Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Good for sales promotion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fig leaf sweet tea and manufacturing method

InactiveCN101297666AKeep the original fragranceRefreshing and sweetening economic incomePre-extraction tea treatmentFood preparationHabitEconomic Income

The invention relates to a fig leaf sweet tea and a manufacturing method thereof. Presently, the exploitation and utilization of fig leaves is few, thereby resources are wasted, and economic income of fruit farmers is reduced. The fig leaves have the mouthfeel of small suffering and are unpleasant to take, which do not conform to the habit of drinking tea of most people, therefore, the processing of the fig leaves is still a difficult problem. The fig leaf sweet tea of the invention is obtained by cleaning, chopping, blanching, rolling, condensing, and drying the fig leaves and matching the fig leaves with the sweet tea. The mixing of the fig leaves and the sweet tea has the functions of deastringency and sweetening, and retaining the pure fragrance of plants, has the mouthfeel of fresh and sweet aftertaste, and the fig leaf sweet tea is the high quality product which is suitable for drinking throughout the year; the tea also synthesizes the functions of health care and strengthening body of the two raw materials which have complementary advantages, thus becoming a pure natural green healthy drink, increasing the economic income of the fruit farmers. The fig leaf sweet tea and the manufacturing method thereof have the advantages of simple processing method, being beneficial to transportation, preservation, promotion and sale, and meeting the market demands.

Owner:魏毕祥

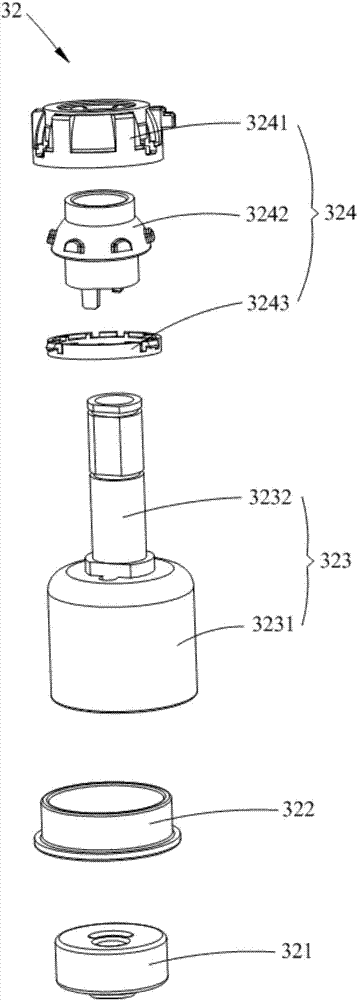

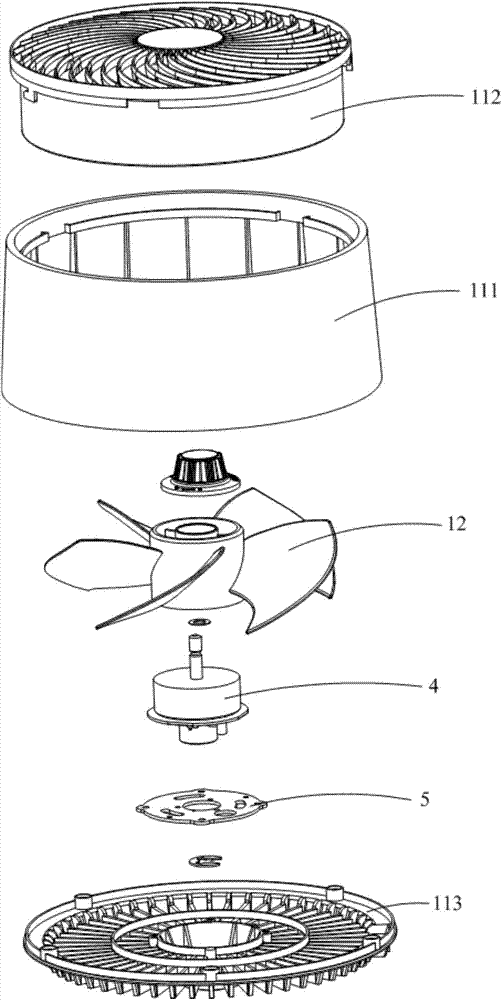

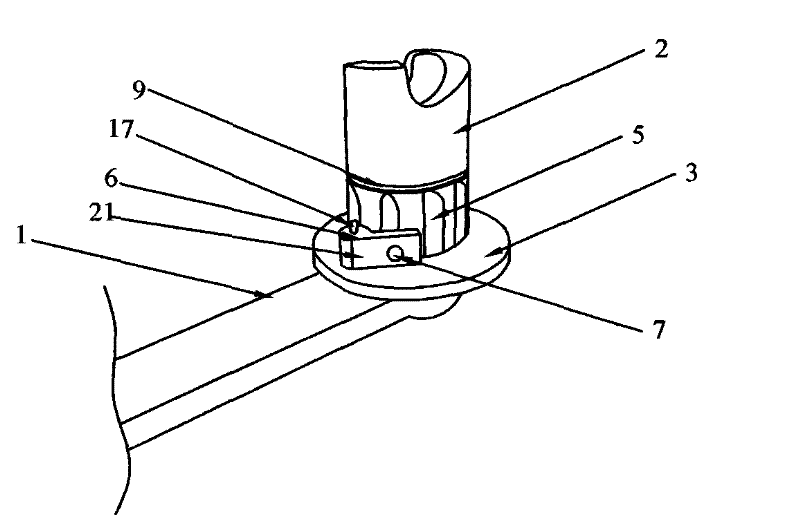

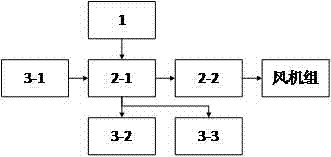

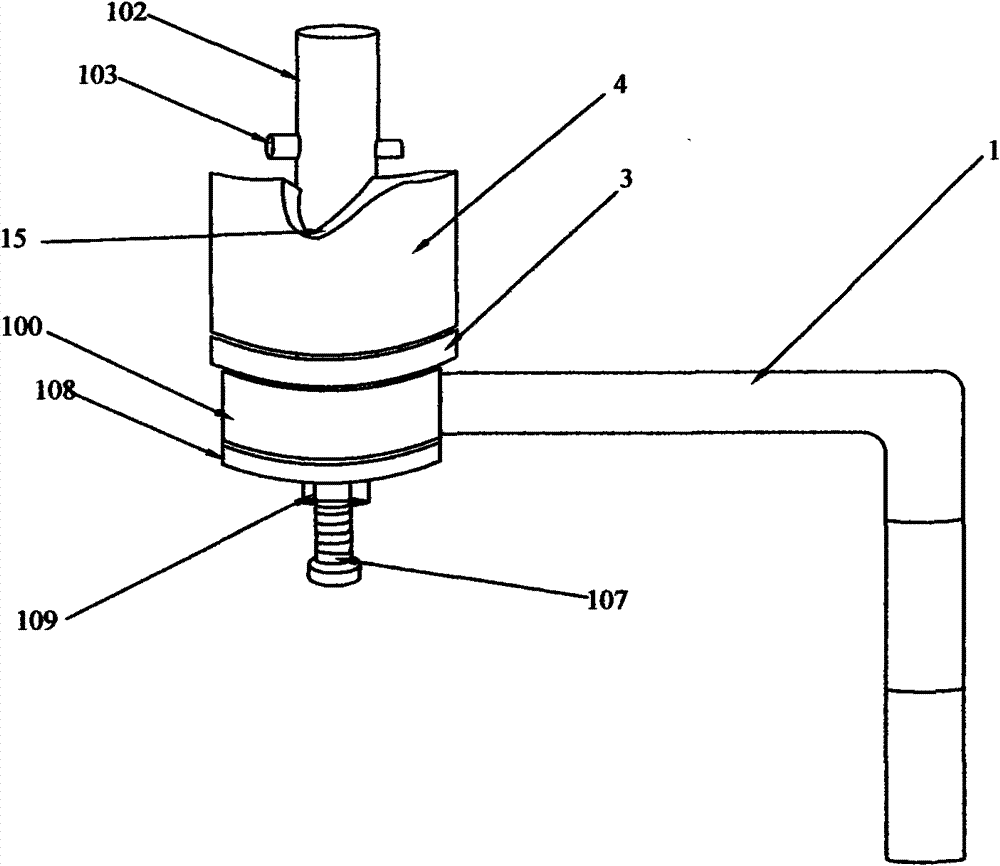

Fan head assembly and fan

ActiveCN107237772APromote homogenizationSolve the problem of no differentiated selling pointPump componentsEngine fuctionsDrive motorEngineering

The invention is suitable for the field of household appliances, and discloses a fan head assembly and a fan. The fan head assembly comprises a wind-out base, a wind-in base and a rotary oscillating mechanism, wherein the wind-in base is arranged on one side of the wind-out base, and the rotary oscillating mechanism is used for driving the wind-out base to conduct rotary oscillating motion relative to the wind-in base. The rotary oscillating mechanism comprises a rotary oscillating driving motor assembled on the wind-in base and a rotary oscillating transmission pair which is in transmission connection with the rotary oscillating driving motor and the wind-out base. According to the fan head assembly and the fan, the wind-out base can conduct the rotary oscillating motion relative to the wind-in base, and a conventional design thinking that a wind-out base and a wind-in base in an existing fan are relatively stationary is broken. Because the wind-out base conducts stereoscopic rotary oscillating motion relative to the wind-in base, products are very cool in the operating process, and the problems that an existing fan product is serious in homogenization and has no differentiated selling point are well solved; and meanwhile the wind-supplying area is effectively enlarged, rotary output of the wind direction is achieved, and the output wind is gentler and more natural.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG

Aldehyde-free liquid glue and artificial board processing method

ActiveCN105295740AGood for sales promotionHigh bonding strengthWood veneer joiningInorganic adhesivesHabitMechanical equipment

The invention relates to aldehyde-free liquid glue and an artificial board processing method. The liquid glue is prepared by mixing and blending an magnesium chloride aqueous solution and magnesium oxide powder, serving as inorganic materials, according to the ratio of 1: 1; the magnesium chloride aqueous solution is prepared from magnesium chloride powder or halogen pieces and water according to the ratio of 1: 1 to 1: 3, and the purity of the magnesium chloride powder or the halogen pieces is 45% to 99%. Therefore, the liquid glue does not contain formaldehyde, also has favorable gluing strength, is low in price and can also be directly applied to existing mechanical equipment to process artificial boards, without adding or transforming original mechanical equipment, and also without changing an operation mode of longtime habit. The liquid glue is easily accepted by artificial board manufacturers, high in market competitiveness and easily promoted and sold; in addition, when the liquid glue is used for manufacturing the artificial boards, the artificial boards can be directly subjected to hot pressing after coated with the aldehyde-free liquid glue, without undergoing cold pressing, so that the processing procedures are simplified, the production efficiency is high, and meanwhile, the hot pressing temperature is relatively low, the energy consumption is reduced and the production cost is lower.

Owner:佛山市乐居轻钢房屋有限公司

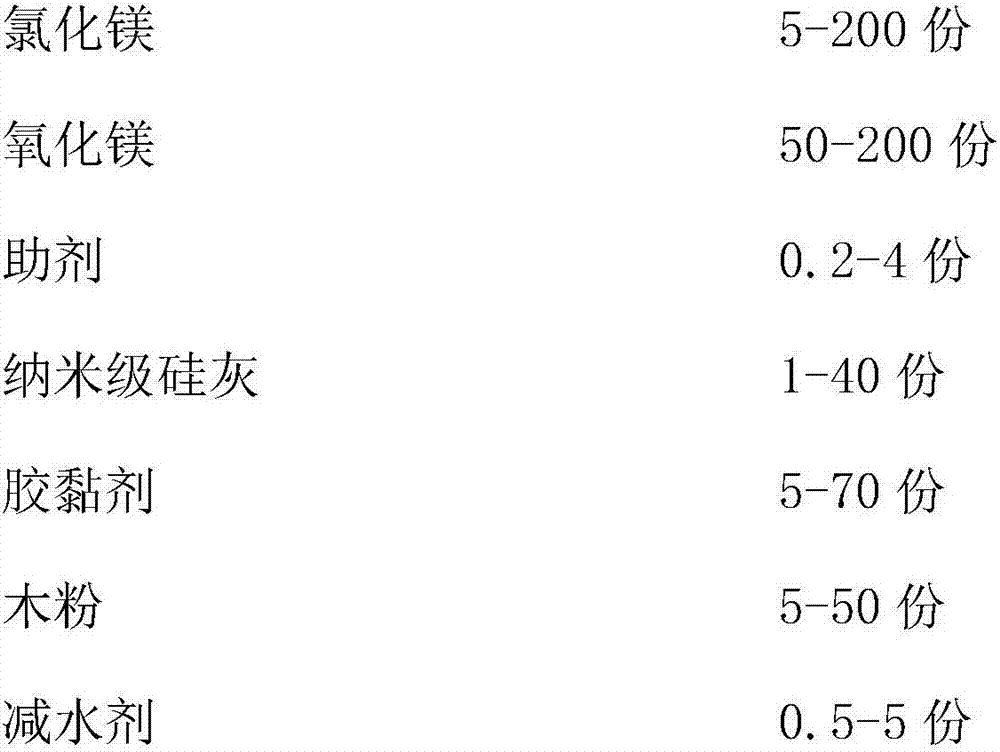

A kind of formaldehyde-free liquid adhesive and wood-based panel processing method

ActiveCN105295740BGood for sales promotionHigh bonding strengthWood veneer joiningInorganic adhesivesHalogenAdhesive

The invention relates to a aldehyde-free liquid adhesive and a wood-based panel processing method. The liquid adhesive is prepared by mixing magnesium chloride aqueous solution and magnesium oxide powder of inorganic materials in a ratio of 1:1; the magnesium chloride aqueous solution is made of magnesium chloride powder or halogenated Tablets and water are prepared according to the ratio of 1:1 to 1:3, and the purity of magnesium chloride powder or halogen flakes is 45% to 99%. In this way, the liquid adhesive does not contain formaldehyde, but also has good bonding strength, and the price is extremely low. It can also be directly applied to existing mechanical equipment to process wood-based panels, without adding or modifying old mechanical equipment, and without changing long-term habitual operations. The model is easy to be accepted by wood-based panel manufacturers, has strong market competitiveness, and is easy to promote and sell; and when used in the manufacture of wood-based panels, it can be directly hot-pressed after coating the formaldehyde-free liquid adhesive, without cold pressing, and the processing process is simplified. , higher production efficiency, lower hot pressing temperature, less energy consumption and lower production cost.

