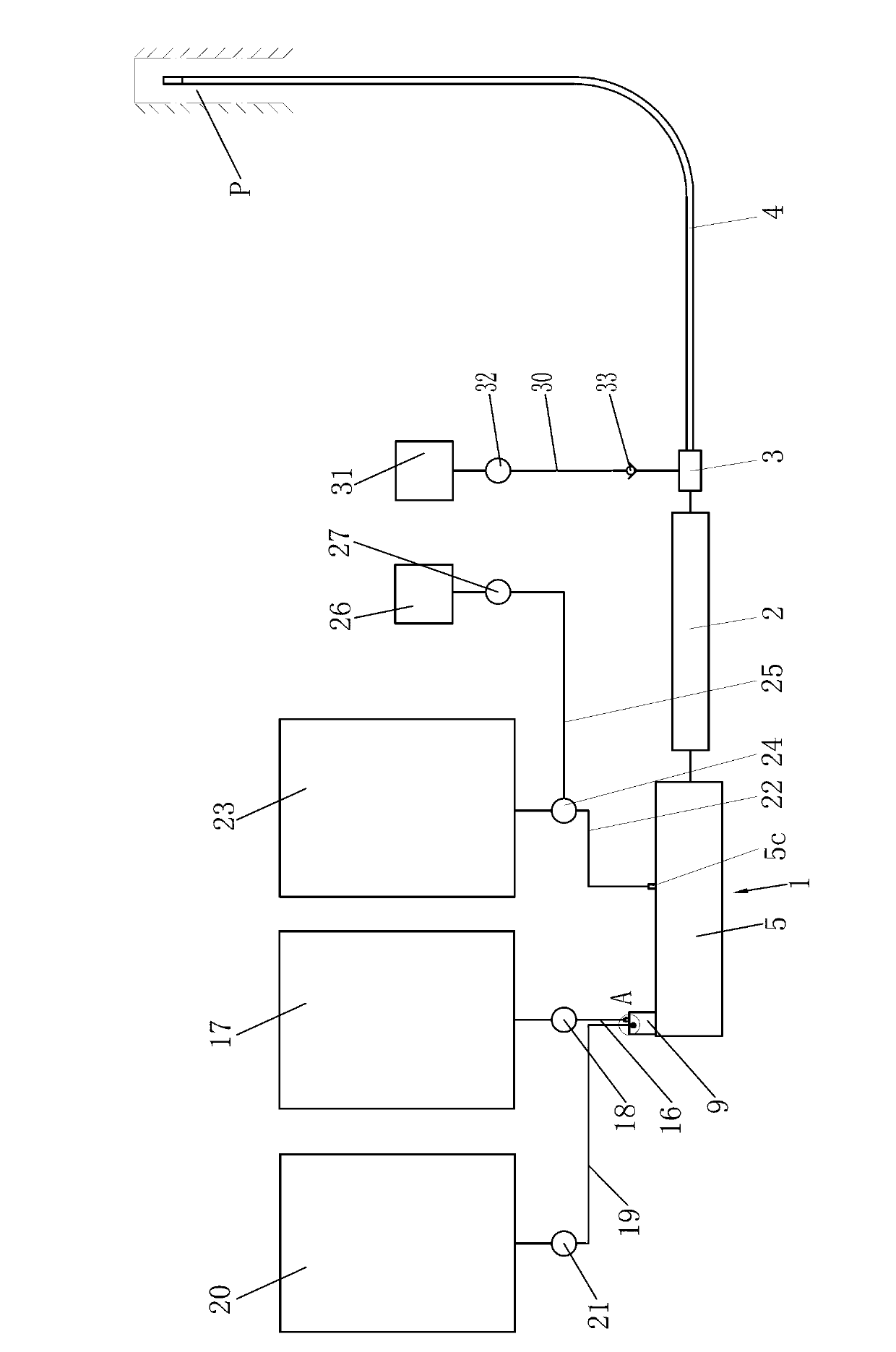

Field emulsion explosive mixing and charging system and charging method suitable for underground engineering

A technology of emulsion explosives and underground engineering, applied in explosives, blasting, etc., can solve the problems of increasing the working pressure of the drug delivery pump, prone to explosion, and large depth, so as to improve the charging effect, prevent material return, and improve the mixing characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

