In-hole micro difference blasting method performing punching in upward direction of medium-deep hole and explosive charging in downward direction of medium-deep hole

A micro-blasting and deep-hole technology, which is applied in blasting, earthwork drilling, discharge machinery, etc., to achieve safe and reliable construction, overcome complex operations, and ensure the effect of blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] A method of in-hole micro-difference blasting in which the hole is drilled upwards and charged downwards in a medium-deep hole, such as figure 1 As shown, the specific operation steps are as follows:

[0026] Step 1: Drill upward blastholes, that is, medium-depth holes 1. During the drilling process, ensure that the blastholes are vertical and control the deflection rate of the blastholes;

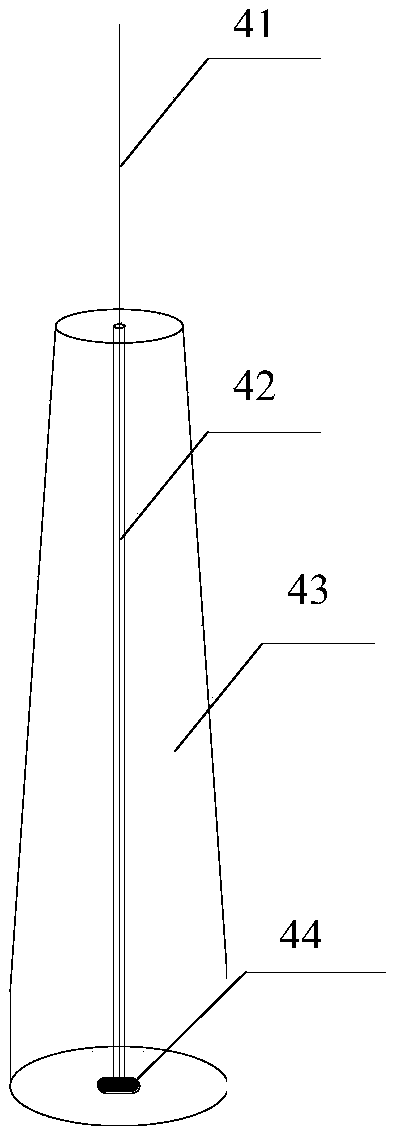

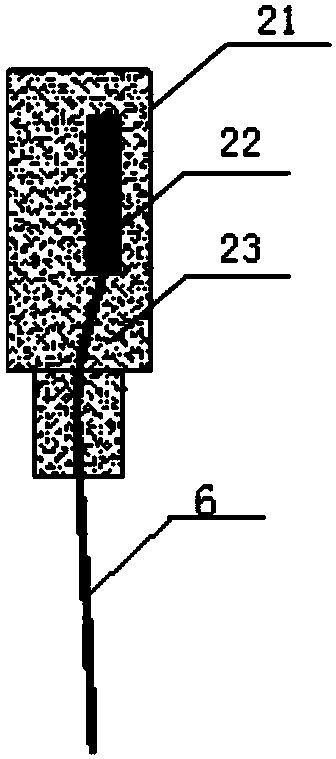

[0027] Step 2: If figure 2 Shown, make blasthole orifice plug 4, and blasthole orifice plug 4 is the conical cork 43 that is made of cork, and the center of conical cork 43 is drilled with steel wire perforation 42, and conical cork 43 bottom The center is provided with a retaining ring 44 at the center of the steel wire perforation 42;

[0028] Step 3: Insert the hole plug 4 of the blast hole into the lower opening of the middle-deep hole 1, and plug it tightly, lower t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com