Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101results about How to "Guaranteed blasting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

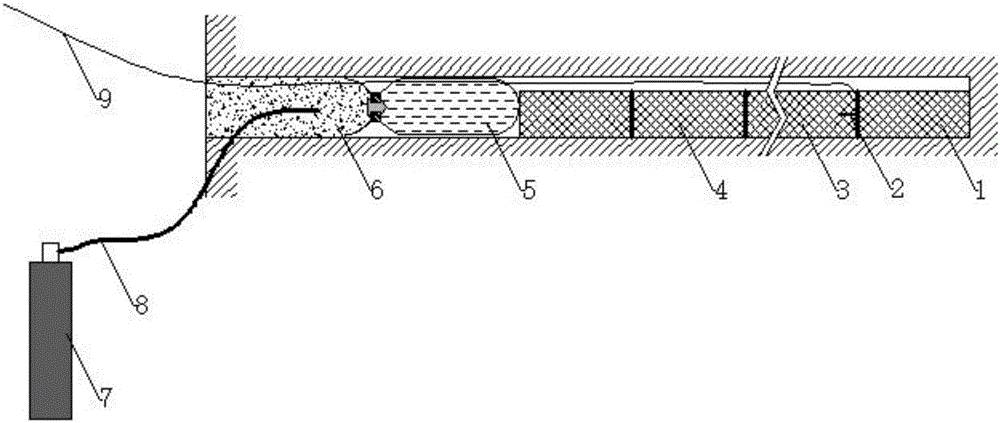

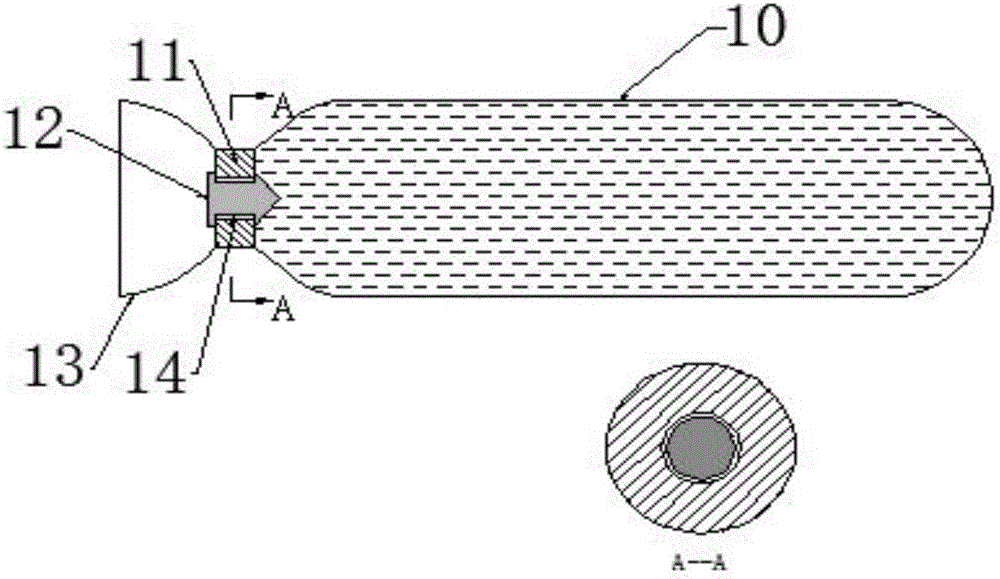

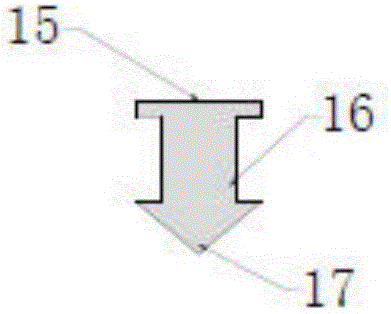

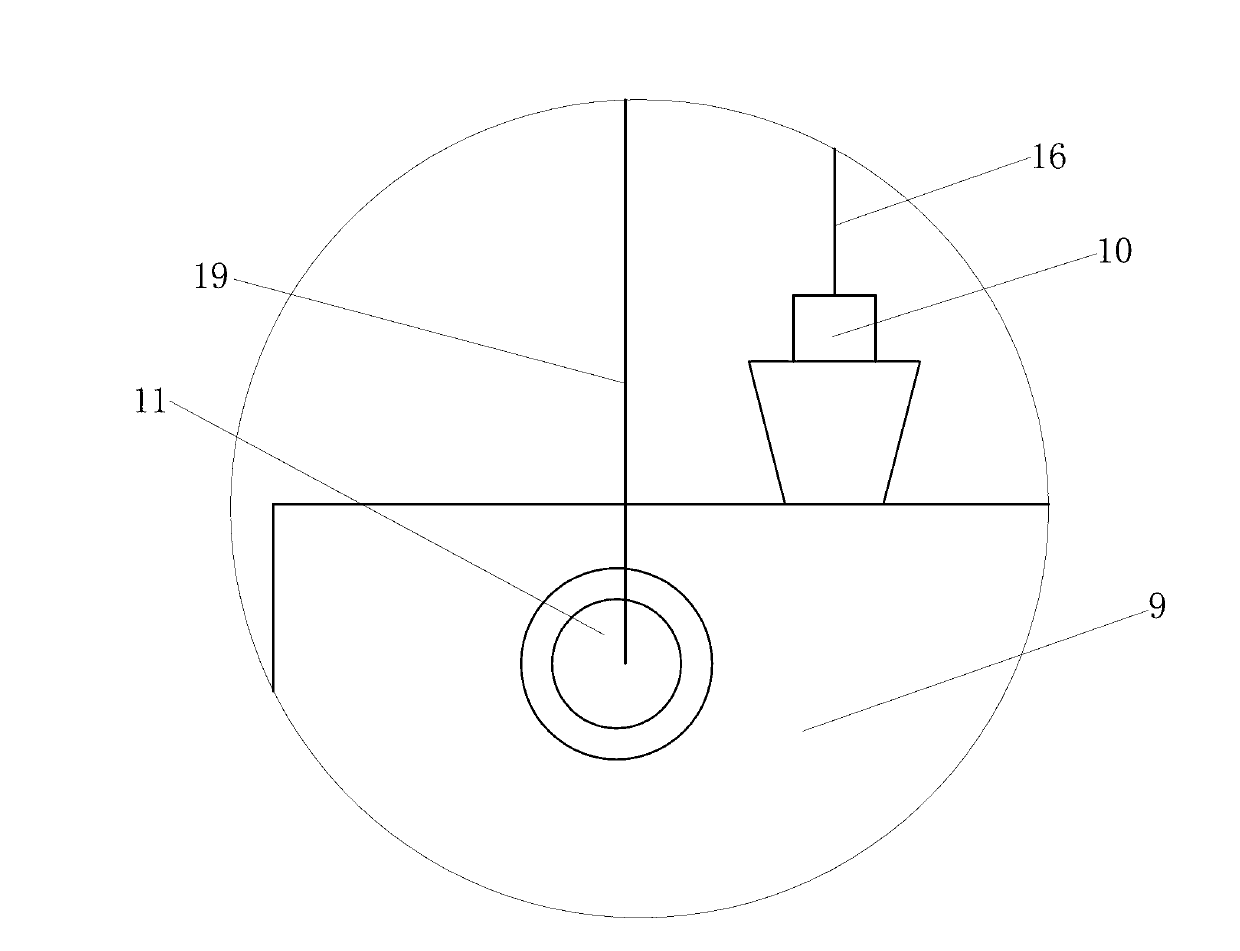

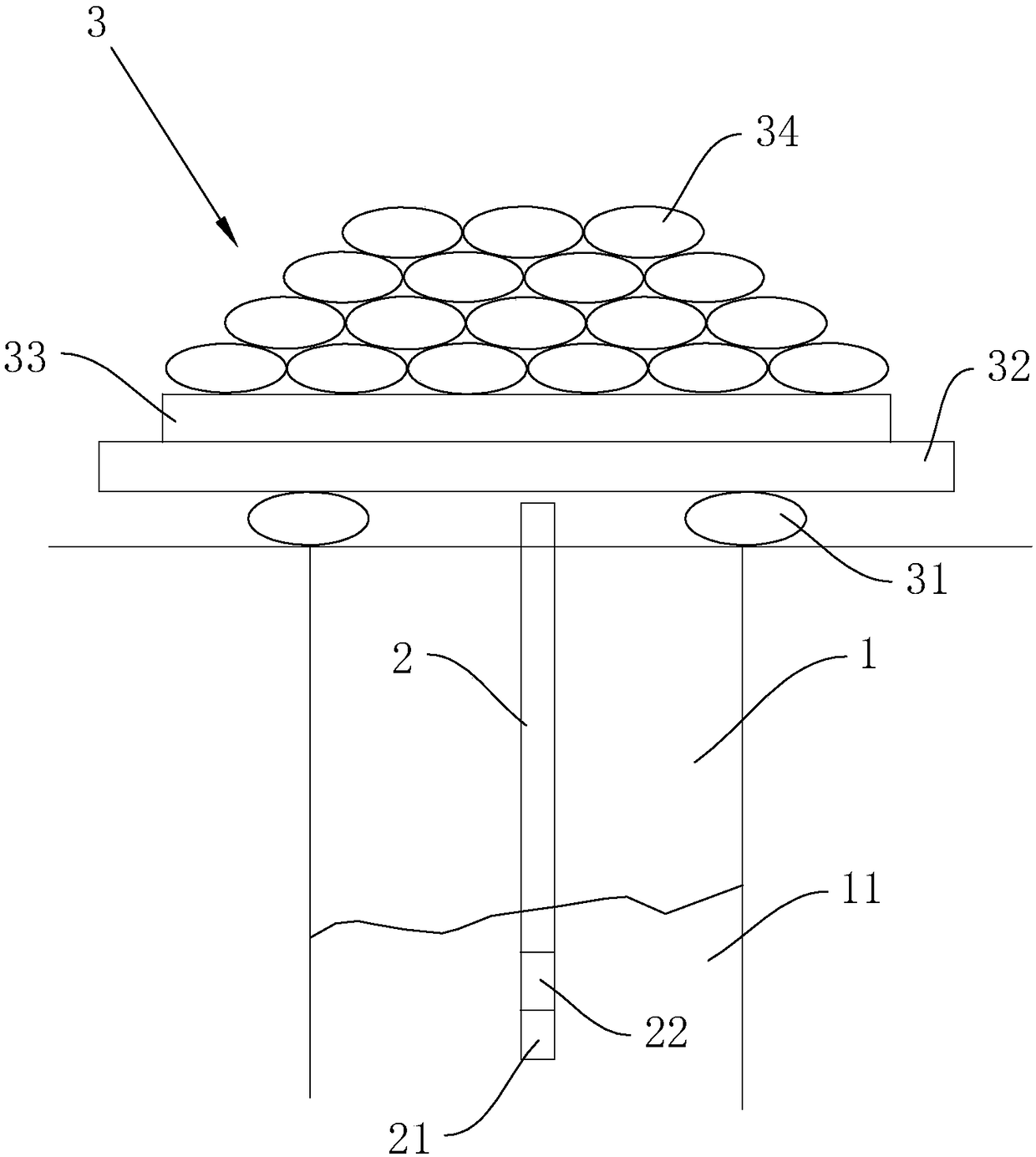

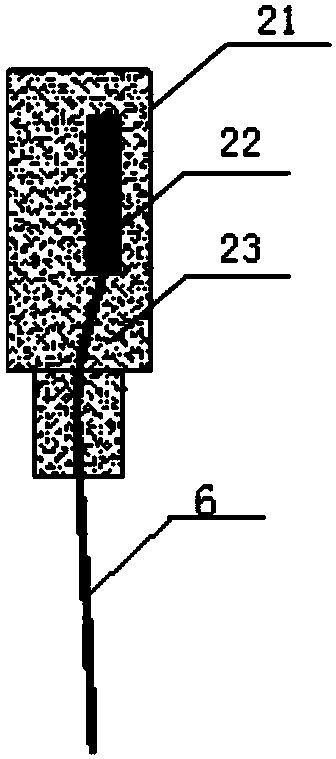

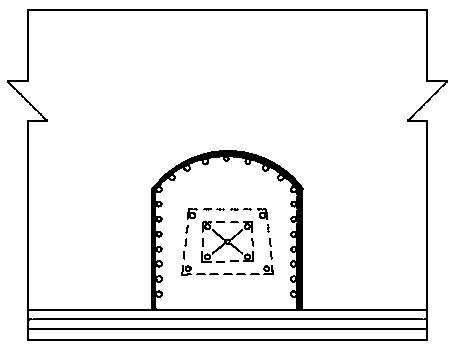

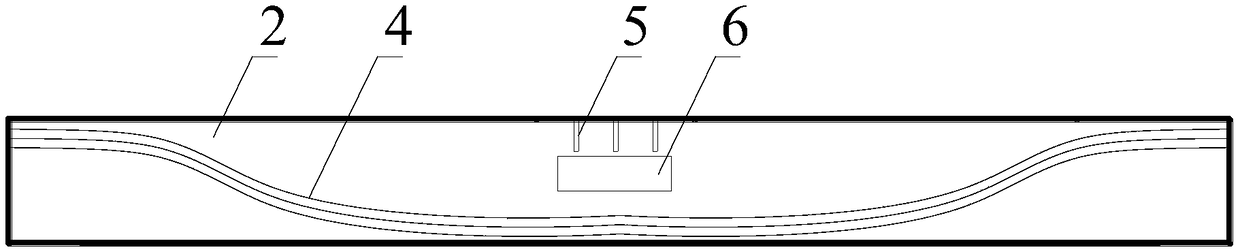

Mine water stemming bag and application of mine water stemming bag in borehole blockage

ActiveCN105066804AConvenient and fast blocking effectEfficient and reliable blocking effectBlastingCombined useSelf locking

The invention provides a mine water stemming bag and an application of the mine water stemming bag in borehole blockage. By means of the mine water stemming bag, local self-locking can be achieved, and leakage of a bag opening can be prevented reliably. By applying the mine water stemming bag to borehole blockage and combining with polyurethane expansion foam composites, a convenient, quick, efficient and reliable borehole blockage effect can be achieved, labor intensity of manual borehole blocking is relieved, construction time is shortened, work efficiency is improved, and the forced mining and forced excavation technical requirements of underground metal mines are met on the premise that the blasting effect is guaranteed.

