Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Guaranteed crispness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

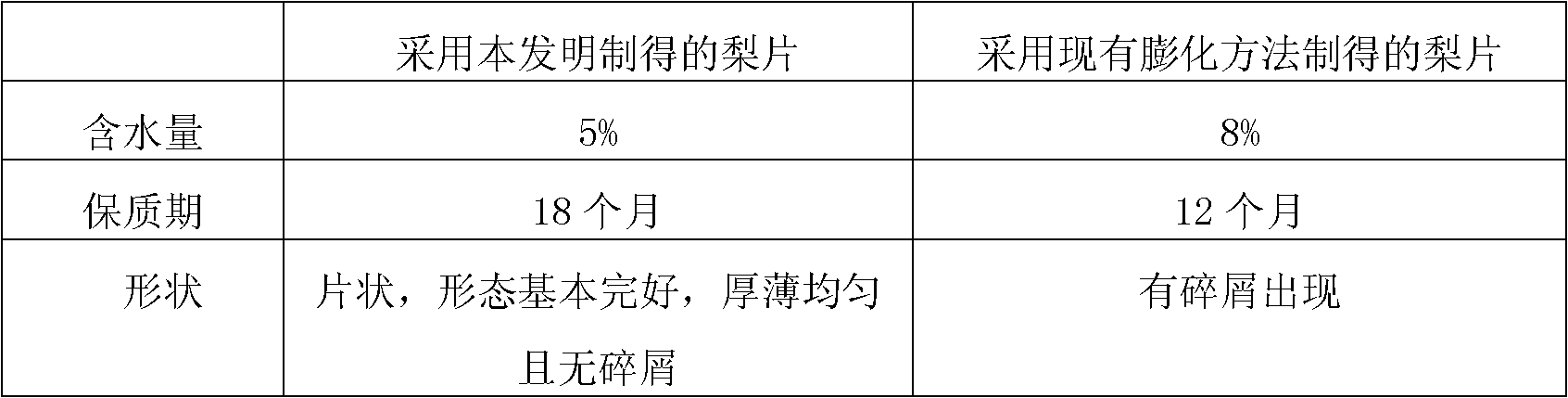

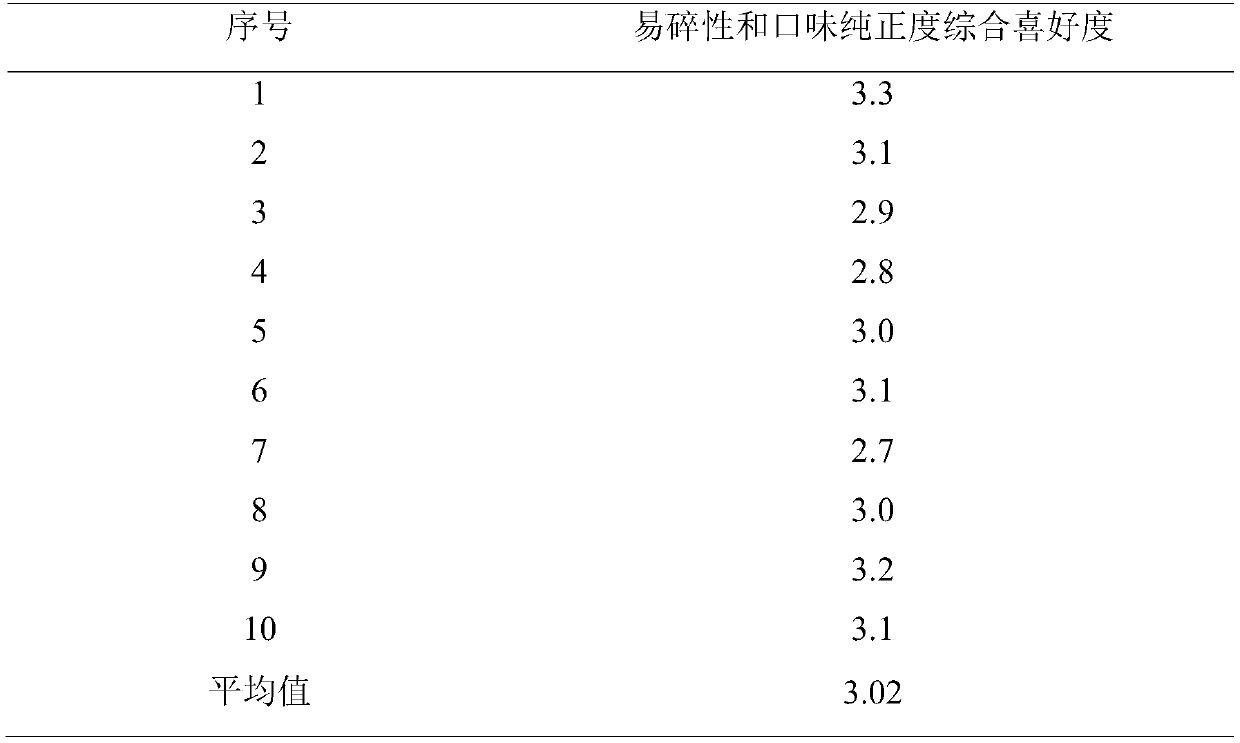

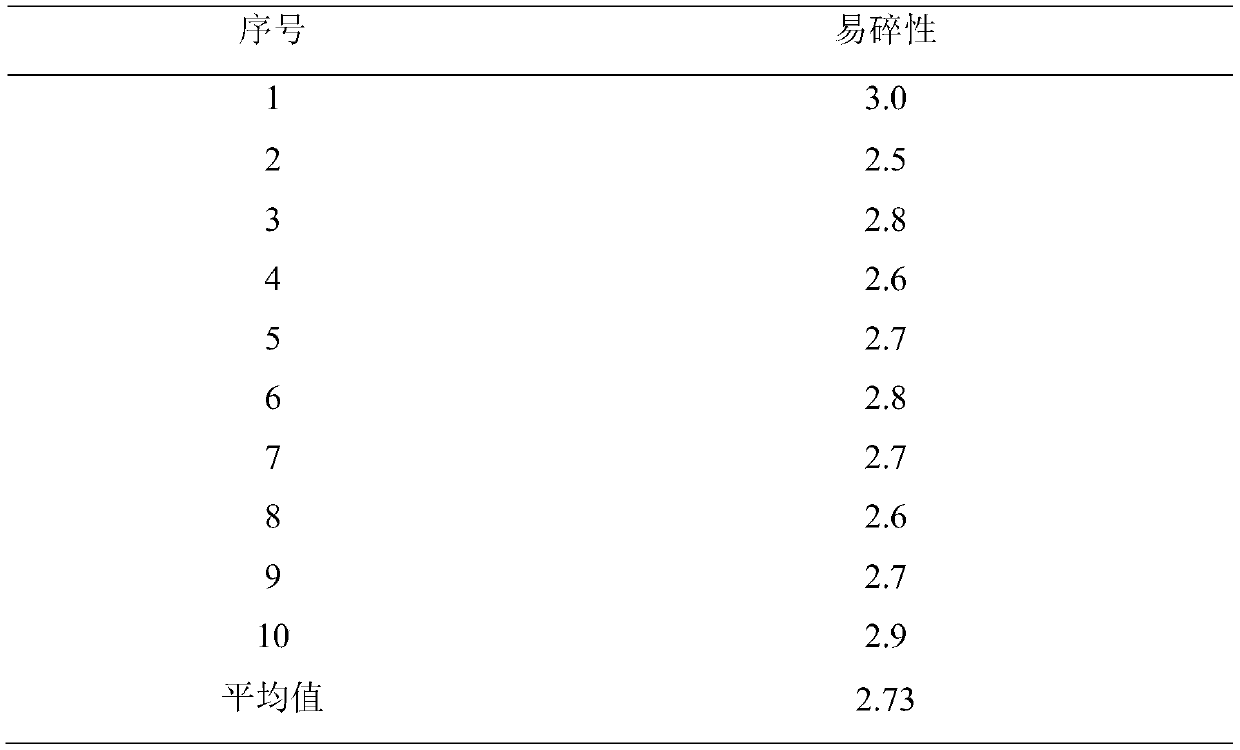

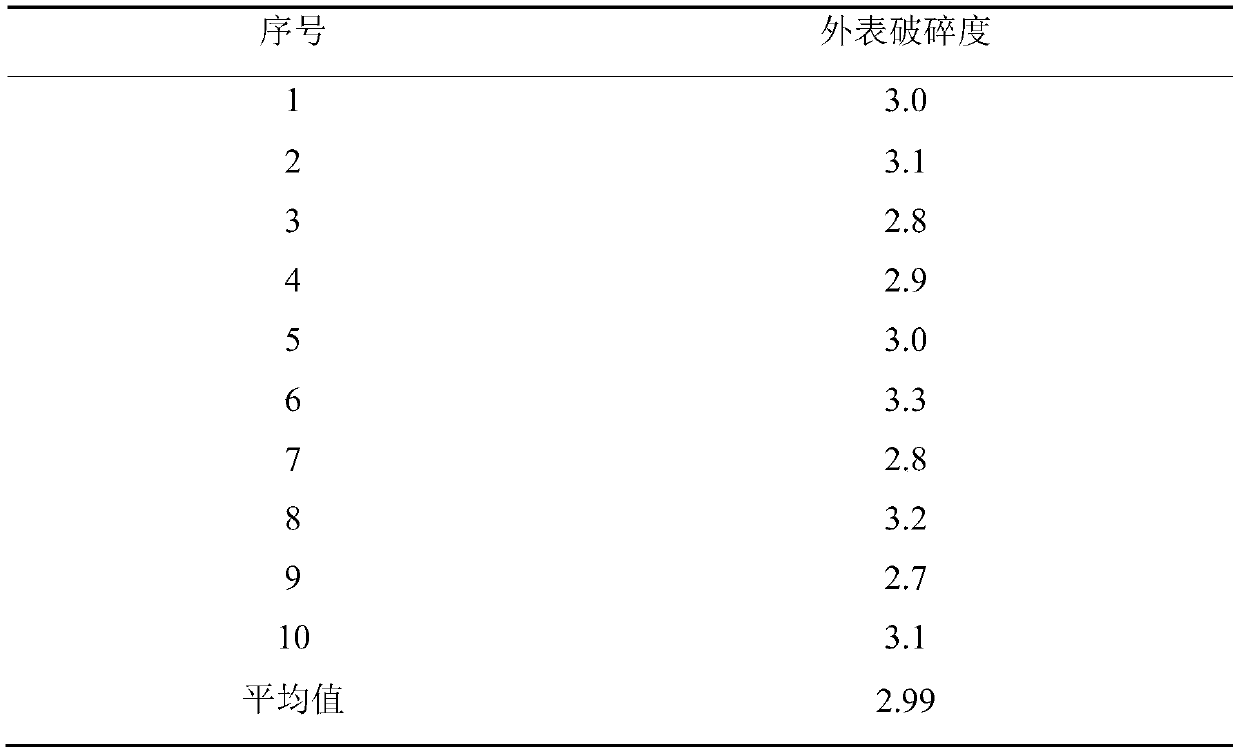

Production method of crispy pear slices

InactiveCN102349631AAvoid shrinkage, deformation or even distortionGuaranteed crispnessFood preparationChemistryMoisture

The invention relates to a production method of crispy pear slices. The method comprises the following steps of pear slicing, color protection, blanching, freezing, differential-pressure puffing, drying, moisture removal and cooling, wherein the moisture removal is performed after the puffing and drying; in the moisture removal, the filtered air is absorbed into a puffing tank, and the vacuum degree in the puffing tank is gradually reduced; and water in the puffed pear slices is dispersed into the puffing tank to form steam, so that the water in the pear slices can be further dispersed out. Therefore, the phenomenon of shrinking deformation or even distortion of the pear slices is avoided, the crispy degree of the pear slices is ensured, and the original color, flavor and vitamin content of fresh pears are maintained.

Owner:JINAN INST OF FRUIT PRODS CHINA GENERAL SUPPLY & MARKETING COOP

Multi-layer and multi-flavor nut seaweed crisp and processing method thereof

InactiveCN111317109AThe filling is evenly distributedGuaranteed flatnessFood coatingUnsaturated fatty acidChemistry

The invention discloses a multi-layer and multi-flavor nut seaweed crisp and a processing method thereof, and belongs to the technical field of food processing. The multi-layer and multi-flavor nut seaweed crisp and the processing method thereof comprises the following steps: the roasted pale spot seaweed, seasoning, sesame, and almond kernel are prepared; before applying the seasoning on the seaweed, the seasoning is roasted for 8-12 minutes under the temperature of 70-80 DEG C to make the seasoning in a sticky state, and thus moisture in the seasoning is prevented from affecting humidity ofthe seaweed; a rolling machine is used to roll to uniformly apply the seasoning on the seaweed, and the smoothness of the seaweed can be guaranteed; and the sesame and the almond kernel are sent on the seaweed by a batch feeder, and one layer is laid again on the top of the sesame and the almond kernel, and the thickness of each layer of seaweed crisp can be facilitated to 1cm through rolling of the rolling machine; and the finished product is roasted for 8-12 minutes at the temperature of 75-90 DEG C to reduce the loss of unsaturated fatty acid of the nuts, finally taste of the seaweed is crisp and delicious, the nut is fresh and free of oil rancidity, and taste of the multi flavors are even.

Owner:CHACHA FOOD CO LTD +1

Making method of chicken feet with capsicum frutescens

The invention belongs to the field of food processing, and particularly discloses a making method of chicken feet with capsicum frutescens. The making method comprises the following steps of selecting chicken feet, unfreezing the selected chicken feet, cleaning the unfrozen chicken feet, blanching the cleaned chicken feet so as to obtain cooked chicken feet, preparing a pickled solution, pickling the chicken feet, air-drying the pickled chicken feet, packaging the dried chicken feet, and performing disinfection treatment. Chicken feet with pickled peppers, made by the making method, have the characteristics that the mouth feel is rich, the crispness and the hardness of the chicken feet can be guaranteed, and the quality guarantee period of the chicken feet with pickled peppers is long.

Owner:CHONGQING ZHOUYI FOOD CO LTD

Pickle preparation method

InactiveCN103919088AHigh purityShort fermentation timeClimate change adaptationFood preparationSaline waterRetention period

The invention discloses a pickle preparation method. The method comprises the following steps: A, preparing raw materials, namely selecting 6-8CM long fresh fruit pods as raw materials, cleaning and removing bases of the fruits, putting the raw materials in a container, and pre-dipping in the container; B, mixing and blending, namely adding saline water with the concentration of 2-6 percent after the previous process, simultaneously adding pepper and ginger, boiling, cooling and adding a lactic bacterial culture; C, sealing a fermentation jar and fermenting, wherein the fermentation time is 36-72 hours, discharging the mixture out of the jar and cleaning after fermentation; D, detecting the salt content, namely