Disengaging safety handle

A handle and safety technology, applied in the field of internal combustion engine starting tools, can solve the problems of complicated structure of the safety handle, injuring people by inversion of the starting handle, unfavorable sales, etc., and achieves the effects of facilitating sales promotion, simple structure, high efficiency and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

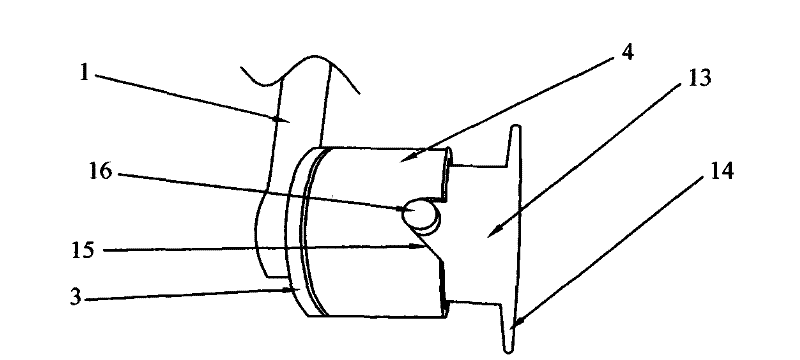

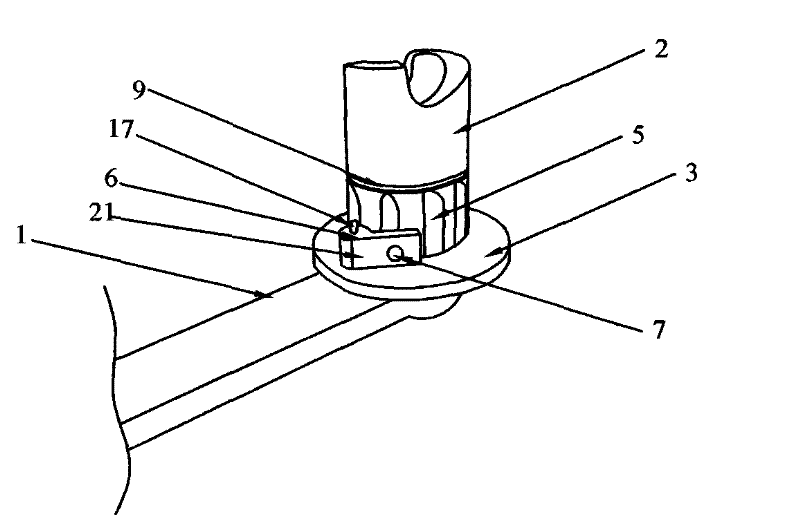

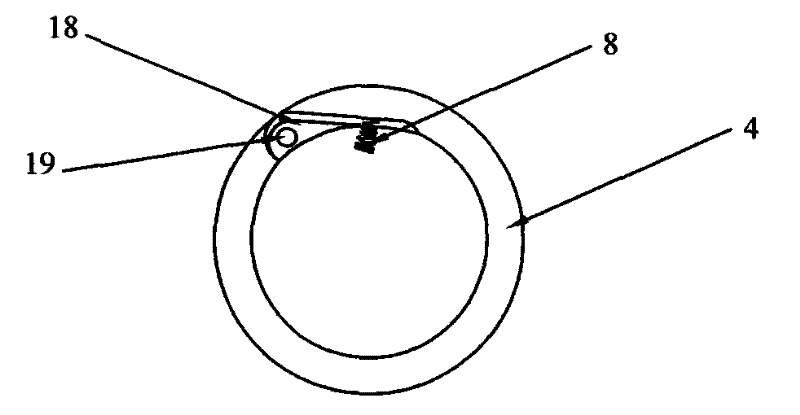

[0024] In order for those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

[0025] see Figure 1 to Figure 9 As shown, the present invention provides a disengageable safety handle, including a handle 1 and its affixed starting shaft 2, and a chassis 3 sleeved on the starting shaft 2 and a notch at the end connected to the chassis. 15, wherein, the lower end surface of the outer cover 4 without the notch 15 is connected to the upper end surface of the chassis 3 facing away from the handle 1, and the upper end surface of the chassis 3 is provided with a shaft connected to the The fixed bolt 6 of the chassis 3, the side 21 of the fixed bolt 6 facing away from the start shaft 2 and the position corresponding to the side 21 of the outer cover 4 are connected with a spring 8, and a spring 8 is arranged on the outside of the shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com