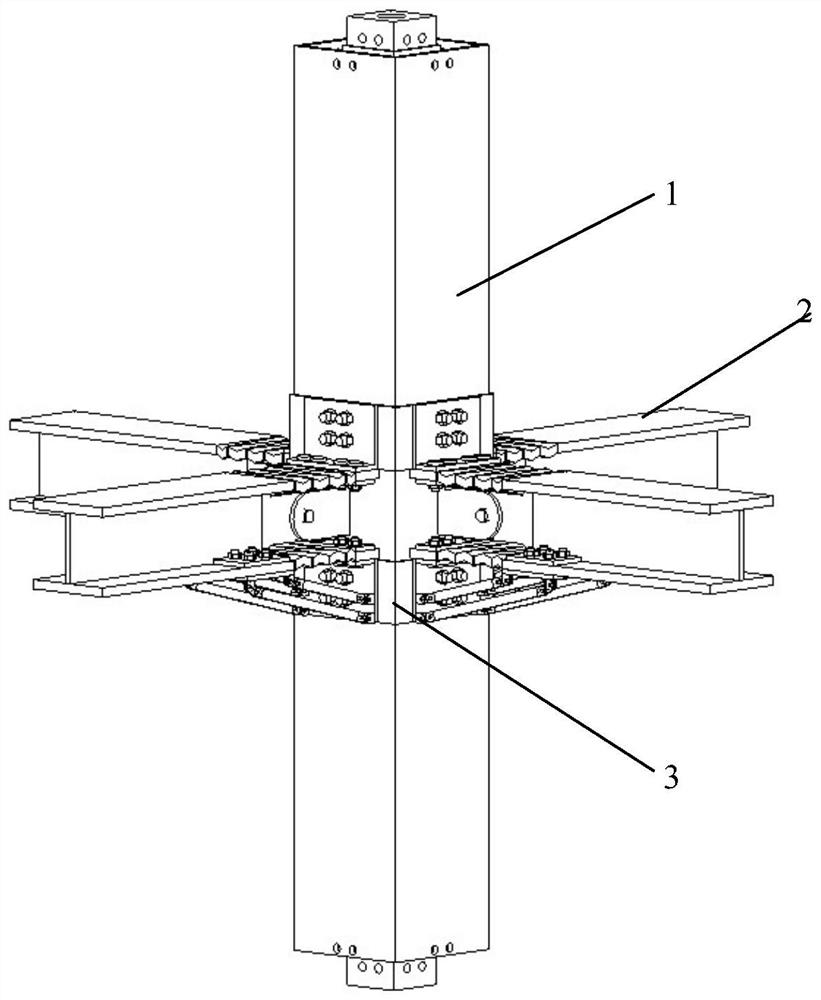

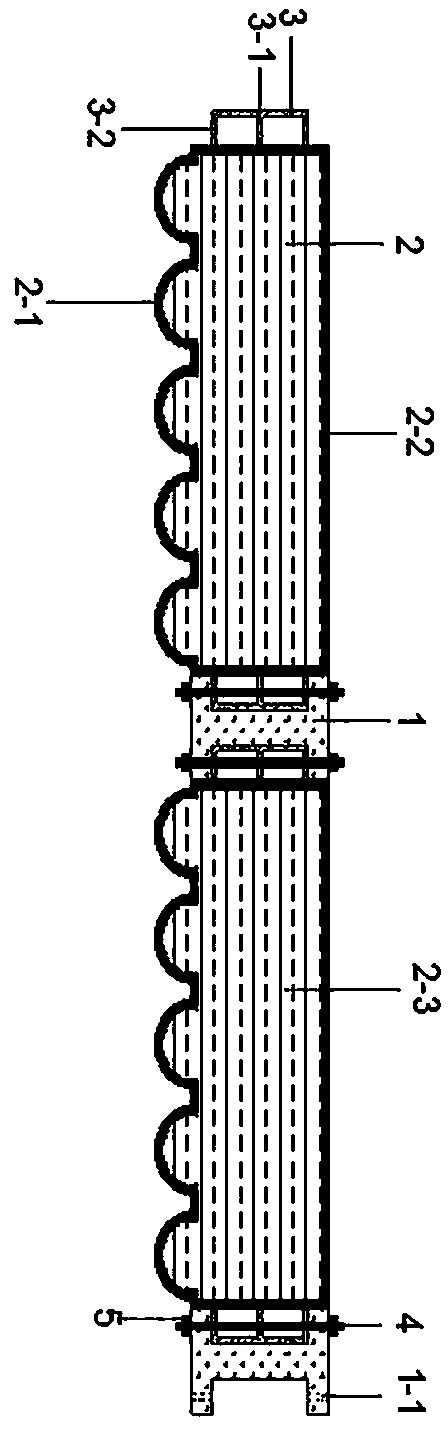

Bamboo joint type energy-dissipation concrete-filled steel tube joint and mounting method thereof

ActiveCN112196122APrevent bucklingHigh strengthProtective buildings/sheltersShock proofingShaped beamSteel columns

The invention relates to the field of building construction, and discloses a bamboo joint type energy-dissipation concrete-filled steel tube joint and a mounting method thereof. The bamboo joint typeenergy-dissipation concrete-filled steel tube joint comprises a steel column, a steel beam and a connecting assembly; the steel column is a double-steel-pipe column and comprises an inner pipe and anouter pipe; the steel beam is an I-shaped beam, the middle section of each flange plate is a flange plate with folds, and the two ends of each flange plate are horizontal plates; the connecting assembly comprises an inner supporting piece, a connecting cylinder kit and a movable connecting piece, and the inner supporting piece comprises a connecting steel column and square blocks fixed to the twoends of the connecting steel column; the connecting cylinder kit comprises an upper connecting cylinder, a middle connecting cylinder and a lower connecting cylinder, the upper connecting cylinder andthe lower connecting cylinder are the same in structure, a circle of boss is arranged in the middle of the inner wall of each of the upper connecting cylinder and the lower connecting cylinder, and double connecting lugs are arranged on each side surface of the middle connecting cylinder; and the movable connecting piece comprises an L-shaped connecting plate, a horizontal connecting plate and aconnecting rod assembly. According to the concrete-filled steel tube joint, the inner supporting piece is arranged in the steel column, and the inner supporting piece is designed in the double-steel-pipe column to form a bamboo joint effect, so that the joint strength is enhanced, the internal steel pipe is prevented from buckling, and the overall strength of the column is improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

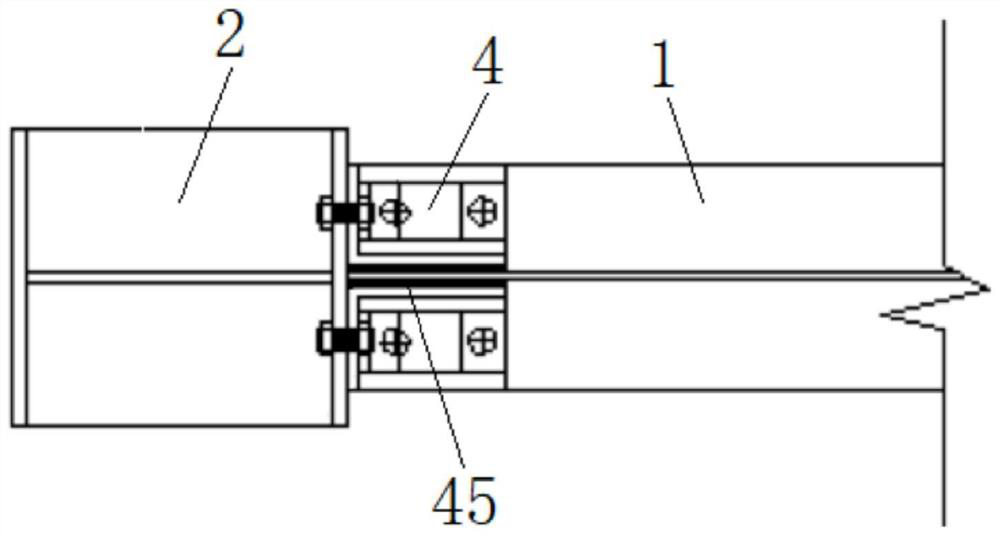

Self-resetting steel frame beam-side column joint and construction method thereof

PendingCN112177174ASimple structureImprove energy consumptionProtective buildings/sheltersShock proofingClassical mechanicsShape-memory alloy

The invention provides a self-resetting steel frame beam-side column joint and a construction method thereof. The self-resetting steel frame beam-side column joint comprises a steel beam, wherein thesteel beam is horizontally arranged on one side of a steel column; a shape memory alloy plate is arranged between a flange of the steel beam and a flange of the steel column, and the shape memory alloy plate is arranged on the outer side of the flange of the steel beam; one end of the shape memory alloy plate is connected with the flange of the steel beam, and the other end of the shape memory alloy plate is connected with the flange of the steel column; and friction energy dissipaters are symmetrically arranged on the two sides of a web of the steel beam, one end of each friction energy dissipater is connected with the steel beam, and the other end of each friction energy dissipater is connected with the flange of the steel column. According to the self-resetting steel frame beam-side column joint and the construction method thereof, the shape memory alloy plate is arranged, and the self-resetting function of the joint is achieved by utilizing the plastic deformation of the shape memory alloy plate; and friction energy dissipation can be achieved between the friction energy dissipaters and the flange and the web of the steel beam, and the friction energy dissipaters and the shapememory alloy plate generate a synergistic effect to jointly absorb seismic energy at the joint, so that the structural ductility and energy dissipation capacity of the steel frame beam-side column joint are effectively improved, and the post-earthquake repair cost of the structure is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-strength, high-elongation and corrosion-resistant aluminum foil for honeycomb core and manufacturing method thereof

InactiveCN111676396AImprove impact resistanceHigh node strengthMetal rolling arrangementsCorrosion resistantHoneycomb

The invention belongs to the field of aluminum alloy foil rolling and discloses high-strength, high-elongation and corrosion-resistant aluminum foil for a honeycomb core and a manufacturing method thereof. The high-strength, high-elongation and corrosion-resistant aluminum foil for the honeycomb core is composed of, by mass, 0.40-0.60% of Fe, 0.15-0.30% of Si, 0.07-0.16% of Cu, 1.10-1.62% of Mn, smaller than 0.05% of Mg, 1.0-1.60 % of Zn, smaller than 0.05% of Ti, and the balance aluminum. The manufacturing method comprises the steps of smelting, casting-rolling, cogging and rough rolling, high-temperature annealing, intermediate rolling, intermediate trimming, finishing rolling, slitting, inspection and packaging and the like. The prepared aluminum foil finished product has the characteristics of being high in mechanical properties, high in impact resistance, high in elongation and easy to stretch and cut; wrinkling is not prone to happen in the core making process, the bonding quality is good, and the dislocation error is small; and meanwhile, an obvious potential difference exists between the aluminum foil and glued aluminum plates on both sides of the aluminum foil, so that a sacrificial protection effect can be formed to improve prolong the corrosion resistant life of a honeycomb panel.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

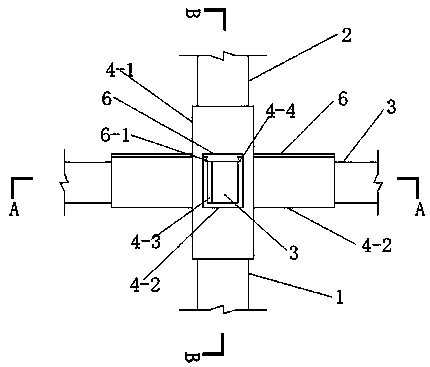

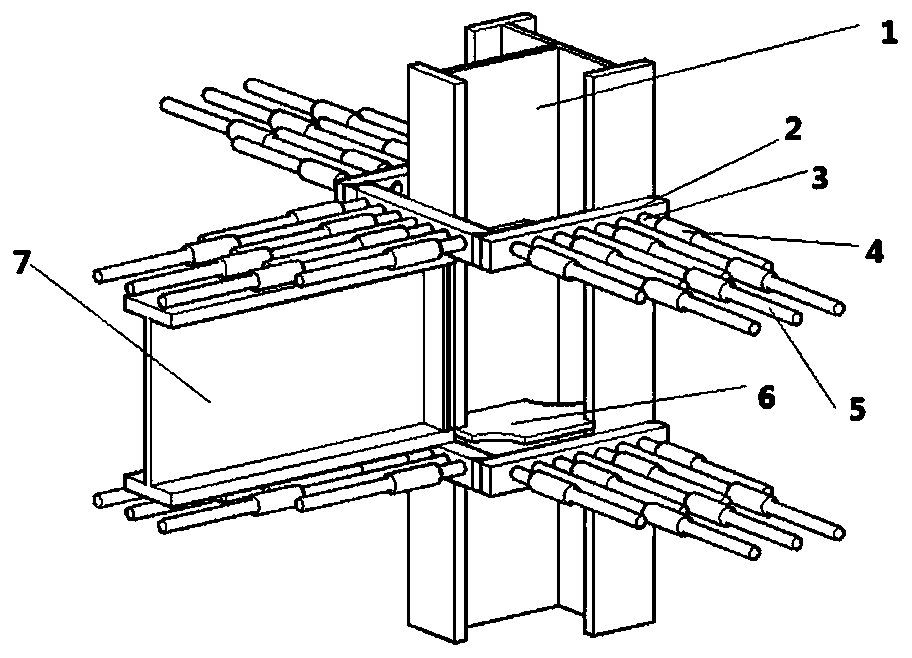

Three-dimensional fabricated beam column node structure

The invention discloses a three-dimensional fabricated beam column node structure. The structure comprises a connecting pipe, a beam structure and a column structure; the two ends of the connecting pipe are fixedly provided with cover plates correspondingly, and a plurality of pieces of connecting-type steel are uniformly and fixedly arranged on the outer wall of the connecting pipe, end plates are arranged at the ends of the column structure, the end plates are fixedly connected with the cover plates, and the beam structure is connected with the connecting-type steel through a connecting assembly; the beam structure comprises a beam steel rib, and the connecting-type steel is arranged opposite to one end of the beam steel rib in a matching mode; and the connecting assembly comprises a connecting plate and reinforcing members, wherein the connecting plate is arranged on one side of the beam steel rib and simultaneously connected with the beam steel rib and the connecting-type steel, and the reinforcing members are arranged on the upper portion and the lower portion of the beam steel rib and simultaneously connected with the beam steel rib and the connecting-type steel. The three-dimensional fabricated beam column node structure is convenient to assemble and install, stable in structure after assembly, and reliable in connection.

Owner:GUANGZHOU UNIVERSITY

Fabricated side plate joint of steel beam and concrete-filled steel tube vertical element

PendingCN112523367APrevent excessive deformationNodal Strength and Stiffness EnhancementsStrutsGirdersSteel tubeEarthquake resistant

The invention discloses a fabricated side plate joint of a steel beam and a concrete-filled steel tube vertical element. The joint comprises the concrete-filled steel tube vertical element, the steelbeam and a connecting assembly; the connecting assembly comprises a connecting side plate and a flange welding plate; the flange welding plate is connected with the end, close to the concrete-filled steel tube vertical element, of the steel beam; the end, close to the steel beam, of the connecting side plate is attached to and connected with the side face of the corresponding flange welding plateon the steel beam; and the end, close to the concrete-filled steel tube vertical element, of the connecting side plate is attached to and connected with the side wall of the tail end of the concrete-filled steel tube vertical element. According to the fabricated side plate joint of the steel beam and the concrete-filled steel tube vertical element, on the premise that joint connection is rigid andconnection is safe and reliable, joint on-site welding work is avoided, joint on-site full-bolt connection is achieved, the problems that bolts are difficult to tighten and construction is complex ina closed section are solved, the construction efficiency is remarkably improved, the influence on the environment is small, good anti-seismic performance is achieved, and the steel structure fabricated building technology can be perfected.