controlling the salt to be not more than 3.5 percent, and if the salt content is extremely high, removing salt through running water; E, dehydration pressure, namely dehydrating until the moisture content is less than 90 percent; and F, filling, namely adding condiments according to the taste requirements, checking, filling, sealing and sterilizing. The pickle preparation method has the advantages that the fermentation time is extremely short, the strain purity is high, and the quality is easily controlled; the amount of harmful components is small; the retention period is prolonged; the processing period is short, and the harvest period is adapted; the aim of reducing the production cost is achieved; and the aims of energy conservation and emission reduction are achieved.

Owner:JIANGSU GUANGYUAN FOOD TECH GRP

Health-care rose bergamot crisp chips and preparation method thereof

ActiveCN108991214AReduce cholesterolPromote proliferationConfectionerySweetmeatsBiotechnologyEnzymatic hydrolysis

The invention discloses health-care rose bergamot crisp chips and a preparation method thereof. The method comprises the following steps: (1) pre-selection of raw materials, i.e., cleaning; (2) slicing; (3) enzymatic hydrolysis; (4) blanching and debittering; (5) sugar immersion; and (6) dehydration and drying. The rose bergamot crisp chips prepared by the method show the pink of a rose liquid, and are good in filling degree, crisp, delicious, moderate in sweetness and excellent in mouthfeel.

Owner:SICHUAN UNIV +1

Sweet sea sedge and manufacturing method thereof

The invention provides sweet sea sedge. The sweet sea sedge is composed of laver and seasoner by the mass ratio of 1.4-1.8, the seasoner is prepared from, by weight, 1000-1500 parts of white granulated sugar, 800-1000 parts of glucose, 10-50 parts of edible salt and 50-100 parts of spice. The sweet sea sedge is richer in mouthfeel, distinctive and instant. The invention further provides a manufacturing method of sweet sea sedge, laver moisture regain and template pressing die processes are adopted, the laver is slightly puffed, mouthfeel crisp of the sweet sea sedge is protruded, the sweet sea sedge is made in rolls, and consumers can eat the sweet sea sedge more conveniently, the method is simple in process, small in equipment investment and suitable for industrial production.

Owner:HEBEI STRONG FOOD

Crispy shredded cake making method

ActiveCN107549264AImprove crispnessGuaranteed non-greasyDough treatmentPre-baking dough treatmentProcess conditionsOrganic chemistry

The invention discloses a crispy shredded cake making method which includes the operation steps: dough kneading; dough leavening; carburetion; cake making; oil coating; baking; cake pressing; quick-freezing to obtain a quick-frozen crispy shredded cake. By controlling shredded cake synthesis process conditions, crispness of the shredded cake is remarkably improved, and the shredded cake is not oily and good in taste.

Owner:上海粮全其美食品技术有限公司 +1

High protein nutrient bean dreg rice crust and preparation method thereof

PendingCN107981215AHigh nutritional valueRich in proteinFood shapingFood ingredient as mouthfeel improving agentNutritive valuesRoll forming

The invention discloses high protein nutrient bean dreg rice crust and a preparation method thereof, and belongs to the technical field of food processing. The high protein nutrient bean dreg rice crust is characterized by being prepared by processing the following main raw materials: bean dregs, wiredrawing protein and glutinous rice flour, wherein the mass ratio of the bean dregs to the wiredrawing protein to the glutinous rice flour is 4: (2 to 2.4):(3.2 to 3.7). The preparation method of the bean dreg rice crust comprises the procedures of weighing raw materials, chopping and mixing, carrying out low-temperature expansion, drying, frying and blending. According to the preparation method disclosed by the invention, the wiredrawing protein and the glutinous rice flour with specific proportions are added into the raw materials of the bean dregs and an eight-way pressing roll forming process is adopted; meanwhile, the expanding treatment temperature, the frying temperature and the frying time are optimally designed, so that the formability of the bean dreg rice crust can be ensured and the loosing of the bean dreg rice crust is prevented; meanwhile, the crispiness and mouth feel ofthe obtained rice crust product can be effectively improved and the high protein nutrient bean dreg rice crust can meet double demands of people on taste and nutritive value of leisure foods at the same time.