Owner:佛山市乐居轻钢房屋有限公司

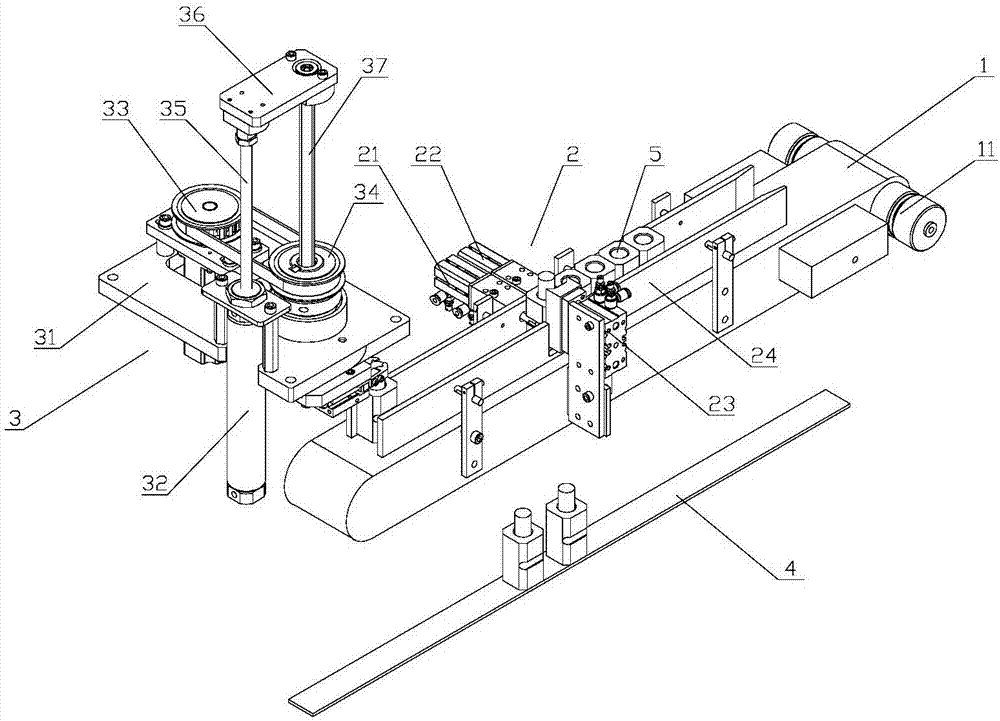

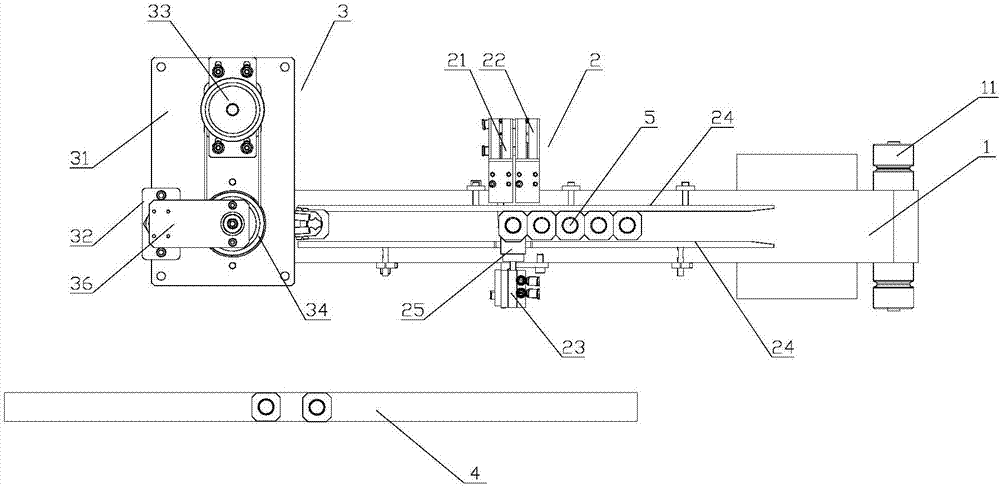

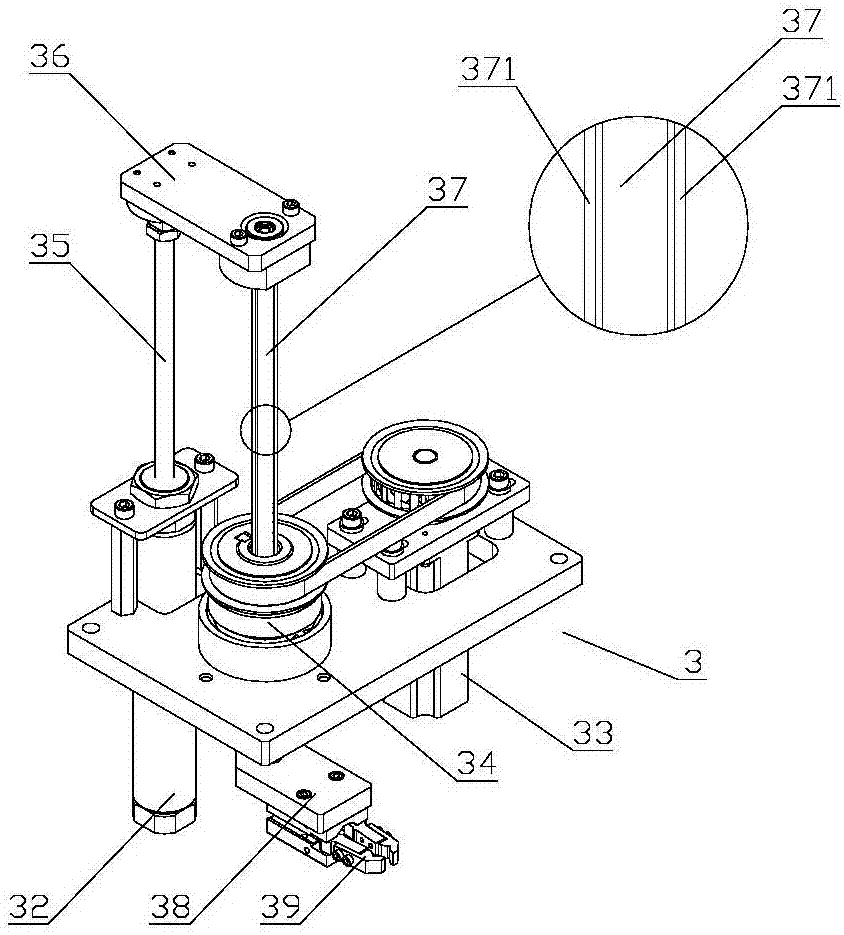

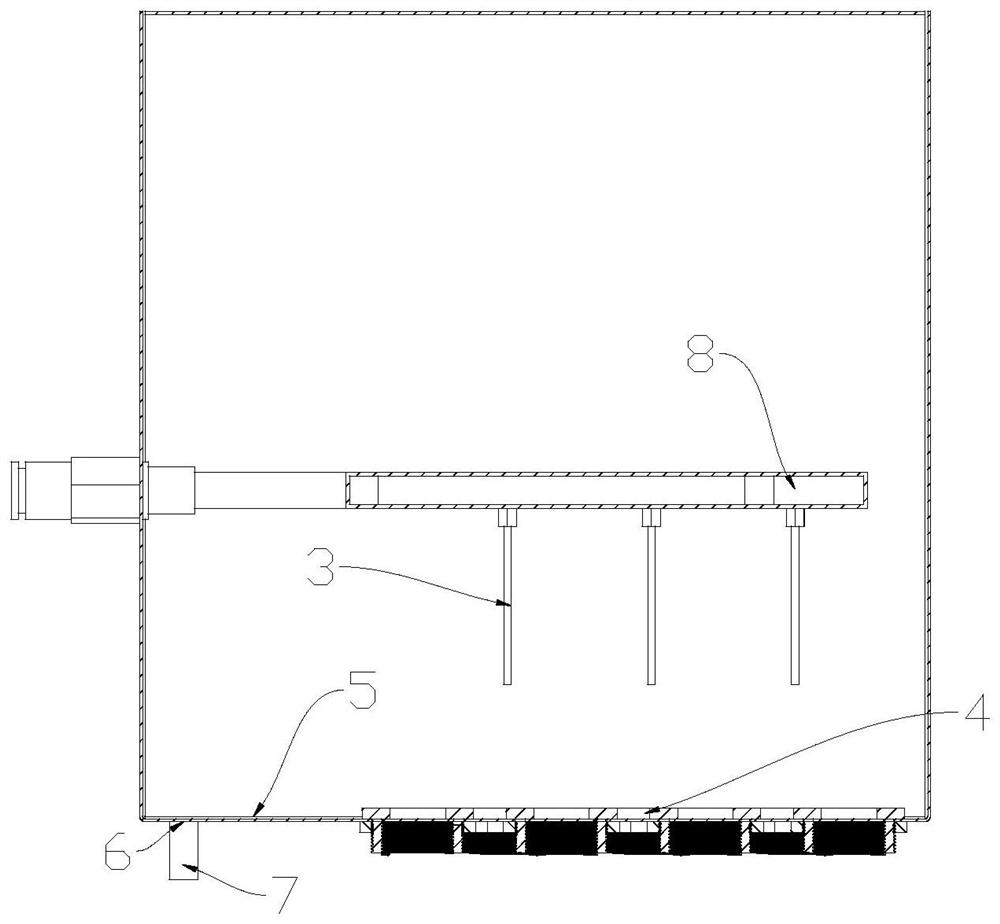

Workpiece assembling and distributing device

The invention is a workpiece assembly and distribution device, which includes a conveying line and a motor-driven conveyor belt, and also includes a positioning assembly device, a transfer distribution device and a control cabinet. The positioning assembly device is fixedly connected to the conveyor belt, and the transfer distribution device is arranged on the conveyor belt. Above; the positioning assembly device includes a limit splint, a first cylinder, a second cylinder and a positioning cylinder, and the transfer and distribution device includes a fixed support plate, a telescopic cylinder, a drive motor, a driven wheel and a gripper assembly; the gripper assembly includes a rotating rod and The claw part includes a claw fixing block and a pair of clamping parts; the rotating rod can move longitudinally relative to the driven wheel and can rotate together with the driven wheel; the first cylinder, the second cylinder, the positioning cylinder, the driving motor, the telescopic Both the cylinder and the gripper are electrically connected to the control cabinet. The invention combines traditional multi-processes into one process, which not only saves operation steps but also saves space.

Owner:广州市康超信息科技有限公司

Seasoning for scallion oil maize flour instant noodles

The invention relates to onion oil corn meal instant noodle seasoning which belongs to food seasoning; a sauce seasoning bag consists of main component of lard and auxiliary components of chicken gravy, green Chinese onion, chili powder, five-spice powder, ginger, garlic, onion, salt, superior soy sauce, monosodium glutamate and balm which are mixed together by different weight; a seafood seasoning bag consists of dried purple seaweed and dried small shrimps which are mixed together by the weight; the seasoning solves the problem that the traditional sauce with butter as the main component cannot adapt to and meet the demand for being used together with corn meal instant noodles, and the corn meal instant noodles with the seasoning are characterized by good taste for eating, fresh flavor, rich nutrition, promotion of the health of human body and wide scope of applicable groups.

Owner:曲静敏

Humulus scandens containing feed additive for black bone chickens

InactiveCN106538875AWide variety of sourcesExtended shelf lifeAnimal feeding stuffAccessory food factorsBiotechnologyGastrointestinal absorption

The present invention mainly relates to the technical field of breeding and discloses a humulus scandens containing feed additive for black bone chickens. The feed additive is prepared from the following raw materials: humulus scandens, eichhornia crassipes, typha orientalis, arundo donax leaves, elodea nuttallii, white granulated sugar, lactic acid bacteria, compound enzymes, an eupatorium coelestinum extract and a conyza canadensis extract. The humulus scandens is rich in sources, the wastes are turned into treasures, and new utilization ways of the humulus scandens are utilized. The feed additive is rich in raw materials and low in prices, contains a variety of health-care ingredients, is fermented by the lactic acid bacteria, can remove the raw and astringent taste, is sour and sweet in mouthfeel, the use of lactic acid bacteria, increases palatability, increases feed intake, promotes gastrointestinal absorption functions, prevents bacteria and inflammation, enhances immunity, keeps fresh and green color and luster, promotes the formation of melanin in the black bone chickens, enhances the health-care functions of chicken meat, enable the mouthfeel of the chicken meat to be fresh and tender, increases an egg production amount by 15.1%, improves an economic income by 13.9%, is simple in use method and less in addition amount, saves a lot of breeding costs, and is easy to promote sales.

Owner:牛保仁

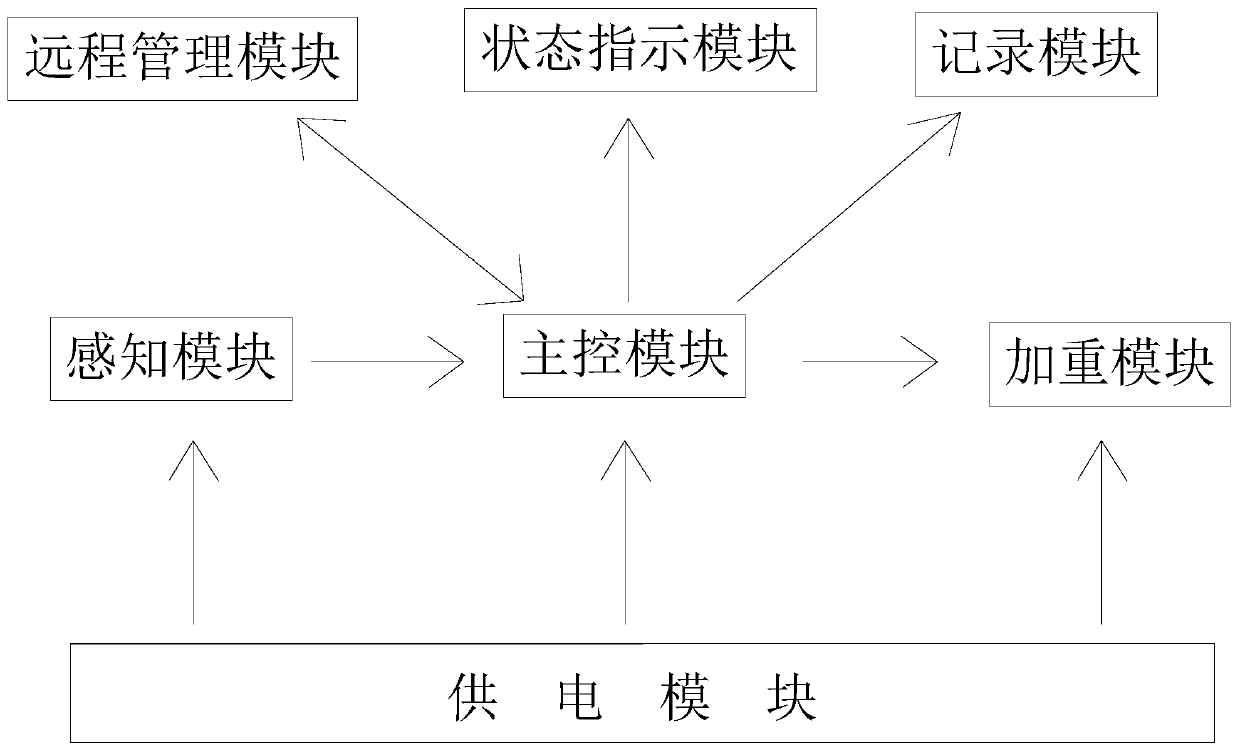

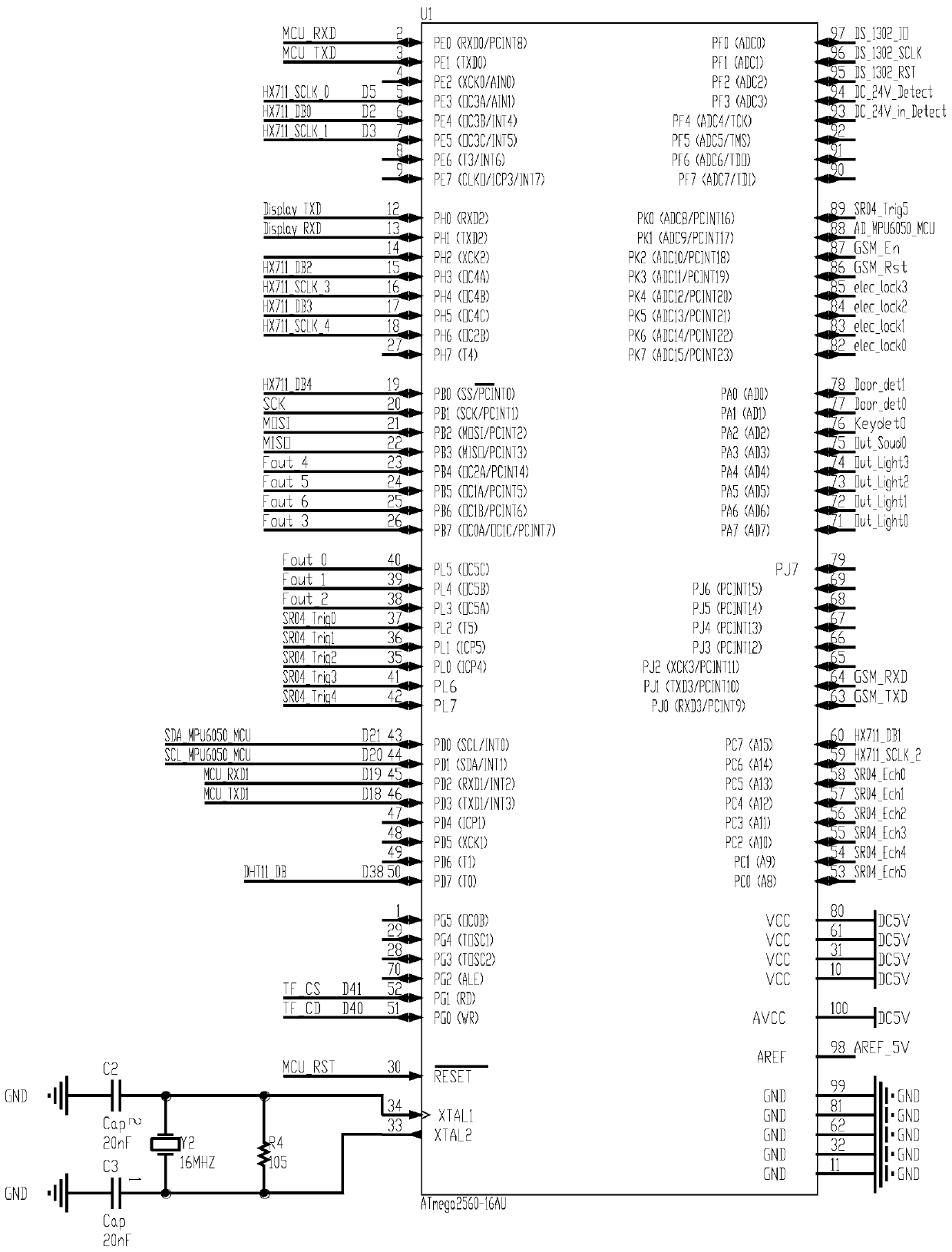

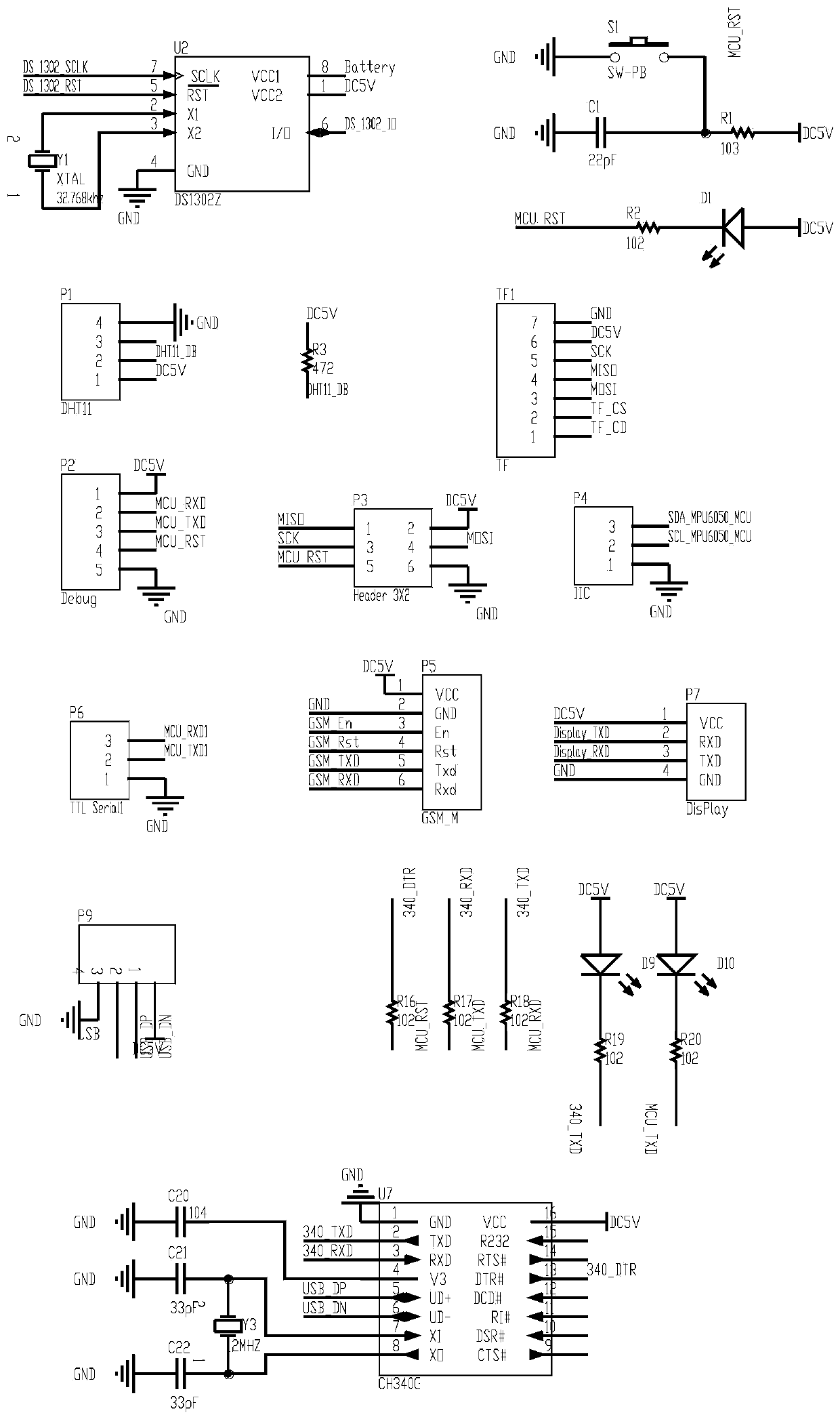

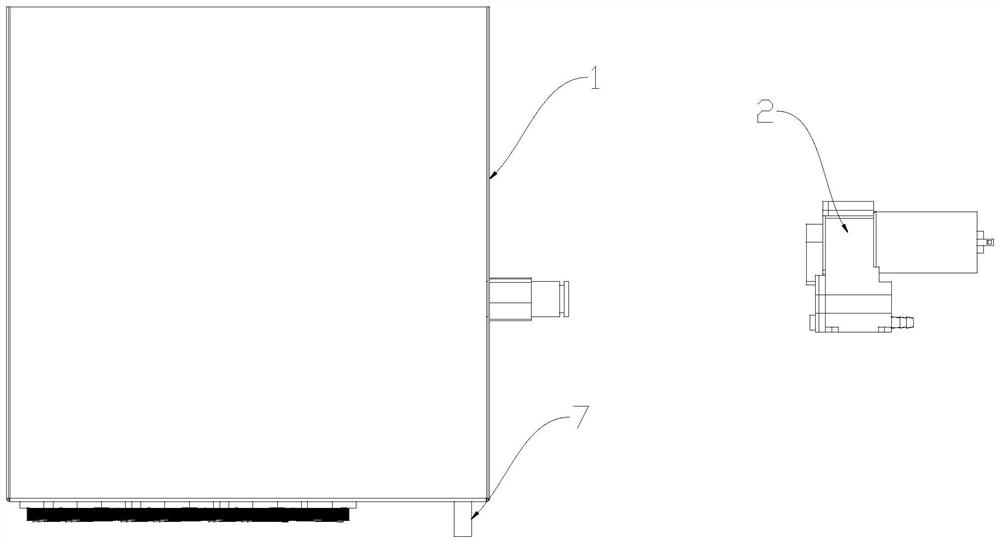

Novel safe box control system

The invention relates to the technical field of safe box control, in particular to a novel safe box control system. The novel safe box control system is characterized in that the novel safe box control system comprises a safe box, a sensing module, a main control module, a weight increasing module and a power supply module; the sensing module comprises a distance detection assembly used for detecting whether the relative position of the safe box changes or not and an infrared detection assembly used for detecting whether a suspicious object is close to the periphery of the safe box or not; andthe weight increasing module comprises a driving unit connected with the main control module and more than one electromagnet assembly which is installed on the safe box and connected with the drivingunit. According to the novel safe box control system, the external environment state of the safe box can be detected, the system can actively respond to crises, free adjustment of the safe box weightcan be achieved without changing the own weight of the safe box, therefore, a thief can not carry the safe box, a user can conveniently move and carry the safe box, and the arranging place of the safe box is easy to replace.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

