Well formation method adopting vertical shaft blasting for mines

A technology for shafts and mines, applied in the field of blasting shafts in mines, can solve the problems of large amount of engineering, large amount of charge in the initiation section, and difficult construction, and achieves reduction of entrapment effect, blasting vibration, and section charge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

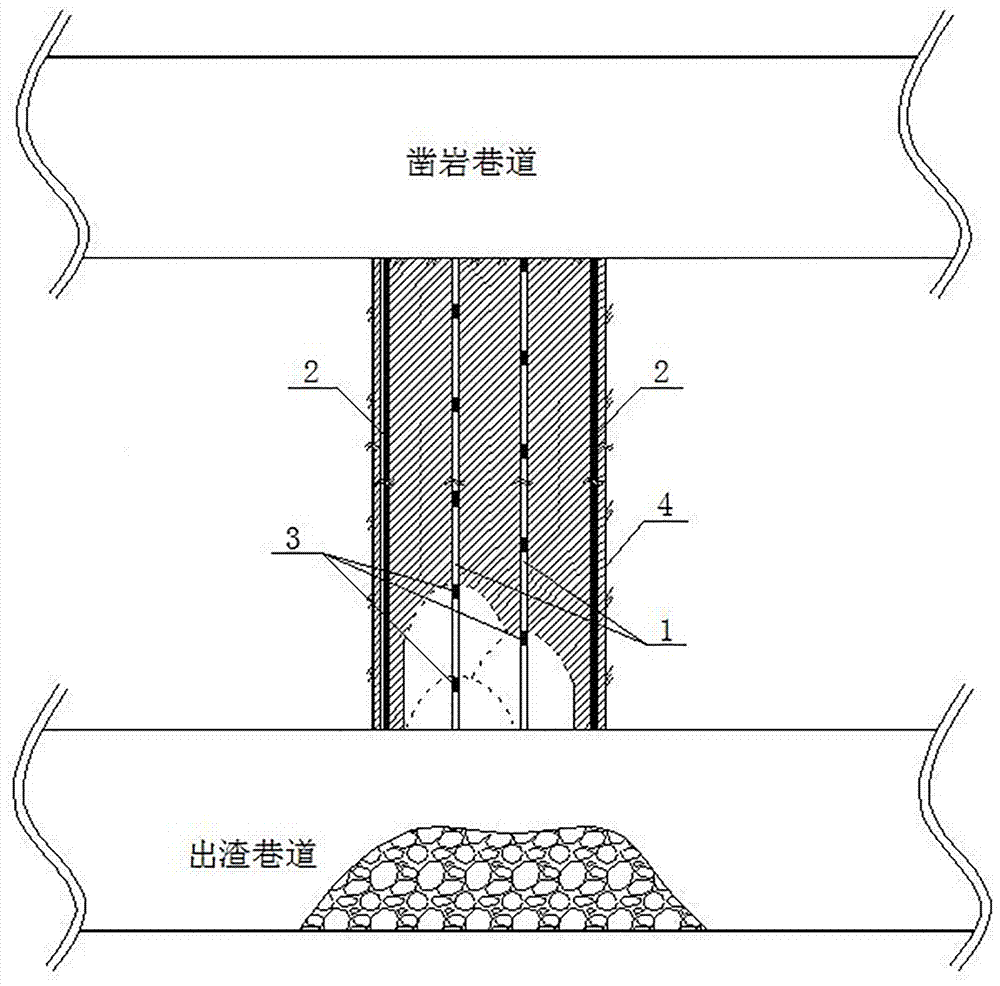

[0017] like figure 1 and figure 2 A mine shaft blasting well forming method is shown, which is characterized in that it comprises the following steps:

[0018] a. A cut hole area and a light explosion layer control hole area are set between the rock drilling roadway and the slag discharge roadway, the cut hole area is located in the light explosion layer control hole area, and the cut hole area is composed of four vertically arranged and It is composed of cut holes 1 arranged in a square shape, and the light explosion layer control hole area is composed of a plurality of vertically arranged light explosion layer control holes 2, and the light explosion layer control holes 2 are arranged circularly around the cut hole area ;

[0019] b. The charging operation is carried out in the cut hole and the control hole of the photoblast layer. The cut hole 1 adopts segmental interval coupling charging, and the charge packs 3 in the adjacent cut holes 1 are staggeredly distributed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com