Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Guaranteed traction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

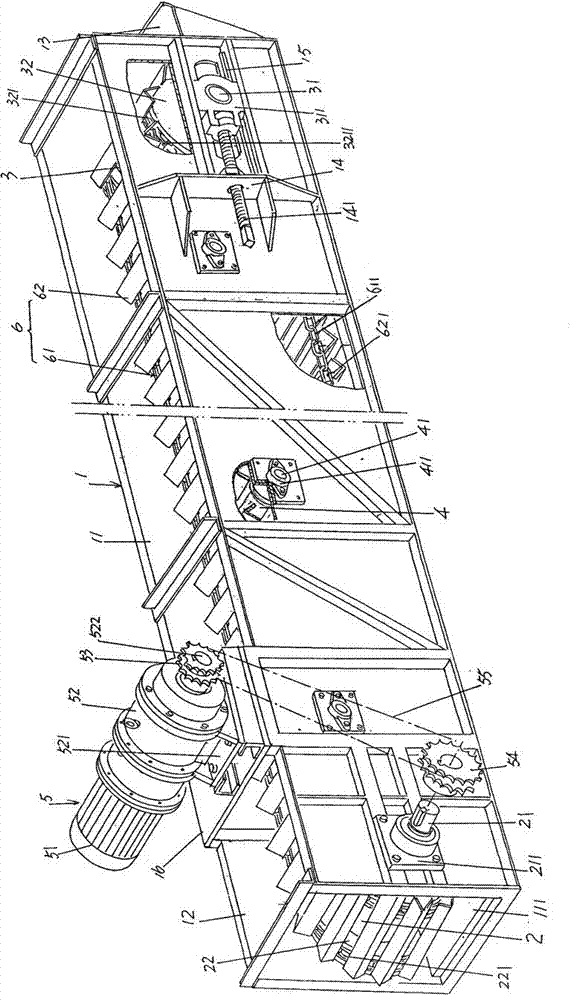

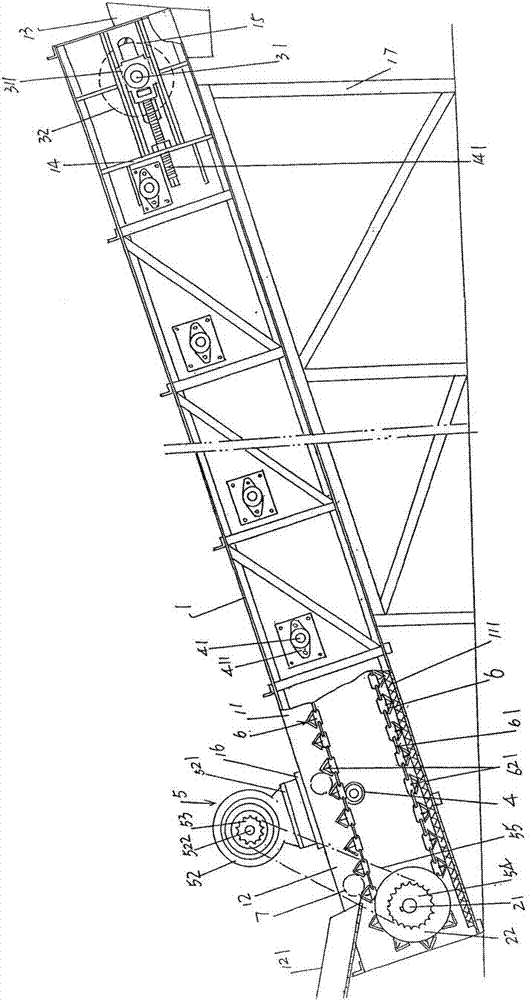

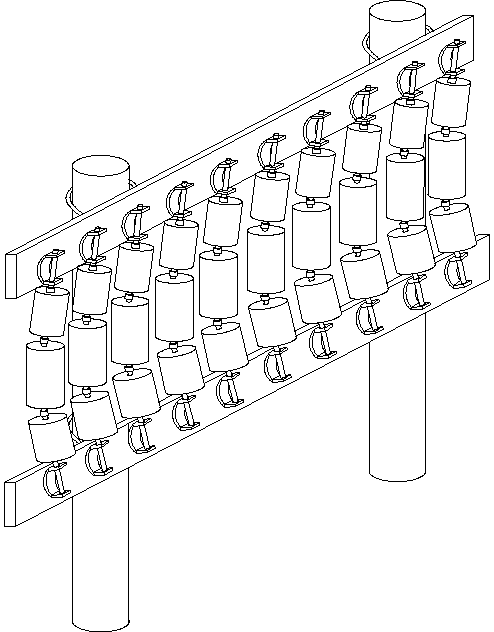

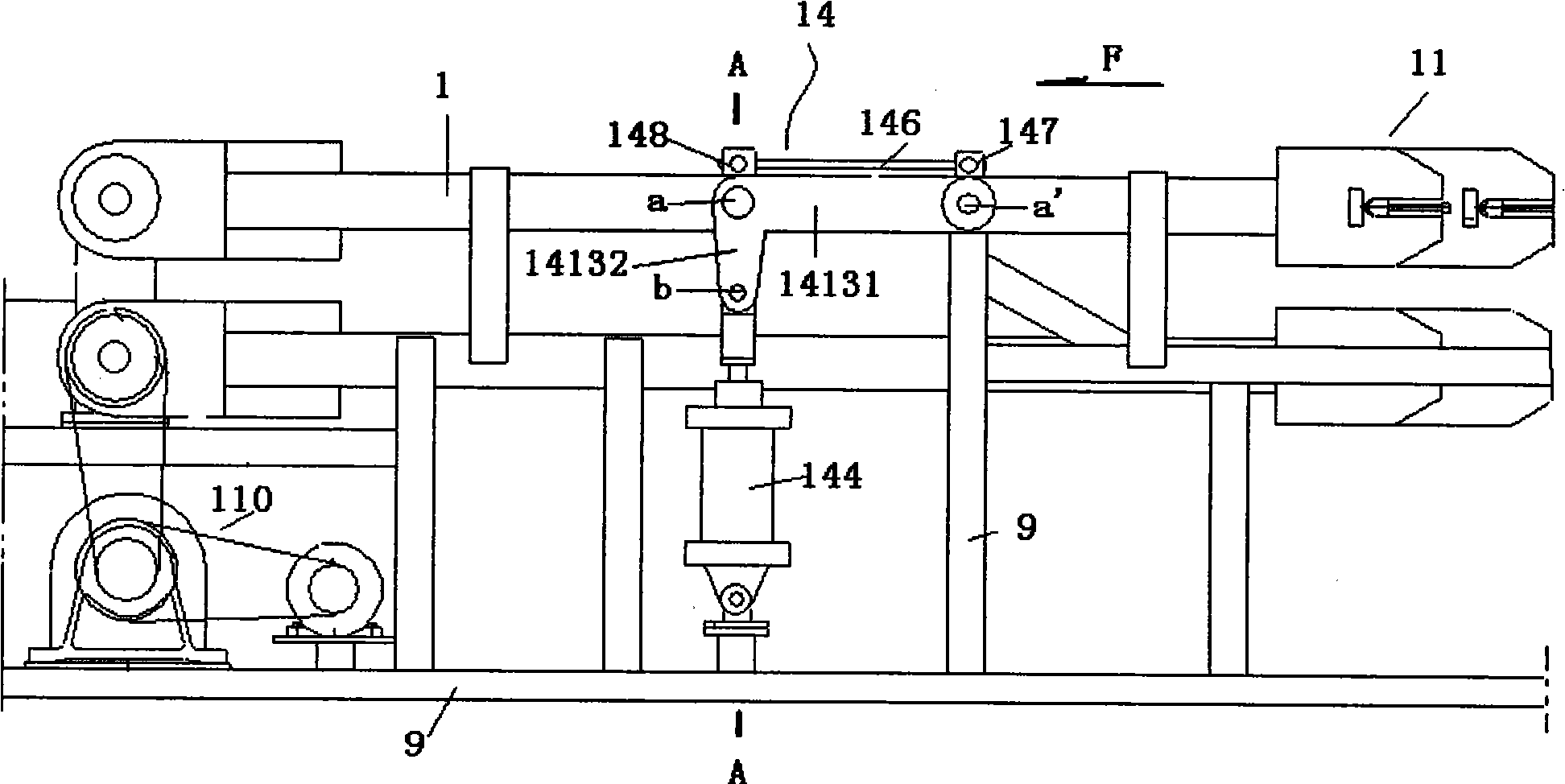

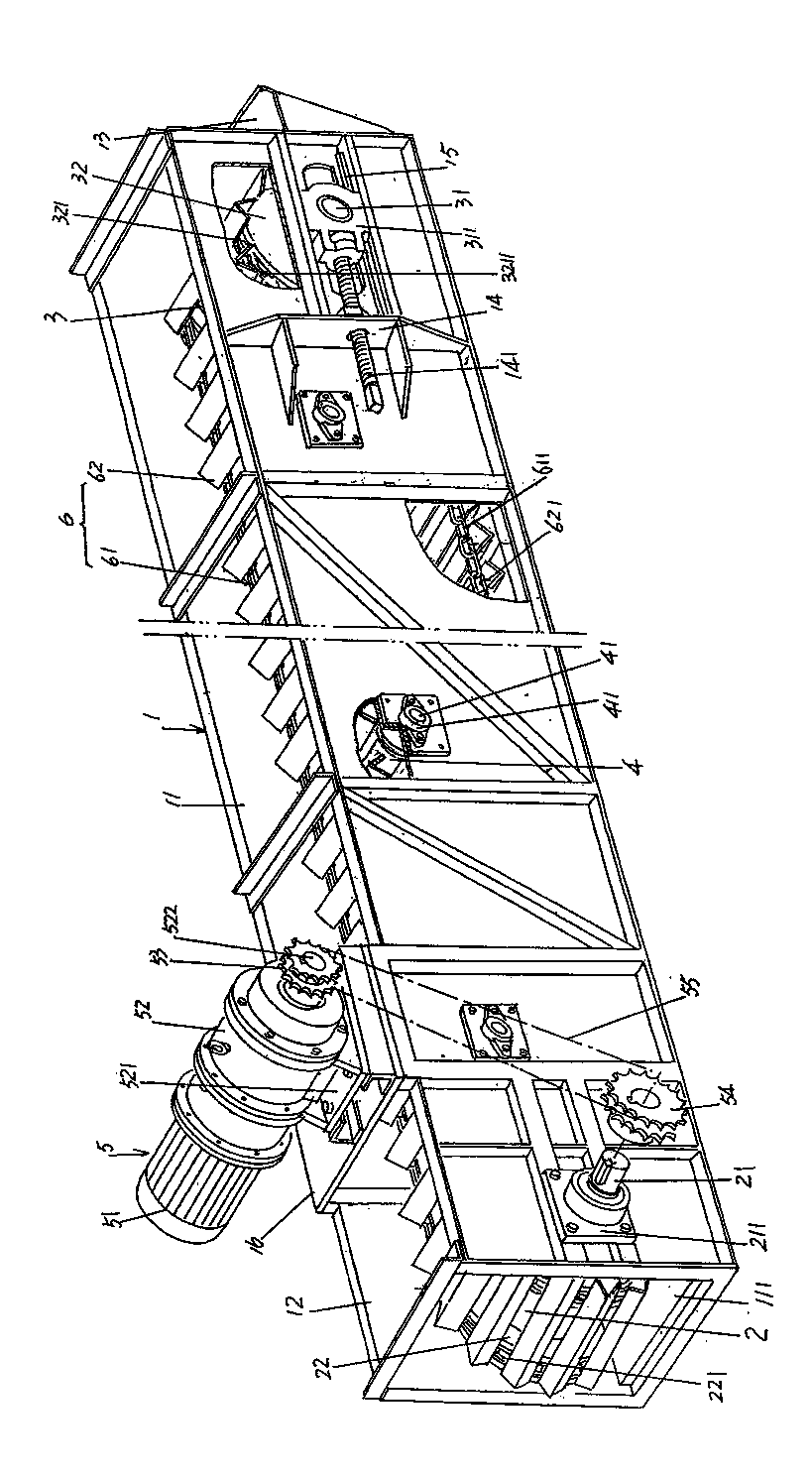

Steel ball conveyor device

ActiveCN103205554AGuaranteed traction effectImprove load effectFurnace typesHeat treatment furnacesSprocketSteel ball

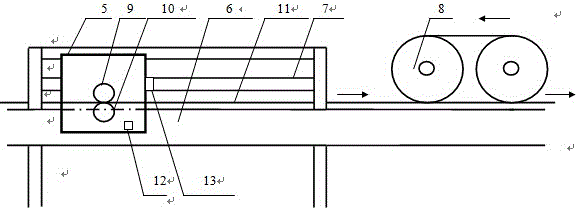

The invention discloses a steel ball conveyor device belonging to the field of conveying machinery. The steel ball conveyor device comprises a conveying box, a main driving roller, a direction-changing driving roller, a group of carrier rollers, a power transmission mechanism and a steel ball carrying mechanism, wherein a wear-resisting plate is arranged in a conveying cavity of the conveying box; the main driving roller is supported on the wall of the conveying box; chain traction chain sprockets are respectively formed at the two ends of the main driving roller; the direction-changing driving roller is supported on the wall of the conveying box; chain direction-changing traction chain sprockets are respectively formed at the two ends of the direction-changing driving roller; the group of carrier rollers are supported in the middle of the conveying box; the power transmission mechanism is arranged on the top of the conveying box; the steel ball carrying mechanism comprises a pair of curtain rail plate traction chains and a group of curtain rail plates; the direction-changing driving roller is supported on a direction-changing driving roller shaft head support bearing seat; the direction-changing driving roller shaft head support bearing seat is arranged a guide rail; the guide rail is arranged on the wall of the conveying box; the wall of the conveying box is provided with an adjusting screw rod seat which is provided with an adjusting screw rod; and the pair of curtain rail plate traction chains are respectively formed by chain links which are connected in a circulating way. The steel ball conveyor device is beneficial to unloading a steel ball, reliable in transmission and matching, good in firmness and long in service life, can guarantee the traction effect for the curtain rail plates, and is simple and convenient to operate, examine and maintain.