Owner:HUNAN CHENZHOU MINING CO LTD +1

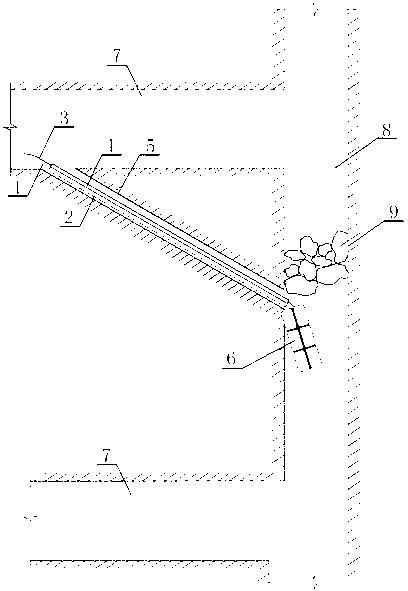

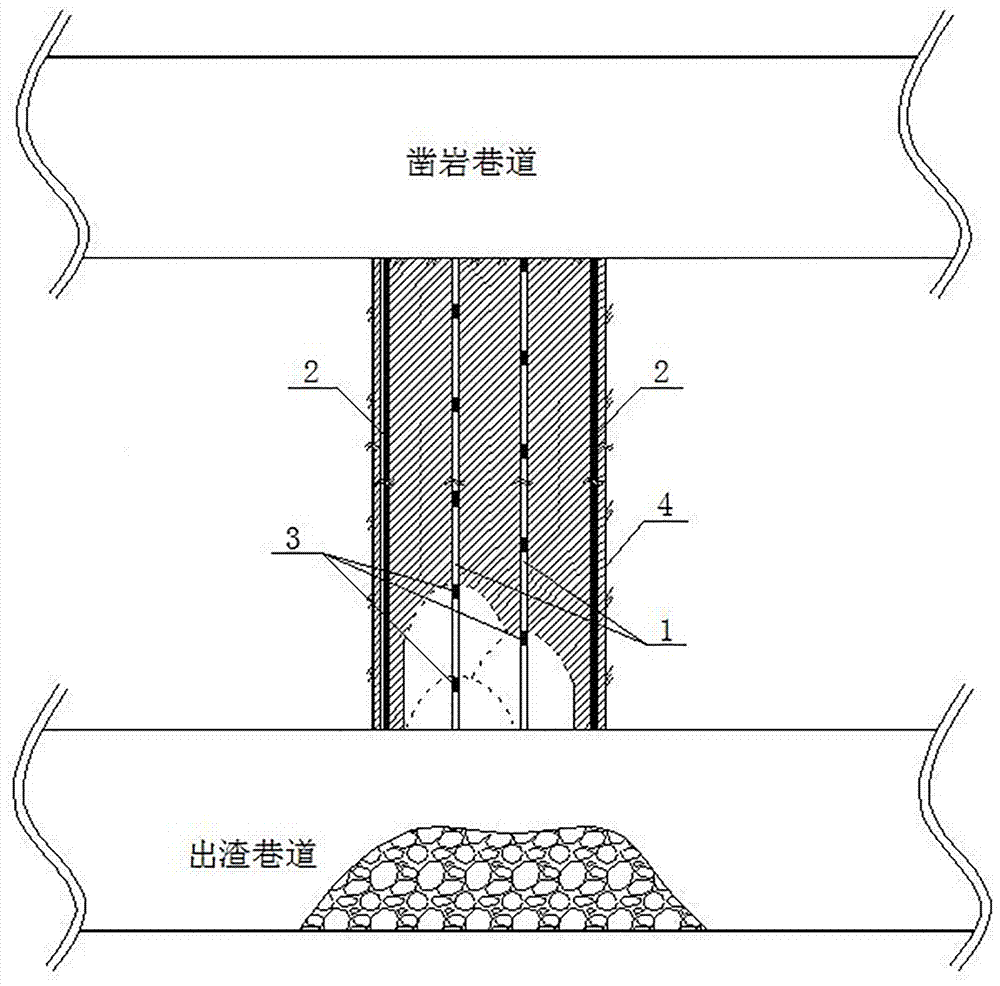

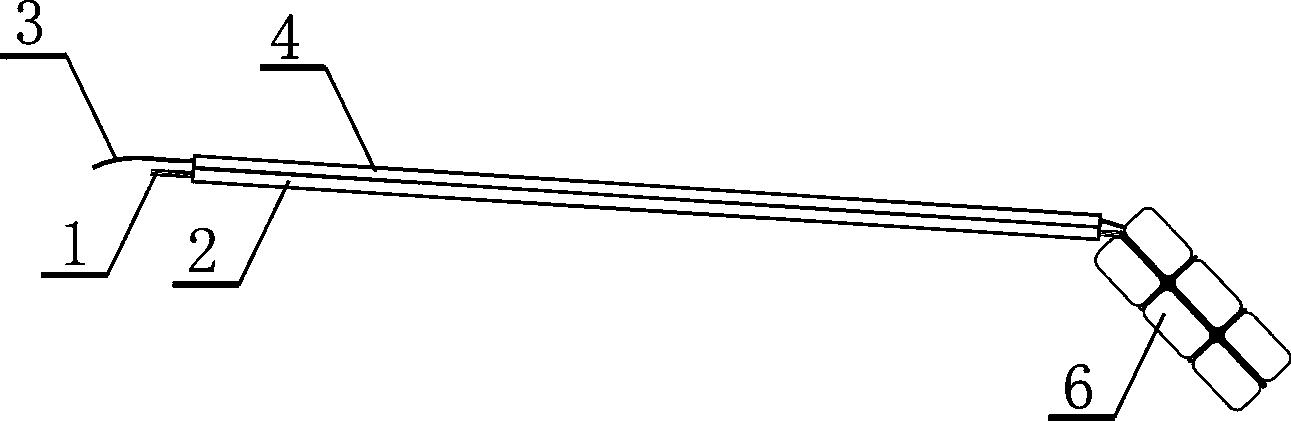

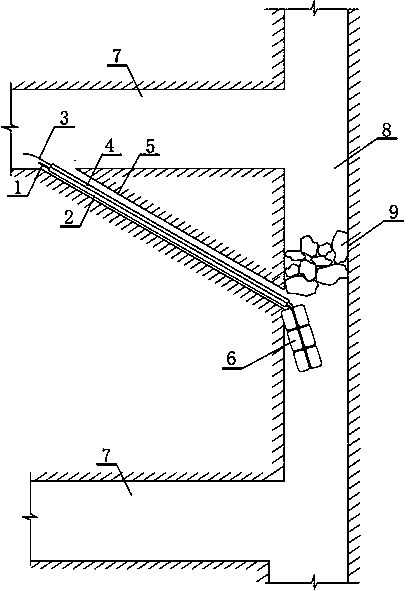

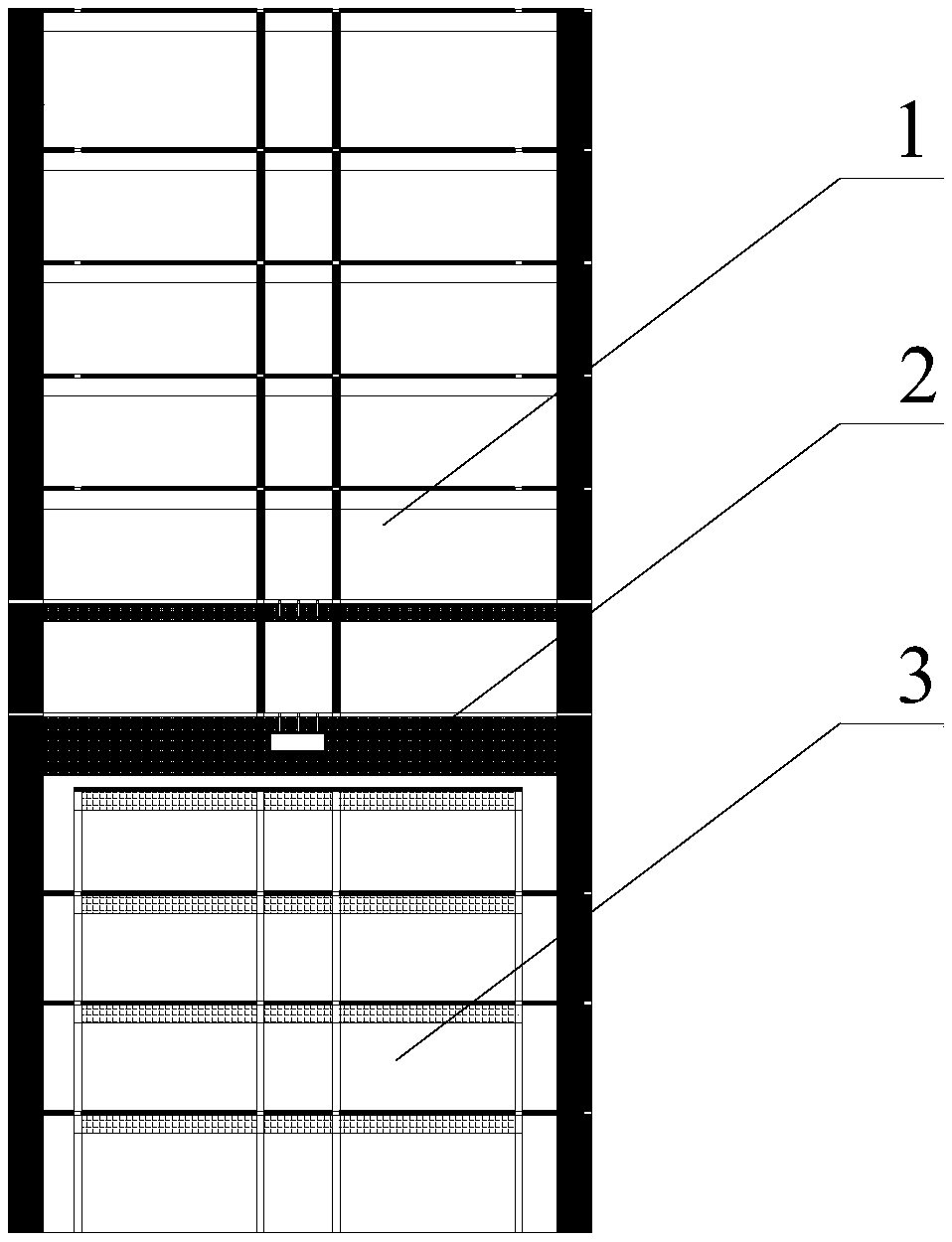

Method for effectively removing ore-pass blockage and blockage removal device

The invention discloses a method for effectively removing ore-pass blockage and a blockage removal device. The method comprises the steps of calculating a blocking point, drilling a guide hole, setting an explosive substance, and removing the blockage by detonation. The blockage removal device comprises a tow rope conduit and a tow rope, wherein the tow rope passes through the tow rope conduit to fix the explosive substance. According to the invention, with smart assistance of ore-pass passages matched with an ore-pass, an ore-pass passage above the blockage point is utilized to determine the position of the blockage point and set the explosive substance, an ore-pass passage above the blockage point is used to determine a drilling direction. The opening of the guide hole is set below an obstruent (and close to the obstruent), and the explosive substance can smoothly cling to the obstruent by the matching of the upper ore-pass passage and the lower ore-pass passage, therefore, a good blasting effect is ensured; and meanwhile, operating personnel and the explosive substance can be naturally separated from each other by the guide hole, and thus the construction security is ensured. The method disclosed by the invention is simple and practical, and the blockage removal device is simple in structure as well as safe and reliable.

Owner:YUXI DAHONGSHAN MINING

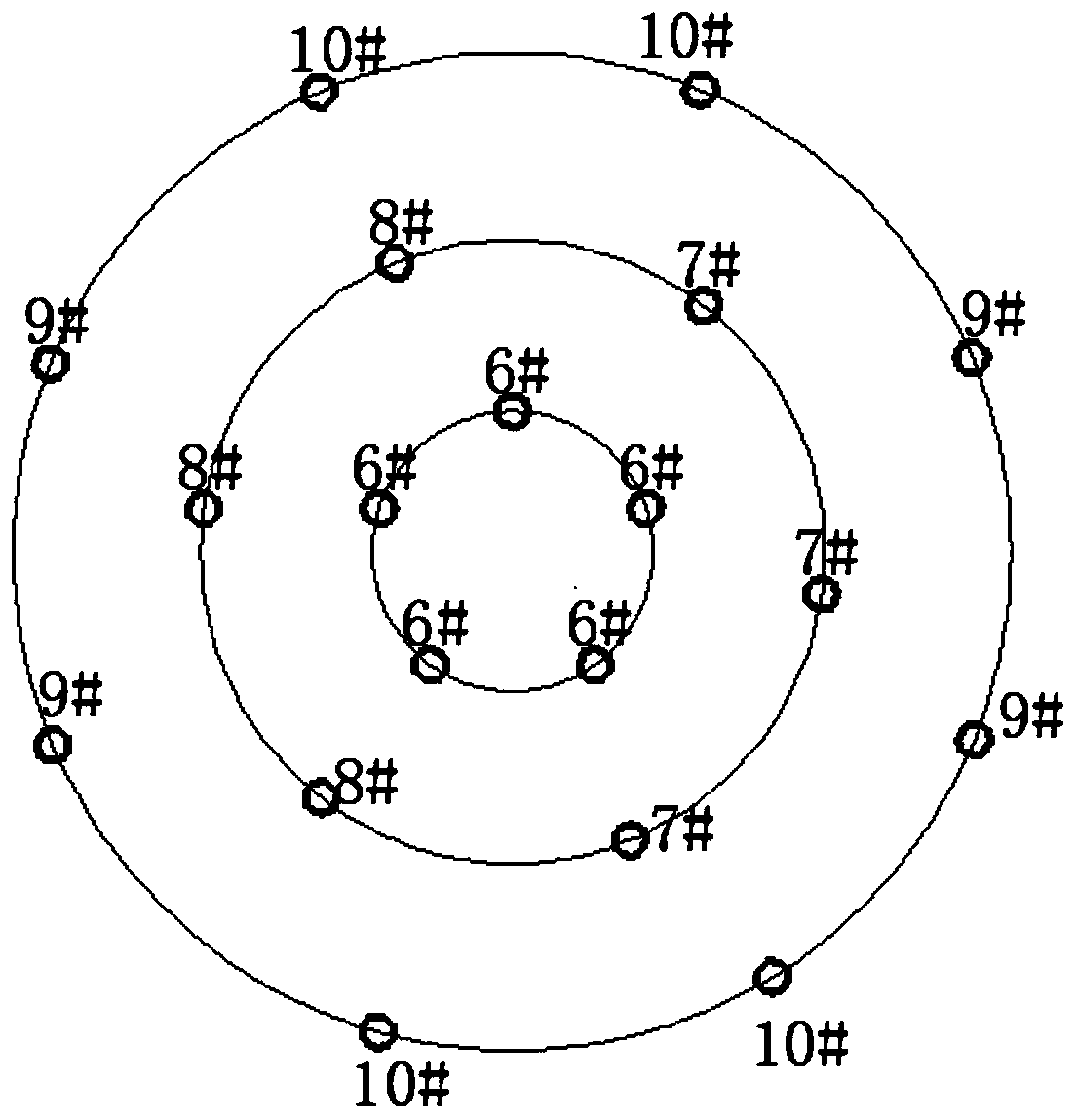

Method for enhancing slotting blasting efficiency of roadway (tunnel) tunneling

InactiveCN107843156APrevent rush outOptimal Blast Compensation CoefficientBlastingTunnelsDetonatorEngineering

The invention relates to a method for enhancing the slotting blasting efficiency of roadway (tunnel) tunneling. The method comprises the steps that four empty holes perpendicular to a working face andwith the diameters being 78 mm are dilled in the lower middle part of a roadway (tunnel) tunneling working face, a first explosive charging hole with the diameter being 50 mm is formed in the centerof a connecting line of the empty holes and serves as a first section hole for detonating, and four evenly-distributed second explosive charging holes with the diameters being 50 mm are drilled in a circumference with the radius being 40 cm by taking the center of the connecting line of the empty holes as a circle center and serve as a second section for detonating. According to the technical scheme, an inverse detonating mode is adopted, the first explosive charging hole in the middle and the surrounding second explosive charging holes adopt the mode of hole-bottom detonating, detonating primers are all arranged at the bottom of blast holes, and energy gathering cavities of both detonators and explosive cartridges face towards the outside of the holes, so that the propagation direction ofexplosive detonating waves and the direction of throwing rock are consistent; and on the one hand, complete crushing of the rock can be ensured, on the other hand, it can be ensured that the more crushed rock can be thrown out of the hole through explosive blasting energy, so that the slotting blasting efficiency is effectively improved.