Owner:JINCAIDI FOOD CO LTD

Production method of spicy and hot salangid peanuts

ActiveCN103829278AMaintain nutrientsGuaranteed crispnessFood preparationMonosodium glutamateZanthoxylum bungeanum

The invention provides a production method of spicy and hot salangid peanuts. The production method comprises the following steps: 1. salting and curing salangid, namely uniformly mixing a yeast extract, a mixed salting material and water, adding the salangid, salting at normal temperature for 1-1.5 hours, drying and curing at 60-65 DEG C for 1-1.5 hours, and drying and curing at 80-85 DEG C for 1-1.5 hours; 2. frying zanthoxylum bungeanum maxim and chili at low temperature; 3. shelling and curing peanuts, namely salting the shelled peanuts and frying; and 4. stirring, namely uniformly mixing the salted and cured salangid, the fried chili, the fried zanthoxylum bungeanum maxim, the fried peanuts, salt and monosodium glutamate in a stirring pot. The spicy and hot salangid peanuts produced by the method provided by the invention are rich in nutrition, crisp in texture, good in mouth feel and outstanding in spicy and delicious flavor, have good sensory effects of visual sensation and taste sensation, and are good in color, aroma and taste.

Owner:ANHUI TRUELOVE FOODS

Method for processing crisp bamboo shoots with agaric

A method for processing crisp bamboo shoots with agaric belongs to the technical field of food processing and comprises the specific steps of: 1) taking fresh bamboo shoots and cutting the same into slices; 2) taking agaric and cutting the same into shreds; 3) preparing accessories and evenly mixing the materials; 4) standing the mixture so that the mixture is flavored; and 5) performing packaging in bags, vacuum sealing, metal detection and sterilization. The product obtained by the method provided by the invention contains no preservative or sweetener, and is delicious and healthy, and has the quality guarantee period of 10-12 months after being processed through rational steps.

Owner:FUYANG HANGFU CANNED FOOD

Sunflower seed processing method

The invention provides a sunflower seed processing method. Sunflower seeds are used as raw materials, and the sunflower seeds are produced after cleaning, positive and negative pressure boiling, microwave hot blast drying, sorting and packaging. The processing method is characterized by comprising specific processing steps as follows: dust on surfaces of the to-be-processed sunflower seeds is cleaned and impurity particles in the seeds are removed by a seed cleaning machine; the cleaned sunflower seeds are placed in a boiling tank to be boiled under the high pressure of 0.18 MPa for 20-30 min and then boiled under the negative pressure of 0.08 MPa for 20-30 min, and 5-6 circulations are performed in such manner; microwave hot blast drying is performed on the boiled sunflower seeds, the microwave length is 2450 MHz, the hot blast temperature is 70-80 DEG C, and the drying time is 20 min; the dried sunflower seeds are cooled and empty seeds are removed by a sorting machine; the sorted sunflower seeds are packaged with paper packaging bags. With the adoption of the method, the crispness of the seeds can be guaranteed, the seeds are tasty by the aid of the negative pressure, the dynamic liquid seed effect can be realized in a negative-pressure slight-boiling manner, the current situation that existing internal, external, upper and lower layers of seeds are not uniformly tasty is improved, the microwave hot blast drying speed is higher, excessive evaporation of aromatic hydrocarbon is avoided, and the flavor of the sunflower seeds is better kept.

Owner:JIANGNAN UNIV

Preparation method of poached vegetable

InactiveCN104996546AMaintain colorAvoid skin breakoutsFruits/vegetable preservation by heatingPickled vegetablesFlavor

The invention relates to the technical field of food producing and processing, and discloses a preparation method of poached vegetable. The preparation method of the poached vegetable comprises the following steps: S1, soaking dried or pickled vegetable in hot water of 80 DEG C to 95 DEG C for over 25min, wherein the mass ratio of the vegetable to the hot water is 1:(7 to 13); S2, fishing up the vegetable processed in S1, draining, and then putting in water of room temperature to soak for 4h to 6h; after that, cleaning and selecting; S3, weighing and bagging the vegetable selected in S2, adding nutrient solution, and then performing vacuum packaging, wherein the pH of the nutrient solution is 4.7 to 5.2; S4, putting the vegetable subjected to vacuum packaging into a sterilizing pot with the water temperature of 60 DEG C to 80 DEG C, heating water to be at least 93 DEG C within 10 to 15min for sterilizing, and keeping constant temperature for 80min to 110min; cooling to obtain a product. By adopting the preparation method, original appearance, color, flavor, taste and brittleness of the vegetable are effectively kept, the nutritional ingredient retaining degree is high, freshness is retained, and the shelf life is long.

Owner:湖南湘春农业科技开发有限公司

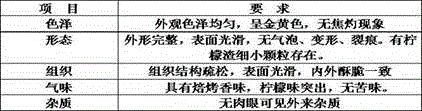

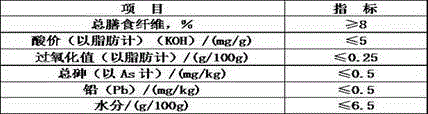

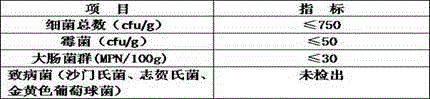

Lemon high-fiber shortbread and preparation method thereof

ActiveCN104430712BIncrease profitImprove efficiencyDough treatmentPre-baking dough treatmentFiberCellulose

The invention discloses a lemon high-fiber cracker which includes the following ingredients, lemon pulp, low-gluten flour, eggs, sugar powder, xylitol, anhydrous butter, milk powder, complex raising agent and water. The lemon high-fiber cracker made by the preparation method of lemon high-fiber crackers used an industrial by-product lemon pulp as raw material. Not only the comprehensive utilization ratio of abandon raw material is decreased, the economical effect and additional value are increased, but also the manufacturing cost is increased and the pollution to environment is reduced. The preparation method of lemon high-fiber crackers has positive economic and social significance. Beta - cyclodextrin - ultrasonic joint processing way is adopted by the preparation method of lemon high-fiber crackers, the cracking of the products is ensured. The lemon high-fiber cracker is rich in lemon cellulose, belongs to the roughage food, and meets the healthy diet concept of modern people.

