Fluorescent processing method for gem

A processing method and technology of gemstones, applied in the direction of stone processing equipment, manufacturing tools, fine working devices, etc., can solve the problems of unfavorable development of gemstone processing industry, high gemstone toxins, environmental pollution costs, etc., to promote sales and application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific embodiments.

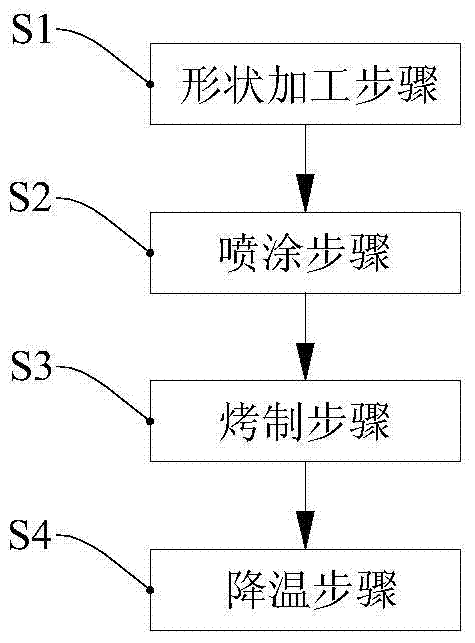

[0018] The flow chart of gem fluorescence processing method in the embodiment of the present invention is as follows figure 1 shown. The gem in this embodiment can be amber, emerald, crystal, ruby / sapphire, pearl, coral stone, jade, coal essence or artificial gem. Such as figure 1 As shown, the fluorescent gemstone processing method of the present embodiment comprises the following steps:

[0019] Shape processing step S1, processing the shape of the gemstone to make it into the desired shape;

[0020] Spraying step S2, using a nano-spraying machine to spray the nano-fluorescent spraying liquid on the surface of the gemstone;

[0021] Baking step S3, baking the gems whose surface has been sprayed with nano-fluorescent spraying liquid to cure the nano-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com