Owner:CHINA SOUTHWEST ARCHITECTURAL DESIGN & RES INST CORP LTD

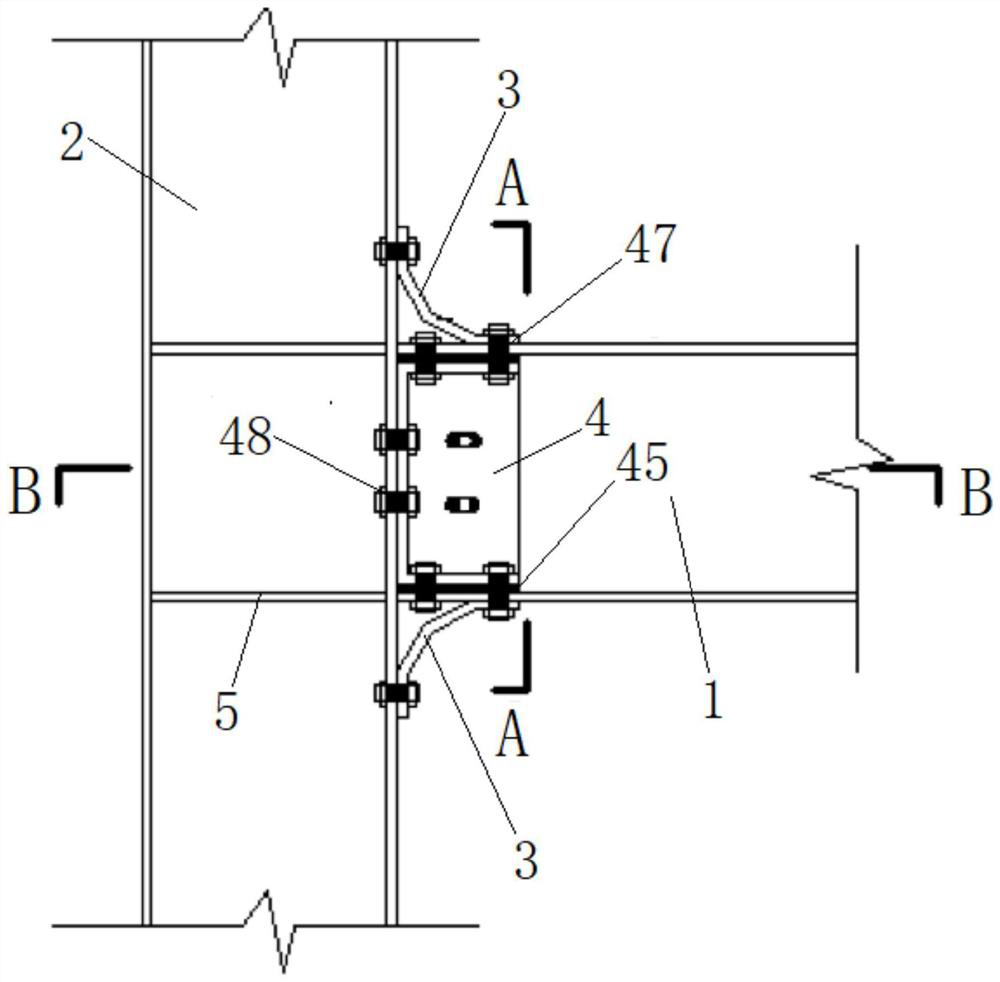

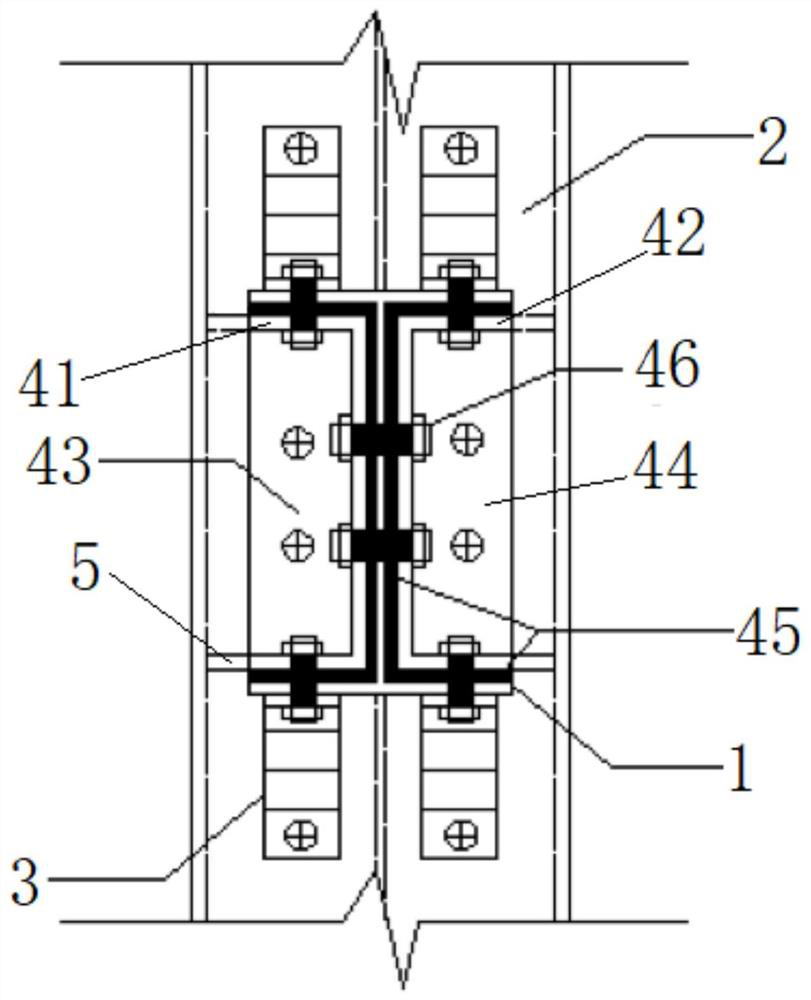

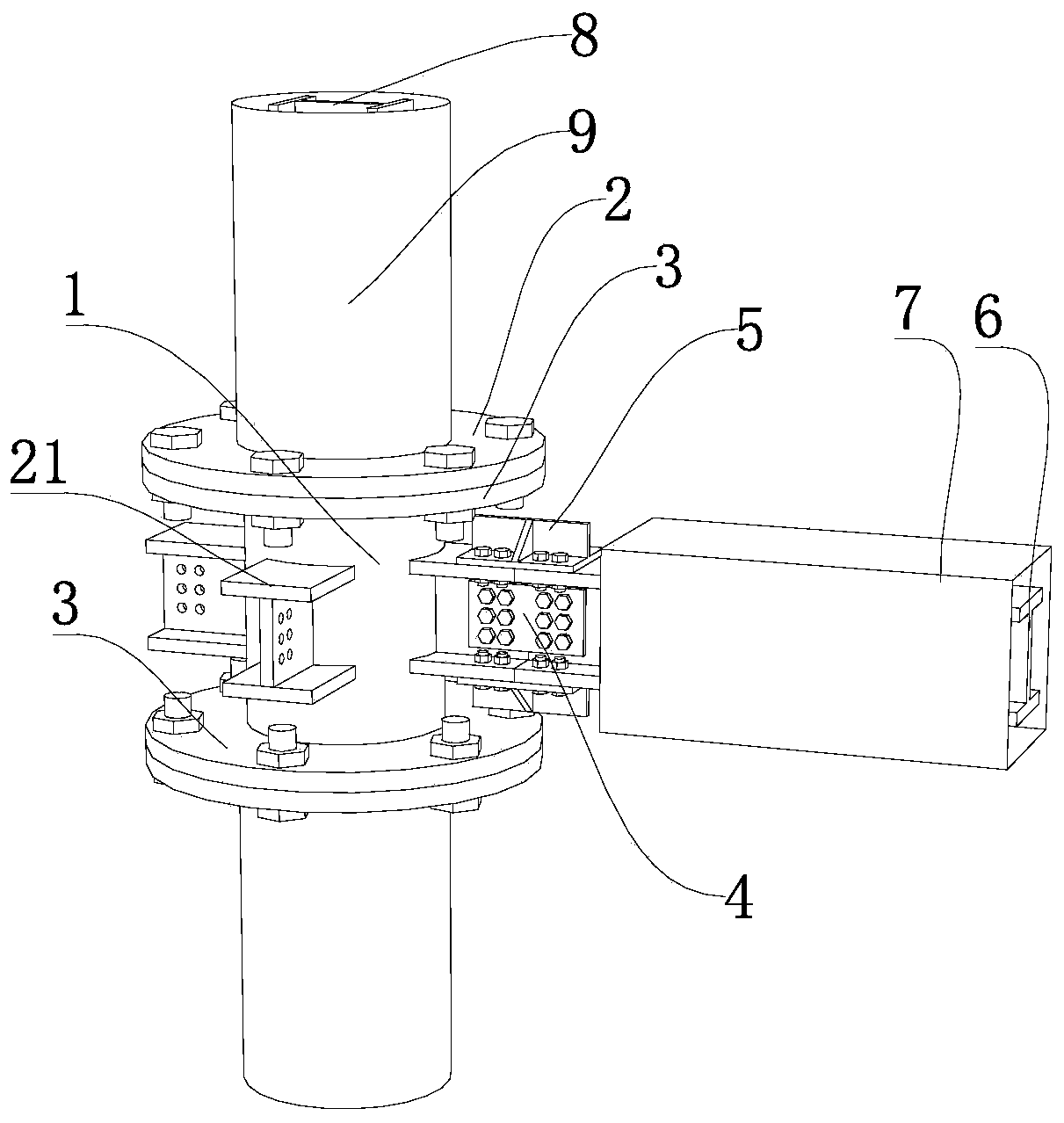

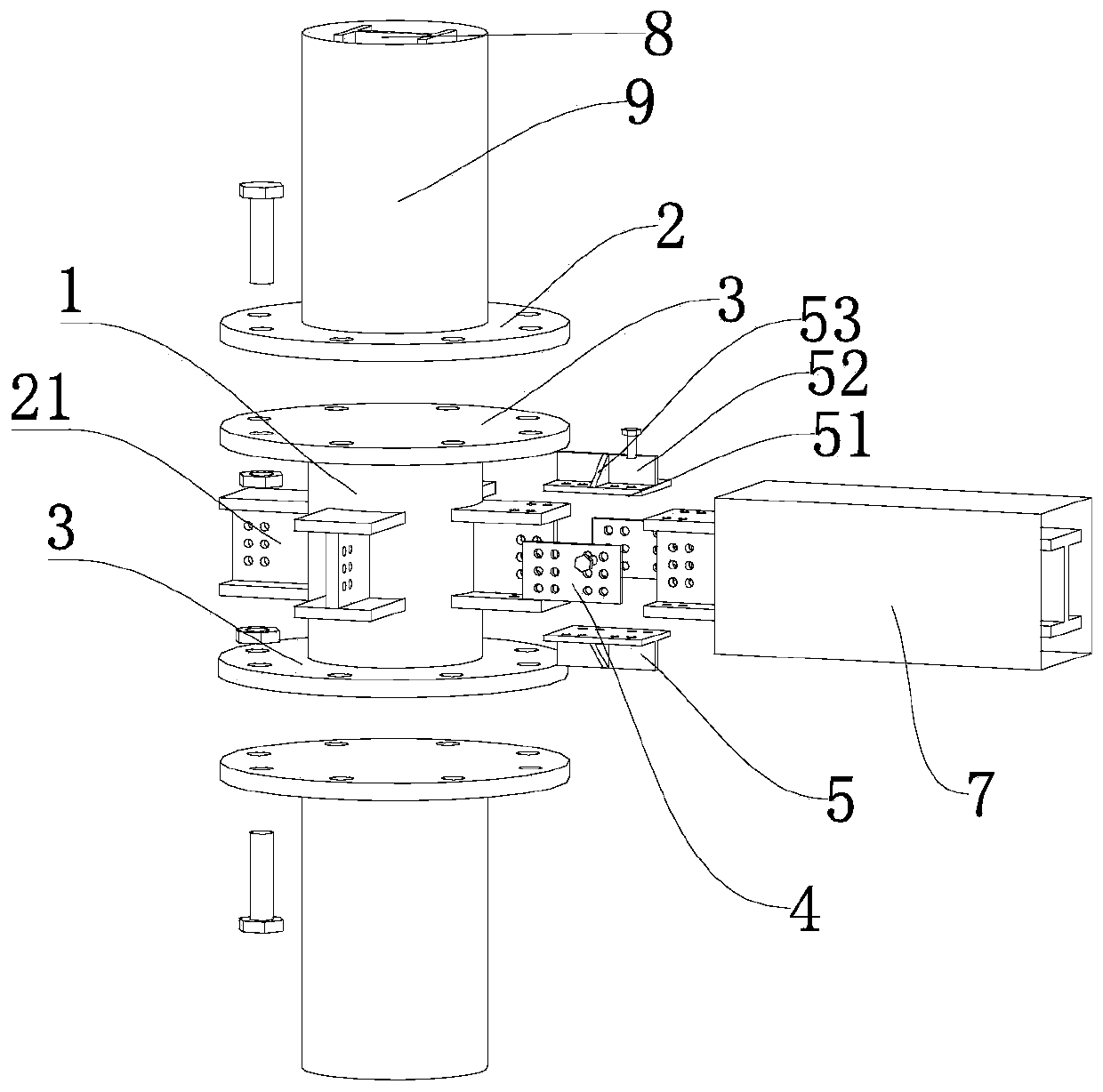

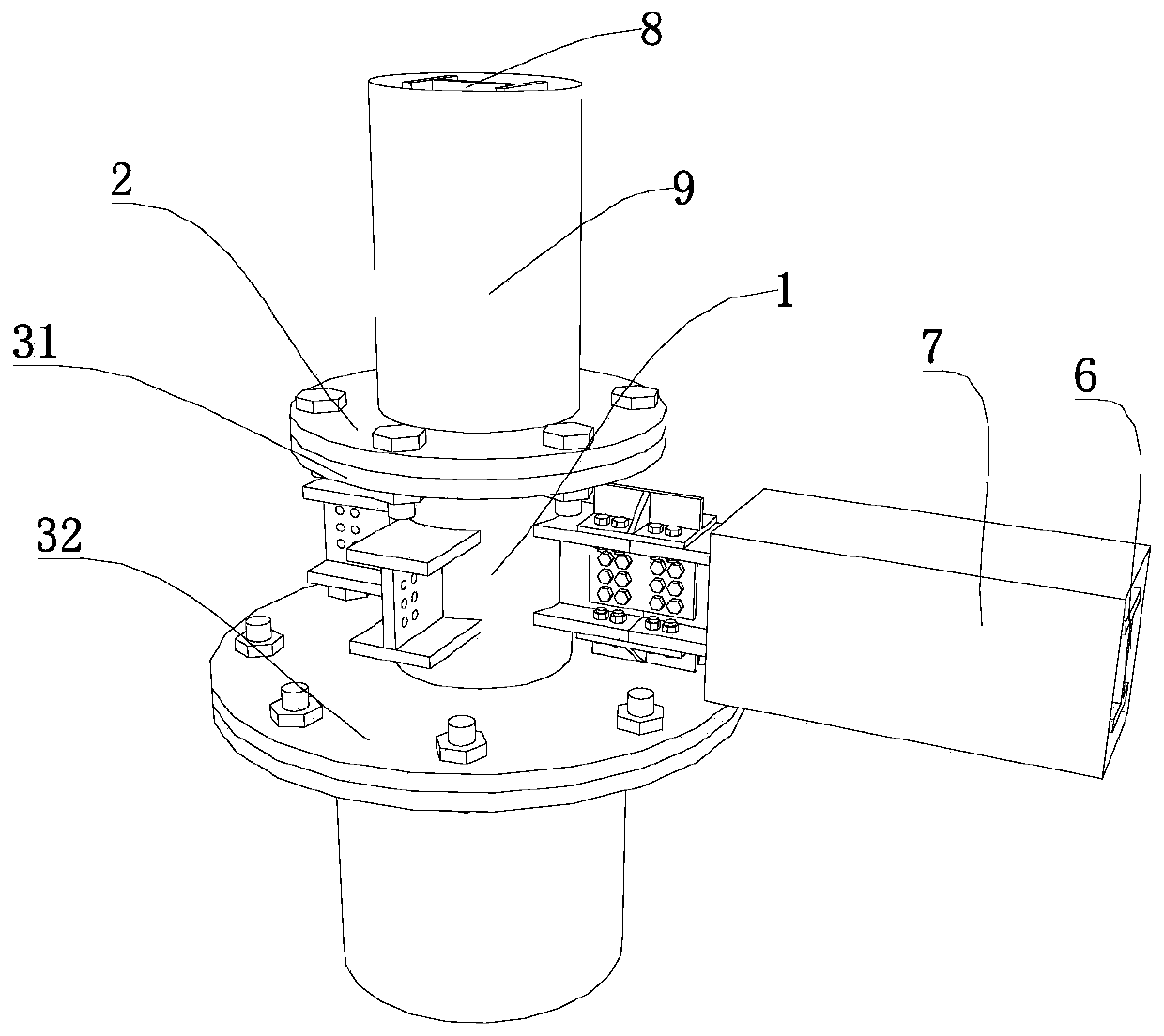

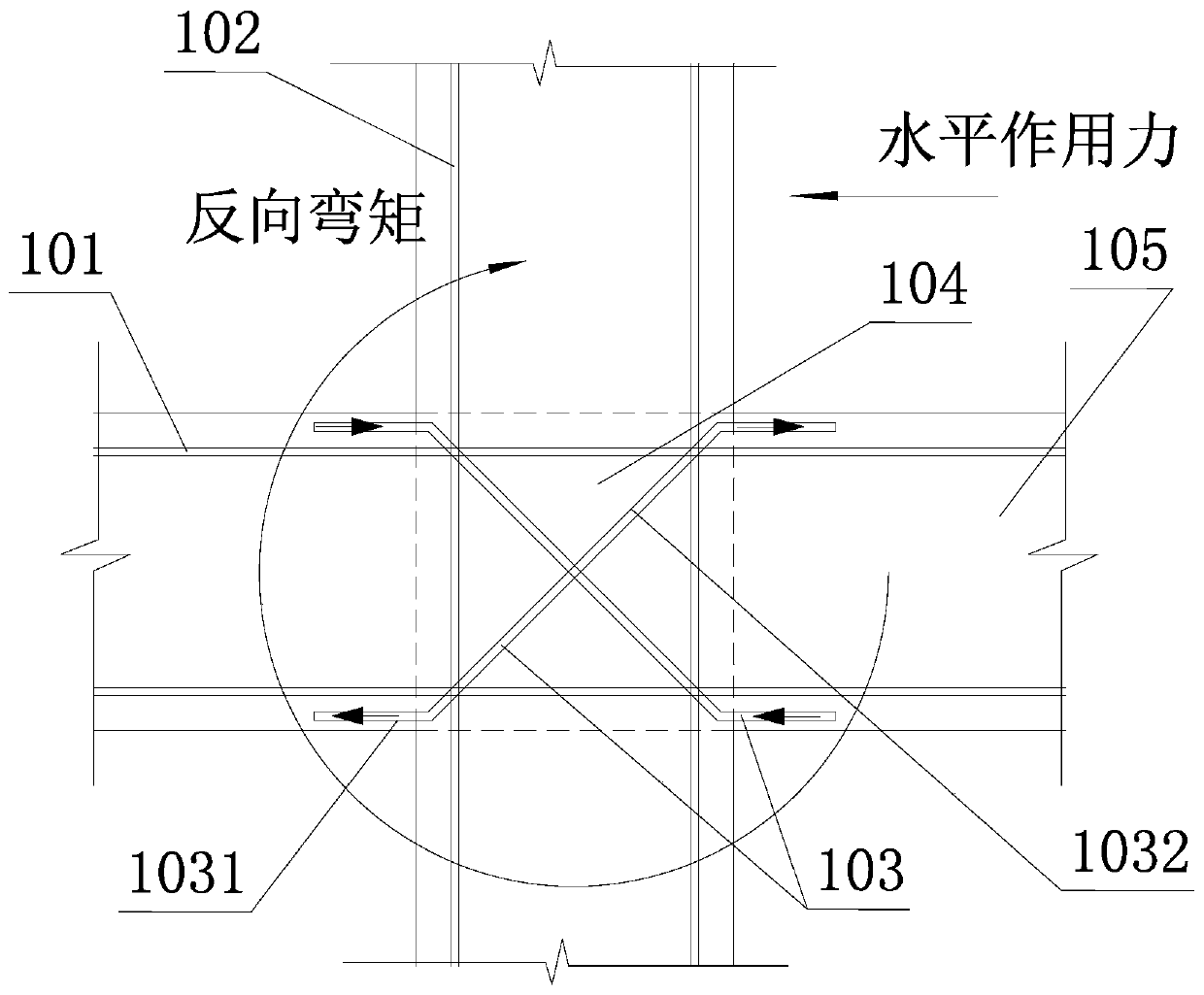

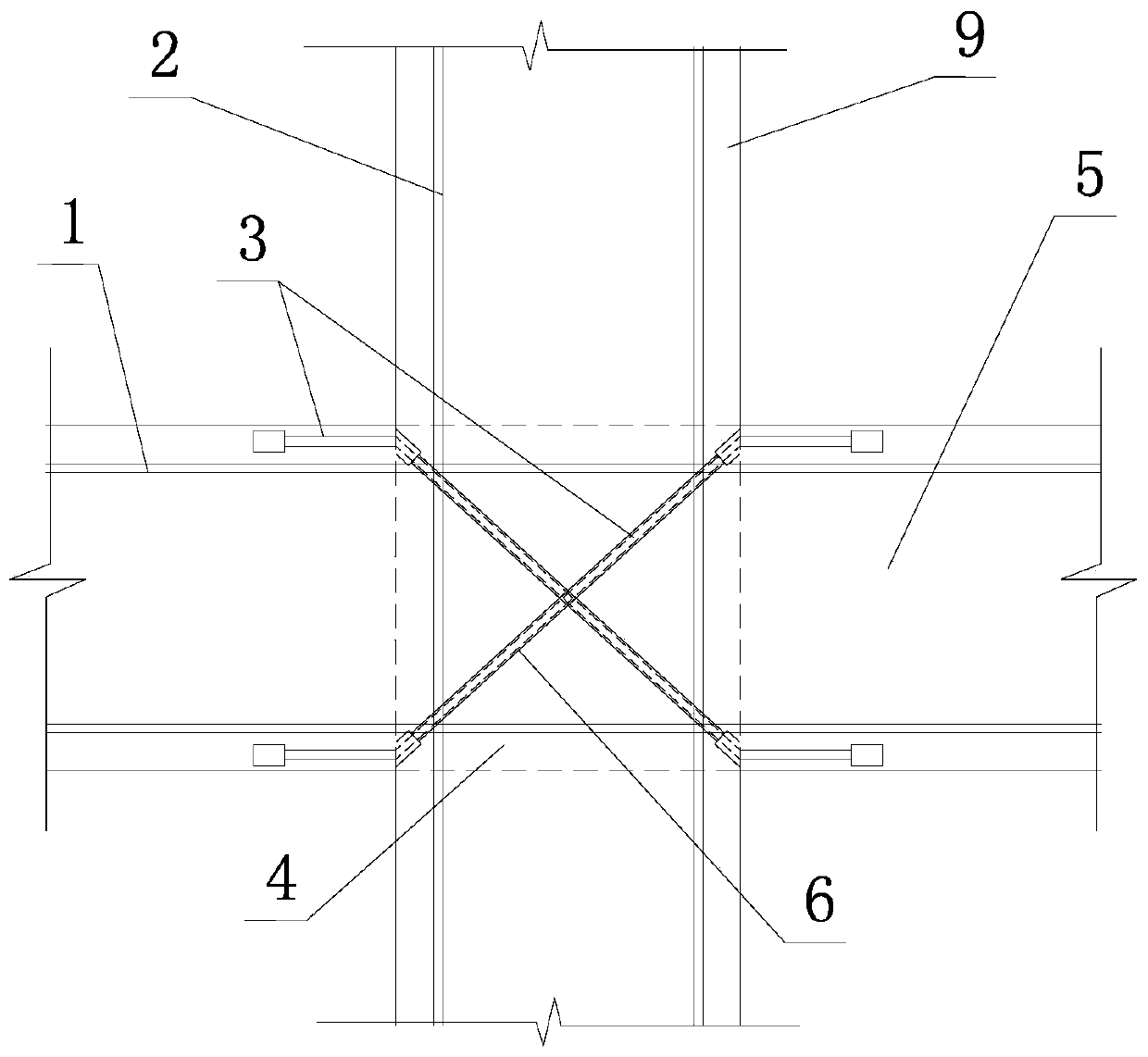

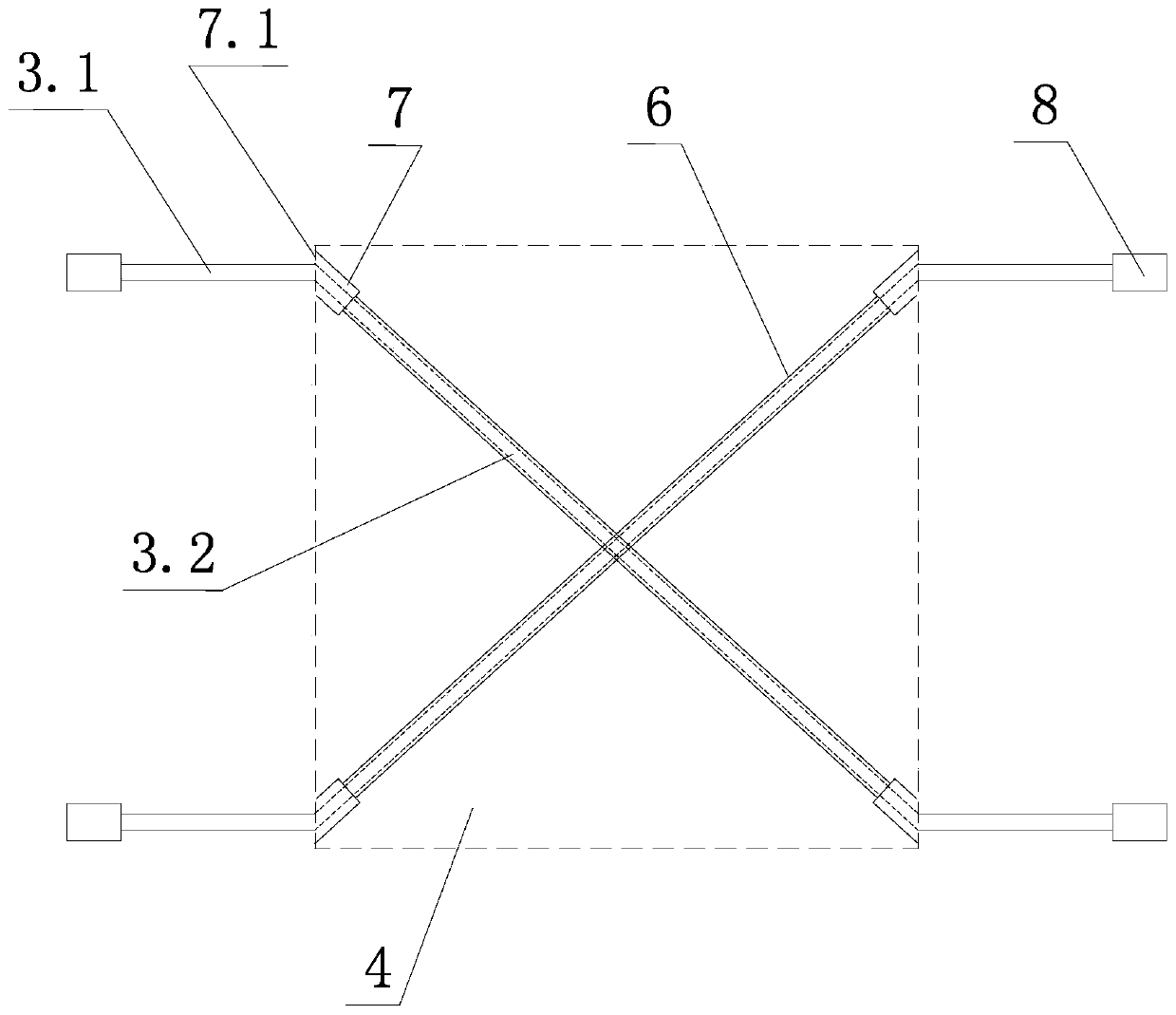

Self-resetting steel frame beam-middle column joint and construction method thereof

PendingCN112144672ASimple structureImprove energy consumptionProtective buildings/sheltersShock proofingShape-memory alloyEngineering