Owner:NANJING MEISHAN METALLURGY DEV +1

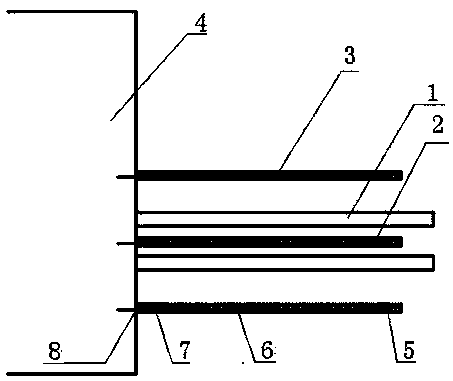

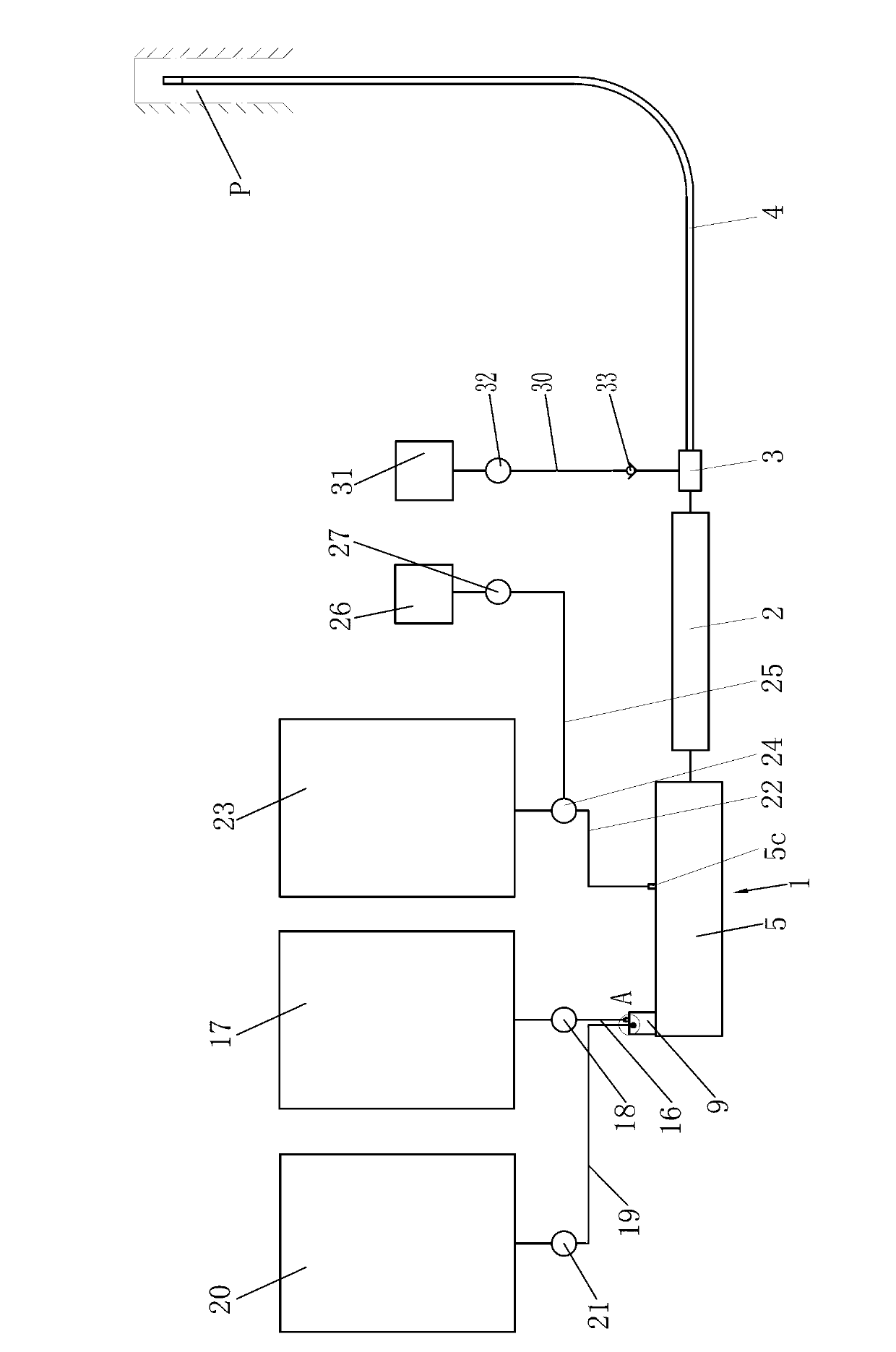

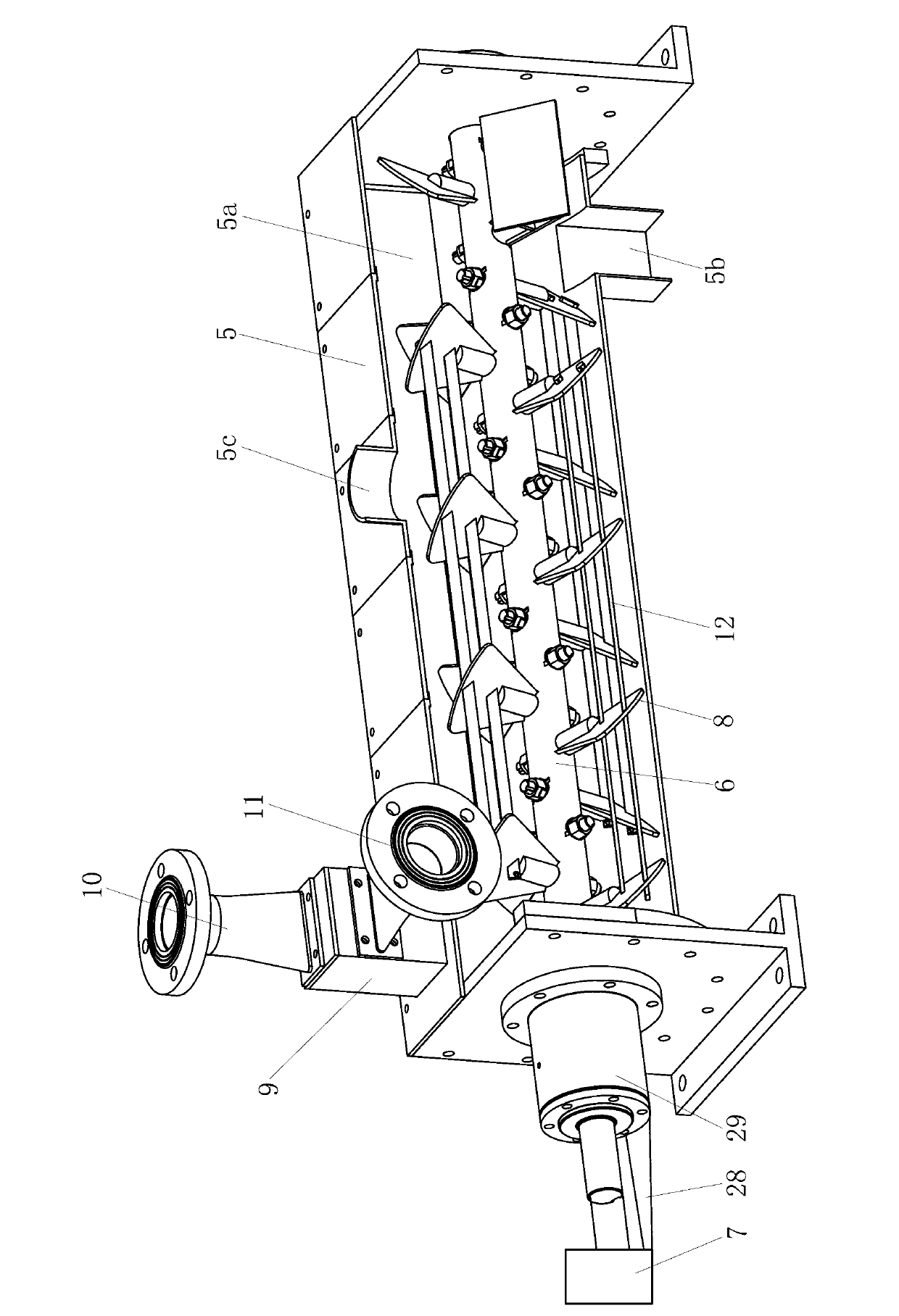

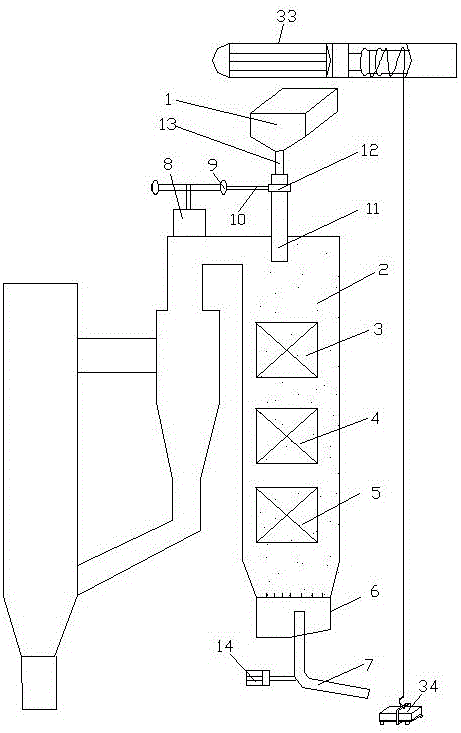

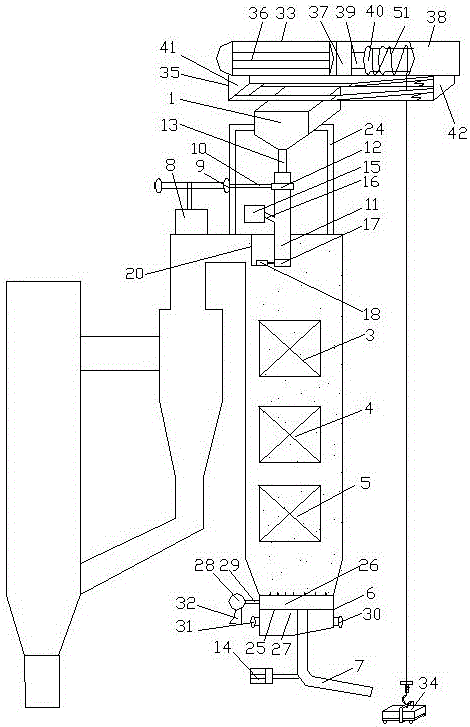

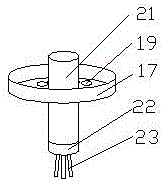

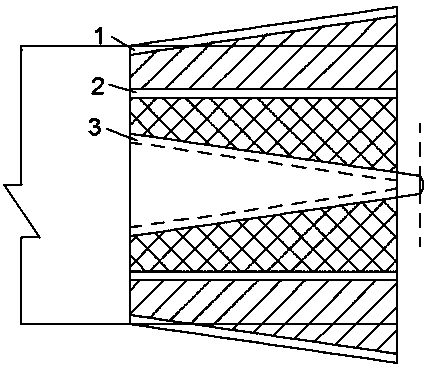

Field emulsion explosive mixing and charging system and charging method suitable for underground engineering

ActiveCN102997767AImprove mixing propertiesEliminate return</u><u>problemsBlastingExplosivesEmulsion explosiveEngineering

The invention discloses a field emulsion explosive mixing and charging system and charging method suitable for underground engineering. The drug outlet of a mixing machine is connected with the drug inlet end of a drug conveying pump; the drug outlet end of the drug conveying pump is communicated with a drug conveying hose through a water ring adding device; a mixing shaft is arranged in the drug mixing cavity of a mixing machine shell; a premixing chamber is formed above the feeding hole of the mixing machine shell; a drug spray device is arranged at the drug outlet end of the drug conveying hose; a spray head of the drug spray device has a cylindrical structure; and the spray head is provided with a main drug spray hole along the axial lead of the spray head. The aim of ensuring the explosion effect is fulfilled mainly through technical innovations on three aspects: I, the pre-mixing chamber is formed on the top of the mixing machine shell; II, the sensitizing way of the emulsion explosive is physical sensitization; and III, the drug spray device is additionally arranged at the upper end of the drug conveying hose. Meanwhile, specific to the aim of lowering the working pressure of the drug conveying pump, a shearing device arranged on the drug conveying hose and used for increasing the viscosity of the emulsion explosive in the prior art is eliminated.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

Blast hole explosion blocking method

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

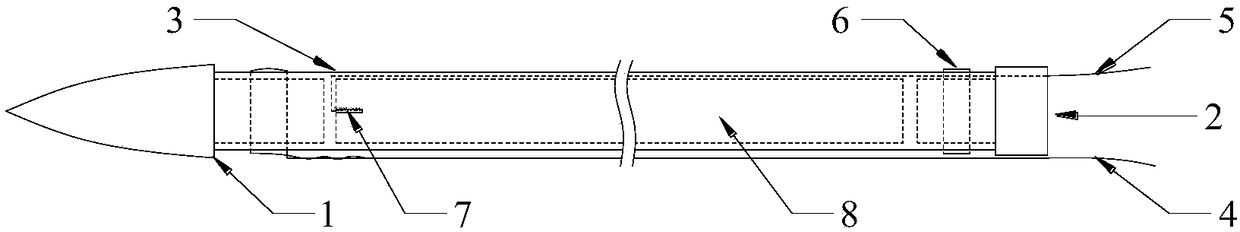

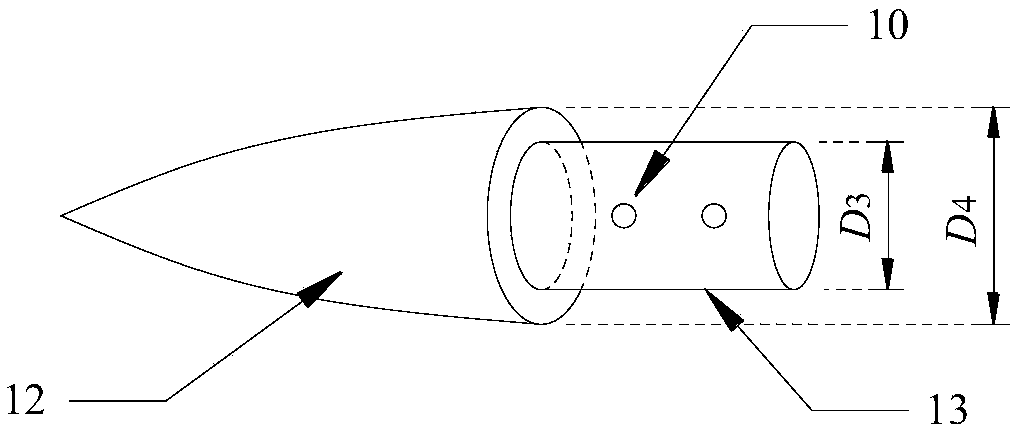

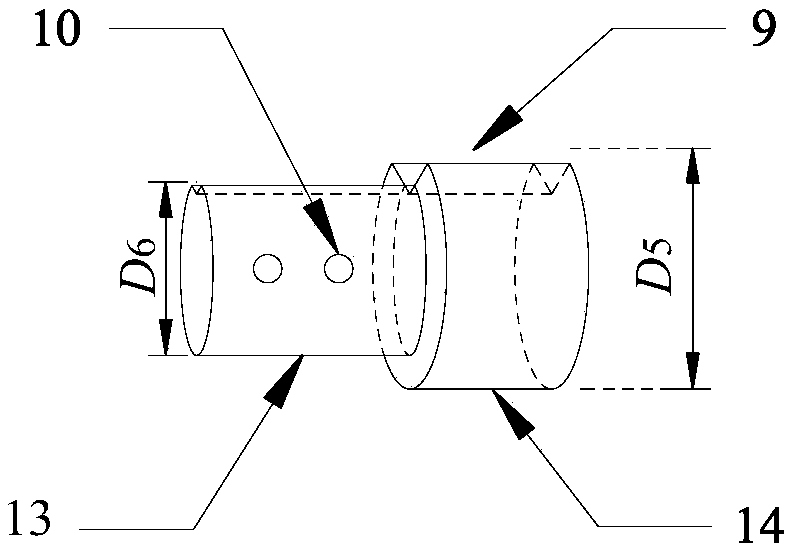

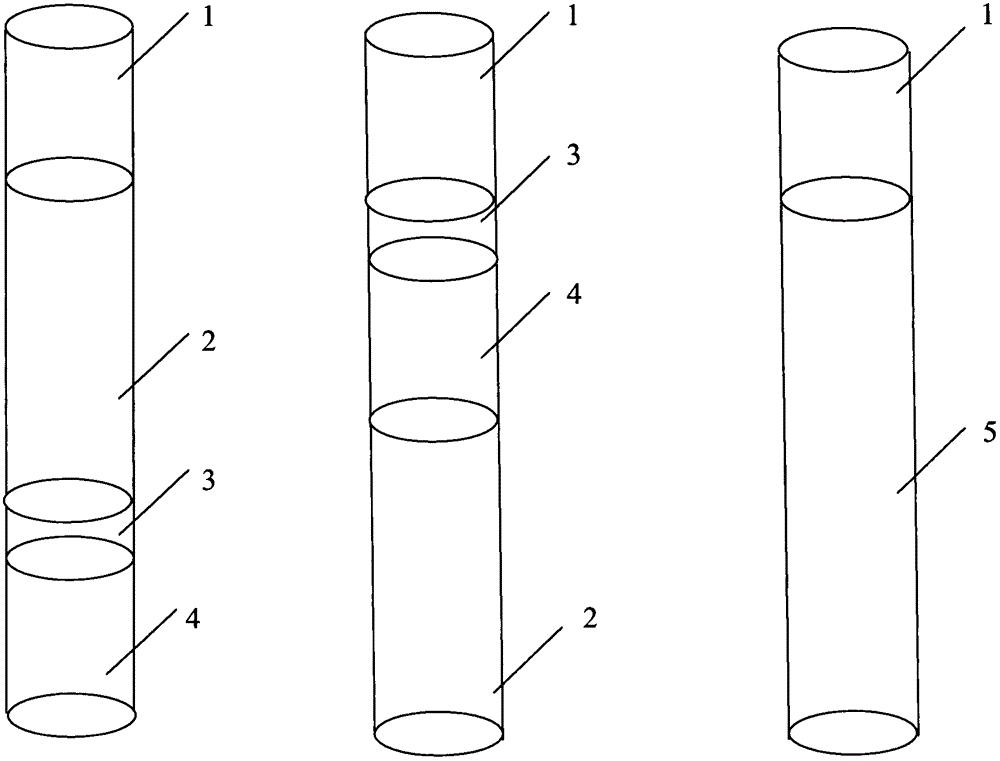

Intrinsically safe type quick explosive loading device for deep hole blasting

An intrinsically safe type quick explosive loading device for deep hole blasting mainly includes: a guiding head positioned on a front end of the device, wherein lots of coal and rock chippings and fragments exist in a constructed drill hole usually, and the conical guiding head can effectively prevent accumulation of the coal and rock chippings and fragments due to explosive loading, and can reduce the explosive loading resistance so as to smoothly complete explosive loading; a tail plug positioned on the tail of the device which can effectively weaken impact on a cartridge during hole sealing, and can prevent explosive overflowing due to the broken cartridge; pipes, wherein the explosive loading demands of blast holes with different lengths or diameters can be met by increasing the number of PVC pipes and changing the diameter of the PVC pipes, and the pipes has high adaptability to change in the length and the diameter of the blast holes; and a safe rope which can quickly pull the cartridge out in a case of blocking of the blast holes, a broken blasting line, or a broken detonating fuse, can prevent the cartridge from being left in the blast holes, and can effectively improve the anti-disaster ability during explosive loading. The intrinsically safe type quick explosive loading device is simple in process, is easy to operate, and is safe and reliable.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