Owner:SICHUAN UNIV

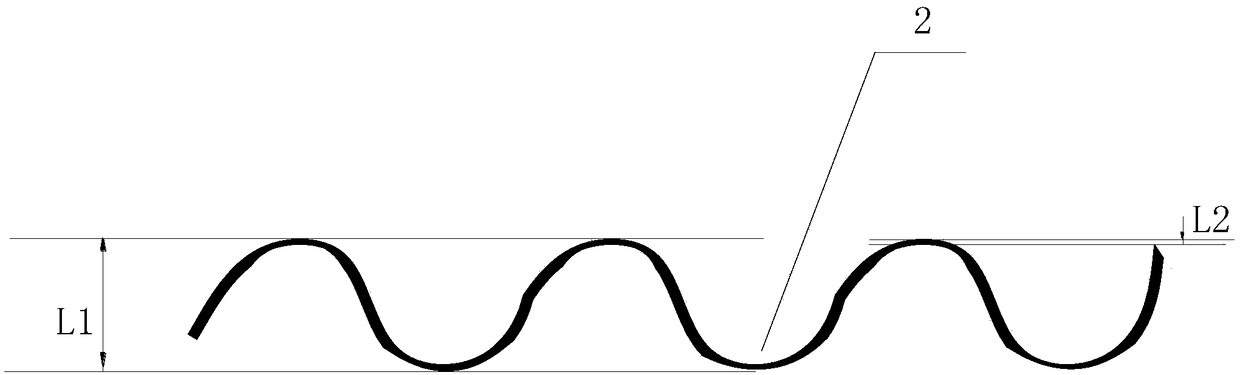

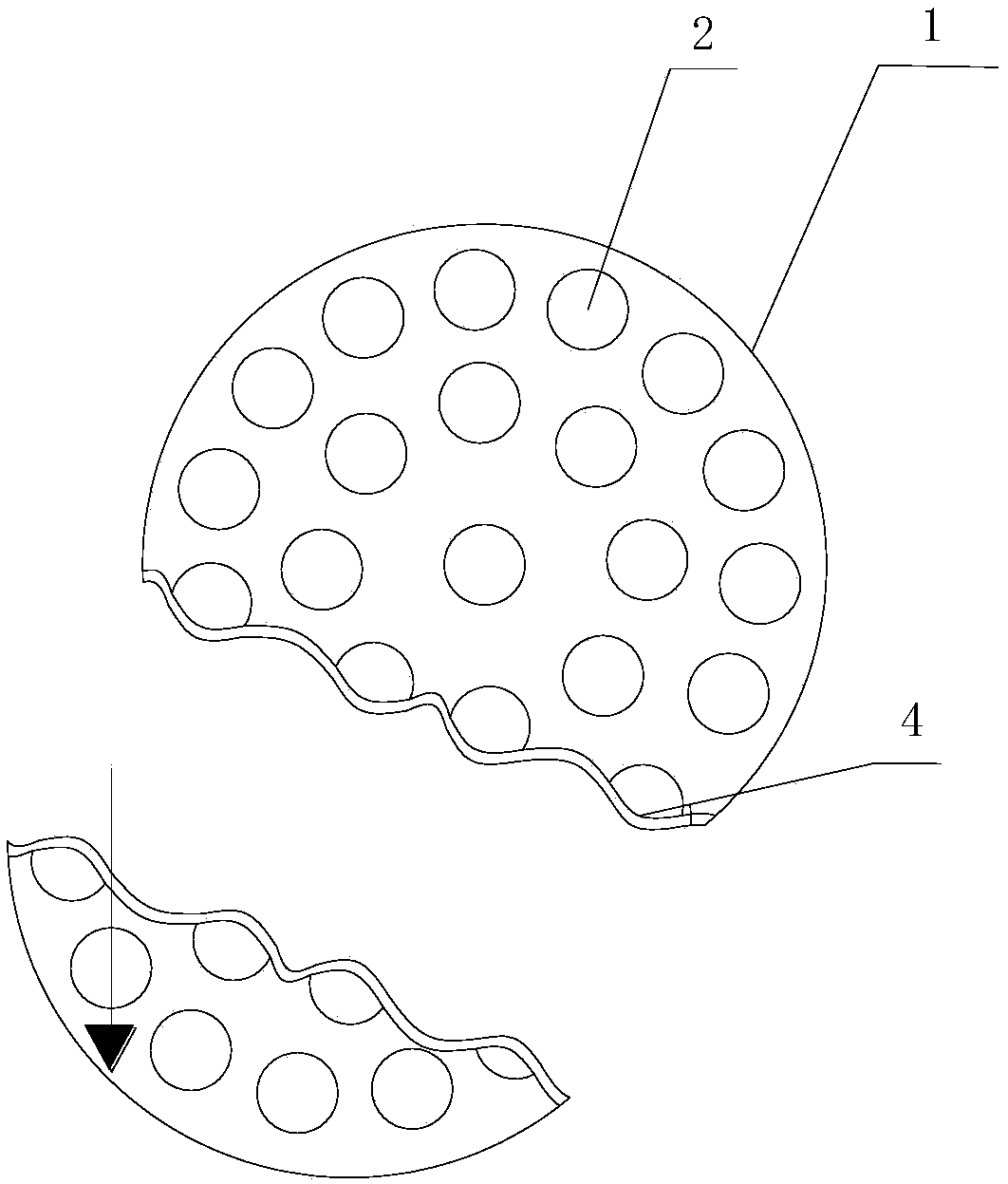

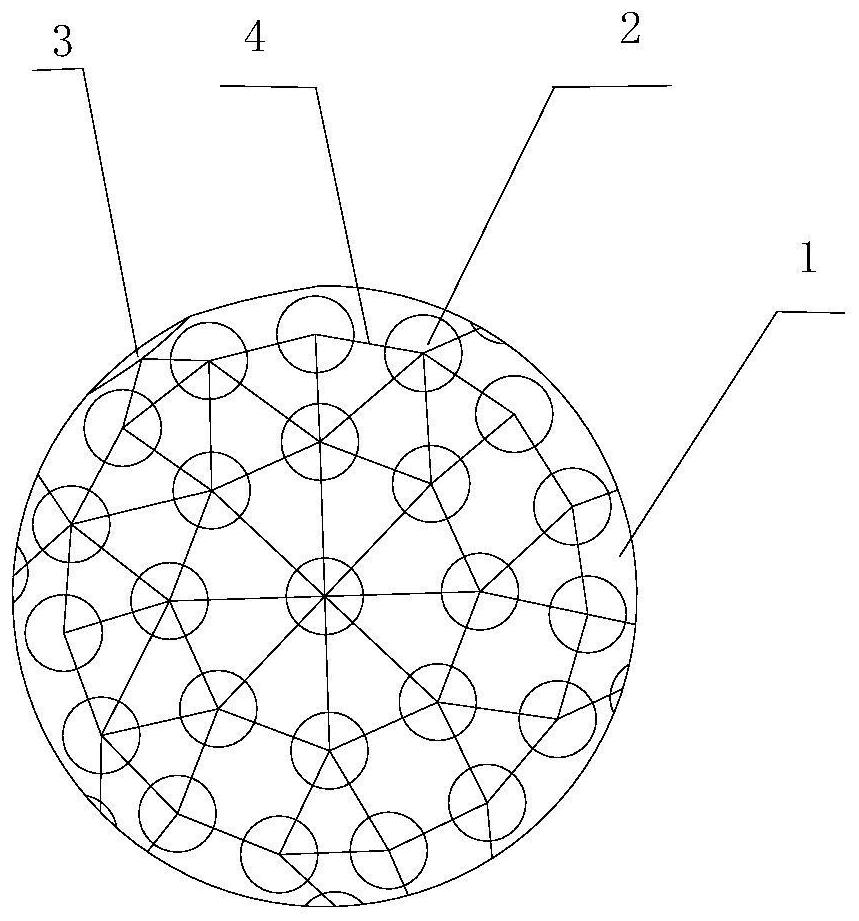

Stone-baked cake and sandwich stone-baked cake

ActiveCN109169796AOptimize structureFacilitate mechanized automatic productionBakery productsEngineeringRespiratory tract

The invention relates to a stone-baked cake and a sandwich stone-baked cake. The stone-baked cake comprises a stone-baked cake body, wherein a plurality of drop pits pressed by hot stones are distributed in the upper cake surface and the lower cake surface of the stone-baked cake body; a plurality of pits pressed by hot stones are distributed at the peripheral side of the stone-baked cake body; the ratio of the center distance between two adjacent drop pits in the same surface to the depth of the drop pits is (1.2-6):1; and the stone-baked cake body is in the form of a sheet. By optimizing thestructure of the stone-baked cake, the stone-baked cake is not likely to generate a lot of stone-baked cake crumbs when the stone-baked cake is broken; a very small amount of stone-baked cake crumbscannot be avoided owing to the material, but the stone-baked cake crumbs generated by the stone-baked cake disclosed by the invention are greatly reduced, the comfort degree of a user is improved during eating, and discomfort experiences that the stone-baked cake crumbs enter the respiratory tracts by accident and drop onto bodies are avoided.

Owner:SHANXI HAIYUYUAN FOOD CO LTD +1

Production method of seasoning bamboo shoot

The invention relates to a production method of a seasoning bamboo shoot and belongs to the field of the food processing technology. The method provided by the invention comprises the following steps: (1), precooking; (2), natural fermentation treatment; (3), sterilization process; (4), blanching; (5), squeezing; and (6) preparation. The production method of the seasoning bamboo shoot has the advantages of reasonable design and suitability for realization of industrialization production of the seasoning bamboo shoot. According to the method provided by the invention, by virtue of reasonable parameter and step design, shredded bamboo shoots are processed before seasoning, so that the freshness and taste frangibility of the bamboo shoots are ensured, and the processed shredded bamboo shootshave original flavor; when seasoning is carried out, by virtue of a reasonable formula, the freshness and frangibility of the shredded bamboo shoot are ensured, so that the shredded bamboo shoots with unexpected delicious flavor can be obtained. The obtained seasoning bamboo shoot in the invention is not added with any preservative and has a quality guarantee period of 1.5-2 years by virtue of reasonable processing steps.

Owner:FUYANG HANGFU CANNED FOOD

Nutritional rice crust and preparation method thereof

InactiveCN108813359AGreat tasteRich in nutrientsFood ingredient as mouthfeel improving agentResource utilizationShiitake mushrooms

The invention discloses nutritional rice crust. The nutritional rice crust is prepared from the following raw materials in parts by weight: 30 to 40 parts of rice, 30 to 40 parts of glutinous rice, 50to 60 parts of soybean residue, 10 to 15 parts of dried shiitake mushrooms, 20 to 30 parts of mung beans and 5 to 8 parts of table salt. The invention further discloses a preparation method of the nutritional rice crust. The invention provides the nutritional rice crust and the preparation method thereof; the soybean residue generated in a bean product production process can be utilized and the utilization rate of resources is improved; the nutritional rice crust has abundant nutrients and a relatively good mouthfeel.

Owner:湖南双晟科技信息咨询有限公司

High-fiber bean dreg rice crust and production process thereof

The invention discloses a high-fiber bean dreg rice crust and a production process of the high-fiber bean dreg rice crust, and belongs to the technical field of food processing. The high-fiber bean dreg rice crust is obtained by processing the main raw materials of bean dreg, dry flour and glutinous rice flour, wherein the mass ratio of the bean dreg to the dry flour to the glutinous rice flour is4:(2.5-3.5):(2.7-3.3). The production process of the high-fiber bean dreg rice crust comprises the procedures of mixing the dry flour, rolling and rubbing, compression moulding, puffing at the low temperature, drying, frying and blending. The dry flour and the glutinous rice flour are added in the raw material of the bean dreg in the specific proportion, eight compression moulding procedures areused, and the puffing temperature, the frying temperature and the frying time are further optimized and designed, so that the formability of the bean dreg rice crust is guaranteed, the bean dreg ricecrust is prevented from getting loose, the crispness and the taste of a rice crust product are also improved effectively, and the rice crust meets the double requirements of people on taste and nutritional value of the snack food.

Owner:JINCAIDI FOOD CO LTD

Digestion-aiding fermentation type ready-to-eat flavored bamboo shoots and preparation method thereof

PendingCN111011780ARich in nutrientsStrong fragranceFood preservationLipidic food ingredientsShiitake mushroomsChemistry

The invention discloses digestion-aiding fermentation type ready-to-eat flavored bamboo shoots and a preparation method thereof, and belongs to the technical field of dried bamboo shoot processing. The main raw materials comprise dried bamboo shoots, one or two of fermented soya beans and shiitake mushrooms, and flavored edible oil. Probiotics beneficial to digestion are utilized, rehydrated dicedbamboo shoots are changed into sour, sweet and tasty fermented bamboo shoots through a solid-state fermentation method, and then the sour, sweet and tasty fermented bamboo shoots, flavored oil and aflavoring agent are boiled and seasoned to obtain the ready-to-eat flavor bamboo shoots beneficial to digestion. The obtained product is sour, sweet and delicious, is rich in nutrition, and can be stored at normal temperature without adding any preservative additive; and the production method is simple, economical, environment-friendly, suitable for large-scale industrial production and relativelylow in production cost.