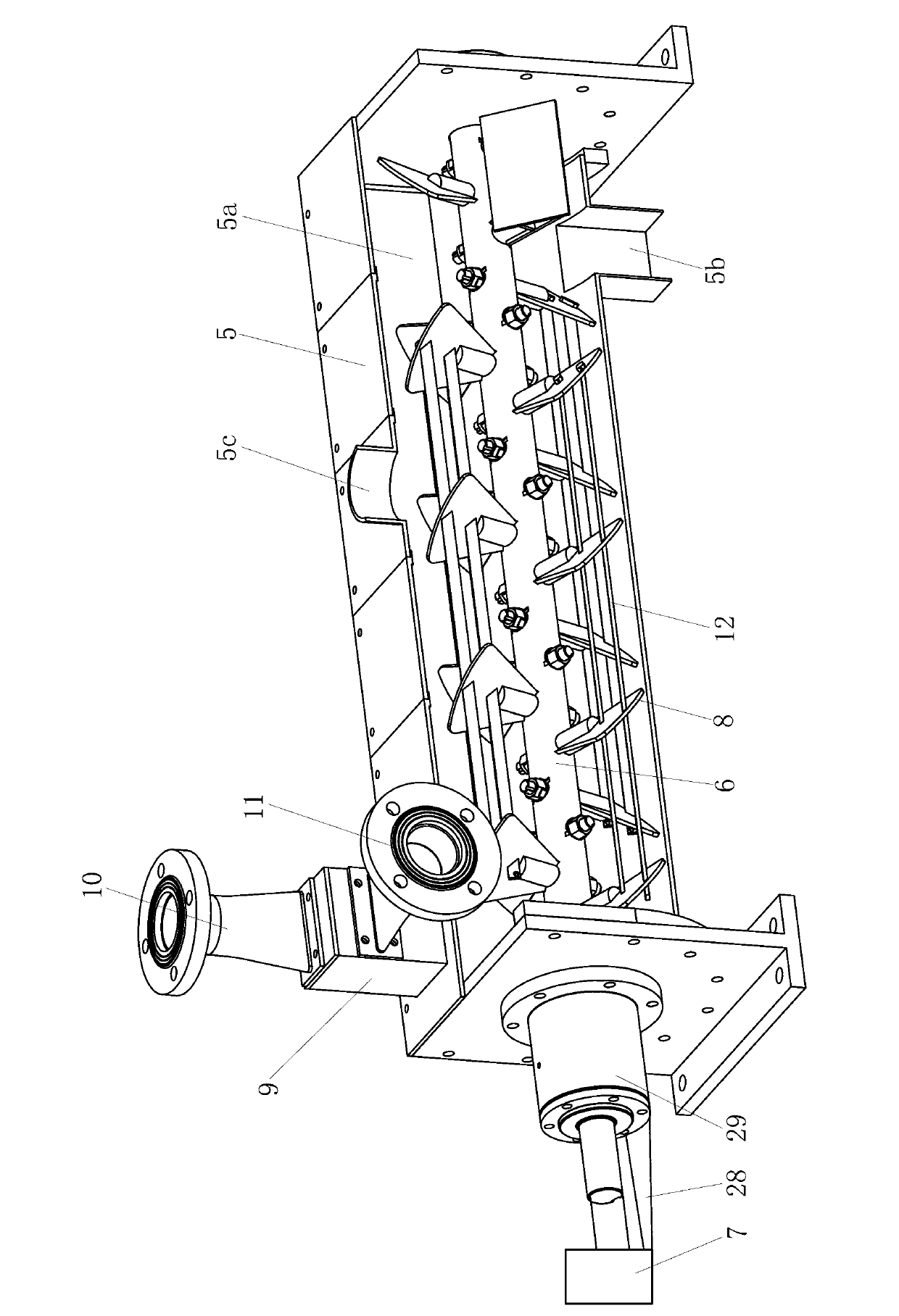

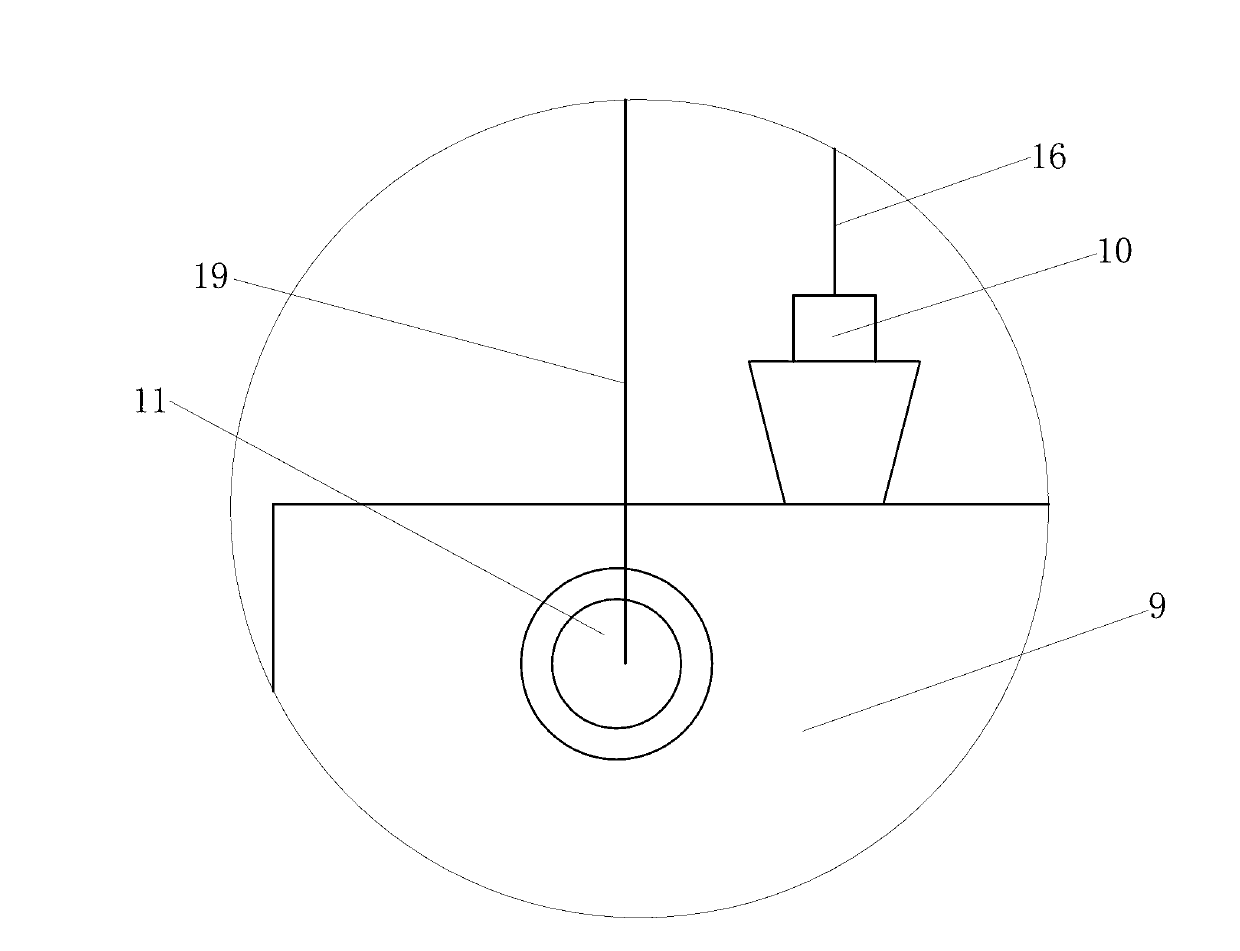

Method used

Image

Examples

Embodiment 1

[0098] Embodiment 1: the diameter of certain underground mine blast hole is 42mm, and blast hole is horizontal hole, and blast hole depth 2m, and the dynamic viscosity of the raw material latex matrix that adopts is 25000cP, and the water content of latex matrix is 18%, and latex matrix accounts for 1% of explosive. The proportion is 98%. The light bulk material is made of glass microspheres. The light bulk material accounts for 2% of the explosive. Dissolve 1g of sodium dodecylsulfate and 1g of sodium dodecylbenzenesulfonate in water to prepare In 1kg of lubricant, the weight ratio of lubricant to explosive is 0.02:1, the inner diameter of the drug delivery hose is 0.75″, and the length of the drug delivery hose is 15m. The relative weight power of the prepared explosive (relative to ANFO) is 0.81, and the relative volume of the explosive is The power (relative to ANFO) is 1.04, the viscosity of the explosive is 300,000cP-500,000cP (varies with changes in temperature and oth...

Embodiment 2

[0099] Embodiment 2: certain underground mine blast hole diameter is 42mm, blast hole is horizontal hole, blast hole depth 2m, the dynamic viscosity of the raw material latex matrix that adopts is 25000cP, and the water content of latex matrix is 18%, and the ratio of latex matrix to explosive The light bulk material is made of glass microspheres, and the light bulk material accounts for 2% of the explosive. Water is used directly as a lubricant. The weight