Board production process and modification of inorganic glue

A production process and technology of inorganic glue, applied in the direction of inorganic adhesives, wood processing appliances, wood veneer bonding, etc., can solve the problems of high-pollution finished products containing formaldehyde, complicated processes, low prices, etc., and achieve market competitiveness The effect of strong, simplified process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

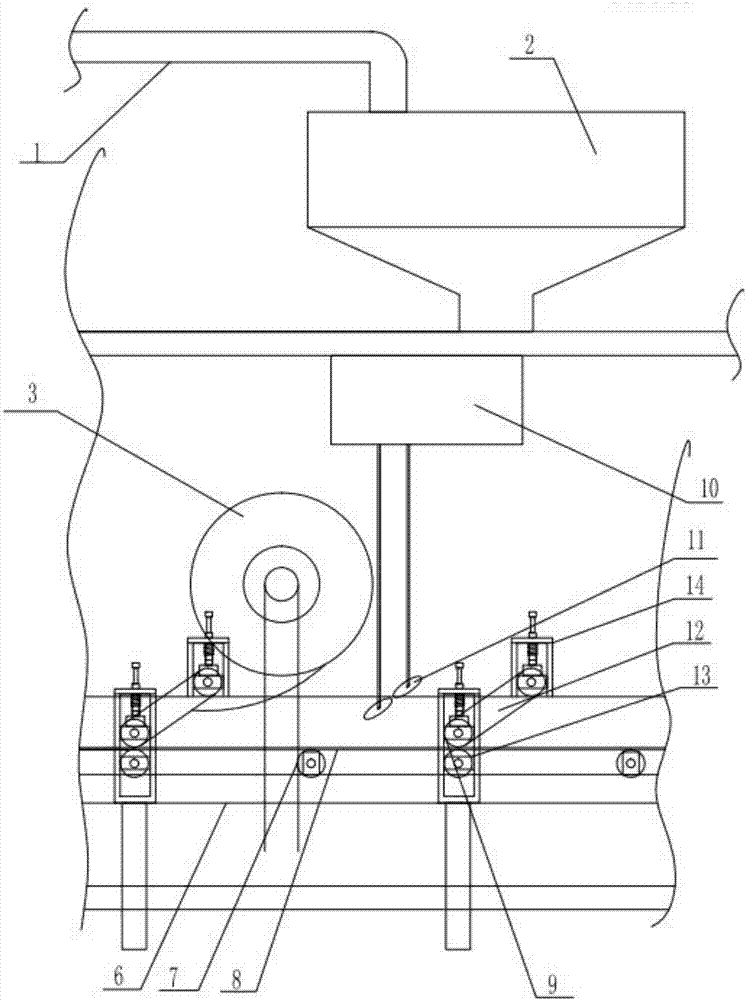

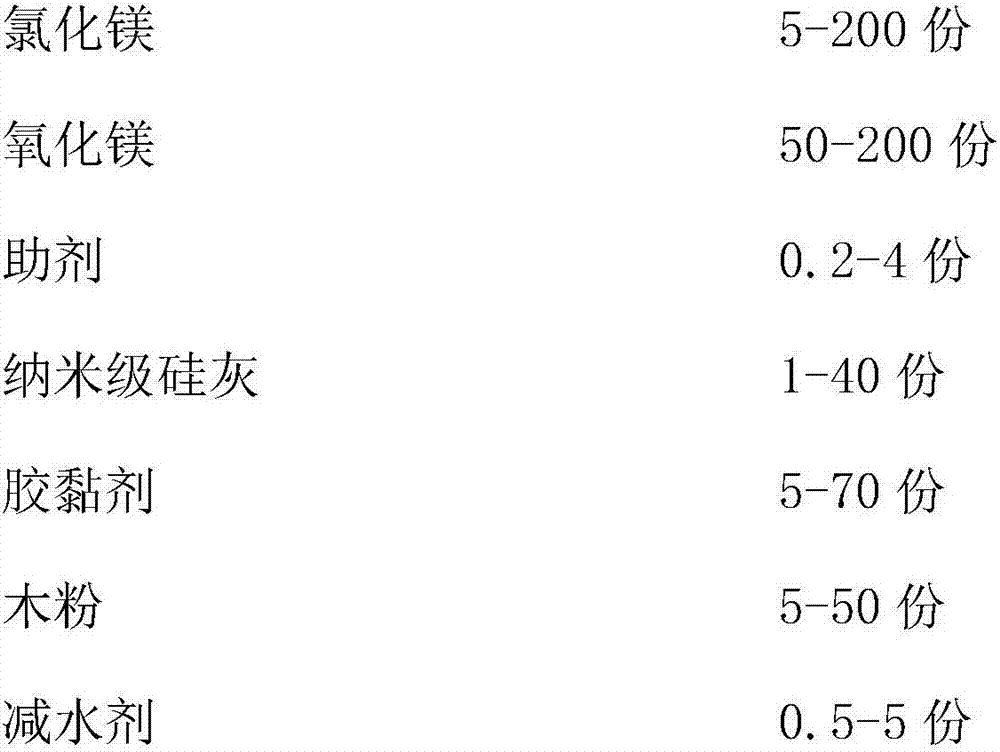

[0051] Plywood production process: add 135 parts of magnesium oxide to 100 parts of magnesium chloride, add 1 part of additives and stir, the order of adding the additives is sodium hexametamate, sodium phosphate, ferrous sulfate, phosphoric acid, and then add 20 parts Nano-scale silica fume, 40 parts of adhesive, 30 parts of wood flour, and 1 part of water reducer are stirred for 2-15 minutes to form a viscous glue for use.

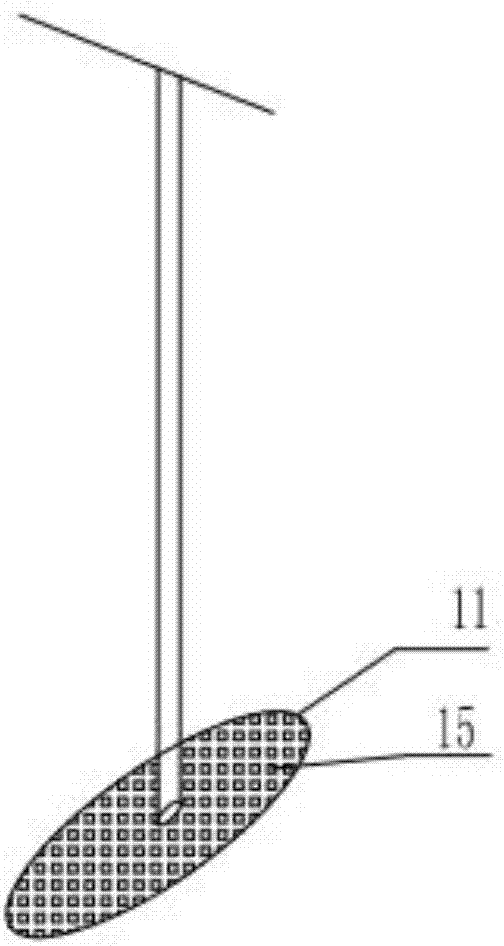

[0052] Carry out cutting according to the length of the raw material processed by the plate, process it into a veneer with the required specification thickness with a veneer rotary cutting machine, the specification is 0.3-6mm, roll it into a veneer roll with a diameter of 1.2m or less with a coiler, and wait Use, the paving machine 6 spreads the surface material on the paving machine conveyor belt 8, the inorganic glue is transported to the spraying machine 10 through the pipeline at the lower end of the glue hopper 2, and the spraying machine 10 transpo...

Embodiment 2

[0054] Cement formwork production process: add 135 parts of magnesium oxide to 100 parts of magnesium chloride, add 1 part of additives and stir, the order of adding the additives is sodium hexametamate, sodium phosphate, ferrous sulfate, phosphoric acid, and then add 6 Mix 1 part of nano silica fume, 20 parts of adhesive, 15 parts of wood flour, and 1 part of water reducer for 2-15 minutes to form a viscous glue for use.