Owner:广西欧唛果科技有限公司

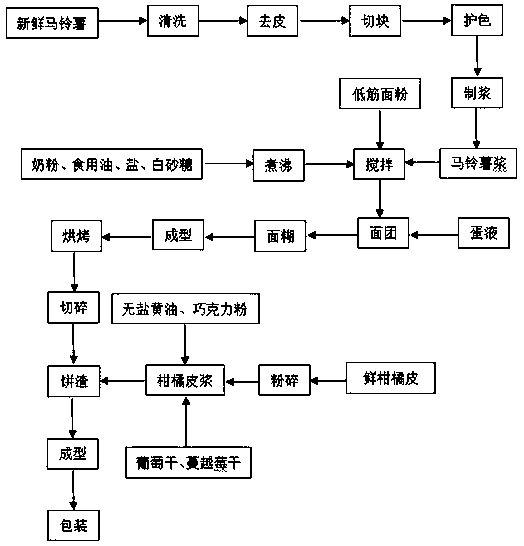

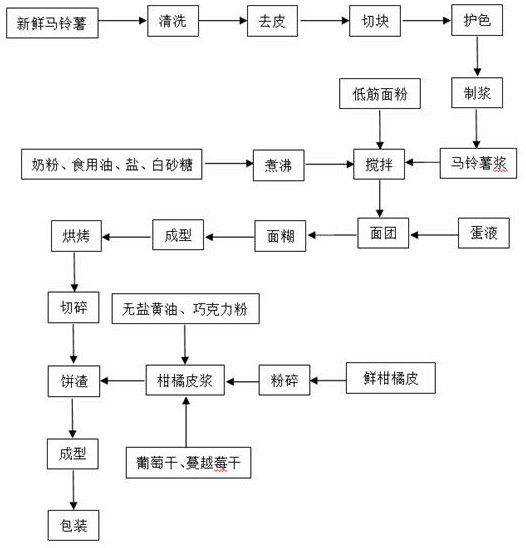

Preparation method of tangerine-flavored crisp potato cakes

ActiveCN108244191AThe formula is novel and reasonableSweet PotatoDough treatmentModified nutritive productsTangerine FruitPotato cakes

The present invention discloses a preparation method of tangerine-flavored crisp potato cakes. The preparation method comprises two steps of preparing potato cakes and preparing tangerine-flavored crisp potato cakes. The prepared crisp potato cakes are moderate in crispness and free of cracks on the surfaces. The preparation method finally ensures the crispness of the tangerine-flavored crisp potato cakes. At the same time, the tangerine-flavored crisp potato cakes are mellow in potato fragrance, comprehensive in nutrients and crisp in mouthfeel, enrich potato products and expand application ranges of potatoes.