The invention provides a self-resetting steel frame beam-middle column joint and a construction method thereof. The self-resetting steel frame beam-middle column joint comprises two steel beams; the two steel beams are horizontally arranged on two sides of a middle column; a shape memory alloy bent steel plate is arranged between the flange of each of the steel beams and the flange of the middle column; the shape memory alloy bent steel plates are arranged on the outer sides of the flanges of the steel beams; one ends of the shape memory alloy bent steel plates are connected with the flanges of the steel beam, and the other ends are connected with the flange of the middle column; friction energy dissipaters are symmetrically arranged on two sides of webs of the steel beams; and one ends ofthe friction energy dissipaters are connected with the steel beams, and the other ends are connected with the flange of the middle column. The self-resetting function of the joint is achieved throughplastic deformation of the shape memory alloy bent steel plates; and friction energy dissipation can be achieved between the friction energy dissipaters and the flanges and webs of the steel beams, the friction energy dissipaters and the shape memory alloy bent steel plates generate a synergistic effect to jointly absorb earthquake energy at the joint, the structural ductility and energy dissipation capacity of the steel frame beam-middle column joint are effectively improved, and the post-earthquake repair cost is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

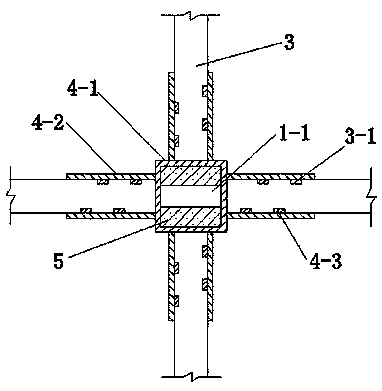

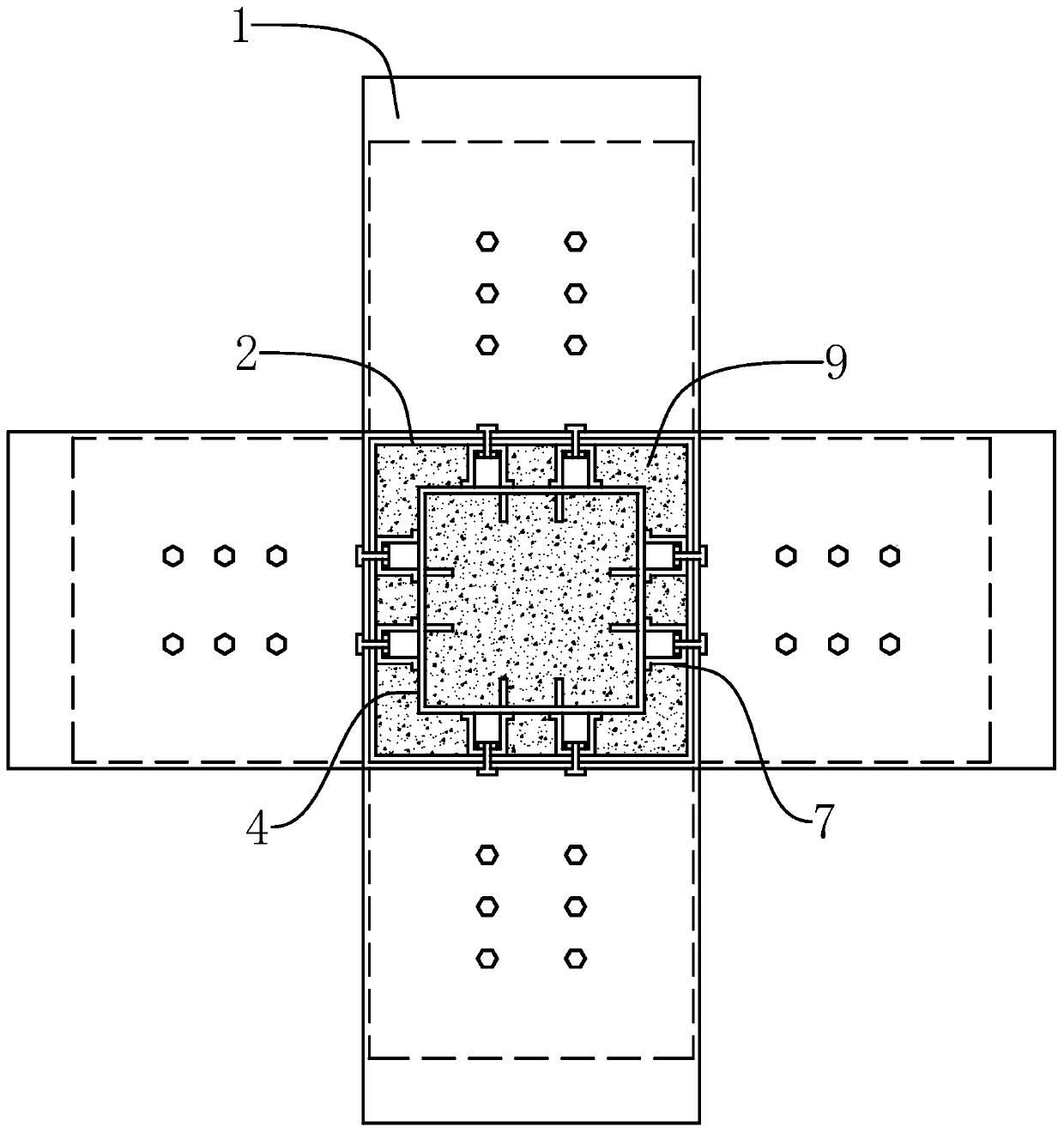

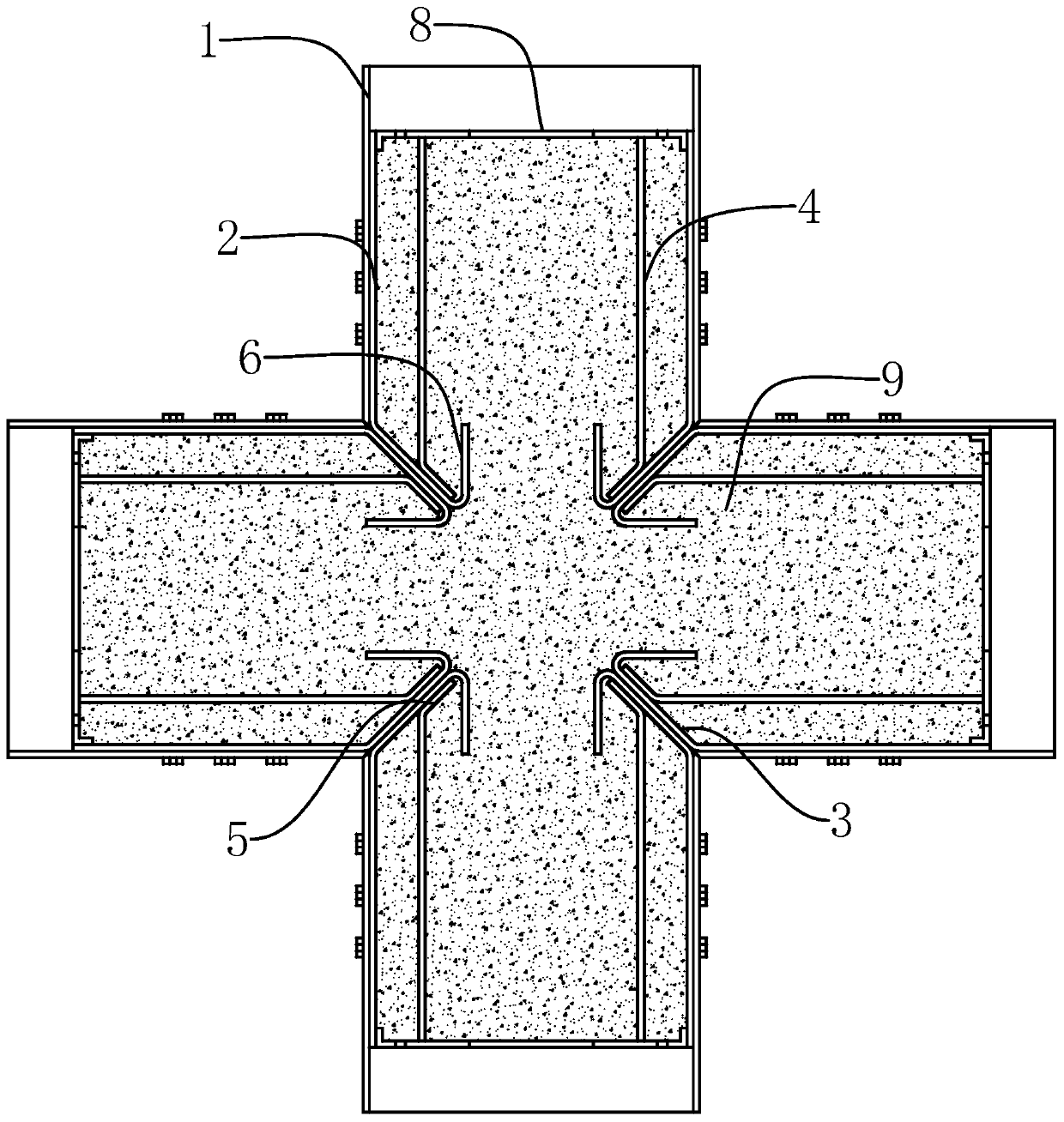

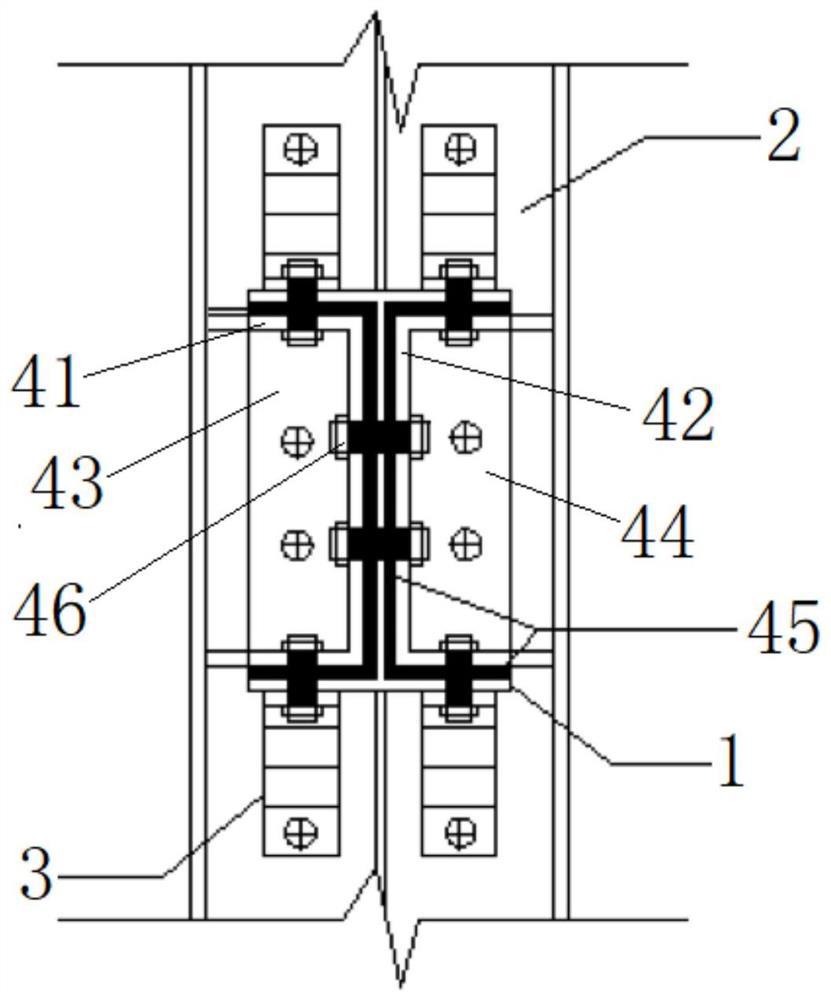

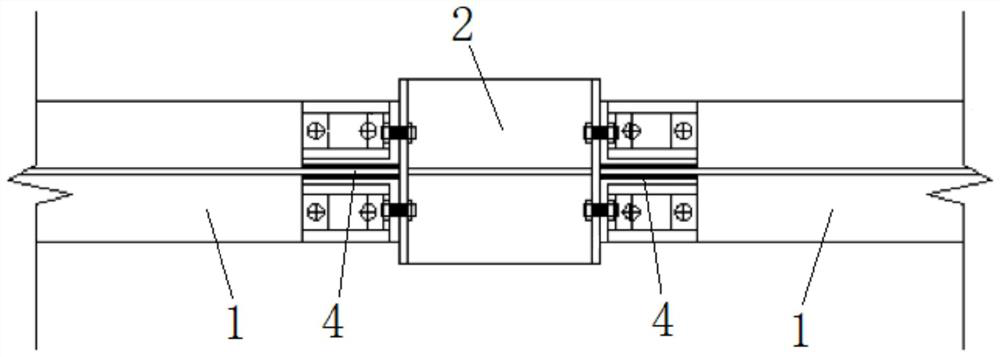

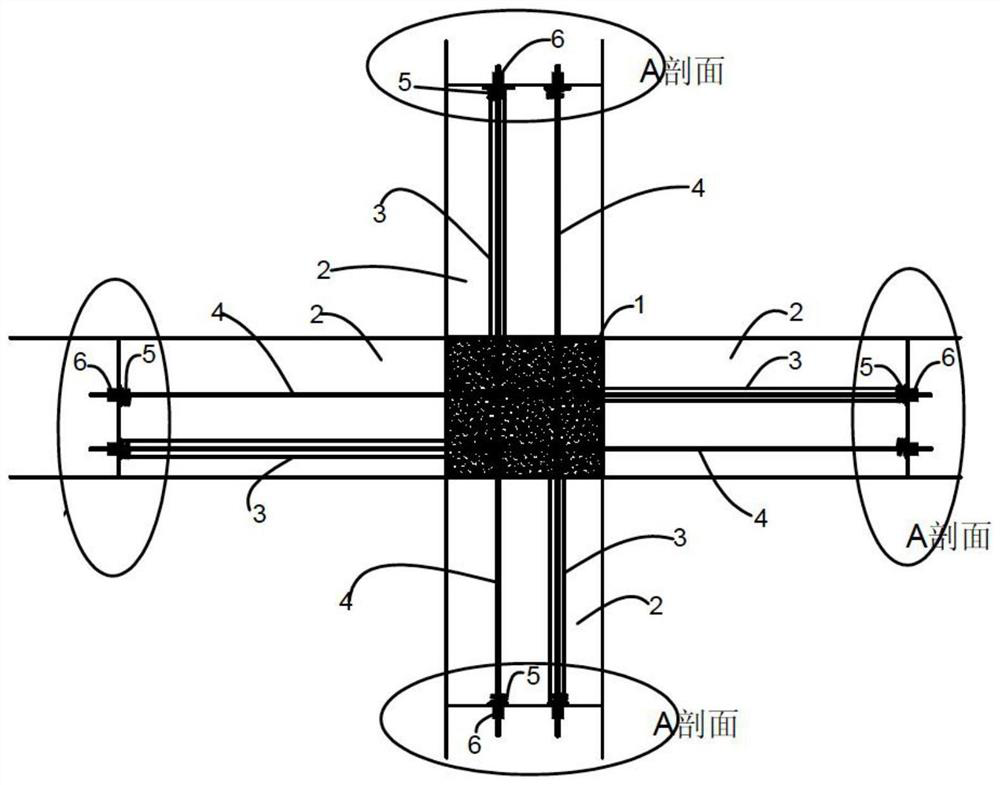

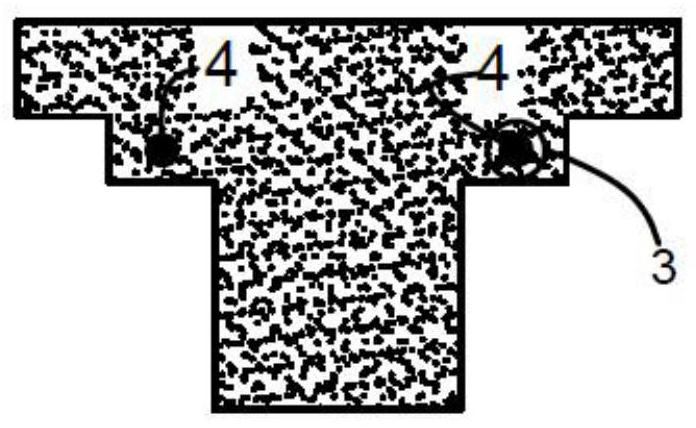

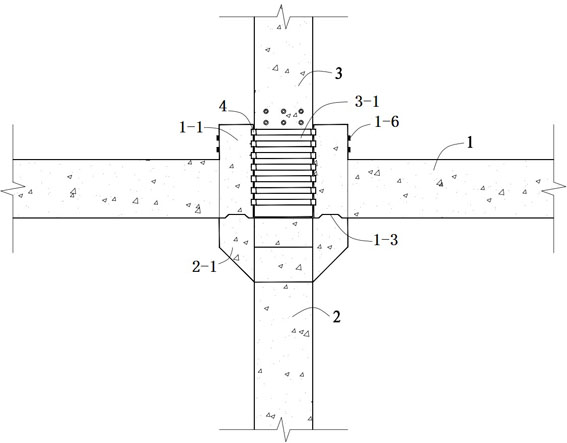

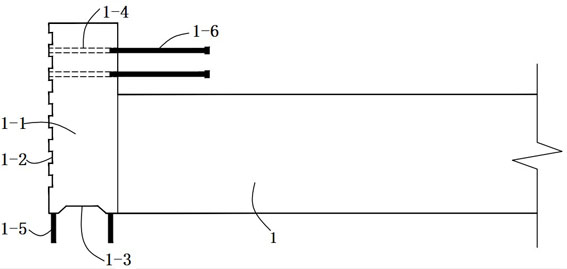

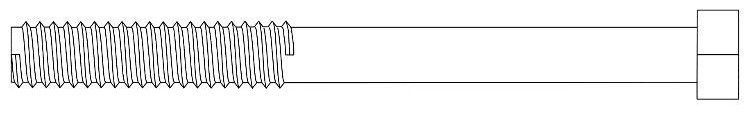

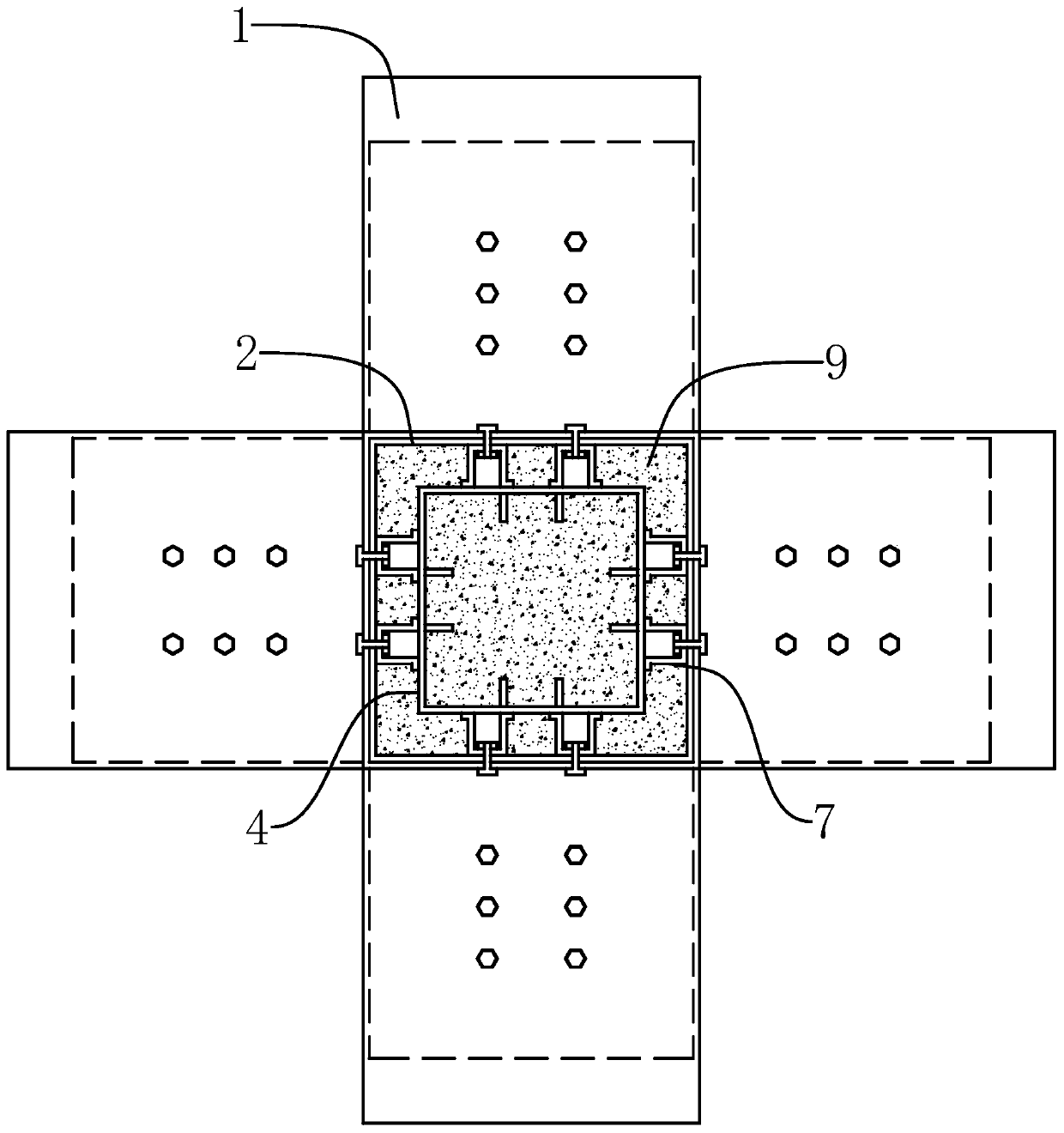

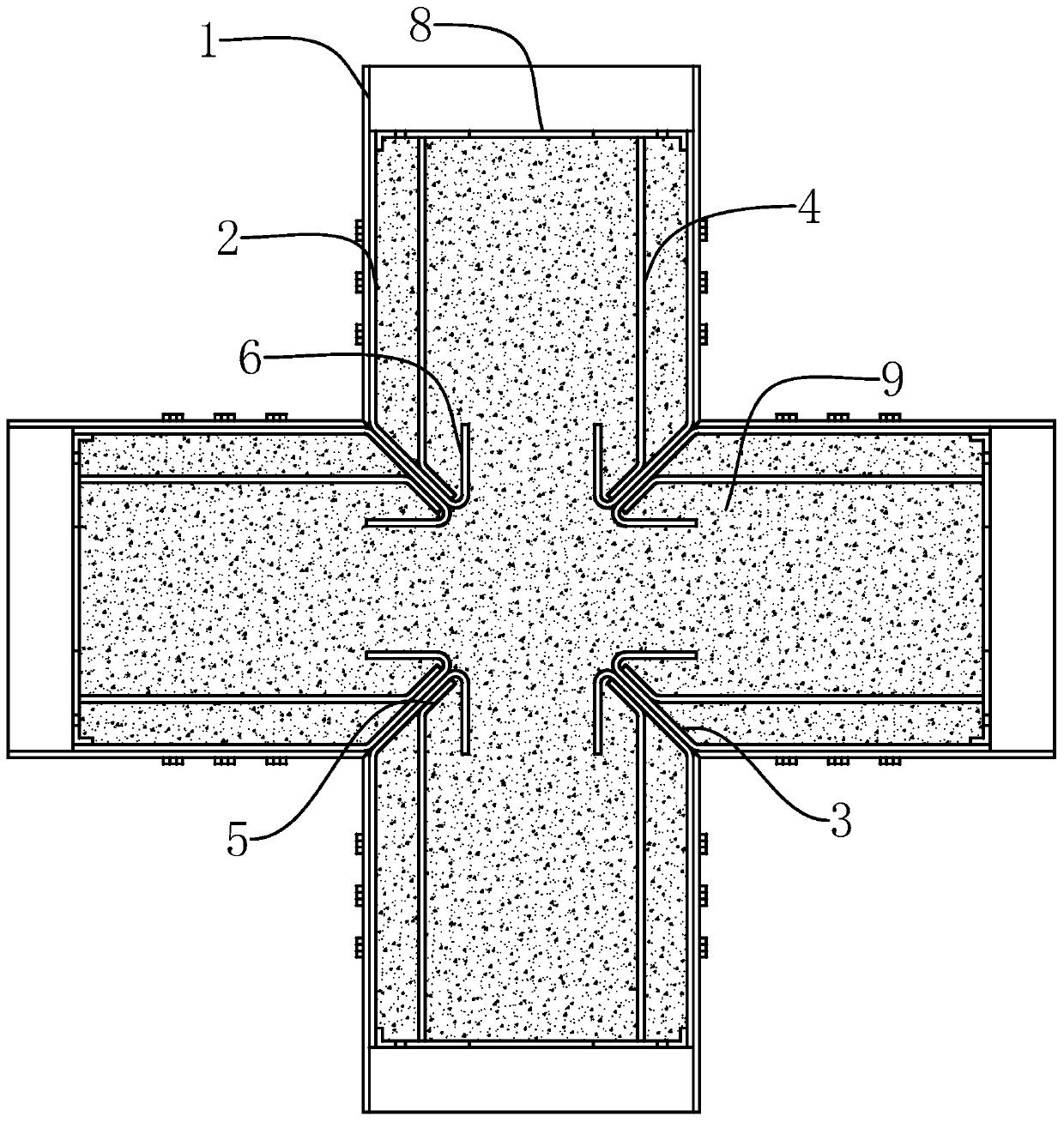

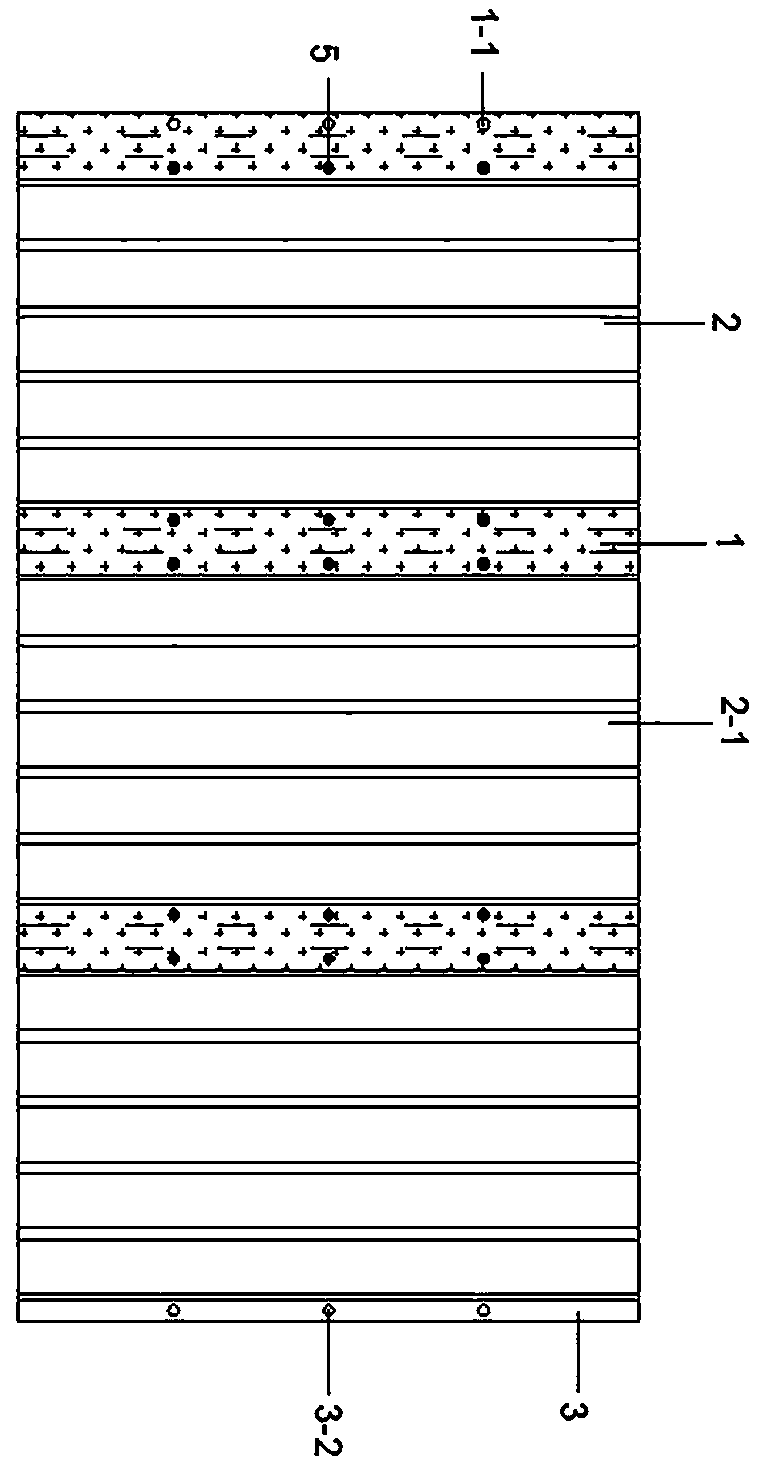

Construction method and structure of four-direction unbonded prestressed crossed beam-column joint

InactiveCN112482567AHigh node strengthEasy to transformBuilding reinforcementsEarthquake resistanceT-beam

The invention discloses a construction method and structure of a four-direction unbonded prestressed crossed beam-column joint. The construction method comprises the following construction technological processes: a, hoisting construction of an assembly structure column; b, hoisting two longitudinal overlapped T beams under a plate in place, and carrying out crossed perforating operation on overhung unbonded prestressed tendons; c, hoisting two transverse overlapped T beams under the plate in place, and carrying out crossed perforating operation on the overhung unbonded prestressed tendons; d,connecting the longitudinal and transverse overlapped T beams under the plate with column steel bars; e, hoisting overlapped plates in place, and anchoring overhung steel bars of the overlapped plates into the overlapped beams; f, pouring and maintaining concrete on the whole surface layer of a post-pouring section; g, mutually crossing, tensioning and anchoring the unbonded prestressed tendons of the longitudinal and transverse overlapped T beams under the plate at the end parts of the sections of the T beams; and h, grouting prestressed ducts. According to the construction method and structure, the strength of the beam-column joint is improved, the earthquake resistance is good, and the construction method and structure play an important role in promoting the better construction of theconstruction industry in China.

Owner:NANTONG SIJIAN CONSTR GRP

Novel prefabricated frame structure beam column dry type connecting joint

PendingCN113006274APrevent slidingEasy to assembleBuilding constructionsConcrete beamsArchitectural engineering

The invention discloses a novel prefabricated frame structure beam column dry type connecting joint, and belongs to the technical field of house building. The novel prefabricated frame structure beam column dry type connecting joint comprises a prefabricated concrete beam, a prefabricated concrete lower column, a prefabricated concrete upper column, a connecting end head and a bracket, wherein the lower part of the connecting end head is provided with a reserved vertical steel bar; a bracket reserved hole is formed inside the bracket; a longitudinal bar reserved hole is formed inside the prefabricated concrete lower column; the connecting end head and the bracket are connected through inserting the reserved vertical steel bar into the bracket reserved hole; the lower end of the prefabricated concrete upper column is provided with a reserved longitudinal bar; and the prefabricated concrete upper column and the prefabricated concrete lower column are connected through inserting the prefabricated longitudinal bar into the longitudinal bar reserved hole. The novel prefabricated frame structure beam column dry type connecting joint has the advantages that the beam is hoisted, so that the beam end is put on the bracket to be limited; the beam is prevented from downwards sliding in the column height direction; the assembly is convenient; the reserved vertical steel bar is inserted into the limiting hole of the bracket and is subjected to grouting; the primary fixation is realized; the integrality and the rigidity of the joint can meet the requirements; the installation is convenient; and the fixing effect is good.

Owner:SHENYANG JIANZHU UNIVERSITY

Quick-split type T-shaped steel concrete beam column connection node

PendingCN109914597AImprove bearing capacityImprove ductilityBuilding material handlingStress concentrationConcrete beams

The invention relates to a quick-split type T-shaped steel concrete beam column connection node, comprising a section steel column, connecting plate assemblies, H-shaped steel beams and reinforcing ribs, wherein the two connecting plate assemblies sleeve the outer side of the section steel column in parallel; threaded holes are respectively formed in all the connecting plate assemblies; the plurality of reinforcing ribs are vertically arranged on each connecting plate assembly; the H-shaped steel beams are vertically fixed on the side face of the section steel column between the two connectingplate assemblies. Compared with the traditional universal node for section steel concrete beam columns, the quick-split type T-shaped steel concrete beam column connection node is produced in a way of connecting reinforcing steel bars with connecting plates and welding the connecting plates with the section steel column; by changing the lengths of studs, the requirement of misaligned connection of reinforcing steel bar joints is met, so that stress concentration is avoided. Furthermore, the percentage of the area of the reinforcing steel bar joints reaches 50%, so that superstrong connectionis realized. The quick-split type T-shaped steel concrete beam column connection node is higher in connection efficiency, and improves the node bearing capacity and ductility.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