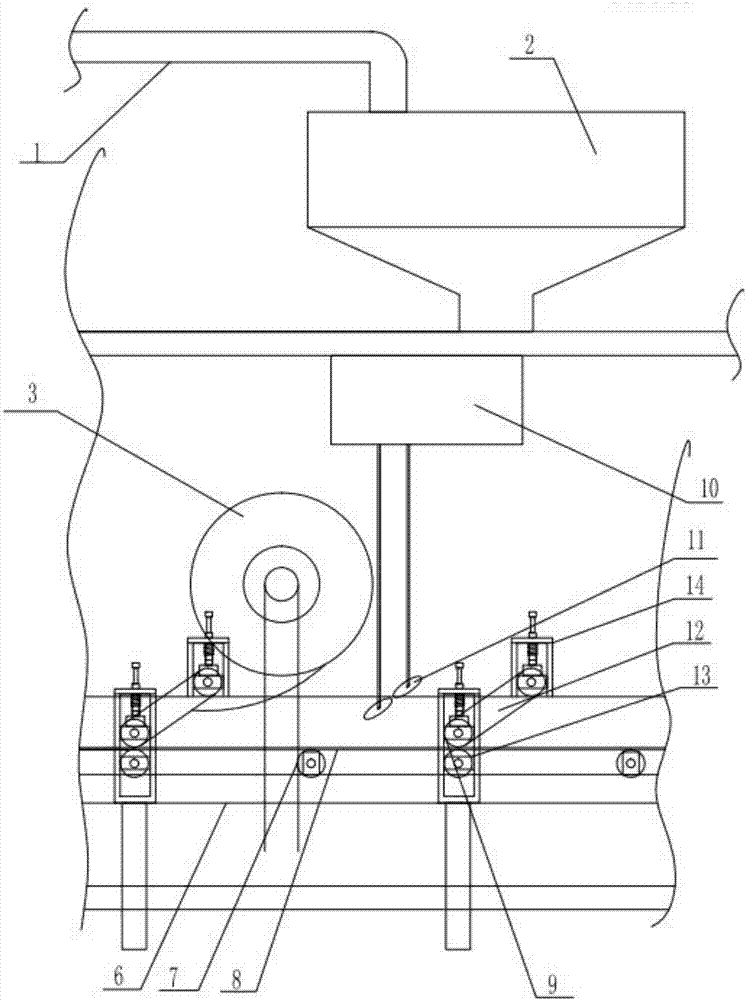

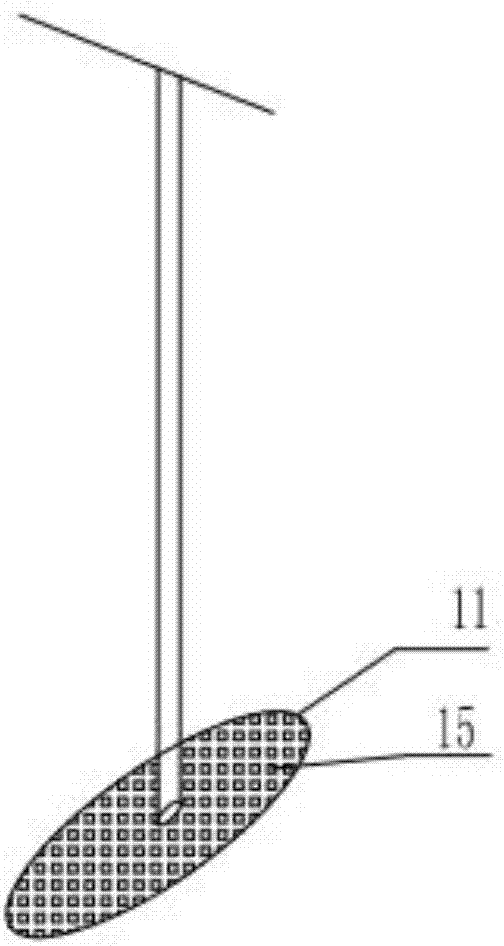

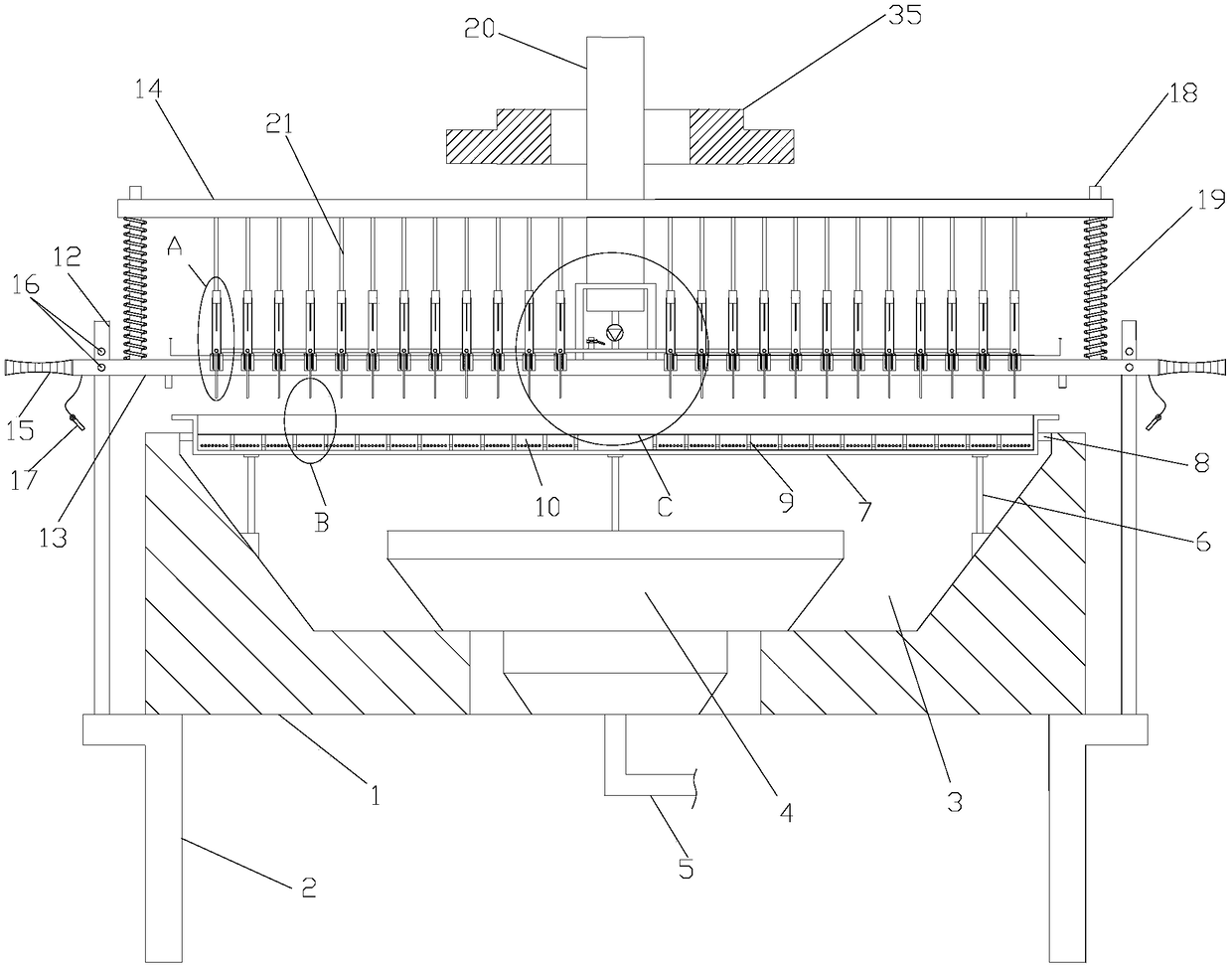

Board production process and modification of inorganic glue

InactiveCN107498649AGood for sales promotionIncrease productivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEngineeringUltimate tensile strength

The invention provides a board production process and modification of inorganic glue. A spreading machine spreads a face material to a spreading machine conveying belt; the inorganic glue is conveyed to a coating machine through a pipeline at the lower end of a glue hopper; the coating machine conveys the inorganic glue to a glue spraying device; the glue spraying device is provided with a plurality of spraying holes; the inorganic glue is coated to a single board at the upper end of the conveying belt through the spraying holes; an unreeling machine paves the reeled single board; a thickness-fixed roller rolls on the single board; the glue spraying device, the unreeling machine and the thickness-fixed roller apply glue, unreel and roll synchronously, and the above pavement sequence is the basic odd number pavement; and after the face board is paved, the thickness-fixed roller rolls evenly to fix the thickness, then short cutting and prepressing are conducted according to the board length, the prepressing is cold pressing and is 0.1-1 MPa, the cold pressing time is 3-24 hours, and thus molding is achieved. The prepared product does not contain formaldehyde and has the inorganic glue with good bonding strength, the problems that in the production of plywood, the process is complex, energy consumption is high, pollution is high, and formaldehyde in finished products is released are solved, the procedure is simplified, the production efficiency is high, and energy consumption is reduced.

Owner:白光瑞

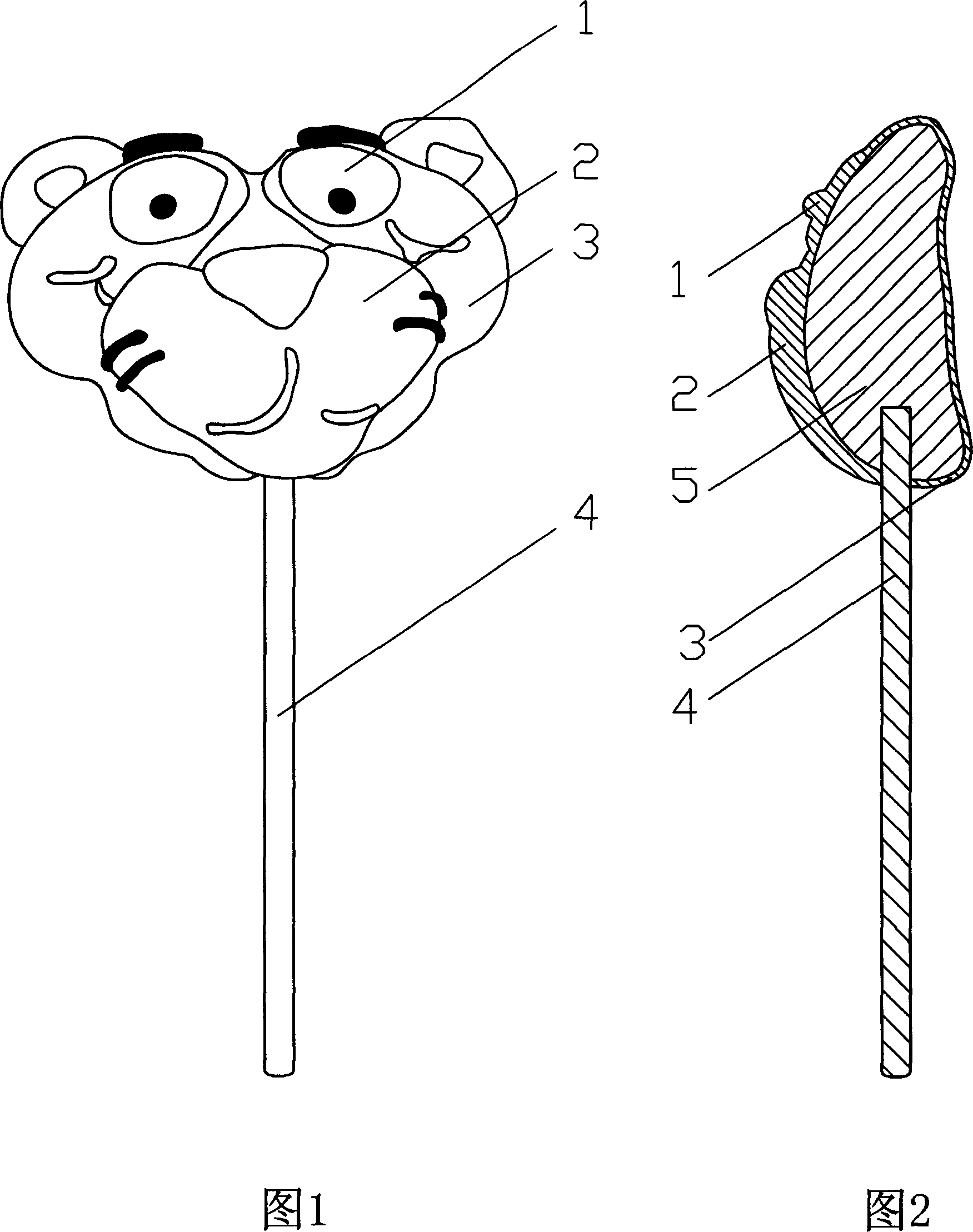

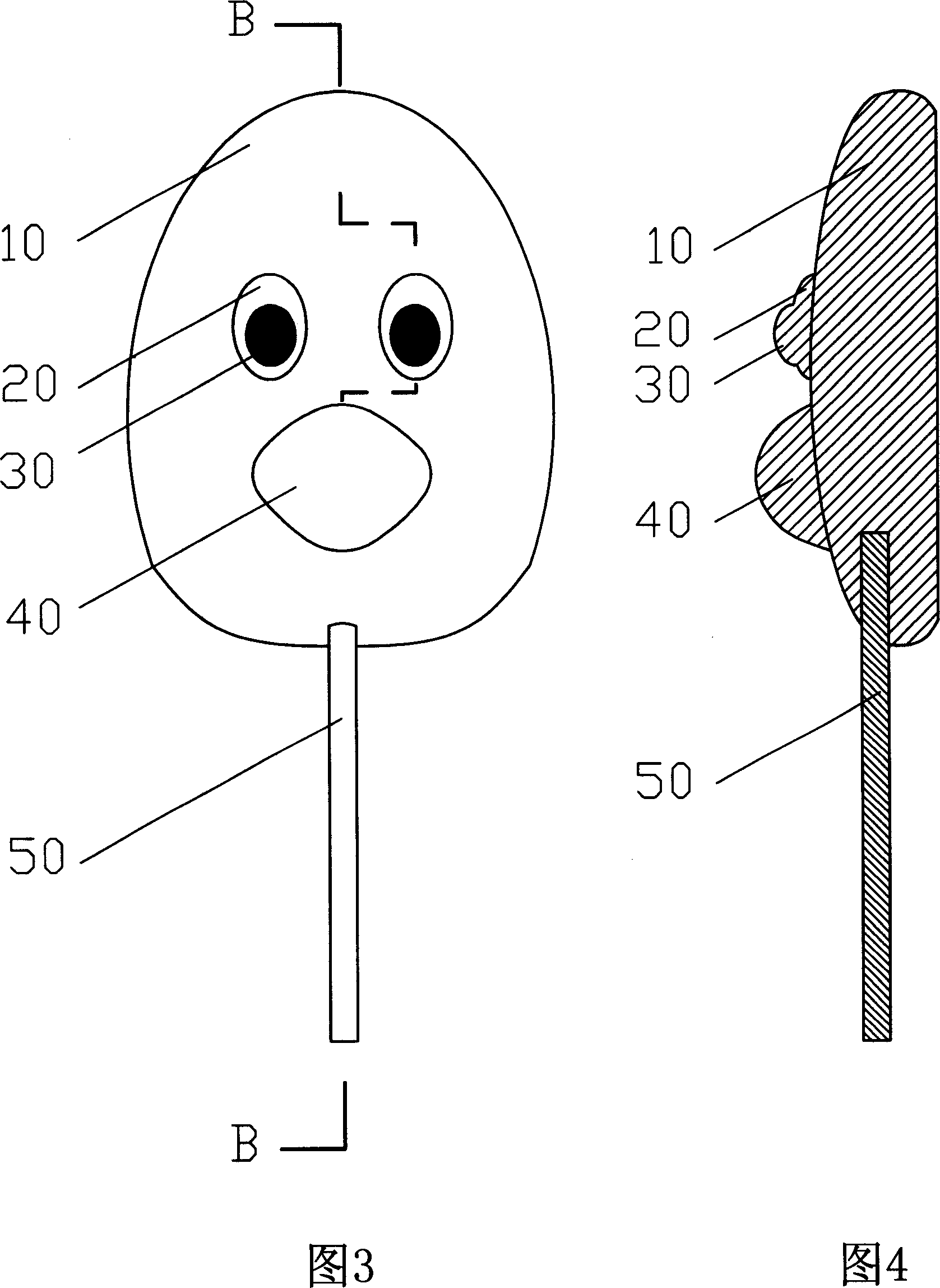

Preparing technique of stereoscopic pattern of stick candy

InactiveCN101015317AAvoid fragileLower authenticity rateConfectionerySweetmeatsEngineeringPointing device

The invention relates to candy processing field, which in detail relates to a process of preparing the stereogram for bar- type candy: feeding paste syrup with specific temperature and color into flower pointing device, and pointing needed stereogram on shaped bar- type candy. The invention is characterized in that it can prepares stereogram of various shape and color, overcomes problems of hard candy shell, easy to break and low standard-piece rate. It is also characterized by simple process, low cost and convenient for spread.