Owner:SHAANXI UNIV OF SCI & TECH

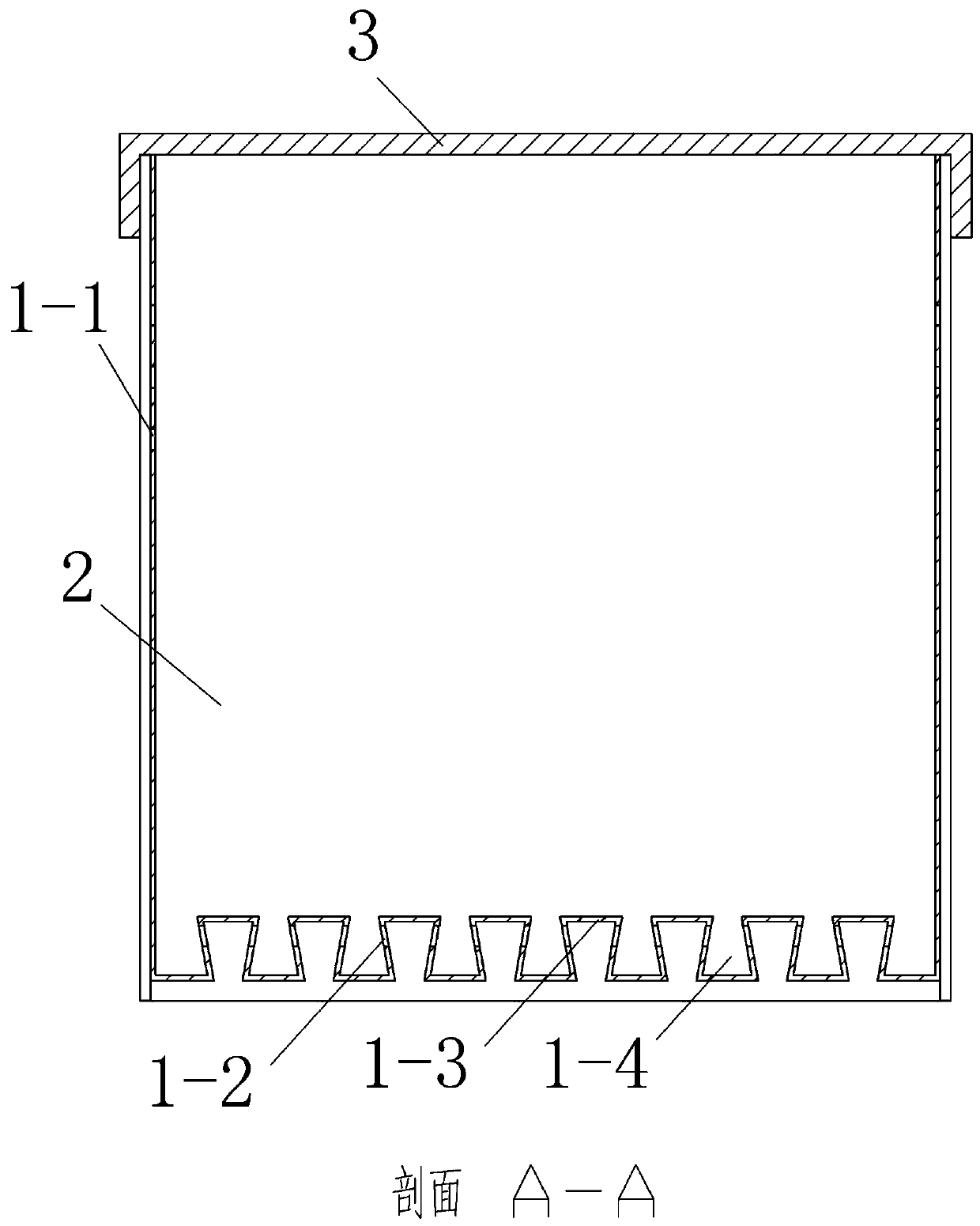

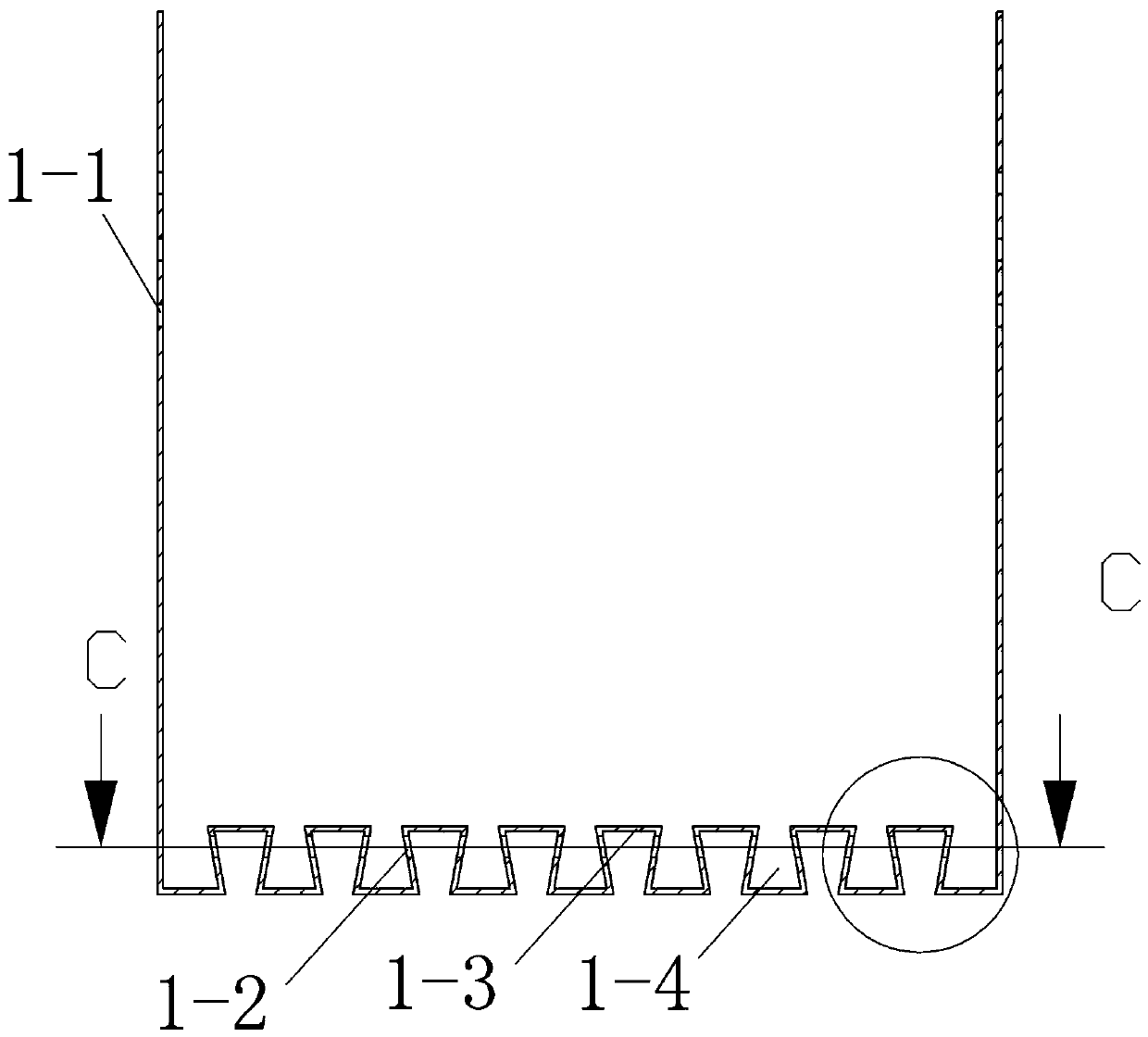

Fried food delivery box with oil drip receiving function

InactiveCN107913009AGuaranteed crispnessAffects surface crispnessKitchen equipmentFlavorSurface layer

A fried food delivery box with the function of dripping oil, including a box body and a cover body, the box body includes a square groove-shaped main body and two side seal heads, and the main body includes a wave Shaped bottom plate and two side plates, the wave-shaped bottom plate is composed of several trapezoidal supports formed by folding, and the adjacent support bodies are oil receiving grooves with narrow tops and wide bottoms. A row of several air inlets are provided on the two side walls of each support close to the upper edge; the head is a plate-shaped body that matches the groove cross section of the main body, and is closed and connected to the groove of the main body. The two ends are followed by the main body to form a box body with an upper opening, the cover covers the upper part of the opening, and the two side plates of the main body are provided with exhaust holes. The invention can prevent the crispy layer on the surface of the fried chicken nuggets from being affected and reduce the taste, and is especially suitable for temporary packaging for delivery, and also has the effect of temporary heat preservation.

Owner:郑州海擎电子技术有限公司

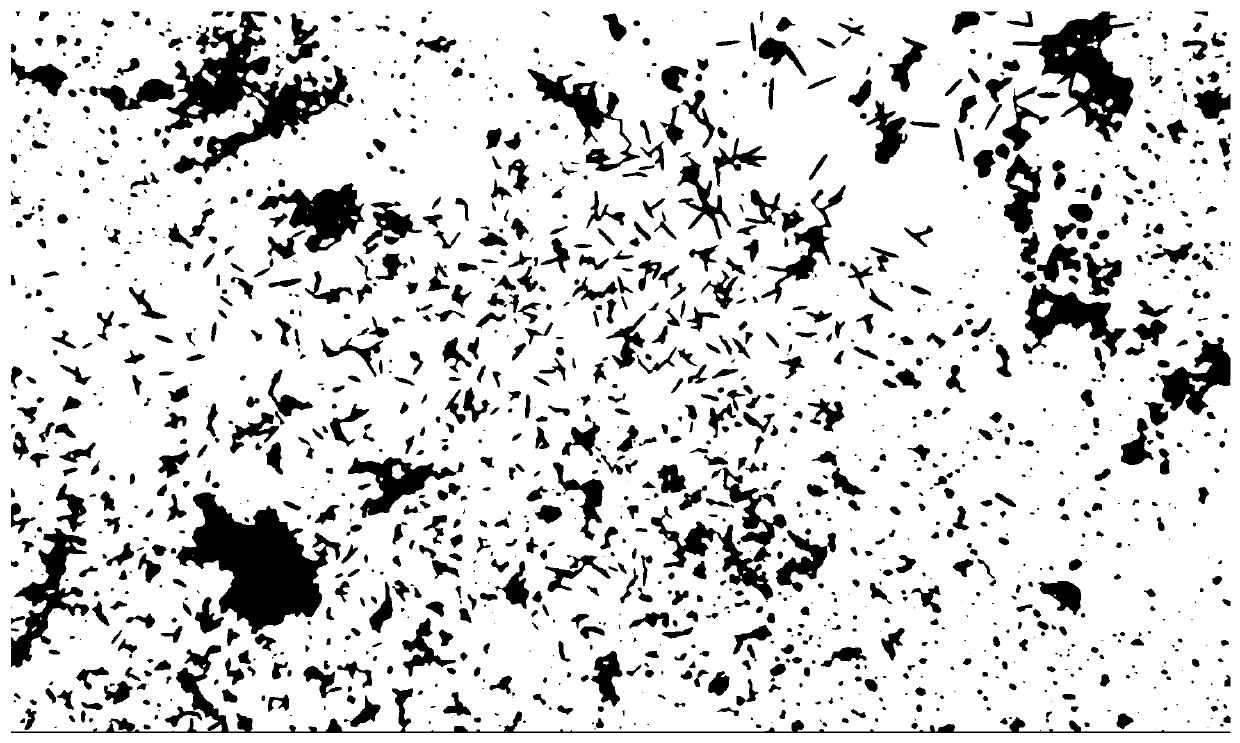

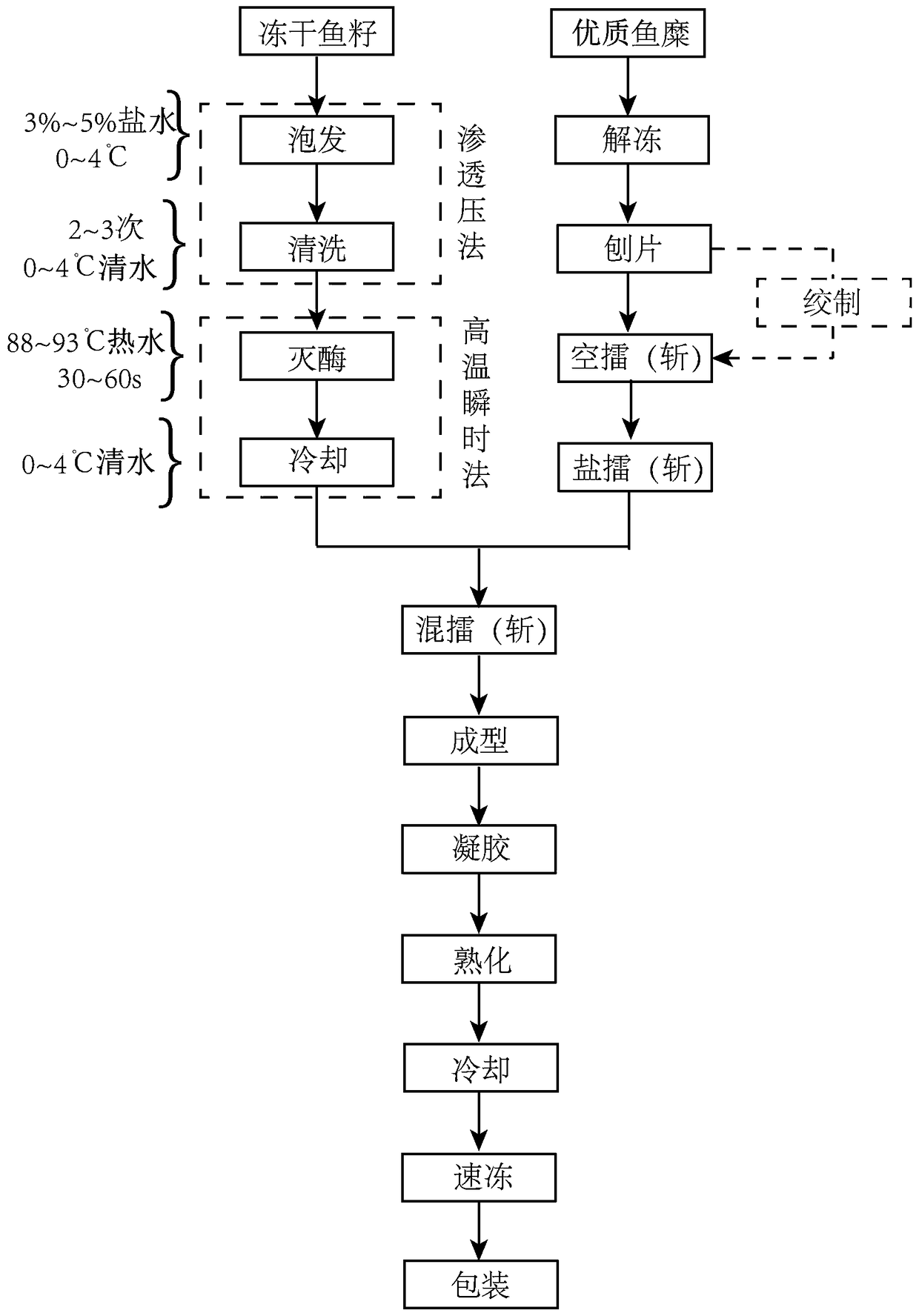

Processing method of high-quality minced fish product containing fish roe grains

InactiveCN108850897AInhibit microbial growthPrevent browningFood ingredient as mouthfeel improving agentChemistrySaline water

The invention discloses a processing method of a high-quality minced fish product containing fish roe grains. The processing method comprises the following technological steps: (1) putting freeze-dried fish roes into saline water with the temperature of 0 to 4 DEG C and the concentration of 3 to 5 percent and soaking for 1 to 4h; stirring for one time every other 10 to 20min; (2) putting the soaked fish roes into clean water with the temperature of 0 to 4 DEG C and washing for 2 to 3 times; after washing, filtering and drying through a screen mesh; (3) putting the filtered and fried fish roesinto hot water with the temperature of 88 to 93 DEG C and blanching for 30 to 60s; stirring and killing enzyme; (4) transferring the fish roes into clean water with the temperature of 0 to 4 DEG C andcooling to be lower than 4 DEG C; filtering and drying through a screen mesh to prepare pre-prepared fish roes; (5) unfreezing high-quality minced fish, flaking, mincing, pounding without anything and pounding with salt to obtain paste with the temperature less than 4 DEG C; (6) adding 2 to 20 percent of the pre-prepared fish roes into the paste to obtain paste with the temperature less than 12 DEG C; (7) molding, gelling, curing, cooling, quickly freezing and packaging the obtained paste obtained by step (6). According to the processing method disclosed by the invention, nutrient loss of thefish roes is reduced and a special mouthfeel of the fish roes is ensured; the activity of proteinase on the surfaces of the fish roes is passivated and bad influences on the quality of minced fish products are reduced.

