Intrinsically safe type quick explosive loading device for deep hole blasting

An intrinsically safe, deep-hole blasting technology, applied in blasting, ground mining, earth-moving drilling, etc., can solve the problems of increasing manpower, material resources and economic investment, threatening mine safety production, unable to meet the charging requirements, etc. Anti-catastrophe ability, ensure blasting effect, weaken the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

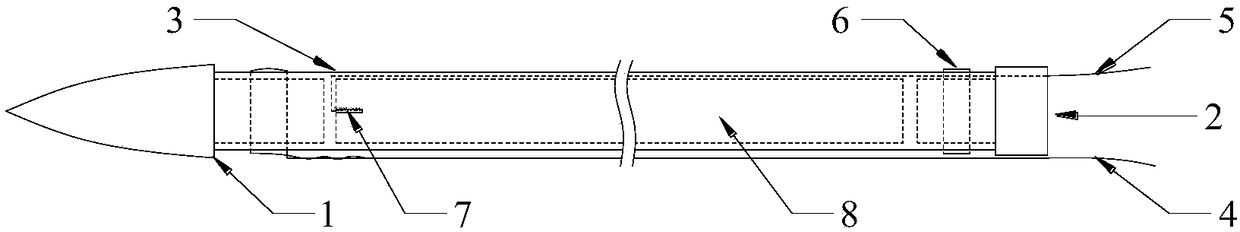

[0052] A deep hole blasting working face is designed with a blasthole depth of 2700cm, a blasthole diameter of 7.5cm, an explosive column diameter of 4.5cm, a charge length of 2000cm, and a sealing hole length of 700cm. use as figure 1 , figure 2 and image 3 The shown intrinsically safe rapid charging device for deep hole blasting, the specific steps include:

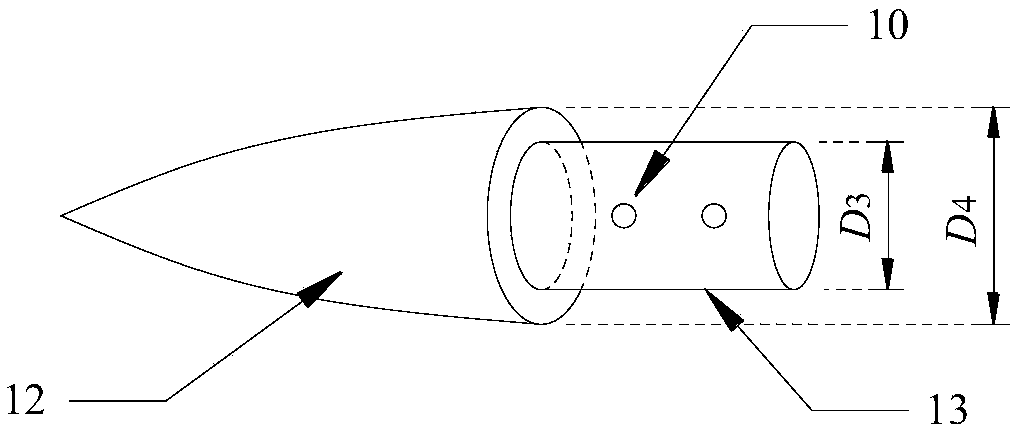

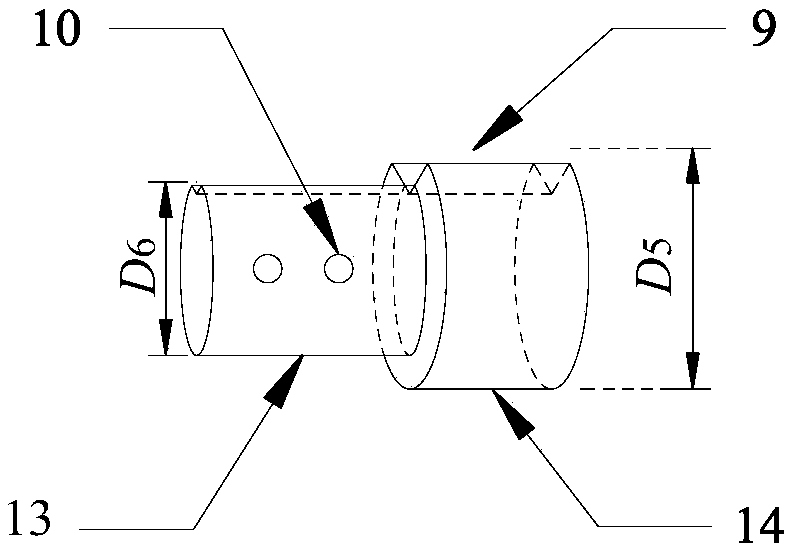

[0053] Step 1: First, insert the stable column part of the guide head into the PVC pipe body with a length of 200cm. Then, take a No. 10 iron wire with a length of 3000cm as a safety rope, and use one end of the iron wire to pass through the stabilizing hole to connect the guide head with the front end PVC pipe body. Among them, the diameter of the thickest end of the tapered end on the guide head is 5.5cm, the diameter of the stabilizing column is 5cm, the inner diameter of the PVC pipe is 5cm, the wall thickness is 0.1cm, and the total length is 2800cm. connected.

[0054] Step 2: Push the PVC pipe body into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com