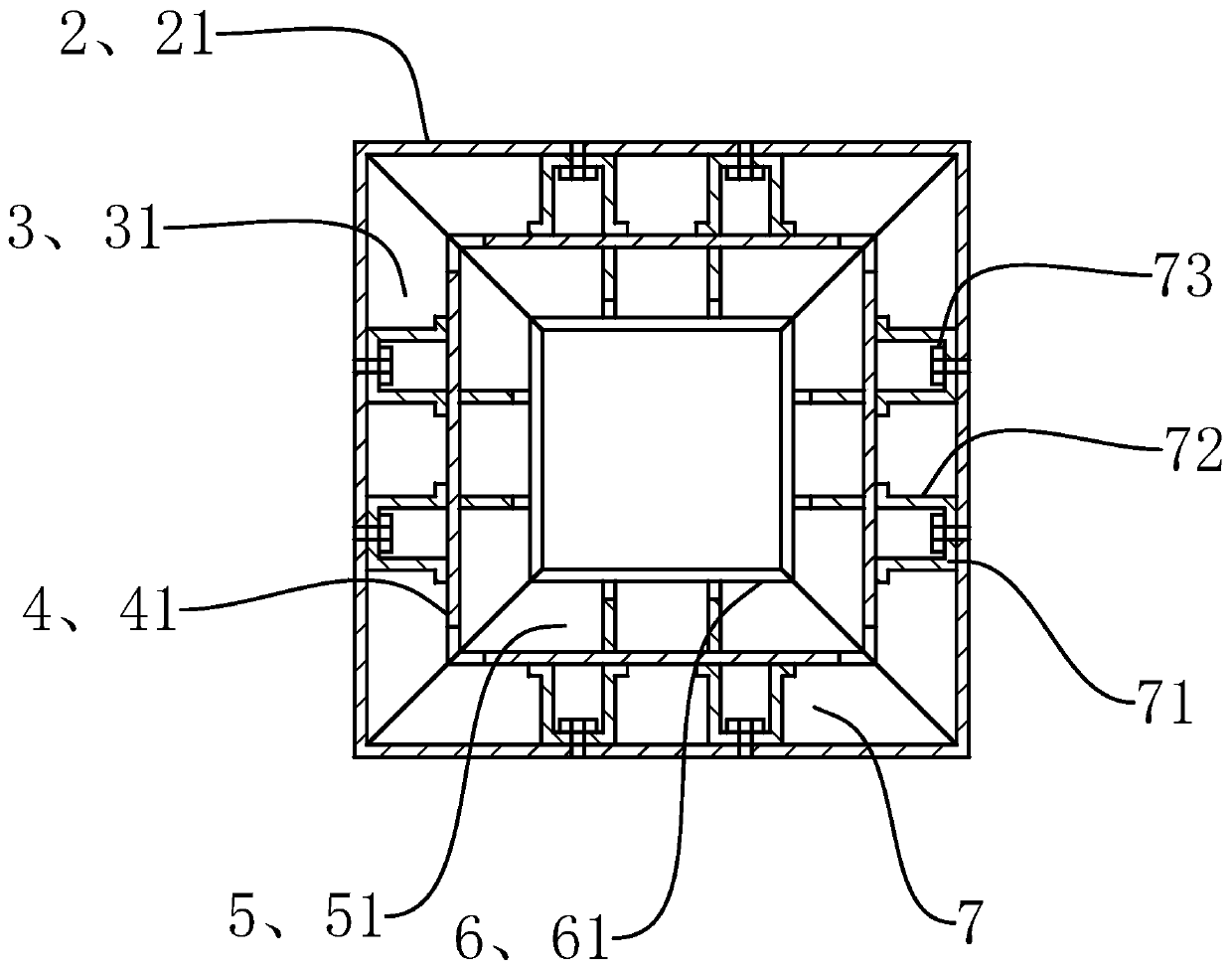

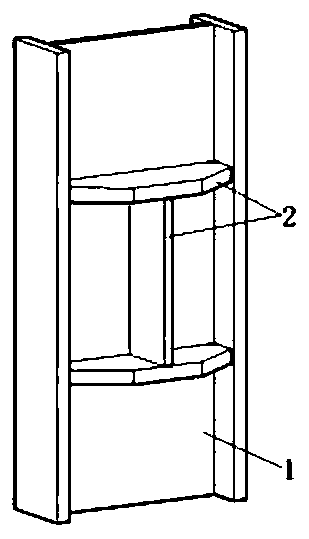

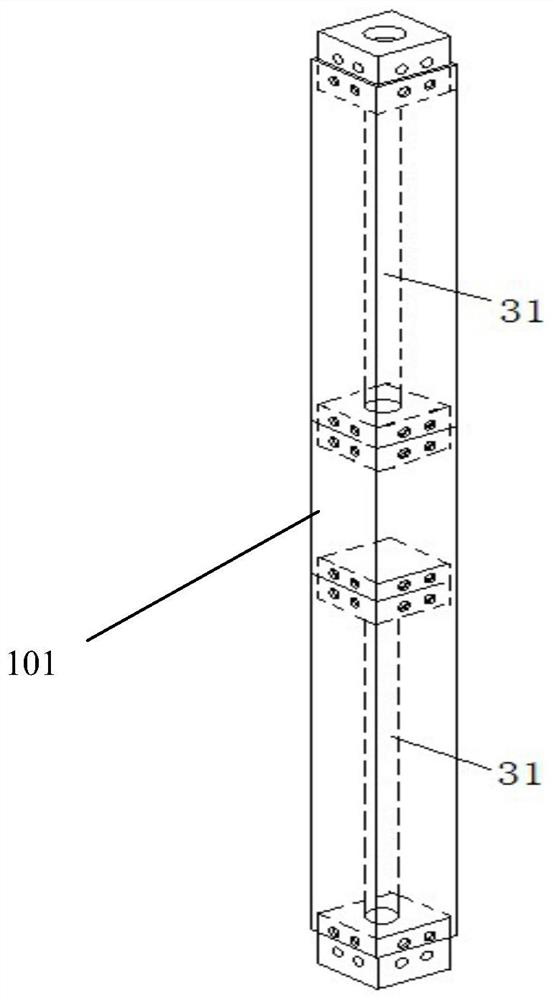

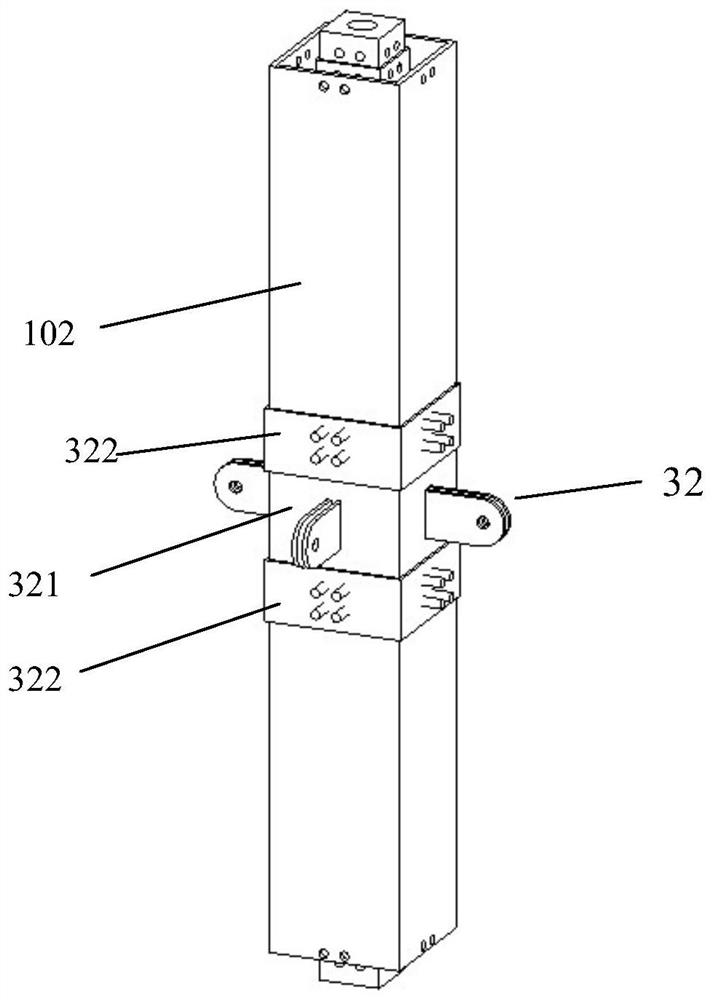

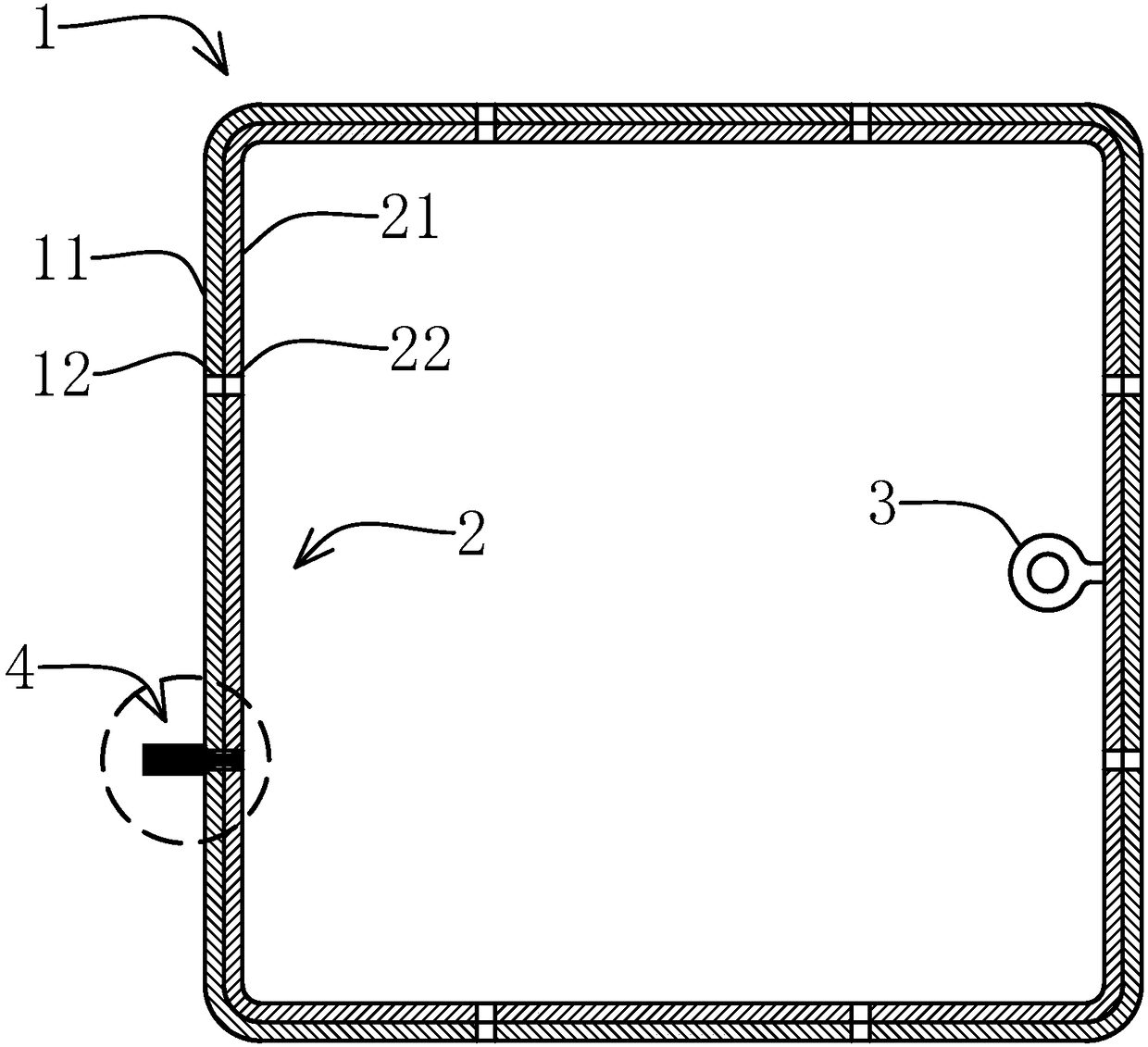

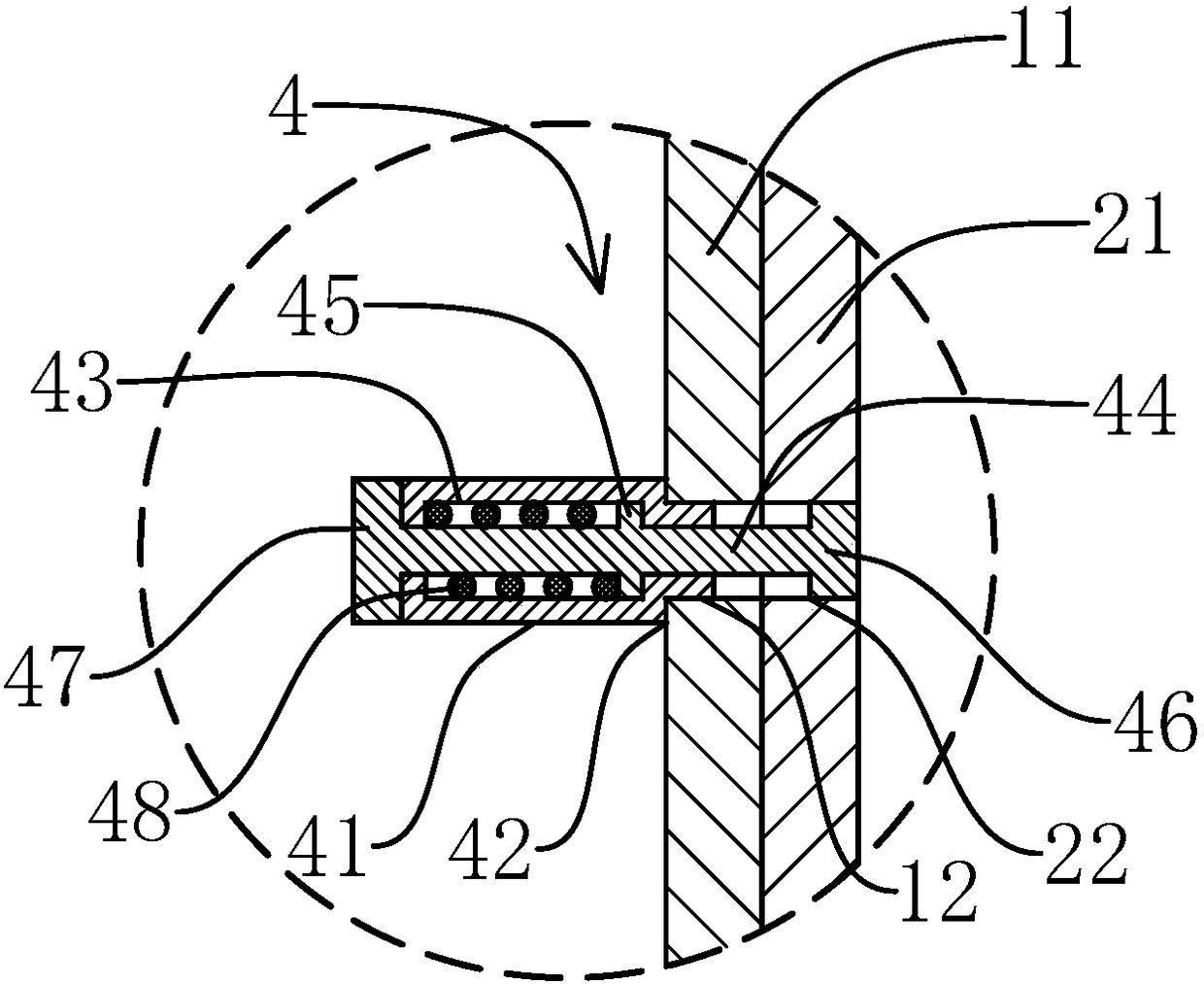

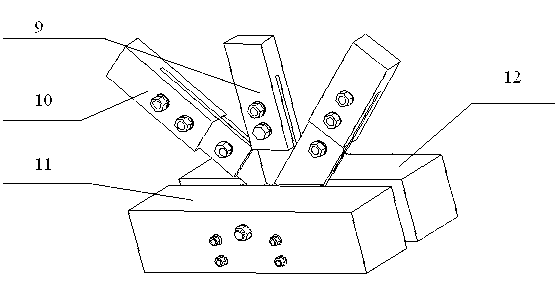

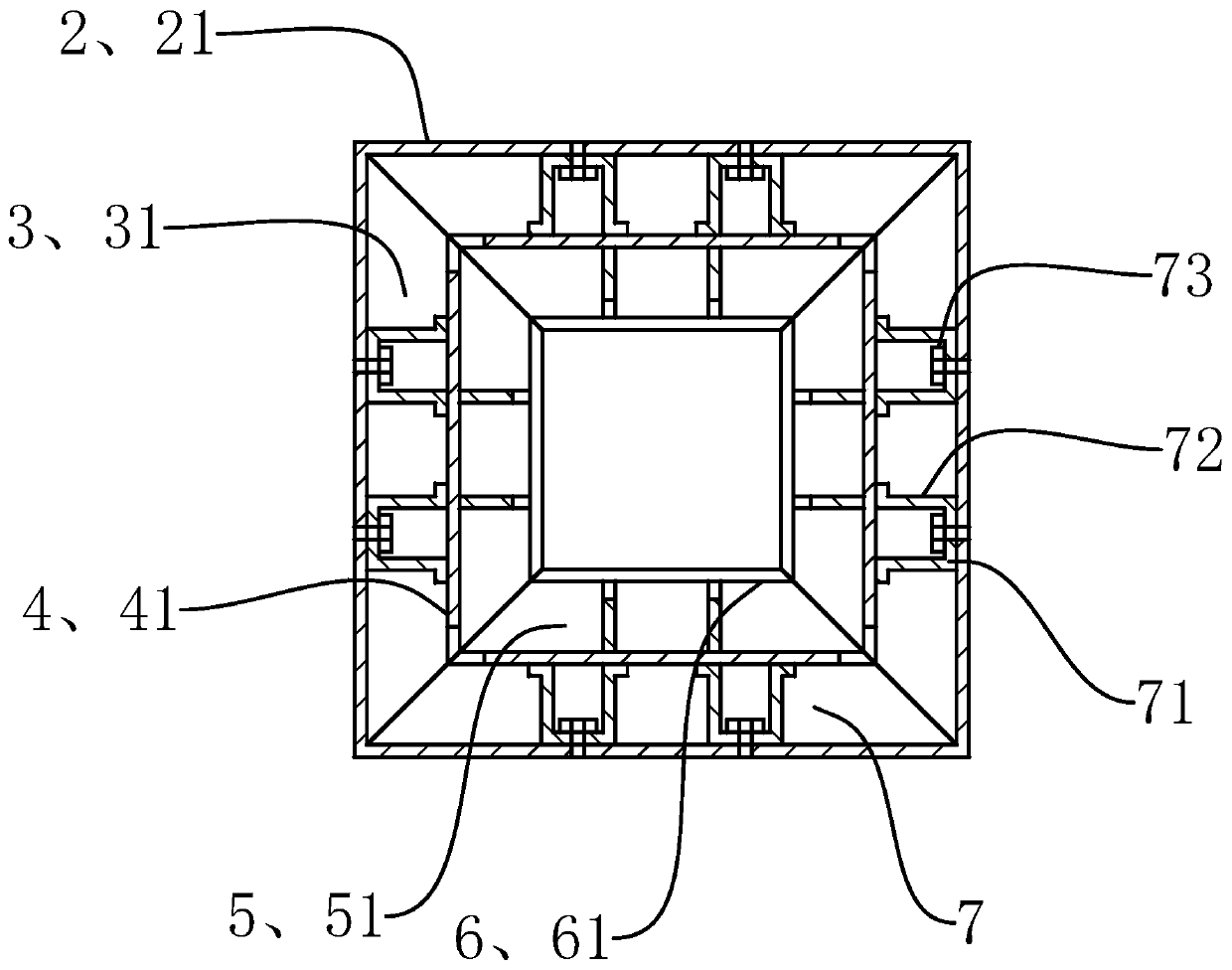

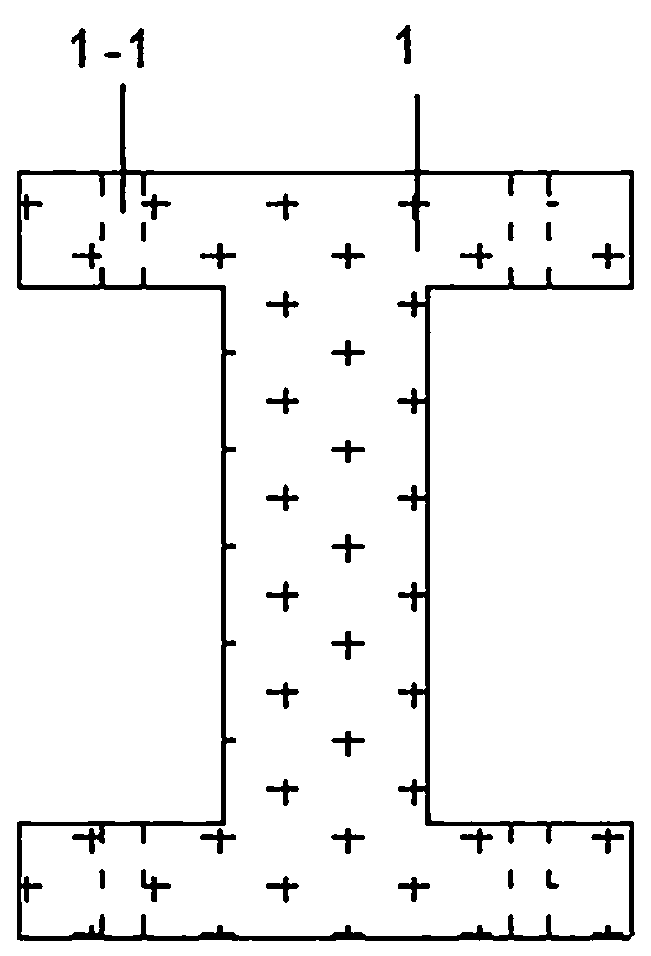

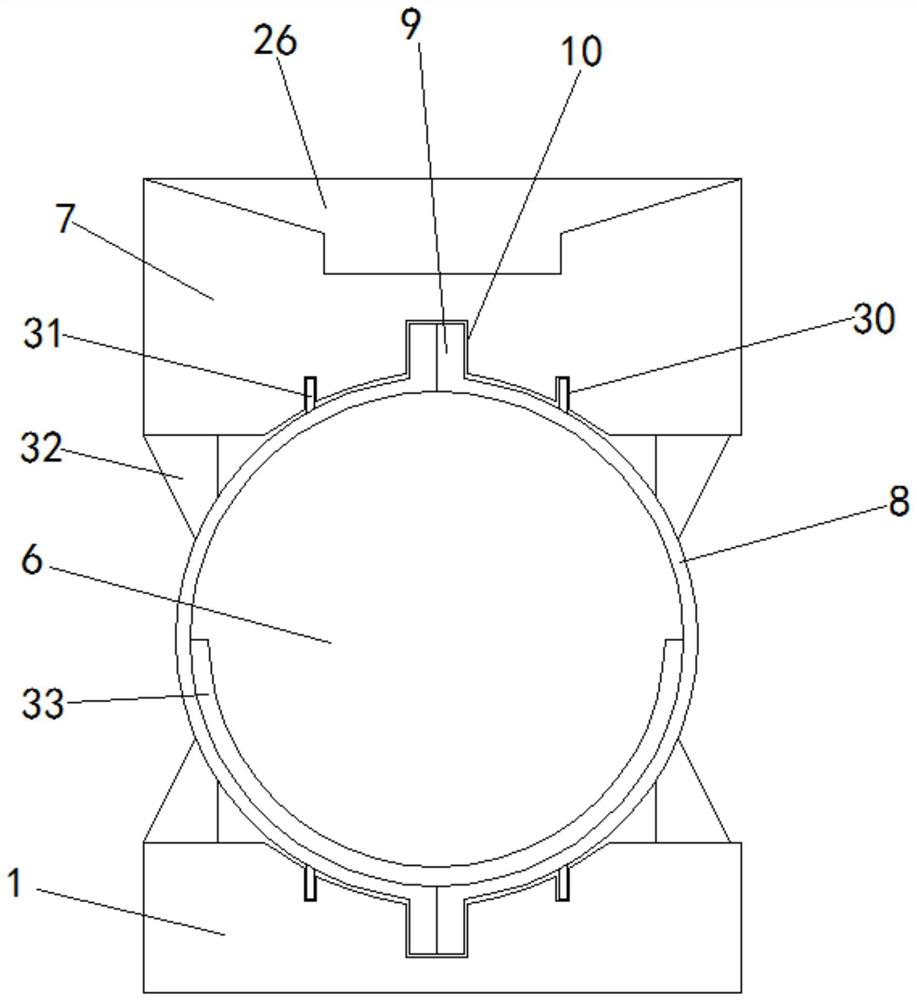

Internally reinforced square pipe column body joint and installation method thereof

InactiveCN108590216AHigh node strengthConvenient post-reinforcementBuilding repairsBody jointsEngineering

The invention provides an internally reinforced square pipe column body joint and an installation method thereof, and belongs to the field of steel structures. According to the internally reinforced square pipe column body joint and the installation method thereof, the problem of low strength of existing square pipe column body joints is solved. The internally reinforced square pipe column body joint comprises a column body, a square-pipe-shaped internally reinforced pipe, a locating piece and a compression spring. The column body comprises four column plates, and the square-pipe-shaped internally reinforced pipe is embedded in the column body in a matched mode. The internally reinforced pipe is sleeved with the column body in a matched mode, the internally reinforced pipe comprises four internally reinforced plates, and a lifting ring is fixed to the inner side face of one of the internally reinforced plates. A plurality of connecting holes are formed in the column plates, and a plurality of reinforced holes are formed in the internally reinforced plates. The locating piece comprises a locating rod and a locating pipe, wherein the locating rod is sleeved with the locating pipe, anexternal thread is arranged on the outer wall of the front end of the locating pipe, the front end of the locating pipe is connected to the outer end of one of the connecting holes in a threaded mode, and a spring groove is formed in the inner wall of the locating pipe. A moving block is arranged on the rod wall of the locating rod, and the locating rod is sleeved with the compression spring. Theinternally reinforced square pipe column body joint can achieve later reinforcement.

Owner:XINCHANG SICHUANG DESIGN CONSULTING CO LTD

Embedded multidirectional frame connection node for packing case

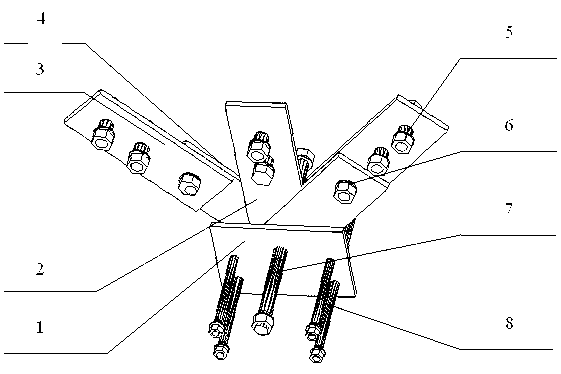

InactiveCN102837873AVersatilityImprove securityRigid containersStructural engineeringUltimate tensile strength

The invention relates to an embedded multidirectional frame connection node for a packing case. The embedded multidirectional frame connection node for the packing case structurally comprises an embedded steel plate base, a multidirectional steel plate connection arm A, a multidirectional steel plate connection arm B and a multidirectional steel plate connection arm C, wherein the embedded steel plate base is hinged with the multidirectional steel plate connection arm A and the multidirectional steel plate connection arm C, and the multidirectional steel plate connection arm C is also hinged with the multidirectional steel plate connection arm B. The embedded multidirectional frame connection node for the packing case has the advantages that firstly the node is embedded into a tray of the packing case and is connected with an upright or an inclined strut, so that the packing case is smooth in the outer surface and is convenient to stack, load and unload and transport; secondly, the tray, the upright and the inclined strut are connected by an adjustable steering connection arm, so that the node has generality and is convenient to produce in a standardization manner; thirdly, the multidirectional connection arm has directional adjustable characteristics, and is low in demand on machining precision of a packing case member, and convenient to install and recover; and fourthly, the adjustable multidirectional connection node adopts a steel plate for connecting a wood member; the strength of the node of a heavy packing case is greatly enhanced, and the security and reliability of the packing case are enhanced.