Owner:FUJIAN ANJOY FOODS CO LTD +3

A kind of preparation method of hickory chick stipe brittle grain

The invention relates to a method for preparing morel stalk brittle grains, which belongs to the field of deep processing of edible fungi. The invention uses the pruned stipe (also called fungus foot) of morel fungus as a raw material, and first undergoes enzymatic hydrolysis, dipping and other treatments. Destroy the internal structure of the stipe, and then puff it through air-flow puffing technology, so as to obtain stipe brittle grains with rich nutrition, strong flavor, full shape, crisp taste, oil-free and low calorie, realize the comprehensive utilization of stipe, improve added value of the product.

Owner:十堰绿筷子食品有限公司

Process for preserving instant hot pickled mustard tuber

InactiveCN1820640AGuaranteed crispnessImproved quality and tasteFood preservationFood preparationPlant TubersHigh oxygen

The present invention relates to one process of producing instant hot pickled mustard tuber. During the production process, the hot pickled mustard tuber after processing is first nitrogen-filling packed and then sterilized and cooled. The nitrogen-filling packing is super to available packing mode, which has relatively high oxygen residue, easy product oxidation, inhomogeneous supplementary material dispersing and more deformation of hot pickled mustard tuber. The filled nitrogen amount is controlled, so that the hot pickled mustard tuber may be sterilized through spraying and water bath for effective sterilization and maintaining product crispness. The technological process can raise the quality of instant hot pickled mustard tuber.

Owner:CHONGQING FULING ZHACAI GROUP

A kind of stone cake and sandwich stone cake

ActiveCN109169796BGuaranteed to be stable and not fragileEasy to identifyBakery productsMechanical engineeringComposite material

Owner:SHANXI HAIYUYUAN FOOD CO LTD +1

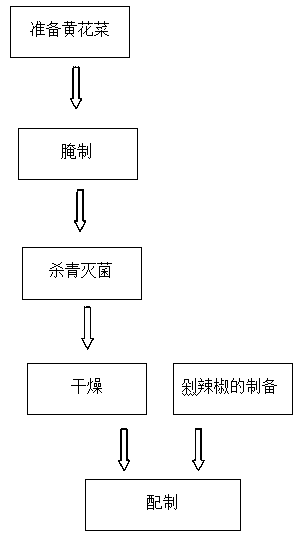

Making method of pickled fresh hemerocallis Fulvs being resistant to storage and fresh

InactiveCN110731479AGreat tasteExtended storage timeFruit and vegetables preservationFood processingHerb medicineCapsicum annuum

The invention provides a making method of pickled fresh hemerocallis Fulvs being resistant to storage and fresh. The making method comprises the following steps of first step, preparing hemerocallis Fulvs; second step, performing pickling; third, performing fixation and sterilization: steaming the hemerocallis Fulvs pickled in the second step with a steamer for 15-60 minutes, wherein the steamer comprises a steaming basket located at the top, the steaming basket is used for loading the hemerocallis Fulvs, and alkaloid and herbal medicines are added in the steamer; fourth step, performing drying; fifth step, preparing chopped capsicum frutescens: pickling the chopped capsicum frutescens with salt for 10-20 days; and sixth step, performing preparation: mixing the hemerocallis Fulvs in the fourth step with the chopped capsicum frutescens in the fifth step in proportion being (5 to 1) to (1 to 3), besides, adding a preservative conforming to the national standard, performing sealed packing, performing fermentation, and performing storage. The scheme can effectively solve the storage problem of pickled hemerocallis Fulvs, and the storage time of the pickled hemerocallis Fulvs can be effectively prolonged, the crispness and the freshness of the hemerocallis Fulvs can be guaranteed, the processing quality and the economic value of the hemerocallis Fulvs are effectively increased, andthe making method is convenient for batch production.

Owner:QIDONG NONGJIAOHUI FOOD CO LTD

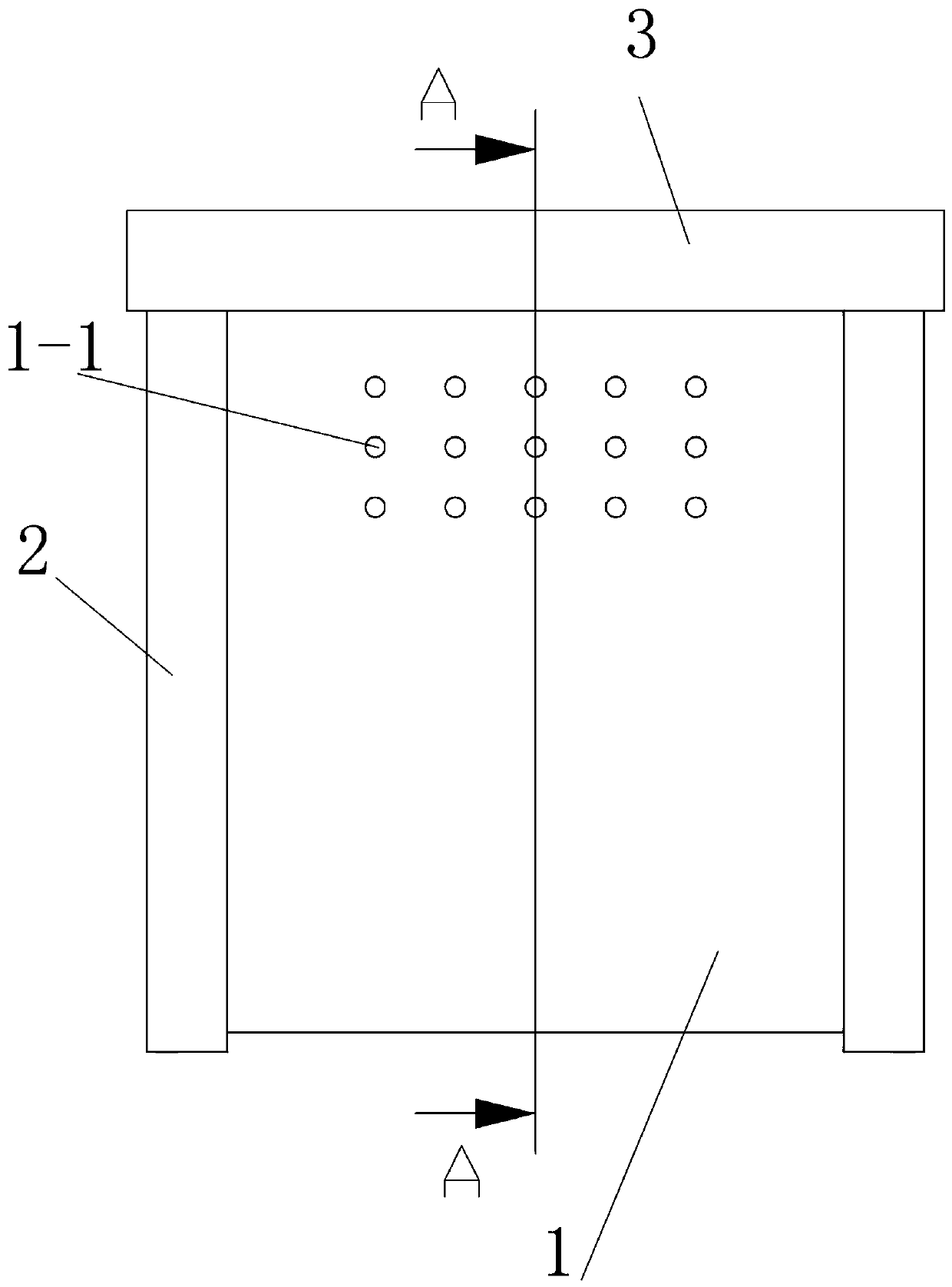

Soybean deep-fried dough stick and making method thereof

PendingCN113796404AHigh nutritional valueReduce sodiumDough treatmentLeguminous plant bakery productsBiotechnologyNutritive values

The invention provides a soybean deep-fried dough stick and a making method thereof. The soybean deep-fried dough stick comprises a soybean deep-fried dough stick core made of soybeans and a soybean deep-fried dough stick outer skin made after the soybean deep-fried dough stick core is wrapped with soybean milk and fried, and the soybean deep-fried dough stick core is a cylindrical core made by soybean milk skin in a double-layer compounding and reciprocating rubbing mode. The soybean deep-fried dough stick produced by the method has the advantages that the soybean deep-fried dough stick core produced by the soybean milk skin in a double-layer compounding and physical reciprocating rubbing manner is used for ensuring the softness of the final soybean deep-fried dough stick product, the crispness and the mouth feel of the soybean deep-fried dough stick product are ensured through the proportion of the wrapping slurry, and the finally processed soybean deep-fried dough stick product is short in frying time, and the oil content is reduced; and as the main raw material is soybean, the soybean deep-fried dough stick product has the advantages of high nutritional value, low carbohydrate and sodium content, high protein content, low total calorie and soybean fragrance, and a bulking agent is not needed in the processing process.