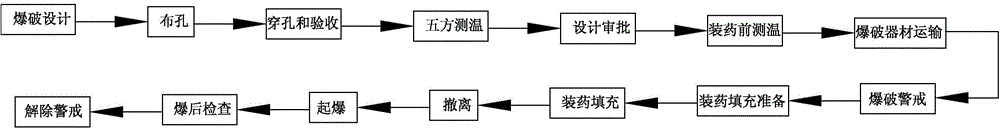

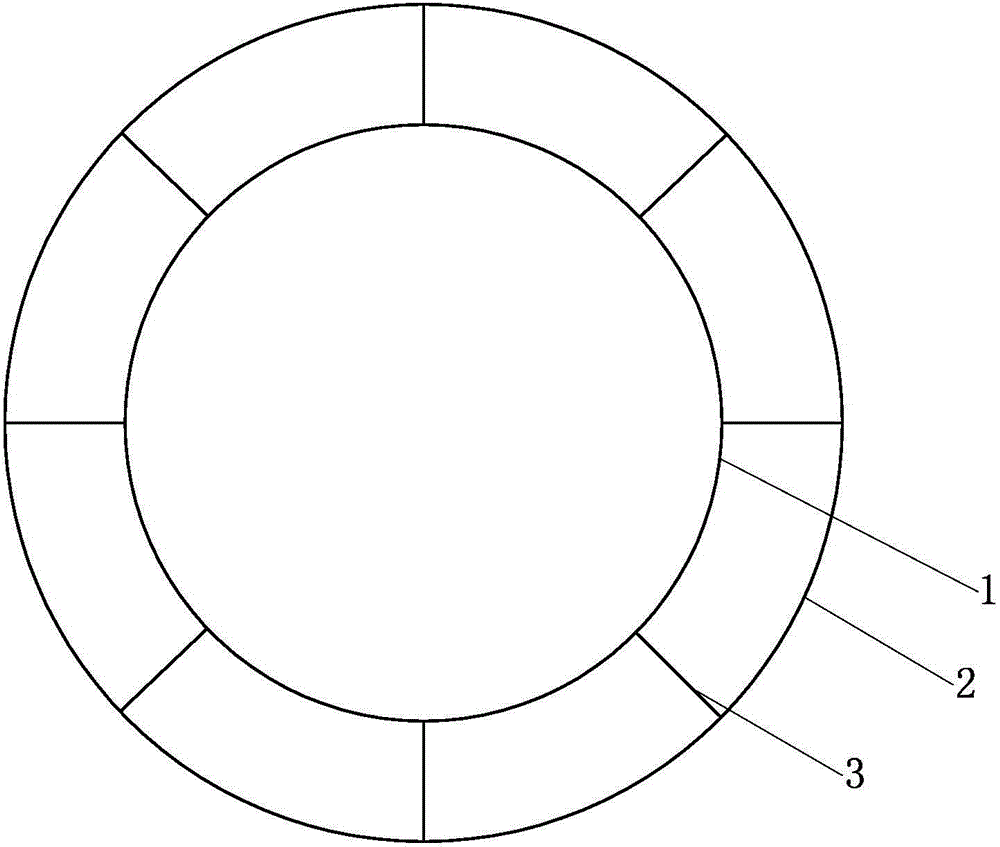

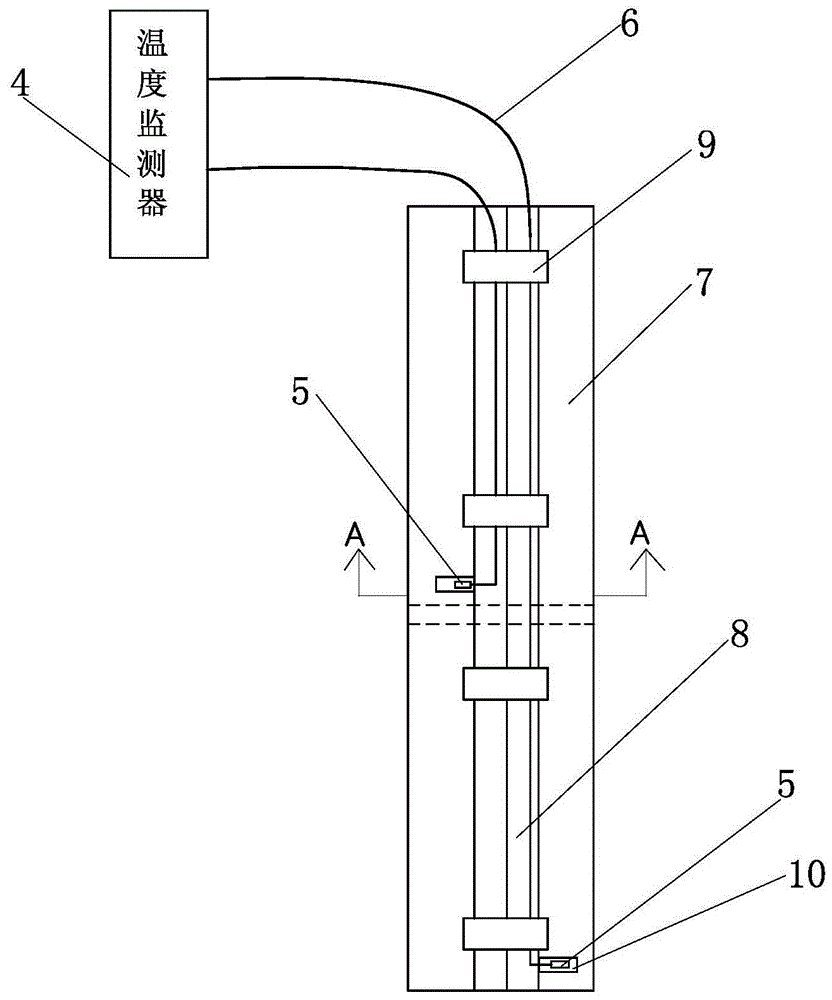

Blasting method for high-temperature sealed fire areas

The invention discloses a blasting method for high-temperature sealed fire areas. The blasting method comprises the following steps that a, blasting design is carried out; b, holes are distributed; c, holes are drilled, checked and accepted; d, five-position temperature measurement is carried out, wherein temperature measurement is carried out twice, according to the temperature measurement of the second time, thermal insulation pieces are placed in blast holes firstly, then the gaps between inner cylinders and outer cylinders of the thermal insulation pieces are filled with water, and the temperatures of all points between the inner cylinders and the outer cylinders are measured ten minutes later; e, design approval is carried out; f, temperature is measured before explosive filling; g, blasting supplies are transported; h, blasting warning is carried out; j, explosive filling preparation is carried out, wherein adhesive plasters are used for fixing explosive columns and filling sections on the same bamboo bar; k, explosive filling is carried out; l, evacuation is carried out; m, initiation is achieved; n, inspection after blasting is carried out; o, warning is withdrawn. According to the method, the thermal insulation pieces are used for separating the temperatures of the blast holes and the explosive and the initiation supplies, the method is simple and reliable, good in safety, low in cost, long in rebound time, and capable of reliably and safely guaranteeing explosive filling and further safely and efficiently achieving blasting.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

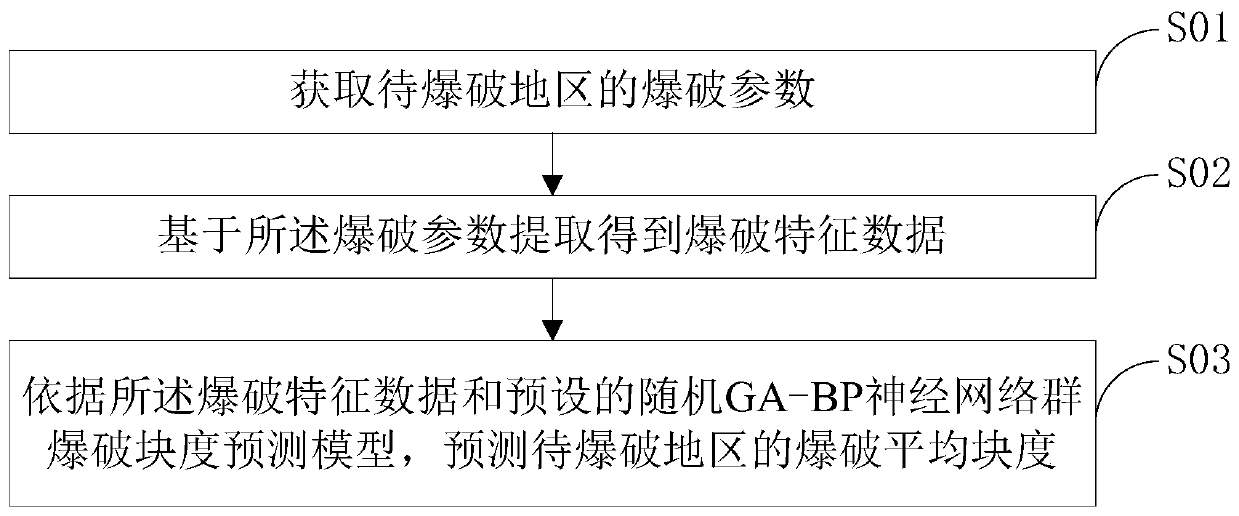

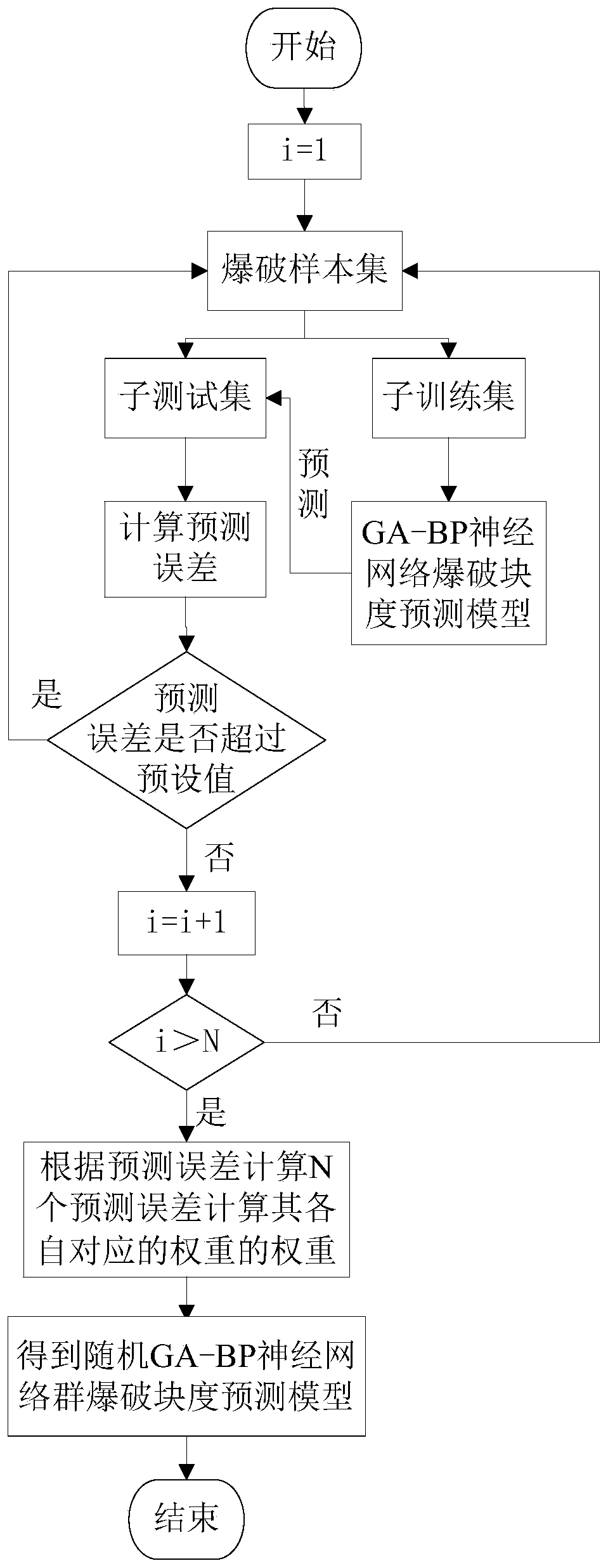

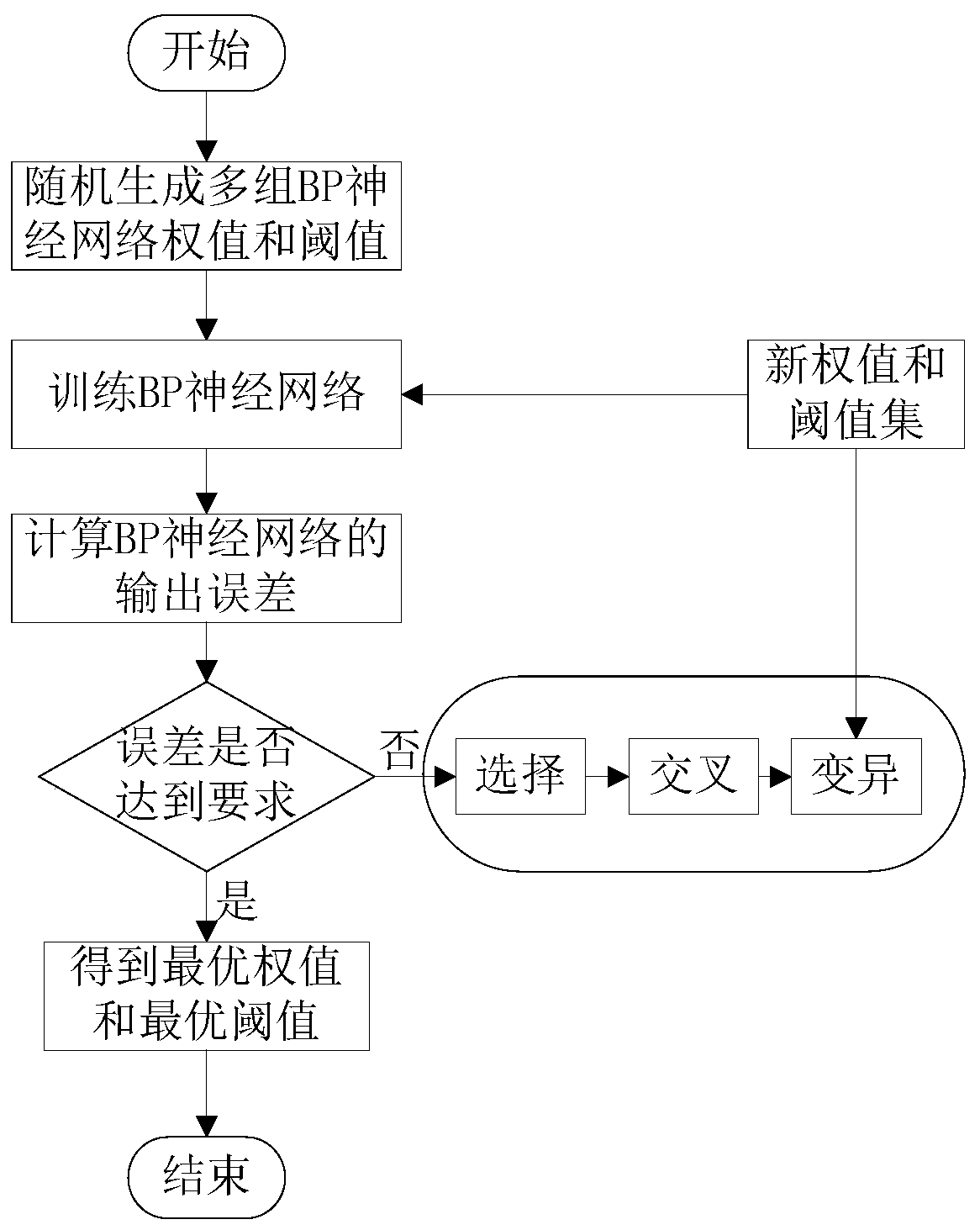

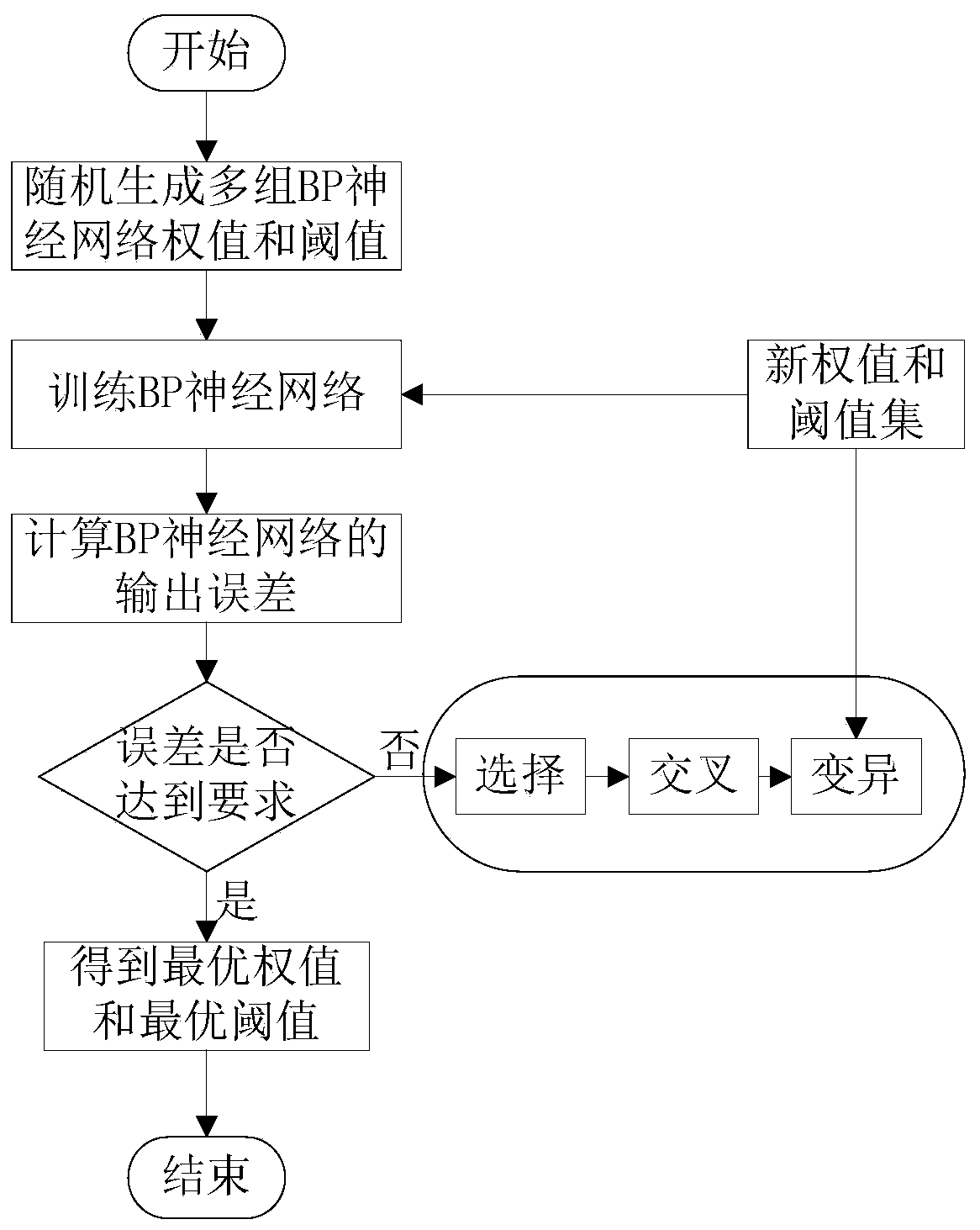

Blasting lumpiness prediction method and device based on random GA-BP neural network group, and medium

PendingCN111259601AGuaranteed blasting effectPrediction results are accurate and stableDesign optimisation/simulationNeural architecturesPrediction methodsAlgorithm

Owner:NANHUA UNIV

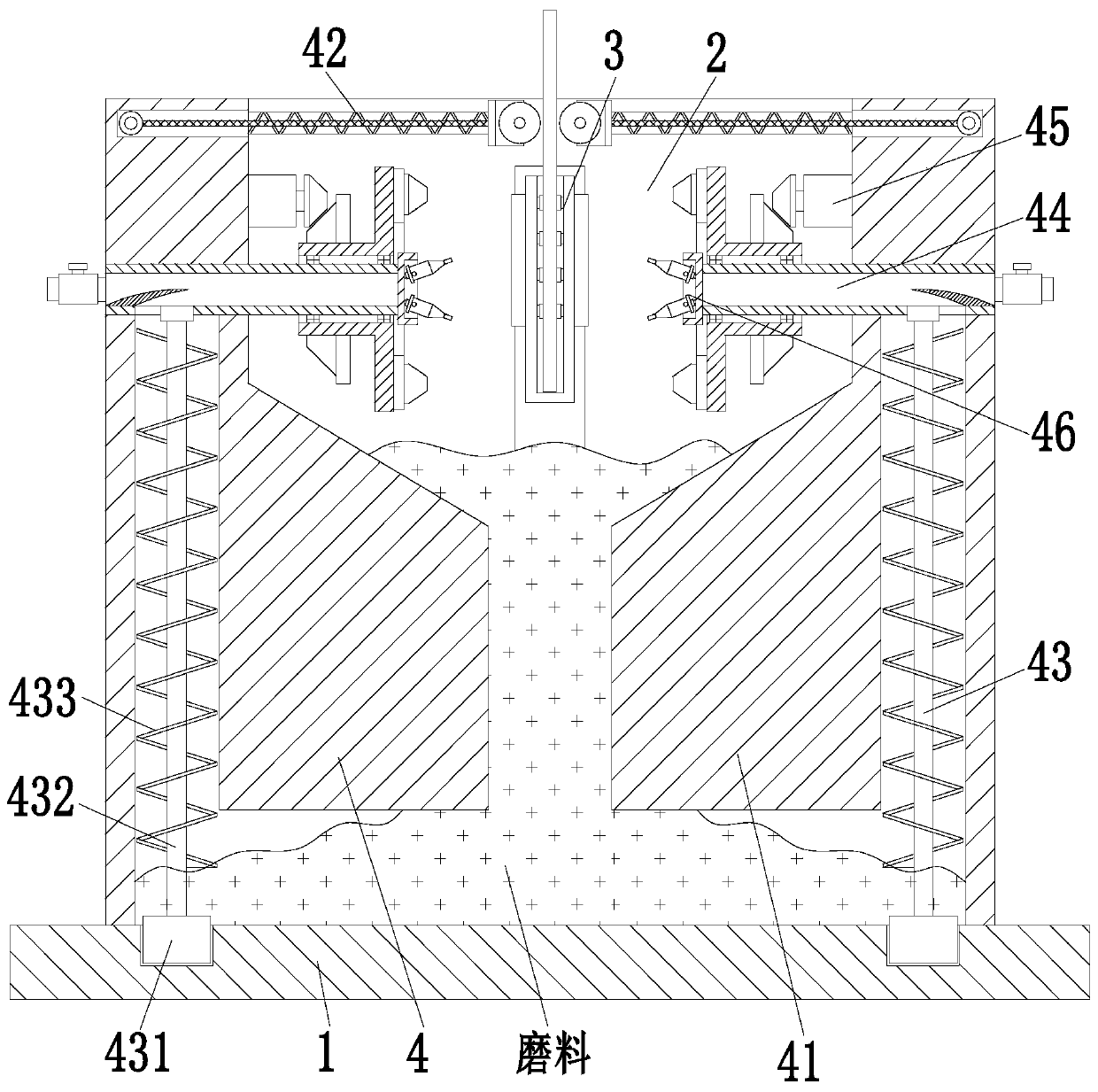

Sand blasting processing treatment technology for glass production and manufacture