Owner:NANJING FORESTRY UNIV

Diagonal reinforcement structure of reinforced concrete beam-column joint

ActiveCN110700493AGuaranteed isolationReduce penetrationBuilding reinforcementsConcrete beamsArchitectural engineering

The invention discloses a diagonal reinforcement structure of a reinforced concrete beam-column joint. The diagonal reinforcement structure comprises a transverse main rib and a vertical main rib which penetrate through a joint region, and further comprises two additional ribs. Each additional rib is composed of horizontal sections on the two sides and an inclined section in the middle, wherein the horizontal sections on the two sides are anchored in beam concrete on the two sides of the joint region correspondingly, and the inclined section in the middle is located in the concrete of the joint region. The two inclined sections of the two additional ribs are arranged in a crossed and diagonal mode. The inclined section of each additional rib is sleeved with a steel sleeve in a clearance mode. The two ends of each steel sleeve are each provided with a hollow anchor head. The outer diameter of each anchor head is larger than the outer diameter of the corresponding steel sleeve. The steelsleeves and the anchor heads are all anchored in the concrete in the joint region. By means of the structure, the permeation of the stress of the stressed area of a beam into the joint region by thestressed additional ribs can be reduced, meanwhile inclined pressed rods formed through pressing in the other diagonal direction in the joint region are effectively constrained, and the anti-shearingperformance in longitudinal and transverse directions of the joint can be enhanced.

Owner:NINGBO NOTTINGHAM NEW MATERIALS INST CO LTD +1

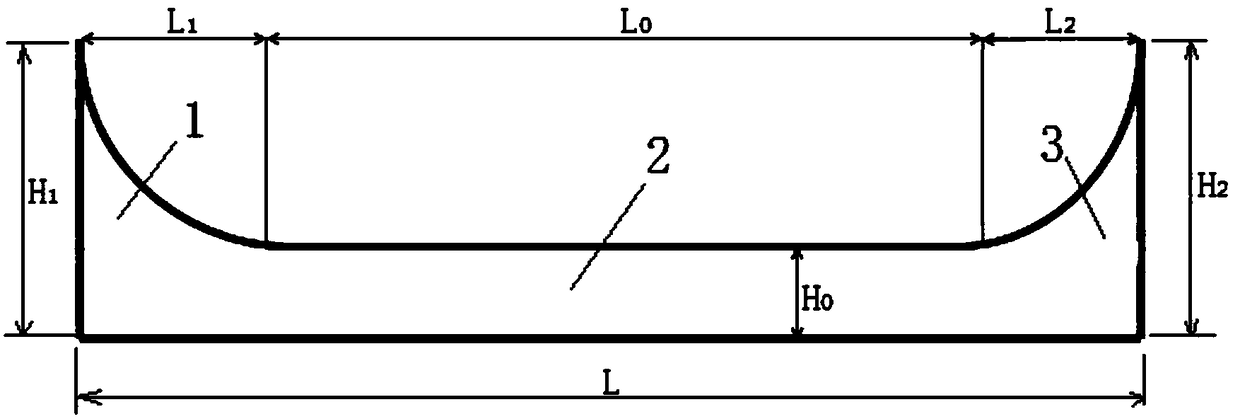

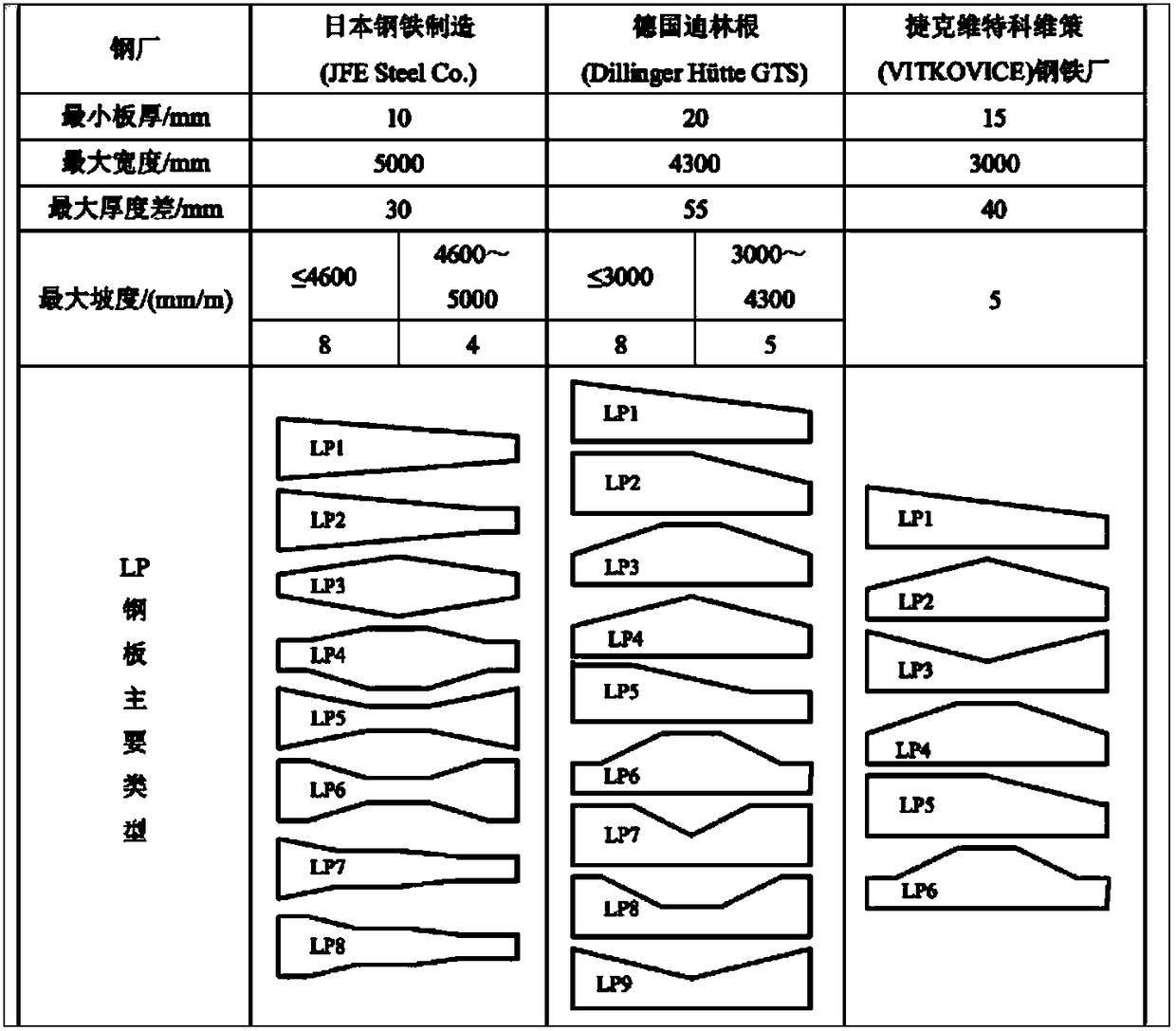

Longitudinal deformed section steel plate and production method

InactiveCN108397681AExpand the range of optionsImprove applicabilitySheets/panelsMetal rolling arrangementsSheet steelEngineering

The invention relates to a longitudinal deformed section steel plate and a production method thereof. The longitudinal deformed section steel plate comprises a first gradual change segment, an equal-thickness segment and a second gradual change segment, wherein the first gradual change segment, the equal-thickness segment and the second gradual change segment are subject to rolling to be continuously formed, and the total length of the three segments is L. The lower surfaces of the first gradual change segment, the equal-thickness segment and the second gradual change segment are a plane, theupper surfaces of the first gradual change segment, the equal-thickness segment and the second gradual change segment are a continuous smooth transition surface, the upper surface of the equal-thickness segment is a plane, and the upper surfaces of the first gradual change segment and the second gradual change segment are curve faces. The special structural shape is adopted, the length and thickness size selective range is large, the adaptation is high, in the actual engineering application process, the machining amount and the welding workloads of steel beams for structures like an extensionbeam can be reduced, joint strength is increased, and connection reliability is improved; the production process is simple, controllability is high, the finished product pattern yield is high, and thesurface quality and the chemical performance can meet the use needs.