Owner:北京香豆豆食品有限公司

A method and application of integrated modulation and heating of cigarette tobacco leaves by roasting and removing impurity gases

ActiveCN112042992BGuaranteed drynessGuaranteed crispnessTobacco preparationHarvestersProcess engineeringMaterial resources

The invention discloses a method and application of a method for integrally modulating and heating cigarette tobacco leaves by roasting and removing miscellaneous gases. The method comprises the steps of harvesting fresh flue-cured tobacco leaves suitable for ripening, weaving rods or putting them into tobacco holders, and then entering the curing barn; , the adjusted heated cigarette leaf can be obtained. The tobacco leaf is the tobacco leaf obtained by the aforementioned method. The application is the application of the tobacco leaves obtained by the preparation method in the preparation of heated cigarettes. Based on the modulation characteristics of the heated cigarette raw materials and the re-baking process, the present invention optimizes the combination of the initial roasting and re-baking process of the tobacco leaf raw materials, and completes the process of re-baking and removing impurities in the initial roasting stage in advance, which solves the cumbersome curing process of the heated cigarette tobacco production line It can not only meet the quality requirements of heated cigarette tobacco raw materials and improve the aroma of tobacco leaves, but also help optimize the production chain of heated cigarettes and effectively improve production efficiency.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

A kind of preparation method of orange-flavored potato crisp

ActiveCN108244191BThe formula is novel and reasonableSweet PotatoDough treatmentModified nutritive productsBiotechnologyPotato cakes

A method for preparing orange-flavored potato crisps, comprising two steps of preparing potato cakes and orange-flavored potato crisps, the prepared potato cakes are moderately crispy and have no cracks on the surface, which finally ensures the crispness of orange-flavored potato crisps, while the potato flavor Rich, full-bodied, and crispy in taste, it enriches potato products and expands the application range of potatoes.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing heating cigarette tobacco leaves through integration of baking and impurity gas removal and application

ActiveCN112042992AGuaranteed drynessGuaranteed crispnessTobacco preparationHarvestersProcess engineeringCuring of tobacco

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

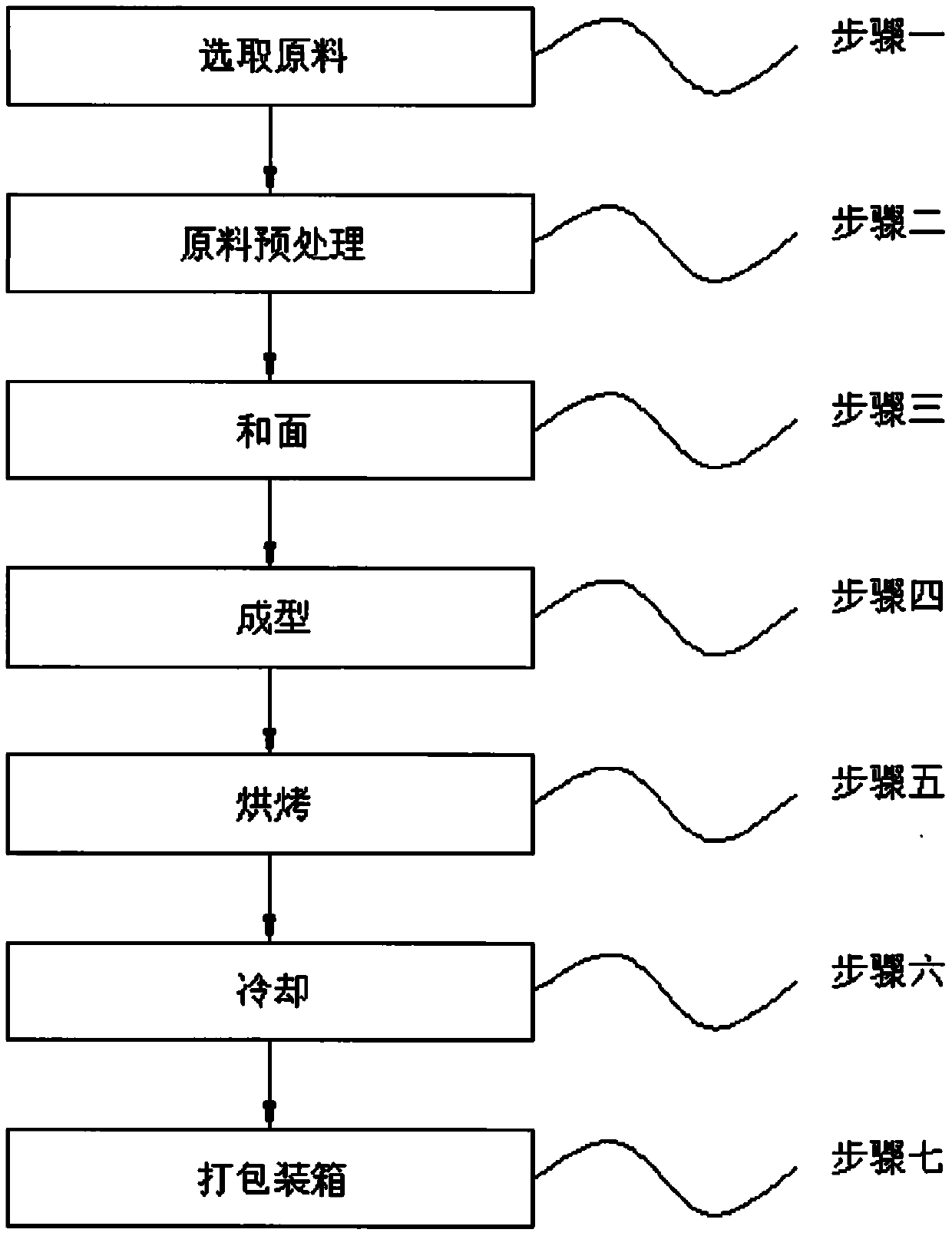

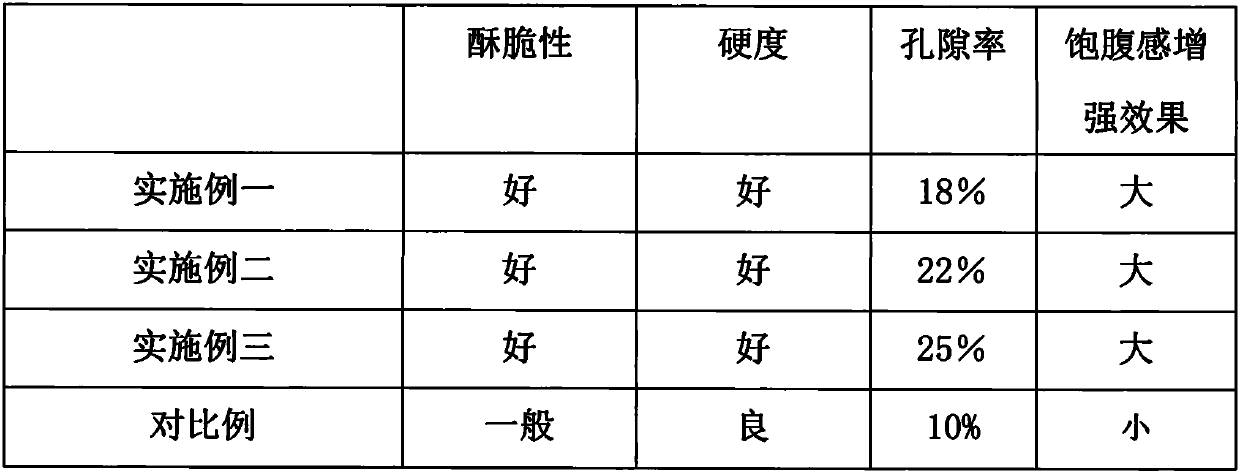

Inulin cookie and preparation method thereof

InactiveCN109924240AHigh hardnessHigh porosityDough treatmentBakery productsCooking & bakingIcing sugar

The invention discloses an inulin cookie and a preparation method thereof. The inulin cookie comprises, by weight, 180-200 parts of low-gluten flour, 2-3 parts of salt, 50-60 parts of sugar, 1 egg, 100-150 parts of butter, 1 egg yolk, 3-5 parts of baking powder, 50-60 parts of powdered sugar, 30-70 parts of inulin and 10-15 parts of milk powder. The preparation method includes the first step of selecting raw materials; the second step of preprocessing the raw materials; the third step of kneading dough; the fourth step of molding; the fifth step of baking; the sixth step of cooling; the seventh step of packaging with boxes. Under the premise that the crispness is ensured, the hardness of the cookie and the porosity of the cookie are improved, and the taste of the cookie is ensured. At thesame time, the satiety is effectively enhanced to promote the metabolism of the cookie, promote the absorption of trace elements and ensure the body health of people.

Owner:QINGHAI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com