Owner:汤镜海

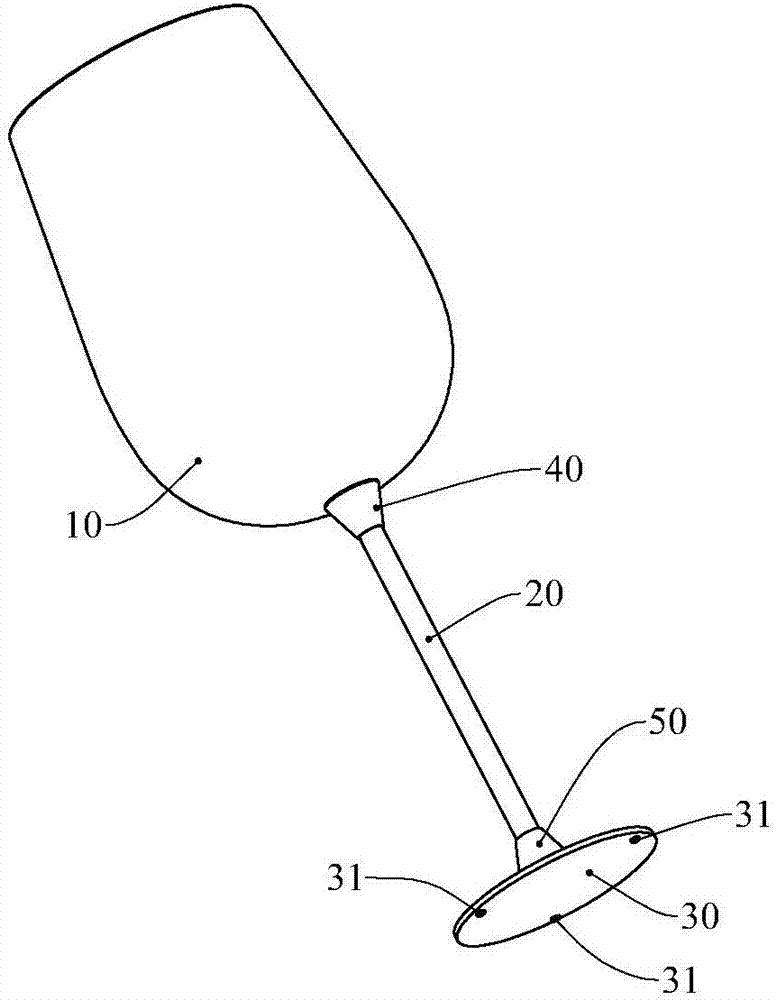

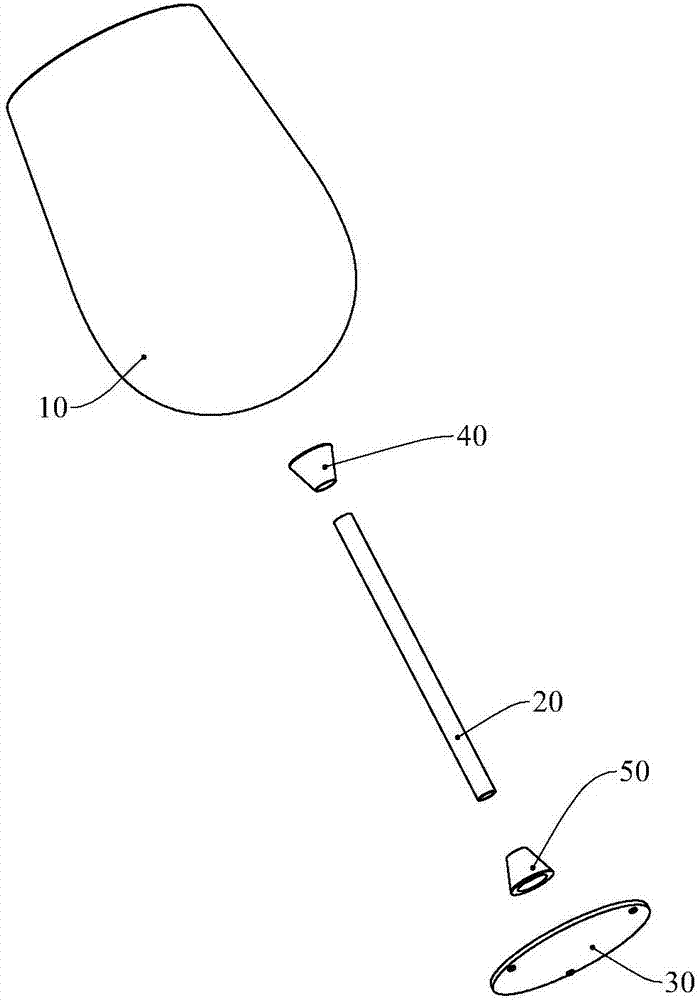

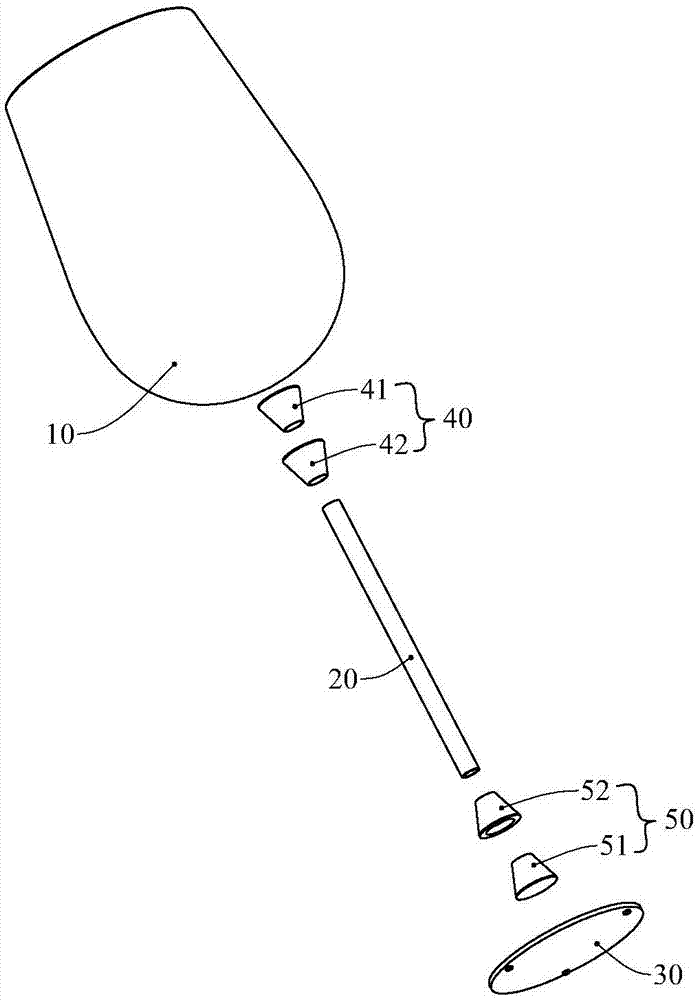

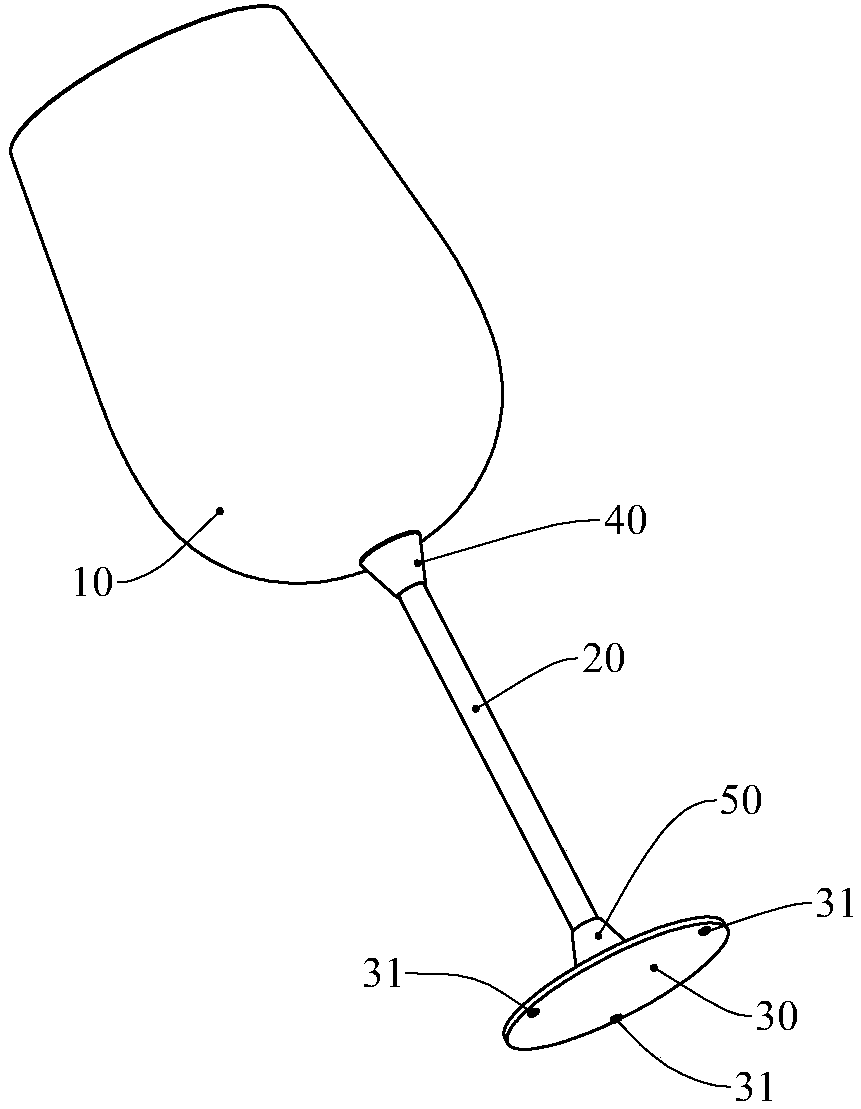

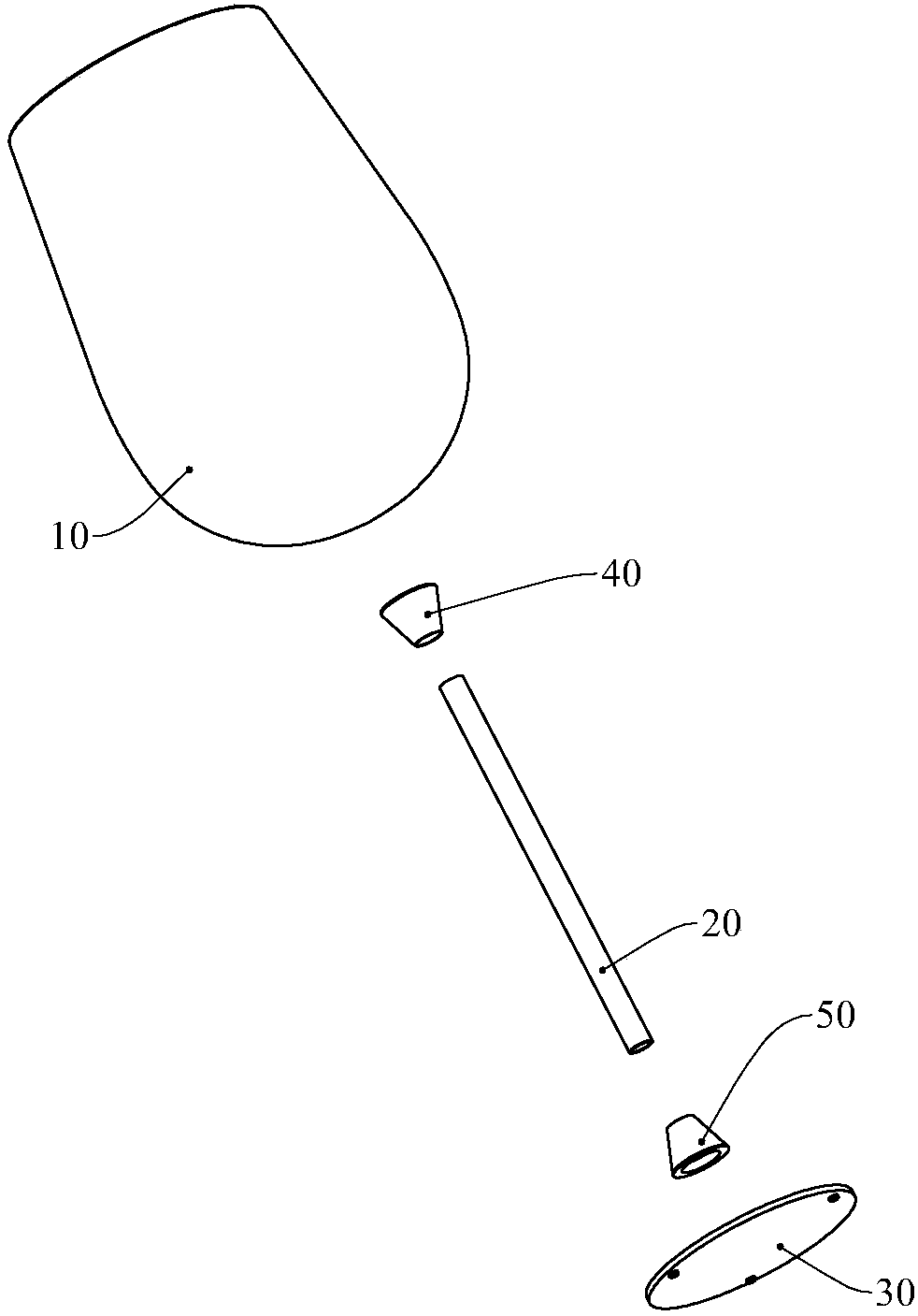

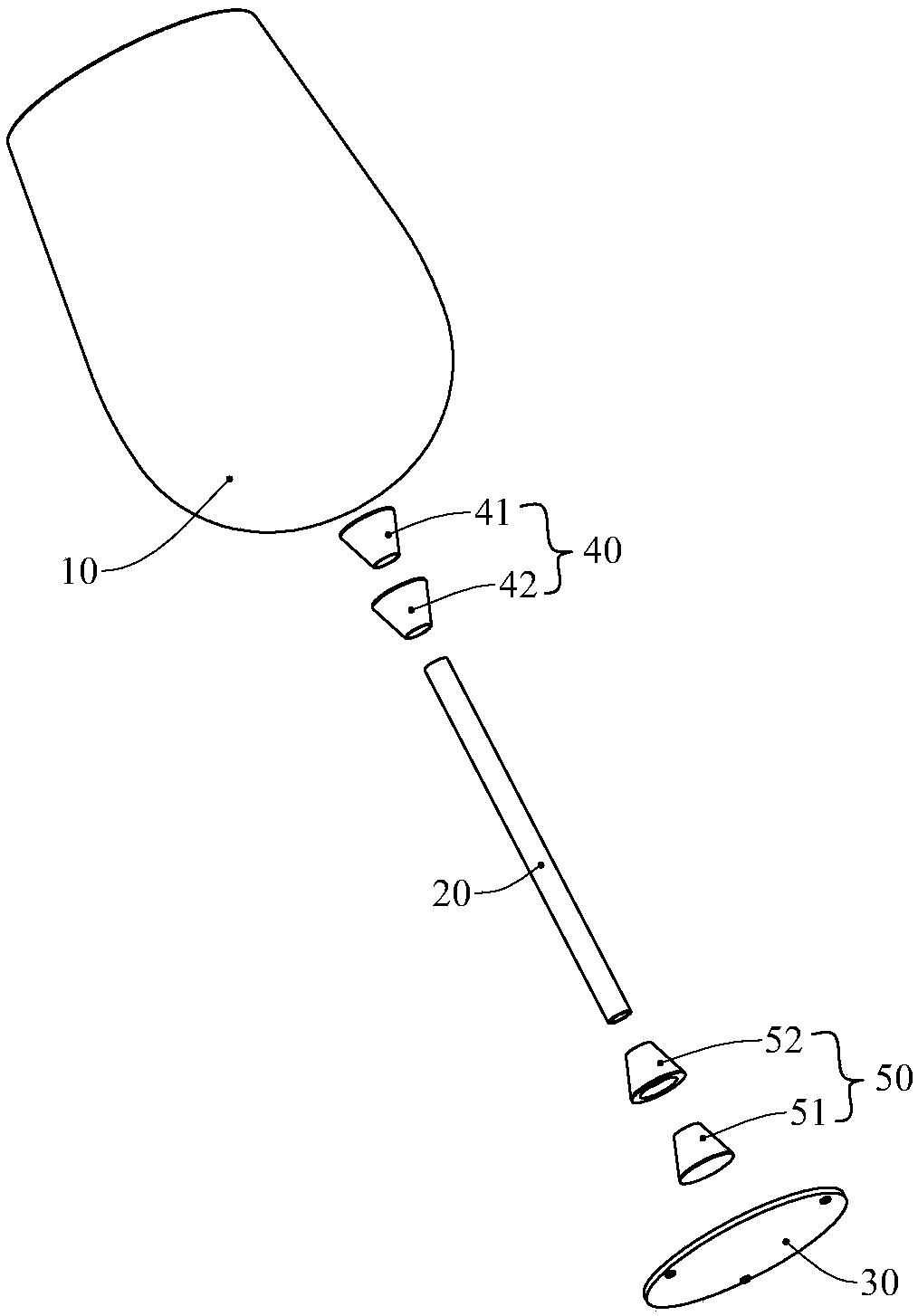

Goblet and assembling fixture and manufacturing method thereof

The invention relates to a goblet and an assembling fixture and manufacturing method thereof. The goblet comprises a transparent goblet body, a disk-shaped base and a transparent vertical hollow supporting tube. The supporting tube is filled with gem / broken cash. The top of the supporting tube is fixedly connected with the middle of the bottom of the goblet body through an upper cone. The outer surface of the upper cone is fixedly sleeved with a precious metal outer cover with a pattern. The bottom of the supporting tube is fixedly connected with the middle of the top face of the base through a lower cone. The outer surface of the lower cone is fixedly sleeved with a precious metal outer cover with a pattern. The goblet is composed of three parts, the supporting tube in the middle is hollow and filled with gem / broken cash and can refract more colorful light, the upper cone and the lower cone at the two ends of the supporting tube are provided with the precious metal outer covers, the value of the goblet is improved, the grade is improved, the decoration sense is enhanced, the individual needs of users are met, and meanwhile the appearance is greatly improved compared with common goblets and the differentiation of the product facilitates the promotion of sales.

