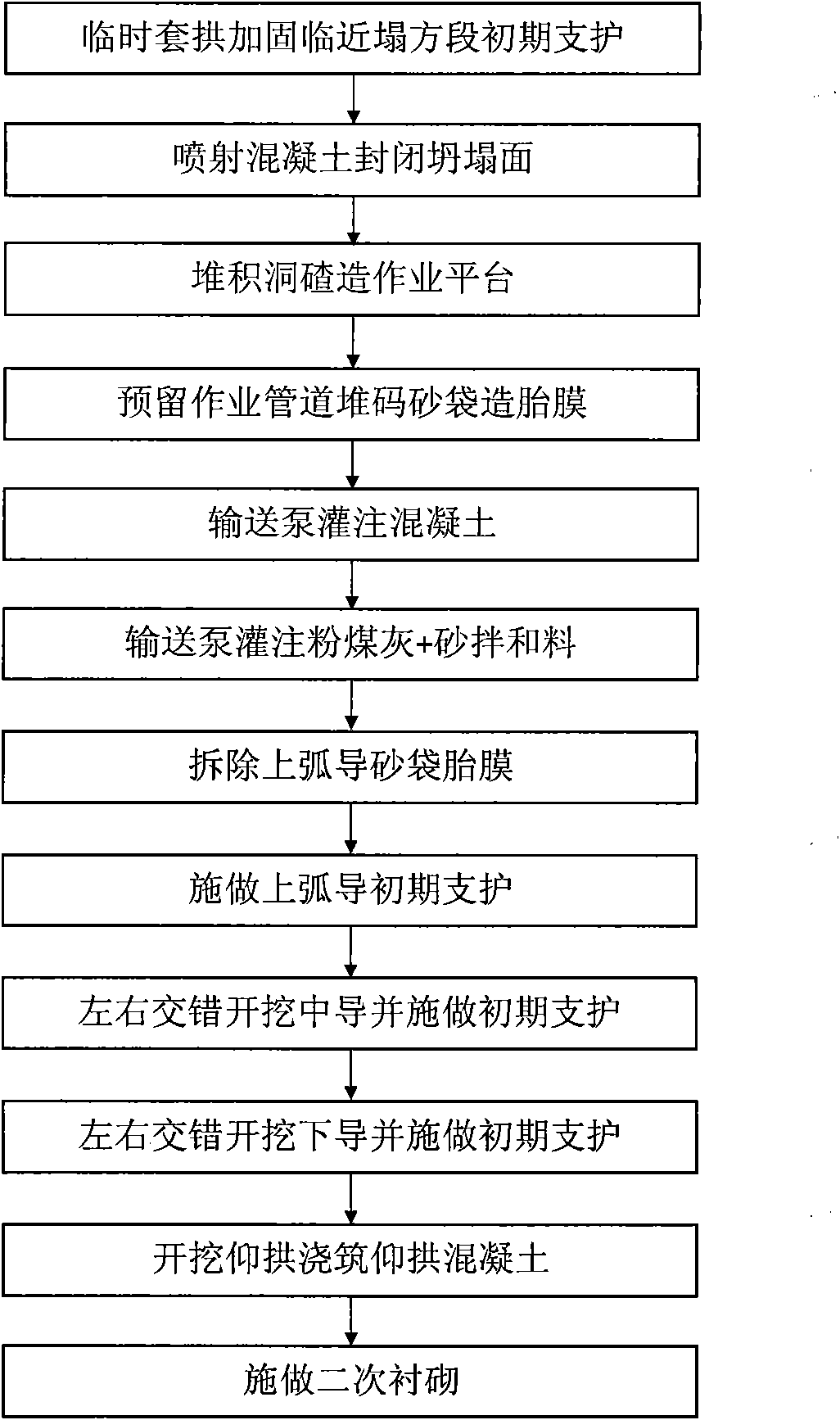

Construction method for dealing with tunnel collapses

A construction method and tunnel technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as high safety risks, difficult construction, secondary safety accidents, etc., and achieve the effect of low cost and convenient materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