Owner:CHANGSHU FEIFAN METALWORK

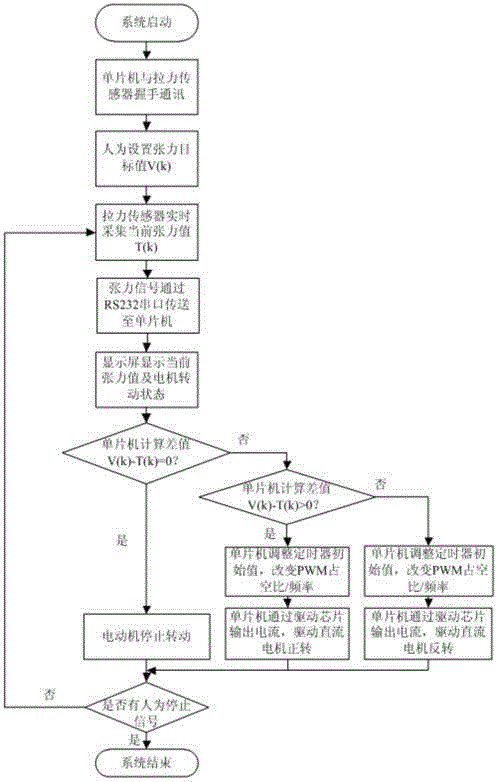

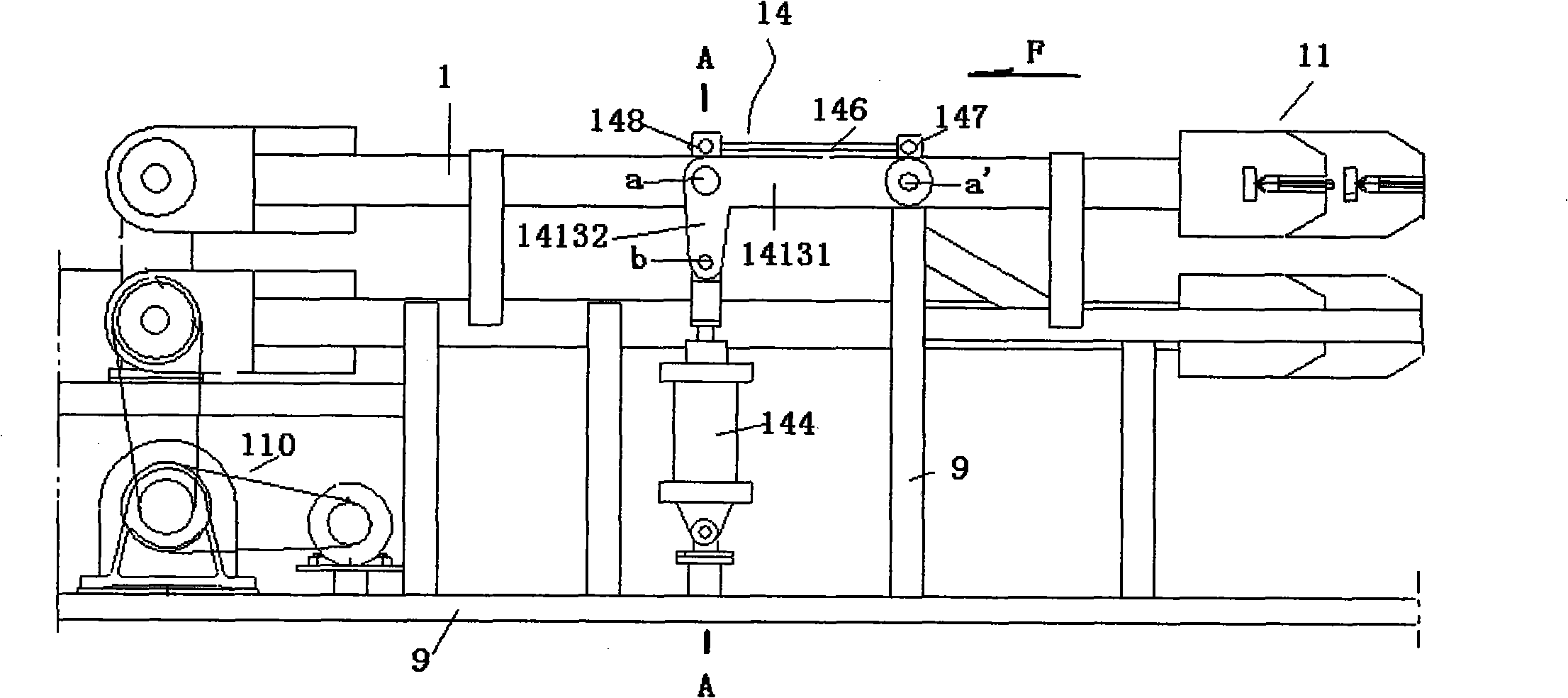

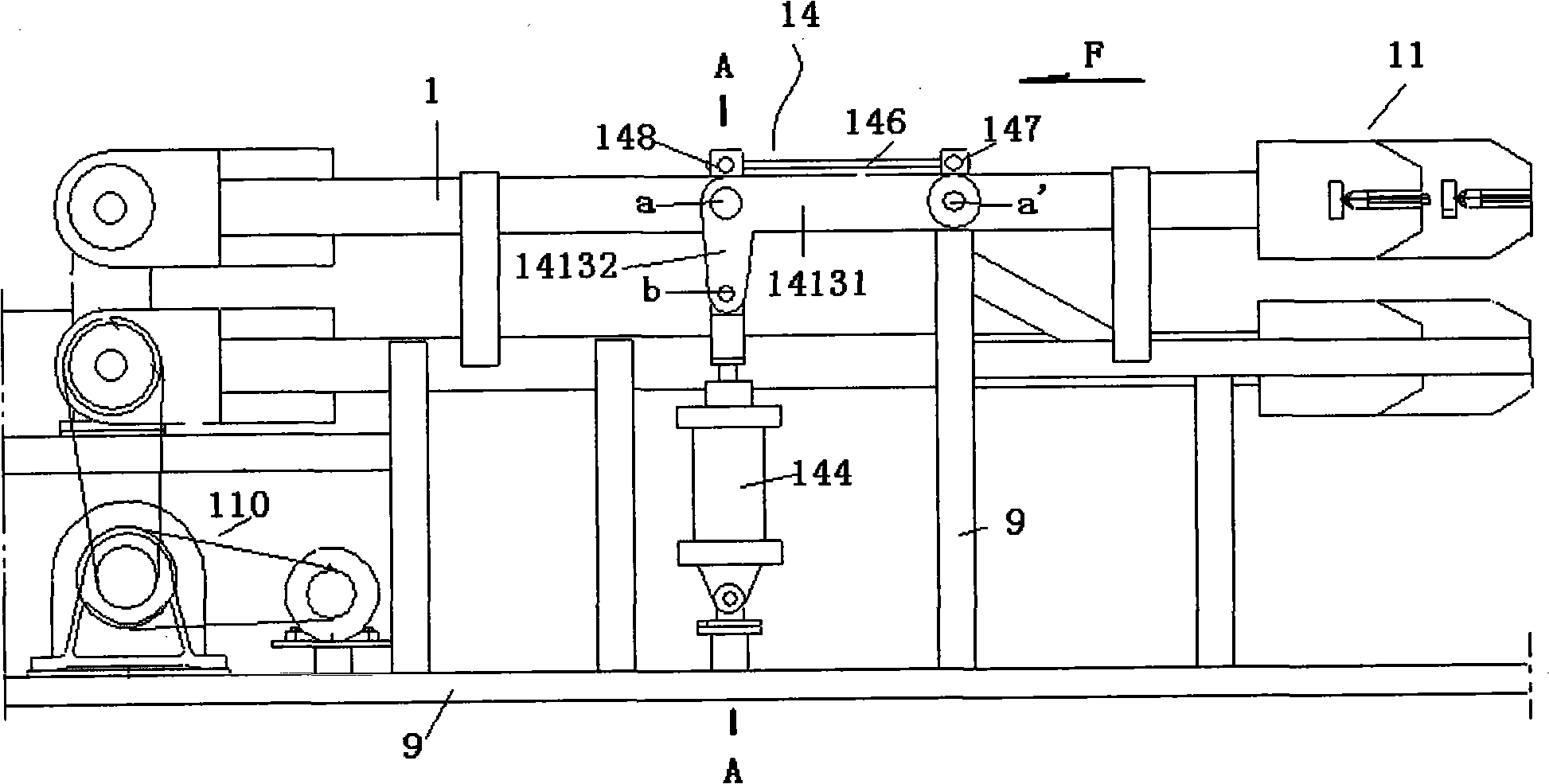

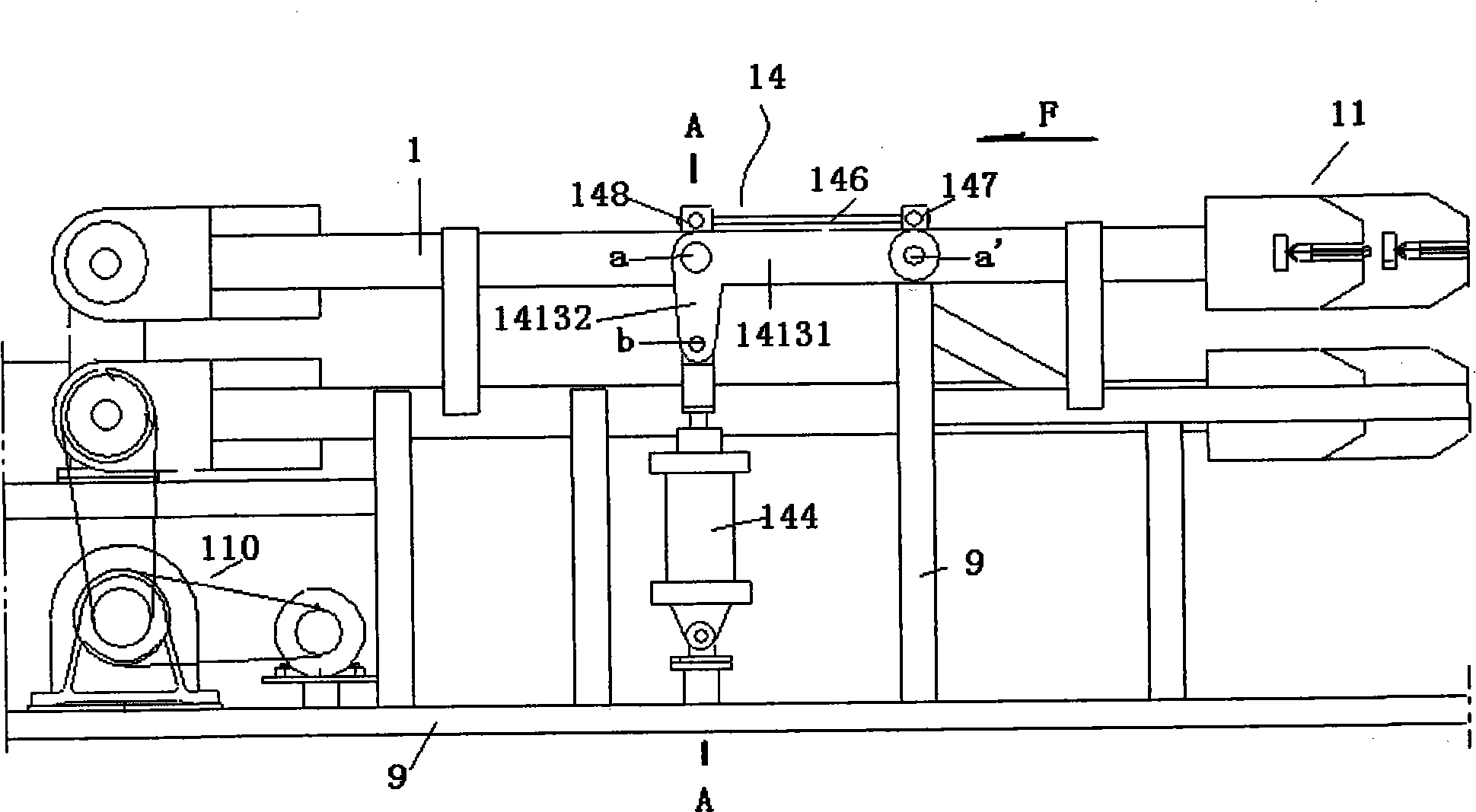

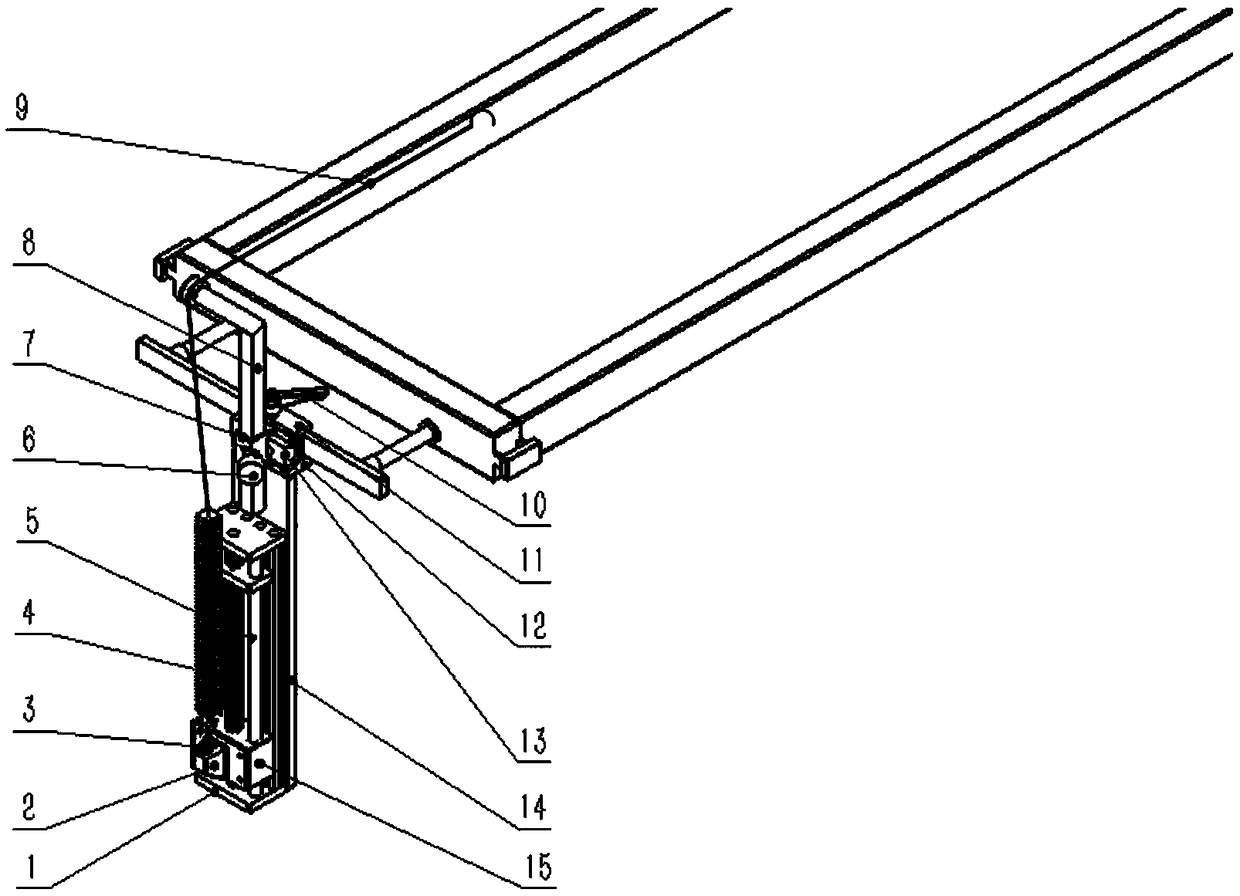

Tension adjusting device and method for steel wire ropes of bidirectional traction type rail transport machine

InactiveCN104692273AGuaranteed traction effectExtended service lifeWinding mechanismsEngineeringWire rope

The invention relates to a tension adjusting device and method for steel wire ropes of a bidirectional traction type rail transport machine. The adjusting device comprises a tension adjusting mechanism and a control system, wherein the tension adjusting mechanism comprises a motor, a lead screw, a lead screw nut and a tension sensor, an output shaft of the motor is connected with the lead screw, the lead screw nut is connected onto the lead screw, one end of the tension sensor is connected with the lead screw nut, the other end of the tension sensor is connected with a mounting base of a winch in the bidirectional traction type rail transport machine, and the mounting base is connected with a supporting frame fixed on the ground through a linear sliding mechanism; the control system comprises a signal feedback unit, a control unit, an execution unit and a power supply, the signal feedback unit consists of the tension sensor, and the execution unit consists of the motor. With the adoption of the adjusting device, the tension of the steel wire ropes can be adjusted automatically in real time, so that the steel wire ropes are in the optimal tensioned state all the time.

Owner:SOUTH CHINA AGRI UNIV +1

Buffering protective device for road safety

ActiveCN104032693AImprove buffering effectReduce stressRoadway safety arrangementsStructural engineeringMechanical engineering

Owner:CHINA MCC5 GROUP CORP

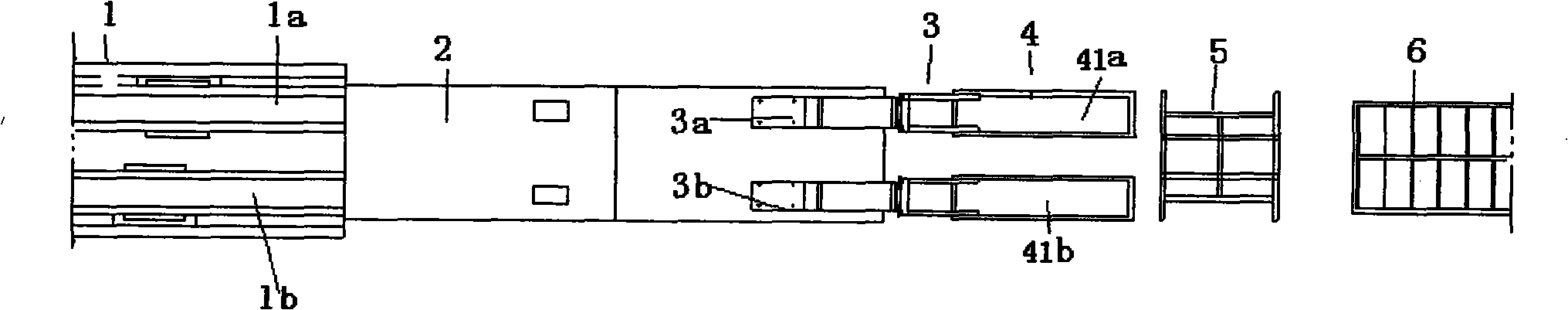

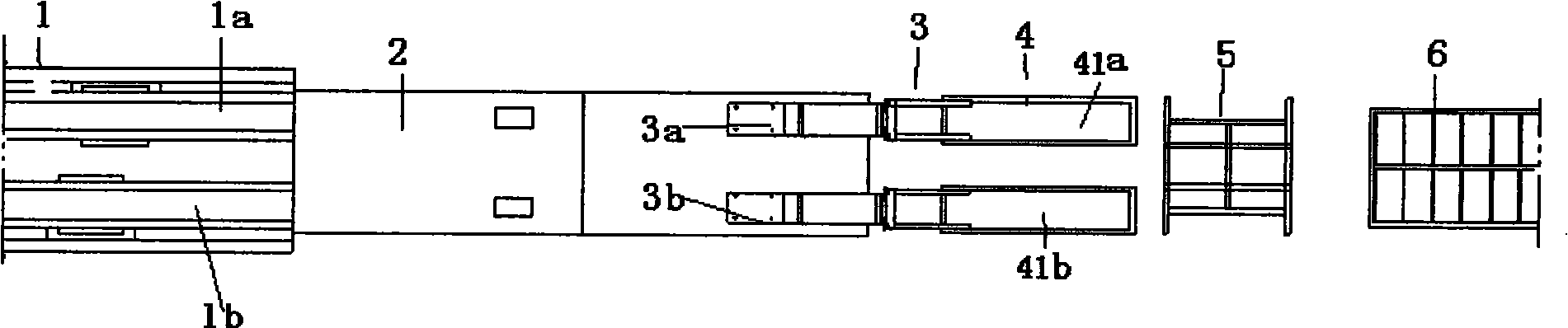

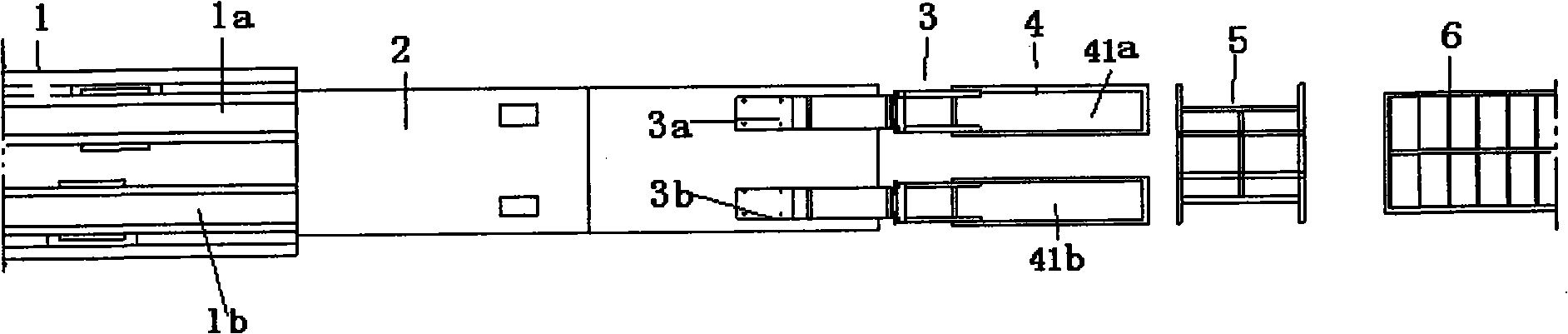

Traction mechanism for composite material pulling extruding machine and pulling extruding machine thereof

ActiveCN101264668ASignificant advantagesSignificant beneficial effectTubular articlesProduction rateYarn

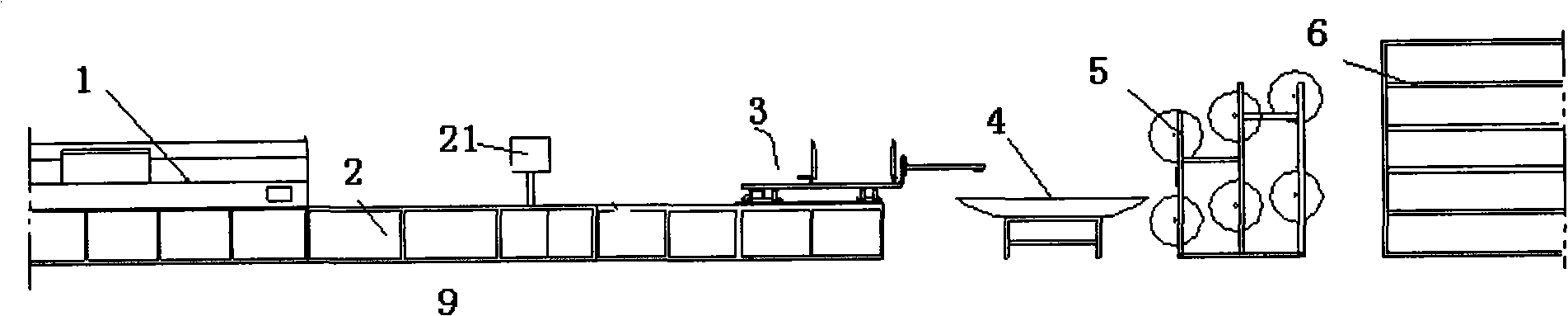

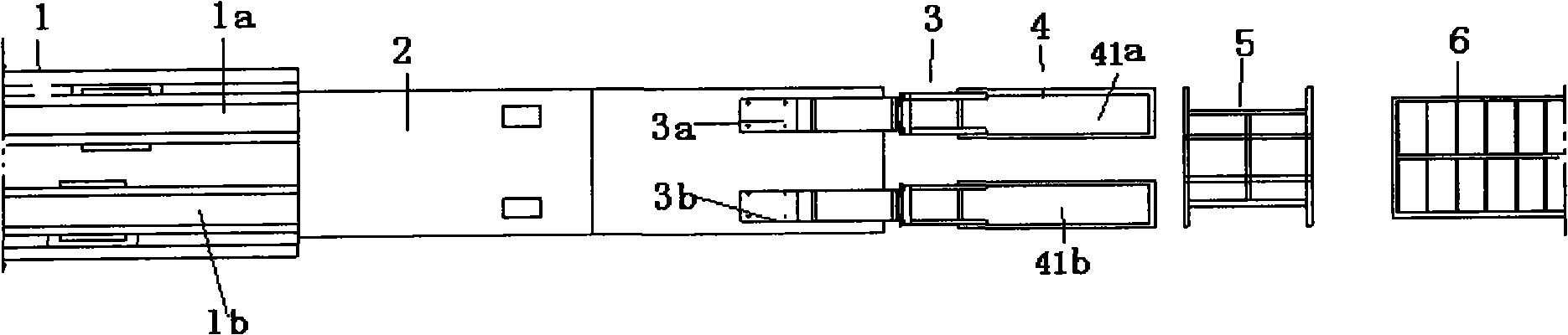

The invention relates to a traction mechanism of a composite material pulling and extruding machine as well as the pulling and extruding machine, in particular to a piece of equipment for hot molding glass yarns and glass mats into continuous profile material; wherein, the traction mechanism comprises a first and a second traction mechanism, one end of a thermoplastic forming mold is adjacent to the traction mechanism, and the other end is adjacent to a dip coating member; the thermoplastic forming mold comprises a first and a second thermoplastic forming mold mechanisms, which are of the identical structure and fixedly arranged respectively; a transmission member comprises a lower chain and an upper chain fitted and combined with the lower chain to form an extruding structure, thus constructing a chain transmission member, and the upper chain is arranged in a manner so that the upper chain can press or release the lower chain by the drive of a cylinder in a pneumatic pressing device; a traction speed detecting mechanism is arranged at the power output end of the lower chain and connected with a machine electric control system; a workpiece online speed detecting device is arranged on a workpiece output part and connected with the machine electric control system. The one-machine and two-channel traction equipment in the embodiment has the advantages of enjoying high production efficiency, realizing online detection, eliminating the slipping defects arising during the extrusion of the workpiece, and guaranteeing the traction effects.