Owner:SHENZHEN JINBAOYING CULTURE

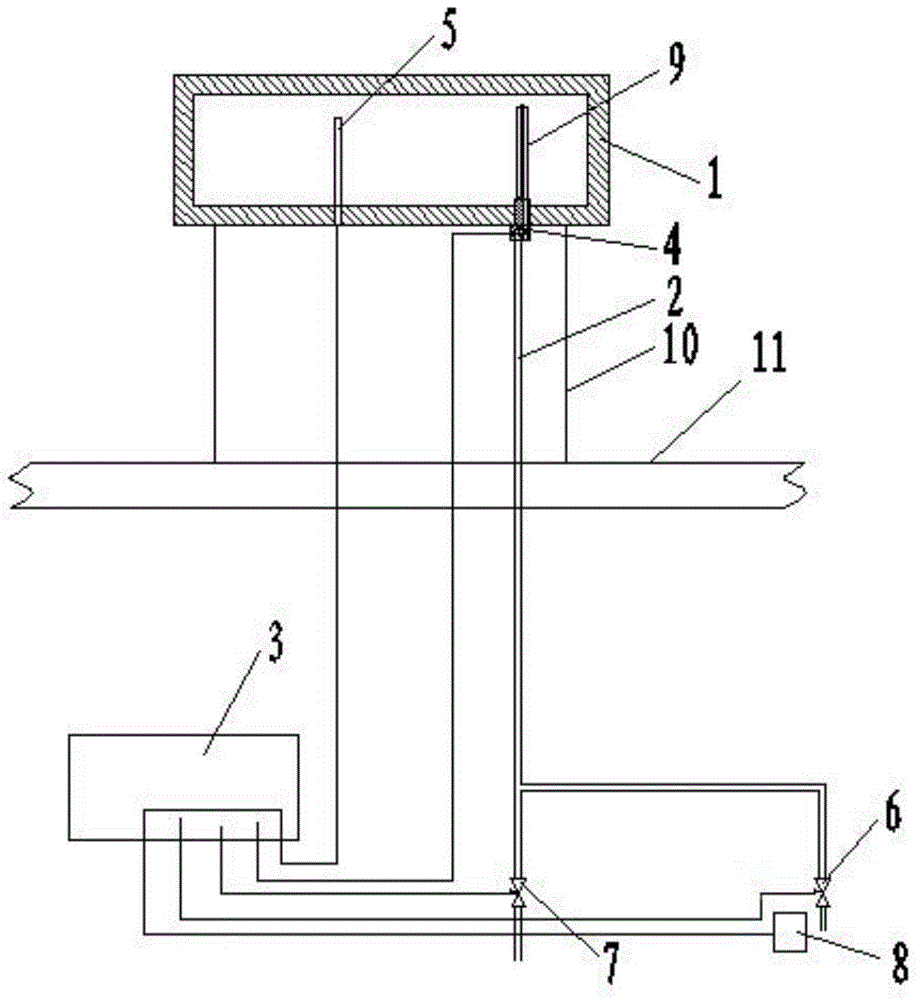

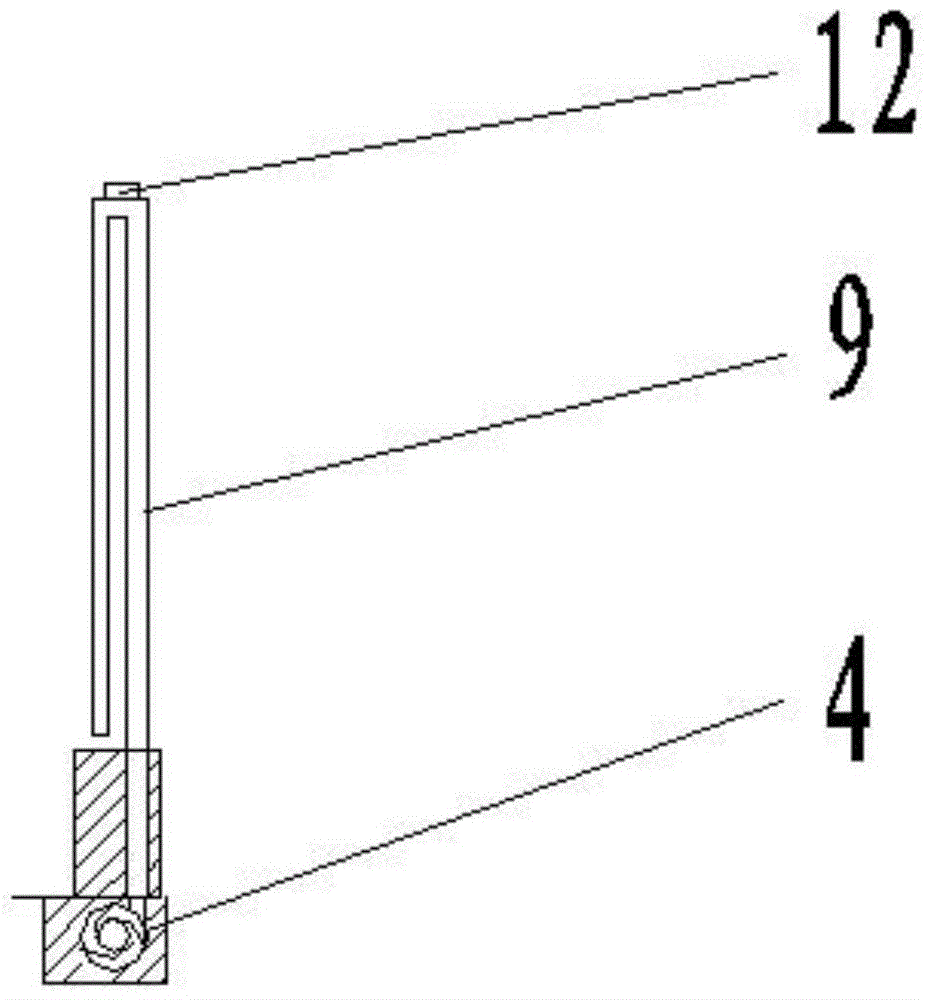

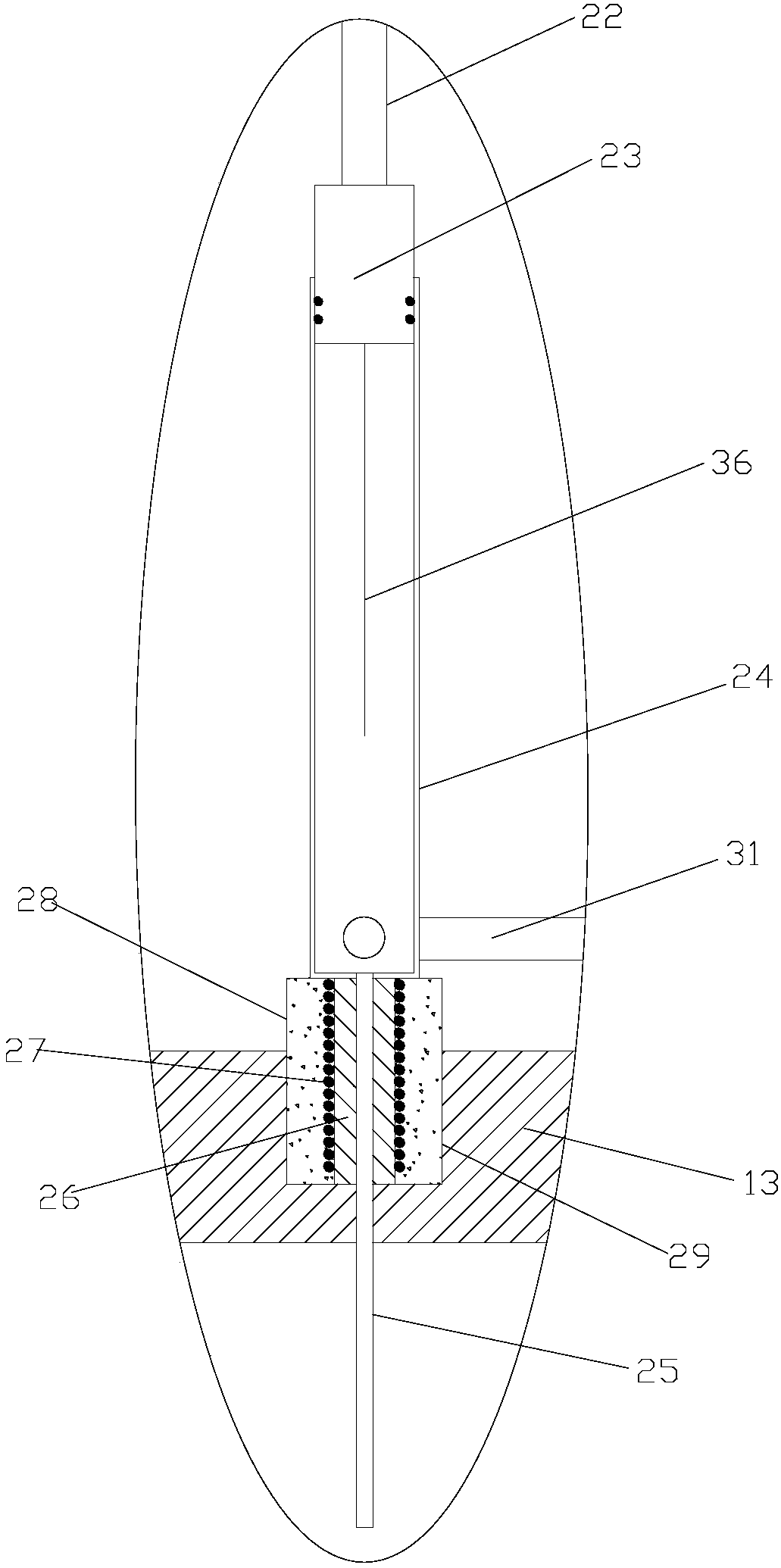

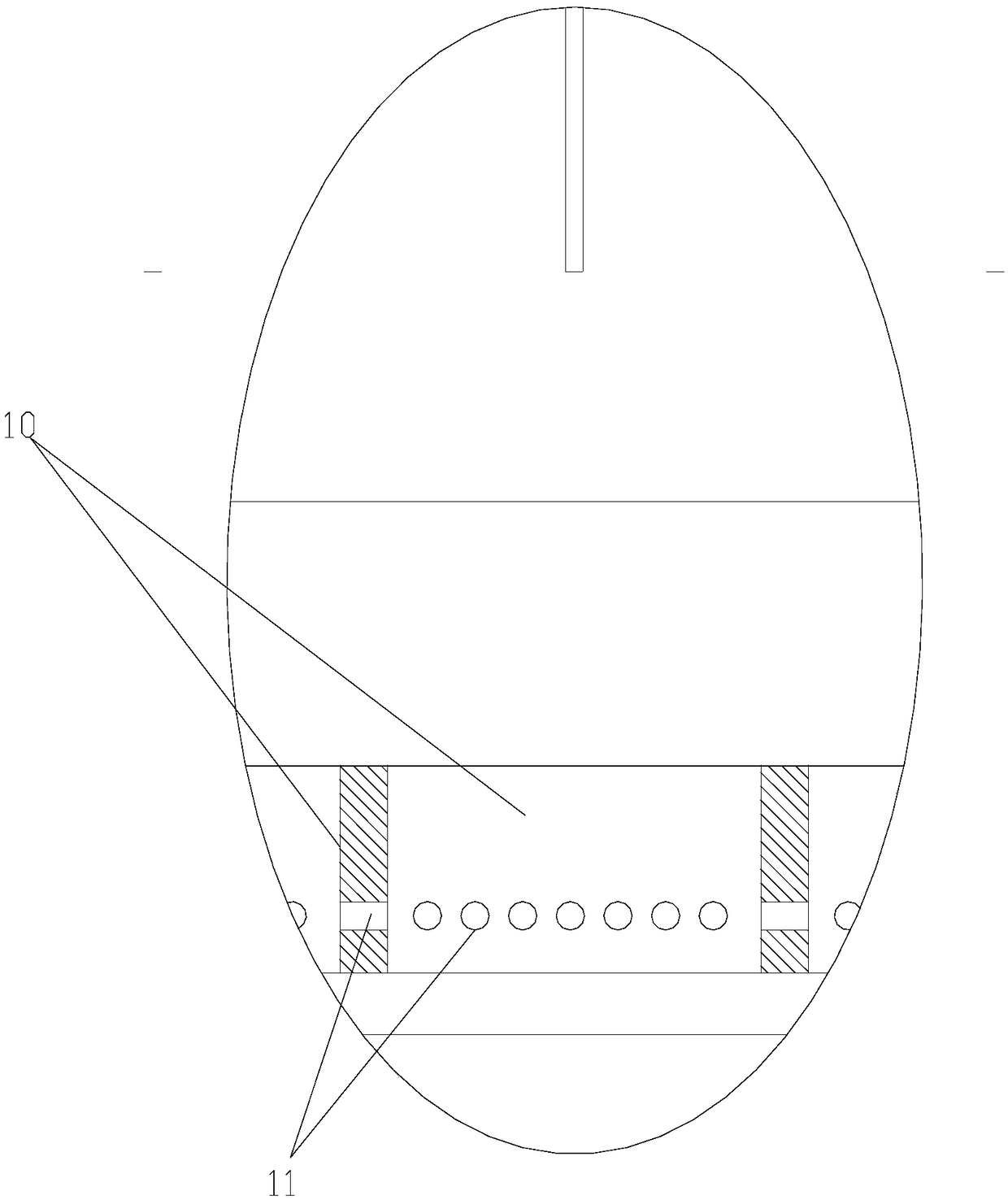

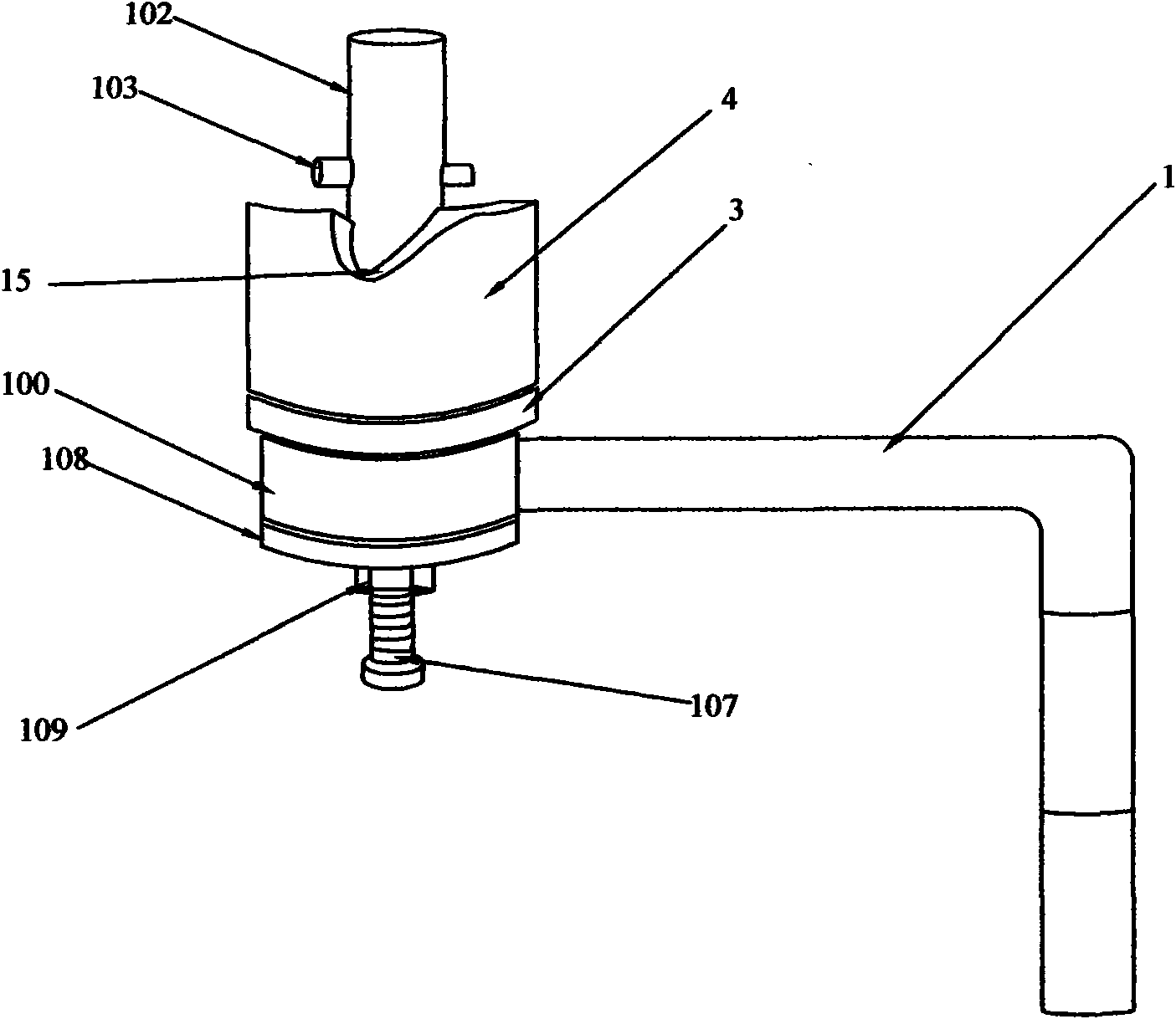

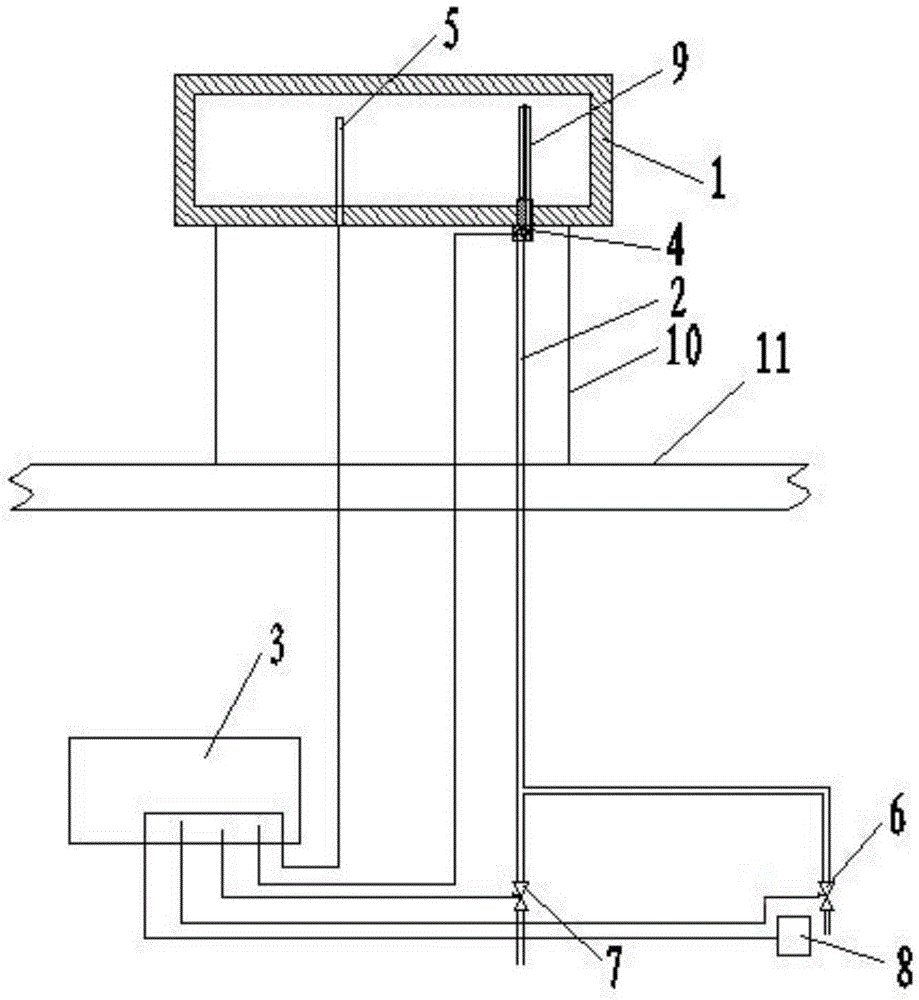

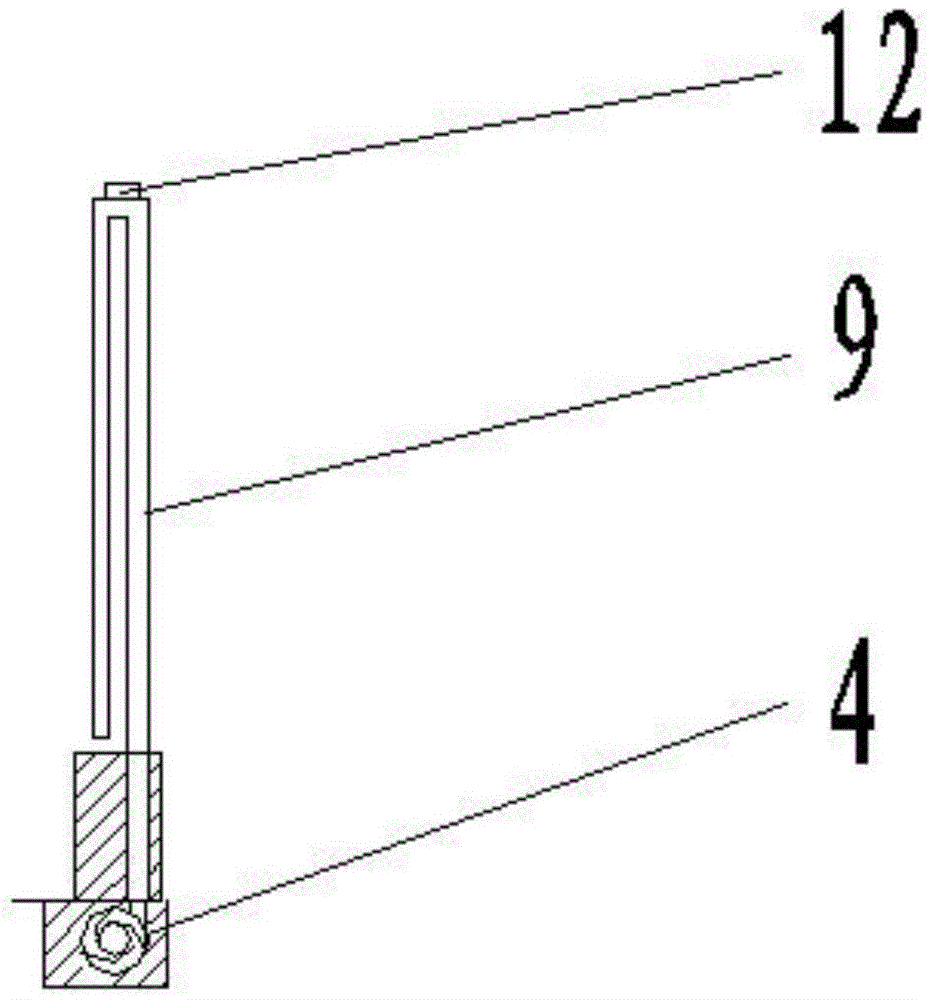

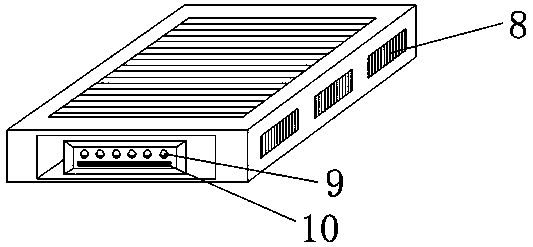

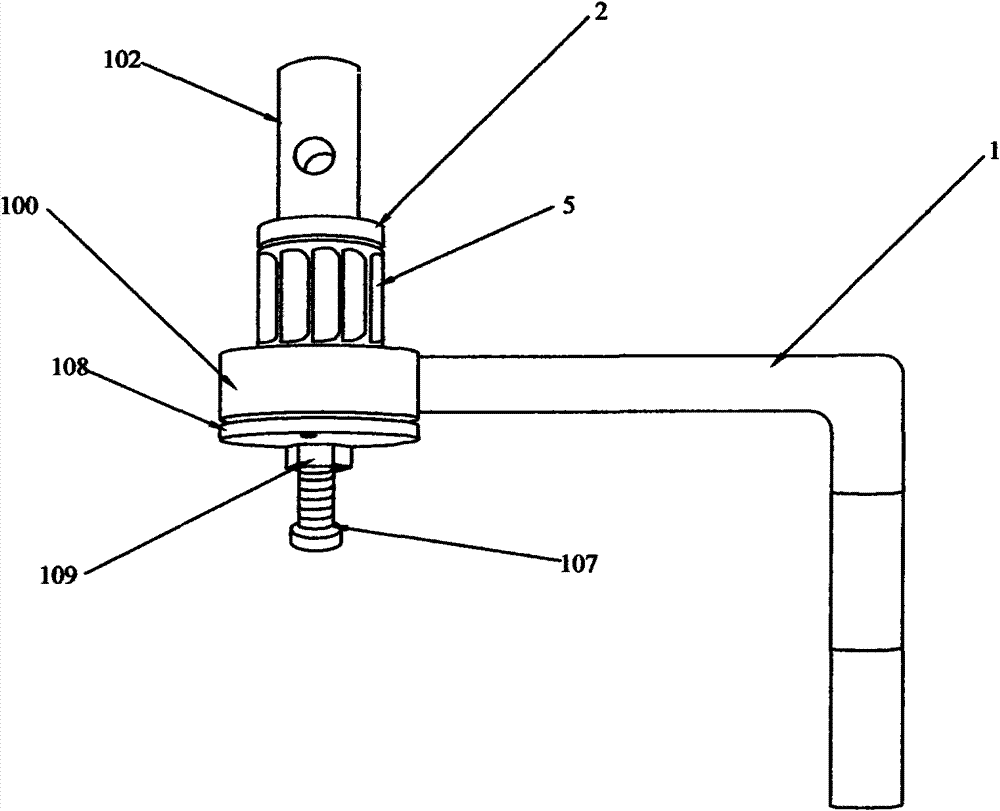

Automatic water feed evacuating and pressurizing device and using method thereof

InactiveCN104567042AAvoid cracking damageSimple structureSolar heat devicesSolar thermal energy generationSolar waterLevel sensor

Disclosed are an automatic water feed evacuating and pressurizing device and a using method thereof. The automatic water feed evacuating and pressurizing device comprises a water tank and a water pipe, and the upper surface of the water tank is provided with vent holes. The automatic water feed evacuating and pressurizing device is characterized in that an underneath type water temperature and level sensor is arranged in the water tank, a pressurizing pump is arranged at the joint of the bottom of the water tank and the water pipe, the U-shaped water pipe in the water tank is a siphoning pipeline, a normally-closed electromagnetic valve is arranged at an upper water port of the water pipe, a normally-opened electromagnetic valve is arranged at a lower water port of the water pipe, and the water temperature and level sensor, the normally-opened electromagnetic valve, the normally-closed electromagnetic valve and an evacuation control switch are connected with a control instrument respectively. The using method of the automatic water feed evacuating and pressurizing device includes steps of feeding water, evacuating fed water, discharging, evacuating the discharged water, and replenishing water. Automatic water