Wood beam column connecting structure

A technology of connecting structures and wooden beams and columns, which is applied in building construction and construction, can solve the problems of high labor intensity, low degree of mechanization, and slow construction speed of workers, so as to reduce the labor intensity and workload of workers and achieve a high degree of industrialization , the effect of high node strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

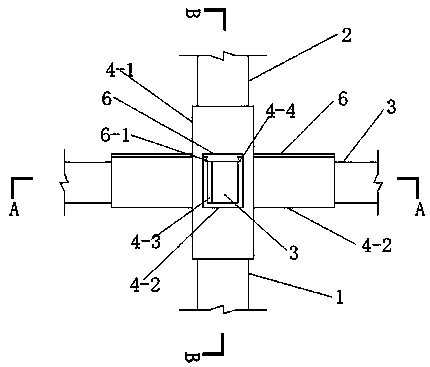

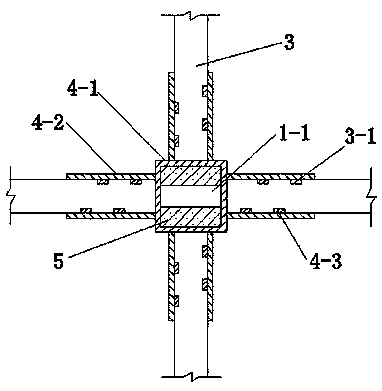

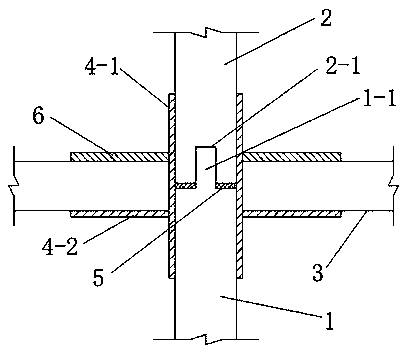

[0020] Such as Figure 1 ~ Figure 4 As shown, a wooden beam-column connection structure of the present invention includes a lower column 1 , an upper column 2 , a wooden beam 3 , a node connecting cylinder 4 , an inner partition 5 and a wedge-shaped cover 6 . Among them, the node connection cylinder 4 includes a box-shaped steel pipe 4-1 and a U-shaped sleeve 4-2 perpendicular to the outer surface of the box-shaped steel pipe 4-1. On both sides of the opening of the U-shaped sleeve 4-2, there are limited vertical sticking. Position protruding teeth 4-3, horizontally provided with wedge-shaped recesses 4-4, correspondingly, wooden beam 3 is provided with groove 3-1 matching with limit protruding teeth 4-3, and wedge-shaped cover plate 6 is provided with A wedge-shaped protrusion 6-1 matching the wedge-shaped recess 4-4; a tenon 1-1 is provided at the upper end of the lower column 1, and a matching mortise 2-1 is provided at the lower end of the upper column 2.

[0021] Further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com