Owner:天津市金锚科技发展有限公司

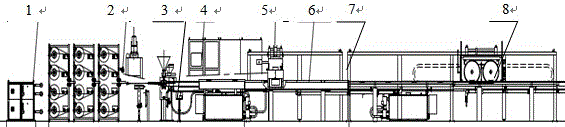

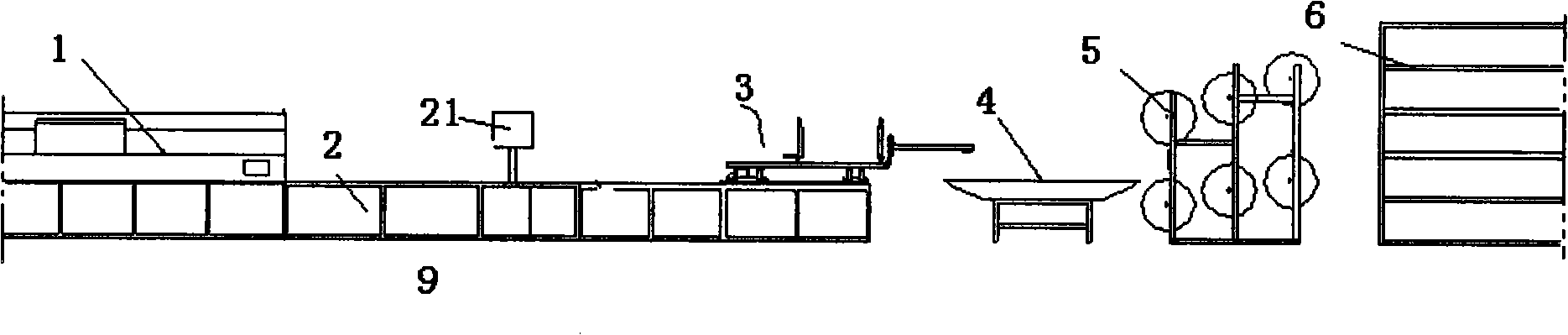

Optical cable casing pipe forming processing device

InactiveCN105904698AGuarantee the quality of productionIncrease production speedFibre mechanical structuresForm processingWater tanks

The invention relates to an optical cable casing pipe forming processing device including an optical fiber releasing frame, an extruder and casing pipe forming mold, a cooling water tank and a traction device. The optical cable casing pipe forming processing device is characterized in that an auxiliary traction device is arranged in the cooling water tank or between the cooling water tank and the traction device along the traction direction of an optical cable casing pipe; the auxiliary traction linear velocity of the auxiliary traction device is higher than the traction linear velocity of the traction device to draw the optical cable casing pipe. The optical cable casing pipe forming processing device has the beneficial effects: 1, residual length of the casing pipe is controlled by arrangement of the auxiliary traction device and is used for compensating the shrinkage amount of the casing pipe after cooling, relatively large after-shrinkage of common casing pipes in production is avoided, the production quality of the optical fiber casing pipe is ensured, the casing pipe production speed and follow-up process control are facilitated to be improved, and the production of complete-dry type casing pipes and PP casing pipes are facilitated; and 2, a longitudinal moving device can adjust the length of a casing pipe lengthened stretched section, and moves the casing pipe to an optimum traction position according to the detected temperature of the casing pipe, so as to ensure the traction effect and the processing quality of the casing pipe.

Owner:YANGTZE OPTICAL FIBRE AND CABLE JOINT STOCK LIMITED COMPANY

Draughting mechanism capable of preventing slip and pultrusion machine

ActiveCN101269544ASignificant advantagesSignificant beneficial effectTubular articlesProduction rateYarn

The invention relates to a slipping-proof traction mechanism and a pultrusion machine, and relates to a device which causes a glass yarn and a glass felt to be composite and thermoplastic to a continuous profile, wherein, the traction mechanism consists of a first traction mechanism and a second traction mechanism, a thermoplastic molding die part consists of a first thermoplastic molding die mechanism and a second thermoplastic molding die mechanism; a chain row transmission part consists of a lower chain row which is driven by power source, and an upper chain row which matches and connects with the lower chain row to form an extruding construction; a traction speed detecting mechanism which detects the traction speed of the chain row is arranged at the power output end of the lower chain row and is connected with the electric control system of a machine unit in an electric apparatus way; a product on-line speed detecting device which detects the output speed of the product is arranged at a product output part which is adjacent to a chain row transmission part, and is connected with the electric control system of the machine unit in an electric apparatus way. The single-machine double-line traction device has high productivity rate, can achieve the on-line detection and eliminate the slipping phenomenon as the product is pulled and extruded, thereby ensuring the traction effect.

Owner:天津市金锚科技发展有限公司

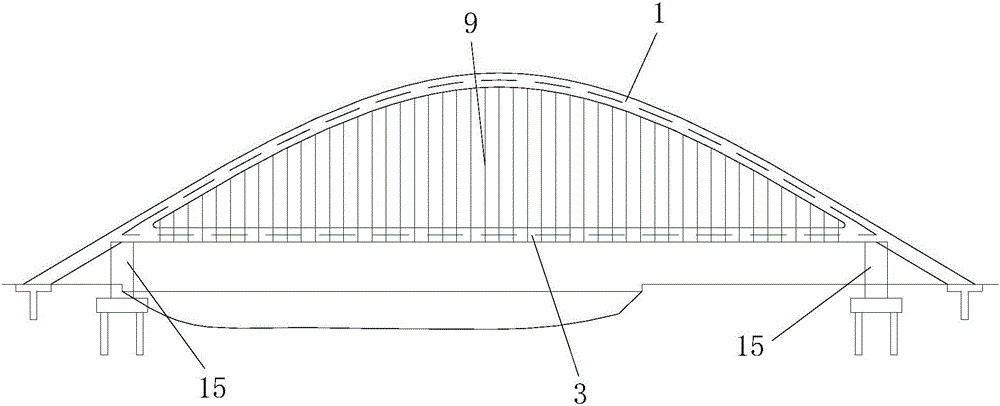

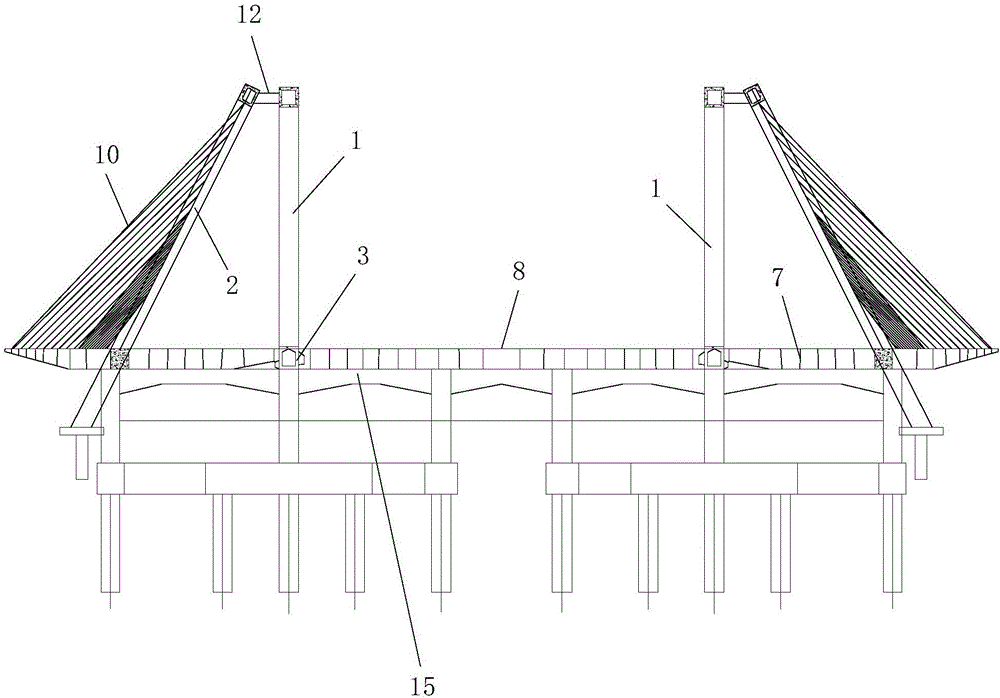

Large-span eccentric lean-against type steel box tied arch bridge surface towing erection construction system

ActiveCN106120565ASimple structureReasonable designBridge erection/assemblyArch-type bridgeTraction systemEngineering

The invention discloses a large-span eccentric lean-against type steel box tied arch bridge surface towing erection construction system. The system comprises a sliding system for supporting and longitudinal sliding of an upper structure of a bridge, a movable supporting device used for supporting the front side of the upper structure of the bridge and a traction system used for dragging the upper structure of the bridge to horizontally move forwards in the longitudinal bridge direction. The movable supporting device is located right in front of the sliding system. The sliding system comprises a temporary supporting structure, a lower sliding way and an upper sliding device. The movable supporting device is a supporting device which is located on a river way and can move forwards and backwards on the river way and comprises a barge and a temporary supporting frame for supporting the upper structure of the bridge. The traction system comprises a traction anchoring structure, a traction mechanism and a traction counter force seat, and the traction counter force seat is located right in front of the upper structure of the bridge. The large-span eccentric lean-against type steel box tied arch bridge surface towing erection construction system is simple in structure, reasonable in design, easy and convenient to construct, good in use effect and capable of simply, conveniently and quickly finishing the surface towing construction process of the large-span eccentric lean-against type steel box tied arch bridge.

Owner:NO 1 ENG LIMITED OF CR20G

Mechanical product cutting equipment for intelligent manufacturing

ActiveCN113547368AScientific and reasonable structureEasy to useFeeding apparatusMetal working apparatusElectric machineStructural engineering

The invention discloses mechanical product cutting equipment for intelligent manufacturing. The equipment comprises fixing frames; mounting plates are fixedly connected with the top ends of the two fixing frames; a transverse frame is fixedly connected with one side position between the two mounting plates; a conveying platform is fixedly connected with the position, corresponding to the bottom of the transverse frame, between the two fixing frames; a reciprocating translation mechanism is arranged at the top end of the transverse frame; and the reciprocating translation mechanism comprises a lead screw, a movable block, a movable frame, a rotating wheel, an electric push rod, a transverse rod and a rotating motor. The mechanical product cutting equipment for intelligent manufacturing is scientific and reasonable in structure, and safe and convenient to use. The reciprocating translation mechanism is arranged, so that power is transmitted through the cooperation of two transmission wheels and a first belt; through the telescopic characteristic of a tensioning spring, a cushion block is tightly attached to a guide wheel, so that the transverse rod and the guide wheel are driven to rotate; and then through cooperation of a second belt, the rotating wheel and the lead screw are driven to rotate, the movable block and one end of the movable frame are pushed, and a metal plate is cut.

Owner:JIANGSU VOCATION & TECHNICAL COLLEGE OF FINANCE & ECONOMICS

Composite material pultrusion machine

ActiveCN101269546ASignificant advantagesSignificant beneficial effectTubular articlesYarnMolding machine

The invention relates to a composite material pultrusion forming machine, and belongs to the field of a pultrusion molding device of composite materials, wherein, a traction mechanism consists of a first traction mechanism and a second traction mechanism which have same constructions; a thermoplastic molding die part consists of a first thermoplastic molding die mechanism and a second thermoplastic molding die mechanism; a plastic-dipped part has two plastic grooves which have same constructions; a felt-supplied yarn-passing mechanism has a bracket body which simultaneously corresponds to two pultrusion lines for supplying the glass yarn, the bracket body is provided with a felt pan which supplies the material for the first traction mechanism and a felt pan which supplies the material for the second traction mechanism; a front yarn-passing plate is arranged at the front row position of the bracket body adjacent to the plastic-dipped part, a rear yarn-passing plate is arranged at the rear row position adjacent to the yarn-supplied mechanism. The composite material pultrusion forming machine can effectively save the occupied area of the device, improve the productivity effect of the device, realize the on-line detection and eliminate the slipping phenomenon as the product is pulled and extruded, and ensure the traction effect, cause the glass yarn to gain the pre-stress from the yarn-released step, and effectively increase the intensity of the fiber reinforced plastic profile.