feeding and discharging and automatic evacuating and water discharge pressurizing of a solar water heater can be controlled, evacuation and water supply are realized under the joint action of the siphoning pipeline and the pressurizing pump in the water tank, damage and cracking of pipelines in winter are avoided, and the automatic water feed evacuating and pressuring device is simple in structure, convenient to use and applicable to promotion and sales.

Owner:春风新能源科技有限公司

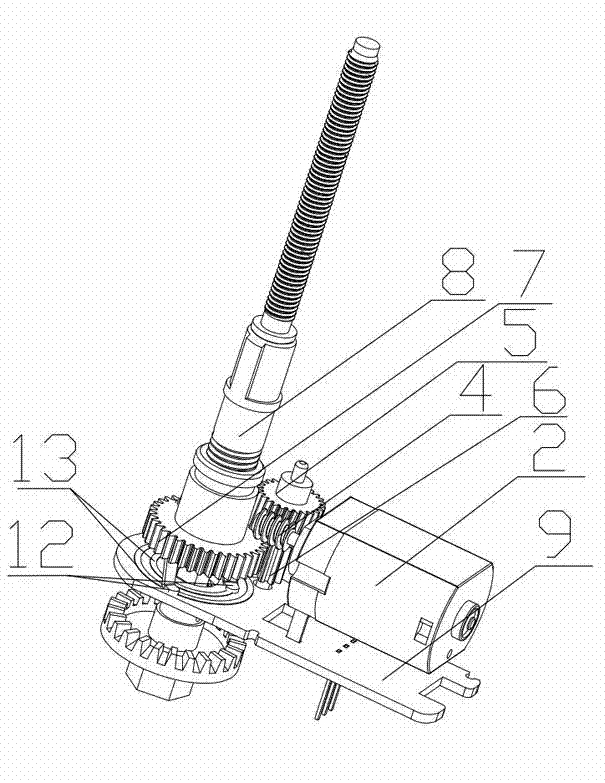

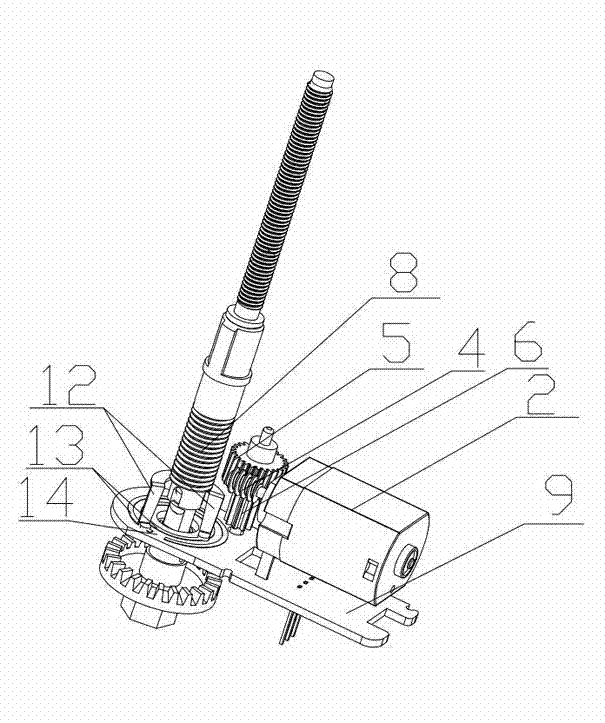

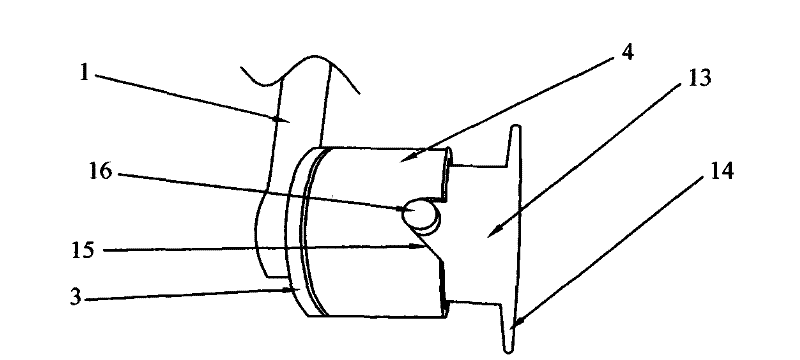

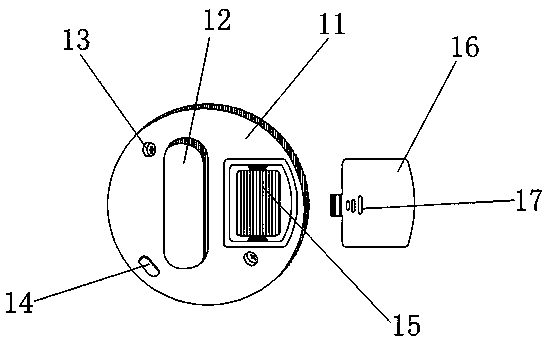

Automobile dimming device

ActiveCN102923045ATo achieve the purpose of dimmingReduce manufacturing costOptical signallingSteering controlConductive materials

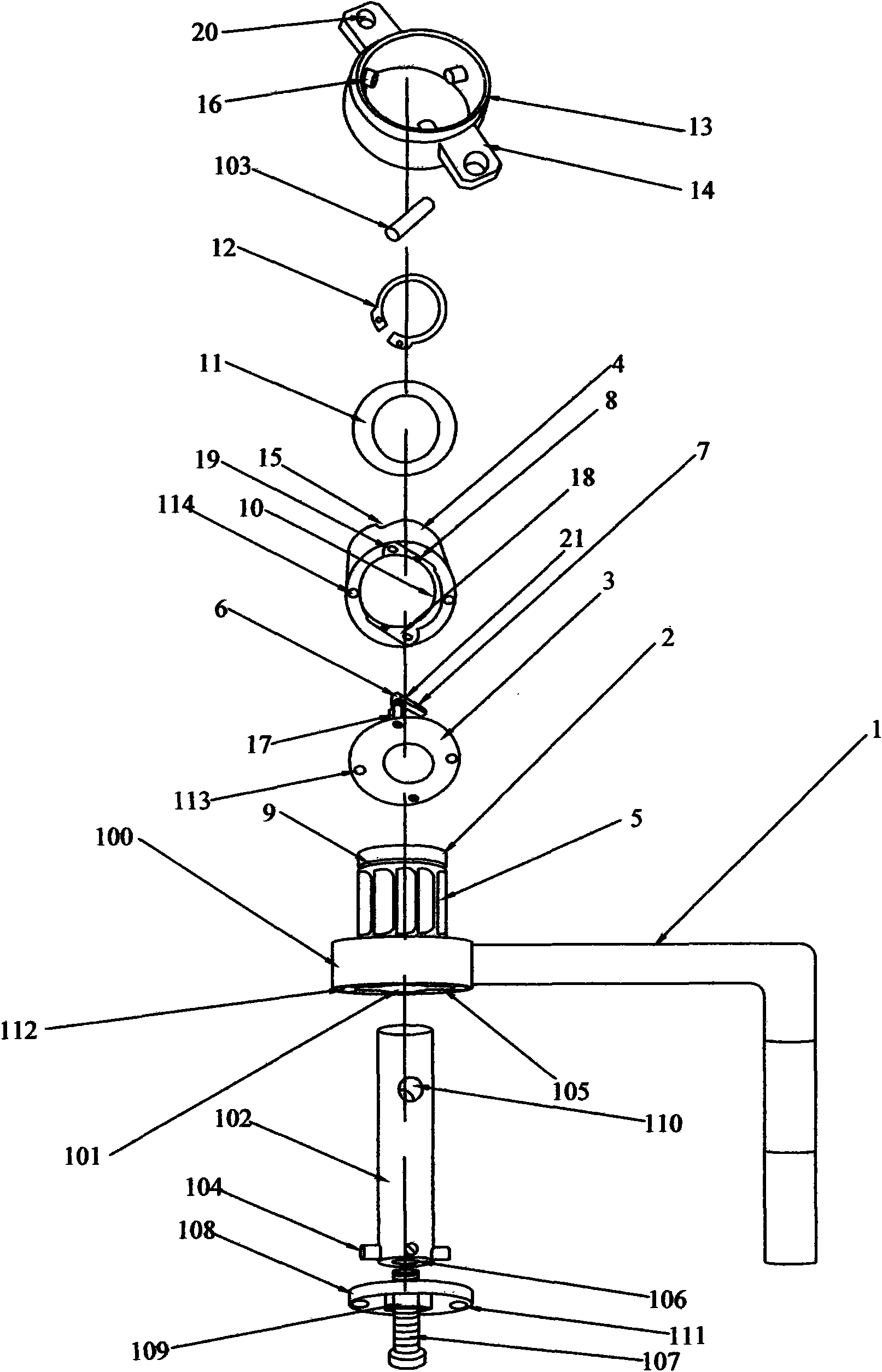

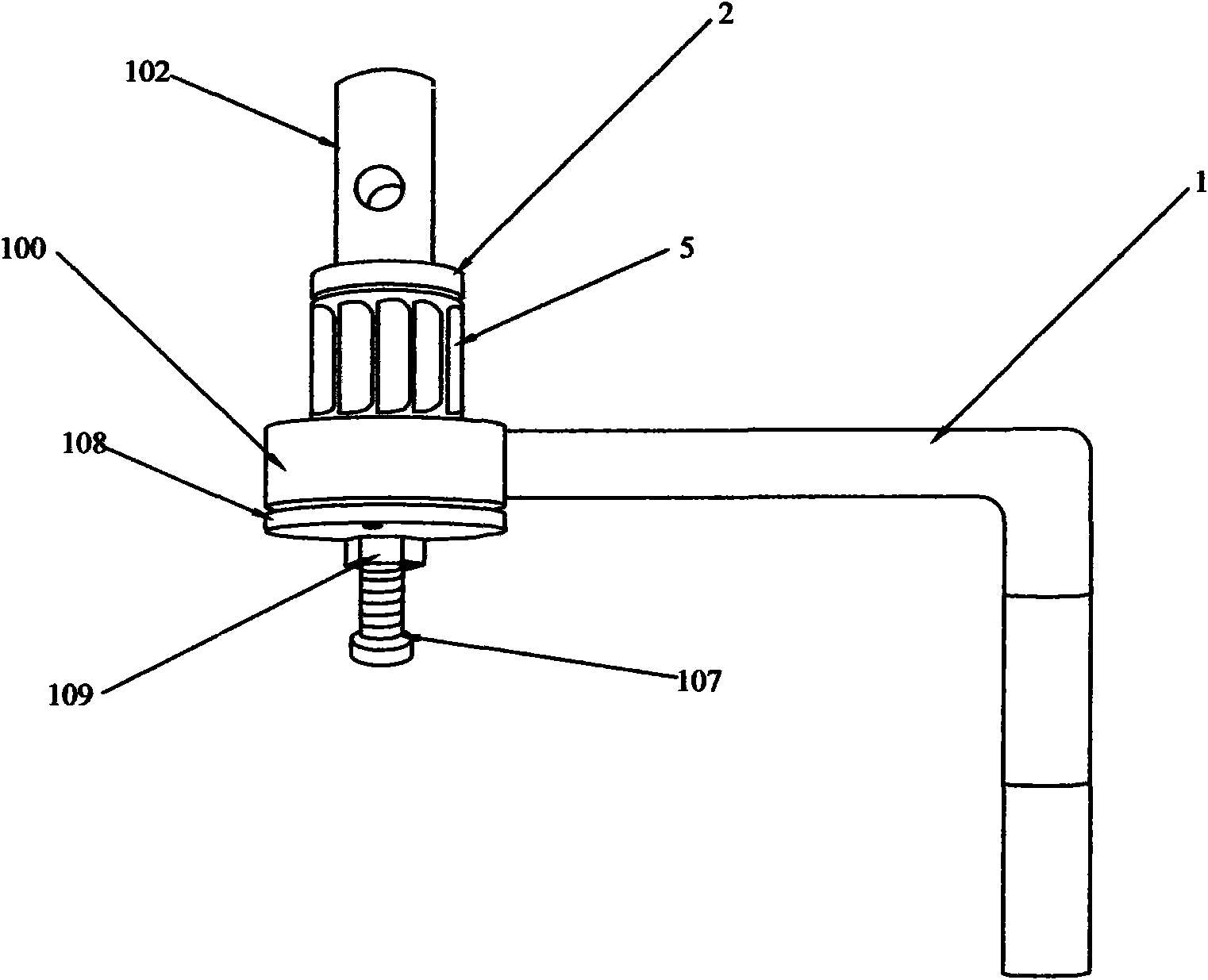

The invention relates to the field of automobile lamp fittings, in particular to an automobile dimming device. The automobile dimming device comprises a steering control module (10) which is used for controlling the steering of a motor (2), and an inching switch (11) which is used for manually controlling the on-off of a power supply of the motor (2); two conductive shrapnels (12) are also fixed on a second gear (6), and are mutually electrically connected; two turns of conductive materials (13) are also arranged on a circuit board (9); the two conductive shrapnels (12) and the two turns of conductive materials (13) are in contact one by one; a gap (14) is also arranged on one of the two turns of conductive materials (13); and the width of the gap (14) is more than the width of the contact position between each conductive shrapnel (12) and each conductive material (13). The automobile dimming device is low in cost and easy to popularize and sell.