ActiveCN111195864ASolve the phenomenon that is prone to ejectionPrevent fallingAbrasive feedersAbrasive machine appurtenancesSand blastingArchitectural engineering

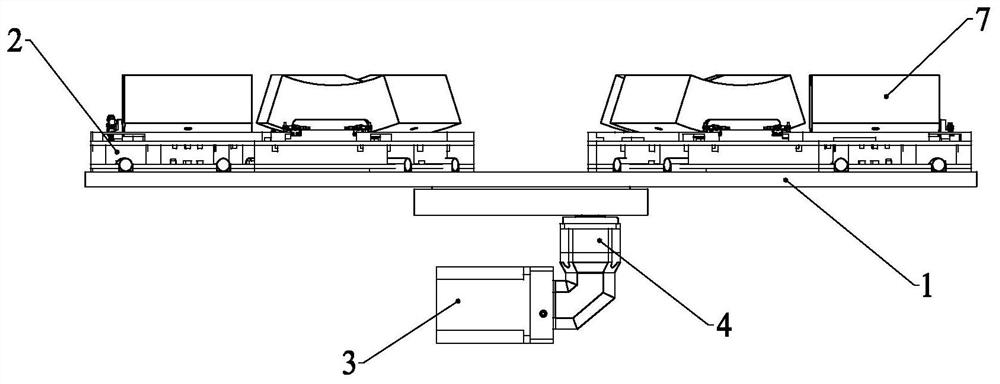

The invention relates to a sand blasting processing treatment technology for glass production and manufacture. A baseplate, baffles, the conveying device and treatment devices are involved. The baffles are symmetrically installed on the upper end of the baseplate, the middles of the side faces in the baffles are provided with the conveying devices, and the treatment devices are symmetrically installed between the two baffles. According to the sand blasting processing treatment technology, the problems can be solved that when existing equipment is used for performing sand blasting on glass, a grinding material is easily splashed to the exterior of the equipment usually, the grinding material cannot be effectively protected and is prone to wasting, since the surface of the glass after beingsubjected to sand blasting cannot be quickly cleaned, the grinding material easily adheres to the surface of the glass, the glass is prone to breaking during stacking, when the existing equipment is used for performing sand blasting on the glass, the sand blasting effect is poor, sand blasting is uneven, the part which is not sprayed exists easily on the surface of a glass plate after being subjected to sand blasting, and the application effect of the glass plate in the later period is influenced.

Owner:TAIZHOU MOCRYSTAL CO LTD

Safe and rapid tunneling process for high-outburst mine coal roadway

InactiveCN101769152AImprove blasting effectSave support materialsUnderground miningBlastingCoalEngineering

The invention relates to a mine coal roadway tunneling technology, in particular to a safe and rapid tunneling process for a high-outburst mine coal roadway, aiming at solving the problem how to avoid gas outburst in the tunneling process of a highly-gassy mine. The safe and rapid tunneling process comprises the following steps of: carrying out coal body forecasting by using a platform drilling machine, charging blastholes of the platform drilling machine and detonating, waiting for 30min after the detonating, entering a working face unit for outputting coal, supporting the platform drilling machine, entering the next circular working procedure, wherein the detonated blastholes adopt a diamond-cutting cylinder cut method, two large-diameter hollow holes are arranged at the middle part of a diamond cuthole, the circular detonation is controlled within 4m-6m, explosives are detonated at a millisecond time interval by utilizing a millisecond detonator, the blastholes are controlled to detonate successively according to a preset sequence, and the personnel withdraws to reach a safety distance before detonation and hides an anti-explosion movable refuge chamber vehicle.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

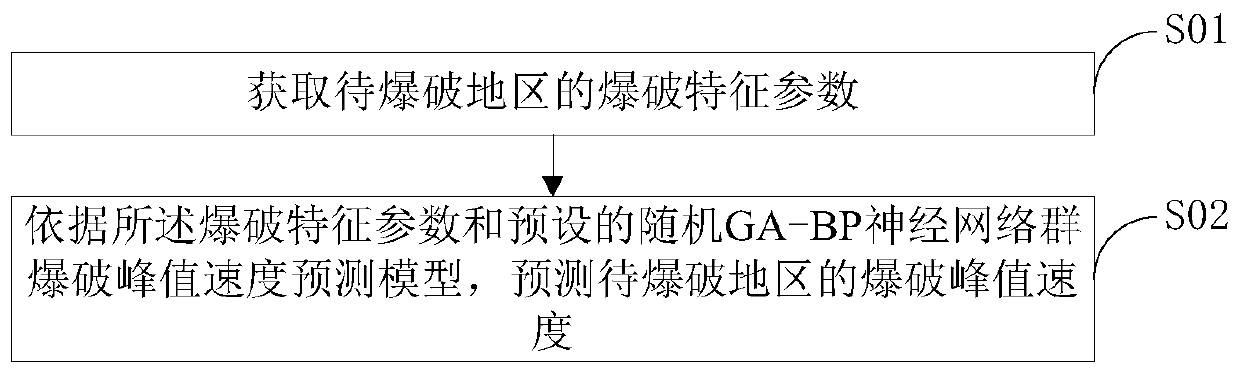

Blasting peak velocity prediction method and device based on RGA-BPNNG and medium

PendingCN111275252AGuaranteed blasting vibration intensityGuaranteed blasting effectForecastingCharacter and pattern recognitionSimulationMechanical engineering

Owner:NANHUA UNIV

Tunneling blasting method comprehensively utilizing detonator short time difference and empty hole vibration reduction technique

InactiveCN108592725AGuaranteed blasting effectAvoid the disadvantage of large blasting vibrationBlastingDetonatorEngineering

The invention discloses a tunneling blasting method comprehensively utilizing the detonator short time difference and an empty hole vibration reduction technique. The center line of a tunnel face of ablasted tunnel serves as the boundary, and the blasted area is divided into a left region and a right region, wherein the left region and the right region are symmetrical to each other; the two sidesof the center line are provided with a plurality of slotting holes, auxiliary holes and peripheral holes correspondingly, wherein the slotting holes, the auxiliary holes and the peripheral holes aresymmetrical to one another, a vibration reduction hole linear array is arranged on the ground between the blasted area and a building, and in the implementation process, the same row of holes are blasted hole by hole in a symmetrical and delayed manner. Hole-by-hole sequential blasting is performed through electronic detonators, and targeted to different types of blastholes, through the setting ofthe optimal delay time of the electronic detonators, vibration waves transferred to the ground interfere with one another and are counteracted partially; and meanwhile, vibration reduction holes of optimized design are formed on the ground, and 50% of blasting vibration can be effectively lowered. Through the combined measure, the blasting effect of a constructed smooth surface can be guaranteed,the defect that traditional smooth surface blasting is large in vibration can also be overcome, and finally influences on the surface buildings are reduced.

Owner:厦门爆破工程有限公司 +1

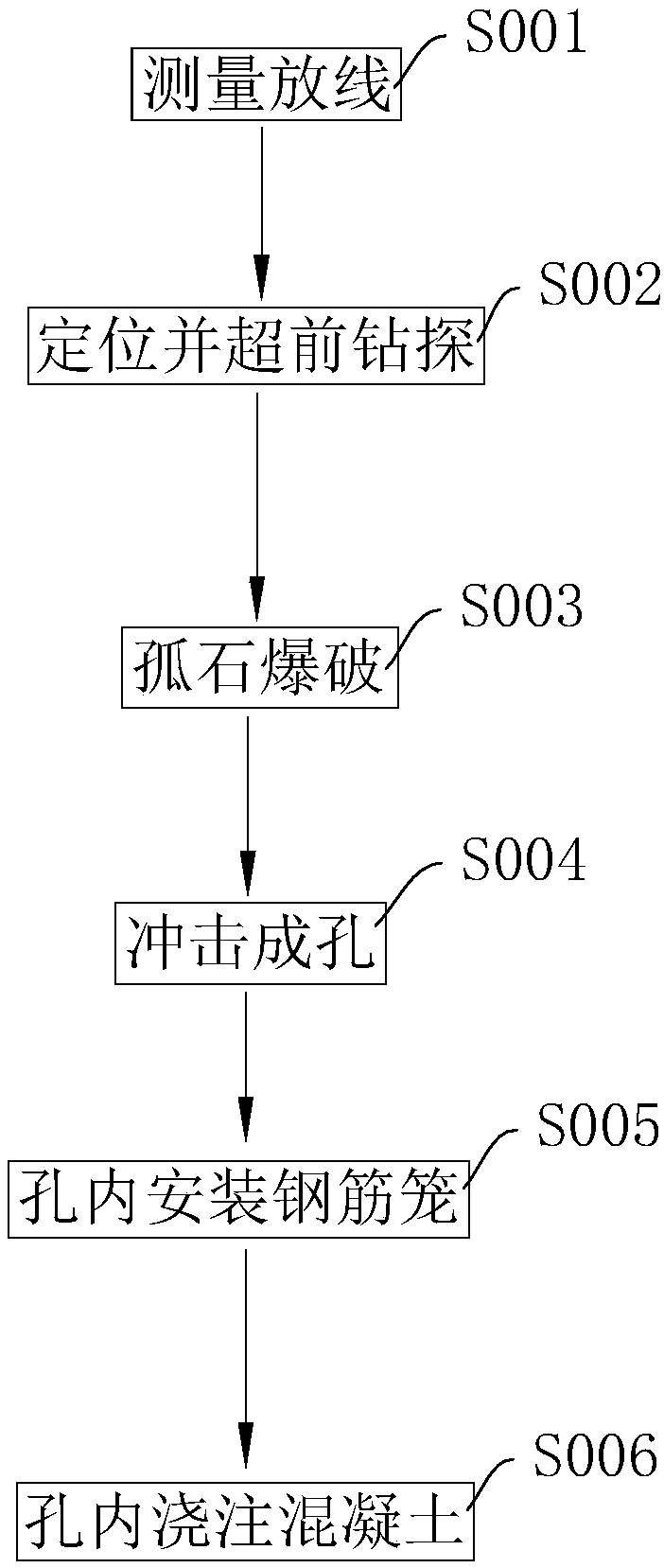

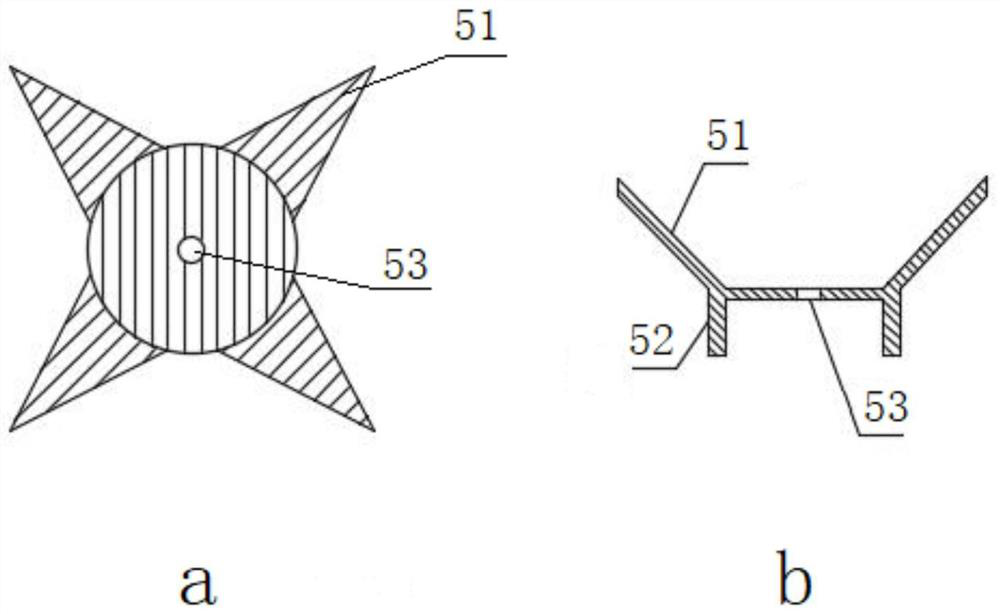

Construction method for impact-cone concrete pile

ActiveCN108589704AImprove verticalityEvenly distributed on the bearing surfaceBlastingBulkheads/pilesSoil massEngineering

The invention relates to the field of building construction. In order to solve the problem that the perpendicularity of a pile hole is low as a result of a locking hammer and an inclined hole, the invention provides a construction method for an impact-cone concrete pile. The stress face of an impact hammer is uniform, so that the perpendicularity of the pile hole is relatively high. The technicalscheme is as follows: the construction method comprises the following steps: surveying and setting out; positioning and drilling ahead; boulder blasting; impact holing, impacting again after hornstonebackfilling when a same horizontal section in the pile hole includes boulders and soil mass at the same time; mounting a steel reinforcement cage in the hole; and pouring concrete in the hole. The stress face of the impact hammer is uniformly distributed when the same horizontal section in the pile hole includes boulders and soil mass at the same time by backfilling the hornstones, the conditionthat the perpendicularity of the pile hole is reduced as the result of the locking hammer and the inclined hole is avoided, and the perpendicularity of the pile hole is ensured to further guarantee the quality of the impact-cone concrete pile.

Owner:广东梁亮建筑工程有限公司

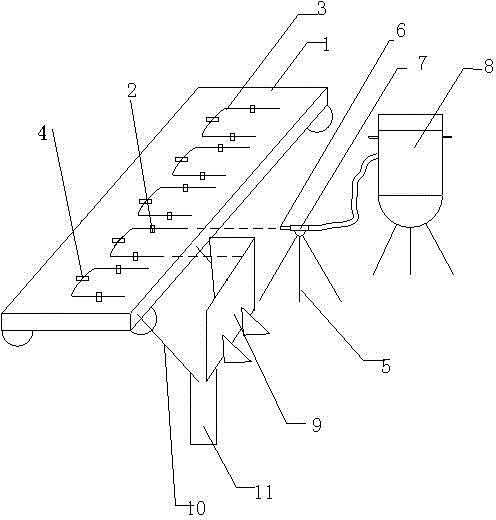

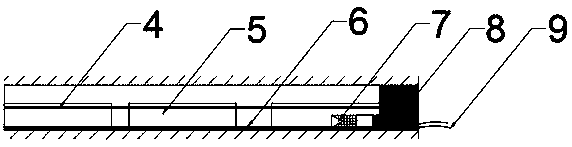

Well formation method adopting vertical shaft blasting for mines

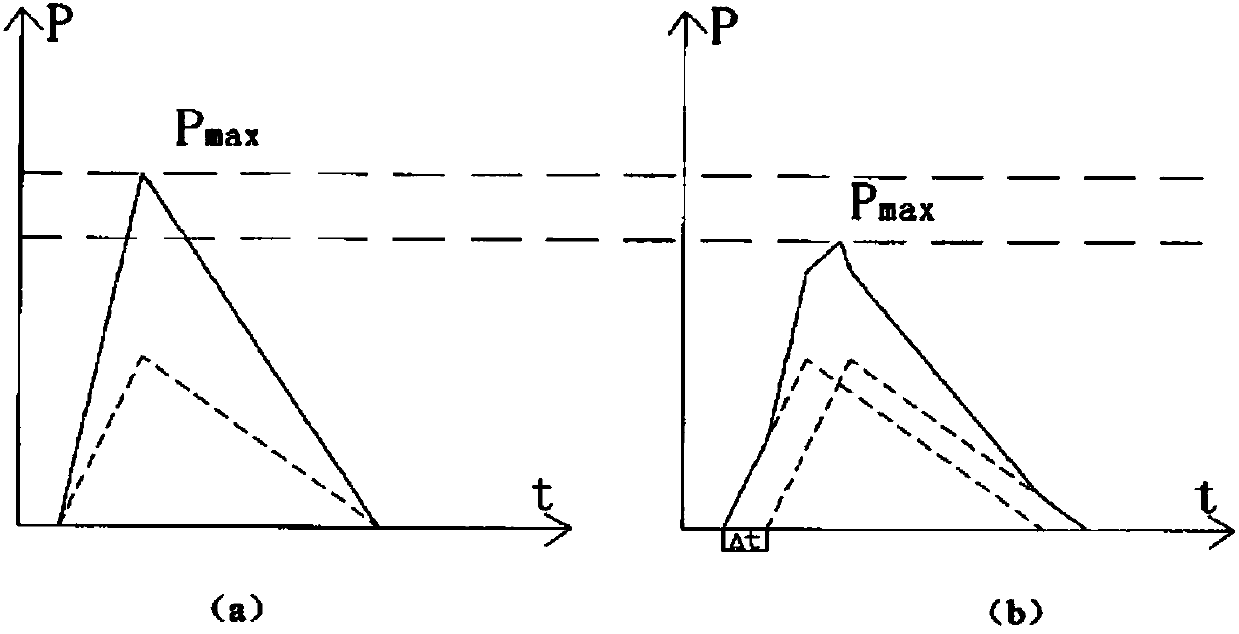

ActiveCN107270791AGuaranteed blasting effectLower drug doseBlastingStructural engineeringBlasting vibration

The invention belongs to the technical field of mining and blasting, and relates to a well formation method adopting a vertical shaft blasting for mines. According to the method disclosed by the invention, explosive charges in a cutting hole are detonated sequentially so as to produce inverted funnel structures which are overlapped to form a blasting hole free surface, and the explosive charges in blasting control holes are synchronously detonated so as to form the vertical shaft of mines; when the blasting effect is ensured, the segment explosive charge can be reduced, the blasting vibration and clamping effects are reduced, the height of well formation by once blasting is improved, and the construction quality and the construction efficiency are improved.