Owner:天津市金锚科技发展有限公司

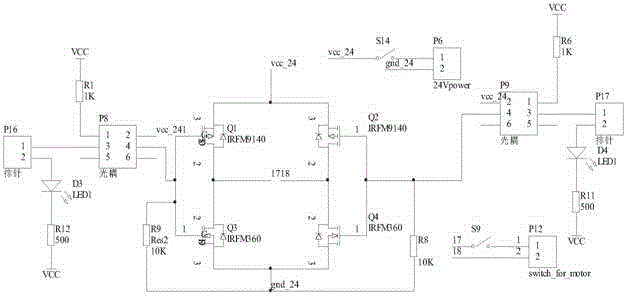

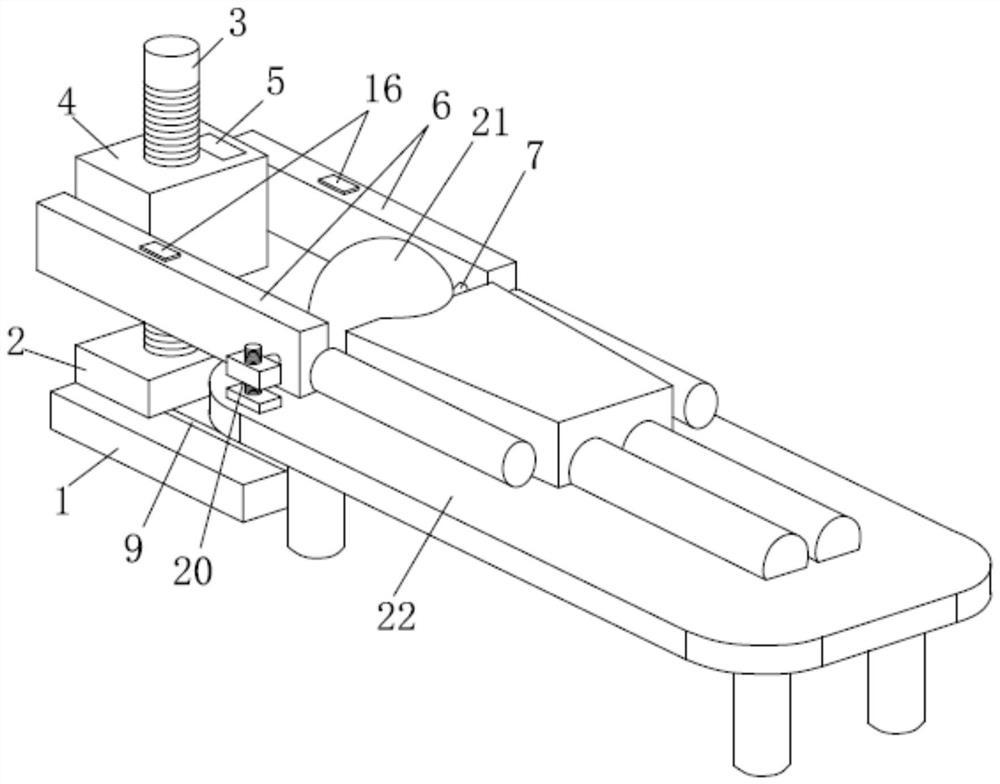

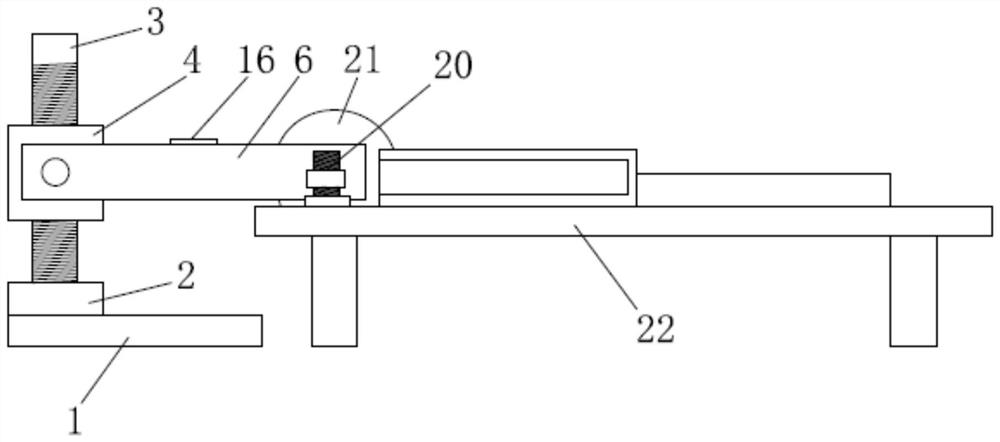

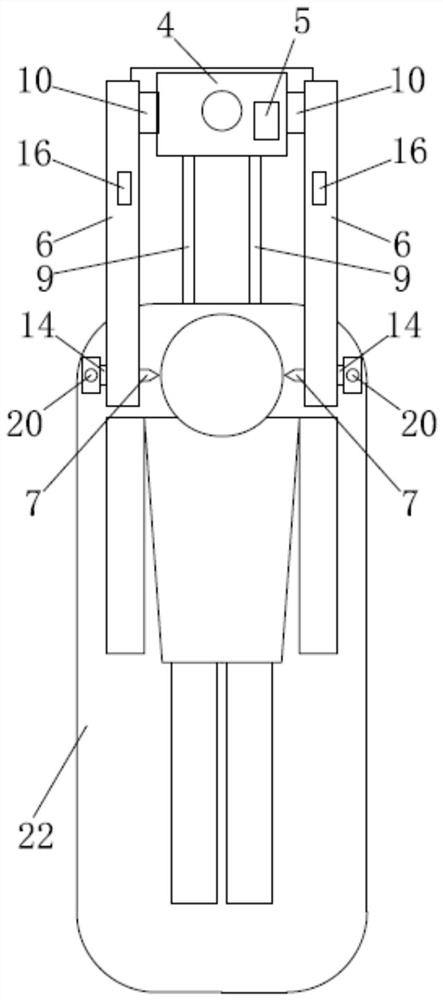

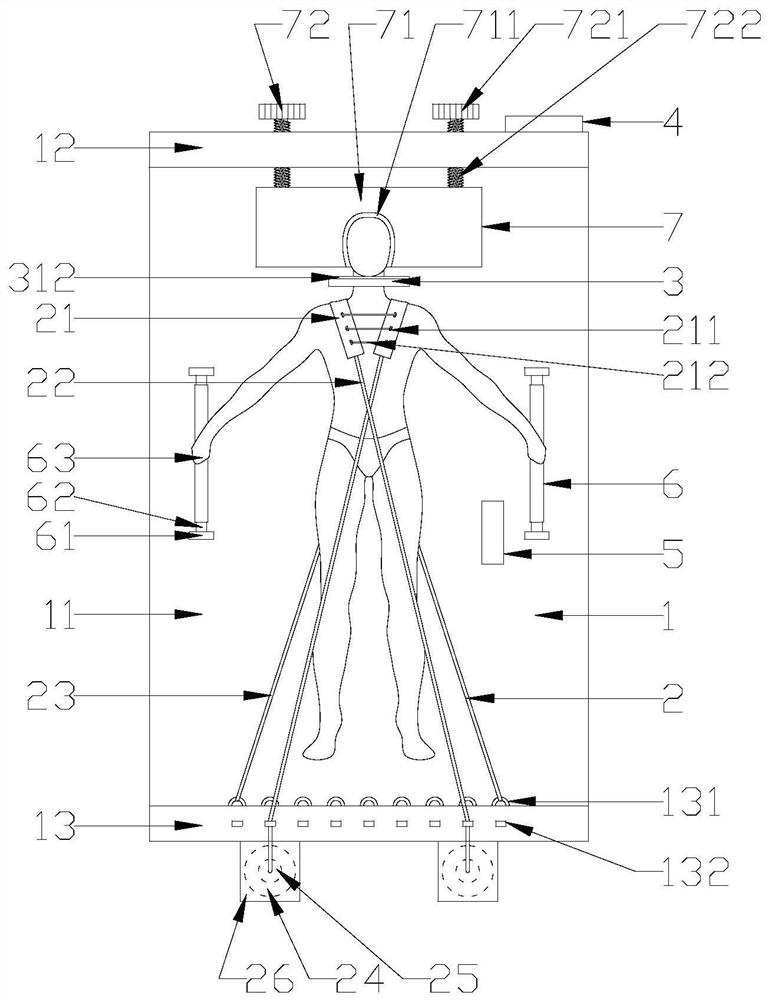

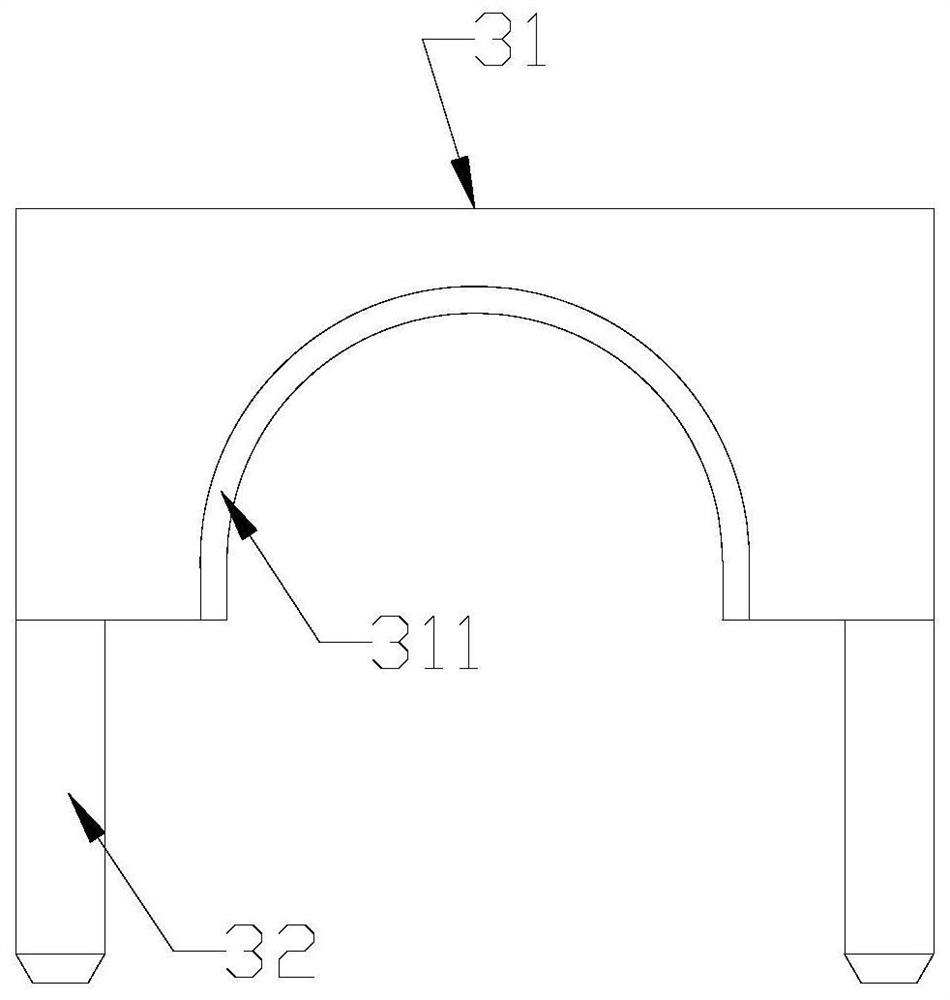

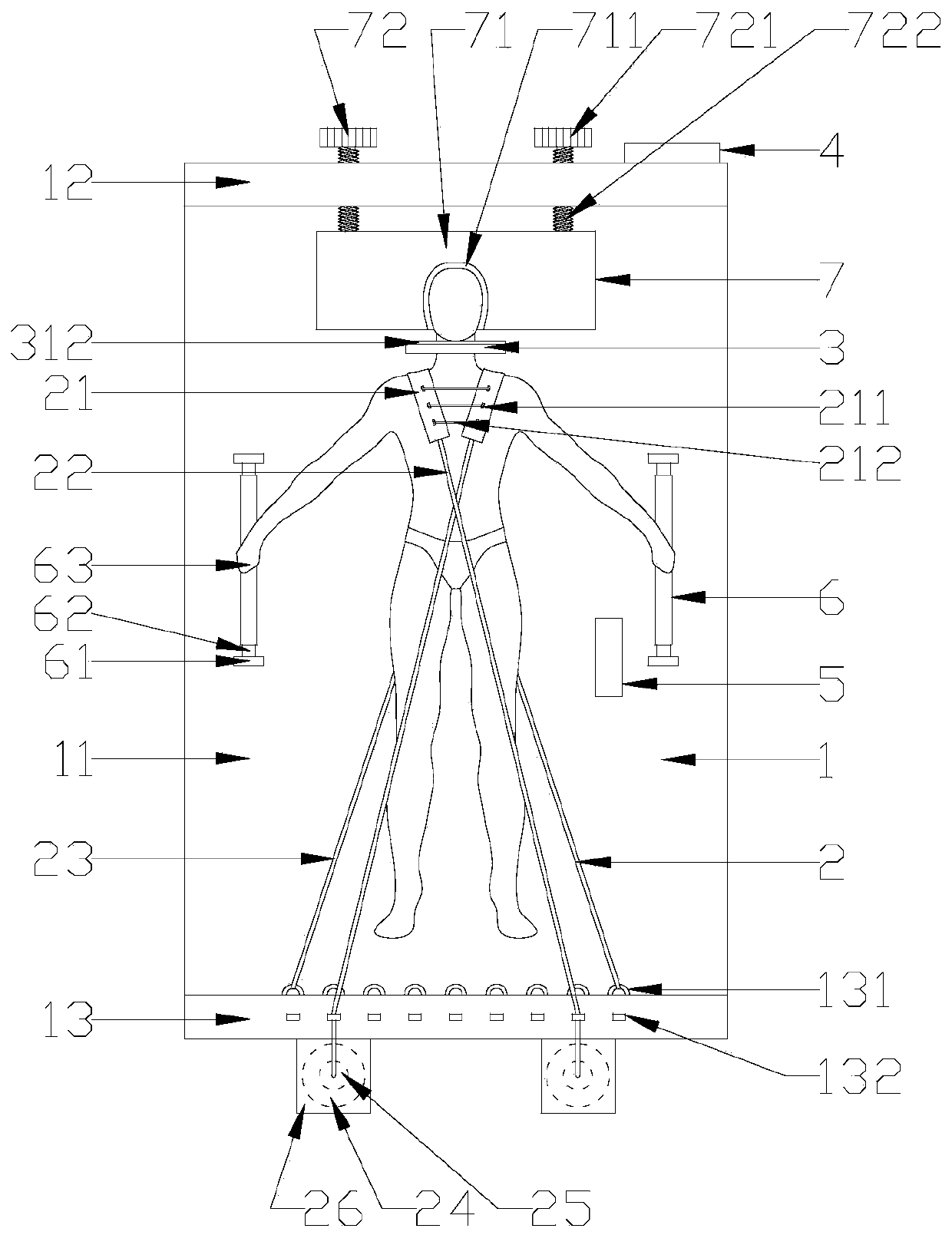

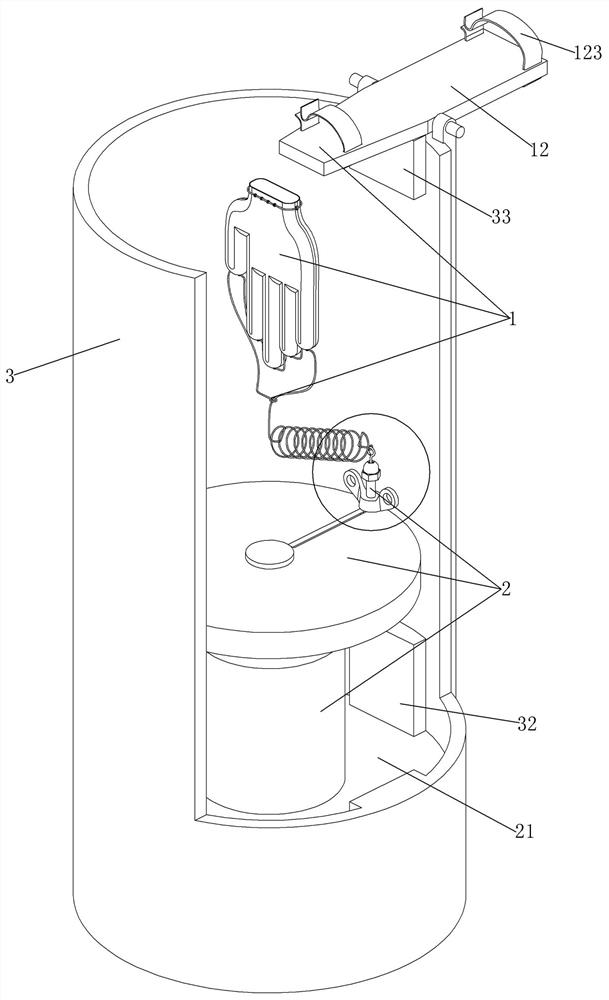

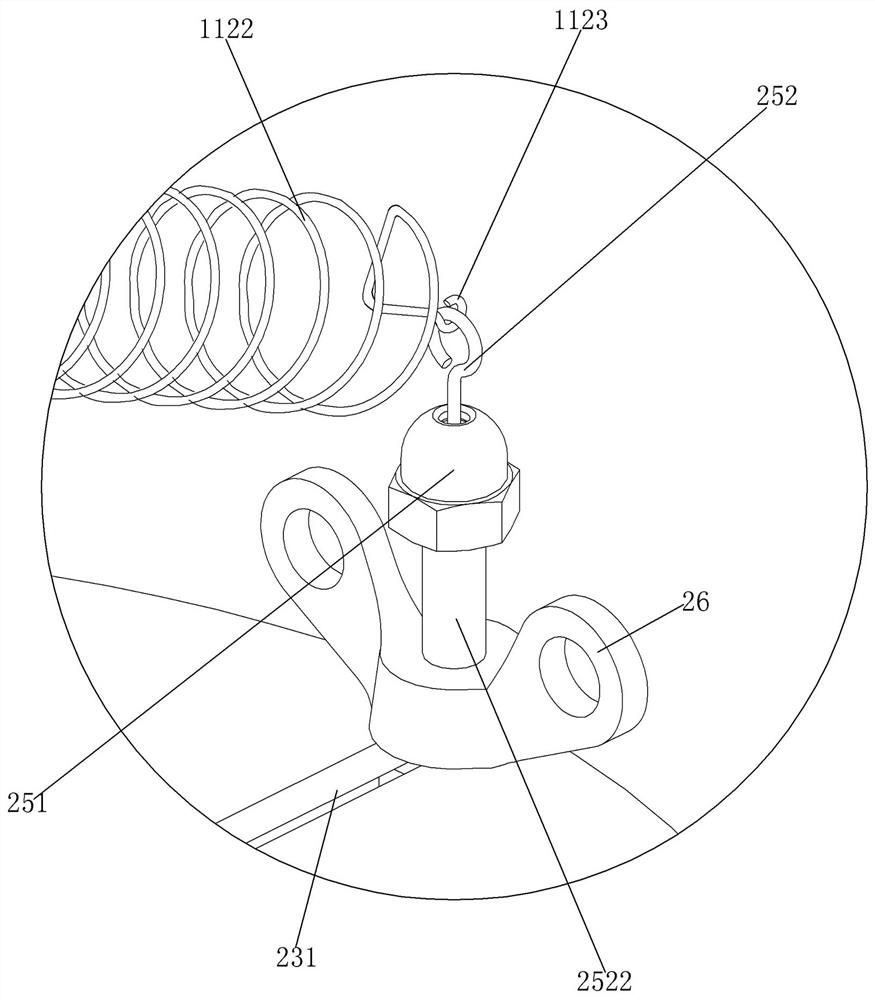

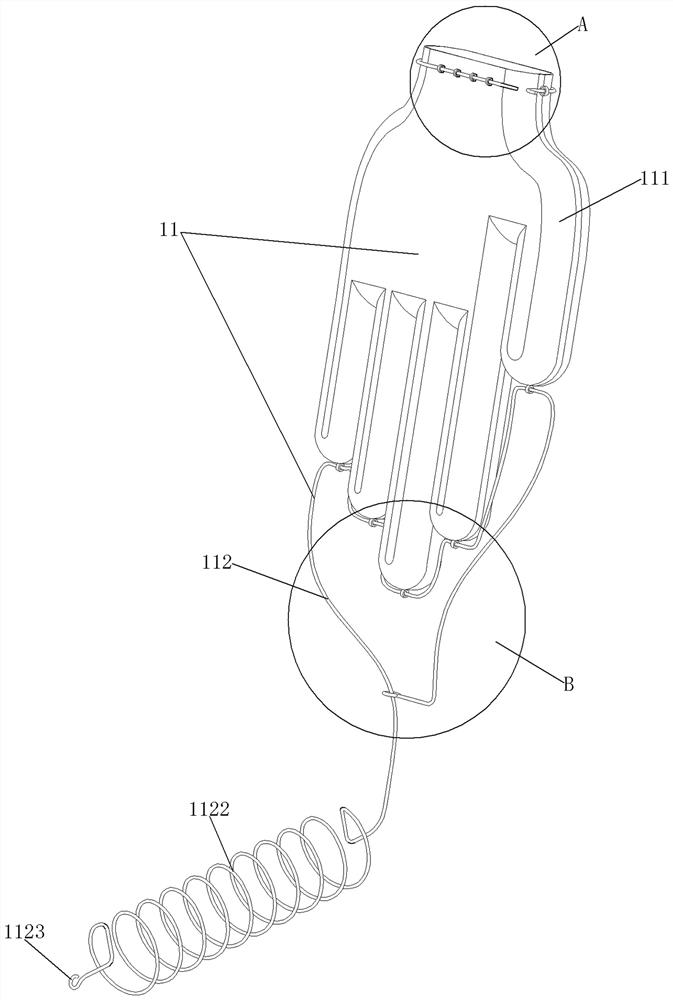

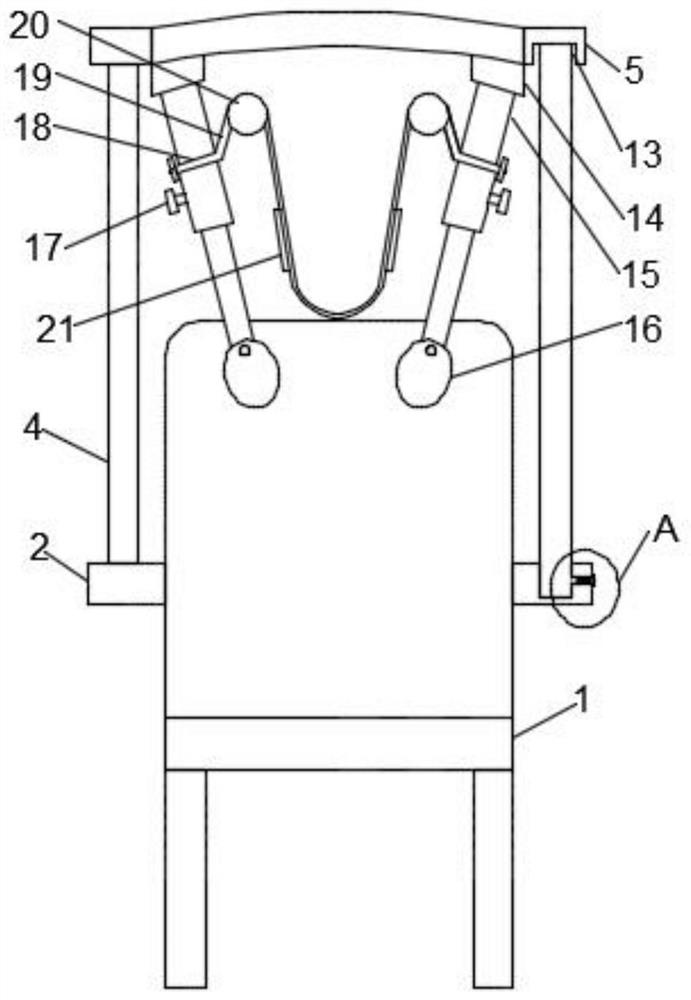

Intelligent bone traction tool, traction system and traction method

PendingCN113768595AAdjustable sizeAdjust sizeExternal osteosynthesisMedical equipmentTraction system

The invention discloses an intelligent bone traction tool, traction system and traction method, belongs to the field of medical equipment, and is used for intelligently monitoring traction force. The intelligent bone traction tool comprises a traction arm mounting frame, two traction arms and two traction thimbles, wherein the two traction arms are distributed in a bilateral symmetry mode, one ends of the traction arms are connected with the traction arm mounting frame, the traction ejector pins are mounted at the other ends of the traction arms, and the traction ejector pins mounted on the two traction arms are oppositely arranged. A bone clamping area is formed between the two traction ejector pins, and each traction ejector pin is provided with a pressure sensor capable of monitoring the traction force. According to the intelligent bone traction tool, the pressure sensors capable of monitoring the traction force are arranged on the traction ejector pins, then traction force data can be monitored through the pressure sensors, the situation that the traction force is too large in change and the like can be fed back to medical staff in time so that adjustment can be performed in time, and the traction effect is guaranteed.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

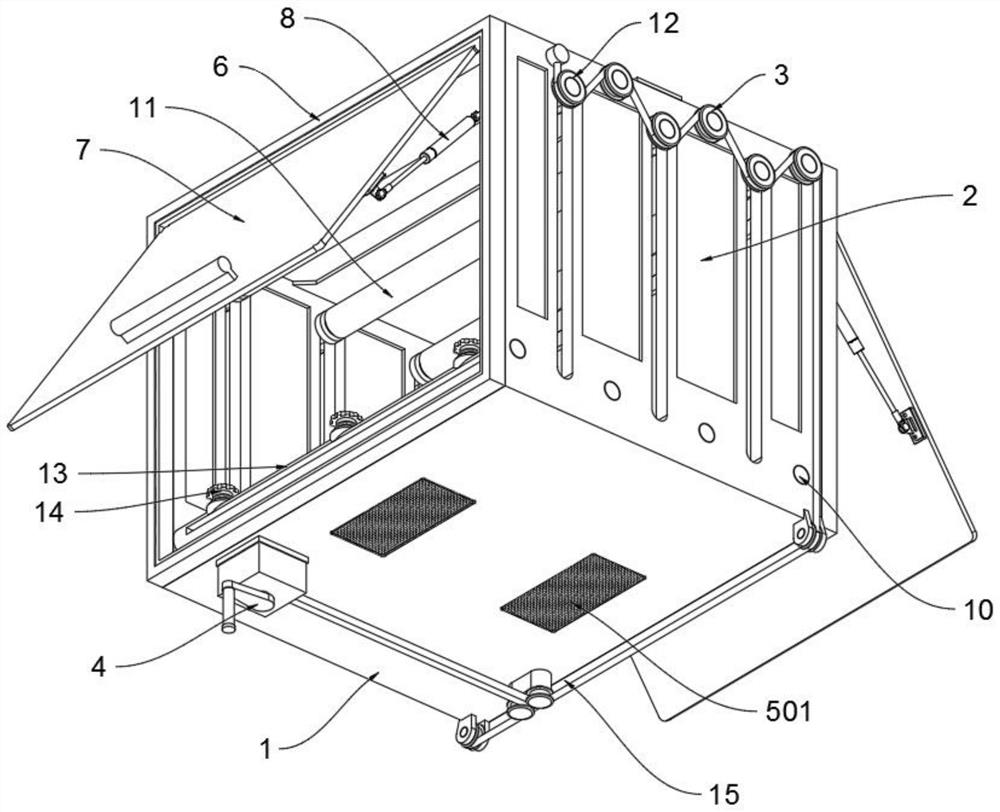

Working box with waste chip screening function for machining

The invention relates to the technical field of machining, and discloses a working box with a waste chip screening function for machining. The working box comprises a working table, the interior of the working table is of a hollow structure, the upper end of the working table is fixedly connected with a connecting plate, the connecting plate is U-shaped and has a forward opening, and the upper end of the connecting plate is fixedly connected with a protective cover. A storage groove is formed in the inner wall of the rear side of the connecting plate, sliding grooves are formed in the inner walls of the left side and the right side of the connecting plate, a cleaning plate is movably clamped in the storage groove, two telescopic holes are formed in the upper surface of the working table, and the two telescopic holes extend out of the surface of the rear side in the working table. According to the working box with the waste chip screening function for machining, waste residues can be recycled more conveniently, the time wasted by secondary screening is shortened, meanwhile, waste of raw materials is reduced, the cost of the screening equipment is reduced, the expenditure of financial resources is reduced, and meanwhile the labor intensity consumed by secondary screening of operators is reduced.

Owner:青岛拓沃机械科技有限公司

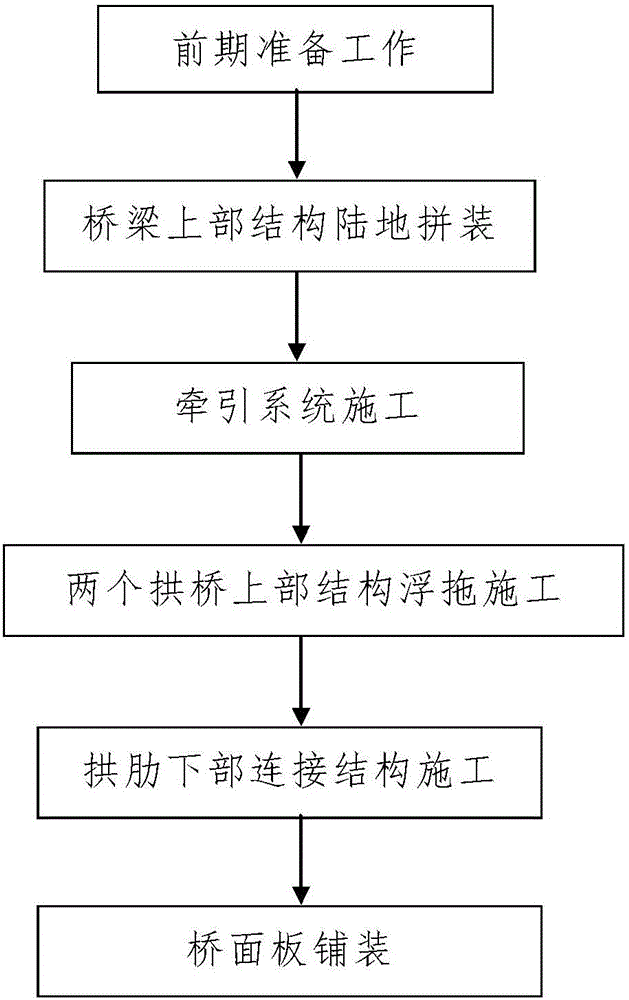

Large-span eccentric leaning type steel box tied-arch bridge float-towing erection construction technology

ActiveCN106087771ASimple construction methodReasonable designBridge erection/assemblyArch-type bridgeArchitectural engineeringBridge deck

The invention discloses a large-span eccentric leaning type steel box tied-arch bridge float-towing erection construction technology. The arch bridge to be constructed is a tied-arch bridge erected on a riverway, and a bridge superstructure comprises bilaterally symmetrically arranged arch bridge superstructures. The float-towing erection construction of the arch bridge to be constructed comprises the steps: 1, making first-phase preparations: sliding system construction and mobile support device processing; 2, bridge superstructure ground splicing: respectively splicing the two arch bridge superstructures by using sliding systems; 3, bridge superstructure float-towing construction, wherein the process is as follows: sliding system construction and arch bridge superstructure float-towing construction; 4, arch rib lower connection structure construction; and 5, bridge deck board paving. The technology is simple in step, and reasonable in design and simple and convenient in construction, the construction effect is good, the large-span eccentric leaning type steel box tied-arch bridge float-towing erection construction process can be completed simply and conveniently and quickly, and the construction quality is easily guaranteed.