Owner:NINGBO JINGHUA ELECTRONICS TECH

Injection device for simple dumpling fryer and simple dumpling fryer

ActiveCN108094459ASimple structureLow costOil/fat bakingDeep-fried productsBiochemical engineeringInjection device

Owner:临沂高新区人才职业培训学校有限公司

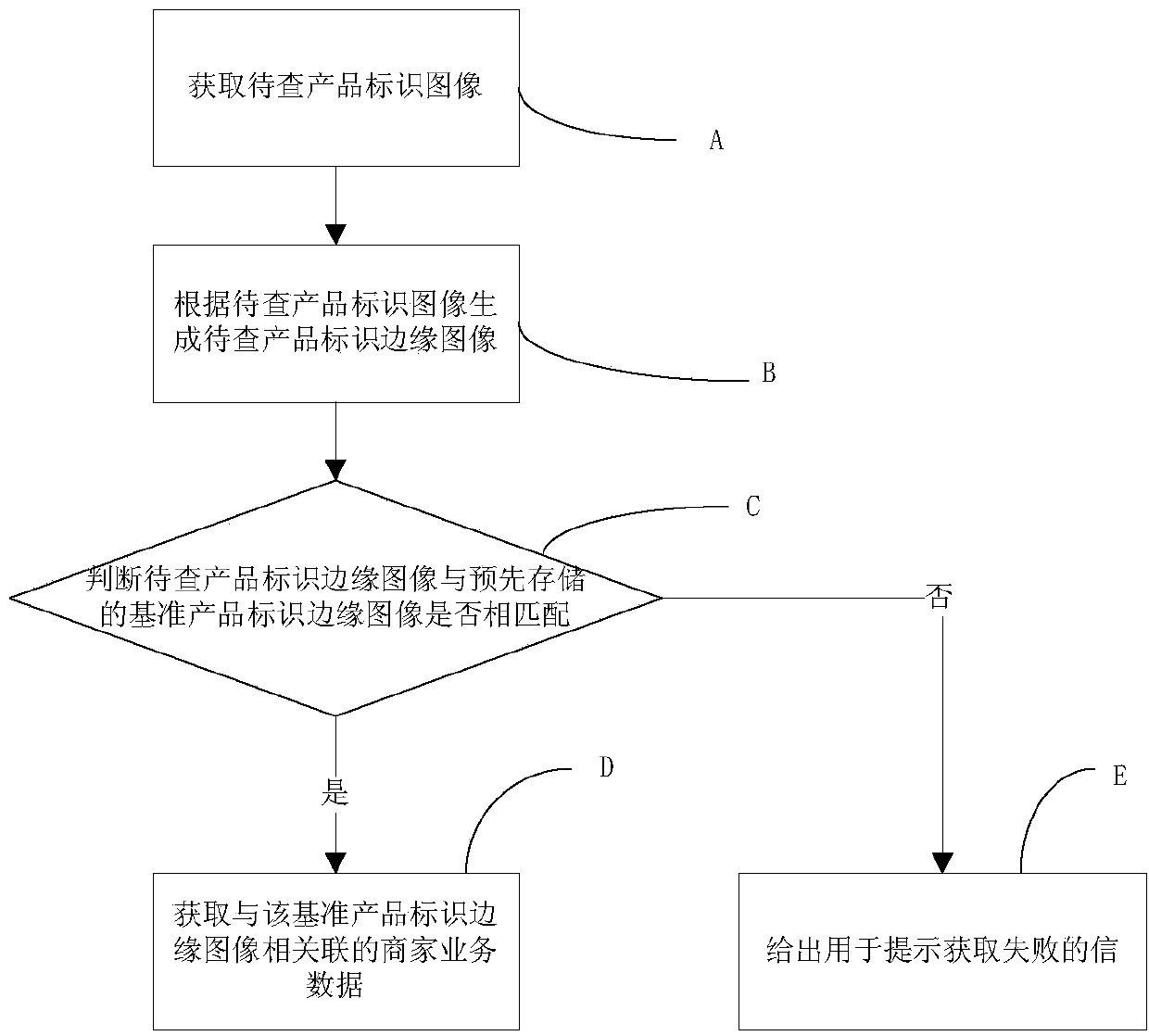

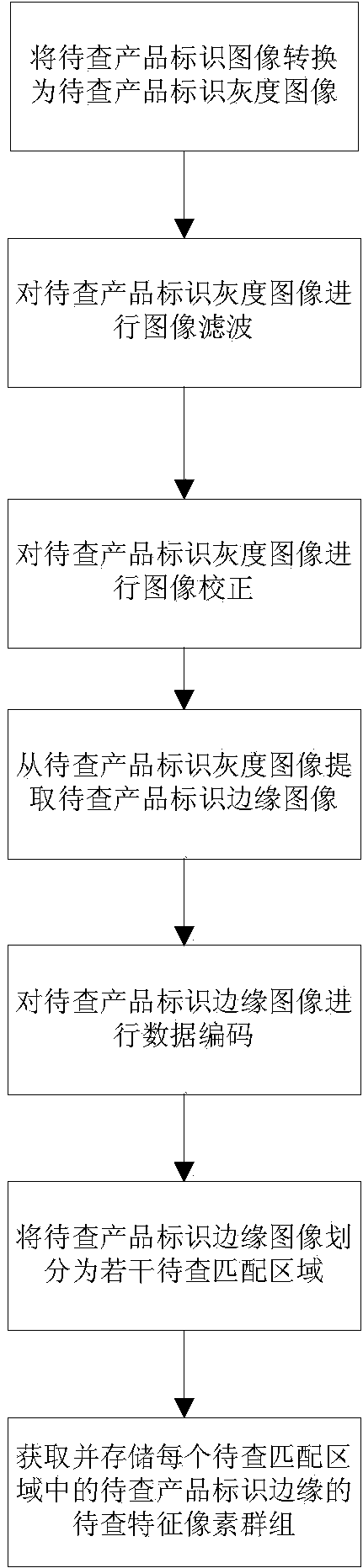

Method and system for obtaining merchant business data by recognizing product identification

InactiveCN104008388ASimple and fast operationImprove securityCharacter and pattern recognitionAlgorithmBusiness data

A method for obtaining merchant business data by recognizing product identification comprises the steps that (A) an image of the product identification to be checked is obtained; (B), an edge image of the product identification to be checked is generated according to the image of the product identification to be checked; (C), the edge image of the product identification to be checked is compared with a pre-stored edge image of standard product identification to judge whether the edge image of the product identification to be checked is matched with the pre-stored edge image of the standard product identification or not, if yes, the step (D) is executed, and if not, the step (E) is executed; (D) the merchant business data relevant to the edge image of the standard product identification are obtained; (E) information used for reminding an obtaining failure is given. The merchant business data can be easily and conveniently obtained by recognizing the product identification through the method, and the merchant business data are convenient to maintain. The invention further relates to a system for obtaining the merchant business data by recognizing the product identification.

Owner:杨军辉

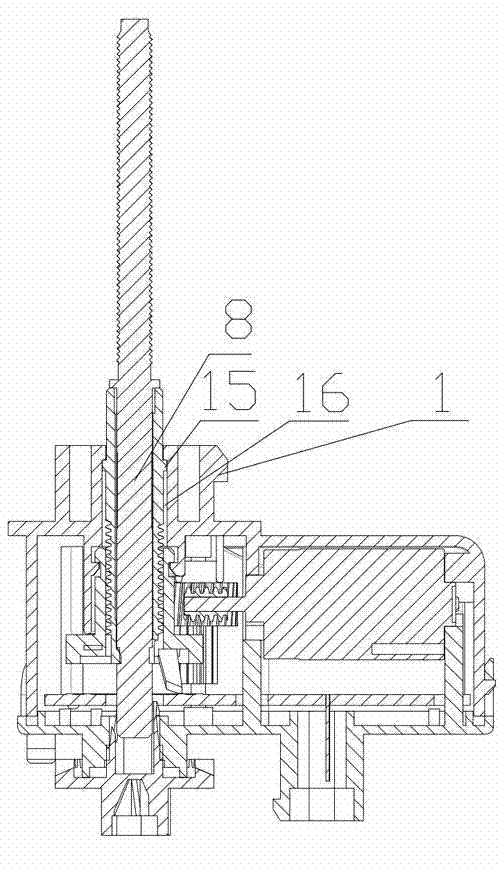

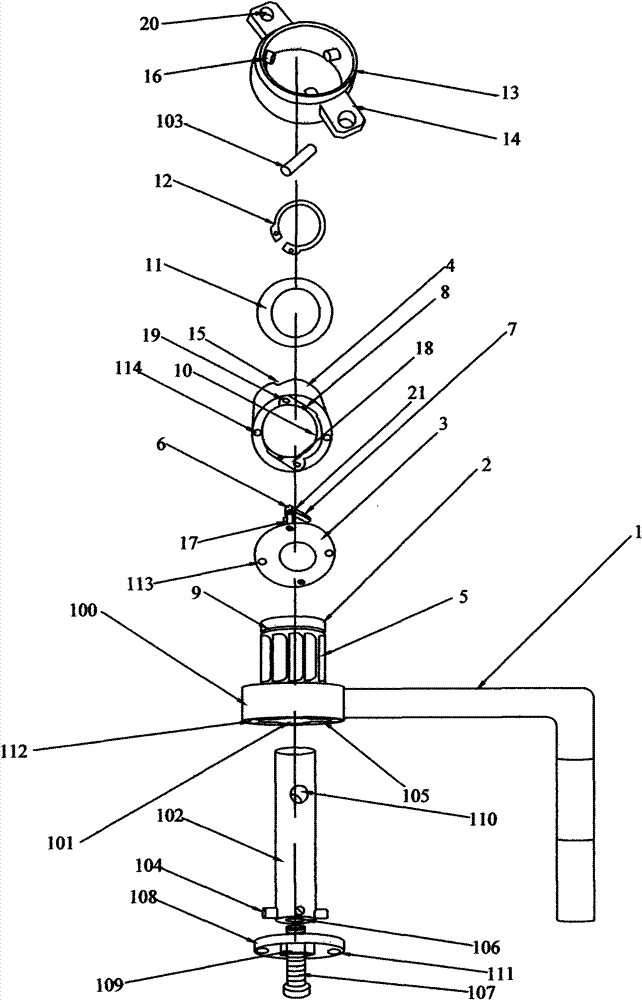

Disengaging adjustable safety handle

InactiveCN102140986APrevent reversalAvoid safety accidentsMuscle operated startersMachines/enginesCombustionEngineering

The invention discloses a disengaging adjustable safety handle. The disengaging adjustable safety handle comprises a rocker, a substrate, an oscillating head which is provided with a start shaft sleeve, a base plate and an outer sleeve, and a fixing seat which is connected with an internal-combustion engine body; the start shaft sleeve is fixedly connected with the substrate; the base plate, and the outer sleeve are sleeved on the start shaft sleeve; the start shaft sleeve has a hollow structure which is provided with a through hole axially; the through hole penetrates through the start shaftsleeve and the substrate and a start shaft is inserted into the through hole; one end of the start shaft corresponding to the fixing seat passes through the through hole, and a start bolt used for rotating and starting an internal-combustion engine is protruded on the part of one end of the start shaft passing through the through hole; the other end of the start shaft is provided with a radial positioning piece; on the end face of the substrate which is back to one side of the start shaft sleeve, a radial positioning groove into which the start shaft sleeve can be embedded adaptively is formed at the position corresponding to the radial positioning piece; the end face of one end of the start shaft which is provided with the radial positioning piece is provided with a bolt connection hole,and an axial positioning bolt which is in bolt connection with the bolt connection hole; the axial positioning bolt is in bolt connection with a bottom mad and a nut; and the bottom mad is positionedbetween the nut and the start shaft and is fixedly connected with the substrate. The disengaging adjustable safety handle is suitable for internal-combustion engines with different shaft depths.

Owner:吕振铁

An automatic water filling, emptying and pressurizing device and its use method

InactiveCN104567042BAvoid cracking damageSimple structureSolar heat devicesSolar thermal energy generationWater dischargeSolar water

Disclosed are an automatic water feed evacuating and pressurizing device and a using method thereof. The automatic water feed evacuating and pressurizing device comprises a water tank and a water pipe, and the upper surface of the water tank is provided with vent holes. The automatic water feed evacuating and pressurizing device is characterized in that an underneath type water temperature and level sensor is arranged in the water tank, a pressurizing pump is arranged at the joint of the bottom of the water tank and the water pipe, the U-shaped water pipe in the water tank is a siphoning pipeline, a normally-closed electromagnetic valve is arranged at an upper water port of the water pipe, a normally-opened electromagnetic valve is arranged at a lower water port of the water pipe, and the water temperature and level sensor, the normally-opened electromagnetic valve, the normally-closed electromagnetic valve and an evacuation control switch are connected with a control instrument respectively. The using method of the automatic water feed evacuating and pressurizing device includes steps of feeding water, evacuating fed water, discharging, evacuating the discharged water, and replenishing water. Automatic water feeding and discharging and automatic evacuating and water discharge pressurizing of a solar water heater can be controlled, evacuation and water supply are realized under the joint action of the siphoning pipeline and the pressurizing pump in the water tank, damage and cracking of pipelines in winter are avoided, and the automatic water feed evacuating and pressuring device is simple in structure, convenient to use and applicable to promotion and sales.

Owner:春风新能源科技有限公司

Disengaging safety handle

InactiveCN101956638BAvoid safety accidentsIngenious principleMuscle operated startersMachines/enginesExternal combustion engineEngineering

The invention discloses a disengaging safety handle comprising a handle and a starting shaft which is fixedly connected with the handle, as well as a chassis sheathed on the starting shaft and an outer sleeve, wherein a notch is formed at one end which is connected with the chassis of the outer sleeve, the lower end surface without the notch of the outer sleeve is connected with the upper end surface back-facing to the handle of the chassis, a fixed bolt which is coupled with the chassis is arranged on the upper end surface of the chassis, a spring is connected between the side face back-facing to the starting shaft of the fixed bolt and the position which corresponds to the side surface of the outer sleeve, a groove is arranged on the outer surface of the starting shaft, one end which is not coupled with the chassis of the fixed bolt is clamped in the groove, the disengaging safety handle is further provided with a fixed seat connected with an internal combustion engine body, a fixing part is arranged at one end which is connected with the internal combustion engine body of the fixed seat, and a clamping part which adapts to the notch of the outer sleeve for clamping is arranged at the other end. Once the starting contrarotation of the disengaging safety handle happens, the fixed bolt can clamp the groove, thereby preventing the contrarotation and avoiding safety accidents.

Owner:吕振铁

Pickling method for keeping nutrition of jerusalem artichokes

InactiveCN109105837ASimple processEasy to operateFood ingredient as taste affecting agentFood ingredient as flavour affecting agentNutrientSoybean Lecithin

The invention discloses a pickling method for keeping the nutrition of jerusalem artichokes, which comprises the following steps: egg white, soybean lecithin and water are stirred, added with sweet potato starch and xanthan gum and stirred, the pH value of the system is regulated to 5 to 5.8, stirring is continued, and after cooling, a first material is obtained; fresh jerusalem artichokes are washed clean, soaked into an aqueous salt solution, kept still, taken out and aired, so that a second material is obtained; the second material, salt, Baijiu, lactic acid, white granulated sugar and water are mixed, sealed for pickling, drained, added with the first material and uniformly stirred, so that a pickled jerusalem artichoke product is obtained. According to the method, the process is simple and convenient to operate; under the condition of not changing the original flavor of jerusalem artichokes, nutrient substances are almost kept; moreover, the shelf life of the obtained pickled jerusalem artichoke product is long, the pickled jerusalem artichoke product is fragrant, tasty and tender and crisp like the bamboo shoot, the flavor is unique, nutrition is rich, and therefore the pickled jerusalem artichoke product is convenient to promote and sell.

Owner:安徽铜雀二乔生物科技有限责任公司

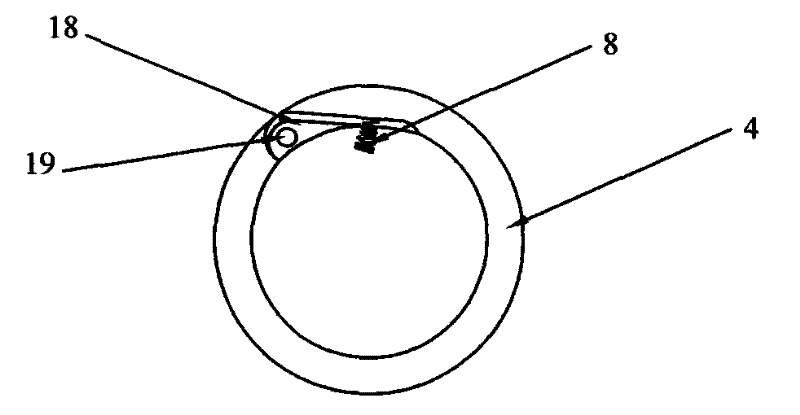

Fluorescent processing method for gem

InactiveCN107009527AWith fluorescent effectThe appearance has not changedPretreated surfacesFine working devicesFluorescenceToxin

The invention relates to a fluorescent processing method for a gem. The method comprises the steps of shape processing, wherein the gem is cut and carved to enable the shape of the gem to become the needed shape; spraying, wherein a nano-fluorescent spraying solution is sprayed on the surface of the gem through a nano spraying machine; and baking, wherein the gem of which the surface is coated with the nano-fluorescent spraying solution is baked, so that a nano-fluorescent layer on the surface of the gem is cured. According to the method, the nano-fluorescent layer is sprayed on the surface of the gem through the nano spraying machine, the processed gem achieves a fluorescent effect as the gem is externally coated with the thin nano-fluorescent layer, and meanwhile the appearance of the gem does not change; environmental pollution does not occur in the processing process, the nano-fluorescent layer can not fall off and generate pollution and toxins, and therefore popularizing and marketing of the fluorescent gem are better promoted.