Owner:JINCHUAN GROUP LIMITED

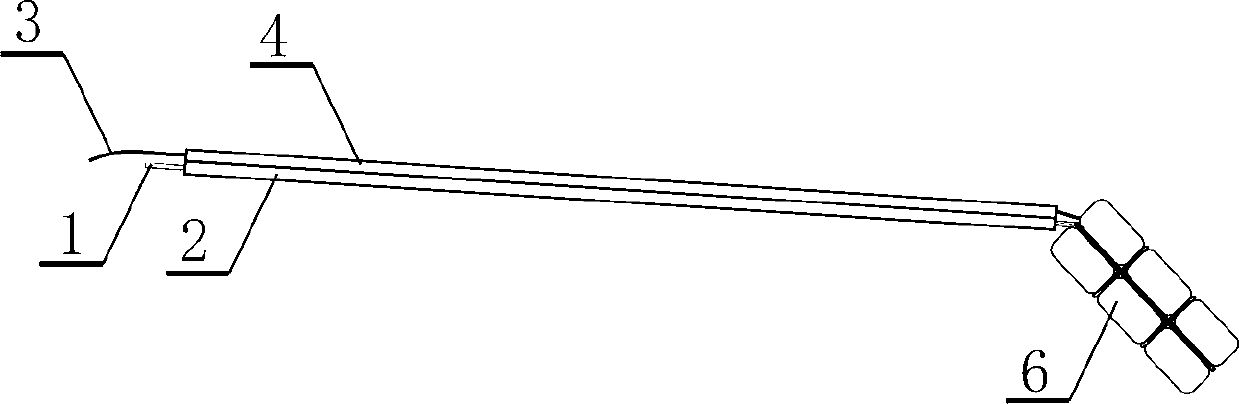

Method for effectively removing ore-pass blockage and blockage removal device

The invention discloses a method for effectively removing ore-pass blockage and a blockage removal device. The method comprises the steps of calculating a blocking point, drilling a guide hole, setting an explosive substance, and removing the blockage by detonation. The blockage removal device comprises a tow rope conduit and a tow rope, wherein the tow rope passes through the tow rope conduit to fix the explosive substance. According to the invention, with smart assistance of ore-pass passages matched with an ore-pass, an ore-pass passage above the blockage point is utilized to determine the position of the blockage point and set the explosive substance, an ore-pass passage above the blockage point is used to determine a drilling direction. The opening of the guide hole is set below an obstruent (and close to the obstruent), and the explosive substance can smoothly cling to the obstruent by the matching of the upper ore-pass passage and the lower ore-pass passage, therefore, a good blasting effect is ensured; and meanwhile, operating personnel and the explosive substance can be naturally separated from each other by the guide hole, and thus the construction security is ensured. The method disclosed by the invention is simple and practical, and the blockage removal device is simple in structure as well as safe and reliable.

Owner:YUXI DAHONGSHAN MINING

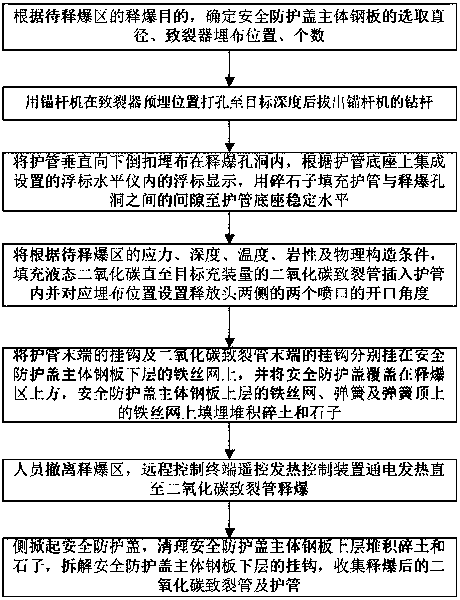

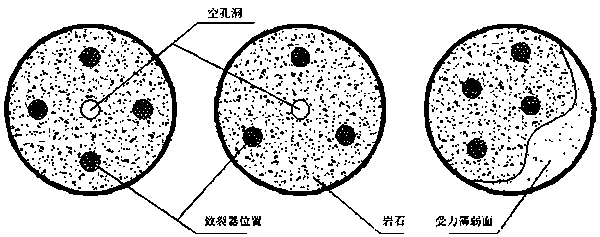

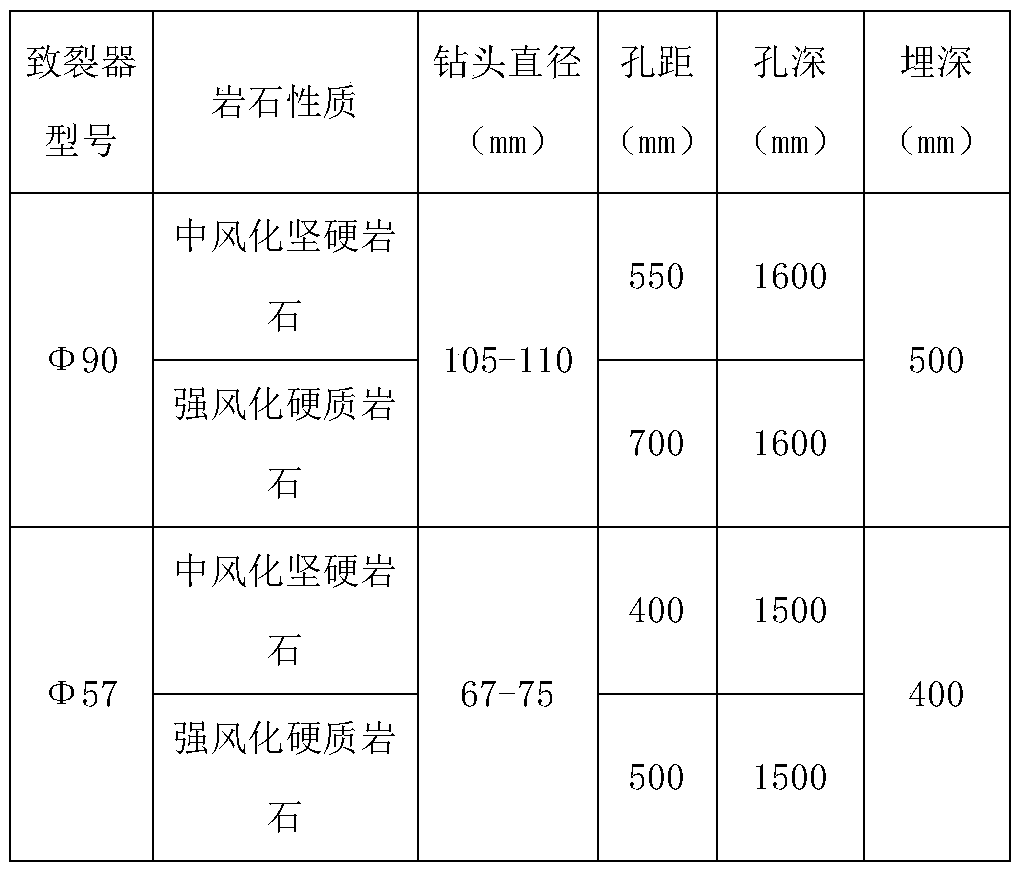

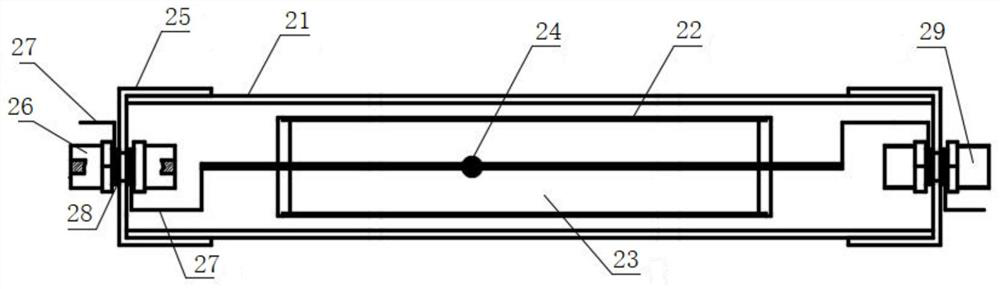

Carbon dioxide fracturing pipe explosion-release improving device and explosion-release method

ActiveCN110132066AImprove securityGuaranteed detonation effectBlasting cartridgesBlastingSteel platesSheet steel

The invention discloses a carbon dioxide fracturing pipe explosion-release improving device and an explosion-release method, and belongs to the technical field of explosion. The device comprises a safety protection cover with the diameter larger than the diameter of an explosion release area, and an upper layer and a lower layer of a safety protection cover main body steel plate are wrapped with iron gauze; springs which are vertically upward and are equal in height are uniformly distributed and hung on the iron gauze on the upper layer of the steel plate, and wire gauze which is the same withthe safety protection cover in size is hung on the tops of the springs; a protection pipe which is hung on the lower portion of the steel plate through a hook and is vertically and downwards and reversely embedded in an explosion-release hole is hung on the iron gauze at the lower layer of the steel plate, a protection pipe main body is provided with an extending-out base, and the inner diameterof the protection pipe main body is slightly larger than the outer diameter of a carbon dioxide fracturing device; and a hook for hanging the iron gauze on the steel plate lower layer is arranged at the tail end, in the protection pipe, of the carbon dioxide fracturing device. According to the carbon dioxide fracturing pipe explosion-release improving device and the explosion-release method, a carbon dioxide fracturing pipe is vertically embedded in the explosion release area, safety protection performed before explosion release and rapid collection of repeatedly used parts obtained after explosion release are facilitated.

Owner:STATE GRID CORP OF CHINA +2

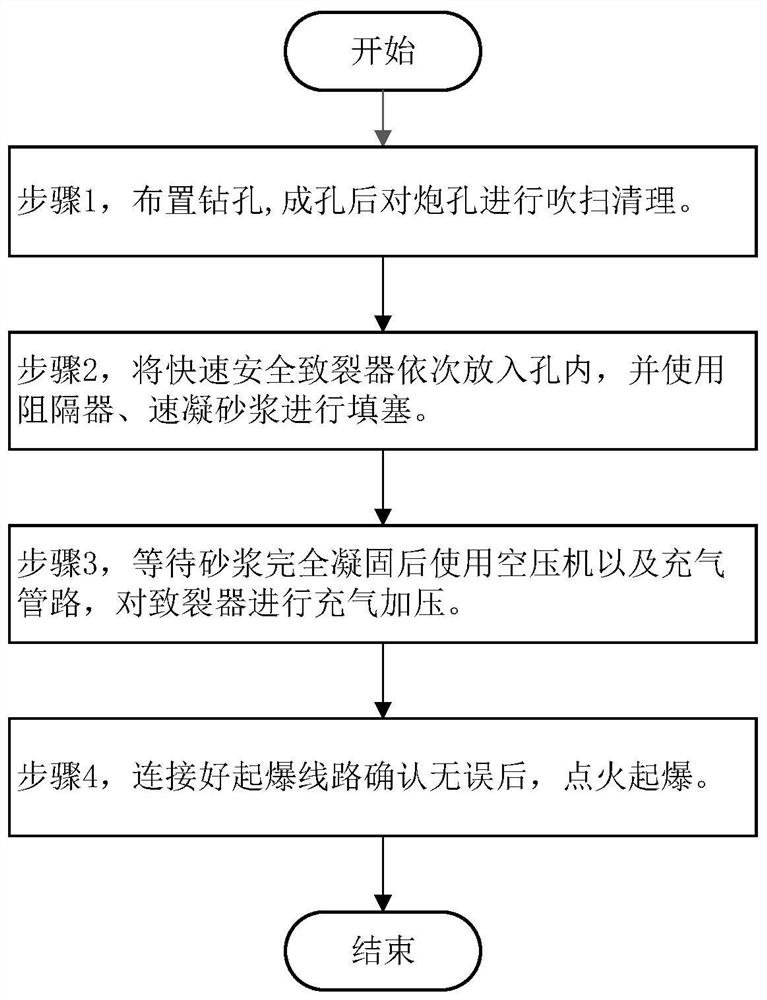

Blasting construction method for blasting equipment

PendingCN111692935AThe blasting implementation process is convenientStrong blasting controllabilityBlasting cartridgesBlastingDetonationArchitectural engineering

The invention discloses a blasting construction method for blasting equipment. The blasting construction method comprises the steps: firstly a hole net is arranged, a first row of holes is formed in the direction of a free face, the hole diameter is larger than 90 mm, the hole distance is 500-1000 mm, the row distance between a second row of holes and the first row of holes is 500-1000 mm, and inthe same way, after hole forming, purging clearing is conducted on the blast holes; then the blasting equipment is sequentially put into the holes, the blast holes are stuffed with barriers, the blasting equipment is sealed in the blast holes, and the exteriors of the barriers are stuffed with quick-setting mortar; after the mortar is solidified, the blasting equipment is inflated and pressurizedthrough an air compressor and an inflating pipeline, and a pressure value reaches the initiation pressure; and finally after connection of an initiation circuit is completed and confirmed, ignition detonation is conducted. According to the method provided by the invention, the blasting implementation process is convenient, blasting controllability is high, blasting vibration can be reduced, greatprotection effect on the construction ambient environment can also be achieved, and meanwhile the blasting effect is ensured.

Owner:马铭泽

Detonator short-interval detonation blasting method for reducing ground blasting vibration

InactiveCN108592724AGuaranteed blasting effectAvoid the shortcomings of traditional blasting vibrationBlastingDetonatorDetonation

The invention discloses a detonator short-interval detonation blasting method for reducing ground blasting vibration. The blasting area is divided into two symmetric areas on the left and the right with the center line of a tunnel face of a blasting tunnel as the boundary. The two sides of the center line are provided with a plurality of symmetric underholing holes, auxiliary holes and peripheralholes, wherein the underholing holes are formed in the center area of the tunnel face, the peripheral holes are formed in the periphery of the tunnel face, the auxiliary holes are formed between the underholing holes and the peripheral holes, and during implementation, in the same row, hole-by-hole symmetric delayed detonation is conducted. According to the detonator short-interval detonation blasting method, electronic detonator hole-by-hole sequential detonation is adopted, for different types of cannon holes, vibration waves transmitted to the ground interfere with one another and are partially offset through setting of the optimal delay time of electronic detonators, the blasting effect of the construction smooth surface can be guaranteed, the defect that traditional smooth surface blasting vibration is large can be overcome, and influences on ground buildings are finally reduced.

