Blasting method for high-temperature sealed fire areas

A fire zone and high temperature technology, which is applied in the blasting field of high temperature fire zone, can solve problems such as rebound time sometimes changed by changes in natural conditions or drilling reasons, potential safety hazards, reducing the scale and progress of blasting in the fire zone, etc., to achieve rebound The effect of long time, convenient material acquisition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

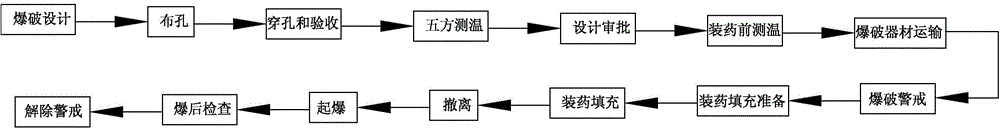

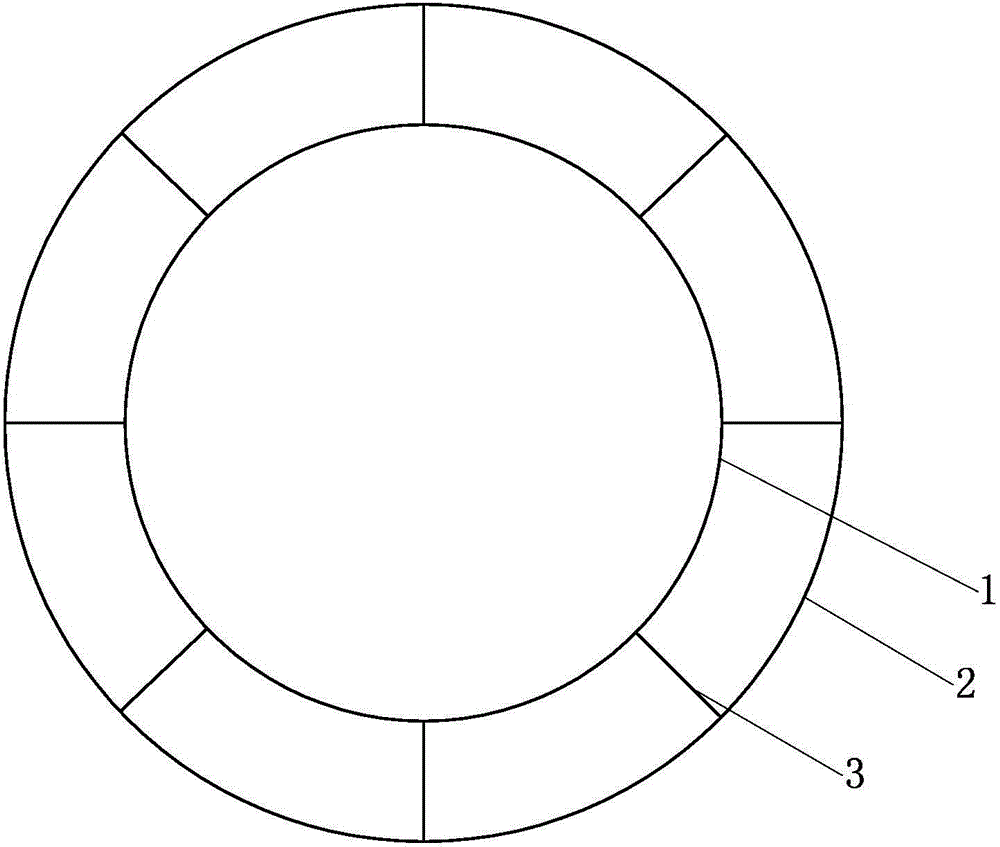

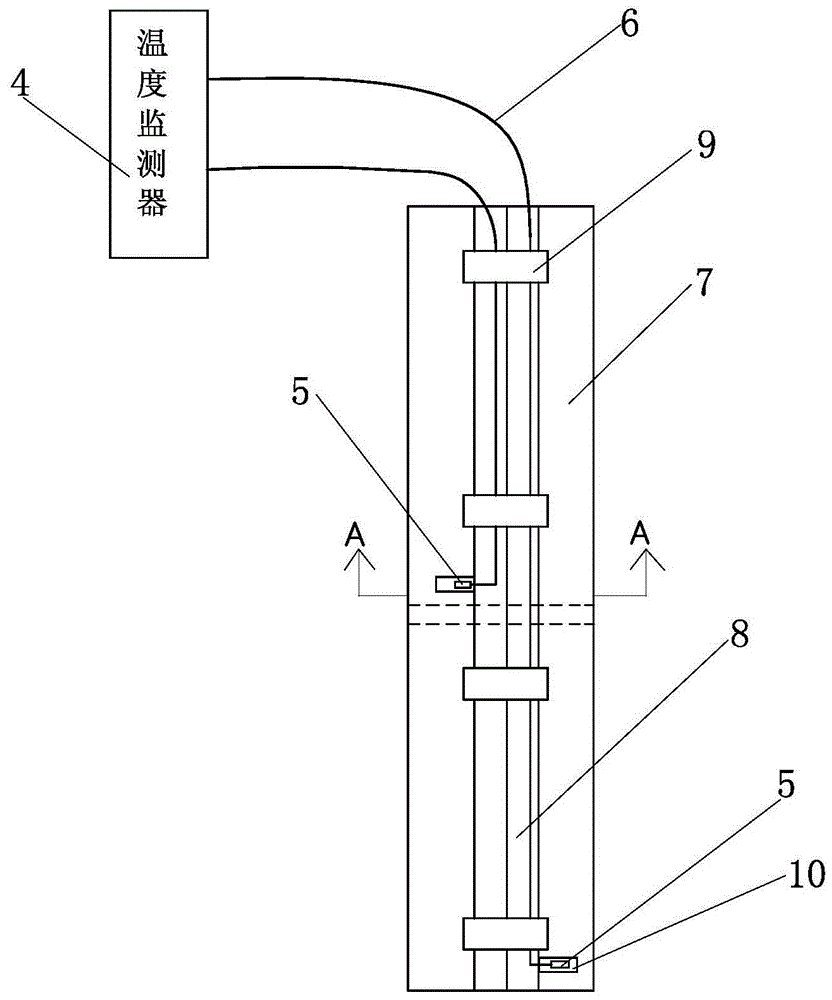

[0037] like Figures 1 to 4 Shown, a kind of blasting method that is used for high temperature fire zone, its steps are as follows:

[0038] a. Blasting design, according to the rock conditions of the working face, several important blasting parameters are designed, such as hole depth, hole row spacing, step height of blast holes, unit consumption, and network. At the same time, according to the law of hole depth and temperature rebound time, the effect is better when the step height of the blast hole is 5-6m. The blasting network adopts the detonating cord network, and the blasting design manual is compiled. In this step, the blasting unit consumption is 0.3kg / m 3 . The drilling angle and hole row spacing are affected by the test site and can be adjusted or laid out according to the terrain.

[0039] b. Hole layout, according to the parameters indicated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com