Owner:ANGANG STEEL CO LTD

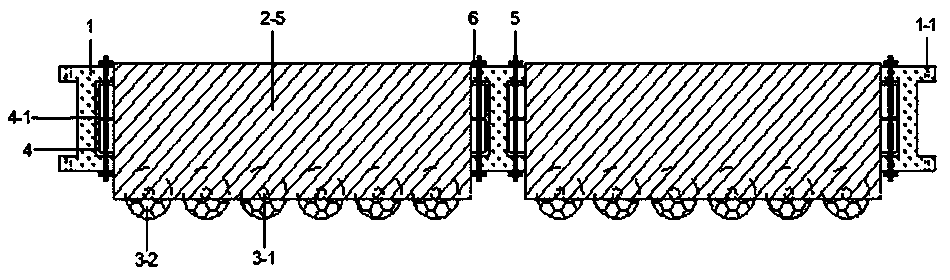

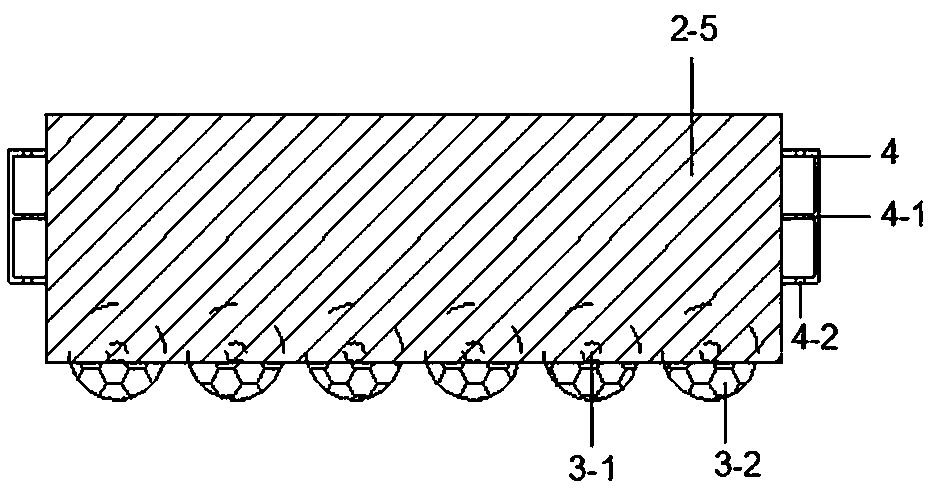

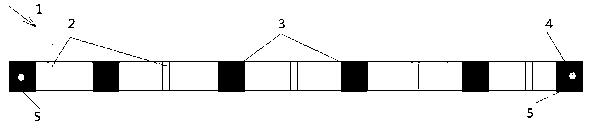

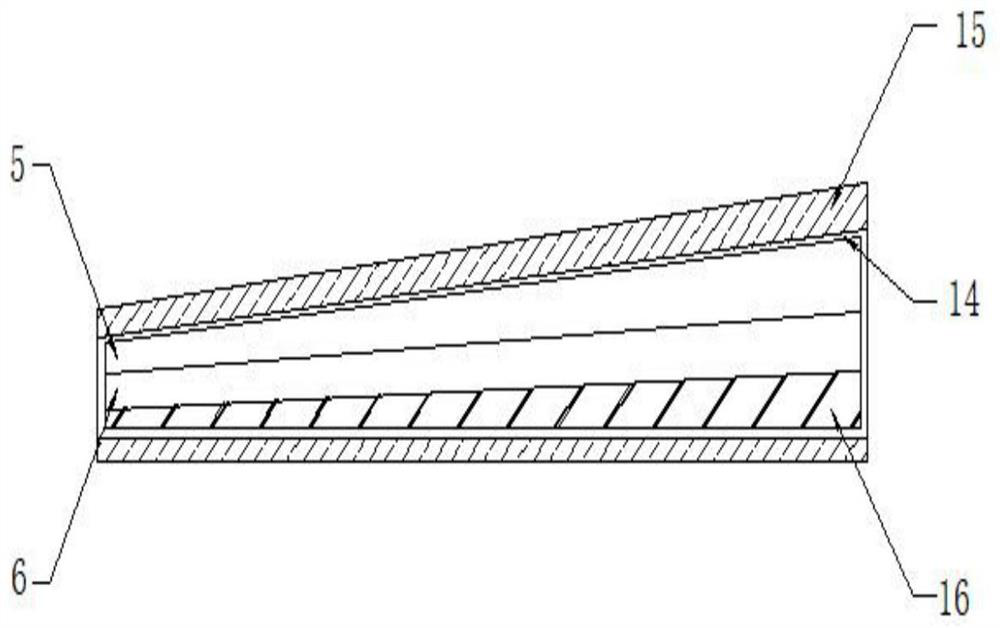

Road sound insulation wall with anti-collision function

PendingCN108457211AHigh strengthHigh node strengthNoise reduction constructionRoadway safety arrangementsSheet steelInter layer

The invention relates to a road sound insulation wall with an anti-collision function and belongs to the field of road traffic. The road sound insulation wall comprises I-shaped upright columns, soundinsulation plates, anti-collision rods, connecting pieces, deformed steel bars and nuts, wherein the I-shaped upright columns are uniformly provided with 3-5 upright column bolt holes in the centralline of each lateral flange along the height direction; the sound insulation plates are divided into three layers, wherein bearing plates are arranged at the inner layer, sound insulation cotton is arranged at the middle layer, and outer-layer steel plates are arranged at the outer layer; support ribs are hollow steel pipes and are connected between the bearing plates and the outer-layer steel plates; a top plate and a bottom plate are positioned on the upper and lower surfaces of the sound insulation plates; the edges of the outer sides of the top plate and the bottom plate are flush with theouter-layer steel plates; the anti-collision rods are cylindrical, outer layers of the anti-collision rods are rubber layers, the inner layers of the anti-collision rods are solid shafts, and the radius of an external ring is 3-4 times that of an internal ring; and the external rings of the anti-collision rods are tangent with the bearing plates. The road sound insulation wall provided by the invention has the advantages of being high in strength, capable of realizing the anti-collision function, obvious in sound insulation effect, reliable in connection, high in node strength, convenient totransport, long in service life, short in construction cycle, simple in installation and convenient to maintain and repair, and assembly parts can be prefabricated directly from the factory.

Owner:SHENYANG JIANZHU UNIVERSITY

A kind of composite material lattice structure and preparation method

ActiveCN107599445BIncrease productivitySuitable for large-scale production of composite lattice structuresLayered productsFiberShell molding

The invention provides a composite lattice structure and a preparation method. The composite lattice structure is composed of an upper face plate, a lower face plate and a lattice core arranged between the upper face plate and the lower face plate. The lattice core is formed in the manner that lattice core triangular fibers and trapezoidal fibers are interlaced. Foam interlayers are arranged in the upper face plate and the lower face plate. A specific injection manner is applied to the composite lattice structure for VARTM formation. The preparation method of the composite lattice structure comprises the seven steps of (1) preparing a fusible alloy mold core; (2) inserting the triangular fibers; (3) laying fibers on the bottom layers of the upper face plate and the lower face plate; (4) inserting the trapezoidal fibers; (5) arranging the face plate interlayers and laying surface fibers of the face plates; (6) conducting VARTM (vacuum assisted resin transfer molding) formation; (7) heating and melting the fusible alloy mold core. The composite lattice structure and the preparation method effectively solve the connection problem between a composite lattice core and the face plates, integrated formation is achieved, the quality is reliable, the technology is simple, and the node strength is high.

Owner:HARBIN ENG UNIV

A steel structure node connection device and manufacturing method thereof

The invention provides a steel structure joint connection device and a manufacturing method thereof, and belongs to the field of steel structures. The problem that existing steel structure joints cannot be connected in a hidden mode is solved. The steel structure joint connection device is used for connecting six hollow steel pipes, a connection device comprises six connection parts, connection parts include outer connection pipes, inner join pipes, outer join pipes and inner connection pipes, connection boxes are arranged between outer connection pipes and inner connection pipes, the connection device further comprises baffles fixed on the inner walls of the top ends of the outer connection pipes, the bottom faces of the baffles abut against the top ends of the inner connection pipes in a sealing mode, grout-venting holes are formed in the baffles, any baffle is provided with a grouting opening, concrete mortar is poured into the connection parts through the grouting openings, and the six hollow steel pipes correspondingly sleeve six outer connection pipes in a matched mode and are fixed through fasteners. According to the steel structure joint connection device, the six hollow steel pipes can be connected in a high-intensive hidden mode.

Owner:东阳市智林科技有限公司

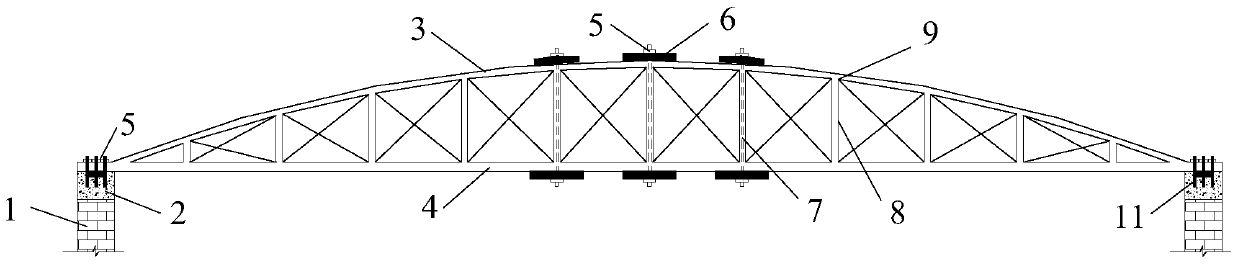

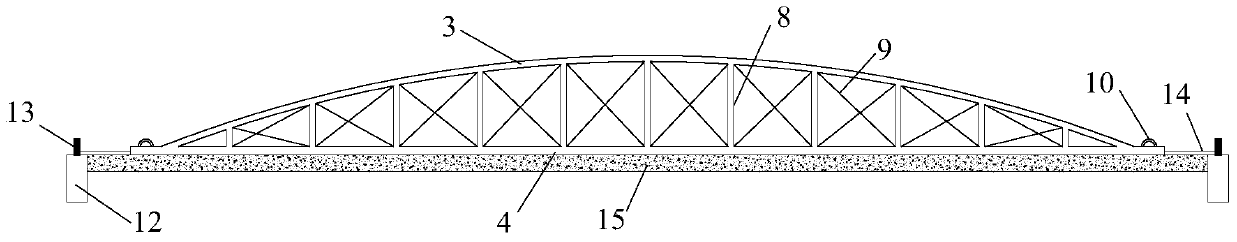

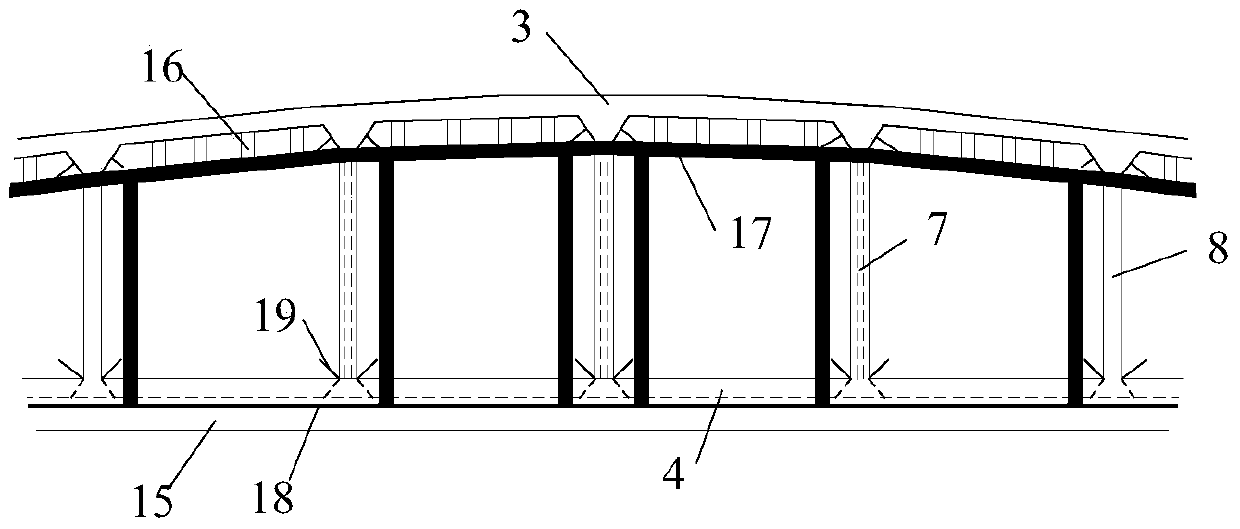

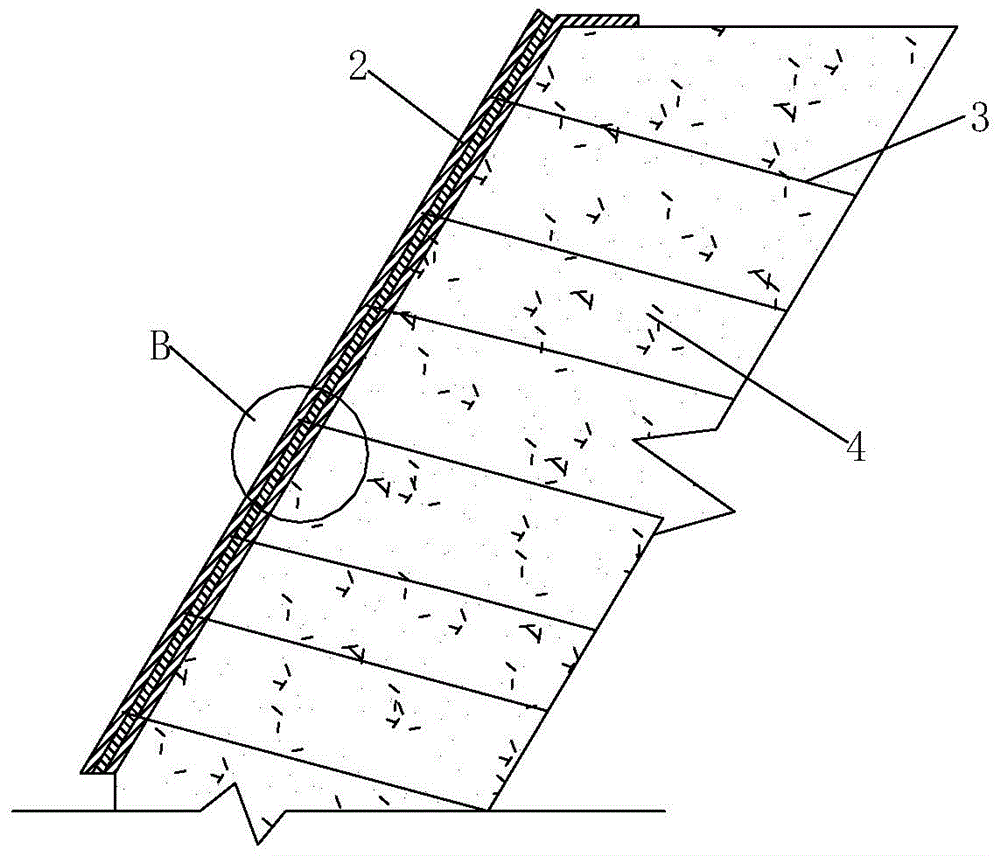

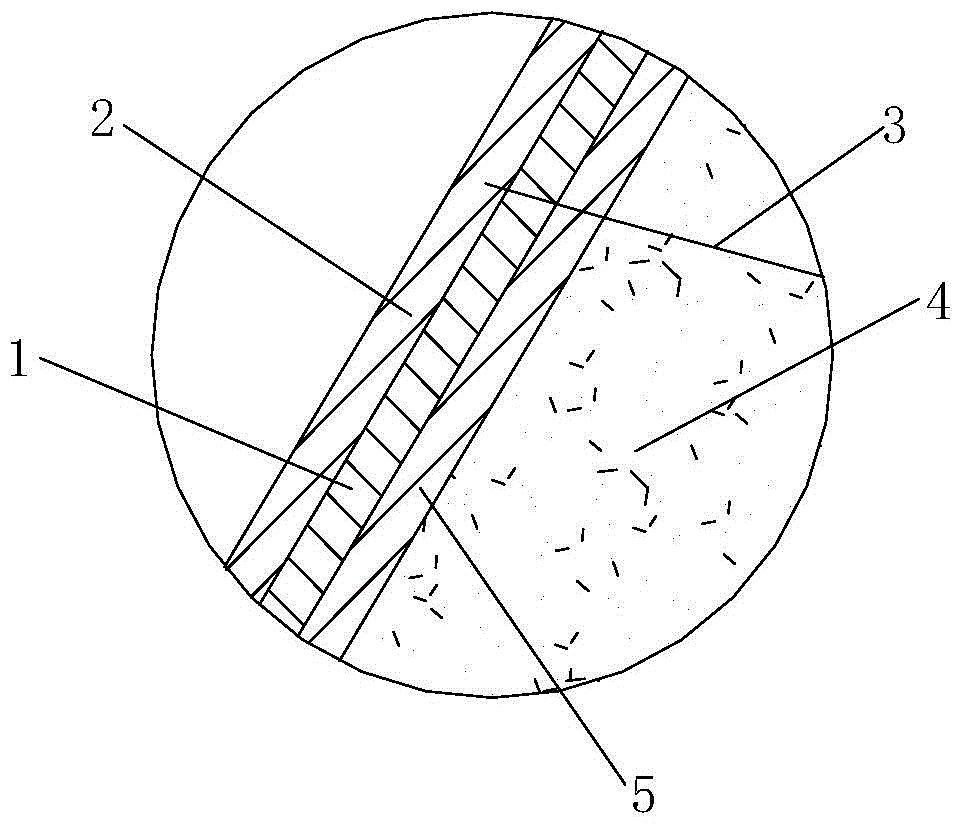

On-site prefabrication and installation construction method of long-span prestressed arch slab

ActiveCN105220808BLose weightReduce earthquake resistanceBuilding roofsCeramic shaping apparatusPre stressEngineering

The invention relates to a construction method for on-site prefabrication and installation of large-span prestressed arch slabs, which mainly includes prestressed tendon layout, middle partition prefabrication, formwork support installation, upper chord curved panel fabrication, middle partition installation, and lower chord prestressed flat slab prestressing. The steps of making flat panels, stretching prestressed tendons, and hoisting arched roof trusses. The method of the invention has the characteristics of safety, reliability, strong stability, high construction efficiency, and can adapt to the site prefabrication requirements of large batches of arch slab roof trusses, etc., and has good economic and technical benefits.

