On-site prefabrication and installation construction method of long-span prestressed arch slab

A construction method and prefabricated installation technology, applied in the direction of manufacturing tools, building components, ceramic molding machines, etc., can solve the problems of no reinforcement treatment at the joints, easy misplacement of square wood skeletons, and structural integrity effects, so as to improve the construction Efficiency, reducing self-weight, and reducing the effect of steel pipe consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] This embodiment mode focuses on the embodiments related to the structure of the present invention.

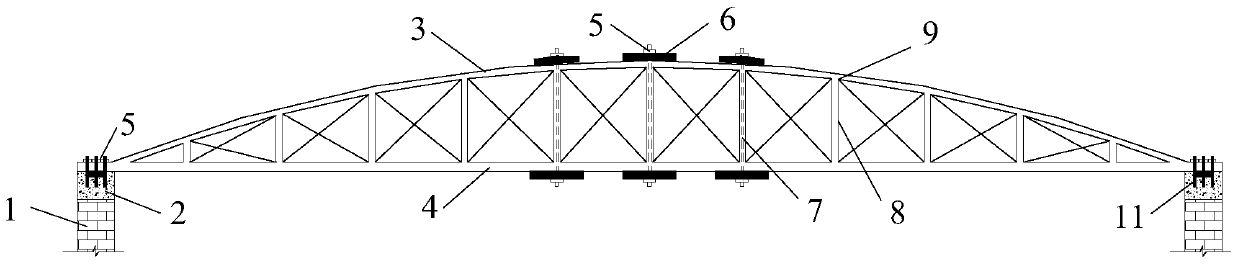

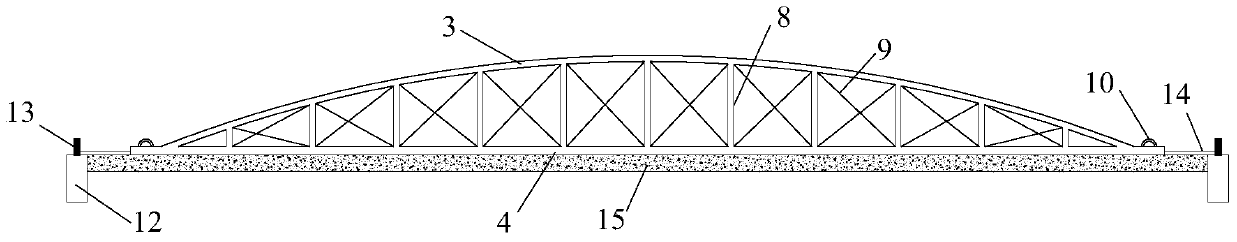

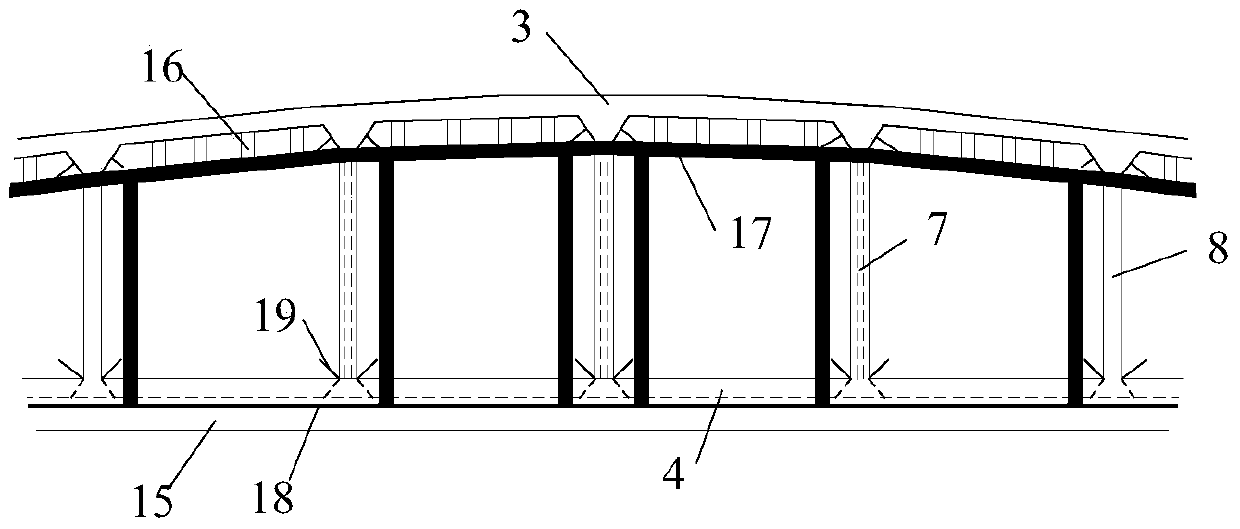

[0034] figure 1 , figure 2 They are the plan view of the long-span prestressed arch slab and the on-site prefabricated elevation of the long-span prestressed arch slab. As shown in the figure, the structure is mainly composed of the upper chord curved panel 3, the lower chord prestressed flat panel 4, the middle partition 8 and the oblique reinforcement 9; the upper chord curved panel 3 is a parabolic groove plate; the lower chord prestressed flat panel 4 is the prestress The groove plate, the prestressed tendon 14 is fixed by the anchor plate 13 on the pedestal 12; the connecting member of the upper chord curved panel 3 and the lower chord prestressed flat panel 4 is the middle partition 8, and the middle partition 8 is a concrete hollow with a rectangular frame structure Prefabricated slabs, the upper and lower ends of the middle partition 8 are provided with reserv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com