Rope winch winding drum for lifting off and retracting of aerostat

A technology of aerostats and drums, which is applied in hoisting devices, spring mechanisms, etc., can solve the problems of reduced service life of cables, high temperature of cable skins, and damage of cable skins, etc., and achieves prolonging service life, simple structure, Reduces the effect of skin abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

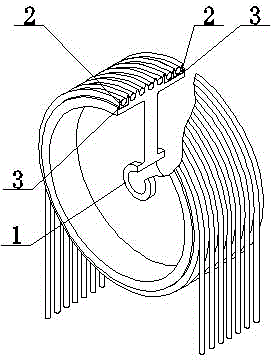

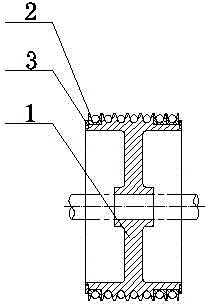

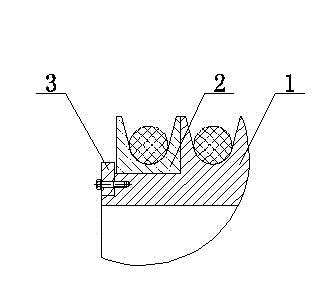

[0013] Such as figure 1 , 2 , 3, the present invention includes a reel (1), a friction ring (2) and a pair of annular shoulders (3), an annular friction groove is opened on the reel (1), and the friction ring (2) is installed on the reel In the annular friction groove on (1), a pair of annular retaining shoulders (3) are respectively installed on both sides of the reel (1) through nuts.

[0014] The friction ring 2 consists of one or more friction rings.

[0015] The reel 1 and a pair of annular shoulders 3 are integrated.

[0016] How to use: Install at least one friction ring (2) on the end of the cable leaving the drum. If the winch is used for two-way traction (or retraction with load) of the cable, a friction ring (2) is provided at both ends of the drum. A friction ring (2) can be added at the end of the cable with less tension. Install shoulders (3) on the outside of the friction ring (2) to prevent the friction ring (2) from slipping out of the rigid reel (1) alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com