Owner:JIANGSU HUAJIANG CONSTR GROUP

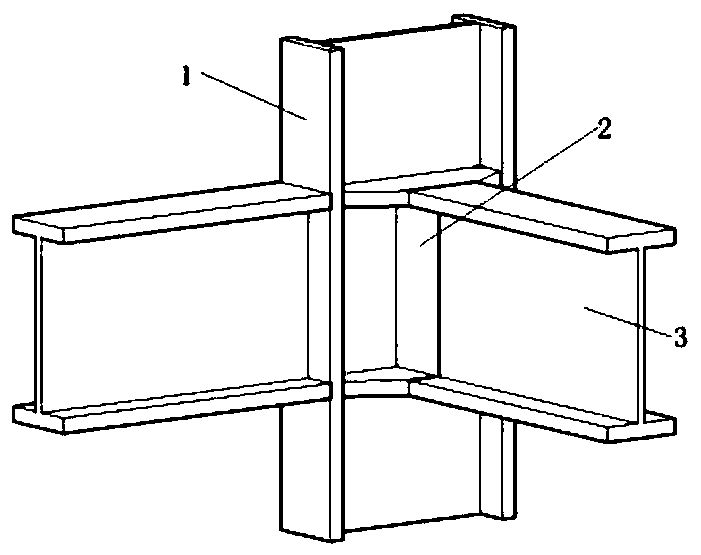

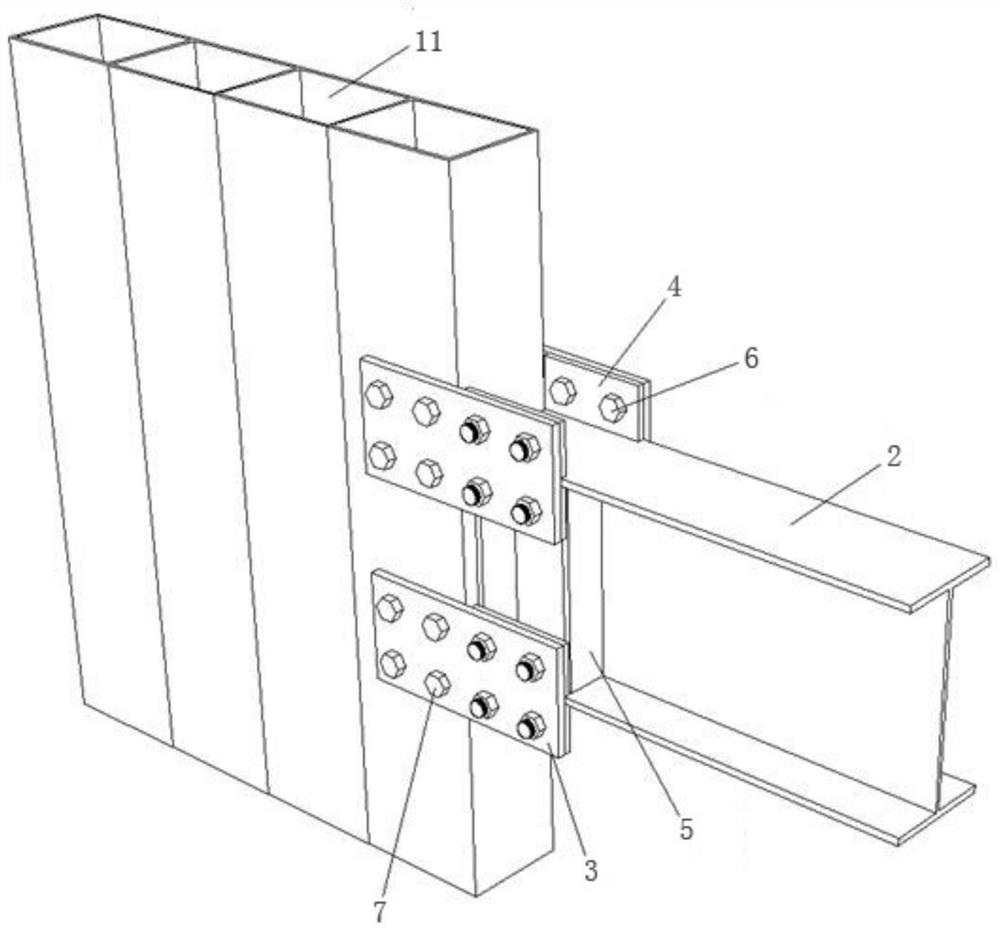

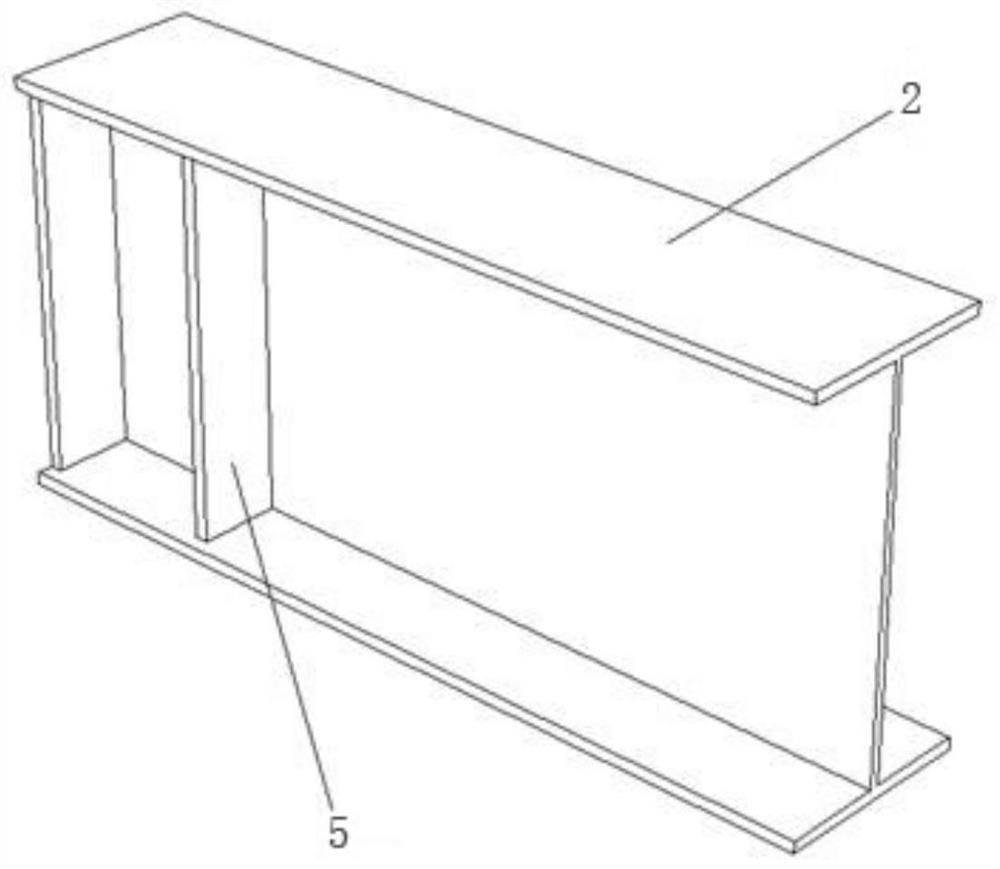

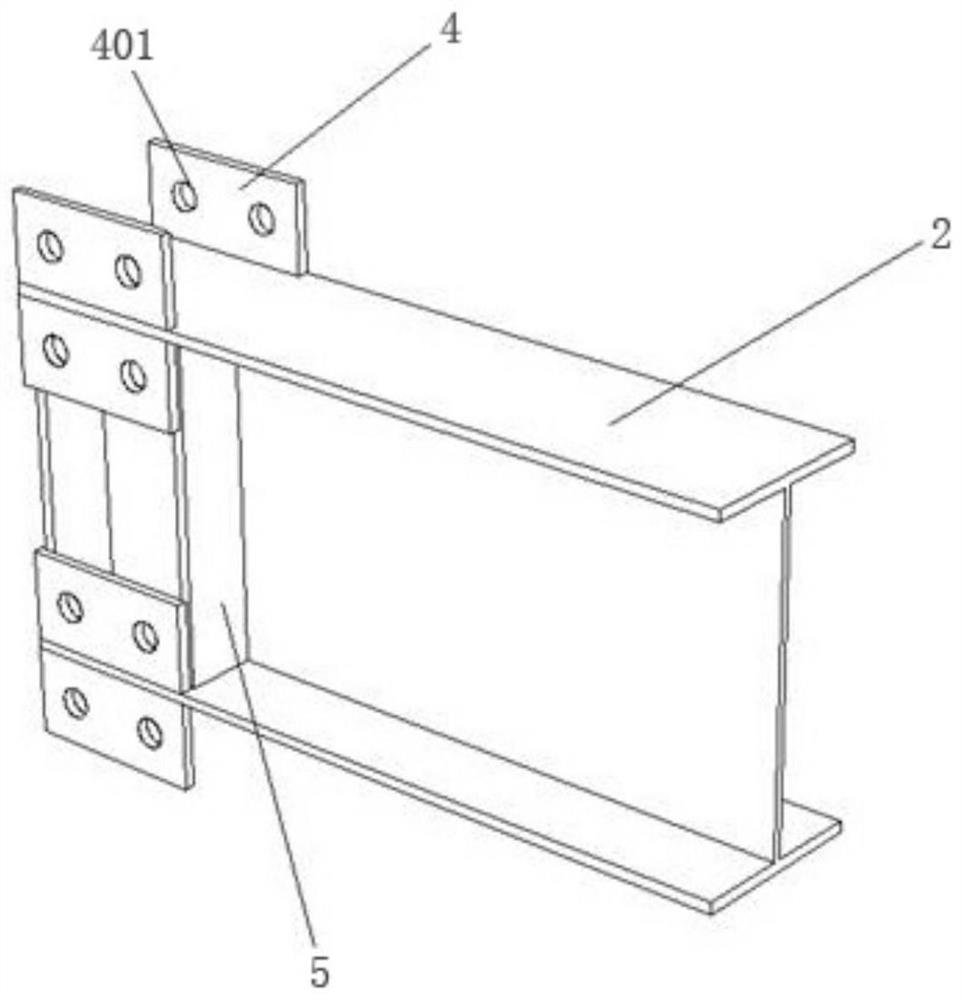

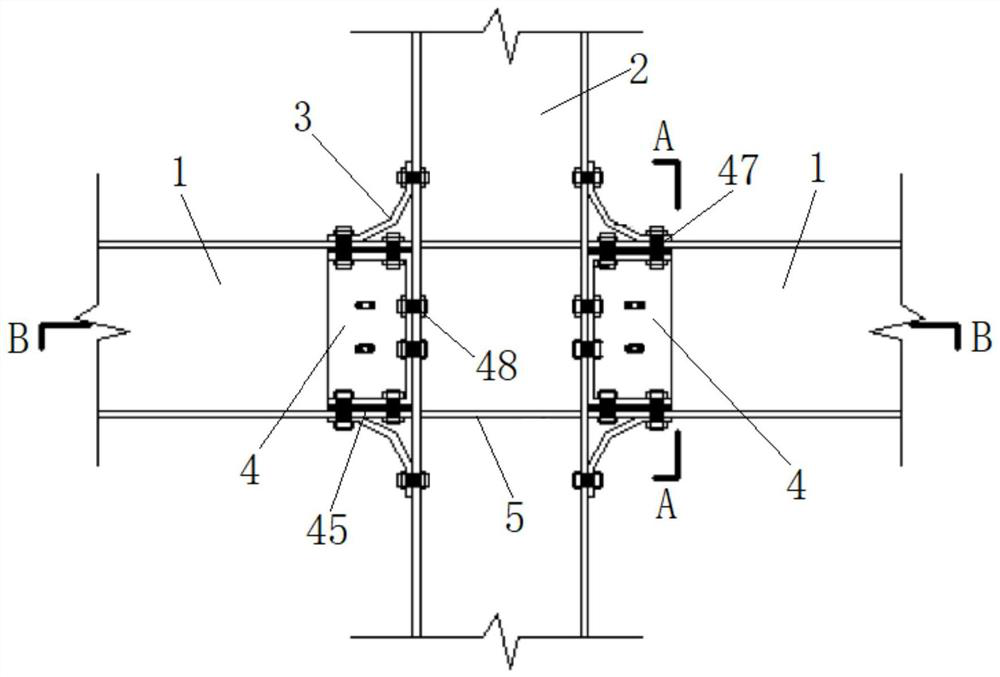

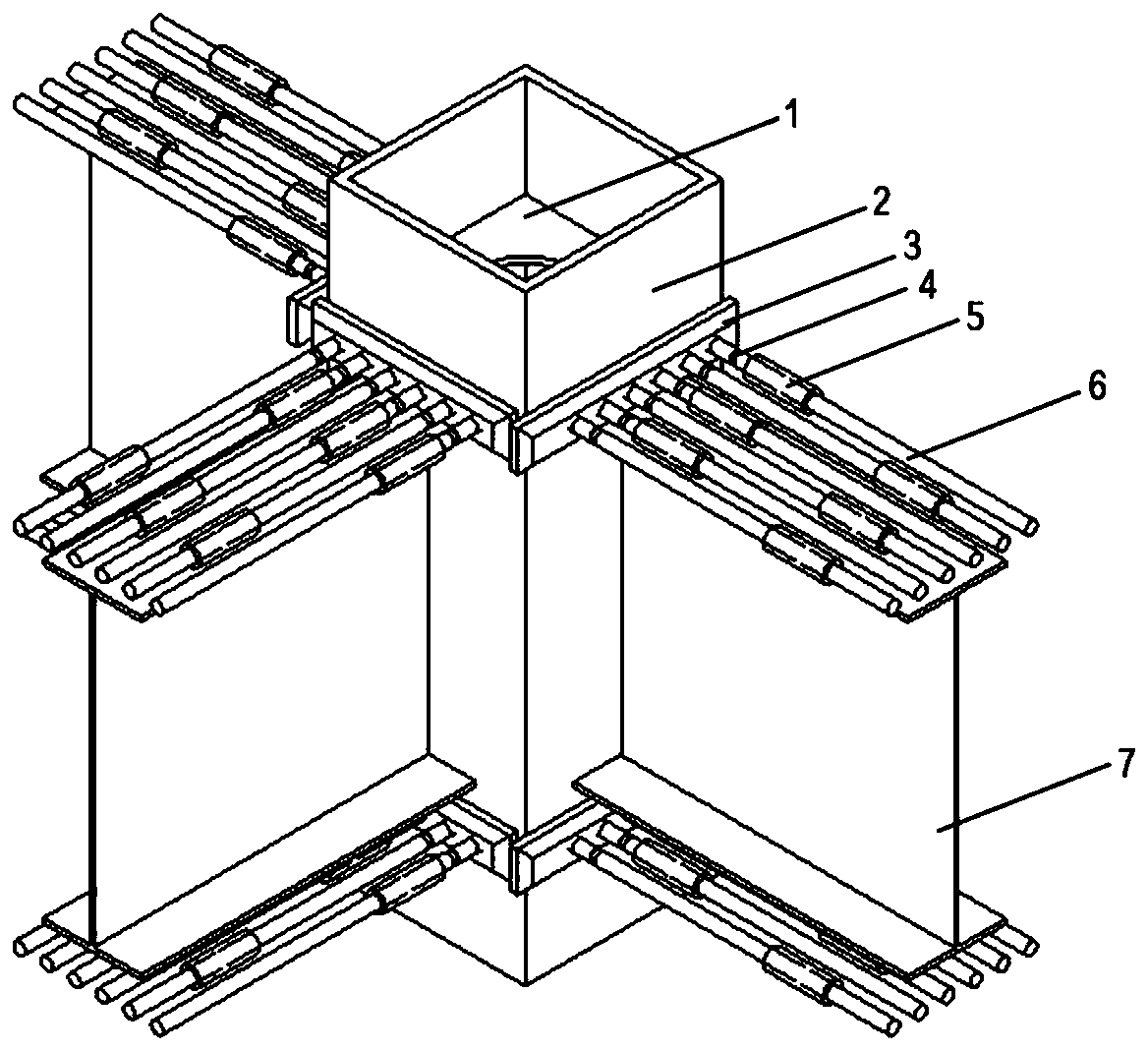

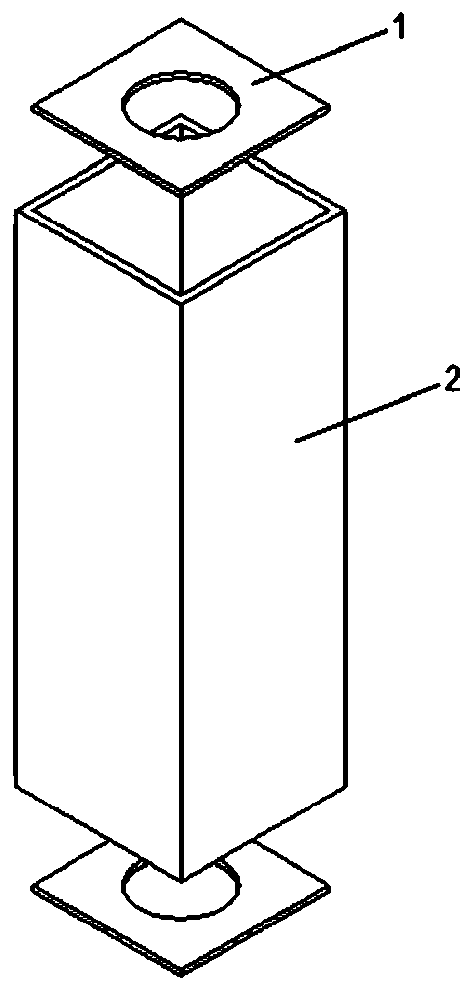

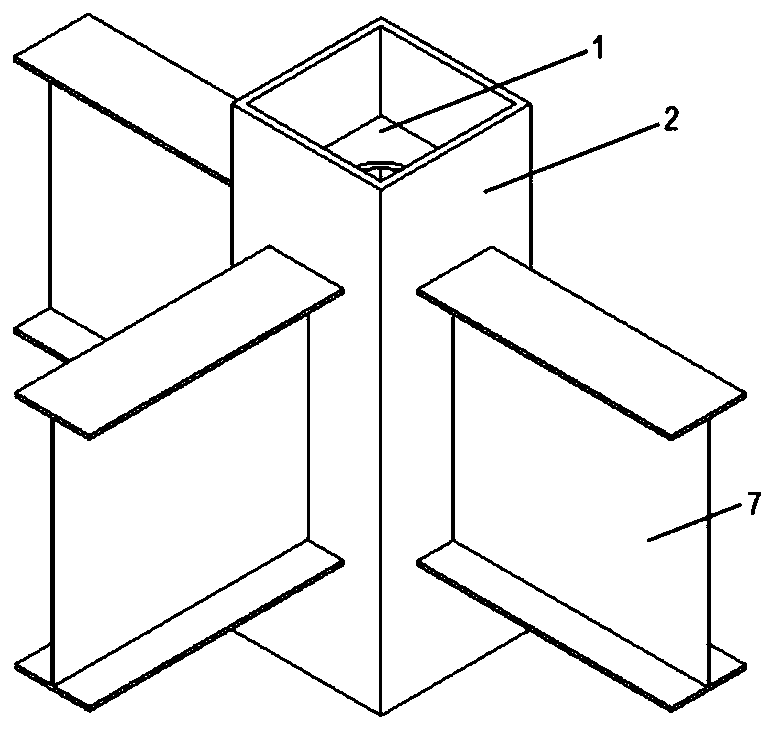

Quick-split type box-shaped section steel concrete column-H-shaped steel concrete beam connection node

PendingCN109914596AImprove bearing capacityImprove ductilityStrutsGirdersStress concentrationConcrete beams

The invention relates to a quick-split type box-shaped section steel concrete column-H-shaped steel concrete beam connection node, comprising a box-shaped section steel column, H-shaped steel beams, connecting plates and reinforcing ribs, wherein the plurality of H-shaped steel beams are separately and vertically fixed on the outer side wall of the box-shaped section steel column; the connecting plates are fixedly arranged on the side wall of the box-shaped section steel column at the parts above and under all the H-shaped steel beams; the connecting plates are provided with a plurality of threaded holes; the plurality of reinforcing ribs are vertically arranged on the connecting plates. Compared with the traditional universal node for box-shaped section steel concrete beam columns, the quick-split type box-shaped section steel concrete column-H-shaped steel concrete beam connection node is produced in a way of connecting reinforcing steel bars with the connecting plates and welding the connecting plates with the box-shaped section steel column; by changing the lengths of studs, the requirement of misaligned connection of reinforcing steel bar joints is met, so that stress concentration is avoided. Furthermore, the percentage of the area of the reinforcing steel bar joints reaches 50%, so that superstrong connection is realized. The quick-split type box-shaped section steel concrete column-H-shaped steel concrete beam connection node is higher in connection efficiency, and improves the node bearing capacity and ductility.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

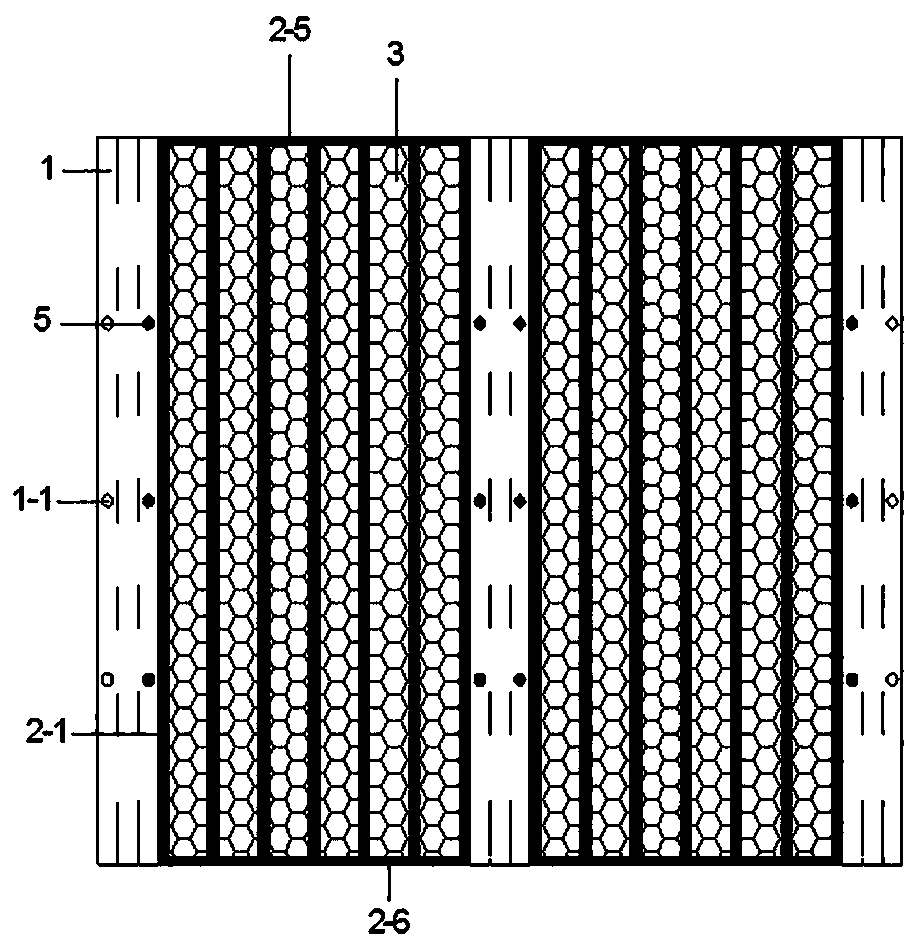

Novel road sound-insulation wall

PendingCN108487101AReliable connectionHigh node strengthNoise reduction constructionMiddle lineSteel plates

The invention relates to a novel road sound-insulation wall, and belongs to the field of road traffics. The novel road sound-insulation wall comprises an H-shaped stand column, a sound-insulation plate, connectors, a deformed steel bar and a nut, wherein 3-5 stand column bolt holes are uniformly formed in a middle line of a wing edge of every side of the H-shaped stand column in the height direction; the sound-insulation plate is divided into three layers; the inner layer is an inner-layer corrugated plate, the middle layer is sound-insulation cotton, and the outer layer is an outer-layer steel plate; the connectors have symmetric E-shaped structures and are positioned on the left side and the right side of the sound-insulation plate; a transverse connector reinforcing plate is arranged inthe middle of the sound-insulation plate; the inner-layer corrugated plate is formed by bending a straight steel plate and consists of semi-circular sections and horizontal sections; the length of each horizontal section is 1 / 6-1 / 4 of the diameter of the corresponding semi-circular section; linearity is corrugations which are uniformly protruded; and the area of noise reflection of the sound-insulation plate can be increased. The novel road sound-insulation wall has the beneficial effects and advantages that the novel road sound-insulation wall is reliable in connection, high in joint strength, obvious in sound-insulation effect, convenient to convey, long in service life, short in construction period, simple to mount and convenient to maintain and repair, and assembled components can bedirectly prefabricated in factories.