[0055] The fiber woven or non-woven surface material is coated with a plastic non-woven machine to form a cement formwork panel. The fiber woven or non-woven surface material on the back of the panel is raised by a raising machine to increase the bonding strength. The inorganic glue is passed through the glue hopper. 2 The pipeline at the lower end is transported to the spraying machine 10, and the spraying machine 10 transports the inorganic glue to the glue spraying device 11. The glue spraying device 11 is provided with several spray holes 15, and the ino...

Embodiment 3

[0057] Cement template production process: add 135 parts of magnesium oxide to 100 parts of magnesium chloride, add 1 part of additives and stir, the order of adding the additives is sodium hexametamate, sodium phosphate, ferrous sulfate, phosphoric acid, and then add 10 1 part of nano-scale silica fume, 30 parts of adhesive, 20 parts of wood flour, and 1 part of water reducer are stirred for 2-15 minutes to form a viscous glue for use.

[0058] Use glue-resolving resin to impregnate the film paper and dry veneer to heat press it into a standard surface material, the specification is 36-48 inches, cut according to the length of the raw material to be processed, and process it into the required specification thickness with a veneer rotary cutting machine The veneer, the specification is 0.3-6mm, is rolled into a veneer roll with a diameter of 1.2m or less with a coiling machine, and is ready for use. The paving machine 6 spreads the surface material on the paving machine conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com