Owner:NO 1 ENG LIMITED OF CR20G

Large-span eccentric lean-against type steel box tied arch bridge surface towing construction method

ActiveCN106120567ASimple construction methodReasonable designBridge erection/assemblyTraction systemArch bridge

The invention discloses a large-span eccentric lean-against type steel box tied arch bridge surface towing construction method. A constructed arch bridge is a tied arch bridge erected over a river way, and an upper bridge structure of the arch bridge comprises two upper arch bridge structures symmetrically arranged left and right. The surface towing construction process of the constructed arch bridge includes the steps that firstly, early stage preparation work is conducted, wherein a sliding system used for surface towing construction is constructed, and a movable supporting device used for surface towing construction is machined; secondly, the upper bridge structure is spliced on land, wherein the sliding system is used for splicing the two upper arch bridge structures; and thirdly, surface towing construction of the upper bridge structure is conducted in the following processes that 301, a traction system is constructed, wherein the traction system used for surface towing construction is constructed; and 302, surface towing construction of the upper arch bridge structures is conducted. By the adoption of the method, the steps are simple, design is reasonable, construction is easy and convenient, the construction effect is good, the surface towing construction process of the large-span eccentric lean-against type steel box tied arch bridge can be easily, conveniently and quickly finished, and the construction quality is easy to guarantee.

Owner:CHINA RAILWAY 20 BUREAU GRP

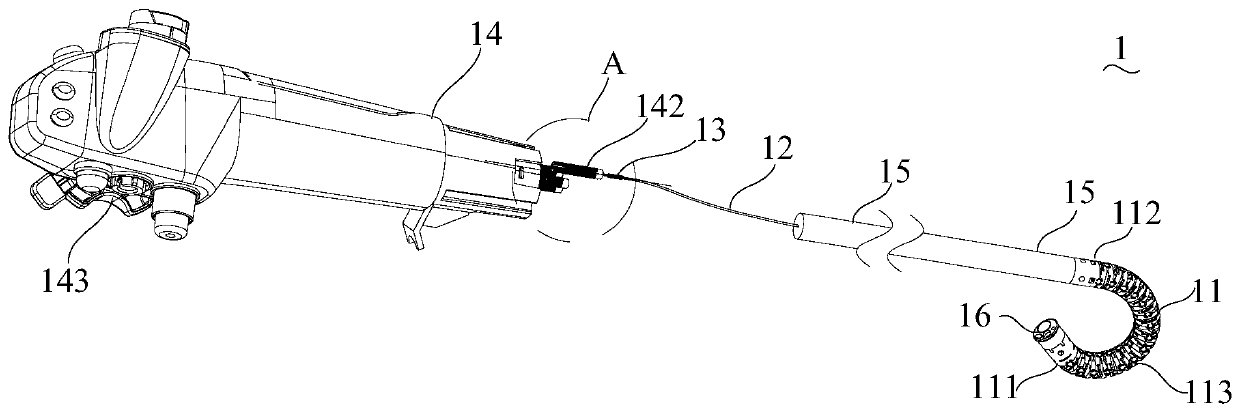

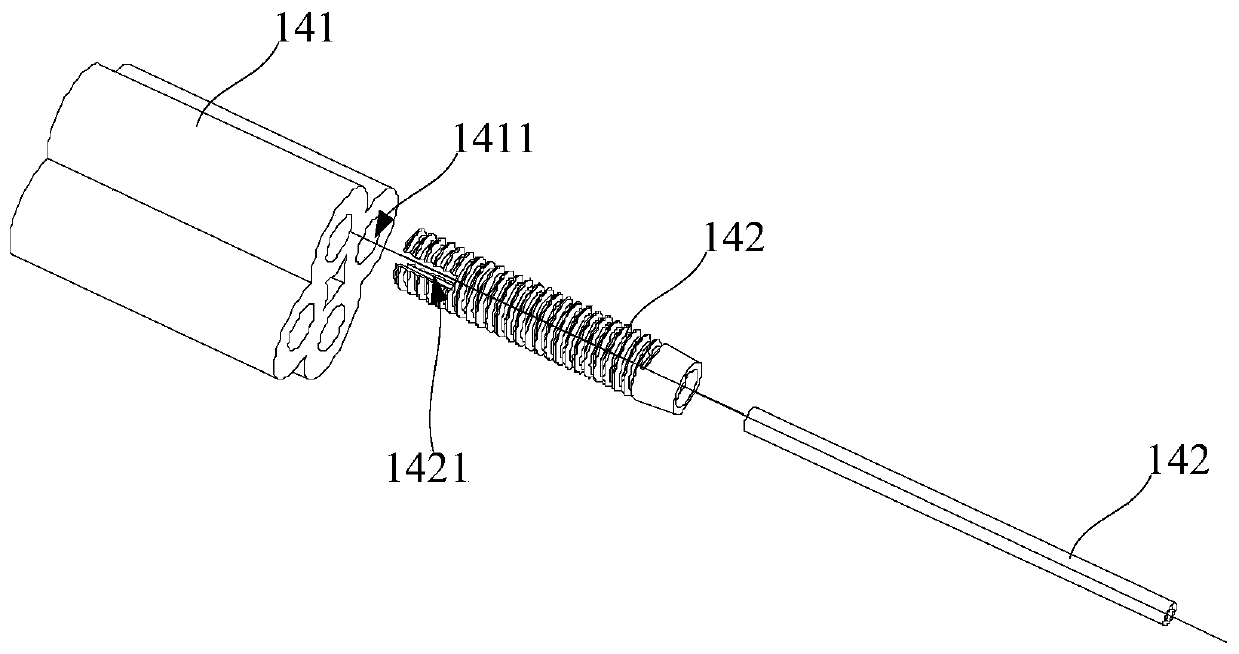

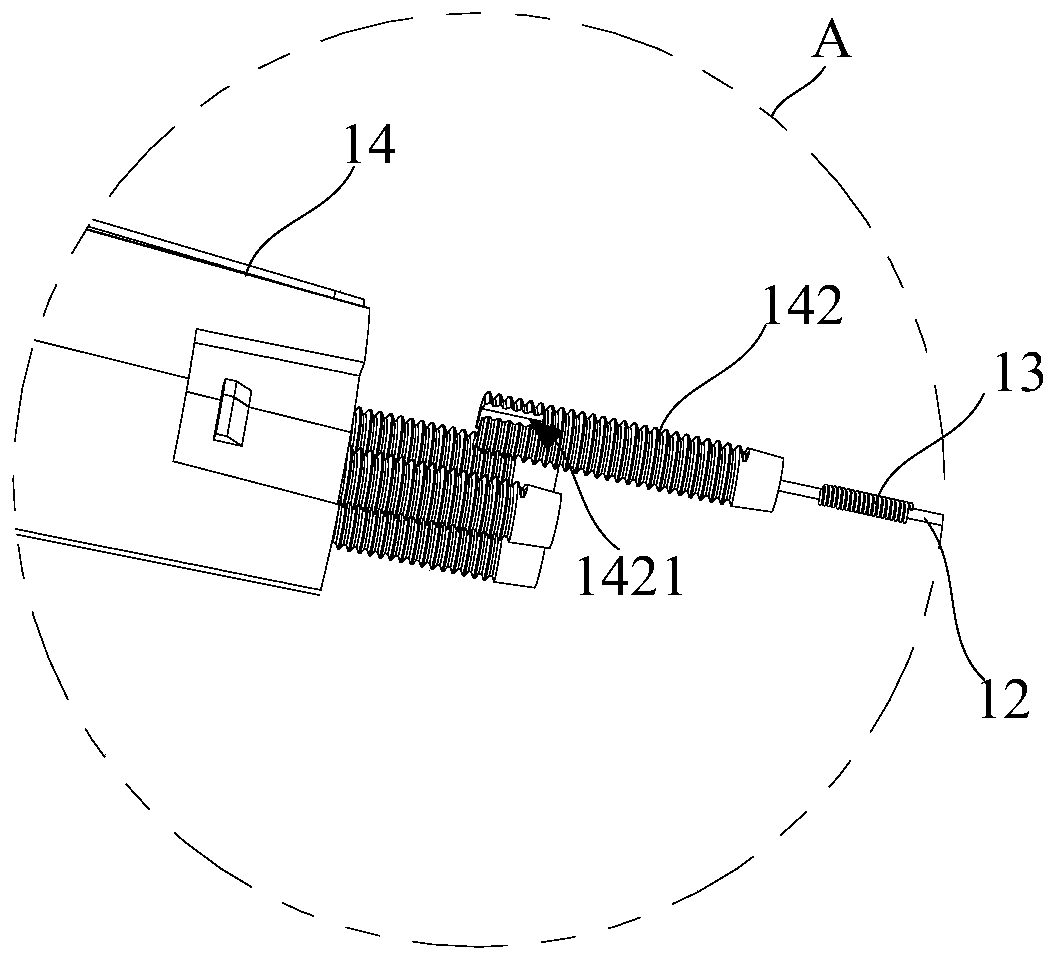

Endoscope

The invention provides an endoscope which comprises an insertion part, a traction line, a spring tube and a handle. The insertion part includes an insertion tube and a bending part; the bending part is arranged at the front end of the insertion tube; the insertion tube is located at the tail end of the bending part; one end of the traction line penetrates the insertion tube from the tail end to beconnected with the front end of the bending part; the spring tube is accommodated in the insertion tube and sleeves the traction line, and one end of the spring tube is connected with the tail end ofthe bending part; the handle is provided with a drive structure, a support and connecting tubes; threaded holes are formed in the support; each of the connecting tubes is provided with an outer thread; one ends of the connecting tubes are in threaded connection with the corresponding threaded holes through the support, the other end of the traction line penetrates the connecting tubes and the threaded holes to be connected with the drive structure on the handle, and the other end of the spring tube is arranged at one ends close to the insertion part, of the connecting tubes in an abutted manner. The endoscope is simple in structure, and accurate installation of the spring tube is realized conveniently.

Owner:SHENZHEN XZING TECH CO LTD +1

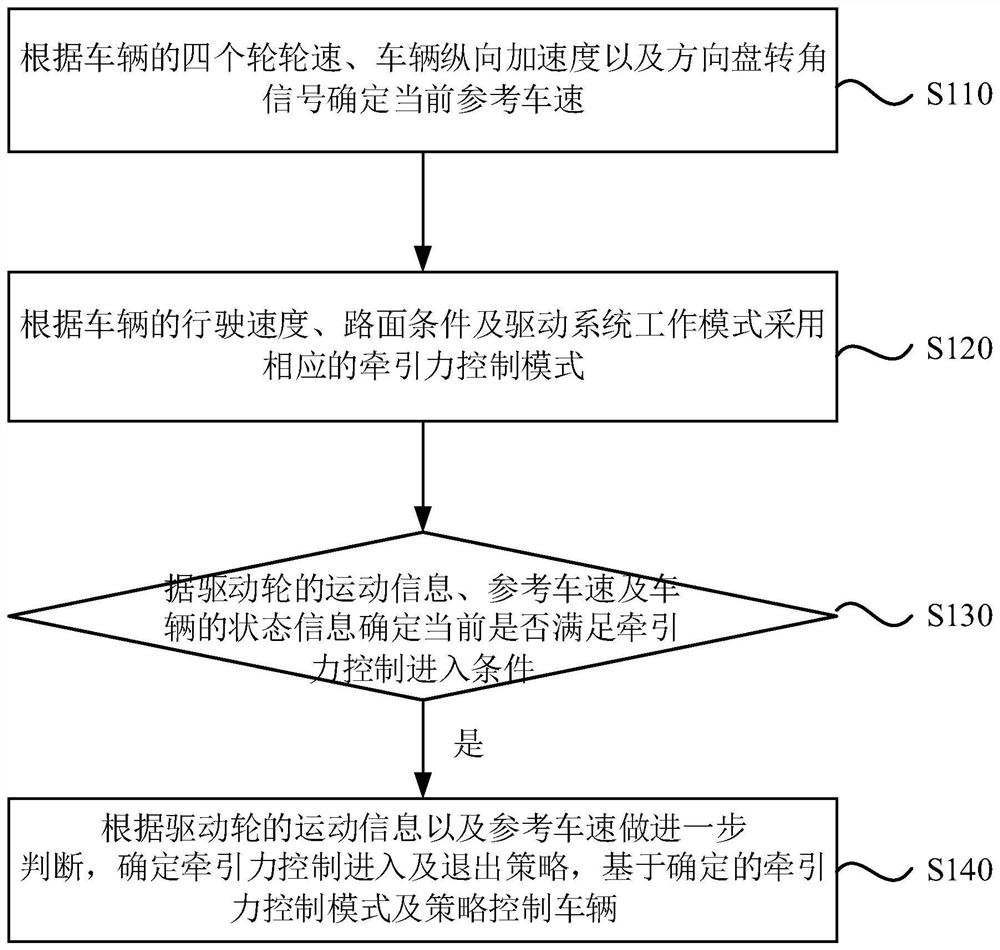

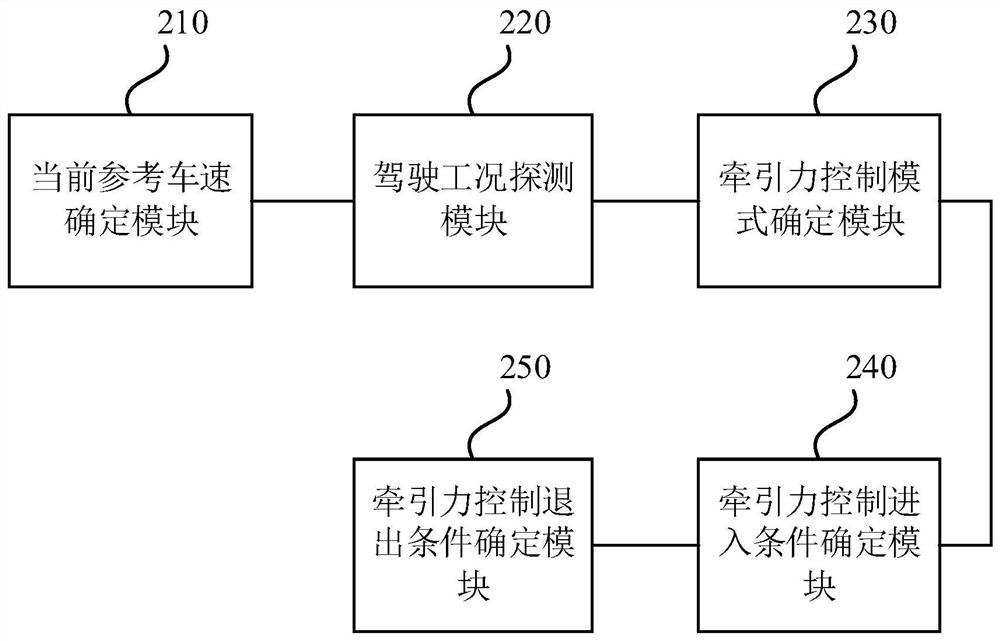

Control method for traction force of hybrid four-wheel drive vehicle

ActiveCN112874500AGuaranteed traction effectGuaranteed stabilityHybrid vehiclesControl modeWheel drive

The embodiment of the invention discloses a control method for traction force of a hybrid four-wheel drive vehicle. The control method comprises the steps of determining a current reference vehicle speed according to four wheel speeds of a vehicle, a vehicle longitudinal acceleration and a steering wheel angle signal; adopting a corresponding traction force control mode according to the running speed of the vehicle, the road condition and the working mode of a driving system; according to the motion information of driving wheels, the reference vehicle speed and the state information of the vehicle, determining whether traction force control entering conditions are met currently; if the vehicle meets the traction force control entering conditions, making further judgment according to the motion information of the driving wheels and the reference vehicle speed, determining traction force control entry and exit strategies, and controlling the vehicle based on the determined traction force control mode and strategy. According to the embodiment of the invention, the traction force control mode and the entry and exit strategies of traction force control are determined according to the current vehicle state and the motion information of the driving wheels, the vehicle is controlled based on the traction force control strategy, and the traction property and stability of the vehicle during slippage are ensured.

Owner:CHINA FIRST AUTOMOBILE

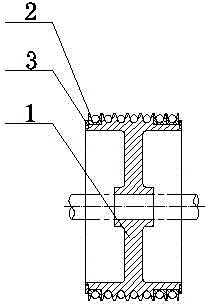

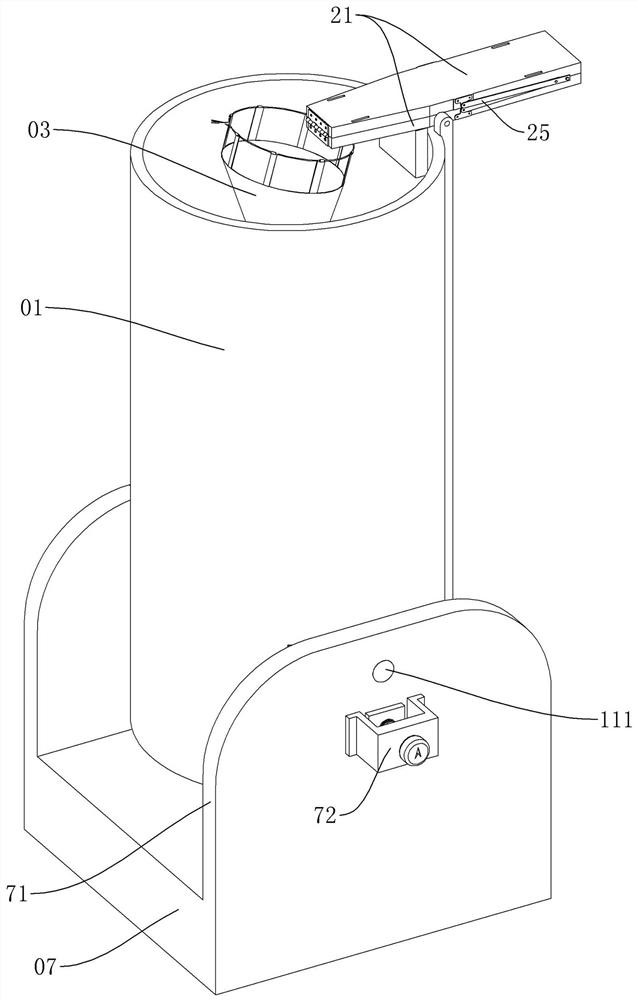

Rope winch winding drum for lifting off and retracting of aerostat

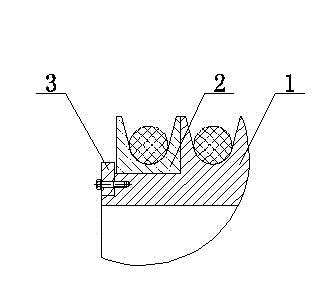

InactiveCN104591020ASimple structurePractical structureWinding mechanismsClassical mechanicsAerostat

The invention provides a rope winch winding drum for lifting off and retracting of an aerostat. The rope winch winding drum comprises a winding drum body (1), a friction ring (2) and a pair of annular stop shoulders (3). An annular friction groove is formed in the winding drum body (1). The friction ring (2) is installed in the annular friction groove in the winding drum body (1). The pair of annular stop shoulders (3) is installed on the two sides of the winding drum body (1) respectively through nuts. The rope winch winding drum for lifting off and retracting of the aerostat has the advantages that the rope winch winding drum is simple in structure and practical, the structural appearance of a conventional winding drum can be guaranteed, the traction performance of the conventional winding drum can be guaranteed, and installation, piece replacement and maintenance are convenient; the surface abrasion and load impact to a rope can be reduced in a large-load state, and the service life of the rope is prolonged.