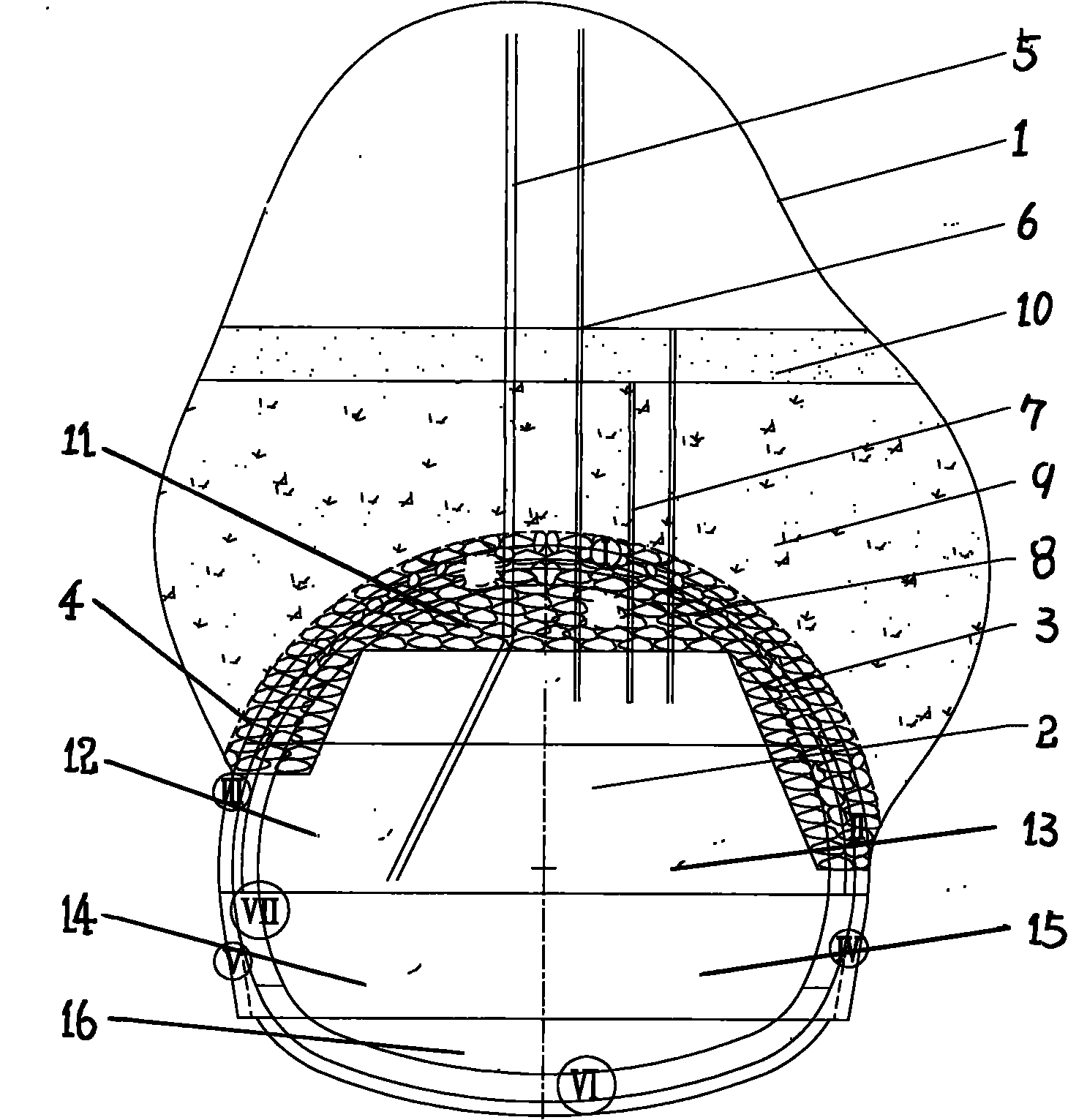

Examples

example 1

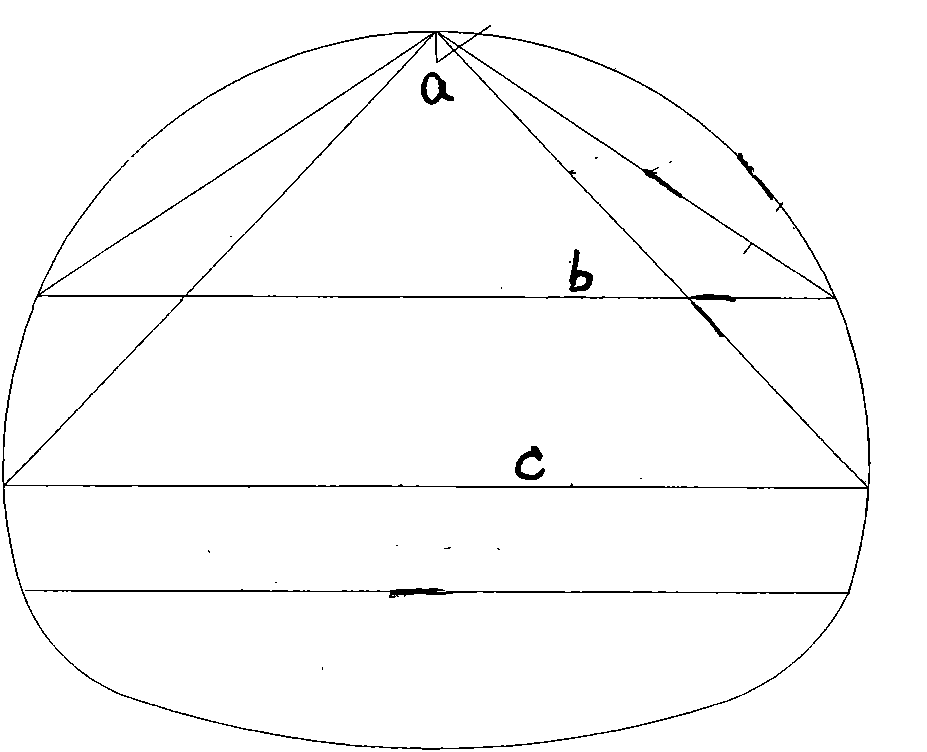

[0035] Landslide situation: The entrance of Jiubao Tunnel was excavated to DK26+857 on May 29, 2008, the left side of the tunnel was excavated to DK26+842, and the right side was excavated to DK26+844. DK26+829~+841 The initial support 1m to the left of the vault was suddenly damaged, and a landslide occurred. The collapse consisted of soil with crushed stones and block stones, and water seepage at the top. Finally, a vertical line with a width of 5m and a parallel line with a length of 12m was formed. , A cave with a height of 6-8m.

[0036] Reason analysis: DK26+829~+841 section is located in the F10 fault fracture zone, the F10 fault fracture belt is 3~5m wide, inclined to the left side of the line, with an inclination angle of about 75°, obliquely intersecting with the cave body at DK26+800~+841, the intersection angle At about 5° to 10°, the fault filling material is breccia-like fragments interbedded with yellow mud, with strand-like and linear water discharges, and the ...

example 2

[0039] Landslide situation: The Jining end of the No. 1 inclined shaft of the Jiubao Tunnel was constructed to DK28+396.5 on June 18, 2008. At 21:40, the front of the tunnel suddenly collapsed and gushed out, resulting in the initial support of the DK28+395~+396.5 section Across the collapse, DK28+395~+405 section collapsed, forming a cavern with a length of 10m, a width of 15m and a height of 5m. The collapsed body is mainly in the shape of fragments and breccias, the collapsed surface is smooth, and the bedrock fissure water is developed, flowing down the rock wall in multiple strands.

[0040] Reason analysis: The design enters the F3 fault affected zone from DK28+370. Due to multi-stage tectonic movements superimposed by the development of surrounding rock joints, the joint surface is smooth and contains soft mud, the rock mass is broken, and it has a gravel-like crushed structure, and structural fissure water and bedrock fissure water developed, local pressure-bearing. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com