Owner:SHENYANG JIANZHU UNIVERSITY

Preparation method of carbon fiber-reinforced moso bamboo serving as secondary structure of steel structure

InactiveCN102392535BReduce steel consumptionMeet low-carbon requirementsBuilding material handlingFiberCarbon fibers

The invention discloses a preparation method of carbon fiber-reinforced moso bamboo serving as a secondary structure of a steel structure. The method comprises the following steps of: selecting dried moso bamboo; winding a layer of carbon fiber cloth between every two bamboo joints of the moso bamboo for bonding to hoop and constrain the moso bamboo with the carbon fiber cloth; reinforcing the tips of the moso bamboo by using carbon fiber cloth by wounding two layers of carbon fiber cloth on the tips of the moso bamboo to enhance the joint strength of the moso bamboo; locally punching the tips of the reinforced moso bamboo; and connecting the moso bamboo with other moso bamboos or steel structures with bolts. In the invention, the moso bamboo is constrained by using the carbon fiber cloth, so that the compression strength and bending strength of the moso bamboo are enhanced remarkably, and the moso bamboo can be connected with other moso bamboos or other steel structures conveniently.

Owner:SHANGHAI JIAO TONG UNIV

A foundation pit support system and its construction method used in expansive soil areas

The invention discloses a foundation pit support system applied to expansive soil regions. The foundation pit support system applied to the expansive soil regions is composed of a flexible impervious layer and a bond layer, wherein the bond layer is composed of a plurality of longitudinal bonding belts and a plurality of transverse bonding belts in a crossed mode; the crossed positions of the longitudinal bonding belts and the transverse bonding belts are fixedly provided with soil nails. The foundation pit support system applied to the expansive soil regions solves the problem of immersion of expansive soil foundation pits in rain and meanwhile solves the problem of abrupt increase of expansive force of immersed slopes. The invention also discloses a construction method of the foundation pit support system applied to the expansive soil regions. The foundation pit support system applied to the expansive soil regions is implemented layer by layer along with the digging depth of foundation pits and is characterized by comprising the steps of drilling soil nail holes and anchor holes; grout-fixing the soil nails and anchor bolts; laying the flexible impervious layer; laying a reinforcing bar mesh; setting the bonding layer; laying lattice beams; laying steel beams; closing after-pouring holes. The construction method of the foundation pit support system applied to the expansive soil regions is simple in operation and high in construction efficiency; the obtained foundation pit support system applied to the expansive soil regions is high in support capacity.

Owner:XIAN UNIV OF SCI & TECH +1

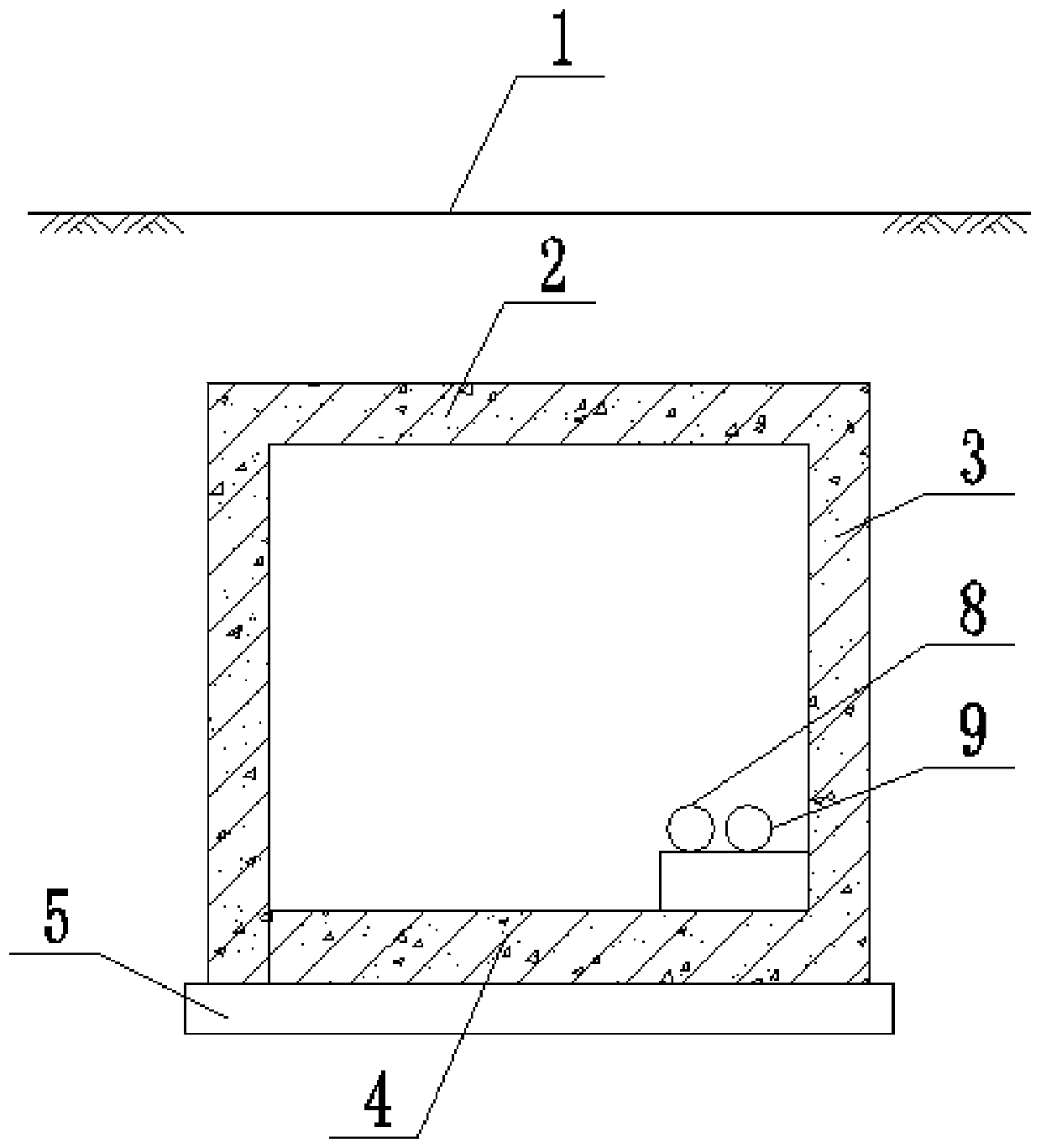

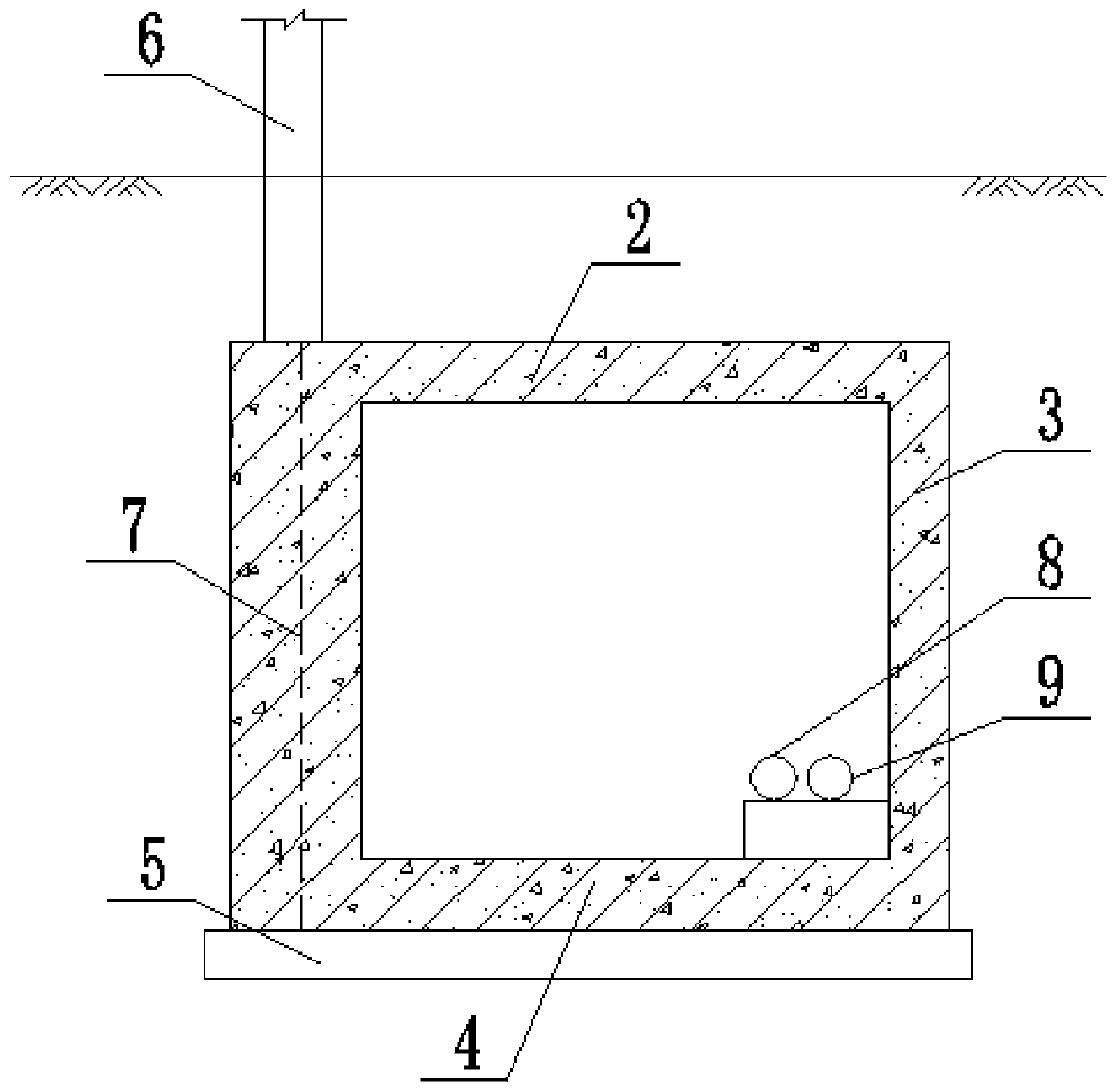

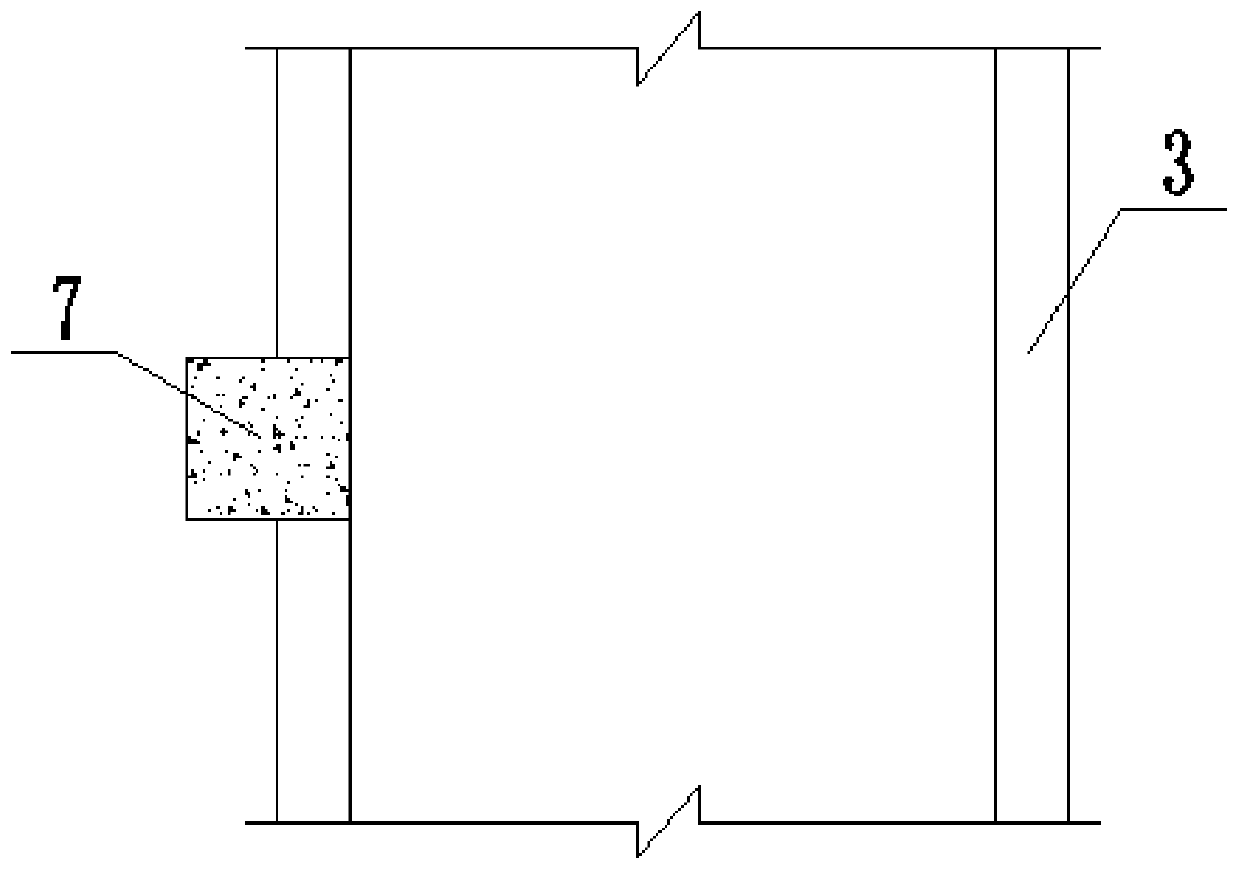

Intensively arranged municipal utility rod and shallowly buried type utility tunnel co-built foundation structure

PendingCN110700316AReduce base sizeHigh base strengthArtificial islandsUnderwater structuresUnderground spaceEnvironmental geology

The invention discloses an intensively arranged municipal utility rod and shallowly buried type utility tunnel co-built foundation structure comprising a utility tunnel body. The utility tunnel body comprises a top wall of a utility tunnel, a side wall of the utility tunnel and a bottom wall of the utility tunnel. The utility tunnel body is located under the ground. A utility tunnel cushion layeris arranged at the bottom of the utility tunnel body. The underground part of a utility rod and the wall of a cable tunnel shallowly buried after put into the ground are combined, the foundation structure of the utility tunnel body is utilized, the underground part foundation size of the utility rod can be reduced significantly, in addition, the influences of separated arrangement of the underground part foundation of the utility rod and the cable tunnel on separation of a road underground space and other underground facilities are reduced, and the underground space is utilized intensively andefficiently. In addition, through combined arrangement of the underground part of the utility rod and the wall of the cable tunnel, foundation strength of the utility rod and the node strength of theutility tunnel body are enhanced, and a mutual benefit effect is achieved.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

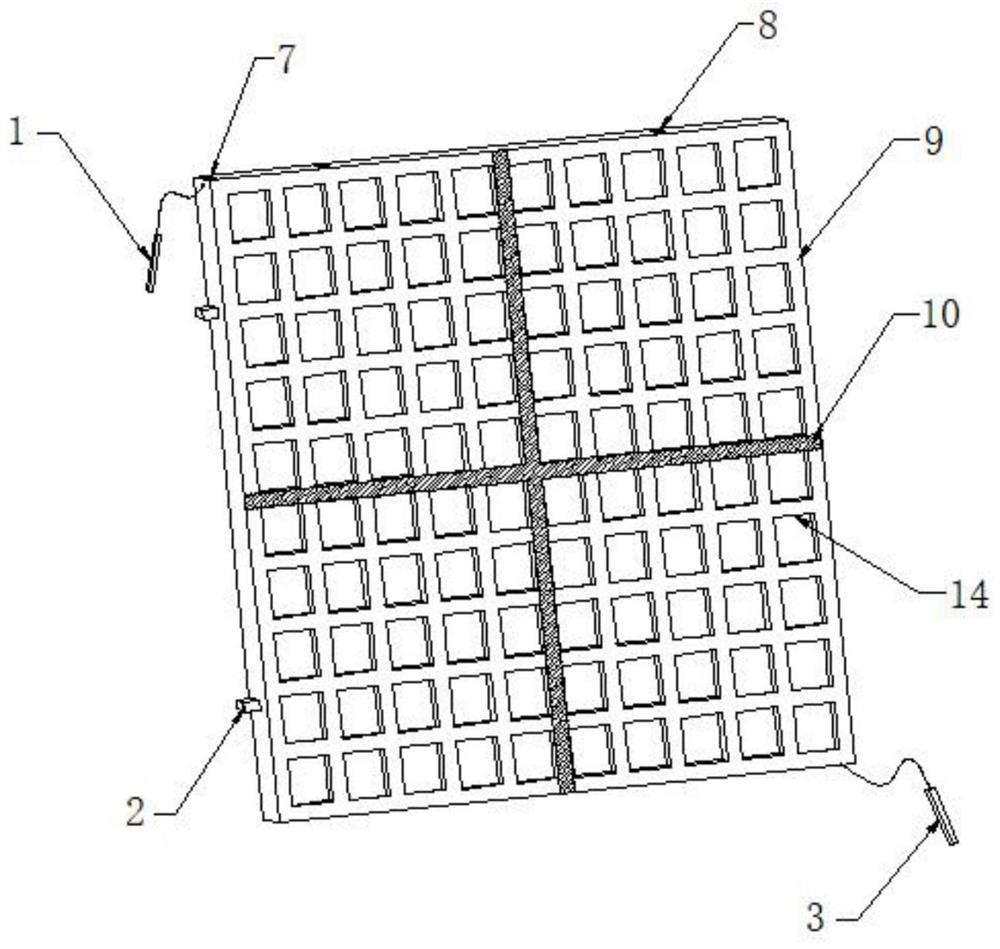

High-strength reticular grid for civil engineering

PendingCN111877521AHigh strengthImprove the friction systemFatty/oily/floating substances removal devicesSewerage structuresConstruction engineeringStructural engineering

The invention discloses a high-strength reticular grid for civil engineering. The high-strength reticular grid comprises a device body, a transverse plug pin is arranged at one side of the device bodyand fixedly connected with the device body, a plug pin hole is formed in the top of the device body, the plug pin hole is formed in the device body in a penetrating manner, and a groove is formed inthe top of the device body; and the groove is formed in the device body in the penetrating manner, and a protrusion is arranged at one side of the device body and is fixedly connected with the devicebody. According to the high-strength reticular grid for the civil engineering, damping filling strips are arranged in transverse ribs, so that the high-strength reticular grid can bear great impact force or constant pressure during working; and the damping filling strips can contract when the high-strength reticular grid is stressed, so that friction between all structures in the device body is reduced, the stability of an internal structure of the high-strength reticular grid is greatly improved, and the high-strength reticular grid can have a good market at present.

Owner:唐本顺

A convenient and clean cat climbing frame

ActiveCN110432173BReduce the chance of infectionProtect healthTaming and training devicesDiseaseEngineering

The invention discloses a convenient and clean cat climbing frame, which comprises a bottom plate, a rest mechanism is arranged on the bottom plate, a bracket is fixed on one side of the rest mechanism on the bottom plate, and a plurality of first brackets are arranged on the bracket. A climbing mechanism, the first climbing mechanism is provided with a second climbing mechanism; the bottom plate is provided with a rest tube, and the rest tube is provided with a first climbing plate, and the number of the rest tubes is two two half tubes, the two ends of the half tube are fixed with protruding blocks, the side of the first climbing board and the bottom plate close to each other is provided with a first card slot, and the first card slot and the first card slot are connected with each other. The protruding blocks are matched, and the thickness of the protruding blocks is equal to one-half of the width of the first slot. Beneficial effects: It can effectively clean its various parts separately, greatly improving the quality of cleaning, reducing the chance of cat infection, ensuring the health of cats, and at the same time releasing the nature of cats, ensuring their exercise volume, and avoiding cat diseases. obesity.

Owner:HUZHOU TIANYUAN PET PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com