Owner:CHINA SPECIAL TYPE FLIER RES INST

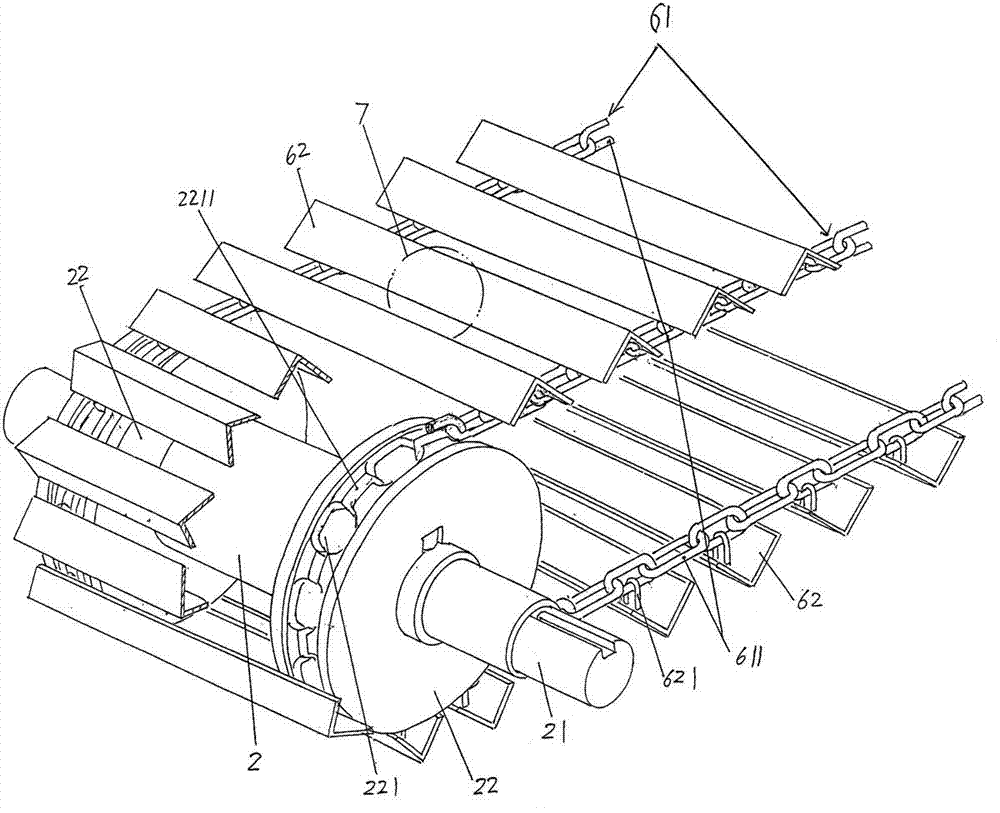

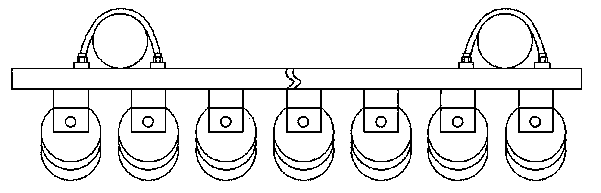

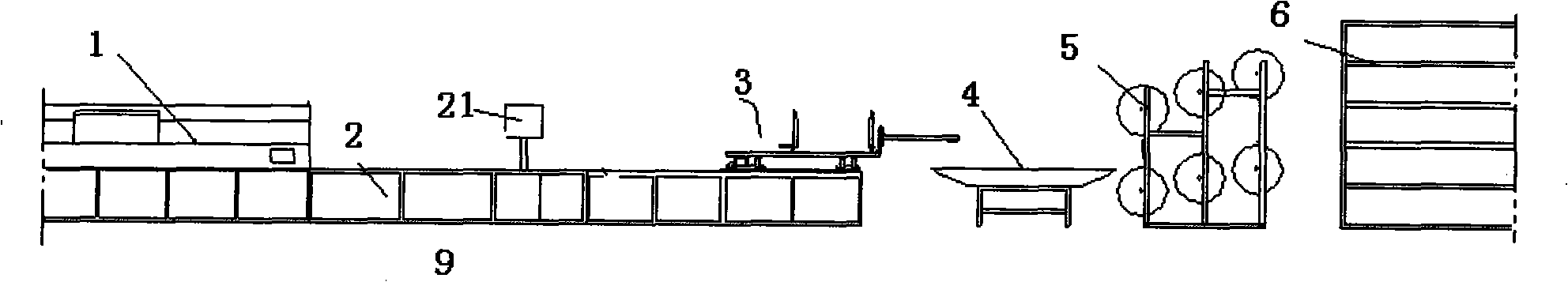

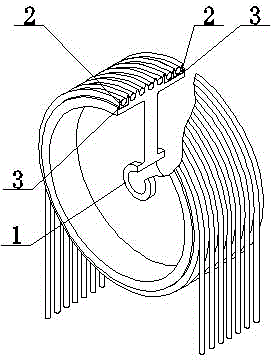

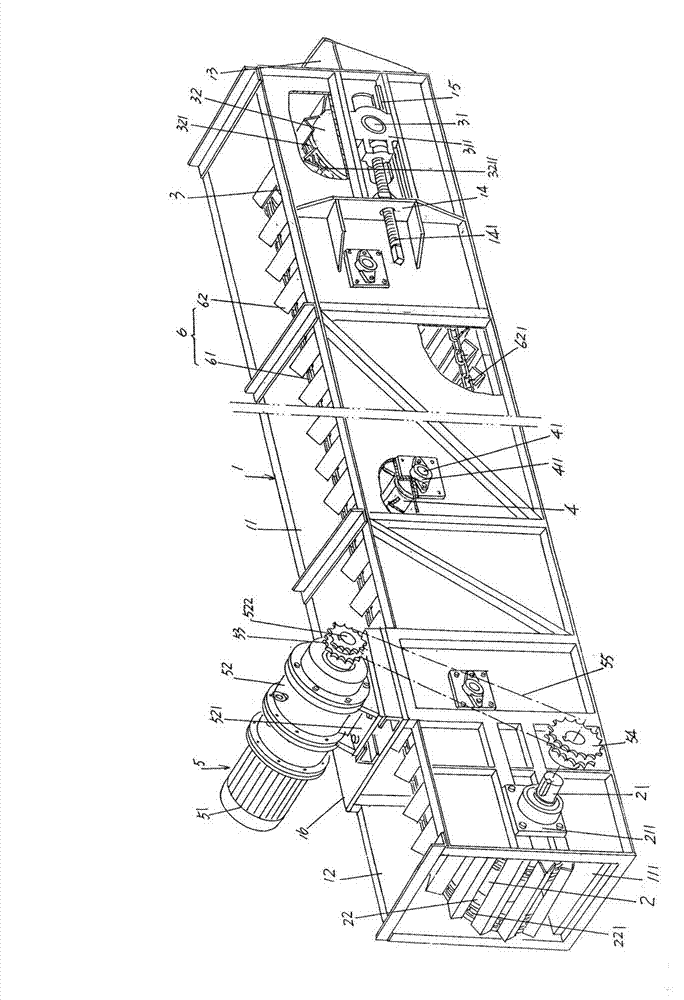

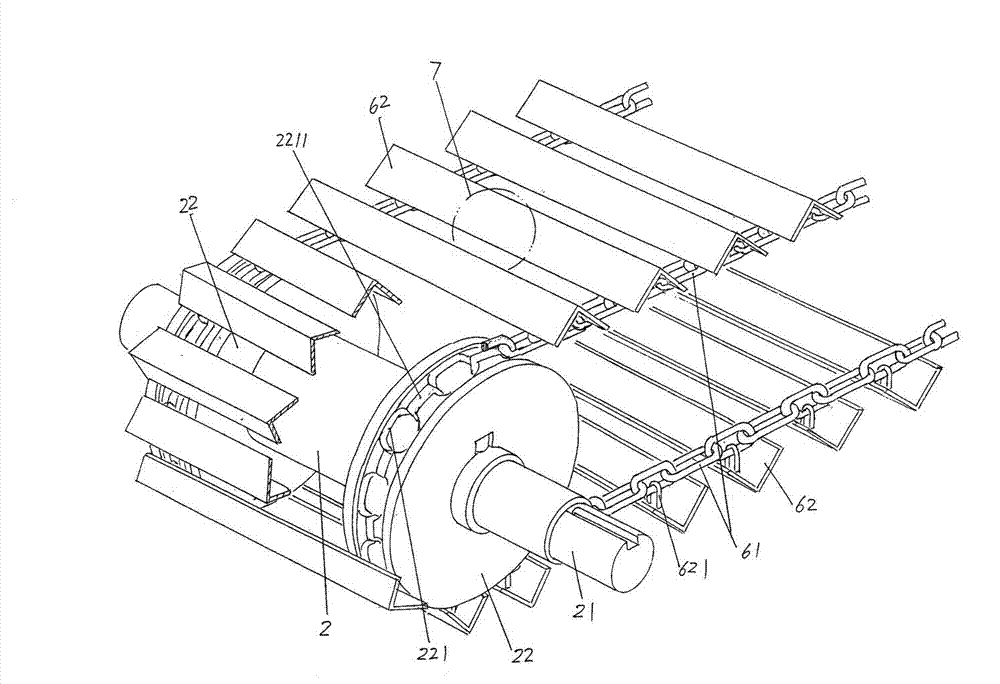

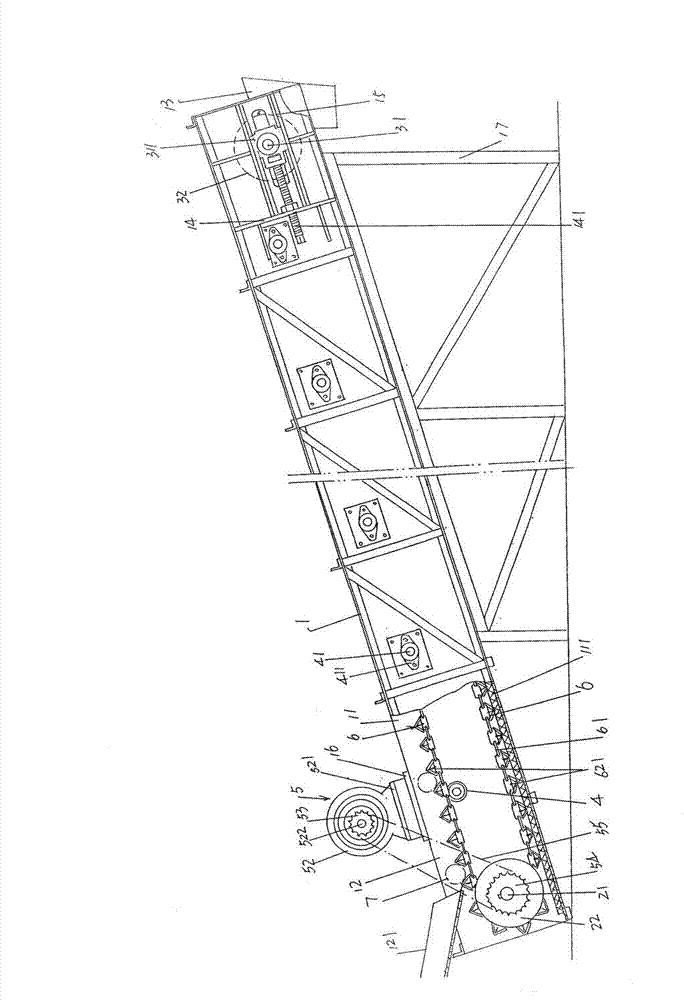

Steel ball conveyor

ActiveCN103205555AGuaranteed traction effectGood loading effectFurnace typesHeat treatment furnacesSteel ballSprocket

The invention relates to a steel ball conveyor belonging to the technical field of conveying machinery. The steel ball conveyor comprises a conveying box, a main driving roller, a direction-changing driving roller, a group of carrier rollers, a power transmission mechanism and a steel ball carrying mechanism, wherein a wear-resisting plate is paved in a conveying cavity of the conveying box; the main driving roller is supported on the wall of the conveying box; two chain traction chain sprockets are respectively formed at the two ends of the main driving roller; the direction-changing driving roller is supported on the wall of the conveying box; chain direction-changing traction chain sprockets are respectively formed at the two ends of the direction-changing driving roller; the group of carrier rollers are supported in the middle of the conveying box; the power transmission mechanism is arranged on the top of one end of the conveying box; the steel ball carrying mechanism comprises a pair of curtain rail plate traction chains and a group of curtain rail plates, wherein the two ends of the curtain rail plates are respectively and fixedly provided with a chain buckling foot; the cross section of each curtain rail plate is in an inverted V shape; the distance between every two adjacent curtain rail plates is smaller than the diameter of a steel ball; and the carrier rollers are contacted with the curtain rail plate traction chains. The steel ball conveyor has good loading effect for the steel ball, is beneficial to unloading the steel ball, is reliable in transmission and matching, has good firmness and can guarantee good service life.

Owner:CHANGSHU FEIFAN METALWORK

A kind of cervical traction bed

ActiveCN110946689BRestricted movementAvoid misalignmentChiropractic devicesFractureCervical tractionRemote control

The invention discloses a cervical vertebra traction bed, which comprises a bed body, two sets of traction mechanisms located on the bed body, a limiting plate inserted in the center of the bed bottom plate of the bed body and close to one end of the headboard, and electrically connected to the traction mechanism A control device and a remote controller communicatively connected with the control device, the traction mechanism includes a shoulder strap, a first rope, a second rope, a motor, a winding drum and a housing, and the housing is fixed on the tailboard of the bed body On the outside, the motor is located in the casing and the output shaft is connected to the winding drum, the two ends of the shoulder belt are respectively bound with the first rope and the second rope, and the other ends of the first rope and the second rope are respectively Fixed on the winding drum and the footboard, it can avoid traction deviation and the traction effect is good.

Owner:THE THIRD AFFILIATED HOSPITAL OF ZHEJIANG CHIENSE MEDICAL UNIV

Construction technology of large-span eccentric leaning steel box tie-rod arch bridge floating tow frame

ActiveCN106087771BSimple construction methodReasonable designBridge erection/assemblyArch-type bridgeArchitectural engineeringBridge deck

The invention discloses a large-span eccentric leaning type steel box tied-arch bridge float-towing erection construction technology. The arch bridge to be constructed is a tied-arch bridge erected on a riverway, and a bridge superstructure comprises bilaterally symmetrically arranged arch bridge superstructures. The float-towing erection construction of the arch bridge to be constructed comprises the steps: 1, making first-phase preparations: sliding system construction and mobile support device processing; 2, bridge superstructure ground splicing: respectively splicing the two arch bridge superstructures by using sliding systems; 3, bridge superstructure float-towing construction, wherein the process is as follows: sliding system construction and arch bridge superstructure float-towing construction; 4, arch rib lower connection structure construction; and 5, bridge deck board paving. The technology is simple in step, and reasonable in design and simple and convenient in construction, the construction effect is good, the large-span eccentric leaning type steel box tied-arch bridge float-towing erection construction process can be completed simply and conveniently and quickly, and the construction quality is easily guaranteed.

Owner:NO 1 ENG LIMITED OF CR20G

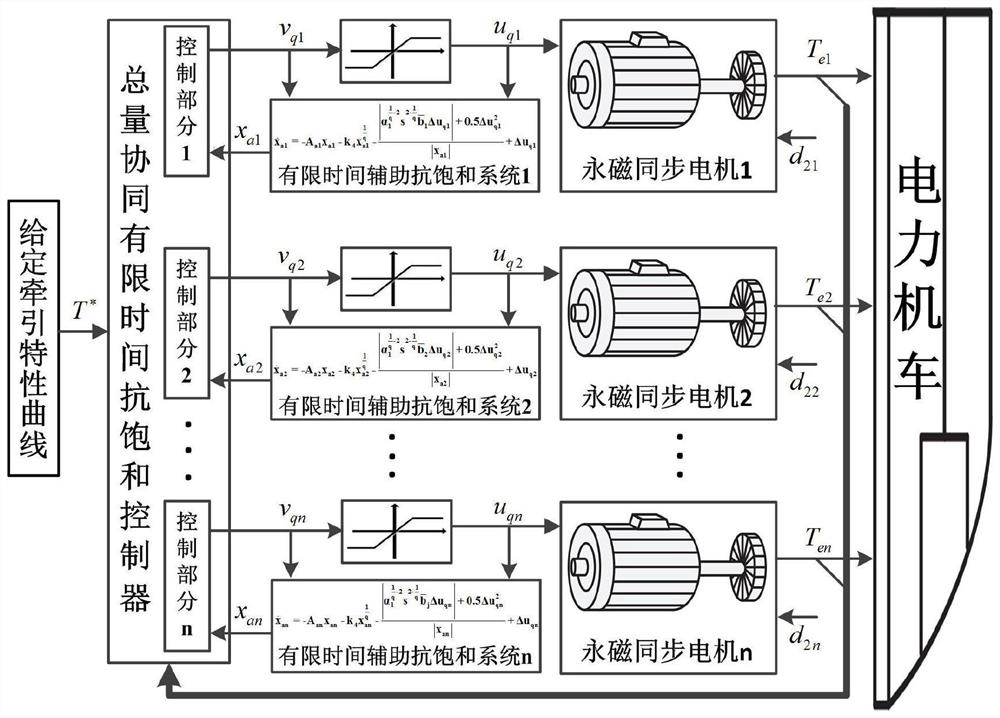

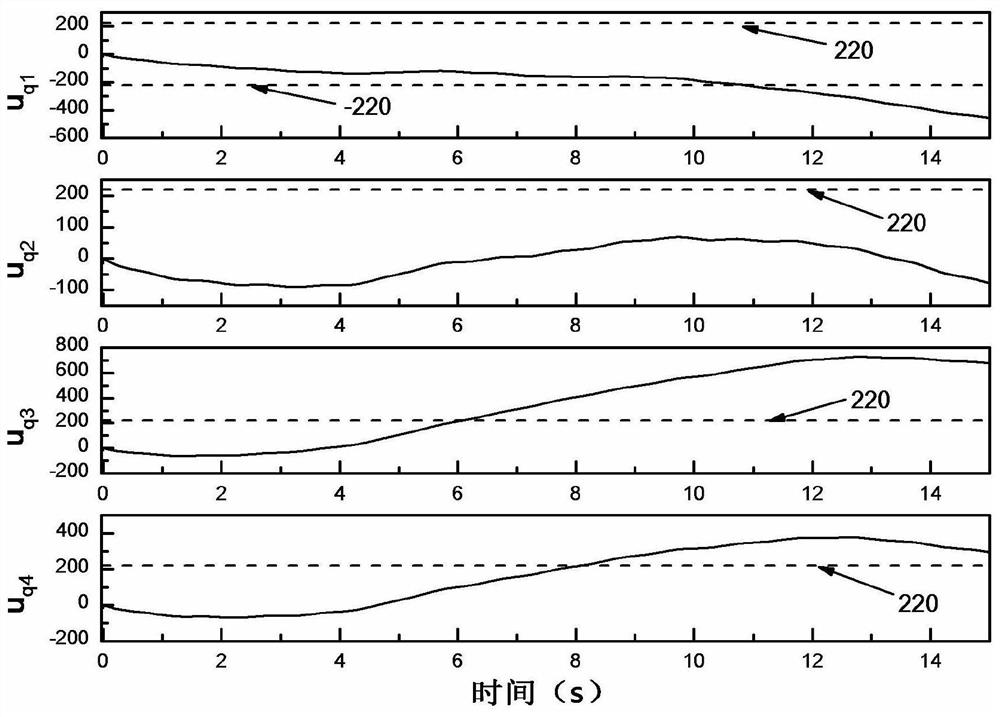

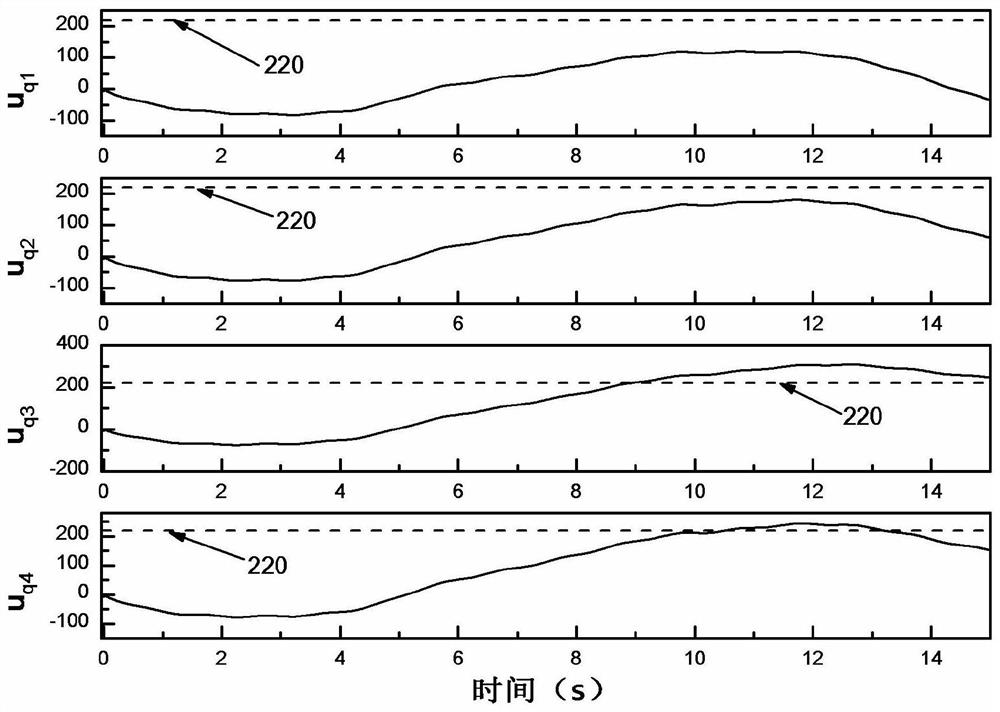

A Coordinated Finite-Time Anti-Saturation Control Method of Multi-motor Aggregate

ActiveCN112398369BGuaranteed traction effectReduce saturationMultiple motor speed/torque controlLyapunov stabilizationKinetics

The present invention provides a multi-motor total amount cooperative finite time anti-saturation control method, including the following steps: S1, deduce the state equation of the motor according to the theory of consistent total amount and the equation in the rotating coordinate system of the permanent magnet synchronous motor; S2, According to the parameters of the motor state equation in S1, an auxiliary anti-saturation system with finite time convergence is designed; S3, according to the theory that the motor state equation in S1 is consistent with the total amount, the error dynamics equation is constructed, and S4, according to the finite time convergence in S2 Auxiliary anti-saturation system and error dynamics equation in S3, based on non-singular terminal sliding mode design total synergistic finite-time controller, and simplified power integral parameters; S5, based on power integral technology and finite-time Lyapunov stability The theorem completes the stability proof of the aggregate cooperative finite-time controller and obtains the finite-time upper bound. The invention weakens the influence of input saturation on the overall traction performance, and provides convenience for practical engineering utilization.

