Beam-shaped blast hole cut blasting method for reducing vibration by using random delay errors of common detonators

A technology of random time delay and blast hole, which is applied in the field of mine blasting, can solve problems such as poor economy, achieve large blasting vibration, good cutting effect, and ensure the effect of cutting blasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

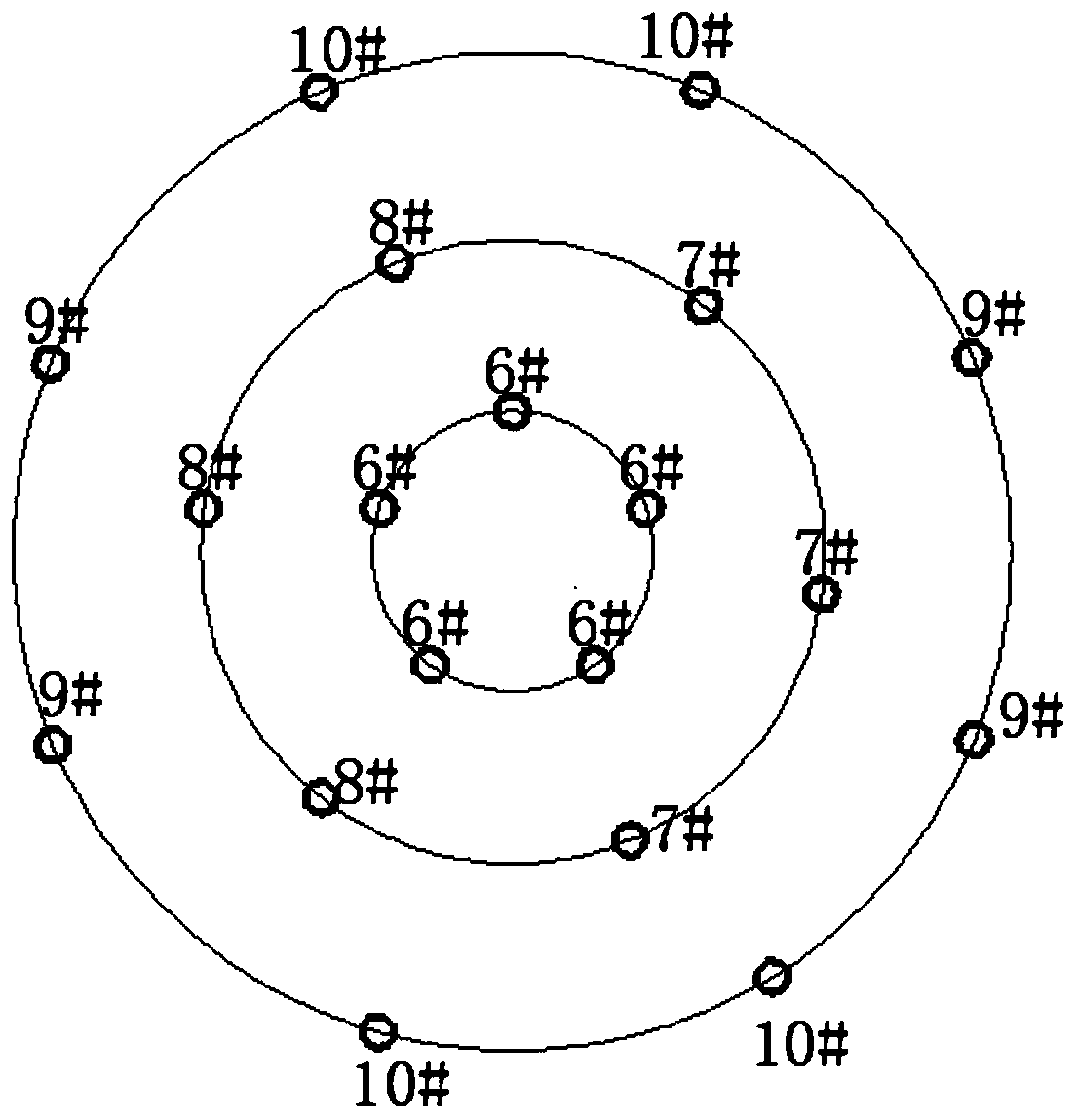

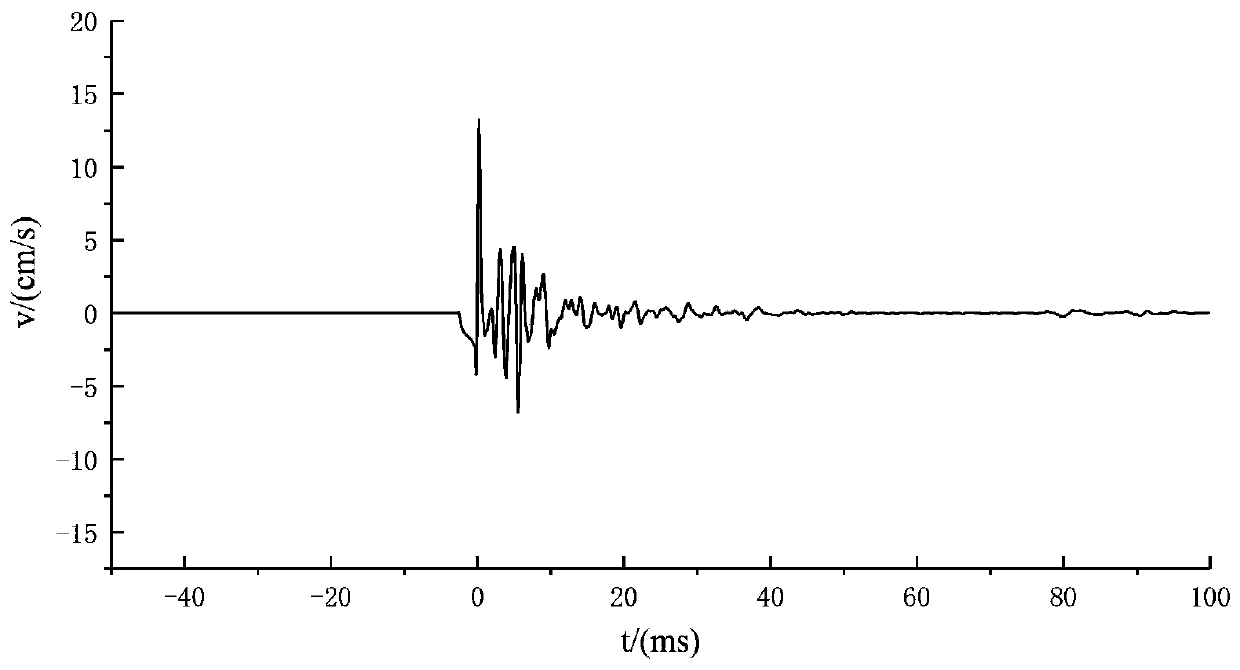

[0032] In the beam-shaped blast hole cutting blasting of the present invention, firstly, according to the properties of the ore rocks on site, a reasonable layout of the blast holes in the cutting blasting area and the charge structure are selected, and then the blasting with high vibration reduction reliability and good cutting effect is selected from ordinary millisecond delay detonators. The blasting detonator of a good beam-shaped blast hole is charged in sections, and the random delay error of the ordinary millisecond delay detonator is used to reduce the vibration of the short-delay blasting of the beam-shaped blast hole.

[0033] The blast holes in the cutting blasting area also include at least one circle of expanding blast holes located on the outer periphery of the beam-shaped blast holes. The beam-shaped blast holes are distributed around the center of the cutting blast area as the center of the circle. The center of the slot blasting area is the center of the circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com