Mixing equipment for exhaust gases in automobiles

A technology for mixing equipment and exhaust gas, which is applied in the direction of mixers, mechanical equipment, fluid mixers, etc., and can solve the problems of deterioration of mixing properties and not causing secondary mixing properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

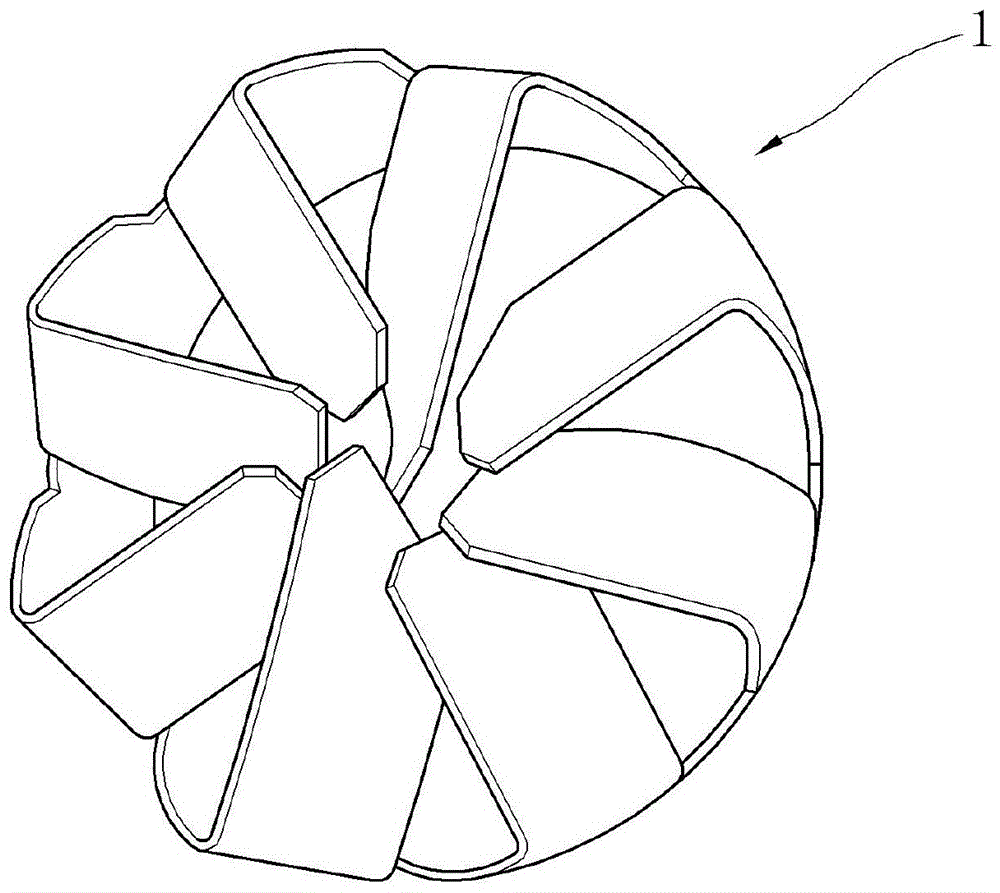

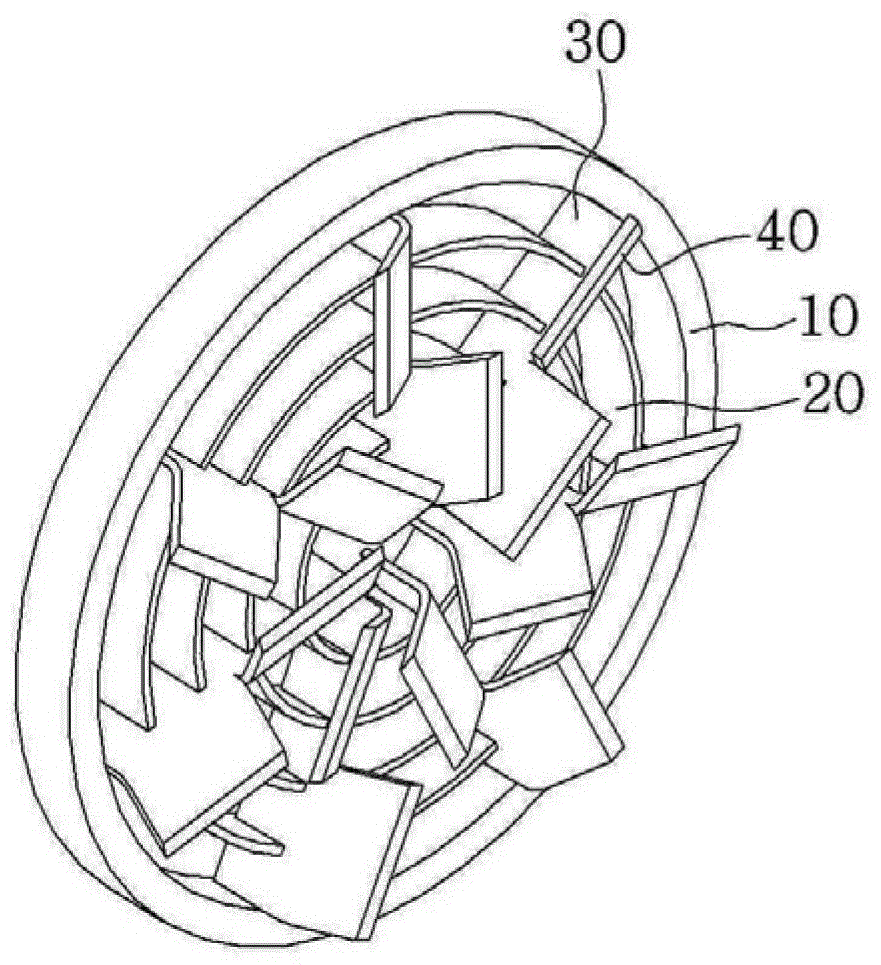

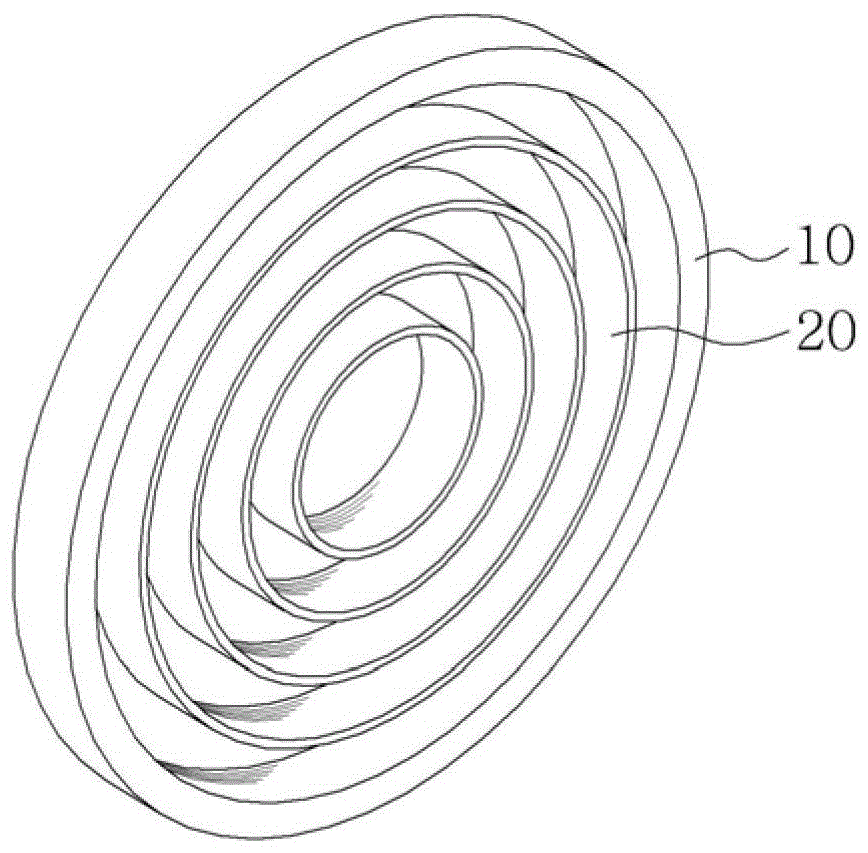

[0028] Hereinafter, a mixing device for exhaust gas according to an exemplary embodiment of the present invention will be described with reference to the accompanying drawings.

[0029] A mixing device for exhaust gas is provided in the exhaust pipe of the engine to cause uniform mixing of the exhaust gas and the reducing agent by uniformly diffusing them, and additionally the double swirl of the exhaust gas passes through said mixing device, thereby increasing the exhaust gas and the reducing agent mixed nature.

[0030] Before describing in detail the mixing device for exhaust gases according to the invention, said mixing device can vary in size so that it can be installed anywhere in the exhaust pipe of the engine, in addition, it can be provided as plug-in type or fixed type . In particular, the fixing device can be arranged in the following positions according to the layout of the exhaust system: where the exhaust flow is concentrated, or where the reducing agent needs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com