Owner:HUNAN UNIV OF TECH

Pultrusion construction of composite material pultrusion machine and the pultrusion machine

The invention relates to a pre-stress pultrusion construction of a composite material pultrusion machine and a pultrusion machine thereof, and relates to a device which causes a glass yarn and a glass felt to be composite and thermoplastic to a continuous profile and comprises a yarn-supplied mechanism, wherein, the yarn-supplied mechanism is provided with a tension yarn-released construction which can cause the glass yarn to be in a tension state and to be released and sent to the next process, a yarn-passing shaft which can cause the glass yarn to be in a tension state and to be dipped with plastics, a plastic-dipped yarn-guide unit, and a die part yarn-guide unit which guides the glass yarn to be in a tension state and to enter into the die for being cured. The pre-stress pultrusion construction causes the glass yarn to be able to gain the pre-stress from the yarn-released step, thus the intensity of the fiber reinforced plastic profile is effectively increased; the single-machine double-line traction construction provided by the invention can effectively reduce the energy consumption, can increase the productivity effect, can achieve the on-line detection and eliminate the slipping phenomenon as the product is pulled and extruded, thereby ensuring the traction effect. The pre-stress pultrusion construction has the advantages that the structure is simple, the production cost is low, the industry repetition is easy, and the technology contribution is significant, thereby fully realizing various invention purposes.

Owner:天津市金锚科技发展有限公司

Dustproof outdoor airing device for dyeing processing of garment cloth

ActiveCN112923672ASave spaceGuaranteed traction effectPV power plantsDrying gas arrangementsEngineeringMechanical engineering

The invention provides a dustproof outdoor airing device for dyeing processing of garment cloth, and relates to the technical field of garment cloth processing. The problems that a traditional airing device for the garment cloth is large in occupied space area, the aired garment cloth is usually exposed in the outside air, dust in the air is prone to being attached to the garment cloth, and the cleanliness of the garment cloth is affected are solved. The dustproof outdoor airing device comprises an airing box and a ventilation fan; the interior of the airing box is of a hollow structure, four rotating holes are formed in the bottom ends of the left side and the right side of the airing box at equal intervals, three air outlet sliding holes are formed in the left side and the right side of the airing box at equal intervals, two light-transmitting plates are installed at the top of the airing box, and four light-transmitting plates are installed on the left side and the right side of the airing box; and four fixed pulleys are rotationally connected to the bottom of the airing box. According to the dustproof outdoor airing device, a movable roller in the airing box is lifted upwards, so that the movable roller drives the cloth to be synchronously lifted upwards, the cloth is located in the airing box in an up-down winding shape, and the space required by cloth airing is saved.

Owner:东莞博源信息咨询有限公司

Cervical traction bed

ActiveCN110946689ARestricted movementAvoid misalignmentChiropractic devicesFracturePhysical medicine and rehabilitationCervical traction

The invention discloses a cervical traction bed which comprises a bed body, two groups of traction mechanisms, a limiting plate, a control device and a remote control, wherein the traction mechanismsare positioned on the bed body; the limiting plate is inserted into the center of the bed bottom plate of the bed body and at one end close to a bed head plate; the control device is electrically connected with the traction mechanisms; the remote control is in communication connection with the control device; the traction mechanisms comprise shoulder belts, first ropes, second ropes, motors, coiling cylinders and shells; the shells are fixed on the outer side of the bed tail plate of the bed body; the motors are positioned inside the shell; output shafts are connected with the coiling cylinders; both ends of the shoulder belts are respectively bound with the first ropes and the second ropes; and the other ends of the first ropes and the second ropes are respectively fixed on the coiling cylinders and the bed tail plate. Traction deviation can be avoided, and the traction effect is good.

Owner:THE THIRD AFFILIATED HOSPITAL OF ZHEJIANG CHIENSE MEDICAL UNIV

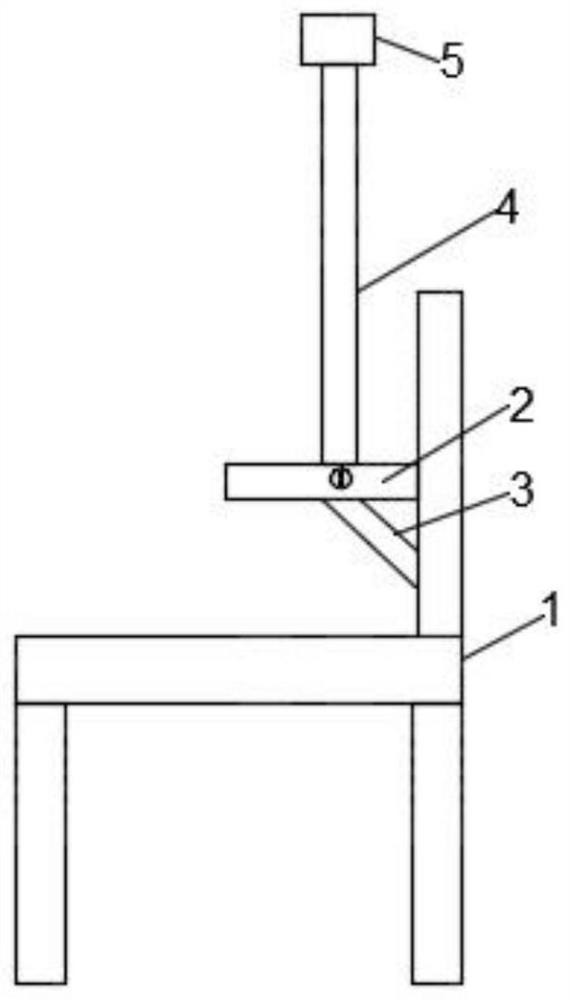

Wrist rotation function rehabilitation training device

ActiveCN112336583AGood for rotation trainingRealize forward and reverse switchingChiropractic devicesHand partsPhysical medicine and rehabilitation

The invention relates to a wrist rotation function rehabilitation training device. The cylindrical support of the training device is rotatably connected to a base and can be vertically and transversely fixed, so that the hands can be trained in a prostrate state and a horizontal state. A lead screw and a roller of a traction device of the training device form lead screw nut transmission. When themotor on the base drives the lead screw to rotate, the idler wheels not only can move circumferentially on the supporting disc, but also can move towards the center of the supporting disc along the lead screw, so that the idler wheels can drive the U-shaped brackets to move inwards or outwards spirally on the supporting disc, and the idler wheels can touch the contact switches when moving to the middle and the edges of the supporting disc. Forward and reverse rotation switching of the motor is achieved, and the U-shaped bracket reciprocates inside and outside and fast and slow alternate spiralmotion provide traction force for a conical sleeve. The device can carry out automatic rehabilitation training on the hands of a patient, extra personnel assistance is not needed, the training diversity is improved, the rehabilitation training effect is good, and the rehabilitation process can be greatly accelerated.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF TCM

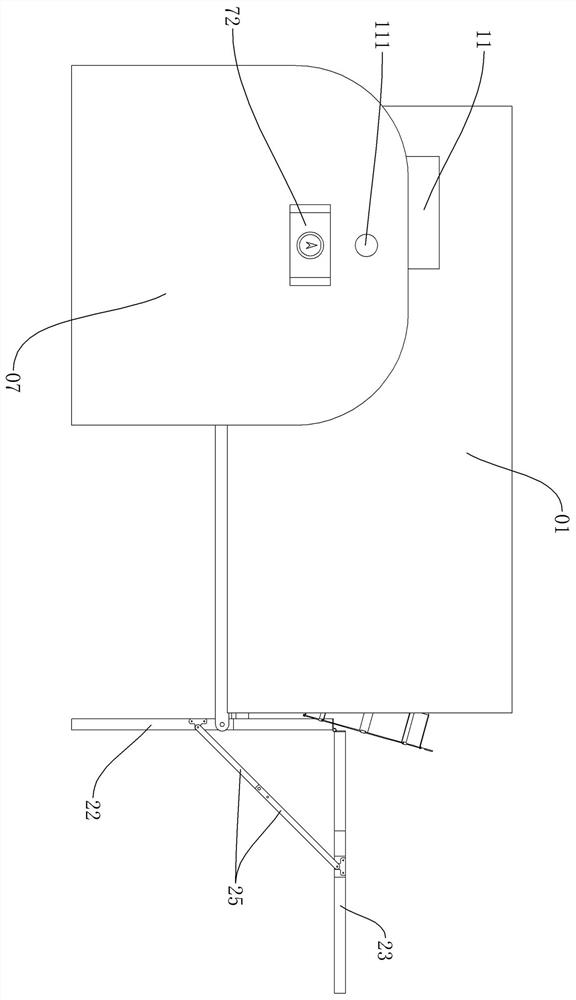

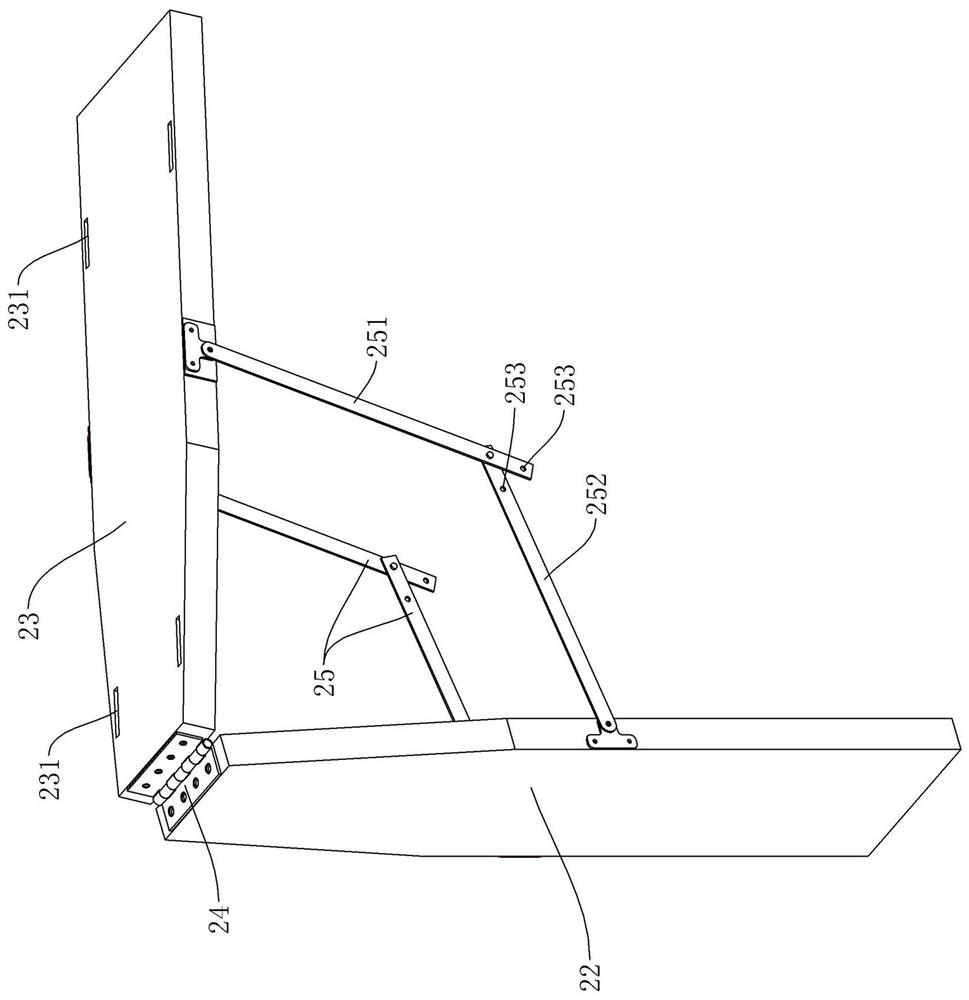

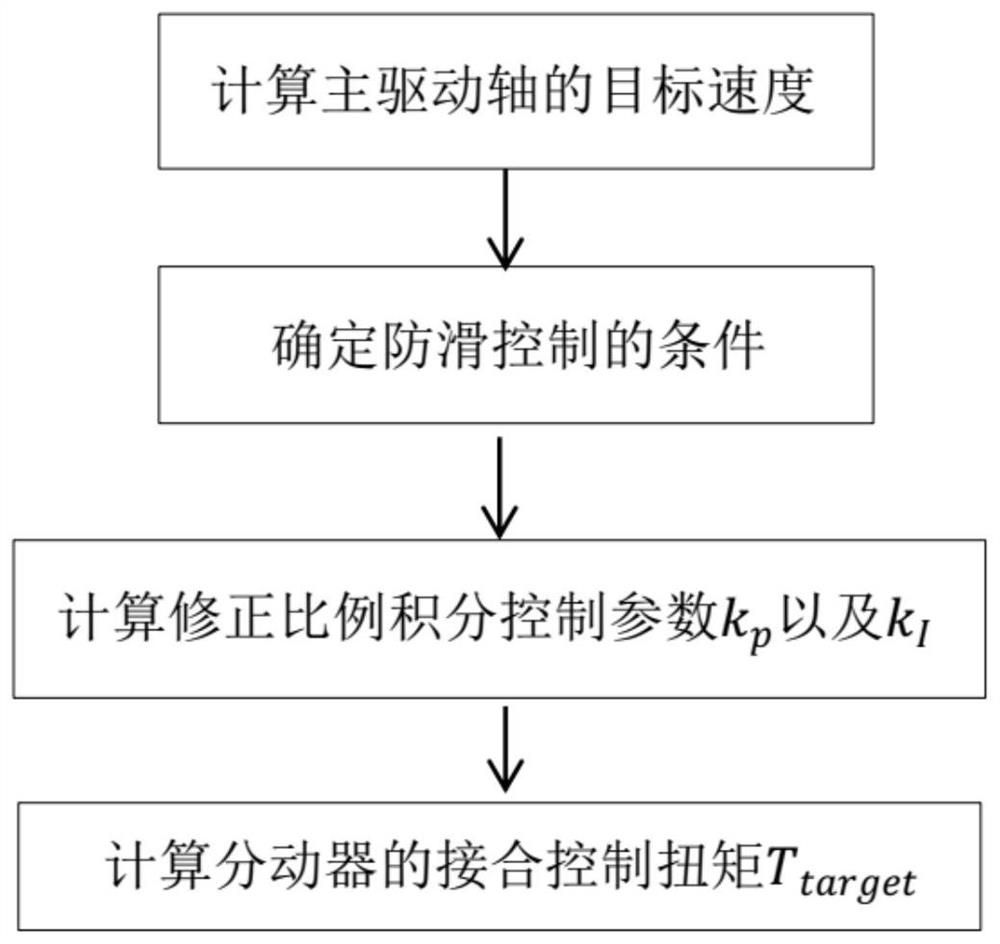

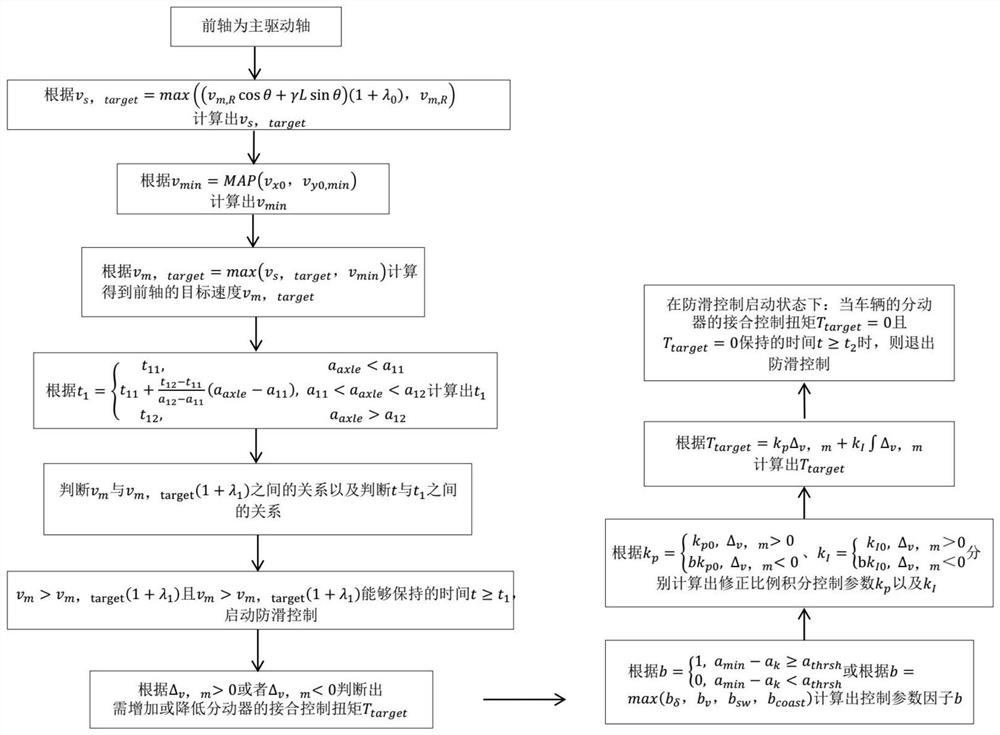

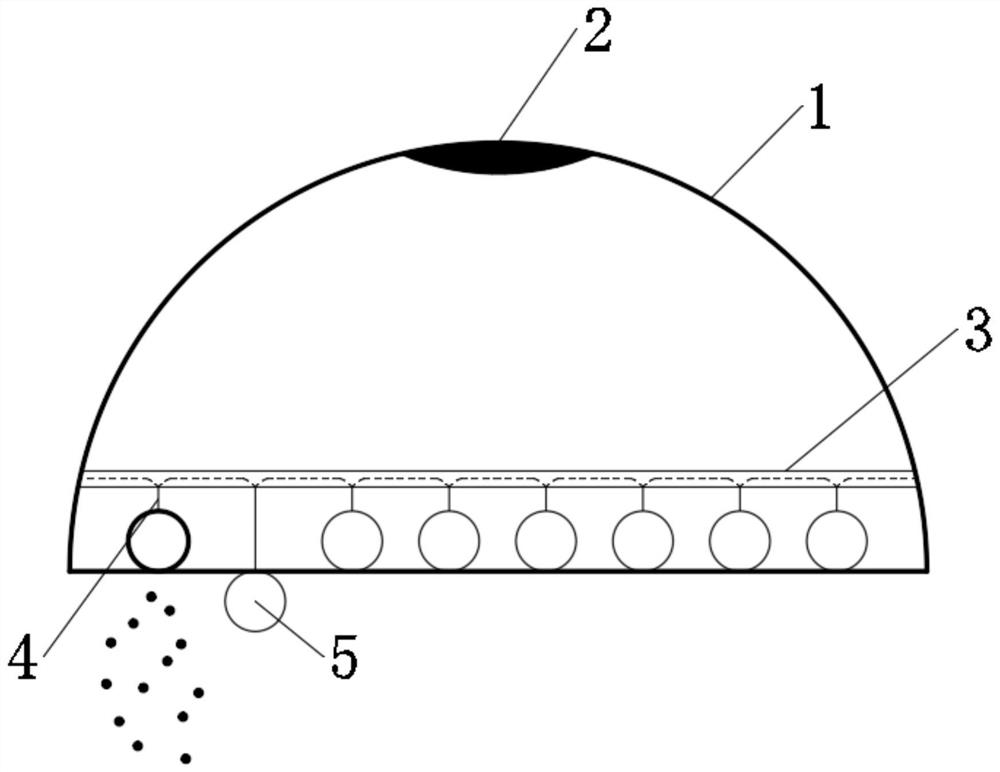

A method for anti-slip control of transfer case

ActiveCN113060119BPrevent slippingGuaranteed traction effectRoad vehiclesDriver input parametersTransfer caseDrive shaft

The invention discloses an anti-slip control method of a transfer case, which belongs to the technical field of anti-slip control. The transfer case anti-slip control method includes the following steps: S10: Calculation of the target speed of the main drive shaft: v m,target =max(v s,target , v min ); S20: Determine the condition of anti-skid control: when v m > v m,target (1+λ 1 ) and v m >v m,target (1+λ 1 ) hold time t≥t 1 , to start the anti-skid control; when the anti-skid control is started: when the transfer case of the vehicle is engaged, the control torque T target = 0 and T target =0 hold time t≥t 2 , the anti-skid control is exited; S30: engagement control torque T of the transfer case target Calculation: T target =k p Δ v,m +k I ∫Δ v,m , k p and k I is obtained by modifying the control parameter factor b of the vehicle in the over-slip state and under-slip state, Δ v,m Speed control deviation of the main drive shaft Δ v,m =v m ‑v m,target , so that after the vehicle starts the anti-skid control, it can follow the T target =k p Δ v,m +k I ∫Δ v,m Calculated T target The value adjusts the engagement control torque of the transfer case. This has the advantage of being able to adjust the engagement control torque of the transfer case while avoiding the effects of slip fluctuations and torque fluctuations.