Owner:厦门爆破工程有限公司 +1

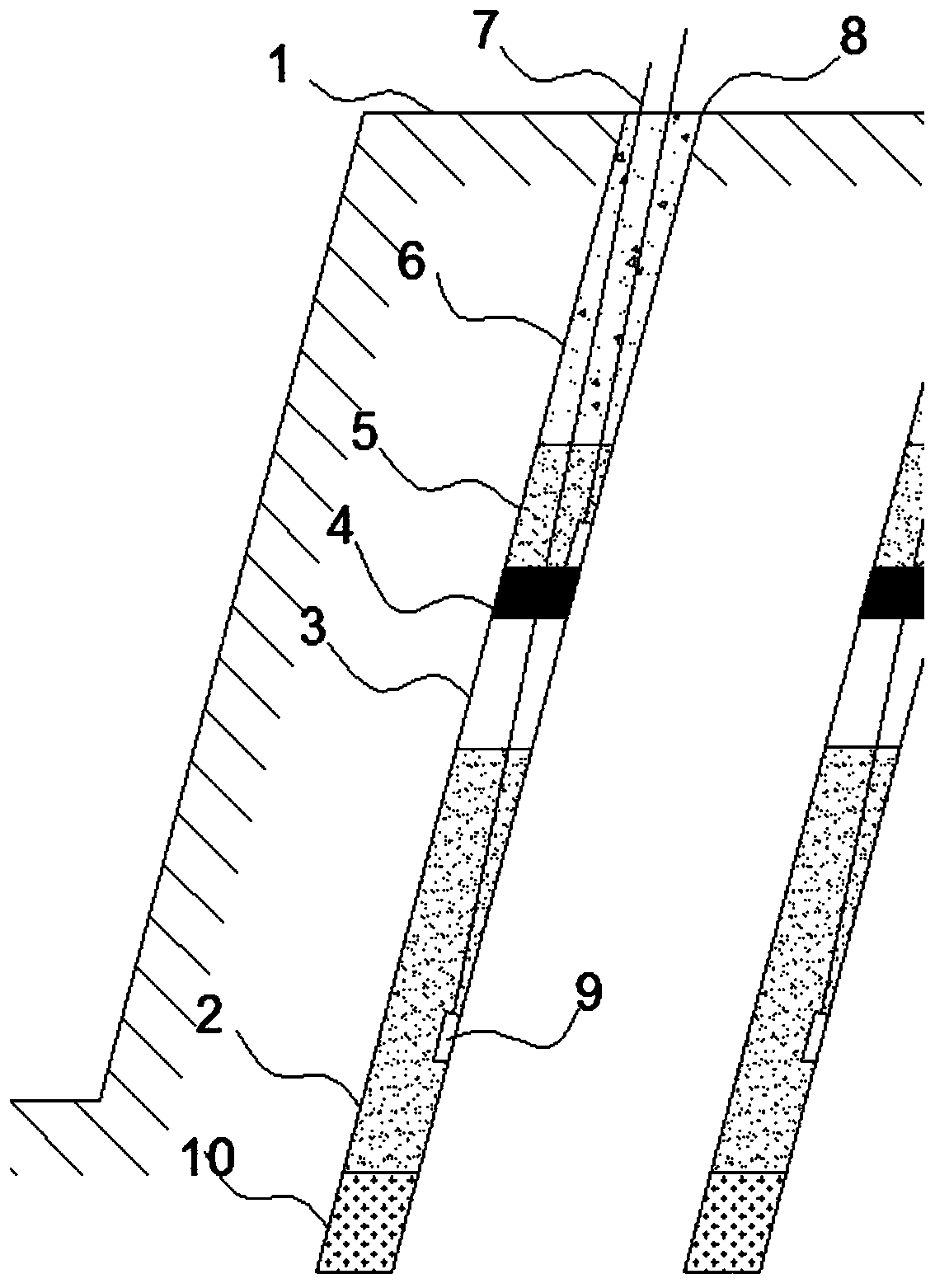

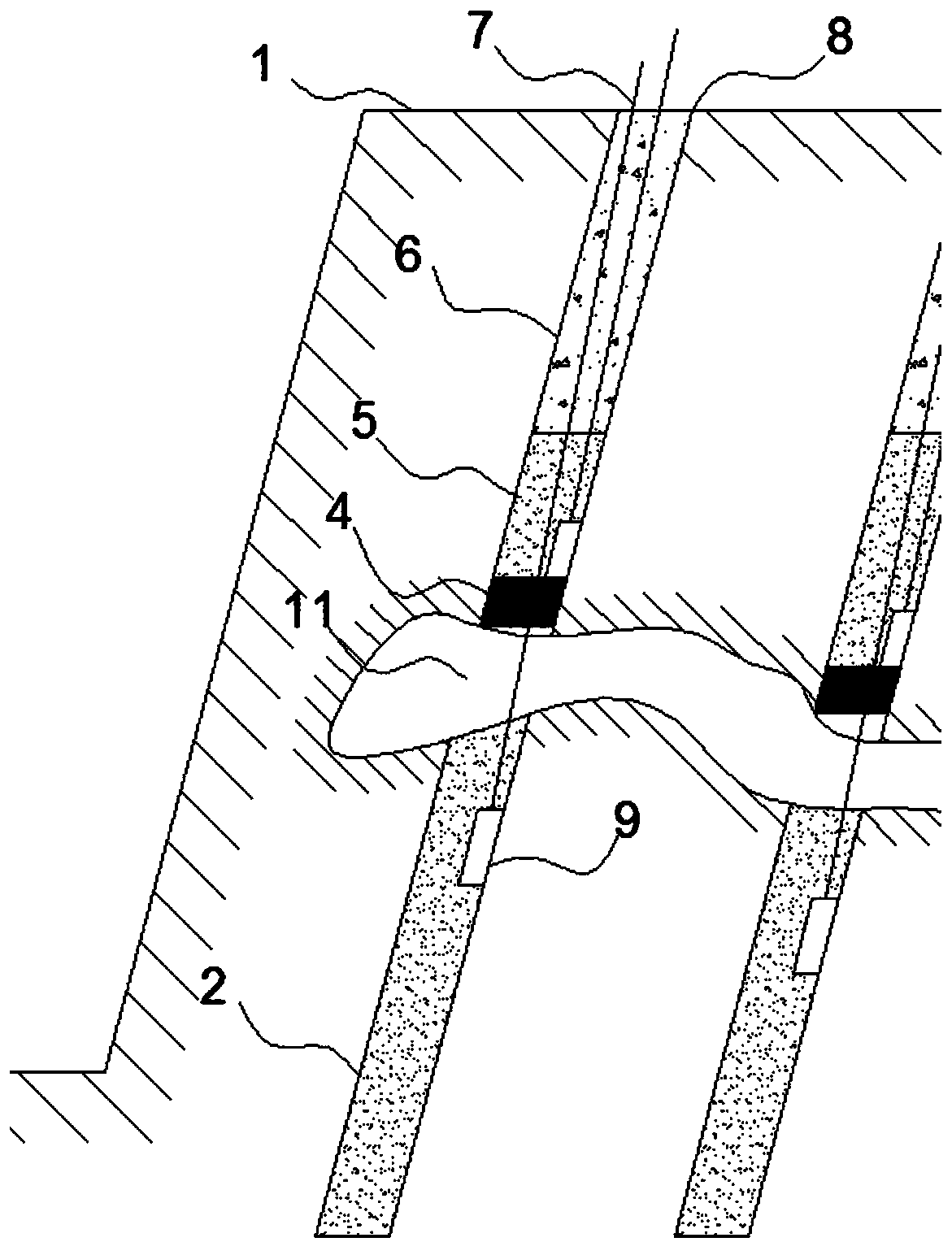

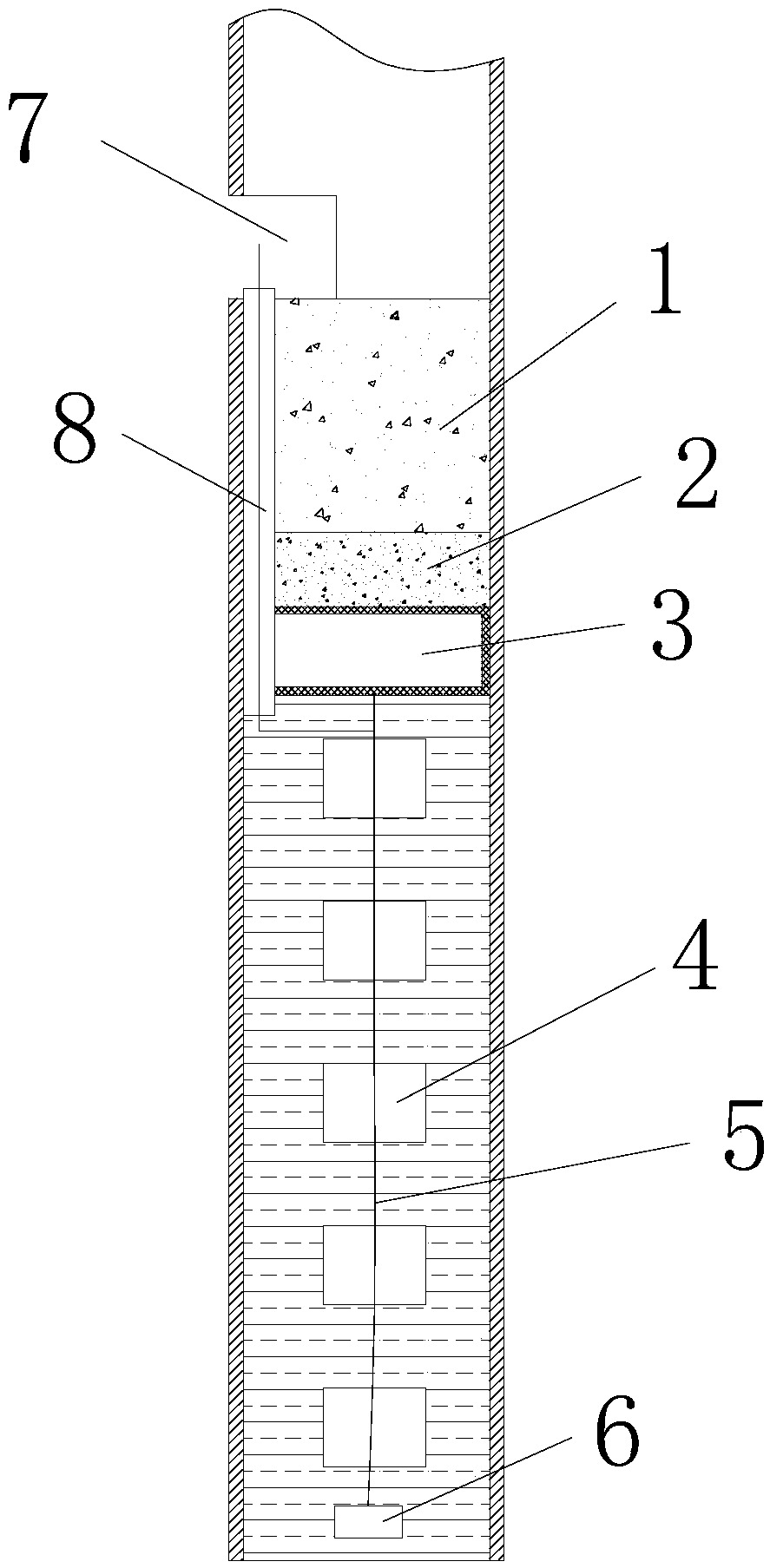

In-hole micro difference blasting method performing punching in upward direction of medium-deep hole and explosive charging in downward direction of medium-deep hole

The invention belongs to the technical field of metal mines and particularly relates to an in-hole micro difference blasting method performing punching in the upward direction of a medium-deep hole and explosive charging in the downward direction of the medium-deep hole. The medium-deep hole is drilled from a lower segment to an upper segment, and communicating with the upper segment is achieved;a blast hole port plug is plugged in a lower hole of a blast hole, blocking stemming is contained in, and hole plugging of a lower hole port is completed; due to the method that a plurality of segments of detonating bombs and bulk explosive are arranged in the blast hole, and the plugging stemming is used in the blast hole to perform multi-segment blasting, the technical problem for achieving in-hole micro difference blasting during medium-deep hole blasting operation under a mine is solved; by means of the method, in-hole micro difference blasting with punching in the upward direction of themedium-deep hole and explosive charging in the downward direction of the medium-deep hole can be achieved, in medium-deep hole blasting simultaneous shaft-sinking, the explosive charging efficiency isimproved, the blasting effect is also guaranteed, and successful blasting shaft-sinking is guaranteed.

Owner:CHANGCHUN GOLD RES INST

Circular ash removing method suitable for fluidized bed boiler

ActiveCN105737143AEffective flushingAvoid damageFluidized bed combustionSolid removalSand blastingFluidized bed

The invention discloses a circular ash removing method suitable for a fluidized bed boiler, and belongs to the technical field of ash removal of boiler equipment. The circular ash removing method suitable for the fluidized bed boiler comprises a sand loading step and a recycling step, and is characterized in that in the sand loading step, sand is loaded in a sand hopper of a circular sand ash blower; in a sand blasting step, the sand in the sand hopper is placed in a sandblast, and is sprayed in a shaft at the tail by the sandblast; in the recycling step, after scouring a superheater, an economizer and an air pre-heater, the sand sprayed in the shaft at the tail flows into a fluidized bed of the circular sand ash blower, and is recycled via an auger connected to the fluidized bed; and in a sand lifting step, the sand recycled by the auger is elevated and moves to a position above the sand hopper through an electric hoist, and is discharged into the sand hopper through a sand discharging trolley to form a circular ash removal cycle. By the circular ash removing method suitable for the fluidized bed boiler, the sand can be circularly used to remove ash on a heat exchange component in the shaft at the tail, the heat exchange efficiency is improved, and boiler steam rate is increased. The circular ash removing method suitable for the fluidized bed boiler has the features of low energy consumption and good ash removal effect.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

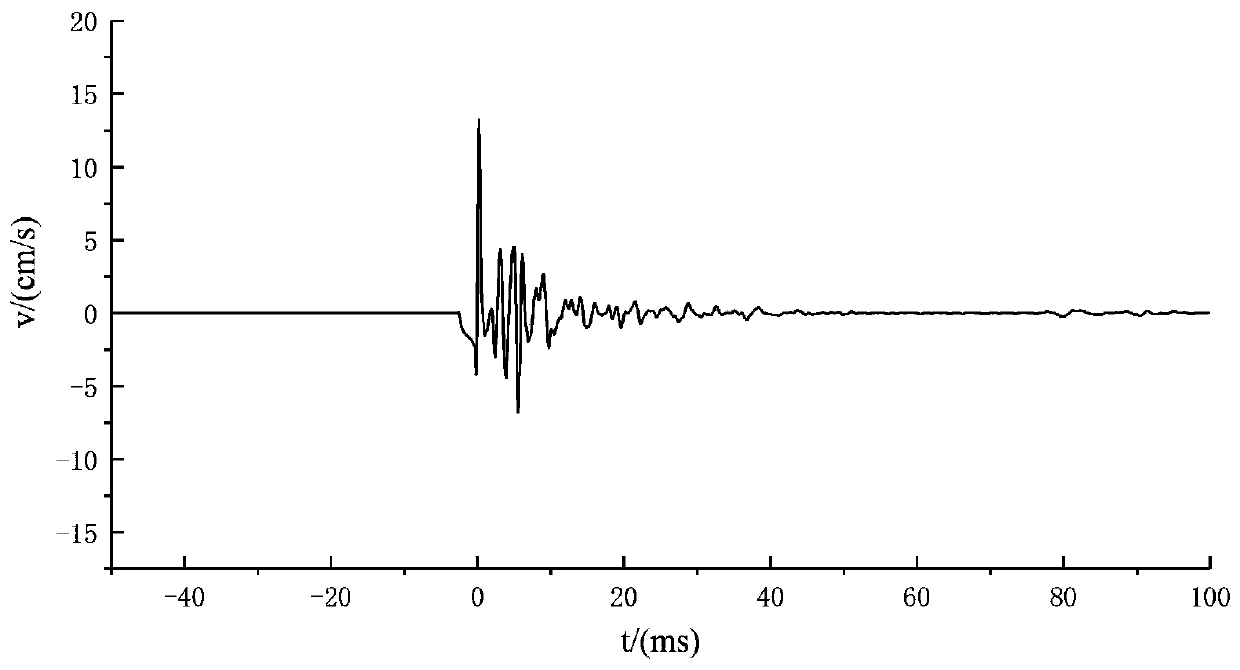

Beam-shaped blast hole cut blasting method for reducing vibration by using random delay errors of common detonators

The invention discloses a beam-shaped blast hole cut blasting method for reducing vibration by using random delay errors of common detonators. Firstly, a reasonable arrangement mode and a charging structure of blast holes in a cut blasting area are selected according to the properties of on-site ore rock, the blast holes in the cut blasting area at least comprise a plurality of beam-shaped blast holes positioned in the middle of the cut blasting area, the common millisecond delay detonators with the same section are adopted as the detonating detonators of the beam-shaped blast holes, and short-delay blasting between the detonators at the same section of the beam-shaped blast holes is realized by utilizing the random delay errors between the common millisecond delay detonators at the same section. According to the method, the short-delay blasting mode is formed by utilizing the random delay errors of the common millisecond delay detonators, the reasonable detonator sections are scientifically selected through a Monte Carlo simulation method, the beam-shaped blast hole cut blasting method with the blasting vibration harm controlled is realized, the cut blasting effect can be guaranteed, the blasting vibration effect can be reduced, and the low-cost common millisecond delay detonators can be scientifically and reasonably adopted as the detonating detonators.

Owner:CENT SOUTH UNIV

Rust removal apparatus for inner walls of bend pipes

InactiveCN104802095AAvoid offsetImprove efficiencyAbrasive machine appurtenancesAbrasive blasting machinesArray data structureSand blasting

The invention relates to a rust removal apparatus for inner walls of bend pipes. The rust removal apparatus comprises a trolley for placing several bend pipes onto a guide rail to move. A sand-blasting gun supported by a triangle support frame is arranged at one side of the trolley. A metal tube sleeves a nozzle of the sand-blasting gun, and sand-blasting equipment for placing river sand is connected at one end of the sand-blasting gun. A baffle plate is also arranged at one side of the trolley. Several fixing devices for fixing the bend pipes are mounted on the trolley. Each fixing device comprises a compression ring for inserting and fixing a bend pipe. A retaining ring for fixing a bend pipe is disposed in the middle of ends of each two compression rings. The distance from the nozzle and an opening of a bend pipe is 300-500 mm, and diameter of a nozzle outlet is 8-10 mm. The rust removal apparatus has a simple structure, is convenient to operate and is reasonably designed. Through rotary sand-blasting, rust is removed cleanly. By using common river sand as the rust removal material, the rust removal apparatus is low-cost. Through production practice, rust removal of a product is smoothly finished. In addition, through inspection, quality of pipes' inner walls accords with the technical standards.

Owner:JIANGSU GREENLEAVES BOILER

Energy-saving and efficient explosive filling method and structure in blast construction

The invention relates to the technical field of blasting, and aims at providing an energy-saving and efficient explosive filling method and structure in blast construction. The energy-saving and efficient explosive filling method and structure adopt both emulsion explosive and powder explosive simultaneously and determine the explosive filling sequence according to the situations in blast holes. Meanwhile, the type of explosive at the bottoms is determined according to the water accumulation situations at the bottoms of the blast holes, and the effect of water accumulation on blasting effect is effectively avoided. Meanwhile, a spacer is also used for solving the problem that a hole area in the blast holes or the blast holes are too deep. In order to ensure the blasting effect, explosive packages are hoisted stably by a specific hoisting structure. By adopting the technical scheme, the consumption of explosive is effectively reduced, and the utilization rate of explosive energy is improved.

Owner:四川中鼎爆破工程有限公司

Tunneling smooth surface blasting method

ActiveCN110388856AGuaranteed blasting effectGood blasting forceBlastingTunnelsStress distributionStress concentration

The invention relates to a tunneling smooth surface blasting method and belongs to the technical field of smooth surface blasting. According to the method, in terms of large-span shallow buried tunnels in urban centers, in order to protect tunnel surrounding rocks and reducing harmful effects of vibration of simultaneous smooth surface blasting to the maximum extent, smooth surface blasting holesare uniformly formed in tunnel rocks, uncoupled charging devices for smooth surface blasting are arranged in the smooth surface blasting holes, and smooth surface hole-by-hole precise short-time-delayblasting is achieved by adopting digital electronic detonators. The delay time of the digital electronic detonators in the holes is set in advance, when hole-by-hole precise short-time-delay blastingis performed, the edge stress distribution of the edges of blast holes is changed through time differences, stress of the blast holes is concentrated, accordingly, cracks are expanded and connected in the blast hole connecting line direction, and compared with simultaneous smooth surface blasting, vibration can be effectively reduced. By means of the blasting method, the smooth surface blasting effect is guaranteed, and blasting vibration in the smooth surface blasting process is also effectively controlled.