ratio of lubricant to explosive is 0.02:1. The inner diameter of the drug delivery hose 0.75″, the length of the drug delivery hose is 15m. The relative weight power of the prepared explosive (relative to ANFO) is 0.81, the relative volume power of the explosive (relative to ANFO) is 1.04, and the viscosity of the explosive is 300000cP~500000cP (varies with temperature and other conditions. Different), the pressure of the infusion pump is about 1.3MPa, and the packing density is 1.1g / cm 3 , the charging efficiency is 20kg...

Embodiment 3

[0100] Embodiment 3: certain underground mine is vertical upwards blast hole diameter is 76mm, and the maximum depth of upward blast hole is 22m, and the dynamic viscosity of the raw material latex matrix that adopts is 25000cP, and the water content of latex matrix is 18%, and latex matrix accounts for 80% of explosives. The proportion of the explosive is 98%. The light bulk material is made of resin microbeads. The light bulk material accounts for 2% of the explosive. Dissolve 1g of sodium dodecylsulfate and 1g of sodium dodecylbenzenesulfonate in water to prepare In 1kg of lubricant, the weight ratio of lubricant to explosive is 0.02:1, the inner diameter of the drug delivery hose is 1.5″, and the length of the drug delivery hose is 50m. The relative weight power of the prepared explosive (relative to ANFO) is 0.81, and the explosive is relatively The volumetric power (relative to ANFO) is 1.04, the viscosity of the explosive is 600,000cP~800,000cP (varies with changes in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com