Owner:CHINA FIRST AUTOMOBILE

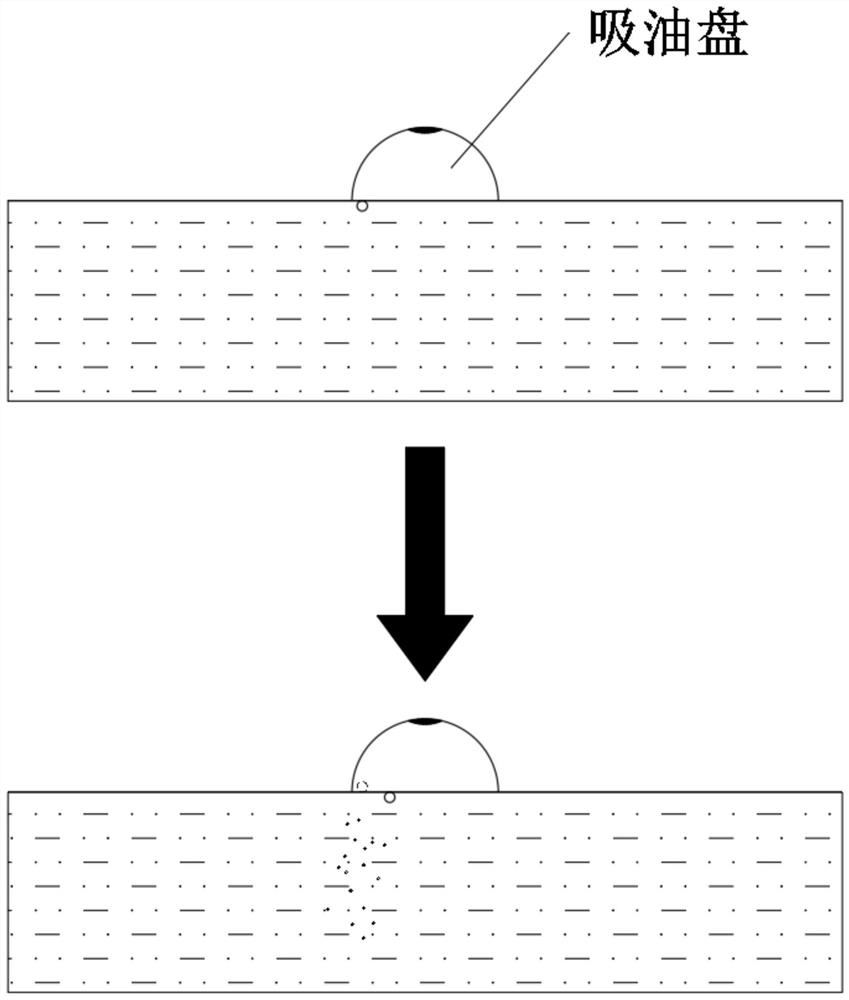

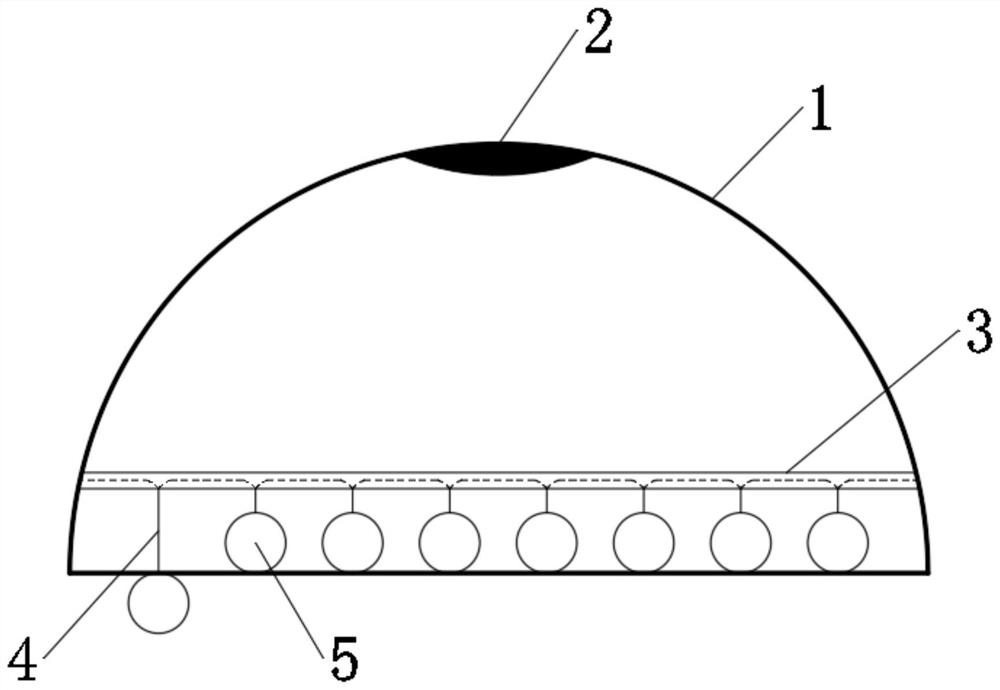

Bidirectional deep adsorption treatment method for oily sewage

ActiveCN113548713AReduce migration resistanceAchieving bi-directional absorptionGeneral water supply conservationWater/sewage treatment by sorptionSewageResidual oil

The invention discloses a bidirectional deep adsorption treatment method for oily sewage, and belongs to the technical field of sewage treatment. After sewage stands for layering, the sewage is put into an oil suction disc, then migration of the sewage is controlled through magnetic attraction force to absorb oil stains on the surface layer, meanwhile, oil absorption particles are continuously released in the absorption process to trigger the transposition floating phenomenon, on one hand, low migration resistance and high oil absorption efficiency of the oil absorption disc in water are always kept, on the other hand, the released oil absorption particles can absorb residual oil drops in the water in the sinking process in the water, and finally sink into the water bottom, and the oil absorption disc floats upwards and is recovered after absorption saturation, so that bidirectional absorption of the oil stains is realized, the absorption efficiency and the absorption effect of the oil stains are remarkably improved, and effective absorption treatment can be realized on both large-area oil stains on the surface layer and residual oil drops in water.

Owner:重庆湿地环保科技有限公司

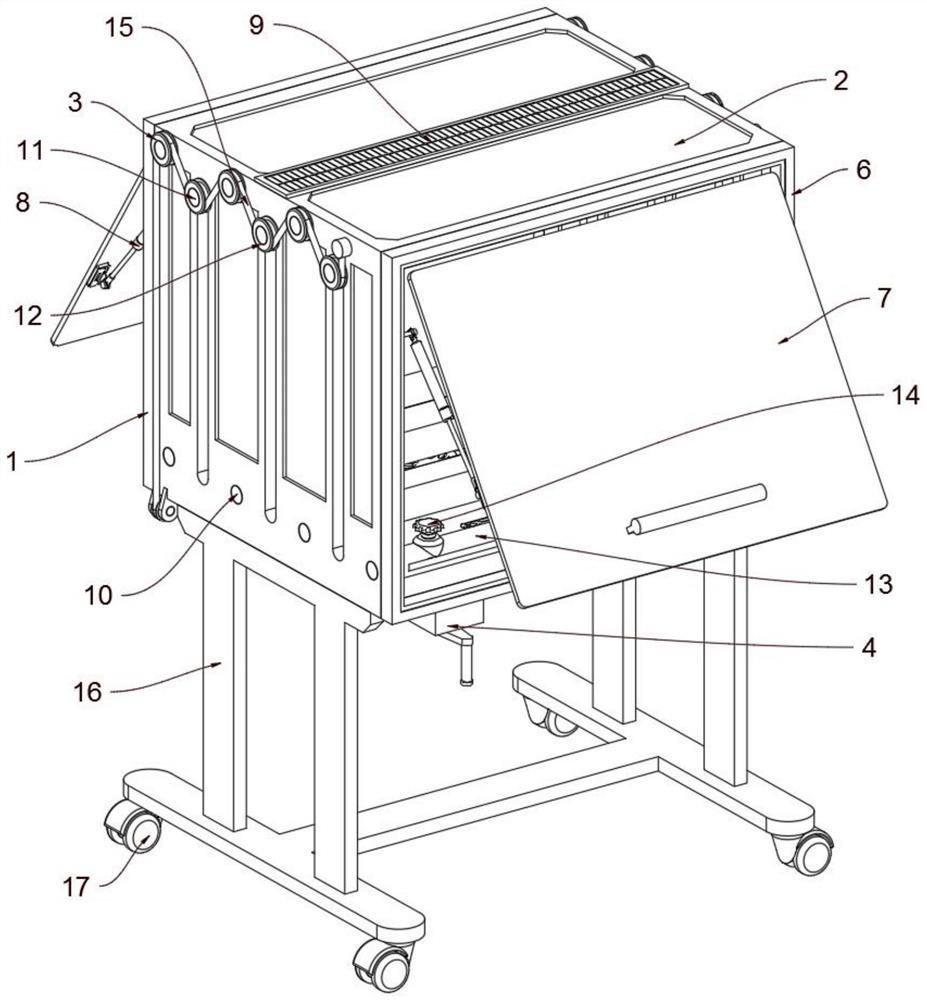

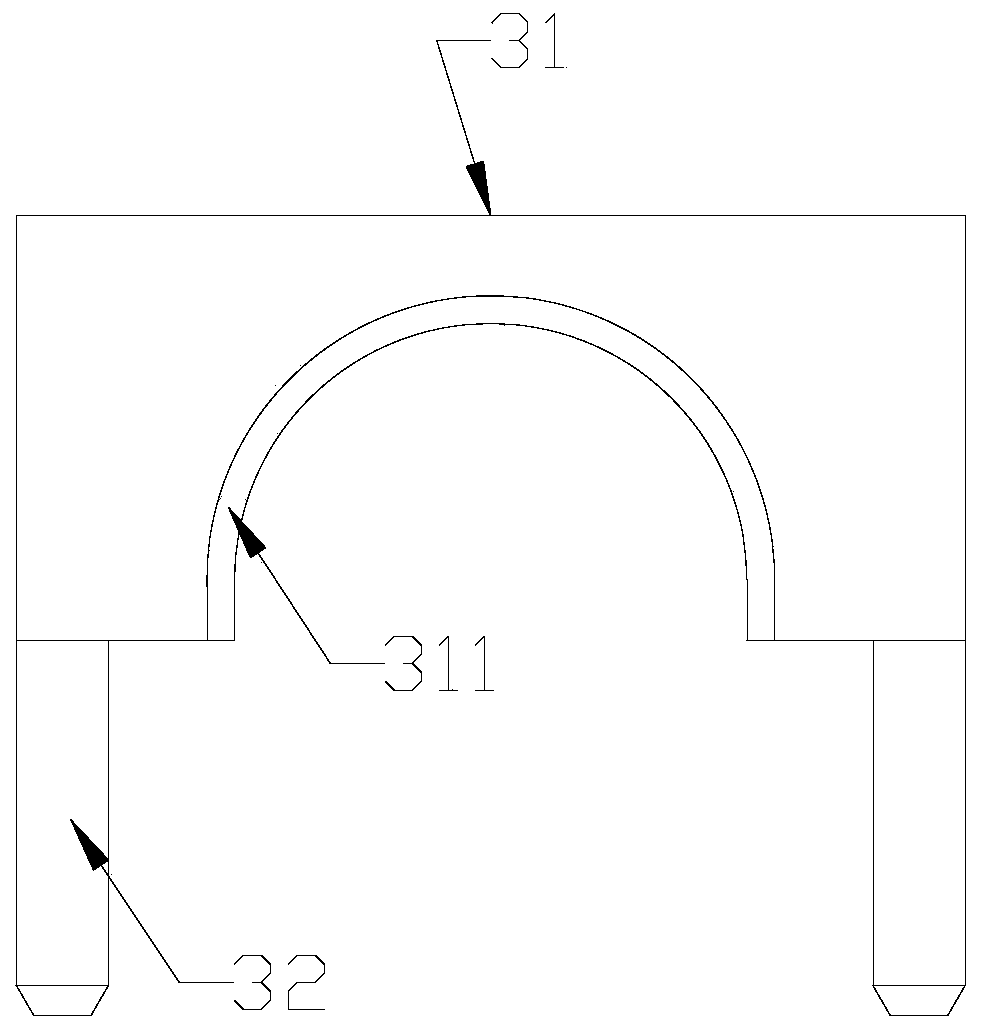

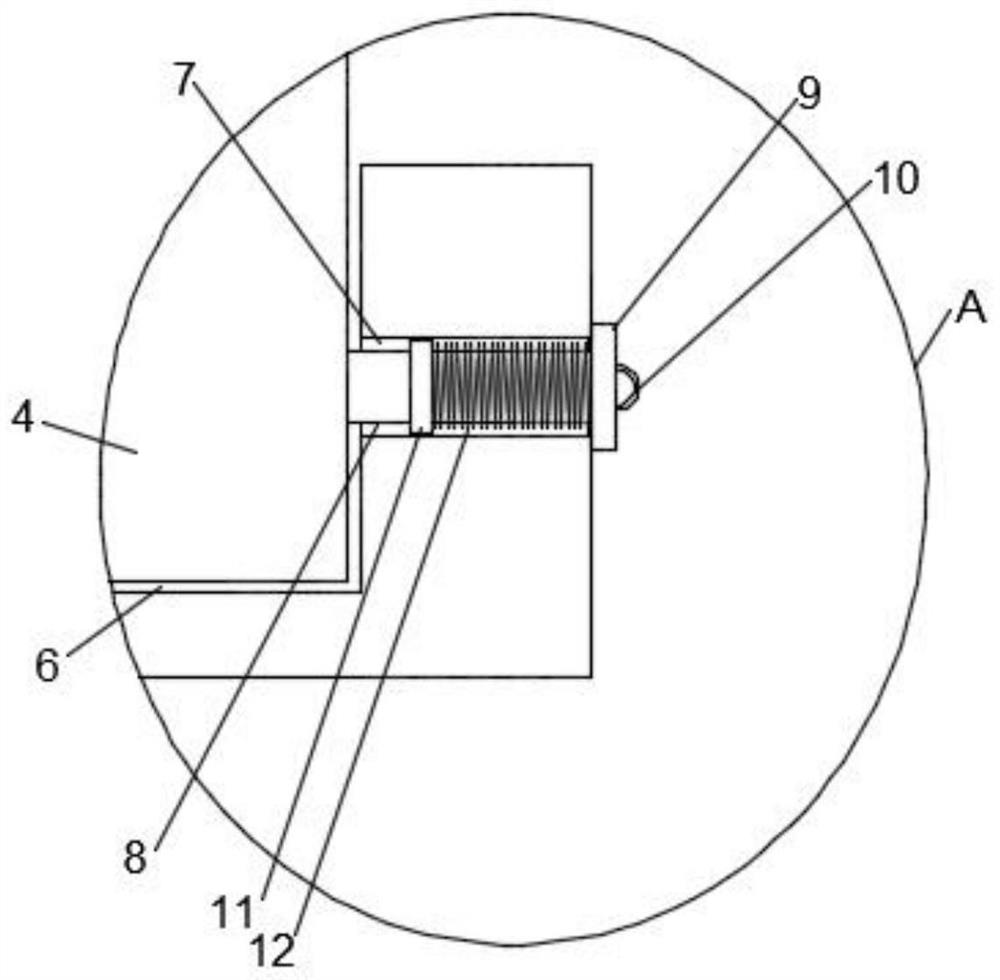

Traction treatment device and traction bed

PendingCN109330804AImprove applicabilityCompact structureDiagnosticsOperating tablesMedical equipmentTraction Treatment

The invention relates to the technical field of traction treatment, and provides a traction treatment device and a traction bed. The traction treatment device comprises a clamping portion, a driving unit, a traction rope and a guiding unit. The driving unit is fixed to the clamping portion, the first end of the traction rope is connected with an output piece of the driving unit, the second end ofthe traction rope winds around the guiding unit, and the second end is used for being connected with a traction treatment apparatus. By arranging the clamping portion, the device can be installed on corresponding medical equipment, for example, the device can be installed on a common surgical bed, and then the traction treatment device is high in adaptability. When the device is used for tractiontreatment, the problems caused by independently arranging a traction bed can be avoided, and the problem caused by freehand operation of a doctor can be avoided. Due to the fact that the installing position of the clamping portion is adjustable, the traction treatment device can be installed at any position needed by the surgical process, the traction effect is ensured, the traction treatment device is exquisite in structure, no surgical tabletop space is occupied, and a physician can conveniently use and operate the device.

Owner:BEIJING ROSSUM ROBOT TECH CO LTD

Stirring action trainer used in nutating state of wrist

ActiveCN111888181APlay the role of tightening and closing fingersAvoid twistingRestraining devicesChiropractic devicesHand partsPhysical medicine and rehabilitation

The invention relates to a stirring action trainer used in a nutating state of a wrist. A hand stirring action restraining device of the trainer can fix and support an arm of a patient to enable a hand of the patient to nutate to the inner end of a supporting plate, and a restraining glove below the inner end of the supporting plate is used for being worn on the hand of the patient to carry out restraint and drag the hand to carry out a stirring action; a traction device is slidably arranged at the lower end inside a cylindrical support, a rotating table is driven by a driving motor to rotateto drag the restraining glove above to carry out the stirring action, and a traction rope can pull the restraining glove to take the continuous stirring action along a conical surface by using the wrist as the center so as to carry out rehabilitation training on the hand of the patient; and the stirring action trainer disclosed by the invention can effectively restrain the hand of the patient andimplement the automatic rehabilitation training action without help of additional personnel, has a good rehabilitation training effect, and improves the rehabilitation process of the patient.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF TCM

Steel ball conveyor device

Owner:CHANGSHU FEIFAN METALWORK

Traction device for general surgery department

InactiveCN111839863APrevent involuntary liftingEasy to decompressFractureIntervertebral spaceEngineering

The invention discloses a traction device for the general surgery department, and belongs to the technical field of medical instruments. The traction device comprises a seat, shoulder fixing pieces, ahead hanging belt and the like. The arrangement of the seat is convenient for the patient to perform cervical traction treatment in a sitting state; the height of the shoulder fixing pieces can be adjusted by adjusting the length of the telescopic sleeve rod; the device is suitable for patients with different body types; the shoulders of the patient are fixed through the shoulder baffles and thearc-shaped plates, the shoulders of the patient are effectively prevented from being lifted up autonomously in the traction treatment process, and the traction effect is guaranteed; the position of the sleeve ring on the telescopic sleeve rod is adjusted and then the height of the head hanging belt can be adjusted to be adaptive to patients with different body types; the lower jaw lifting belt issleeved on the lower jaw part of the patient, the ear fixing belt is sleeved on the rear part of the ear, and the head hanging belt plays a role in lifting and fixing the neck part of the patient so that the intervertebral space of the cervical vertebra is enlarged, the decompression of the intervertebral disc is facilitated, the vertebral artery distortion is corrected, and the nerve root compression is reduced.

Owner:于翔诚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com