Owner:KUNMING UNIV OF SCI & TECH

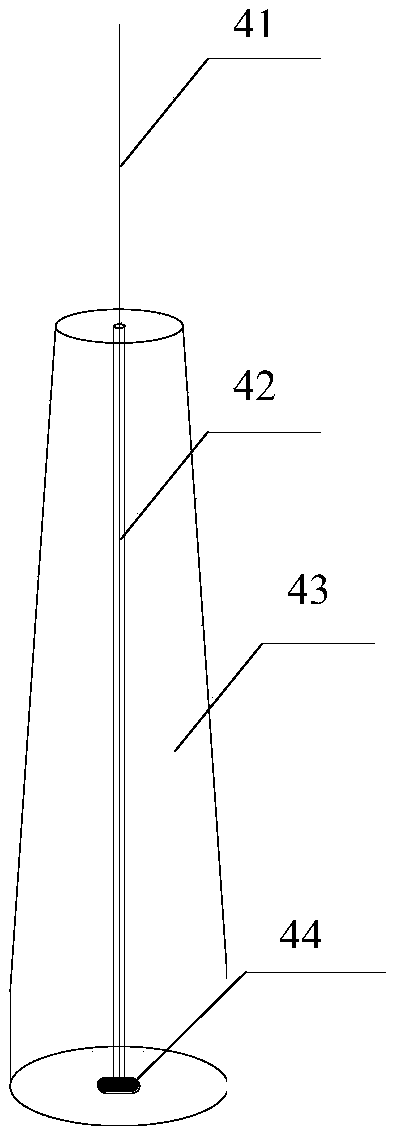

Demolition blasting method of cylindrical steel column structure building

InactiveCN108915295AIncrease the degree of blast damageGuaranteed blasting effectBuilding repairsLiquid waterSteel columns

The invention discloses a demolition blasting method of a cylindrical steel column structure building. The demolition blasting method comprises the following steps that 1, a gap is cut in a tubular steel column to be blasted; 2, the steel column is filled with water from the gap position; 3, a guide pipe, an inflation bag, a thin rope and a sinking block connected with the thin rope are put in thetubular steel column; 4, the inflation bag is put in the tubular steel column and is inflated; 5, the tubular steel column is filled with cement mortar to form a first concrete block, and the tubularsteel column is filled with cement mortar again to form a second concrete block after first concrete solidifies; 6, after curing is completed, a cartridge bag is blasted, and blasting of the tubularsteel column is completed. The gap is formed in the steel column and is filled with liquid water, the cartridge bag is put, the inflation bag is put and is filled with a thin layer of concrete, the liquid water is sealed in the steel column through concrete, the cartridge bag is blasted, the blasting destroying degree is greatly improved, and a blasting effect can be ensured.

Owner:ARMY ENG UNIV OF PLA +1

Blasting demolition method of prestressed beams of complex building structure

InactiveCN108613602AReduce intensitySolve problems that are difficult to disassembleBlastingPre stressEngineering

The invention relates to the technical field of building construction, and in particular to a blasting demolition method of prestressed beams of a complex building structure. The method comprises thefollowing steps that 1), the ultimate tensile strength of the prestressed beams is calculated, blast holes are drilled in the prestressed beams, and explosives capable of damaging the structural stability of the prestressed beams are buried into the blast holes; 2), blasting points are arranged on the portions, above the prestressed beams and below the prestressed beams, of a building structure; and 3), the blasting points on the building structure are sequentially detonated until the structure is all completely collapsed. The method has the characteristics of reasonable design, safety, reliability and simplicity and convenience in construction, and is suitable for demolition blasting of the prestressed beams of the various complex-structure buildings.

Owner:中铁四院集团工程建设有限责任公司

Method for filling blast holes

The invention discloses a method for filling blast holes. The method comprises the following steps of: step 1, calculating the explosive consumption of the blast holes per unit or in blasting area per unit according to the blasting environment and a preset blasting purpose; step 2, presetting different explosive densities according to the blasting environment or the blasting purpose of the rock hardness, the rock joint, the surrounding water content and the like; step 3, filling various blast holes with explosives in various densities in a blasting field according to the various explosive densities preset in the step 2; and step 4, backfilling and sealing the blast holes, wherein in the step 3, the explosives in preset densities are filled in the blast holes, the space of the blast holes can be filled, a spacer can be abolished, and sealing opening backfilling sections in certain lengths can be preserved at the outermost ends of the blast holes. The chemical reaction generating efficiency of the explosives can be increased, the blasting effect can be improved, the explosive consumption per unit can be reduced as well, and the purchasing cost of the spacer can be saved.

Owner:QINGDAO TARGET MINING SERVICES

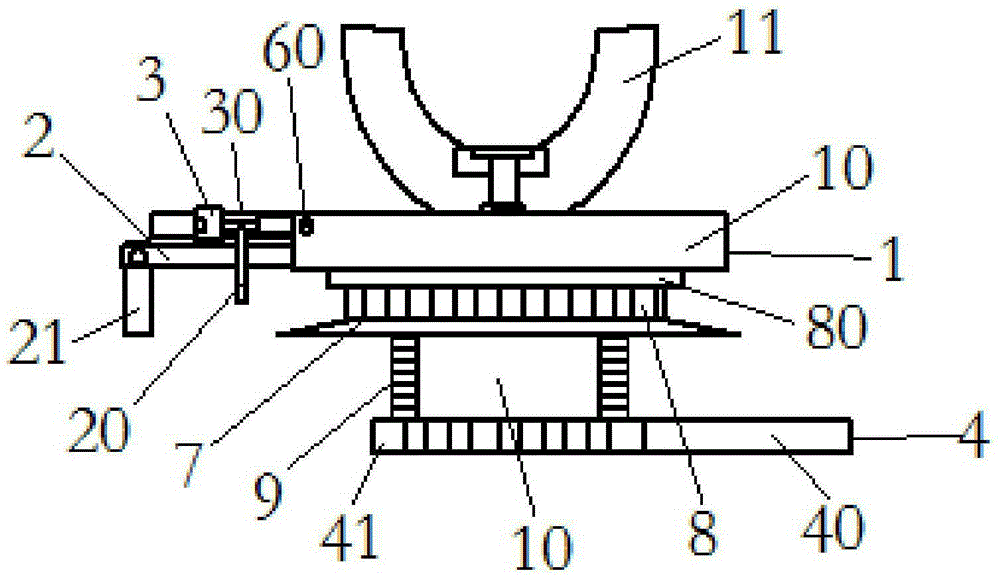

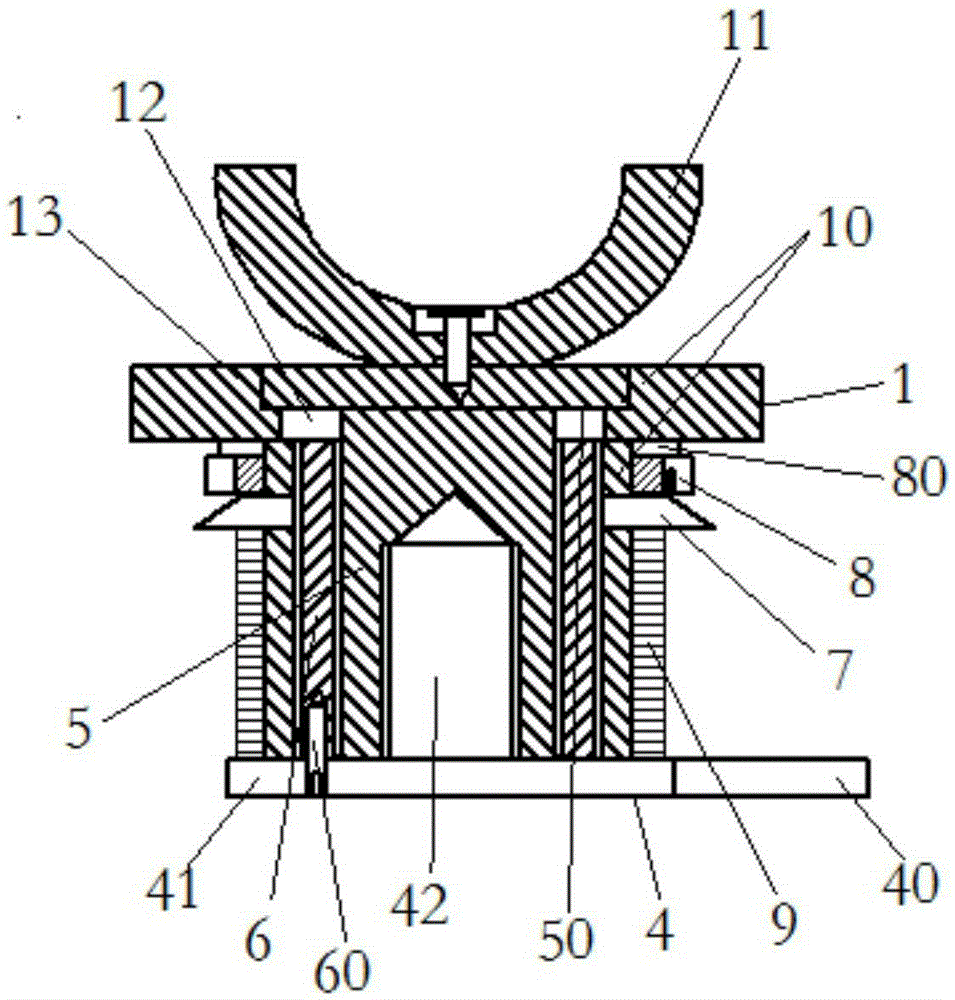

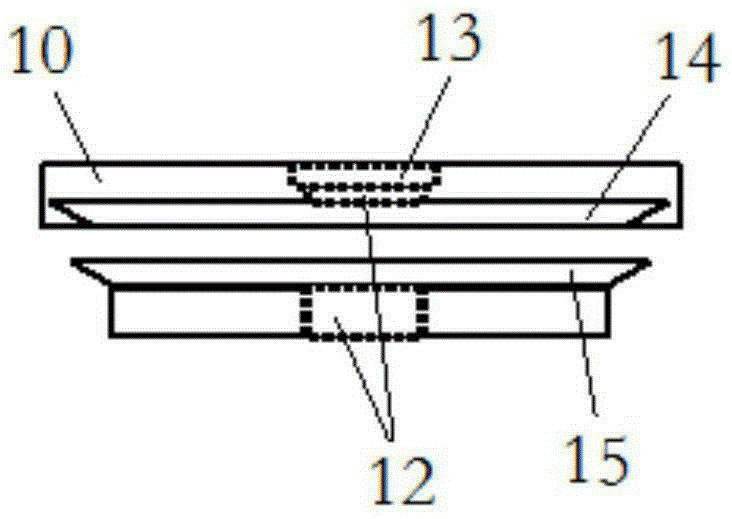

Fine adjusting device for pipeline inner wall sand blower

ActiveCN105397644AGuaranteed blasting effectHeight adjustableAbrasive machine appurtenancesAbrasive blasting machinesEngineeringStructural engineering

The invention discloses a fine adjusting device for a pipeline inner wall sand blower. The fine adjusting device comprises a supporting base, a transverse adjusting rod, a transverse limiting rod, a height adjusting column, a handle, a connecting cylinder, a sleeve, snap spring pieces, a clamping base and springs. The supporting base is formed by a base body and a rotating base. The height adjusting base is formed by a base and a connecting base. An inner thread and an outer thread are arranged on the connecting cylinder. The connecting base and the sleeve are both in threaded connection with the connecting cylinder. The springs are arranged on the outer side of the supporting base. The base and the sleeve are connected through a stop screw. The transverse adjusting rod is arranged on the side face of the base body and is in threaded connection with the base body. The transverse limiting rod is arranged on the side face of the base body and connected with the base body through a stop screw. According to the fine adjusting device for the pipeline inner wall sand blower, adjustment on the height and angle of a nozzle of the pipeline inner wall sand blower is achieved by arranging a transverse adjusting mechanism, a longitudinal adjusting mechanism and a limiting mechanism and adjusting the transverse position and the longitudinal position of the fine adjusting device, and the pipeline inner wall sand blowing effect can be better guaranteed.

Owner:东莞市富锐百通科技制造有限公司

Simple, convenient and efficient hole plugging device and construction method thereof

PendingCN114111488APrevent rush outProlong the action timeBlastingTunnelsSocial benefitsEconomic benefits

The invention discloses a simple, convenient and efficient hole plugging device and a construction method thereof. The device comprises a blast hole, an expansion substance, a detonating device, a buffer material, an auxiliary plug and a plug. Wherein one end of the auxiliary blanking plug is a pointed end, the pointed end points to the blanking plug, and the pointed end can slide along a blast hole under the action of an expansion substance and then is inserted into the blanking plug to be used for increasing the friction force between the blanking plug and the blast hole; the buffer material is used for protecting the auxiliary blanking plug from being damaged by the expansion substance; the detonating device is used for manufacturing a detonating explosive package. The device can improve the hole plugging quality, prolong the action time of the expansion substances, improve the crushing degree of rocks and the effective energy utilization rate of the expansion substances, and ensure the tunnel blasting effect, thereby improving the tunnel blasting tunneling progress. In addition, the device and the construction method thereof are time-saving and labor-saving in practical application, simple and convenient to operate and beneficial to site construction management, and have remarkable economic benefits and social benefits.

Owner:SOUTHWEAT UNIV OF SCI & TECH

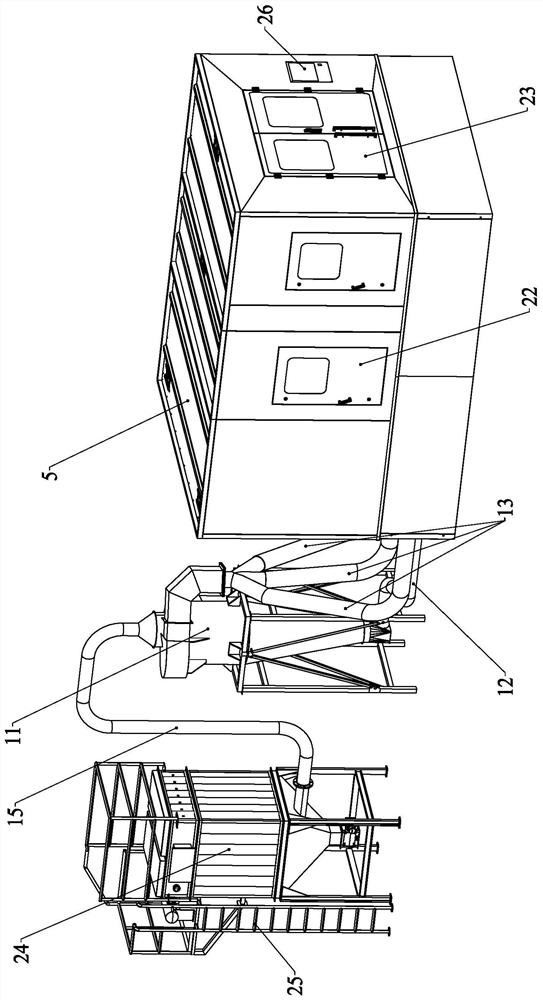

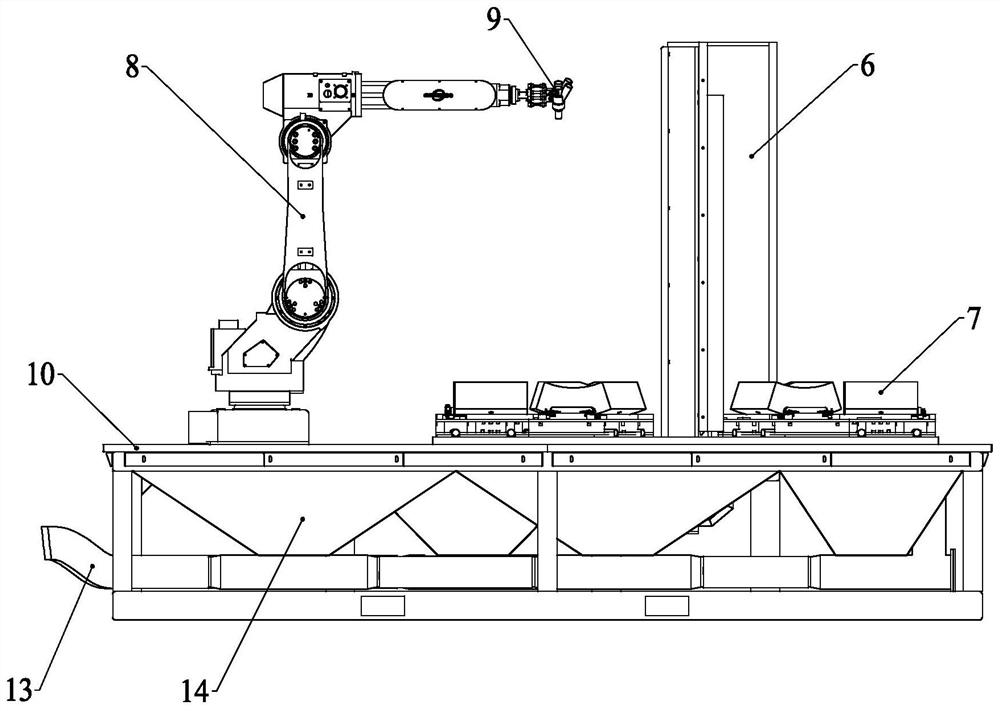

Automatic sand blasting and recycling device for industrial robot

PendingCN112847162AConsistent sandblasting effectUniform thicknessAbrasive machine appurtenancesAbrasive blasting machinesSand blastingDust control

The invention relates to an automatic sand blasting and recycling device for an industrial robot, which is characterized in that a conveying rotary table of a workpiece feeding, discharging and conveying mechanism is arranged in a sand blasting chamber, the sand blasting chamber is divided into a feeding and discharging area and a sand blasting area through a partition plate, and workpiece toolings are distributed on the conveying rotary table in an annular array mode; a laser positioning assembly is arranged in the sand blasting chamber and controls positioning of each workpiece, and the conveying rotary table controls rotation of the workpiece toolings; a robot of a sand blasting mechanism is externally wrapped with protective clothing and is arranged on a rack in the sand blasting chamber, and a spray gun is used for performing sand blasting treatment on a workpiece in the sand blasting area; sand blasting sand grains of a sand supply and recovery mechanism are sprayed out through a sand conveying pipeline connected with a spray gun, wherein the sand conveying pipeline is connected with a cyclone separator, a funnel arranged on the rack is used for recovering redundant sand grains and the redundant sand grains enter the cyclone separator through a sand return pipeline; a dust removal mechanism exhausts air and removes dust for the cyclone separator; and a host computer controls the robot to act through an operation interface of control software. The device has the advantages that manual sand blasting is replaced, the sand blasting efficiency is improved, and sand blasting dust is fully recycled.

Owner:广东培创智能技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com