Owner:SHENZHEN JINBAOYING CULTURE

Water-retaining agent used for pickling sour-sweet tender ginger and preparation method thereof

InactiveCN109170832AGood dispersion performanceHigh bond strengthClimate change adaptationFood ingredient as taste affecting agentNutrientFlavor

The invention discloses a preparation method of a water-retaining agent used for pickling sour-sweet tender ginger. The preparation method of the water-retaining agent used for pickling sour-sweet tender ginger comprises the following steps: mixing whey protein, soybean lecithin and water by performing stirring; adding corn starch and sodium alginate into the mixture so as to adjust pH value of the system to 5-5.8; and then, continued stirring, and carrying out cooling so as to obtain the water-retaining agent used for pickling sour-sweet tender ginger. The invention further discloses the water-retaining agent used for pickling sour-sweet tender ginger. The invention further discloses a method for pickling sour-sweet tender ginger. The method for pickling the sour-sweet tender ginger comprises the following steps: thoroughly washing fresh tender ginger, statically soaking the washed tender ginger in an edible salt solution, taking the soaked tender ginger out, and carrying out air-drying so as to obtain pretreated tender ginger; mixing the pretreated tender ginger with edible salt, glutinous rice wine, malic acid, white granulated sugar and water, carrying out sealed pickling, andcarrying out draining; and then, adding the water-retaining agent used for pickling sour-sweet tender ginger, and carrying out uniform stirring so as to obtain the sour-sweet tender ginger. The methodfor pickling the sour-sweet tender ginger is simple in processes, and capable of having nutrients of tender ginger basically preserved under the premise of keeping original flavor of the tender ginger unchanged; moreover, the prepared pickled tender ginger products are relatively long in shelf lives, refreshing and palatable in taste, unique in flavor and rich in nutrients.

Owner:安徽铜雀二乔生物科技有限责任公司

Method for preparing substitutional tea from lilium pinifolium tubers

The present invention relates to the technical field of substitutional tea preparation, and discloses a method for preparing substitutional tea from lilium pinifolium tubers. The method comprises thefollowing steps of collecting lilium pinifolium; breaking the collected lilium pinifolium into pieces and cleaning the pieces; naturally sun-drying the pieces in sunlight; grinding the dried pieces into flour by a grinder; adding water, and fully mixing the flour and the water into dough; granulating the dough into granules by using a granulator; putting the granules into a tea frying machine forfrying; performing cooling treatment; and performing packet encapsulation. According to the method for preparing the substitutional tea from the lilium pinifolium tubers, the fresh, tender, high-quality, large-sized and old lilium pinifolium is selected and used, so that nutritional ingredients of the prepared lilium pinifolium tea product is ensured; the lilium pinifolium is ground into the flourby the grinder, and the water is added for mixing to prepare the granules, so that quick soaking of the tea product is facilitated and the nutritional substances in the tea product are fully emanated; and the lilium pinifolium tea product prepared with the method is good in taste, high in quality and easy to absorb.

Owner:威宁俄索农业科技有限公司

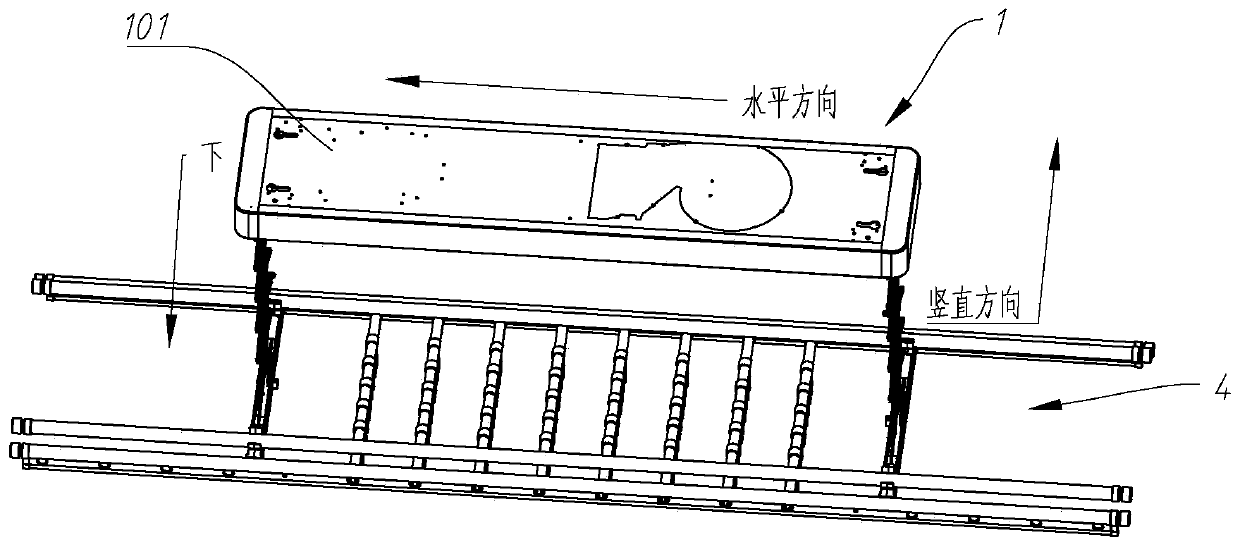

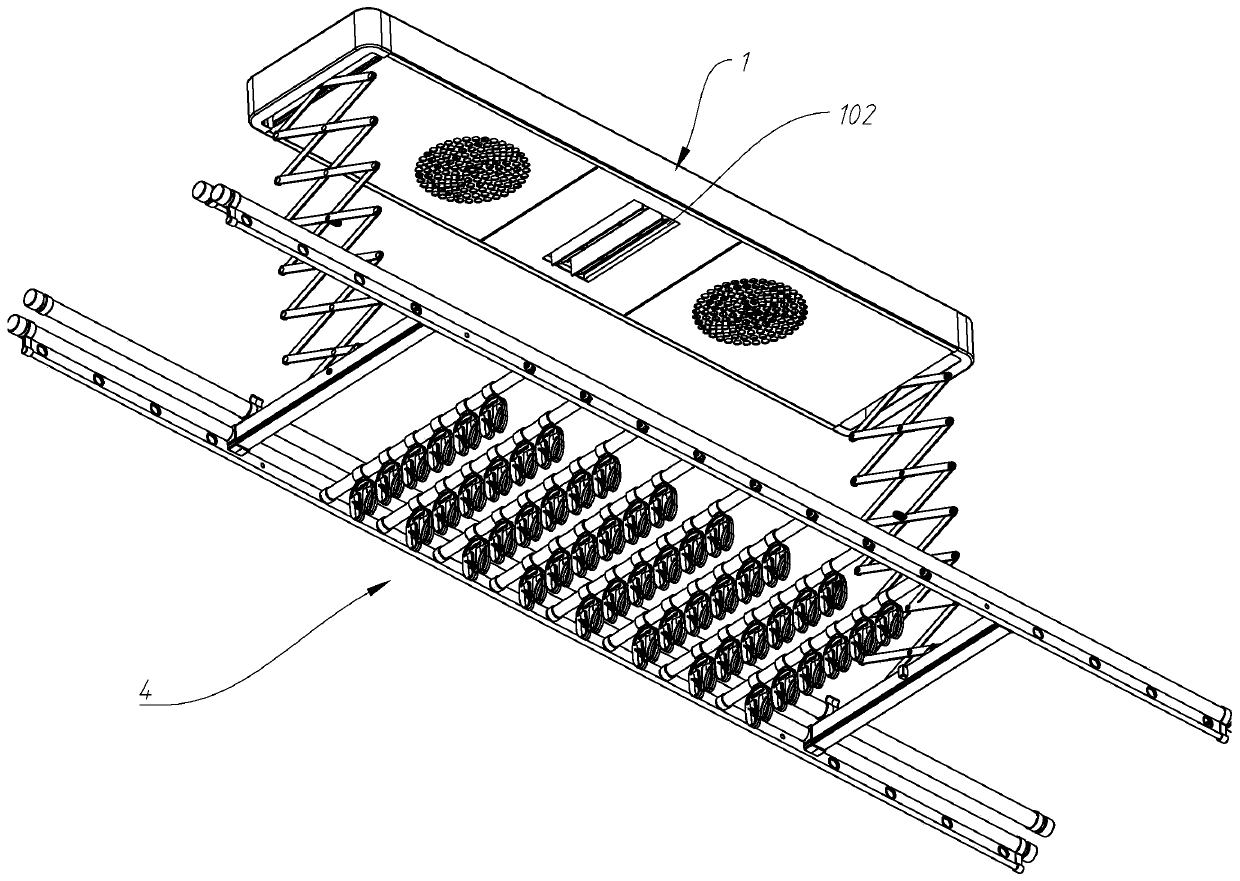

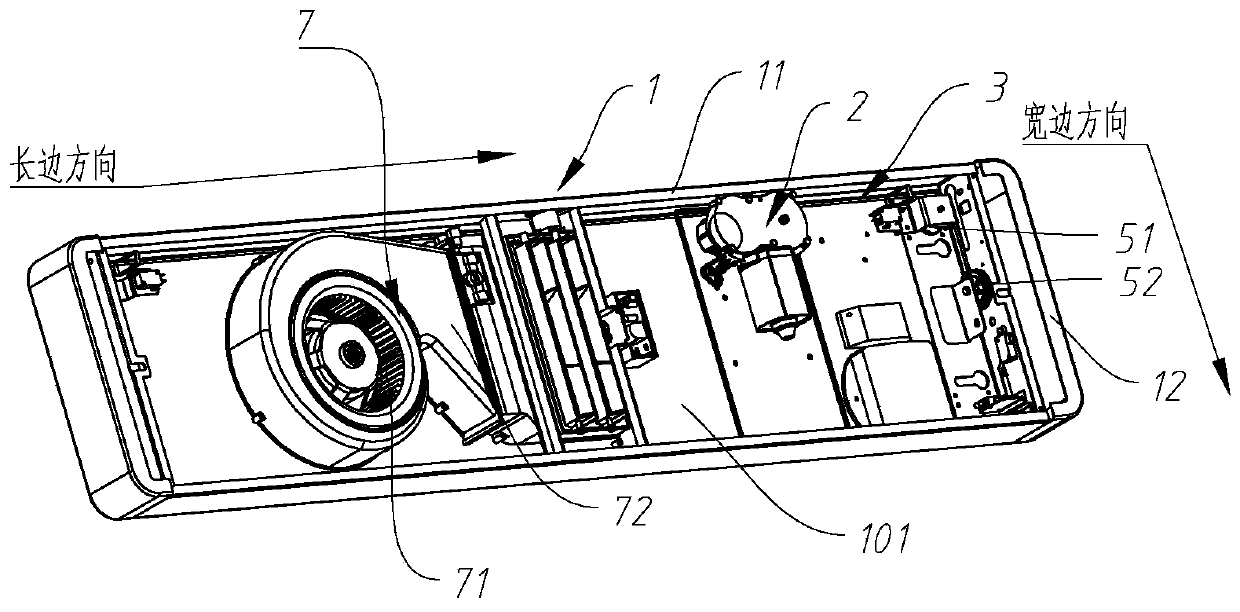

Electric clothes air-drying machine

ActiveCN111271690AAvoid shakingAvoid sliding wearMechanical apparatusLighting elementsLight guideEngineering

The invention discloses an electric clothes air-drying machine, and belongs to the technical field of clothes air-drying machines. According to an electric clothes air-drying machine in the prior art,a split type assembly structure is adopted for preventing a light guiding plate assembly from being scraped or abraded, a light guiding assembly is fixed through an edge press frame and a base platewhich are independent from each other, the structure is complex, and the manufacturing cost is high; and furthermore, because a corresponding connecting structure needs to be arranged, assembly is complex, and the assembly efficiency is low. According to the electric clothes air-drying machine obtained after continuous exploration and tests, an existing sequential overlaying fixed connection manner is changed into an insertion connection manner, and the technical prejudice that an existing panel light must be assembled in a split manner is broken; because an integrally formed edge-overturned part with folded edges is arranged, and an elastic part is assembled to a concave cavity of the edge-overturned part, it is implemented that the light guiding assembly is assembled to the edge-overturned part without abrasion in an insertion connection manner, and sliding abrasion between a panel and the light guiding assembly can be effectively avoided; and after further insertion connection of the panel is completed, the panel can be effectively limited by the elastic part so as to be prevented from shaking, the structure is simple, the manufacturing cost is low, assembly is convenient to carry out, and the conception is ingenious.

Owner:AUPU HOME STYLE CORP LTD

Pork soaked with oil

InactiveCN109221368ASlow down the Harmony processEasy to industrializeFood ingredient as antioxidantMeat/fish preservation using chemicalsFlavorPork meat

The invention discloses pork soaked with oil, and belongs to the technical field of processing of pork products. The pork is prepared from the following raw materials in parts by weight: 60 parts to 65 parts of fresh pork, 32 parts to 37 parts of fresh lard oil, 3 parts to 4 parts of edible salt, 0.4 part to 0.6 part of sichuanese peppercorn and 0.4 part to 0.6 part of papain. The raw materials are weighed, and meat and oil are sliced, boiled and uniformly stirred with salt; canning and cooling are carried out. The lard oil soaked with the oil prepared by the method disclosed by the inventionhas the advantages that the guarantee period of the product is greatly prolonged while the flavor and quality of the product are maintained at the same time.

Owner:云南撒坝农业开发有限公司

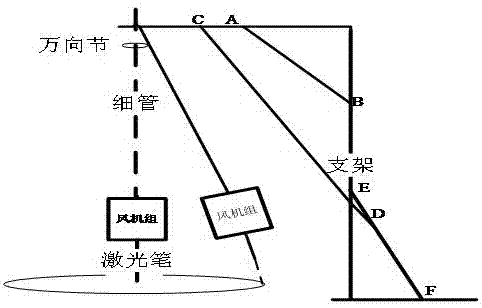

Wind pendulum toy and method of use

InactiveCN105641951BImprove practical abilityInterestingToysTeaching apparatusWind drivenCost effectiveness

Owner:青岛工学院

How to make a goblet

The invention relates to a goblet and an assembling fixture and manufacturing method thereof. The goblet comprises a transparent goblet body, a disk-shaped base and a transparent vertical hollow supporting tube. The supporting tube is filled with gem / broken cash. The top of the supporting tube is fixedly connected with the middle of the bottom of the goblet body through an upper cone. The outer surface of the upper cone is fixedly sleeved with a precious metal outer cover with a pattern. The bottom of the supporting tube is fixedly connected with the middle of the top face of the base through a lower cone. The outer surface of the lower cone is fixedly sleeved with a precious metal outer cover with a pattern. The goblet is composed of three parts, the supporting tube in the middle is hollow and filled with gem / broken cash and can refract more colorful light, the upper cone and the lower cone at the two ends of the supporting tube are provided with the precious metal outer covers, the value of the goblet is improved, the grade is improved, the decoration sense is enhanced, the individual needs of users are met, and meanwhile the appearance is greatly improved compared with common goblets and the differentiation of the product facilitates the promotion of sales.

Owner:SHENZHEN JINBAOYING CULTURE

Electric clothes drying machine

PendingCN110499630AMake full use of spaceLower vertical heightOther drying apparatusTextiles and paperEngineeringMechanical engineering

The invention discloses an electric clothes drying machine, and belongs to the technical field of clothes drying machines. Shells of the existing clothes drying machines are relatively high and cannotbe thin, the application range of the clothes drying machines is narrow, and popularization and sales are not facilitated. A winder is assembled on the side wall or the end wall of an adjacent machine shell, and the extending direction of a rotating shaft of the winder is perpendicular to the long edge of the machine shell, so that the winding direction of a pull rope is parallel to the long edgeof the machine shell. Due to continuous exploration, the existing technical prejudice that the pull rope has to be centrally arranged is broken, and a pull rope side end arranging structure is provided. The pull rope is arranged along the side end of the machine shell and adjacent to the side wall of the machine shell, can avoid a fan, an air duct and other parts, and fully utilizes the space ofthe machine shell. The pull rope, the fan and other parts are not in the same vertical surface, and the vertical height of the machine shell can be effectively reduced, so that the machine is compactin structure, popularization and sales can be facilitated, the reversing frequency of the pull rope can be effectively reduced, friction of the pull rope is reduced, the service life of the pull ropeis prolonged, and popularization and sales of the electric clothes drying machine are facilitated.

Owner:AUPU HOME STYLE CORP LTD

Ultrasonic atomizer convenient to clean and use method thereof

PendingCN113101471AEasy to useGood for sales promotionMedical devicesMedical atomisersEngineeringMicro pump

The invention provides an ultrasonic atomizer convenient to clean and a using method thereof. The ultrasonic atomizer convenient to clean comprises a shell with an inner cavity, transduction pieces and a bottom plate arranged on the bottom face of the inner cavity, a plurality of holes penetrating through the outer wall of the shell are formed in the bottom plate, the transduction pieces are arranged in one-to-one correspondence with the holes, and an air outlet of each transduction piece is aligned with the corresponding hole; the ultrasonic atomizer also comprises a micro pump, air pipes hung in an inner cavity of the shell, and a water outlet formed in the bottom plate, an opening penetrating through the inner cavity of the shell is formed in one side wall of the shell, the micro pump is partially clamped to the opening in an interference mode, an air outlet of the micro pump is embedded into the inner cavity, one end of each air pipe is connected with the air outlet of the micro pump, and the other end of each air pipe is closed; and a plurality of nozzles which are in one-to-one correspondence with the plurality of transducers extend out of the bottom of each air pipe. Under the condition that the ultrasonic atomizer does not need to be disassembled, the ring energy piece can be cleaned, a user can use the ultrasonic atomizer conveniently, and popularization and sales of manufacturers are facilitated.

Owner:广东鑫隆崟丰智能设备有限公司

Disengaging adjustable safety handle

InactiveCN102140986BPrevent reversalAvoid safety accidentsMuscle operated startersMachines/enginesCombustionEngineering

The invention discloses a disengaging adjustable safety handle. The disengaging adjustable safety handle comprises a rocker, a substrate, an oscillating head which is provided with a start shaft sleeve, a base plate and an outer sleeve, and a fixing seat which is connected with an internal-combustion engine body; the start shaft sleeve is fixedly connected with the substrate; the base plate, and the outer sleeve are sleeved on the start shaft sleeve; the start shaft sleeve has a hollow structure which is provided with a through hole axially; the through hole penetrates through the start shaft sleeve and the substrate and a start shaft is inserted into the through hole; one end of the start shaft corresponding to the fixing seat passes through the through hole, and a start bolt used for rotating and starting an internal-combustion engine is protruded on the part of one end of the start shaft passing through the through hole; the other end of the start shaft is provided with a radial positioning piece; on the end face of the substrate which is back to one side of the start shaft sleeve, a radial positioning groove into which the start shaft sleeve can be embedded adaptively is formed at the position corresponding to the radial positioning piece; the end face of one end of the start shaft which is provided with the radial positioning piece is provided with a bolt connection hole, and an axial positioning bolt which is in bolt connection with the bolt connection hole; the axial positioning bolt is in bolt connection with a bottom mad and a nut; and the bottom mad is positioned between the nut and the start shaft and is fixedly connected with the substrate. The disengaging adjustable safety handle is suitable for internal-combustion engines with different shaft depths.

Owner:吕振铁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com